0

Model K29

ENGLISH.......................2

FRANÇAIS. ................. 16

ESPAÑOL....................30

BEST BY BROAN P.O. Box 140 Hartford, WI 53027

READ AND SAVE THESE INSTRUCTIONS

!

INTENDED FOR DOMESTIC COOKING ONLY.

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions,

contact the manufacturer at the address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service panel and lock service

panel to prevent power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a prominent warning device, such as

a tag, to the service panel.

3. Installation work and electrical wiring must be done by a qualified person(s) in accordance with all applicable codes and standards, including fire-rated construction codes

and standards.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue

(chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment manufacturer’s guidelines and safety standards such as those published by the

National Fire Protection Association (NFP A), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other

hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any solid-state speed control device.

8. T o reduce the risk of fire, use only metal ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

A . Never leave surface units unattended at high settings. Boilovers cause smoking and

greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when cooking flaming foods.

C. Clean ventilating fans frequently . Grease should not be allowed to accumulate on fan or

filter.

D. Use proper pan size. Always use cookware appropriate for the size of the surface

element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE T OP

GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet, or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS. If the flames do not go out immediately,

EVACUA TE AND CALL THE FIRE DEPAR TMENT .

2. NEVER PICK UP A FLAMING P AN - You may be burned.

3. DO NOT USE WA TER, including wet dishcloths or towels - violent steam explosion will

result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know how to operate

it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. Y ou can fight the fire with your back to an exit.

* Based on “Kitchen Fire Safety T ips” published by NFP A.

- 2 -

!

CAUTION

1. To reduce risk of fire and to properly exhaust air, be sure to duct air outside. Do

not vent exhaust air into spaces within walls or ceilings or into attics, crawl

spaces, or garages.

2. Take care when using cleaning agents or detergents.

3. Avoid using food products that produce flames under the Range Hood.

4. For general ventilating use only . Do not use to exhaust hazardous or explosive

materials and vapors.

5. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep

drywall spray, construction dust, etc. off power unit.

6. Your hood motor has a thermal overload which will automatically shut off the

motor if it becomes overheated. The motor will restart when it cools down. If the

motor continues to shut off and restart, have the hood serviced.

7. For best capture of cooking impurities, the bottom of the hood should be a

minimum of 24" and a maximum of 30" above the cooking surface. See “Install

Mounting Bracket” section for mounting instructions.

8. Two installers are recommended because of the large size and weight of this

hood.

9. This product is equipped with a thermostat which may start blower automatically. To reduce the risk of injury and to prevent power from being switched on

accidentally, switch power off at service panel and lock or tag service panel.

10. Use with approved cord-connection kit only.

11. Please read specification label on product for further information and requirements.

- 3 -

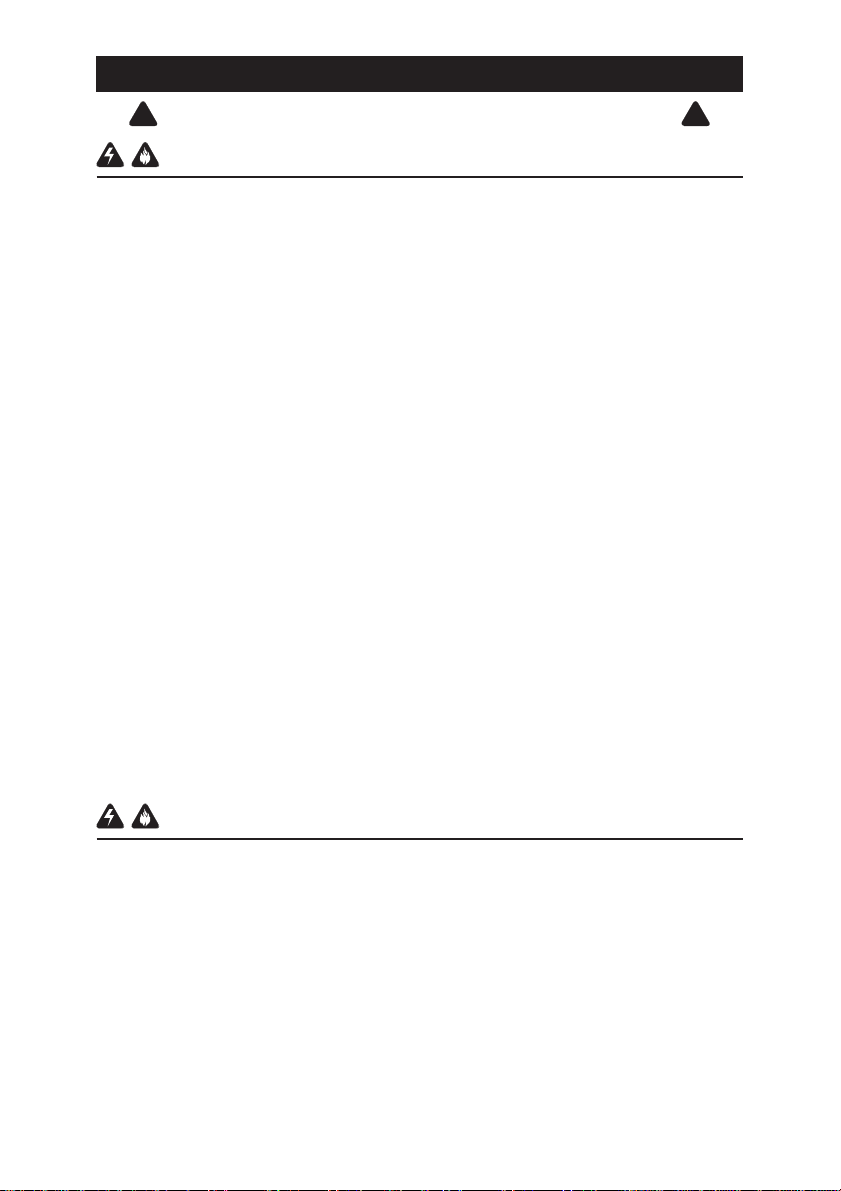

OPERATION

Controls

The hood is operated using the (4) push-buttons located at eye-level, on the front edge of

the hood.

The light switch turns the halogen lights on

LIGHT

SWITCH

BLOWER

ON-LOW /

OFF

SWITCH

BLOWER

MEDIUM

SPEED

BLOWER

HIGH

SPEED

PILOT

LAMP

and off.

The blower on-low / off switch turns the blower

on to its lowest running speed. The blower

0

must be turned on using this switch. Turn the

blower off by pressing this switch a second time.

The blower medium speed switch changes the blower speed to medium. This

switch works only if the blower is already running at low or high speed.

The blower high speed switch changes the blower speed to high. This switch

works only if the blower is already running at low or medium speed.

The pilot lamp lights up whenever the blower is on.

Heat Sentry

TM

Your hood is equipped with a HEAT SENTRY™ thermostat. This thermostat is a

device that will turn on or speed up the blower if it senses excessive heat above

the cooking surface.

1) If blower is OFF - it turns blower ON to HIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up to HIGH speed.

When the temperature level drops to normal, the blower will return to its original

setting.

WARNING

The HEA T SENTRY thermostat can start the blower even if the hood is

turned OFF . When this occurs, it is impossible to turn the blower OFF with its

switch. If you must stop the blower, do it from the main electrical panel.

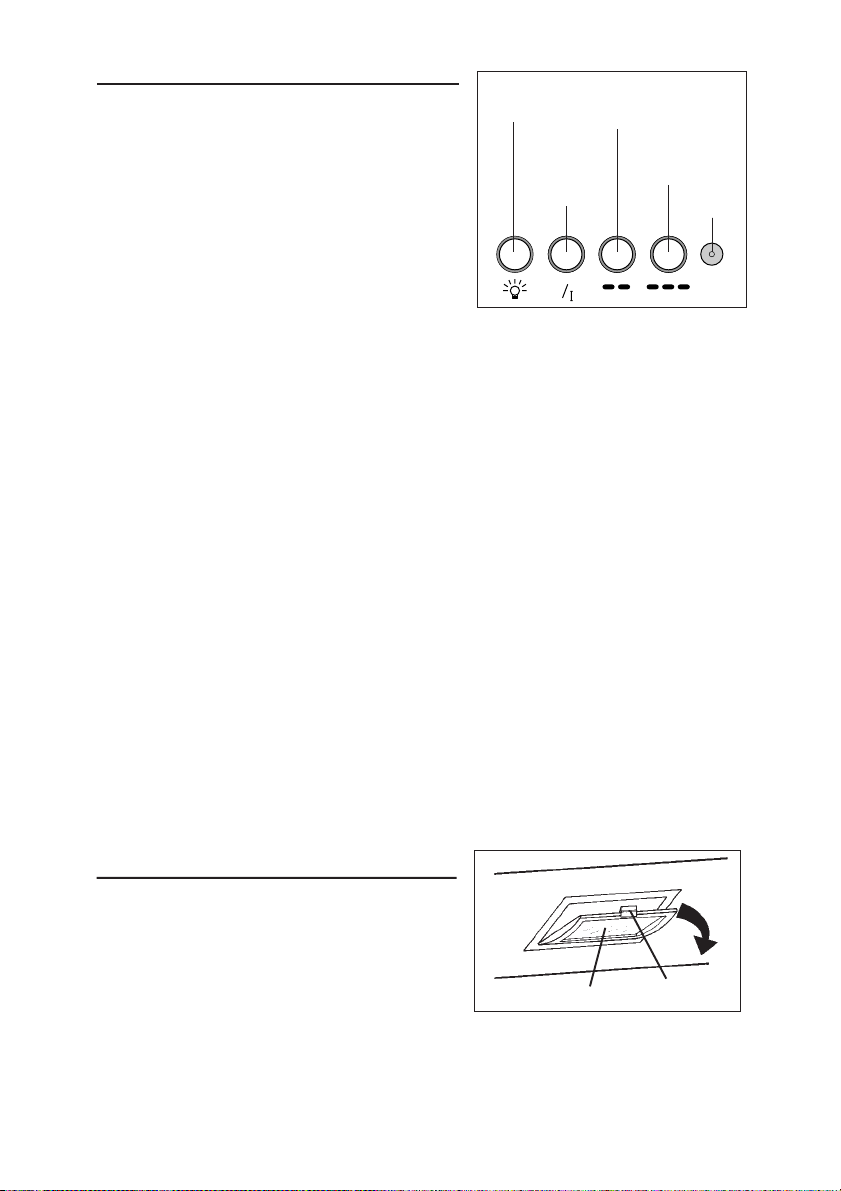

HALOGEN BULBS

This range hood requires two or four halogen

bulbs (Type JC, 12V, 20W, G4 Base).

To change bulbs:

1. Open the light lens by grasping the tab on

the lens and rotating lens downward.

2. Remove the bulb by pulling sideward (Do

not rotate). CAUTION: BULB MAY BE HOT!

3. Do not touch replacement bulb with bare

hands! Push bulb securely into lamp socket

and snap lens closed.

- 4 -

LIGHT LENS

TAB

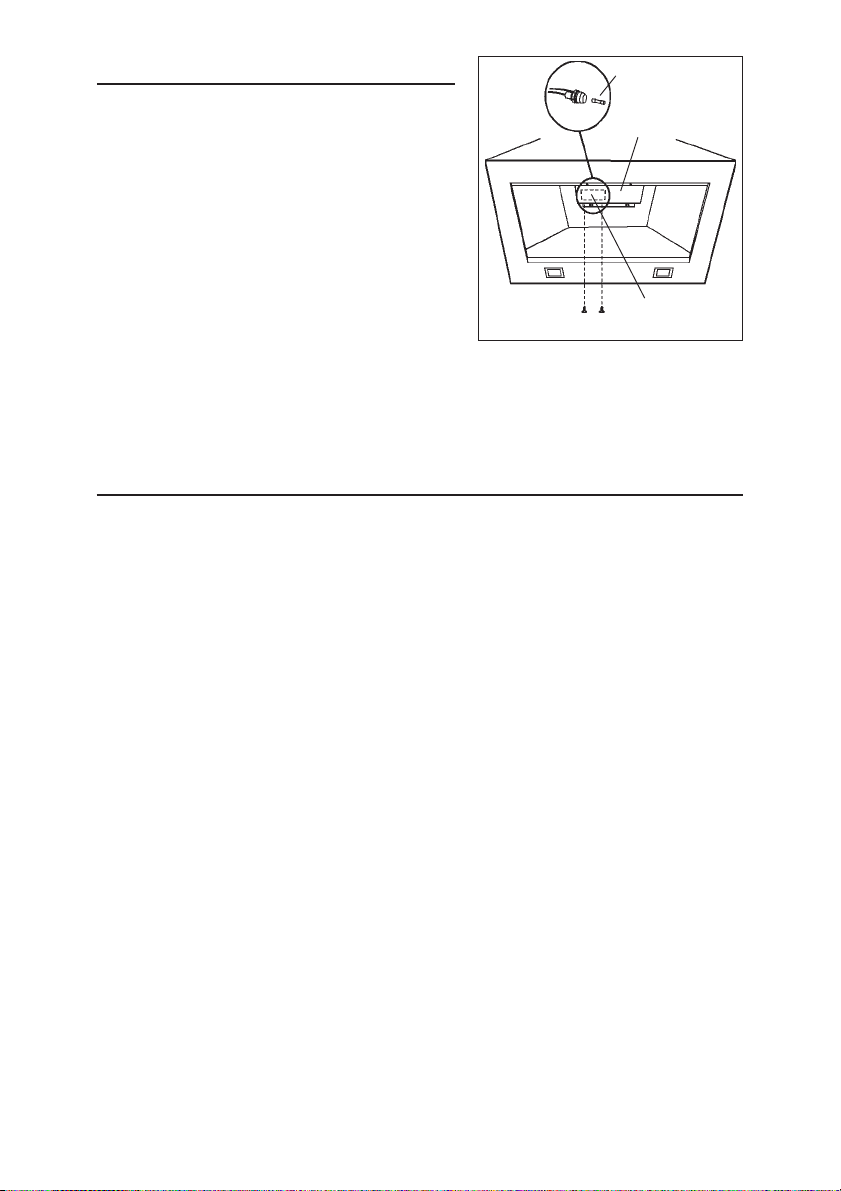

FUSE REPLACEMENT

IF THE LIGHTS F AIL TO OPERA TE, DISCONNECT THE POWER AT THE SERVICE EN-

FUSE

ELECTRICAL

BOX

SUPPORT

TRANCE. CHECK THE FUSE AND REPLACE IF NECESSARY.

1. Remove the filters.

2. Remove the electrical box support.

3. Remove screws from the fuse box and

open the cover.

4. Locate the fuse holder. Unscrew its cap

and remove the fuse.

FUSE BOX

5. Replace the fuse with the same size and

amperage (5 x 20mm, 4A, 125V).

6. Reinstall the fuse box cover, electrical box

support, and filters.

7. Reconnect power at the service entrance.

MAINTENANCE

Grease Filters

The grease filters should be cleaned frequently. Use a warm detergent

solution to clean filters. Filters are dishwasher safe. See “INSTALL FILTER”

section for installation and removal instructions.

Ductfree Filters

The ductfree filter should be changed every 6 months. See “INSTALL FILTER”

section for installation and removal instructions.

Hood Cleaning

Stainless steel is one of the easiest materials to keep clean. Occasional care will

help preserve its fine appearance.

Cleaning tips:

• Hot water with soap or detergent is all that is usually needed.

• Follow all cleaning by rinsing with clear water. Wipe dry with a clean, soft cloth

to avoid water marks.

• For discolorations or deposits that persist, use a non-scratching household

cleanser or stainless steel polishing powder with a little water and a soft cloth.

• For stubborn cases, use a plastic scouring pad or soft bristle brush together

with cleanser and water. Rub lightly in direction of polishing lines or "grain" of

the stainless finish. A void using too much pressure which may mar the surface.

• DO NOT allow deposits to remain for long periods of time.

• DO NOT use ordinary steel wool or steel brushes. Small bits of steel may

adhere to the surface causing rust.

• DO NOT allow salt solutions, disinfectants, bleaches, or cleaning compounds

to remain in contact with stainless steel for extended periods. Many of these

compounds contain chemicals which may be harmful. Rinse with water after

exposure and wipe dry with a clean cloth.

Painted surfaces should be cleaned with warm water and mild detergent only.

- 5 -

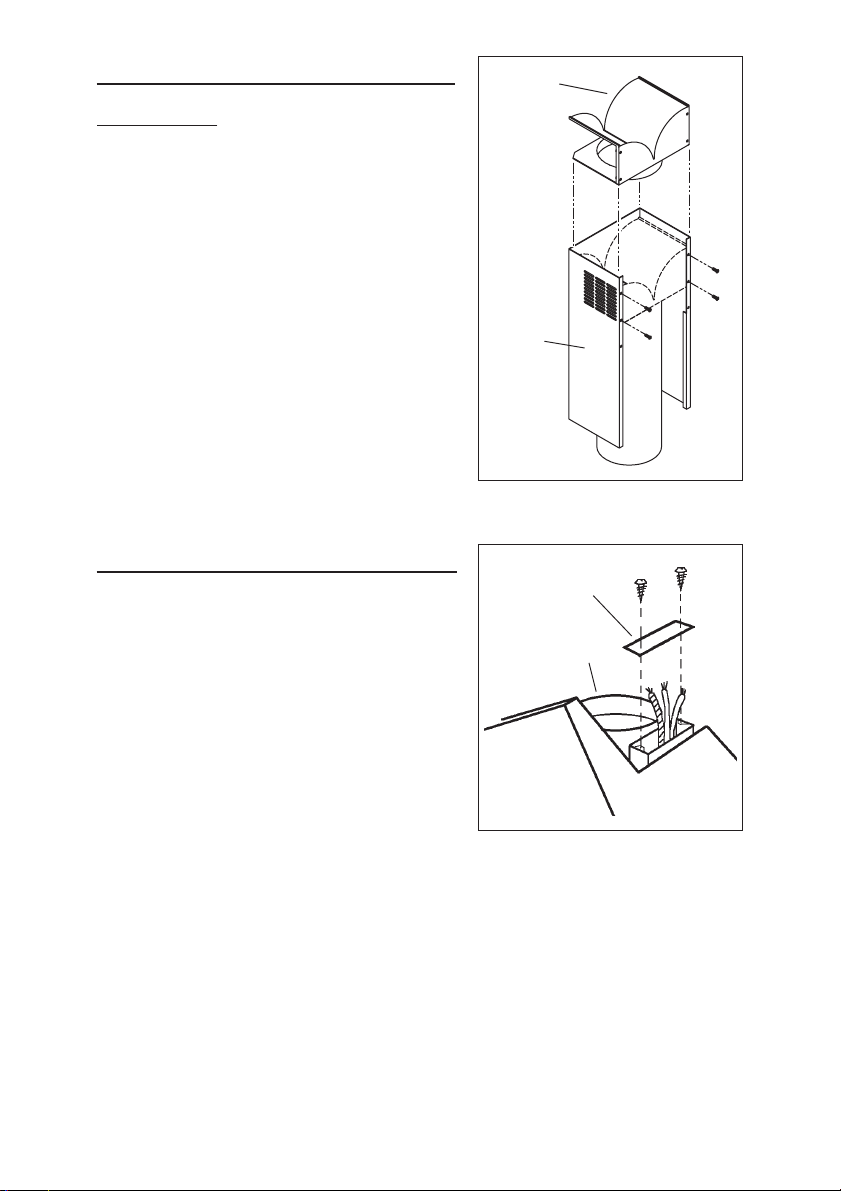

PREPARE THE HOOD

Unpack hood and check contents.

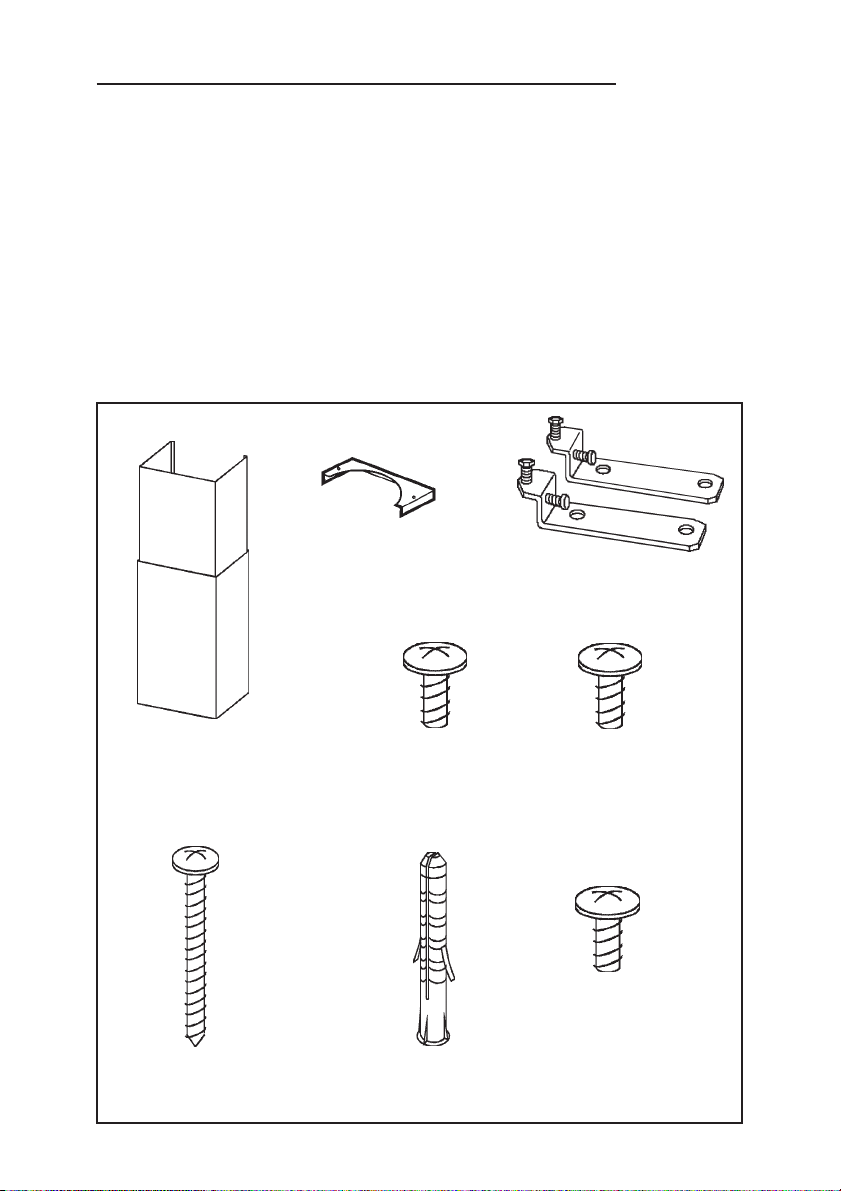

You should receive:

1 - Hood

1 - Decorative Flue Assembly

1 - Parts Bag (B08081189) containing:

1 - Flue Mounting Bracket

2 - Mounting Brackets

8 - Mounting Screws (4.8 x 38mm Pan Head)

4 - Mounting Screws (3.9 x 9.5mm Pan Head)

4 - Mounting Screws (3.2 x 13mm Pan Head)

4 - Mounting Screws (3.2 x 13mm Pan Head - Black)

8 - Drywall Anchors

1 - Installation Instructions

1 - Warranty Card

FLUE MOUNTING

BRACKET

MOUNTING

BRACKETS

DECORATIVE

FLUE

8 MOUNTING SCREWS

(4.8 x 38mm Pan Head)

4 MOUNTING

SCREWS

(3.9x9.5mm Pan

Head)

8 DRYWALL

ANCHORS

- 6 -

4 MOUNTING

SCREWS (3.2x13mm

Pan Head - Black)

4 MOUNTING

SCREWS (3.2x13mm

Pan Head)

INSTALL BACKSPLASH

OPTIONAL

If optional Model BSK6 series backsplash is

used, attach it to the finished wall. Secure hood

mounting brackets to the backsplash and omit

wall framing described below.

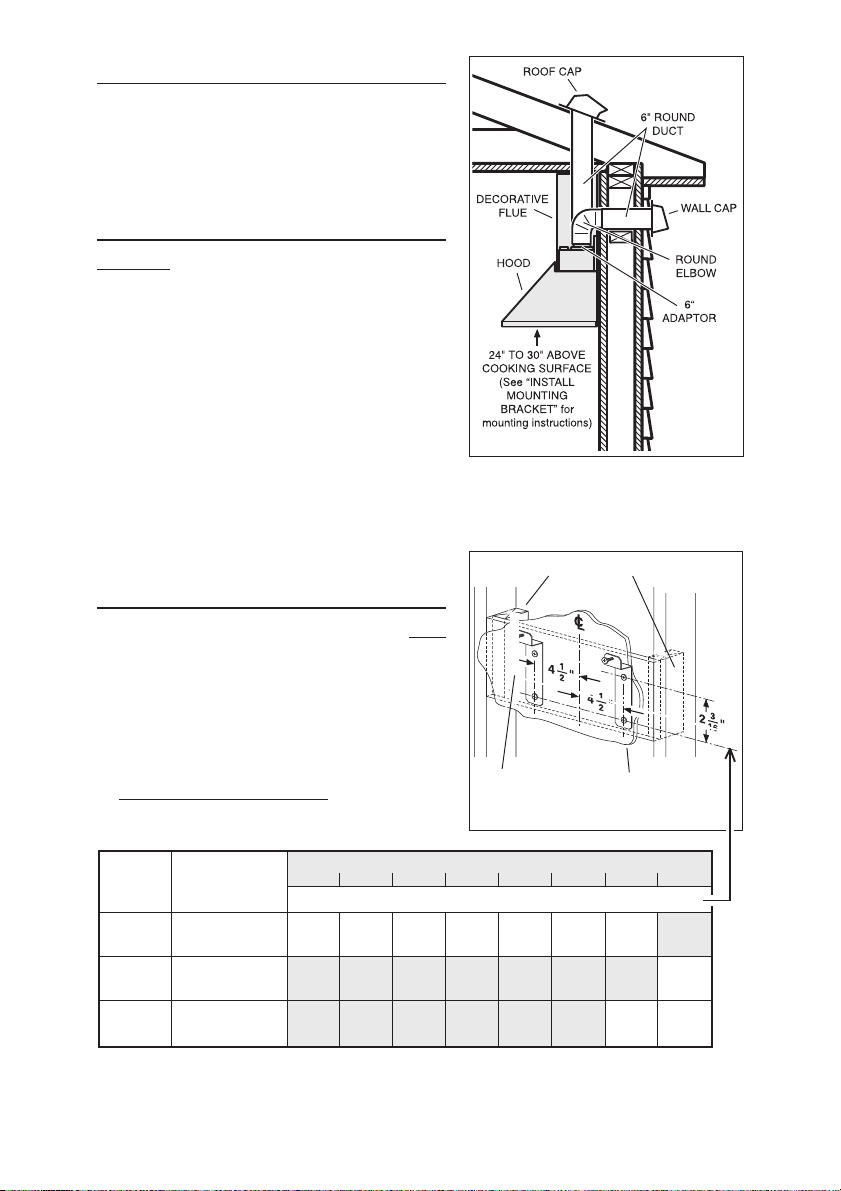

INSTALL THE DUCTWORK

DUCTED CONFIGURA TION ONLY

NOTE: To reduce the risk of fire, use only

metal ductwork.

1. Decide where the ductwork will run between the hood and the outside.

2. A straight, short duct run will allow the hood

to perform most efficiently.

3. Long duct runs, elbows, and transitions will

reduce the performance of the hood. Use

as few of them as possible.

4. Install a roof or wall cap. Connect 6" round

metal ductwork to cap and work back towards hood location. Use duct tape to seal

the joints between ductwork sections.

INSTALL MOUNTING

FRAMING BEHIND CROSS SUPPORT

BRACKETS

1. Construct wood wall framing that is flush

with interior surface of wall studs.

Make sure:

a) the framing is centered over installa-

tion location.

b) the height of the framing will allow the

mounting brackets to be secured to the

framing within the dimensions shown.

2.

After wall surface is finished, secure mounting brackets to framing using dimensions

shown.

CEILING

HEIGHT

8 FEET

9 FEET

10 FEET

DUCT METHOD

DUCTED OR

NON DUCTED

DUCTED OR

NON DUCTED

DUCTED WITH

FEXTK23

HOOD DISTANCE ABOVE 36” HIGH COOK TOP

24” 25” 26” 27” 28” 29” 30”

MOUNTING BRACKET LOCATION ABOVE 36” HIGH COOK TOP

28-1/4”

29-1/4” 30-1/4” 31-1/4” 32-1/4” 33-1/4”

Note: minimum hood distance above cook top must not be less than 24”. A maximum

of 31” above cook top is highly recommended for best capture of cooking impurities.

Distances over 31” are at the installer and users discretion; and if ceiling height and

flue length permit.

WOOD CROSS

SUPPORT

BEHIND DRYWALL

DRYWALL

(SEE NOTE BELOW)

31”

34-1/4”

35-1/4”

34-1/4” 35-1/4”

- 7 -

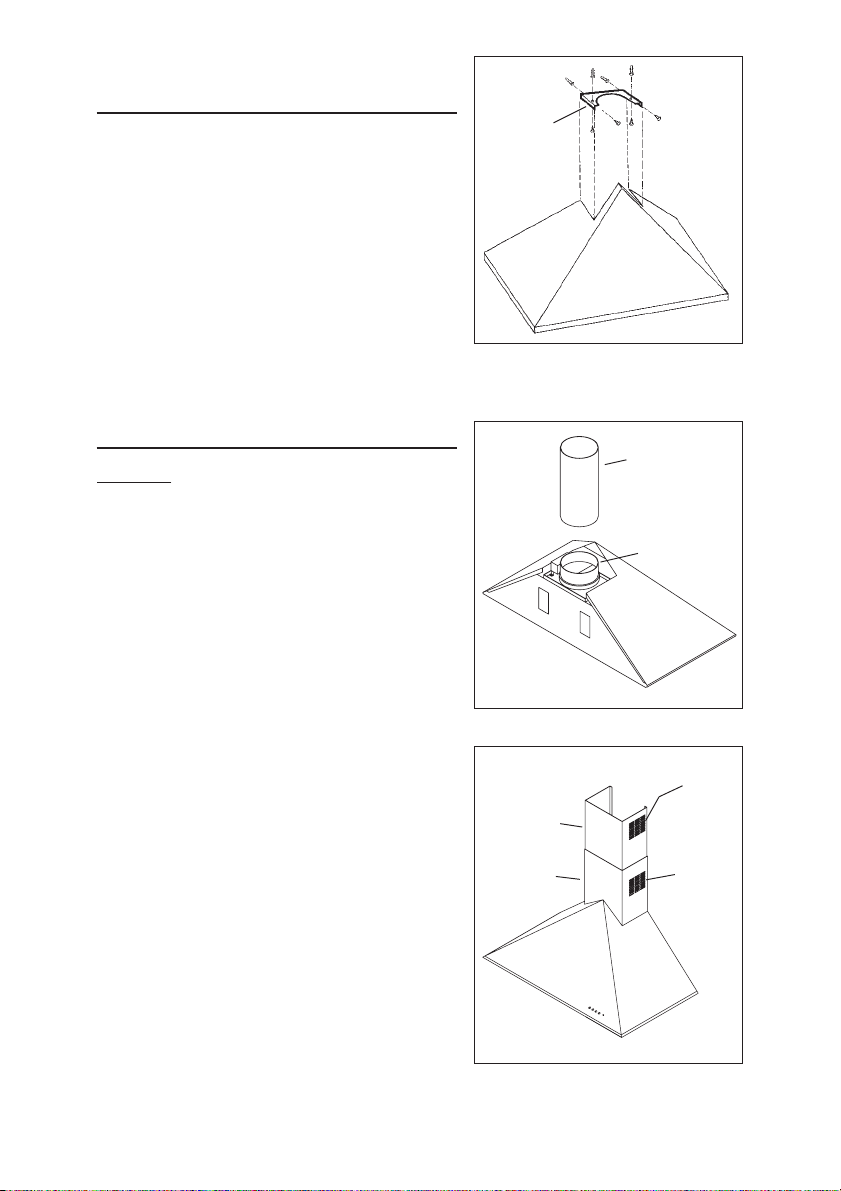

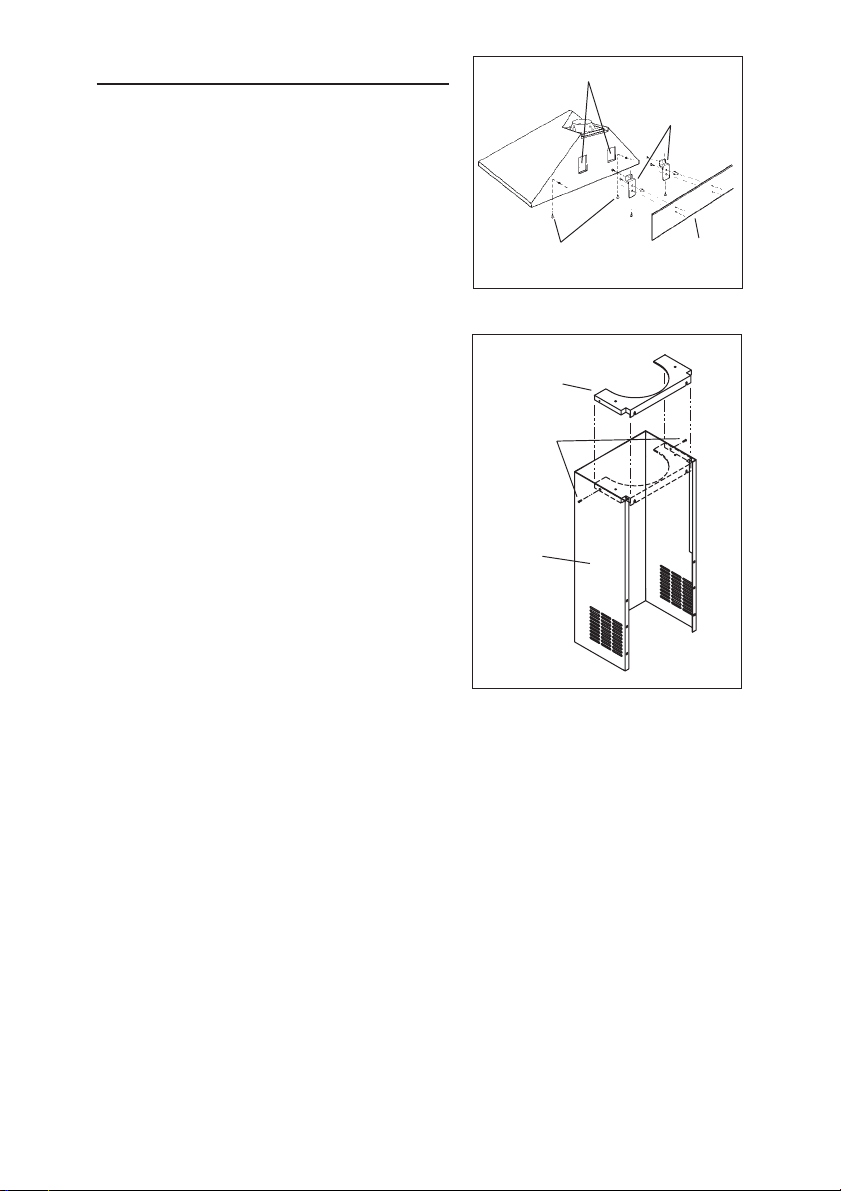

INSTALL FLUE MOUNTING

BRACKET

1. Carefully center the mounting bracket directly over the range hood location.

2. Secure the bracket assembly to the ceiling

using (2) 4.8x38mm mounting screws and

drywall anchors. Make sure the bracket is

pushed into the corner, tight against the

wall and centered over the hood.

PREPARE THE HOOD

DUCTED CONFIGURA TION ONLY

Note: On stainless steel hoods, carefully

remove the plastic protective film from all

exterior surfaces of the hood and decorative flues, prior to final installation.

1. Attach an adequate length of 6” round

metal duct to the range hood duct connector.

FLUE

MOUNTING

BRACKET

6” DIAMETER

METAL DUCT

DUCT

CONNECTOR

2. Duct tape all joints to make them secure

and air tight.

3. Carefully place the lower decorative flue

into the recessed area of the range hood

top.

4. Carefully slide the upper decorative flue

down inside the lower flue.

Note: On 8' ceilings the air vents on the upper

flue are concealed by installing the flue with

air vents down.

On 9' ceilings, air vents on the upper flue will

be exposed after installation.

- 8 -

UPPER

FLUE

LOWER

FLUE

UPPER

FLUE

VENTS

EXPOSED

LOWER

FLUE

VENTS

CONCEALED

PREPARE THE HOOD

NON-DUCTED CONFIGURATION ONLY

Note: On stainless steel hoods, carefully remove the plastic protective film

from all exterior surfaces of the hood and decorative flues, prior to final installation.

Note: The following material must be purchased separately for non-ducted

recirculation installations.

• Non-Ducted Recirculation Plenum Part Number SB08089123

• 6" diameter expandable / flexible aluminum duct

• 1/16" diameter twist drill

• Recirculating filter model FILTERK3490CM (for 90 cm wide hoods) or

FILTERK3448 (for 48" wide hoods).

Caution: Use flexible metal duct.

Do not use plastic or rigid metal ducting.

1. Determine length of the compressed flexible metal duct using the following

formula:

39” MINUS PLUS =

Distance above

cook top.

12” if ceiling height

is 9-feet

Compressed

length of

flexible

aluminium

ductwork

Worksheet:

2. Remove and discard the damper

flaps from inside the hood's duct

connector.

39” - __________ + __________ (for 9' ceiling only) = __________

PLENUM

(3) SCREWS

3. Attach 6" round metal flexible duct

to the hoods 6" duct connector.

Tape all joints with duct tape.

4. Assemble the recirculation plenum

6” ROUND

METAL

FLEXIBLE

DUCT

to the flexible duct.

5. Drill three 1/16" diameter equally

spaced holes though the duct and

DUCT

CONNECTOR

duct connector on the recirculation

plenum.

6. Secure the duct to the plenum’s

connector with (3) sheet metal

screws. Tape all joints with

aluminum duct tape.

- 9 -

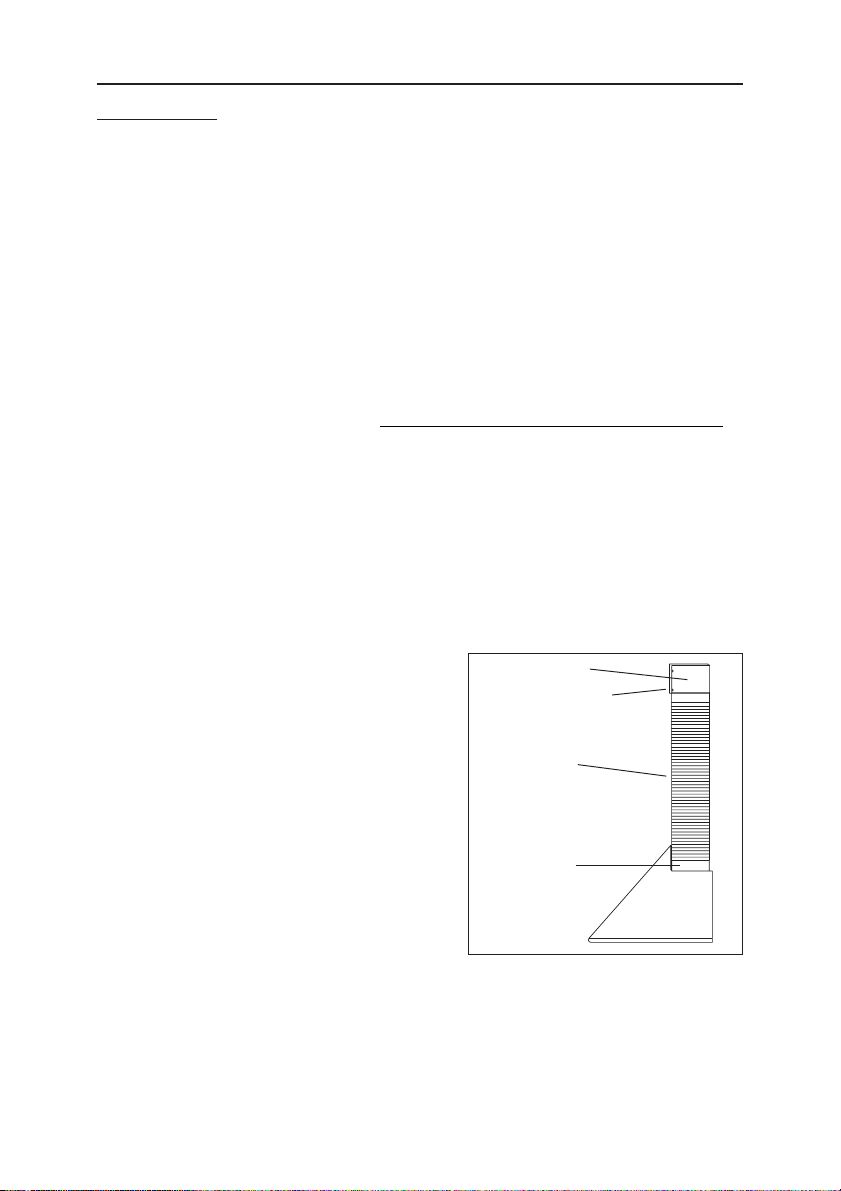

PREPARE THE HOOD

(CONTINUED)

NON-DUCTED CONFIGURATION ONLY

7. Carefully place the lower flue into the

recessed area of the range hood.

8. Carefully slide the upper flue down

inside the lower flue.

9. Secure the recirculation plenum to the

upper flue with (4) flat head screws.

WIRING

Note: This range hood must be properly

grounded. The unit should be installed by a

qualified electrician in accordance with all

applicable national and local electrical

codes.

PLENUM

UPPER

FLUE

WIRING BOX

COVER

DUCT COLLAR

1. Remove the wiring box cover. Remove a

knockout from the wiring box.

2. Feed 6" of power cable through the knockout opening and secure cable to the wiring

box with an appropriate connector.

3. Make electrical connections. Connect

white to white, black to black and green to

green.

4. Replace wiring box cover and screws.

Make sure that wires are not pinched between cover and box.

- 10 -

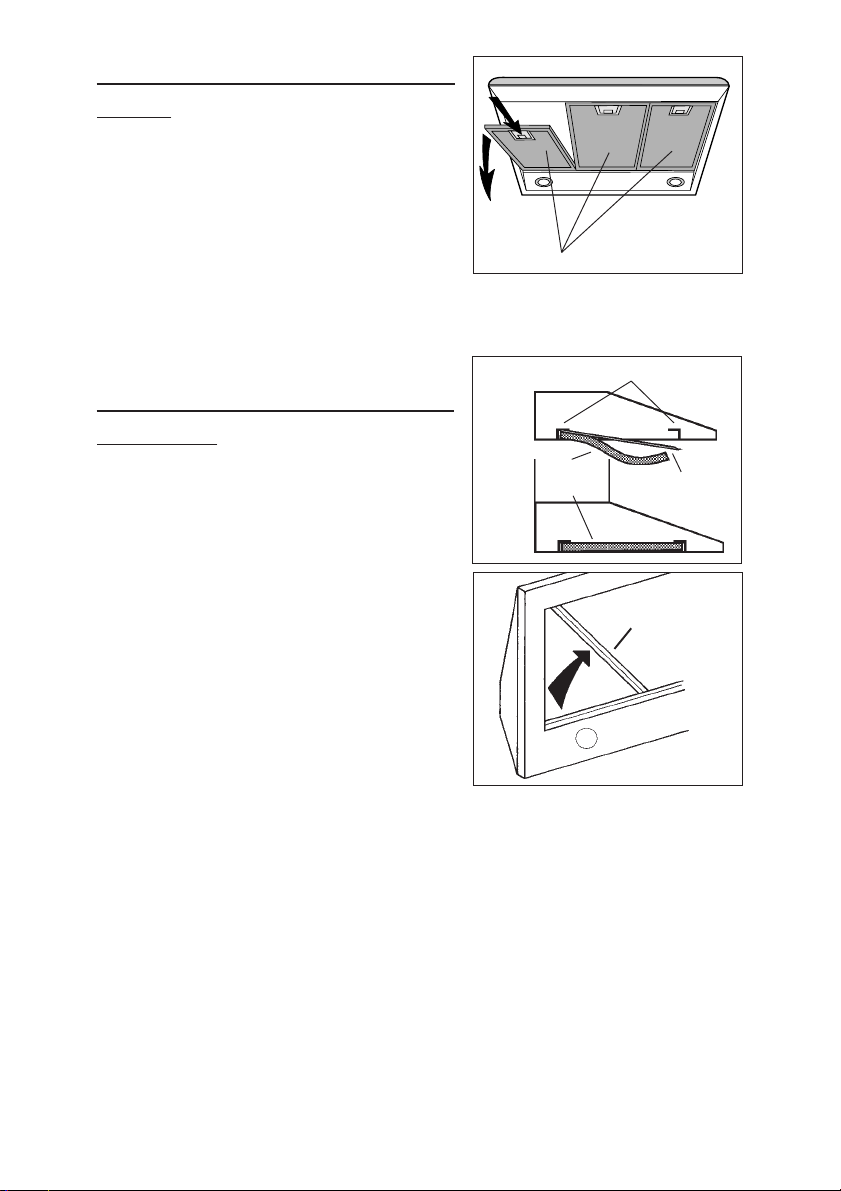

INSTALL THE HOOD

Note: at least two people will be required to

mount the hood.

1. Raise the hood into its mounting position.

2. Align the rectangular openings on the

back of the hood with the wall-mounting

brackets. Gently lower the hood until it

securely engages the bracket.

3. Level the hood and secure with (2)

mounting screws. Use drywall anchors

provided if wall studs or framing are not

available.

4. Raise the upper flue until its holes align

with holes in the flue mounting bracket

(located on ceiling).

5. Secure the flue with (2) mounting screws.

RECTANGULAR CUTOUTS

ADDITIONAL

MOUNTING SCREWS

FLUE

MOUNTING

BRACKET

MOUNTING

SCREWS

UPPER

FLUE

MOUNTING

BRACKETS

WALL

FRAMING

- 11 -

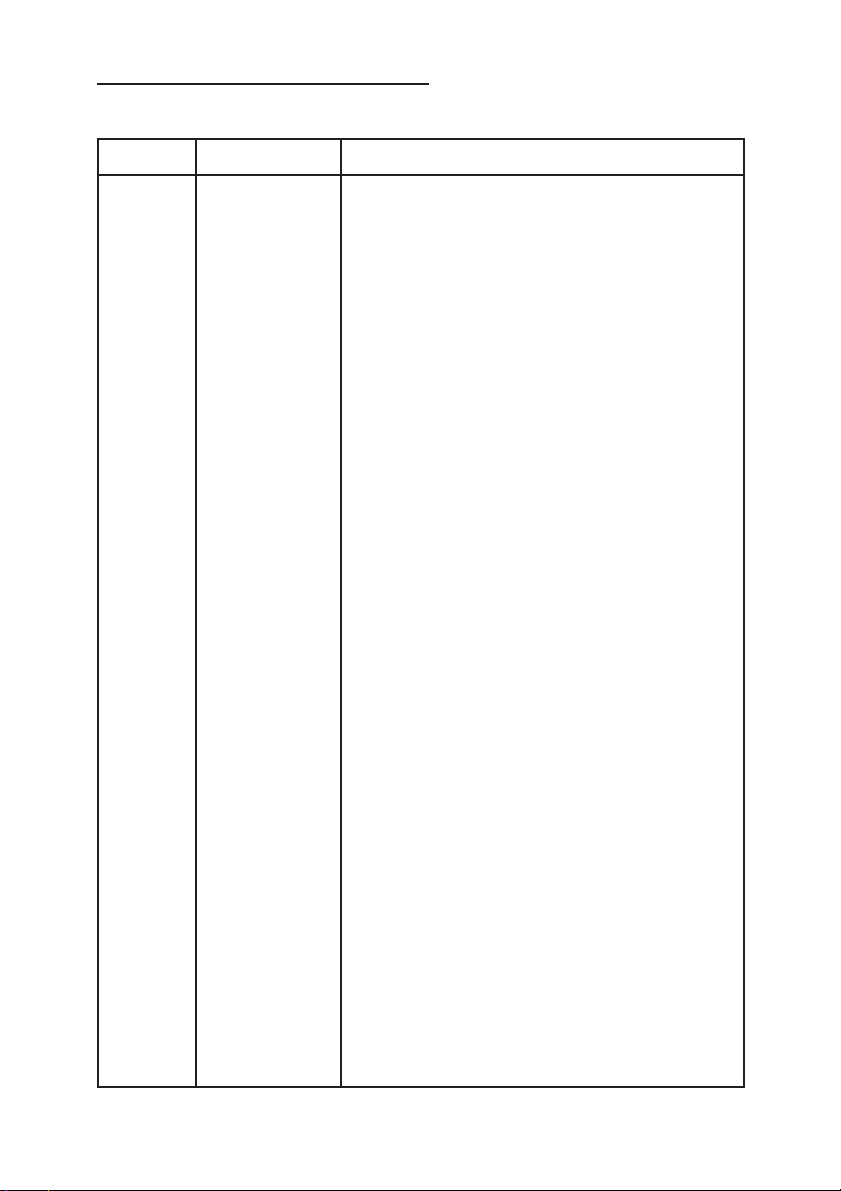

INSTALL FILTERS

DUCTED CONFIGURATION ONLY

1. To remove the GREASE filter, grip the latch

tab and pull it down. This will disengage

the filter from the hood. Tilt the filter downward and remove.

2. To install the GREASE filter, align rear filter

tabs with slots in the hood. Pull latch tab

down, push filter into position and release.

Make sure the filter is securely engaged

after assembly.

DUCTFREE FILTER

INSTALLATION

NON DUCTED CONFIGURATION ONLY

1. Purchase a ductfree filter kit (model no.

FILTERK3490CM or FILTERK3448) from

your dealer.

2. Remove the grease filters by pushing them

back to compress the retaining springs,

then tilt filters down and out of front groove.

3. Holding the ductfree filter on its side, insert

one of the support rods, (supplied with filters) into the upper groove in back that runs

parallel with the front of the hood, in order

to avoid that the filter might be sucked onto

the motor.

4. Fold the filter and insert it into the front.

GREASE

FILTERS

DUCTFREE

FILTER

GROOVES

SUPPORT

SUPPORT

ROD

ROD

- 12 -

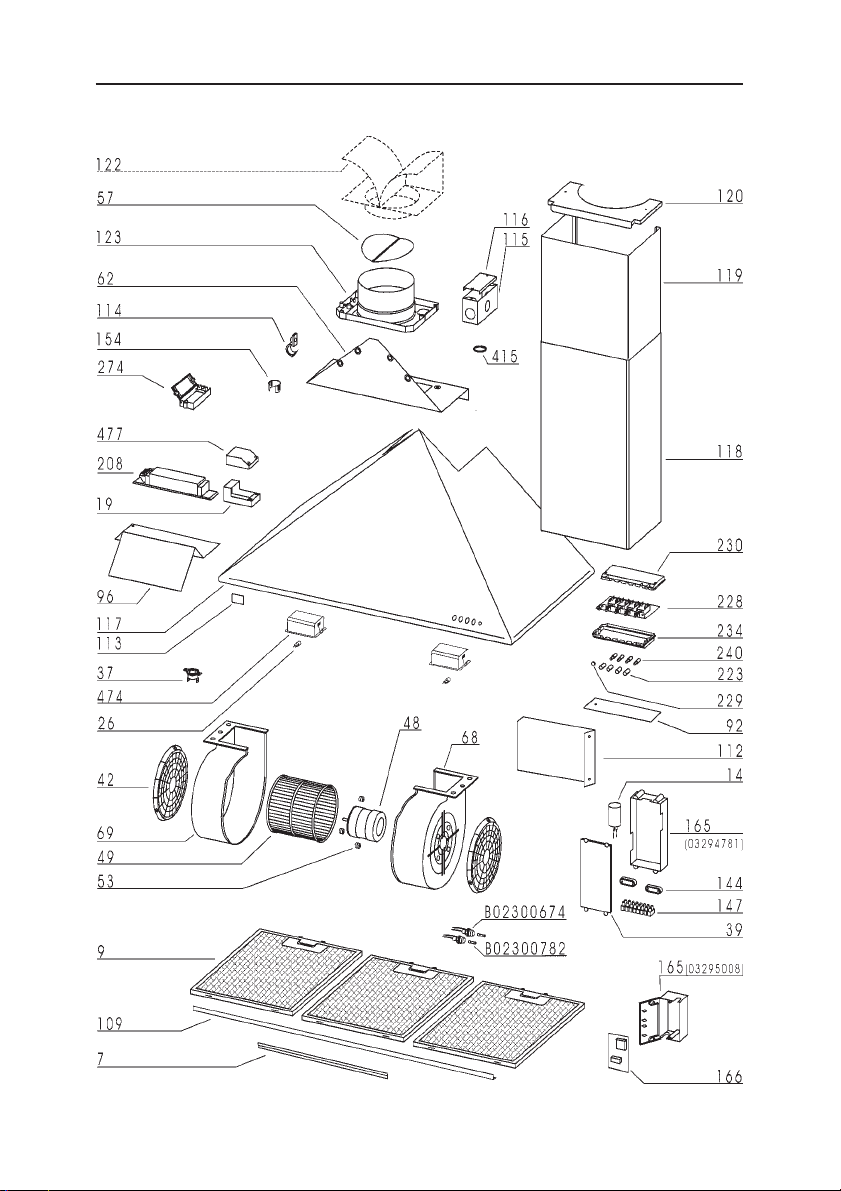

SERVICE PARTS

MODEL K29 -

or white models, call Broan Customer Service.

KEY NO. P ART NO. DESCRIPTION

9 B08087163 Grease Filter

14 B02300233 Motor Capacitor

19 B03295005 Terminal Box

26 B02300891 Halogen Lamp Bulb

37 B02300787 Heat Sentry

39 B03294033 Control Board Box Cover

48 B02310201 Motor

49 B03295071 Blower Wheel

53 B03202007 Rubber Washer

57 B02000756 Damper Flap

62 B08088597 Blower Mounting Cover

68 B02000295 Right Blower Housing

69 B02000296 Left Blower Housing

96 BE3245849 Ballast Support

109 BE3342578 Filter Channel - Front (48” models)

109 BE3333676 Filter Channel - Front (90cm models)

112 BE3345848 Electrical Box Support

113 B08091852 Nameplate

115 BE3335228 Wiring Box

116 BE3334252 Wiring Box Cover

118 BE3342581 Decorative Flue Bottom

119 BE3342582 Decorative Flue Top

120 B03292118 Flue Mounting Bracket

123 B03292283 Duct Connector

144 B03292287 Wire Clamp

147 BR2300135 Terminal Block

154 B03202286 Lead

166 B08086668 Control Board

208 B02300792 Transformer (48” models)

208 B02300783 Transformer (90cm models)

223 B03200351 Switch Button

229 B03201014 Lamp Lens

240 B03292301 Switch Activator

274 B03295035 Fuse Box

474 B02300719 Halogen Lamp Housing

477 B03295006 Terminal Cover

* B06002017 Blower Assembly

* B06107659 Control Board Assembly

* B06107657 Switch Box Assembly (48” models)

998 B08081189 Hardware Package

- B02300782 Fuse

- B02300674 Fuse Holder

Parts for stainless steel models shown. For service parts for black

(Includes Key Nos. 42, 48, 49, 53, 68, 69)

(Includes Key Nos. 14, 39, 144, 147, 165, 166)

(Includes Key Nos.92,223,228,230,234,240)

* Not shown assembled.

- 13 -

SERVICE PARTS

MODEL K29

- 14 -

Loading...

Loading...