Concentration Meters

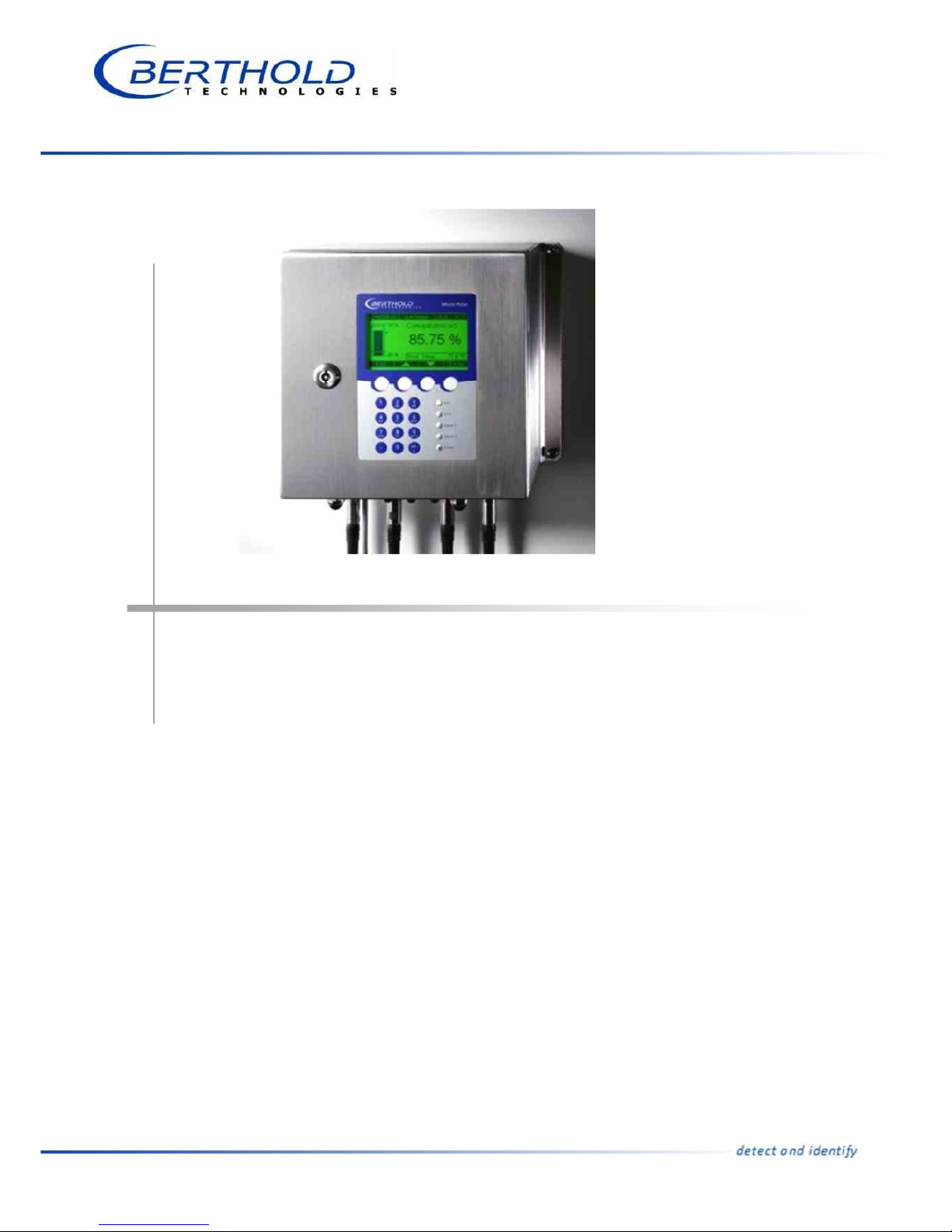

MicroPolar (++)

LB 566

User’s Guide

Hardware Manual

41986BA2

Rev. Nr.: 06-E, 09/2017

MicroPolar (++) LB 566

The units supplied should not be repaired by anyone other than Berthold

Technologies Service engineers or technicians by Berthold Technologies.

In case of operation trouble, please address to our central service department

(address see below).

The complete user’s guide consists of the hardware manual and the

software manual.

The hardware manual comprises:

mechanical components

installation

electrical installation

technical data

electrical and mechanical drawings

The software manual comprises:

operation of the evaluation unit

parameter description

basic setup

calibration

error messages

The present manual is the hardware description.

Subject to change without prior notice.

BERTHOLD TECHNOLOGIES GmbH & Co. KG

Calmbacher Str. 22 D-75323 Bad Wildbad

Switchboard: Service:

Phone +49 7081 177 0 Phone +49 7081 177 111

Fax +49 7081 177 100 Fax +49 7081 177 339

industry@Berthold.com Service@Berthold.com

www.Berthold.com

Table of Contents

MicroPolar (++) LB 566 5

Table of Contents

Page

Safety Summary 7Chapter 1.

1.1 Symbols and Warnings 7

1.2 General Information 8

1.3 General Safety Instructions 9

General Information 11Chapter 2.

2.1 Use and Function 11

2.2 Frequency License 12

2.3 Intended Use 14

2.4 Explanation of Terms 15

System Description 17Chapter 3.

3.1 Principle of Measurement 17

3.2 Calculation of Measured Values 18

3.3 Temperature Compensation 19

3.4 Throughput Calculation and Output 20

3.5 Mechanical Components 21

3.5.1 Evaluation Units 23

3.5.2 FlowCell 25

3.5.4 Container Probe 27

3.5.5 High-frequency Cable 30

3.6 Assembly on a Pipeline 32

3.7 Assembly on a Container 33

Getting Started 35Chapter 4.

4.1 Transport 35

4.2 Commissioning the FlowCell 36

4.2.1 Installing the FlowCell 36

4.2.2 Installing the Evaluation Unit 38

4.2.3 Connecting the HF Cable 39

4.3 Commissioning the Container Probe 41

4.3.1 Installing the Container Probe 41

4.3.2 Setting Up the Evaluation Unit 43

4.3.3 Connecting the HF Cable 43

4.5 Connecting the Evaluation Unit 45

4.5.1 Pin Configuration of the Connector Strip 46

4.5.2 Digital Outputs, Relay 48

Service instructions 51Chapter 5.

5.1 General Information 51

5.2 Wear Parts 52

5.3 Instrument Cleaning 53

5.4 Battery 53

5.5 Fuse Replacement 54

Table of Contents

6 MicroPolar (++) LB 566

Technical Data 55Chapter 6.

6.1 Technical Data Evaluation Unit 55

6.2 Technical Data Sensors 58

6.3 Technical Data HF Cable 61

6.4 Format of Serial Data Output RS232 and RS485 62

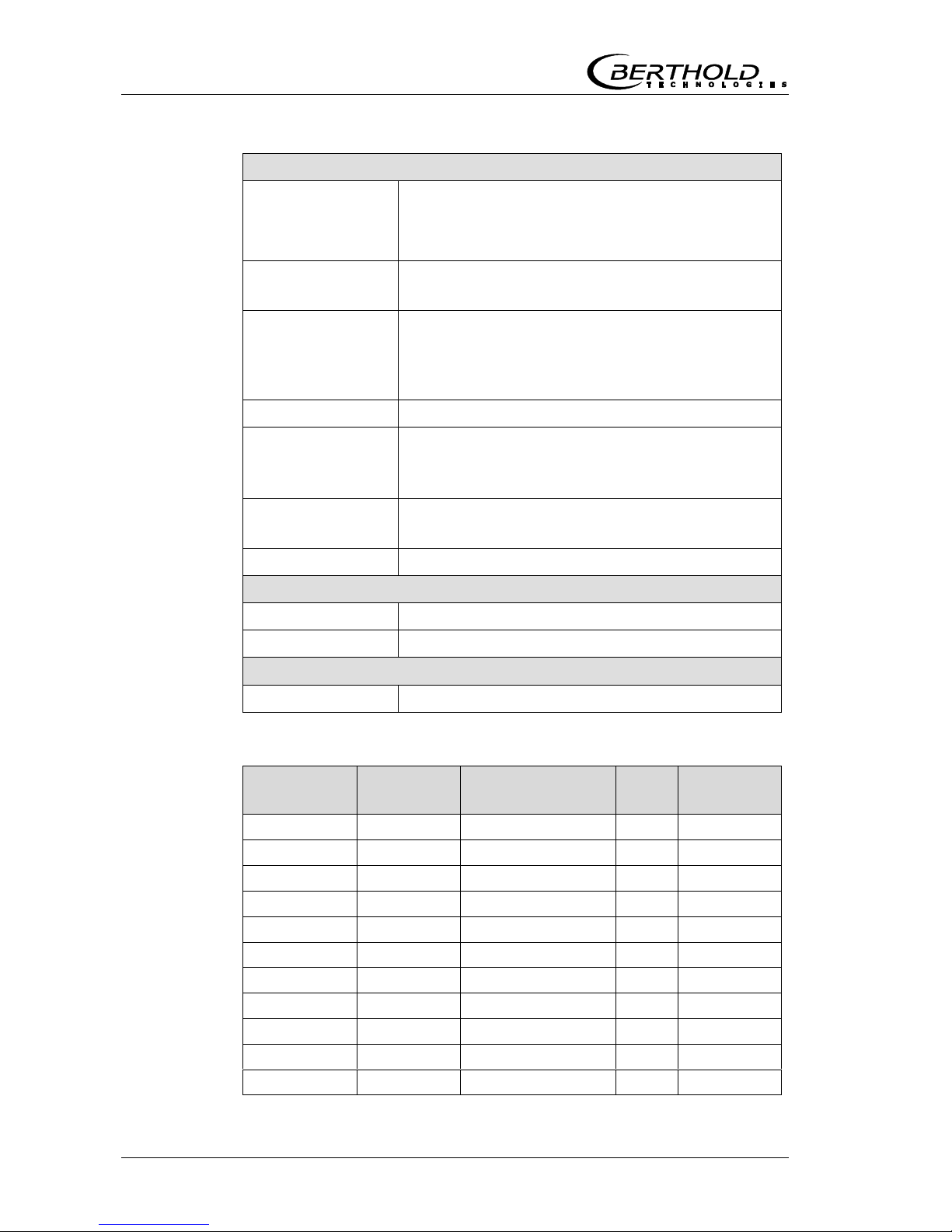

Certificates 63Chapter 7.

7.1 EC Declaration of Conformity 63

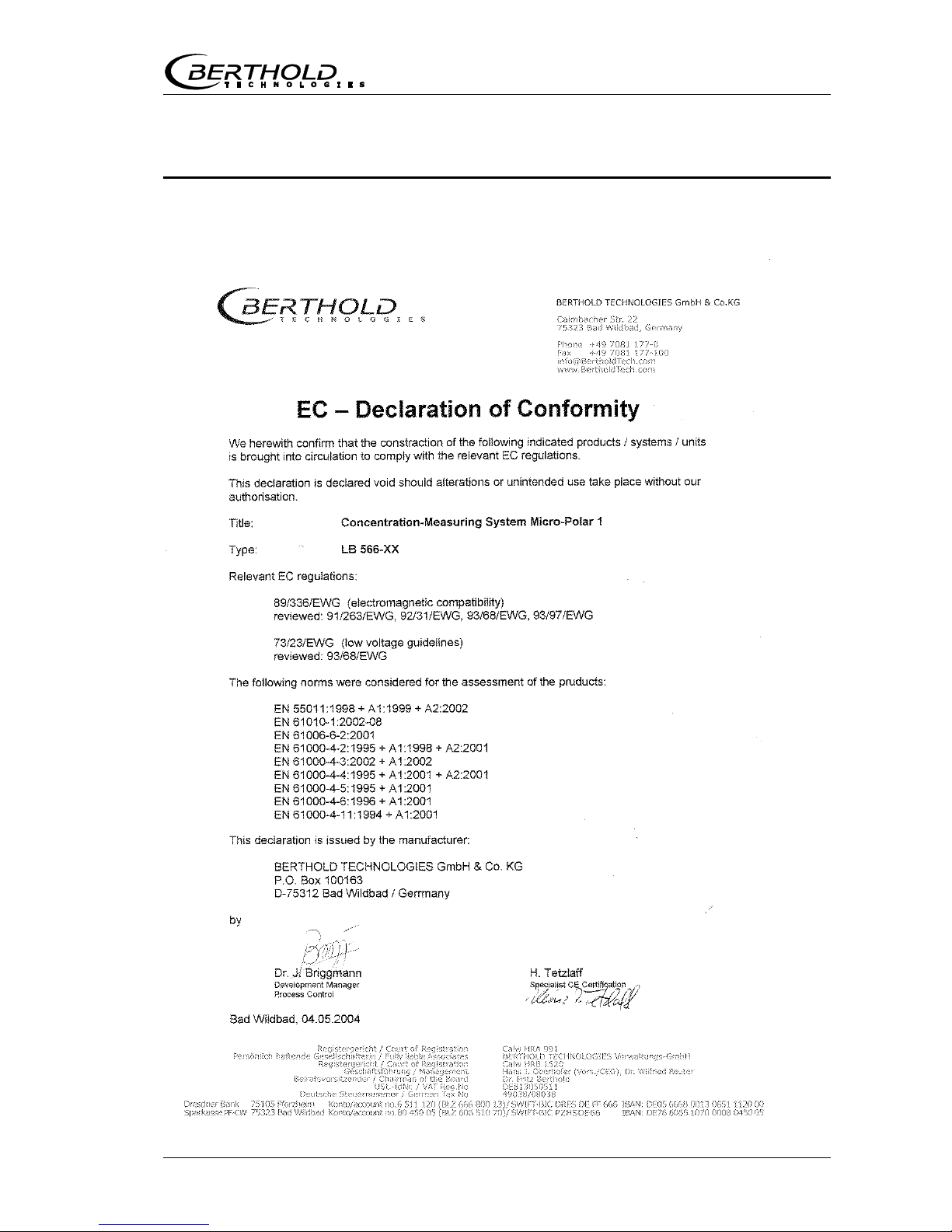

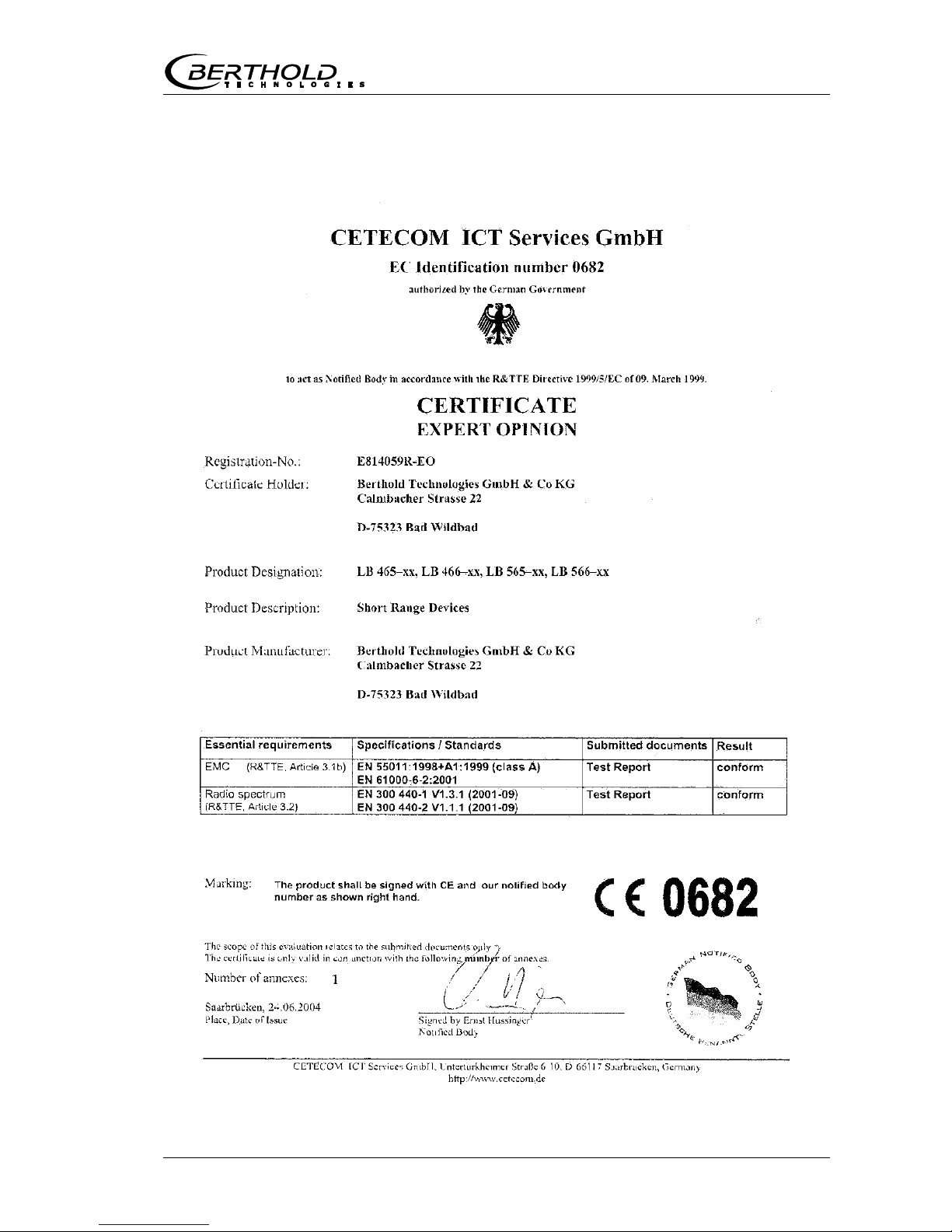

7.2 Frequency License 65

Technical Drawings 73Chapter 8.

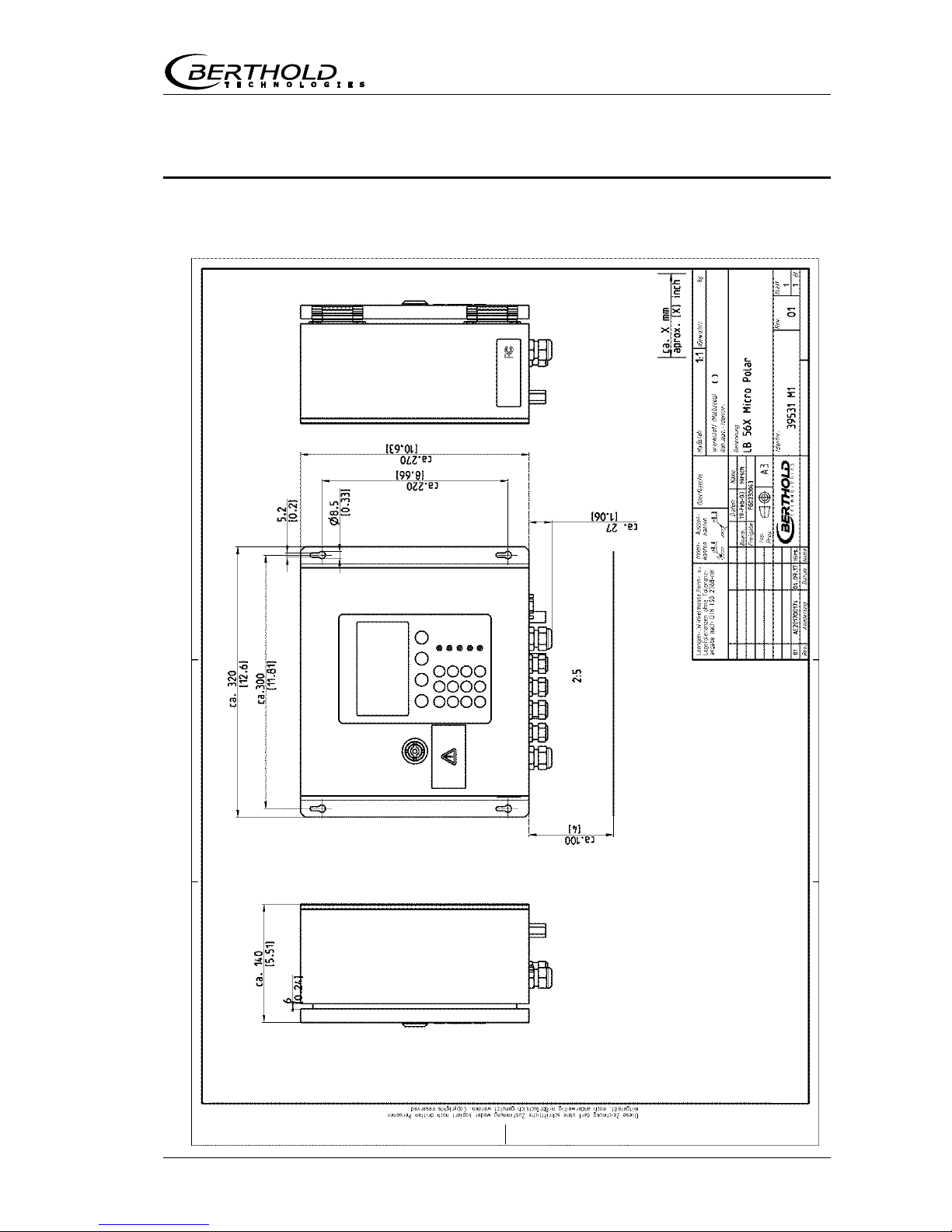

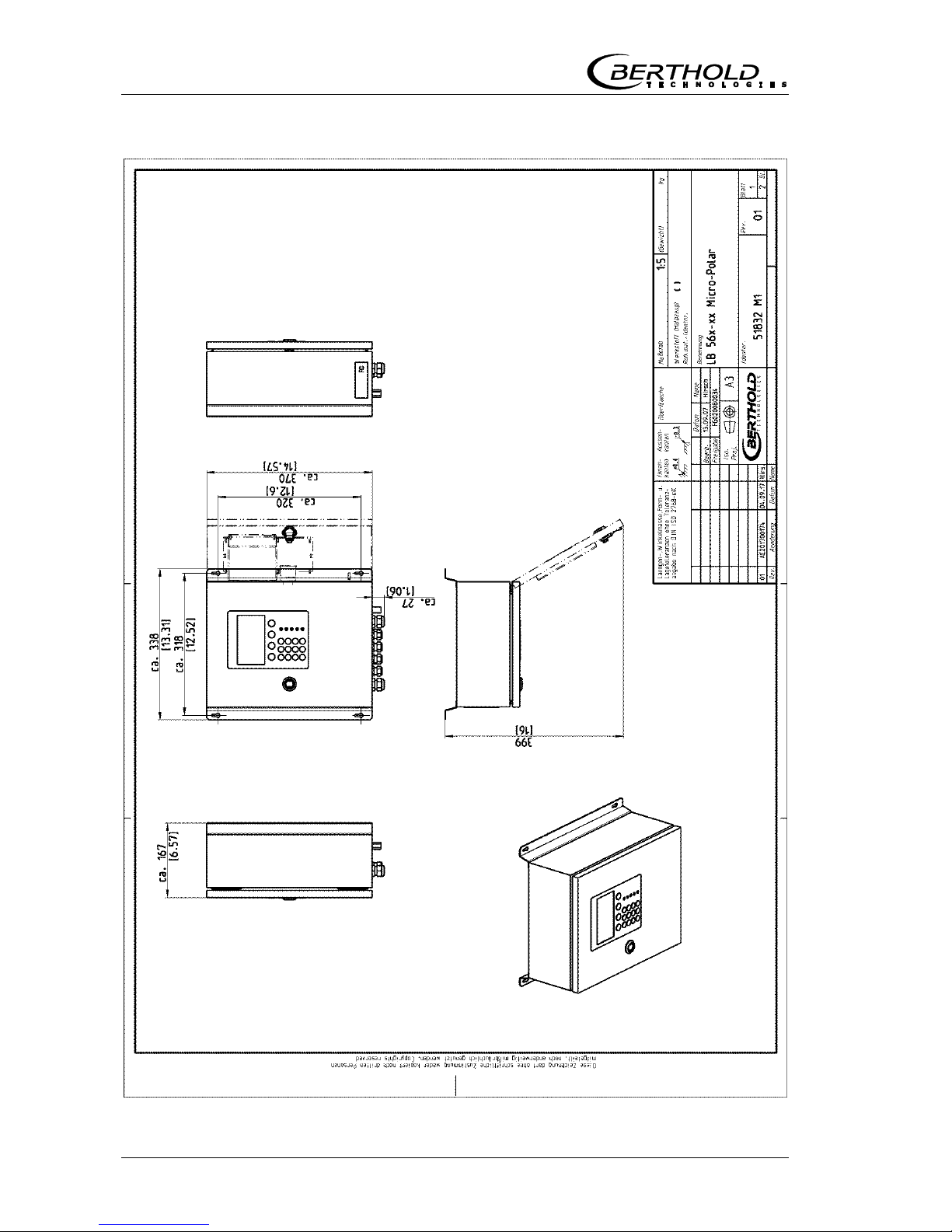

8.1 Dimensions Drawings Evaluation Unit Wall Housing 73

8.2 Electrical Wiring Diagram 75

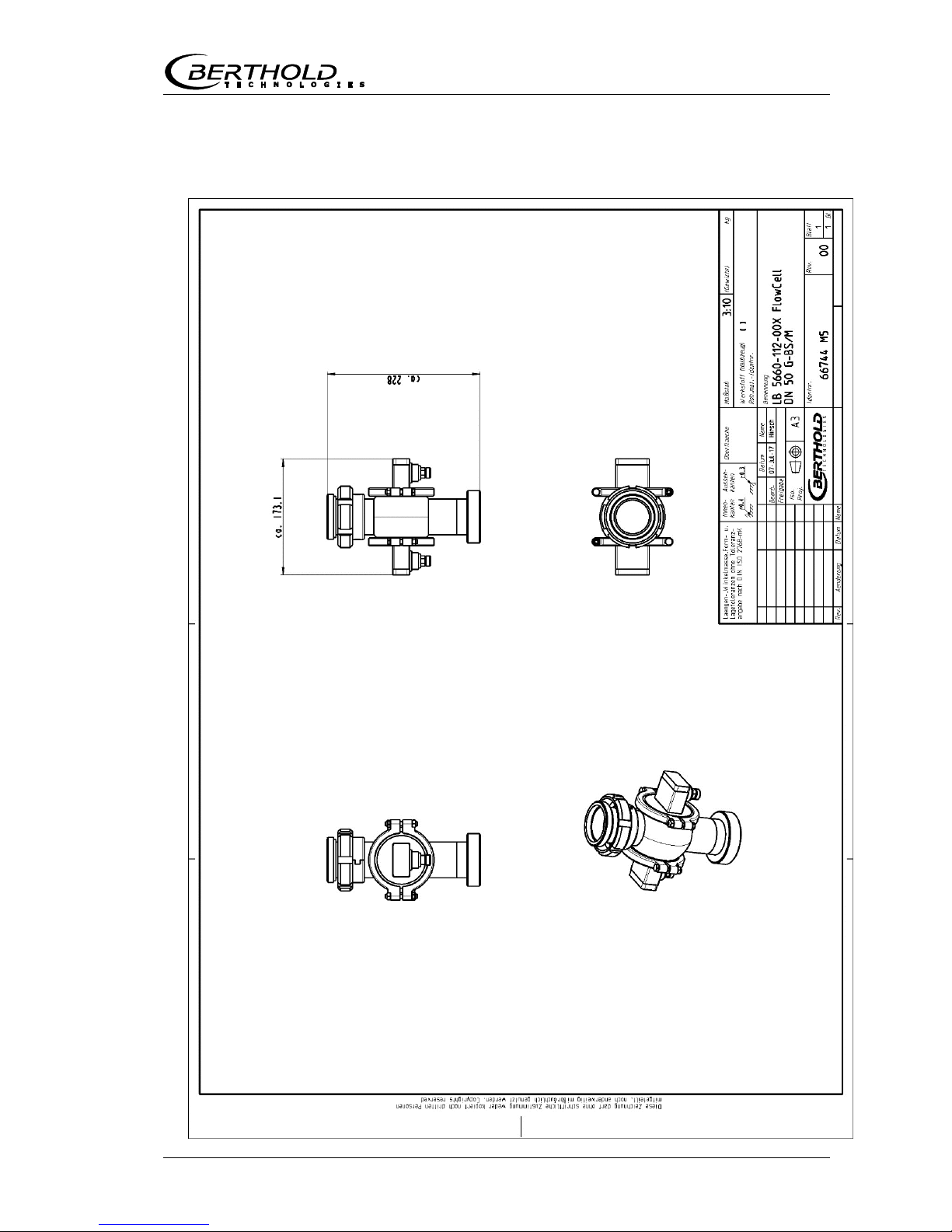

8.3 Dimensional Drawings FlowCell 76

8.3.1 Type LB 5660-102-00X FlowCell DN 50 VFL. FOA 76

8.3.2 Type LB 5660-112-00X FlowCell DN 50 G-BS/M 77

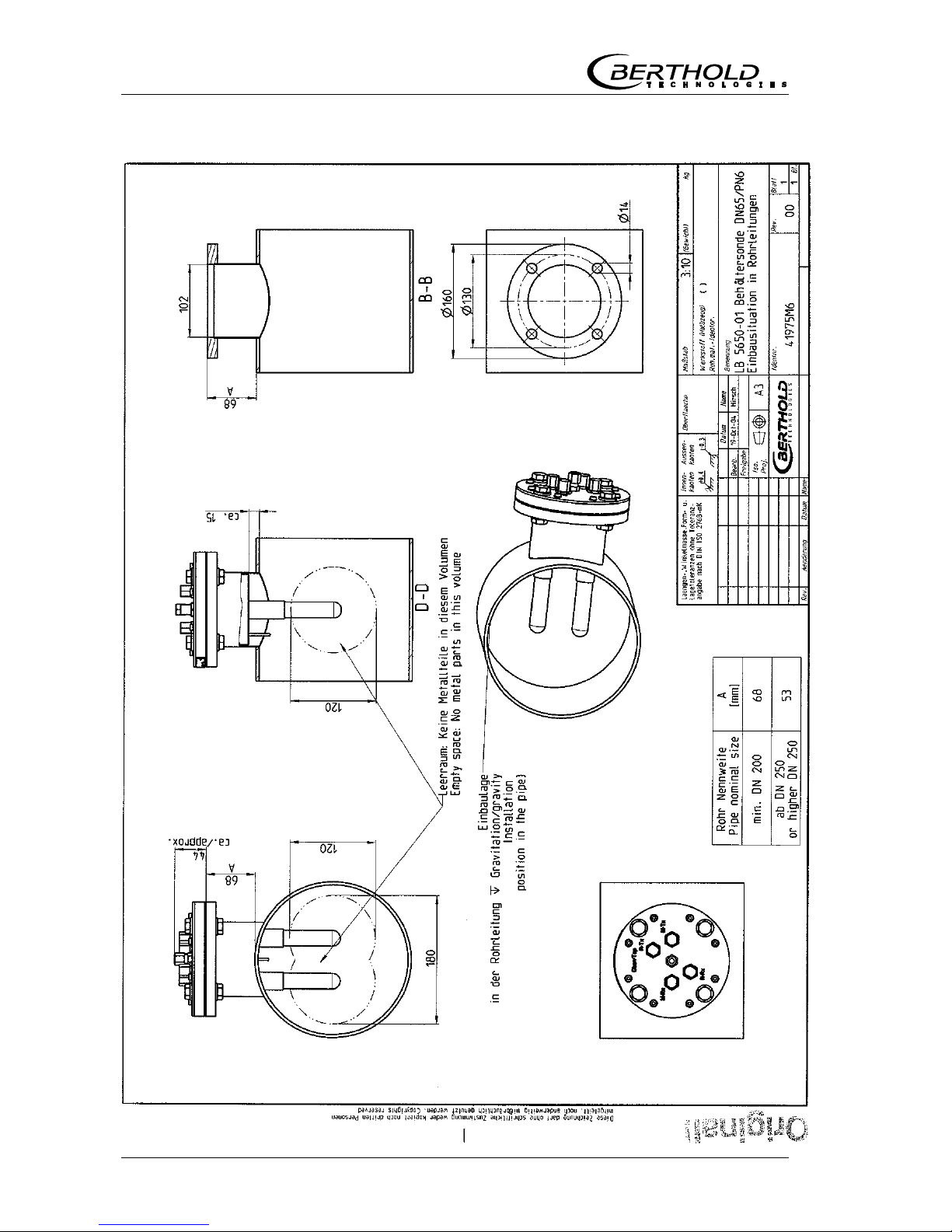

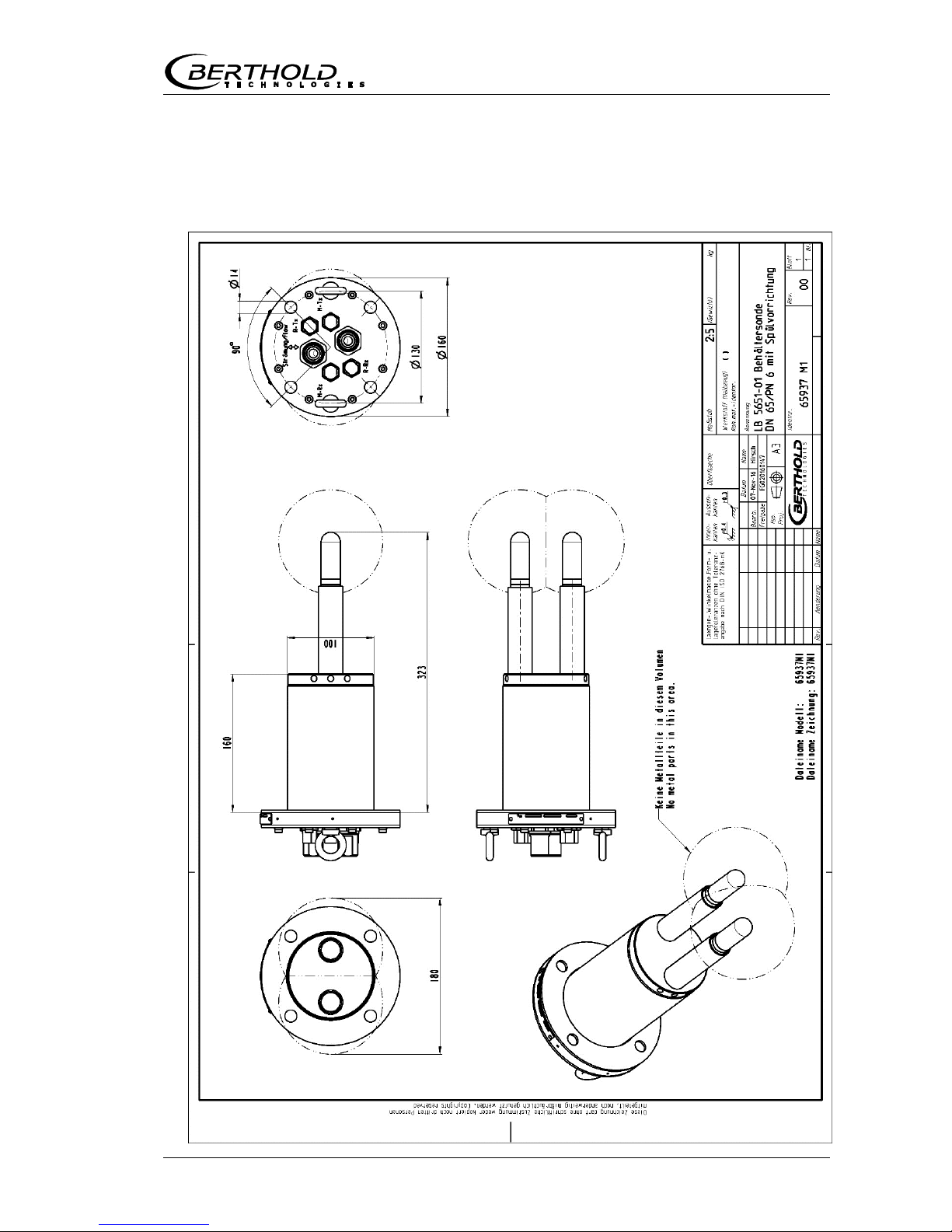

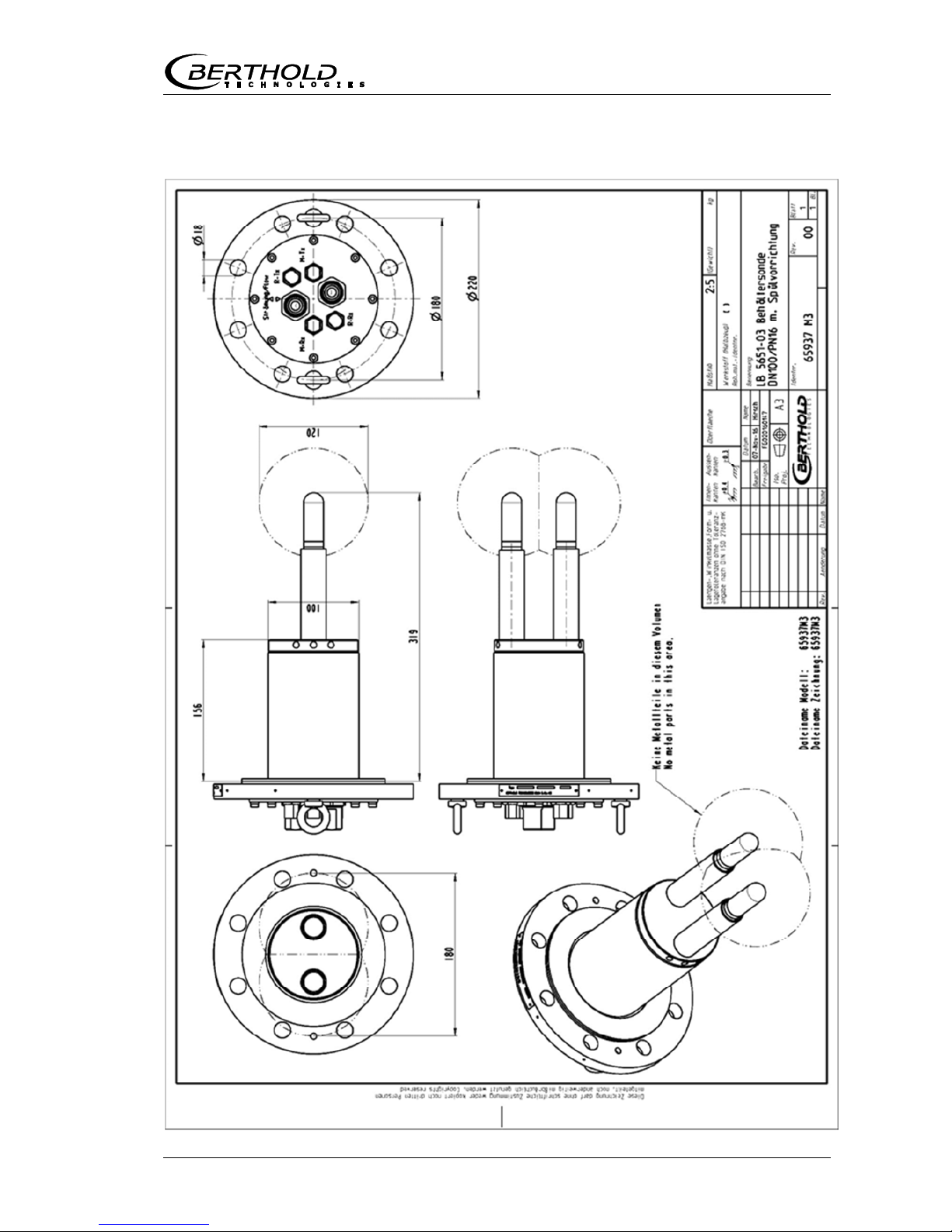

8.4 Dimensional Drawings Container Probes 78

8.4.1 Type LB 5650-01 78

8.4.2 Type LB 5650-02 79

8.4.3 Type LB 5650-03 80

8.4.4 Type LB 5650-04 81

8.4.5 Type LB 5650-05 82

8.4.6 Type LB 5650-09 83

8.4.7 Installation Situation in Pipelines 84

8.5 Dimensional Drawings Container Flush Probes 85

8.5.1 Type LB 5651-01 85

8.5.2 Type LB 5651-02 86

8.5.3 Type LB 5651-03 87

8.5.6 Installation Situation in Pipelines 88

Chapter 1. Safety Summary

MicroPolar (++) LB 566 7

Safety SummaryChapter 1.

1.1 Symbols and Warnings

In this user manual, the term Berthold Technologies stands for

the company Berthold Technologies GmbH & Co.KG.

To rule out bodily injury and property damage, please keep in

mind the warning and safety instructions provided in this user

manual. They are identified by the following sings: DANGER,

WARNING, CAUTION or NOTICE.

Indicates imminent danger. If it cannot be avoided,

death or most severe personal injuries may be the

consequence.

Indicates a possibly dangerous situation. The consequences

may be death or most severe personal injuries.

Indicates a possibly harmful situation The consequences

may be minor or medium personal injuries.

Indicates a situation that may cause material damage if the

instructions are not followed.

IMPORTANT

Paragraphs with this symbol provide important information on

the product and how to handle it.

TIP

Contains user tips and other useful information.

Chapter 1. Safety Summary

8 MicroPolar (++) LB 566

Other symbols used in this documentation:

Warning: No intervention, do not alter anything

Requirement: Disconnect power

Requirement: Wear safety boots

1.2 General Information

The most important safety measures a summarized in this user

manual. They supplement the corresponding regulations which

must be studied by the personnel in charge.

Please pay attention to:

the national safety and accident prevention regulations

the national assembly and installation directions

the generally recognized engineering rules

the information on transport, assembly, operation, service,

maintenance

the safety instructions and information in these operating in-

structions

the enclosed technical drawings and wiring diagrams

the characteristic values, limit values and the information on

operating and ambient conditions on the type labels and in

the data sheets

the signs on the devices

the country-specific licensing schemes

Chapter 1. Safety Summary

MicroPolar (++) LB 566 9

1.3 General Safety Instructions

IMPORTANT

The equipment housings have IP 65 protection and are

suitable for outdoor applications. The units are factory tested

and are delivered in a condition that permits safe and reliable

operation.

For outdoor applications, the measuring systems must be

protected from direct sunlight and rain, for example by a

suitable shelter.

IMPORTANT

Never change the installation and the parameter settings

without a full knowledge of these operating instructions, as

well as a full knowledge of the behavior of the connected

controller and the possible impact on the operating process to

be controlled.

The systems may only be used in perfect technical condition

and only for the intended use!

Only let persons work with the systems who are mandated to

do this and are suitably qualified and adequately trained!

Installations and modifications on the systems which may

affect the operational safety are not permitted!

IMPORTANT

All system components require non-corrosive ambient

conditions during transport, storage and operation.

IMPORTANT

If liquid gets inside the instrument, cut off the power supply.

The equipment must be inspected and cleaned by an authorized service center.

Ambient

conditions

Chapter 1. Safety Summary

10 MicroPolar (++) LB 566

Electrical hazards

Disconnect power to ensure that contact with live part is

avoided during installation and when servicing.

Disconnect the power supply before opening the instrument.

Work on open and live instruments is prohibited.

Caution! Potential hazards, material damage!

Device type:

LB 566-12 MicroPolar ++ (ID no. 51833-02)

When connecting the 24 V DC power supply, the + and –

poles must be connected correctly. There is no reverse

polarity protection!

Spare fuses must match the rating specified by the device

manufacturer. Short-circuiting or manipulation is not permitted.

IMPORTANT

The LB 566 and all additional equipment must be connected to

mains via grounded connection.

IMPORTANT

The concentration meter LB 566 may be installed, serviced

and repaired only by qualified specialists.

Qualified persons Qualified specialists are persons who through professional

training have acquired sufficient skills in the respective field and

who are familiar with the relevant national industrial safety regulations, accident prevention directions, guidelines and accepted

engineering standards. They must be able to safely assess the

results of their work and they must be familiar with the contents

of these user manual.

Chapter 2. General Information

MicroPolar (++) LB 566 11

General InformationChapter 2.

2.1 Use and Function

The MicroPolar LB 566 has been designed as a concentration

measuring system and may be used only for this purpose. If the

devices are used in a manner that are not described in this user

manual, the protection of the devices is compromised and the

warranty will be lost.

Berthold Technologies is liable and guarantees only that the devices comply with its published specifications. The LB 566 may

only be installed in an undamaged, dry and clean condition. Alterations and modifications to the system components are not

permitted.

The LB 566 is not qualified as a "safety-related measurement".

The standards and guidelines the LB 566 complies with are

itemized in these device instructions in chapter 2.2 Frequency

License and chapter 7.1 EC Declaration of Conformity.

The protection type of the LB 566 to IEC 60529 is max. IP 65.

The following use is inappropriate and has to be prevented:

The use under conditions other than the terms and condi-

tions stated by the manufacturer in their technical documentation, data sheets, operating and installation manuals and

other specifications.

The use after repair by persons not authorized by Berthold

Technologies.

The use in a damaged or corroded state.

Operation with open or inadequately closed cover.

Operating with insufficiently tightened adapters and cable

glands.

Operation without the manufacturer’s recommended safety

precautions.

Manipulating or bypassing existing safety facilities.

Authorized persons are those who, by law, are permitted to perform the respective activity, or who have been approved by

Berthold Technologies for certain activities.

Conformity to

standards

Protection type

Warning

against misuse

Authorized persons

Chapter 2. General Information

12 MicroPolar (++) LB 566

2.2 Frequency License

This device complies with Part 15 of the FCC Rules and with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired

operation.

Le présent appareil est conforme aux CNR d'Industrie Canada

applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'appareil doit accepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of

the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and re-

ceiver.

License labels

Chapter 2. General Information

MicroPolar (++) LB 566 13

- Connect the equipment into an outlet on a circuit differ-

ent from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician

for help.

Changes or modifications made to this equipment not expressly

approved by BERTHOLD TECHNOLOGIES may void the FCC authorization to operate this equipment.

The MicroPolar and MicroPolar ++ comply with the R&TTE Directive 1999/5/EC and thus meet all the requirements for this

type of high-frequency devices. As a mark of conformity in accordance with the CE mark, the devices bear the no. 0682 of

the certification body. The certificate can be found in chapter

7.3 Frequency License.

IMPORTANT

The frequency approvals and conformities are only applicable

in combination with the container probes and the FlowCell.

To comply with ETSI (European Telecommunications Standards Institute), the LB 566 ++ in combination with horn and

spiral antennae may only be operated with a 10dB attenuator

pad in the sending path (MTX).

IMPORTANT

The LB 566 has been manufactured in compliance with the

safety requirements for microwave devices. It will be the

user’s responsibility to adhere to any special legal provisions

regarding the use of microwaves.

IMPORTANT

Any change in the frequency or otherwise tampering with the

microwave device will lead to a loss of the frequency license

and may result in criminal consequences.

The microwave modules do not include any replaceable

components and must not be opened.

Chapter 2. General Information

14 MicroPolar (++) LB 566

2.3 Intended Use

The LB 566 can be used to determine the water or moisture

content and the concentration of virtually any material. The following sensors and evaluation versions are available:

1. The container probes have been designed for installation into containers and pipelines with a nominal width of 200

mm. The probe is mounted so that both measuring rods

(transmitter and receiver) are immersed into the product

being measured.

2. The FlowCell is a tubular probe, with the microwave transmitter and receiver being firmly welded onto the outside of

the tube. The tube is lined with Teflon to ensure smooth

walls. The FlowCell is either installed directly into the existing pipeline system or into a bypass.

The evaluation unit is available in two versions: The standard

model MicroPolar and the high dynamic version MicroPolar ++.

The Micro Polar ++ requires a microwave signal attenuation of

at least 40 dB. The MicroPolar must be used for lower microwave attenuation.

During operation, the concentration meters MicroPolar and MicroPolar ++ emit electromagnetic radiation in the frequency

range between 2.4 GHz and 2.5 GHz (range limitations depending on local regulations in your country). Microwaves are not

dangerous to human beings and the environment (power radiation < 10 mW). The microwaves are emitted directed from the

microwave window; the product is not altered by the microwaves.

To ensure proper function of the measuring system, please pay

attention to the following:

TIP

The material to be measured may be electrically conduc-

tive only to a limited degree.

The product must not contain any gas bubbles or gas

bubbles have to be compressed with adequate pressure

when carrying out measurements in pipelines.

The ion concentration, for example, salt content must be

nearly constant.

Chapter 2. General Information

MicroPolar (++) LB 566 15

2.4 Explanation of Terms

Attenuation Weakening of microwave signals, microwaves measuring effect.

EVU Evaluation Unit

Factory setting In the factory setting all parameters have been set to default

values. In most cases this considerably facilitates the calibration of the instrument. Despite factory setting, calibration

always has to be performed.

FlowCell Tubular probe for simple integration into the existing pipeline

system.

Flush probe Container probe with flushing device.

HF cable High frequency cable

Microwaves Designation for electromagnetic waves in a specific frequency

range.

Phase Phase or phase shift, microwave measuring effect.

Quad cable Combination of four HF cables of equal length in a corrugated

tube.

Softkeys Software associated keys.

TC Temperature compensation

Chapter 3. System Description

MicroPolar (++) LB 566 17

System DescriptionChapter 3.

3.1 Principle of Measurement

As the microwaves pass through the product, their propagation

velocity is slowed down (= phase shift) and their intensity is attenuated (= attenuation). Figure 3-1 illustrates the principle of

measurement: Compared to a reference signal, the propagation

velocity of microwaves passing through the product is slowed

down (phase shift) and their intensity (attenuation) is reduced.

Phase shift

Messgut

Phase comparison

--> Phase

Amplitude comp.

--> Attenuation

Referencepath

Referencesignal

Measurementsignal

Measured value:

Concentration %DS

HF sources

Receiver

Transmitter

The prerequisite is that the product being measured shows dielectric properties. Generally, water is a very distinct dielectric

fluid. The water or dry mass concentration can therefore be determined by measuring the phase shift and/or attenuation.

The concentration to be detected in the product is therefore in

good approximation linearly dependent on the phase shift and

the attenuation. For this reason, we can measure the concentration or the dry matter content of the product using a linear

calibration (see chapter 3.2 Calculation of Measured Values).

Figure 3-1:

Schematic diagram:

Change in

microwave by

product

Chapter 3. System Description

18 MicroPolar (++) LB 566

3.2 Calculation of Measured Values

The microwave parameters phase and attenuation are calibrated according to an automatic plausibility analysis.

During calibration, the phase and/or attenuation of a concentration value (or density value) are assigned through sampling.

The calibration is done automatically and the sampling process

is supported by the evaluation unit.

Which of the parameters (phase, attenuation or both) will be

used for the calibration depends on the size and interference of

the measuring effect. For example, the attenuation is significantly more sensitive to electrolytic conductivity (salt content).

In many cases, the pure phase measurement is recommended

and the measured value is calculated as follows:

Measured value = A ∙ Phase + C Eq. 3-1

where:

Measured value Concentration / Moisture / Dry matter

A, C Coefficients of the respective calibration

function

The LB 566 allows you to calibrate, display and output two concentrations: Con1 and Con2. You have to enter the calibration

coefficients separately for concentration 1 and 2. For more information please refer to the Software Manual.

Limitations

Weakly bound water can be detected depending on the

strength of the binding. Thus, the measuring effect may be

dependent on the grain size distribution and the chemical

properties of the product being measured, provided this

changes the binding of water to the solid matter.

Walls made of plastic, rubber or insulation materials with

fairly low dielectricity hardly affect the measurement and are

calibrated at a constant level.

Ice and crystal water cannot be measured because the water

molecules cannot rotate freely (ice and crystal water are

dry).

Chapter 3. System Description

MicroPolar (++) LB 566 19

Conductive materials such as graphite or coke cannot be transmitted by microwaves. Metal walls can also not be transmitted

by microwaves.

Compensation In addition to the water content, the product temperature,

product density and a varying material load (varying microwave

irradiation path) may have an influence on the phase and attenuation. This influence has to be compensated for during calibration.

3.3 Temperature Compensation

Temperature compensation (TC) is required for fluctuating

product temperature. It is generally advisable to provide a temperature compensation, i.e. a temperature signal (0/4...20 mA

or PT100) to be connected to the evaluation unit and, optionally, to enable the compensation in the evaluation unit. The evaluation unit is designed so that the required TC’s can be calculated automatically. The variation in temperature where TC becomes absolutely essential is dependent on the product and on

the water content. In the first approximation, 2° C should be

set as fluctuation limit.

For example, if the product temperature is measured via the

PT100 input, then Eq. 3-1 is expanded as follows:

Measured value = A · Phase + D · T

meas

+ C Eq. 3-2

where:

Measured value Concentration / Moisture / Dry matter

A, D, C Coefficients of the calibration function

T

meas

Product temperature

How to work with the temperature compensation is described in

detail in the Software Manual.

Chapter 3. System Description

20 MicroPolar (++) LB 566

3.4 Throughput Calculation and Output

For pipeline applications, the LB 566 allows you to calculate the

throughput (mass flow) and to output the result via a current

output.

The calculation is based on the microwave measured value; if

this value correlates with the product density, one can calculate

the throughput, if some additional information is available. The

additional information needed is: internal pipe diameter/cross

section and the product speed. The product speed has to be fed

via current input.

For details, please see the Software Manual, chapter 4.2.12

Mass Flow.

Chapter 3. System Description

MicroPolar (++) LB 566 21

3.5 Mechanical Components

The measuring system comprises an evaluation unit, a

probe/antenna pair and one set of special high-frequency cables

(short HF-cable). The evaluation unit is available in two versions: the standard model MicroPolar LB 566 and the high dynamics version MicroPolar ++ LB 566 (see Figure 3-4 and Figure 3-5).

Figure 3-4:

Evaluation unit

MicroPolar

LB 566

Figure 3-5:

Evaluation unit

MicroPolar ++

LB 566

Chapter 3. System Description

22 MicroPolar (++) LB 566

The probes/antenna pairs are available in different versions, as

pipeline and container probe with or without flushing device

(see Figure 3-6 to Figure 3-7).

The FlowCell is available in the nominal pipe sizes 50 -150 mm

(50, 65, 80, 100, 125 and 150) The following connections types

are available:

Hygiene milk pipe screw connection DIN 11853

V flange EN 1092-1

Figure 3-6:

From left:

Container probe

LB 5650 and

LB 5651 with

flushing device

Figure 3-7:

FlowCell LB 5660-102-00x

nominal width 50 mm

with V flange

Chapter 3. System Description

MicroPolar (++) LB 566 23

3.5.1 Evaluation Units

The evaluation units comprise the evaluation computer and the

microwave unit. The microwaves are generated, received and

analyzed in the microwave unit. Signal processing and communication take place in the evaluation computer. For simple operation, the measuring system includes a display, 4 softkeys and

an alphanumeric keypad. Different functions are assigned to the

softkeys on the display.

Differences between MicroPolar ++ und MicroPolar

The MicroPolar ++ evaluation unit has an additional HF amplifier

module in comparison to the standard model; therefore, it also

has a larger wall housing (dimensions see chapter 6.1 Technical

Data Evaluation Unit). Otherwise, the evaluation units differ only in their application.

MicroPolar ++ The high dynamics version MicroPolar ++ permits higher

product attenuations. Larger measuring paths can be irradiated,

i.e. flow cells with larger nominal diameters can be used. Which

type of evaluation unit is used depends on the product attenuation. MicroPolar is used up to an attenuation of 50 dB; MicroPolar ++ is used for higher attenuations. The MicroPolar ++ generally requires an attenuation of 40 dB. If this attenuation is not

reached, the software displays an error message.

An RS232 interface is included on the bottom side of the instrument.

and cable feed-through

Lock

Numerical

keypad

Softkey buttons

LED’s

LCD display

RS232 connection

HF connections for

signal cable reference cable

Micro-Polar

Figure 3-8:

Evaluation unit –

front view

Chapter 3. System Description

24 MicroPolar (++) LB 566

Interpretation of LEDs

Five LEDs on the instrument front panel indicate the current de-

vice status.

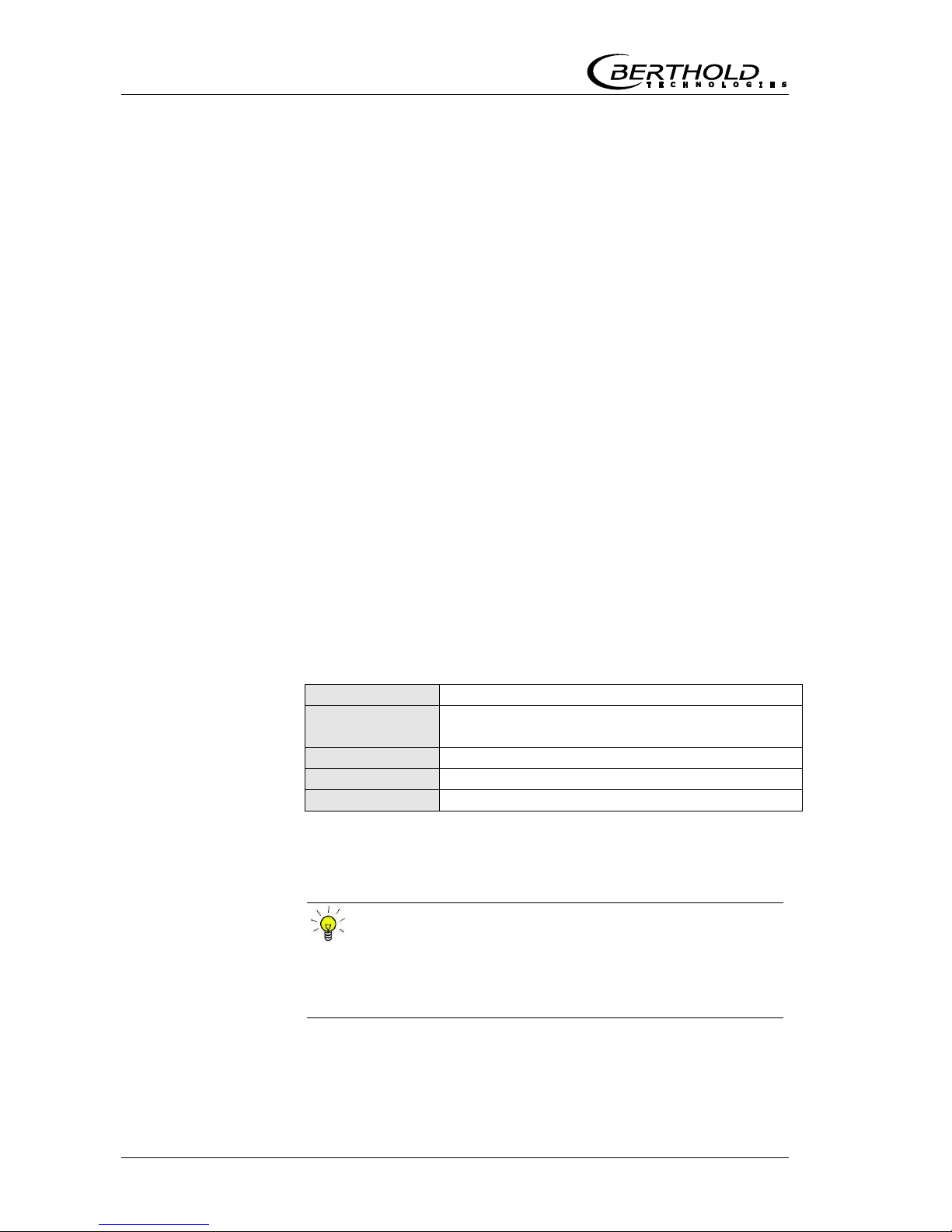

LED Function

Run On: Device in measurement mode

Flashes + ERROR LED off: Device in warning

state, on hold, paused or low load state.

A display message with error code indicates the

cause (see Software Manual, chapter 11. Error

Lists and Device States).

Error On: Device in error state.

A display message with error code indicates the

cause (see Software Manual, chapter 11. Error

Lists and Device States).

Canceled after reset or if error has been eliminated.

Signal 1 Display depending on the selected function of

relay 1, possible functions:

Error, no product, alarm min., alarm max.,

measurement stopped, low load

Signal 2 Display depending on the selected function of

relay 2, possible functions:

Error, no product, alarm min., alarm max.,

measurement stopped, low load

Comm Communication active, e.g. via RS232 and RS485

Figure 3-9:

Evaluation unit –

bottom view

Figure 3-10:

LEDs on the

front panel of

the evaluation unit

Run

Error

Signal 1

Signal 2

Comm

Cable feed-through

M 20 and M 16

High-frequency connections

Rs232

9 pole SubD-connector

M-TxM-Rx R-Tx

R-Rx

Chapter 3. System Description

MicroPolar (++) LB 566 25

Terminal block

The electrical connections of the LB 566 are located on a connector strip in the wall cabinet. The terminal block can be accessed from the front by opening the cover of the housing.

There, you also find the power cut-off switch and the fuses. The

high-frequency terminals are located on the outside of the

housing. All other elements, especially the voltage-carrying elements (on the motherboard) are provided with a protective

cover.

3.5.2 FlowCell

The FlowCell is available in the nominal sizes of 50 to 150 mm

(see fig. 3-11). As connection, the versions V flange EN 1092-1

or Hygiene milk pipe screw connection DIN 11853 are available.

For technical data please see chapter 6.2 Technical Data Sen-

sors.

A: with V flange EN 1092-1

B: with Hygiene milk pipe screw connection DIN 11853

Figure 3-11:

FlowCell versions

Chapter 3. System Description

26 MicroPolar (++) LB 566

The flow cell consists of a sturdy stainless steel body. The microwave transmitter and receiver are firmly welded to the outside of the pipe. The entire product pipe is PTFE-coated and

thus meets the special requirements for use in food for use in

food.

There are no objects that extend into the pipe (e.g. a measuring

sensor). Depending on the version, the FlowCell can be mounted with the V flange or milk pipe screw connection to the piping.

For the versions with V flange, ASA adapter flanges are available as accessory.

The FlowCell has two HF ports to feed in and output the microwave signals. The input and output can be allocated as needed

(M-Tx, M-Rx). The microwave signals transmit the product over

the entire pipeline cross-section.

For all versions, the following accessories are available:

1. Pipe-mounted PT100 or Inline PT100

2. Conductivity measuring device

3. Sampling valve

Chapter 3. System Description

MicroPolar (++) LB 566 27

3.5.4 Container Probe

The container probe is available in a version with and without

flushing device (see Figure 3-12). The technical data are listed

in chapter 6.2 Technical Data Sensors.

A: High-frequency connections

B: Process connection, flanges of different sizes

Container probe type LB 5650 and type LB 5651

The container probe has been specially designed for concentration measurements in containers. Both measuring rods are immersed into the product. Microwaves are emitted from one end

of the rod and received by the other end of the rod; they are

emitted only towards the opposite end of the rod. This directional characteristic of the probe minimizes the interfering influence of metal parts in the vicinity of the probe and allows installation if only limited space is available. For example, the concentration of sugar strike can be measured continuously to find

the suitable inoculation time.

The plastic caps of the measuring rods meet the special requirements for application in foodstuffs.

Two different probe types are available:

The standard type is the container probe without flushing

device.

The flushing probe is used in processes where incrustations

are likely to occur, for example, due to increased depositions. The flushing device prevents deposition on the microwave exit windows.

Figure 3-12:

Container probe

versions

Chapter 3. System Description

28 MicroPolar (++) LB 566

For the case depicted in Figure 3-13, the flow direction of the

product being measured must be perpendicular to the drawing

plane. This ensures a representative product between the

measuring rods, provided the product is mixed thoroughly.

The container probe LB 5650 is the only one equipped with a

PT100 connection and can be connected to the evaluation unit

via a 4-core cable. The PT100 wiring diagram is described in

chapter 4.6.1 Pin Configuration of the Connector Strip. To minimize the danger of incrustation in the immediate vicinity of the

measuring rods, the container flush probe is not provided with a

PT100.

Warning: Possible material damage!

Do not open the cover screws on the front of the container

probes, see Figure 3-14.

Figure 3-13:

Container probe LB 5650

Figure 3-14:

Front view

container probe

PT100

Chapter 3. System Description

MicroPolar (++) LB 566 29

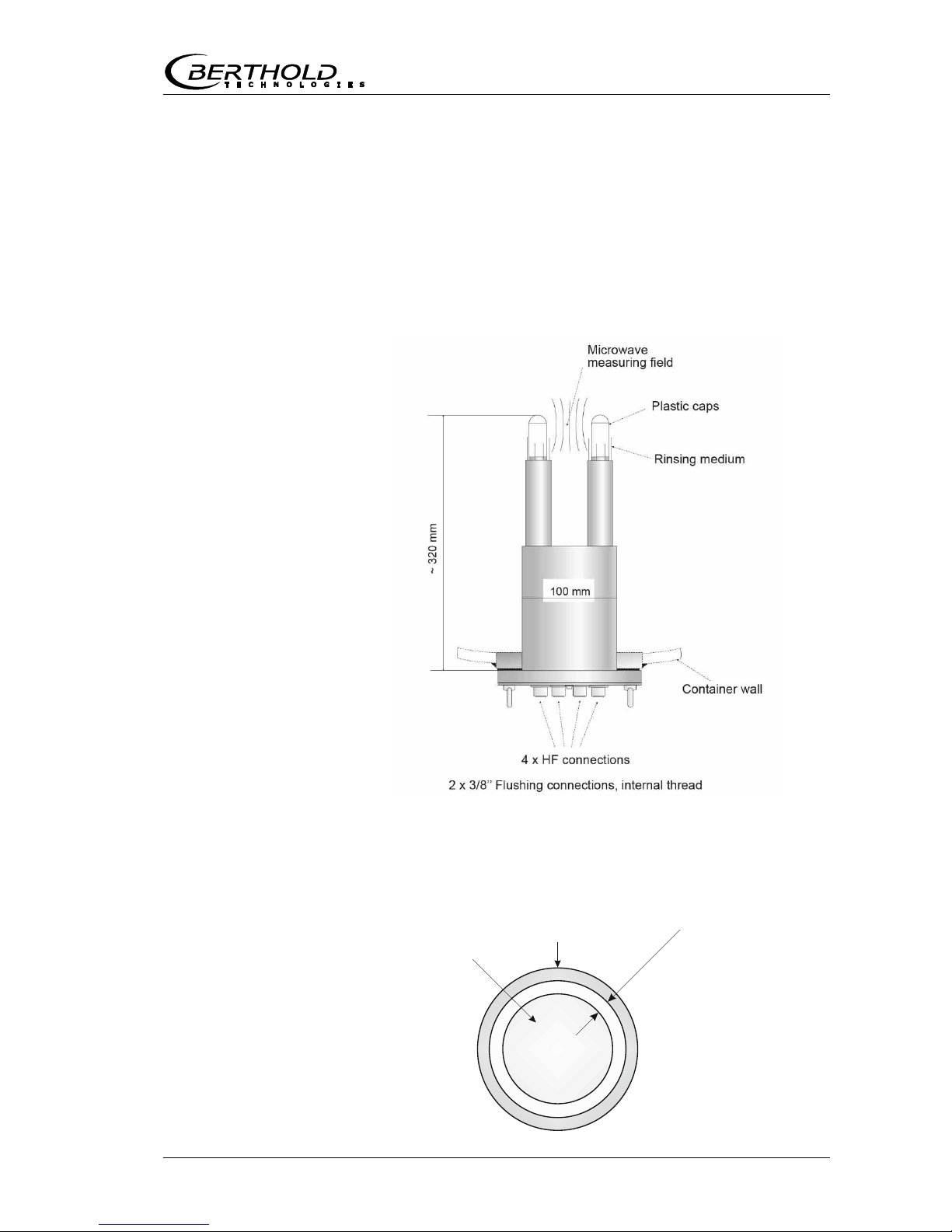

Container probe type LB 5651 with flushing device

The flushing probe LB 5661 has been designed for processes in

which depositions, for example, due to incrustations are likely to

occur on the probe.

The flushing probe has two flushing channels which keep the

measuring rods free from incrustations; this ensures that the

microwaves come into direct contact with the product being

measured. All probe parts coming into contact with the product

meet the special requirements for application in foodstuffs. Fig-

ure 3-15 shows the probe design.

The flushing slit width is the same for both probe rods and is

depicted in Figure 3-16.

Figure 3-15:

Flushing probe

LB 5651

Figure 3-16:

Rod head with

flushing pipe

Plastic rods

Flushing pipe

Flushing

s

l

i

t

~

1.5

m

m

Chapter 3. System Description

30 MicroPolar (++) LB 566

3.5.5 High-frequency Cable

High-frequency cables (HF cable) are used to transmit microwave signals.

HF cables change their conductivity (for microwaves) with temperature and would therefore produce measurement errors with

varying ambient temperature. This error is compensated for by

enabling the automatic cable compensation. The influences of

the ambient temperature on the signal cable are compensated

for by means of the reference cable. To this end, the sum of the

reference cables has to match the length of the sum of the signal cables.

Two different HF cable types of different lengths are available:

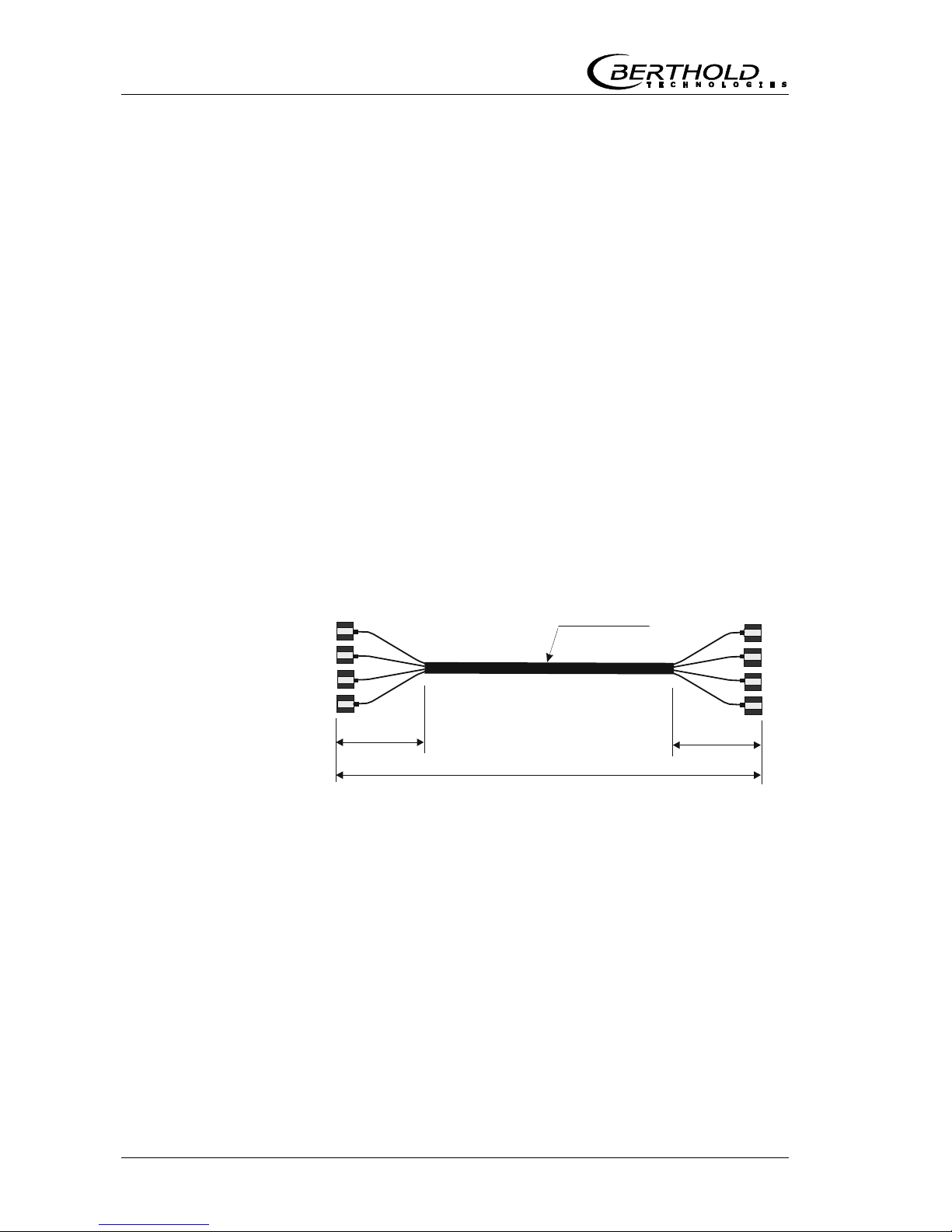

Version 1: The so-called HF-cable quad: It consists of four single HF-cables of equal length, whose ends are terminated by

one HF-connector (N-type). Available cable lengths: 2, 4, 6 and

10 m (see Figure 3-17).

The HF-cable quad is used exclusively for the container probe

and the FlowCell. For the FlowCell, the reference line on the

probe side is short-circuited using an N-connector (see Figure 3-

18).

Figure 3-17:

HF cable quad

Lengths 2, 4, 6 and 10 m

Corrugated tube

4 x N-connector

ø18.5 mm

0.35 m

0.35 m

4 x N-

4 x N-connector

Chapter 3. System Description

MicroPolar (++) LB 566 31

Figure 3-18:

HF cable quad

probe side:

The ends of the

reference line

R-Rx and R-Tx are

short-circuited

using an

N-connector.

N-connector

(ID-no. 20608)

Sensor side

R

-

R

x

R

-

T

x

M

-

R

x

M

-

T

x

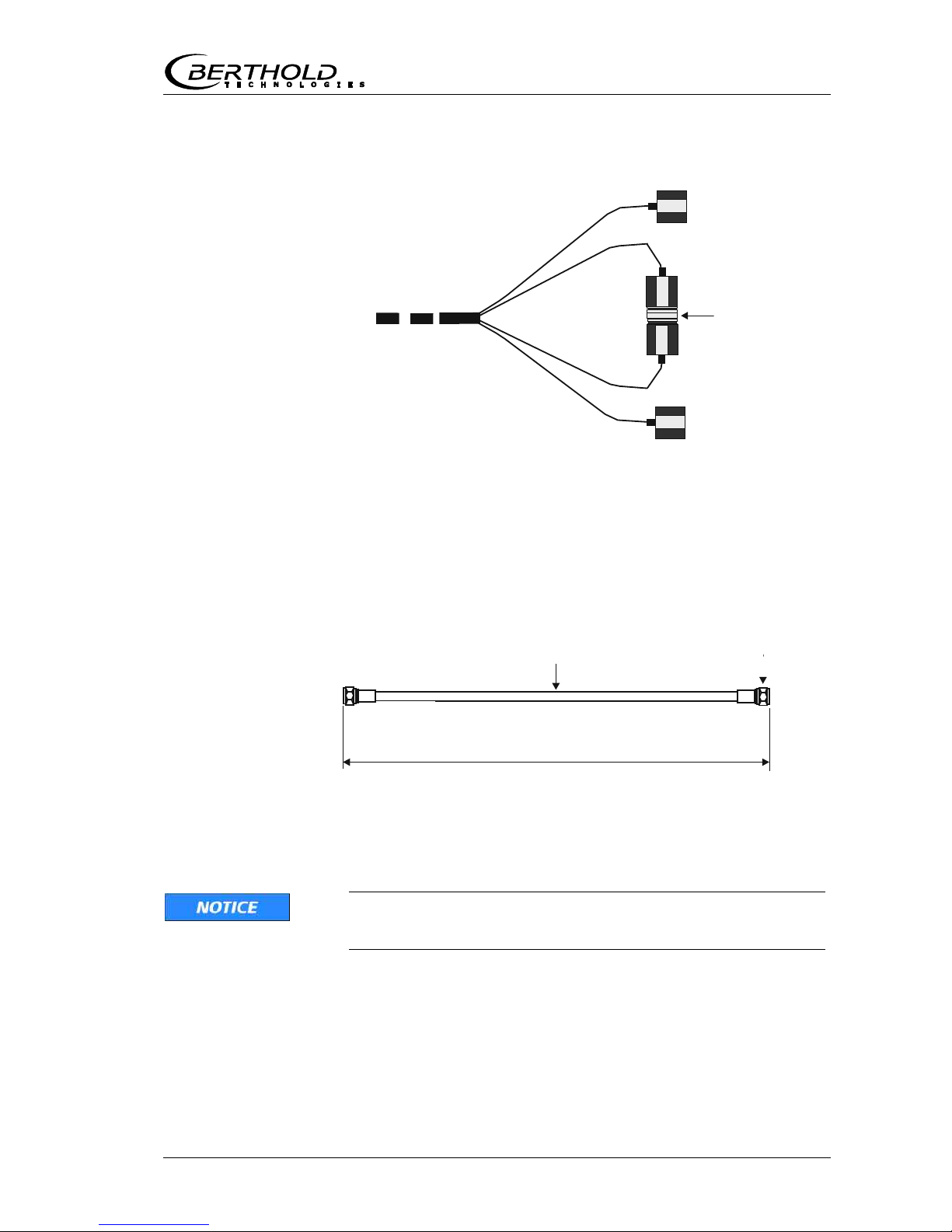

Version 2: It consists of a single HF-cable whose ends are terminated by an HF-connector (N-type). Available lengths: 2, 2.5,

3, 3.5 and 4 m (see Figure 3-19).

Figure 3-19:

HF cable

Lengths 0.5 to 4 m

ø10 mm

19 mm wrench

For further technical data see chapter 6.5 Technical Data HF-

Cable.

During assembly, ensure that the end of the corrugated tube

is bent down on the probe side. By doing so, the ingress of

fluids into the corrugated tube is prevented.

Chapter 3. System Description

32 MicroPolar (++) LB 566

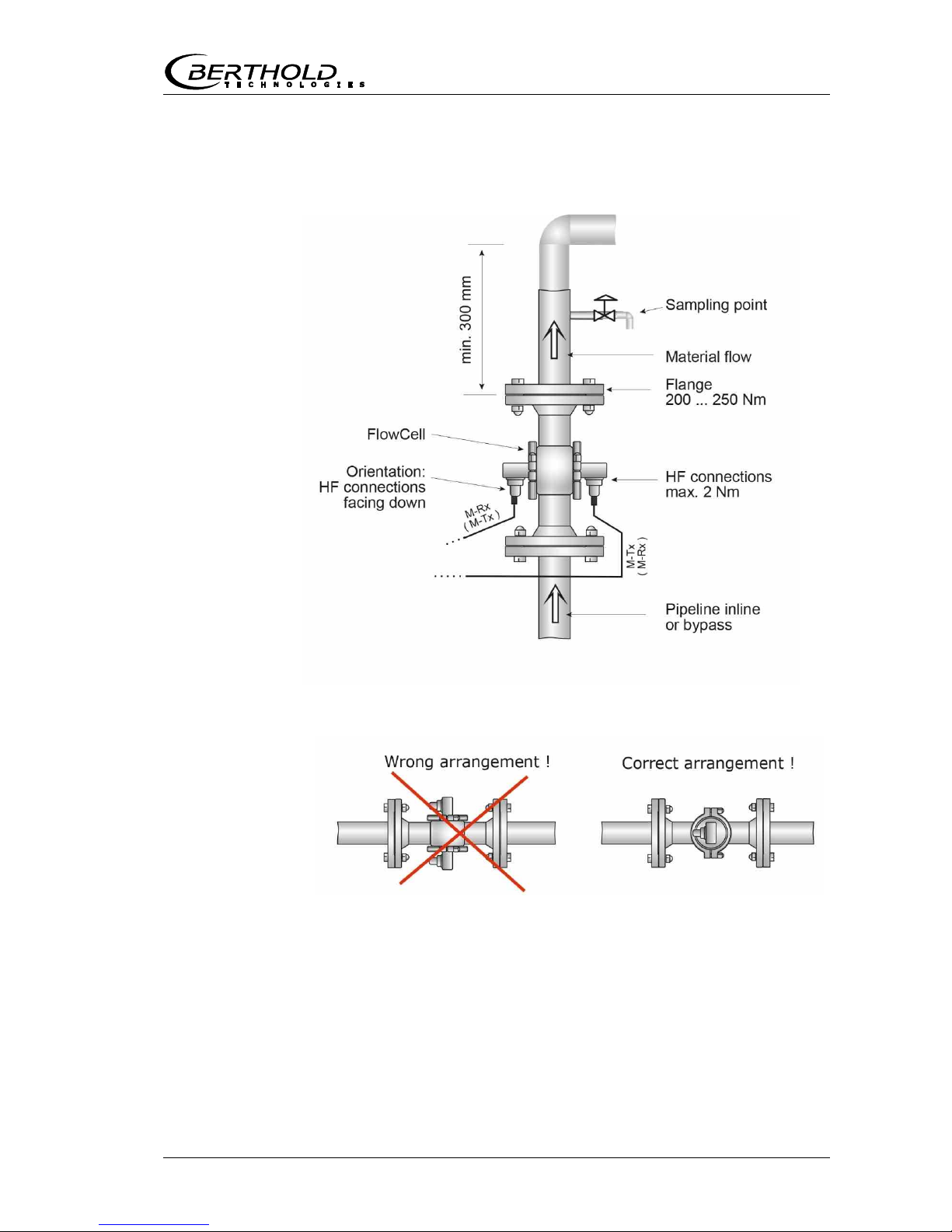

3.6 Assembly on a Pipeline

The evaluation unit is installed close to the FlowCell to keep the

HF cable between evaluation unit and probe as short as possible. The shorter the cable connection, the better the stability of

the measurement. The standard length is 2 m and the maximum length of the HF cable is 10 m. The HF cable must be at

least 2 m long.

The FlowCell is integrated into the existing pipeline system or in

a bypass. The orientation of the FlowCell can either be vertical

or horizontal. To avoid possible sedimentary deposits, vertical

installation in a riser is preferred (see Figure 3-20).

The installation should preferably be close to a sample sampling

point to ensure representative sampling for calibration.

A representative temperature signal (current signal or PT100)

should be connected to the evaluation unit for product temperature compensation.

Figure 3-20:

Typical measurement

arrangement on

a pipeline

Chapter 3. System Description

MicroPolar (++) LB 566 33

3.7 Assembly on a Container

The evaluation unit is installed in the immediate vicinity of the

container probe to keep the HF-cable between evaluation unit

and probe fairly short. The shorter the cable connection, the

better the stability of the measurement. The standard length is

2 m and the maximum length of the HF cable is 10 m. The HF

cable must be at least 2 m long.

The installation should preferably be close to a sampling point

to ensure representative sampling for calibration. A representative temperature signal (current signal or PT100) should be

connected to the evaluation unit for a possibly required product

temperature compensation.

Our example in Figure 3-21 shows the measurement configuration on a process container. The probe is fixed to the container

wall using a flange coupling so that both measuring rods are

immersed into the product.

Figure 3-21:

Example:

Pipeline measurement

configuration on a

process container

Chapter 4. Getting Started

MicroPolar (++) LB 566 35

Getting StartedChapter 4.

4.1 Transport

Warning: Possible material damage!

System parts may get damaged during transportation!

Transport all components in their original packaging.

Protect parts against shocks.

In particular, the measuring rods of the container probes must

be protected against mechanical shock!

After unpacking, make sure all parts listed on the packing list

have been delivered and show no sign of damage; if necessary,

clean these parts.

If you detect any damage, please notify the forwarder and the

manufacturer immediately.

The weight of the system components may exceed 25 kg,

depending on the version. We recommend, therefore, that you

wear safety boots.

Chapter 4. Getting Started

36 MicroPolar (++) LB 566

4.2 Commissioning the FlowCell

4.2.1 Installing the FlowCell

Note the following points when installing the FlowCell:

The FlowCell is integrated at a suitable location in the pipe-

line system. Keep in mind that material sampling directly

behind the FlowCell should be possible for calibration.

The FlowCell should be installed in a vertical riser, if possi-

ble. It must be ensured that material deposits cannot form

on the pipe walls and no bubble formation occurs in the

product. In case of horizontal installation, please observe

the correct orientation of the HF connections, see Figure 4-

2.

There should be a straight pipe section of at least 300 mm

and equal nominal width before and after the FlowCell to ensure a fairly homogeneous flow profile and to rule out possibly occurring microwave reflections in the pipeline. Also, not

fittings must be installed in these pipe sections.

No gas inclusions should be present in the product. If gas

bubbles cannot be ruled out, a pressure of at least 4 bar is

required in the pipeline to minimize the influence of gas

bubbles. Please observe the max. permissible operating

pressure, see chapter 6.2 Technical Data Sensors.

The high-frequency cables should preferably be connected to

the FlowCell from below to prevent flowing water from getting to the connection sockets.

The signal and reference cable should as far as possible fol-

low the same path to make sure both cables are exposed to

the same temperature and should not come into contact

with hot pipelines. We recommend installing the HF cable

through a single protection tube. If you are working with the

HF cable quad, this function is taken over in good approximation by the corrugated tube.

Chapter 4. Getting Started

MicroPolar (++) LB 566 37

Abb. 4-2:

Horizontal installation:

Orientation of

HF connectors

Abb. 4-1:

Installation in a

vertical riser

Chapter 4. Getting Started

38 MicroPolar (++) LB 566

4.2.2 Installing the Evaluation Unit

Note the following points when installing the evaluation unit:

Position the evaluation unit depending on the length of the

HF cable in the vicinity of the microwave probe.

The evaluation unit has to be protected against vibrations.

In some cases, it is advisable to set up the evaluation unit

on a stand separated from the pipeline system.

For instrument installation you should foresee a cutoff de-

vice to allow easy and quick disconnection of the device

from the power supply.

Provide an automatic separating device (line circuit breaker)

that disconnects the unit from power within 0.03 seconds in

case of failure. The separating device must be matched to

the cable cross-section of the supply line, but at least it

must be designed for 1 A continuous current.

When installing the evaluation unit on a crystallizer, use a

distance rail to minimize the thermal radiation and conduction. See Figure 4-3:

For outdoor applications, the evaluation unit must be pro-

tected from direct sunlight and rain, for example by a suitable shelter.

Figure 4-3:

View from above:

Installation of the

evaluation unit on a

hot container wall

Insulation container wall

Spacer

Evaluation unit

Chapter 4. Getting Started

MicroPolar (++) LB 566 39

4.2.3 Connecting the HF Cable

The FlowCell is connected with the evaluation unit via the HF

cables. Two different options are available:

Version 1: 1 x HF cable quad and 1 x N-connector

Version 2: 2 x HF cables (as signal cable)

1 x HF cable (as reference cable)

The decision for a certain cable version is taken by Berthold

Technologies in the planning stage. It is subject to the application and the desired distance between evaluation unit and

FlowCell.

Prerequisite for a correct measurement is the correct installation

of cables! Please keep in mind:

TIP

Make sure the cable does not get into contact with hot pipes

over the entire length (corrugated tube and single cable

section after splitting), e.g. direct contact with the device wall

(not insulated). This will ensure that all individual cables are

exposed to the same ambient conditions and that the compensation of the cable drift works properly.

Never bend the HF cable! The bending radius should not be

less than 100 mm. Fix the HF cable with cable binders or other

suitable means, so that the cable cannot slip anymore!

During assembly, ensure that the end of the corrugated tube

is bent down on the probe side. By doing so, the ingress of

fluids into the corrugated tube is prevented.

Version 1 The HF cable quad and the HF connectors on the evaluation unit

are labeled. Connect the FlowCell to the evaluation unit as

shown in Figure 4-4; only cables with identical labeling can be

combined. The two connections on the FlowCell are not labeled,

the assignment of both cable connectors M-Tx and M-Rx is arbitrary. Connect the cable connectors R-Tx and R-Mx with the Nconnector (short-circuited).

Version 1 Connect the FlowCell to the evaluation unit as shown in Figure

4-5; make sure that the reference cable (ring line) is connected

to R-Tx and R-Mx.

The reference cable must be as long as the sum of both signal

cables.

Chapter 4. Getting Started

40 MicroPolar (++) LB 566

Hand tighten all screwed connections of the HF cable (2 Nm =

0.2 kg/m)! Before tightening, carefully screw on the cable by

hand. Caution! Threaded joint jams easily.

Check occasionally if the screwed connection is still properly

tightened. If the installation is exposed to vibrations, the

screwed connection may come loose and this may result in inaccurate measurements or corrosion of the connections.

Abb. 4-4:

FlowCell connection,

version 1

Abb. 4-5:

FlowCell connection,

version 2

Chapter 4. Getting Started

MicroPolar (++) LB 566 41

As long as the cables are not connected, the coaxial sockets

have to be covered with plastic caps and the cable connectors

have to be protected against moisture and dirt.

4.3 Commissioning the Container Probe

4.3.1 Installing the Container Probe

For installation of the probes, please keep in mind:

Select the installation site such that good mixing and a ho-

mogeneous product are ensured and no bubbles are present

in the probe. A sample tap should be available in the direct

vicinity to allow representative sampling.

The probe must be flanged to the container so that the ma-

terial to be measured flows between the two measuring

rods. That means the fork (both measuring rods) must be

installed perpendicular to the material flow.

The distance between the measuring rod tips and any metal-

ized walls (heating element, stirrer, container wall) should

be at least 60 mm.

The following mounting hole dimensions in the fitting

flange are required for installation of the probe:

Flange Minimum mounting hole size (mm)

DN 65 / PN 6 102 0.3

others 104 0.5

For further installation dimensions, such as the required in-

stallation depth, please refer to chapter 8.6 and 8.7 Assem-

bly Sheets.

Use the appropriate flat gasket (standard accessory) to

compensate for minor surface tolerances in the fitting

flange.

Installation on process containers

Figure 3-26 shows the position of the container probe on the

container. This position is also valid for the container flush

probe. Follow the instructions in chapter 3.9 Assembly on a

Container.

The assembly sheets in chapters 8.6 and 8.7 include all the information required for installation.

Depending on the process, the probe flange may stick to the

process flange. In such case, during the dismounting process,

Dismounting in the

event of a stuck

flange

Chapter 4. Getting Started

42 MicroPolar (++) LB 566

remove the two eyebolts first. Then insert two longer screws

(M8) into their bore holes up to the process flange. If you continue to rotate the screws, you will push the probe away from

the process flange.

Installation in pipelines

Container probes can be installed in pipelines with a nominal

width 200 mm using an adapter flange. Note the position and

orientation of the container probe, see the technical drawings in

chapter 8.4.7 and 8.5.6 Installation Situation in Pipelines.

Connecting the flushing pipes

The container probe with flushing device has two flushing connections with G3/8'' female thread (DIN ISO 228-1). The flushing connections should be sealed only at this thread. Sealing the

probe cover, for example with silicone, is not permitted.

Flushing parameters (only for flushing probe)

The degree of deposition or incrustation is essential for the flush

settings, i.e. flush interval and flush duration. The flushing parameters must be matched to the product and the process.

The following product and process independent flushing parameters must be strictly adhered to:

Flush solution Water, condensate

Temperature of

flush solution

Maximum 120°C

Pressure

3 bar, max. 8 bar

Fittings 2 x G3/8'' female thread (DIN ISO 228-1)

Supply pipe

1/2 inch

In general: The flushing connections can be flushed simultaneously or sequentially. The flushing parameters are valid for each

flushing connection.

TIP

The required flush duration has to take into account possible

inertias of the system, e.g. valve openings. The flush supply

pipes must be well insulated to prevent that the flush solution

is initially colder.

Amounts of water With a 5 bar flushing pressure, the amount of water per flushing

connector is approximately 0.8 liters per second.

Chapter 4. Getting Started

MicroPolar (++) LB 566 43

4.3.2 Setting Up the Evaluation Unit

Set up the evaluation unit as described in chapter 4.2.2.

4.3.3 Connecting the HF Cable

Connect the container probe to the evaluation unit via the HF

cable quad.

Prerequisite for a correct measurement is the correct installation

of cables! Please keep in mind:

TIP

Make sure the cable does not get into contact with hot pipes

over the entire length (corrugated tube and single cable

section after splitting), e.g. direct contact with the device wall

(not insulated). This will ensure that all individual cables are

exposed to the same ambient conditions and that the compensation of the cable drift works properly.

Never bend the HF cable! The bending radius should not be

less than 100 mm. Fix the HF cable with cable binders or other

suitable means, so that the cable cannot slip anymore!

The HF cables and the HF connections on the evaluation unit

and on the probe are labeled. Connect the probe to the evaluation unit as shown in Figure 4-6; only cables with identical labeling can be combined.

Chapter 4. Getting Started

44 MicroPolar (++) LB 566

Hand tighten all screwed connections of the HF cable (2 Nm =

0.2 kg/m)! Before tightening, carefully screw on the cable by

hand. Caution! Threaded joint jams easily.

Check occasionally if the screwed connection is still properly

tightened. If the installation is exposed to vibrations, the

screwed connection may come loose and this may result in inaccurate measurements or corrosion of the connections.

As long as the cables are not connected, the coaxial sockets

have to be covered immediately with plastic caps and the cable

connectors have to be protected by suitable provisions against

moisture and dirt.

Figure 4-6:

Connecting the

container probe

to the

evaluation unit

Chapter 4. Getting Started

MicroPolar (++) LB 566 45

4.5 Connecting the Evaluation Unit

Electrical hazards:

Disconnect power to rule out any contact with live parts during

installation and servicing.

Turn off power before opening the instrument.

NEVER work on open and live instruments.

Caution! Potential hazards, material damage!

Device type:

LB 566-12 MicroPolar ++ (ID no. 51833-02)

When connecting the 24 V DC power supply, the + and –

poles must be connected correctly. There is no reverse

polarity protection!

The line cross-section the for power supply must be at least 1.0

mm2.

Connect all desired input and output signals to the terminal

strip as shown on the following pages. Use the M feedthrough to keep the degree of protection.

Check if the voltage indicated on the type plate matches

your local supply voltage.

Connect the deenergized power cable to the terminals 3(L1),

2(N) and 1(PE).

Verify that the test switch (power interruption) is in position

"ON" (see Figure 5-1).

Close the instrument housing and turn on the power supply.

Chapter 4. Getting Started

46 MicroPolar (++) LB 566

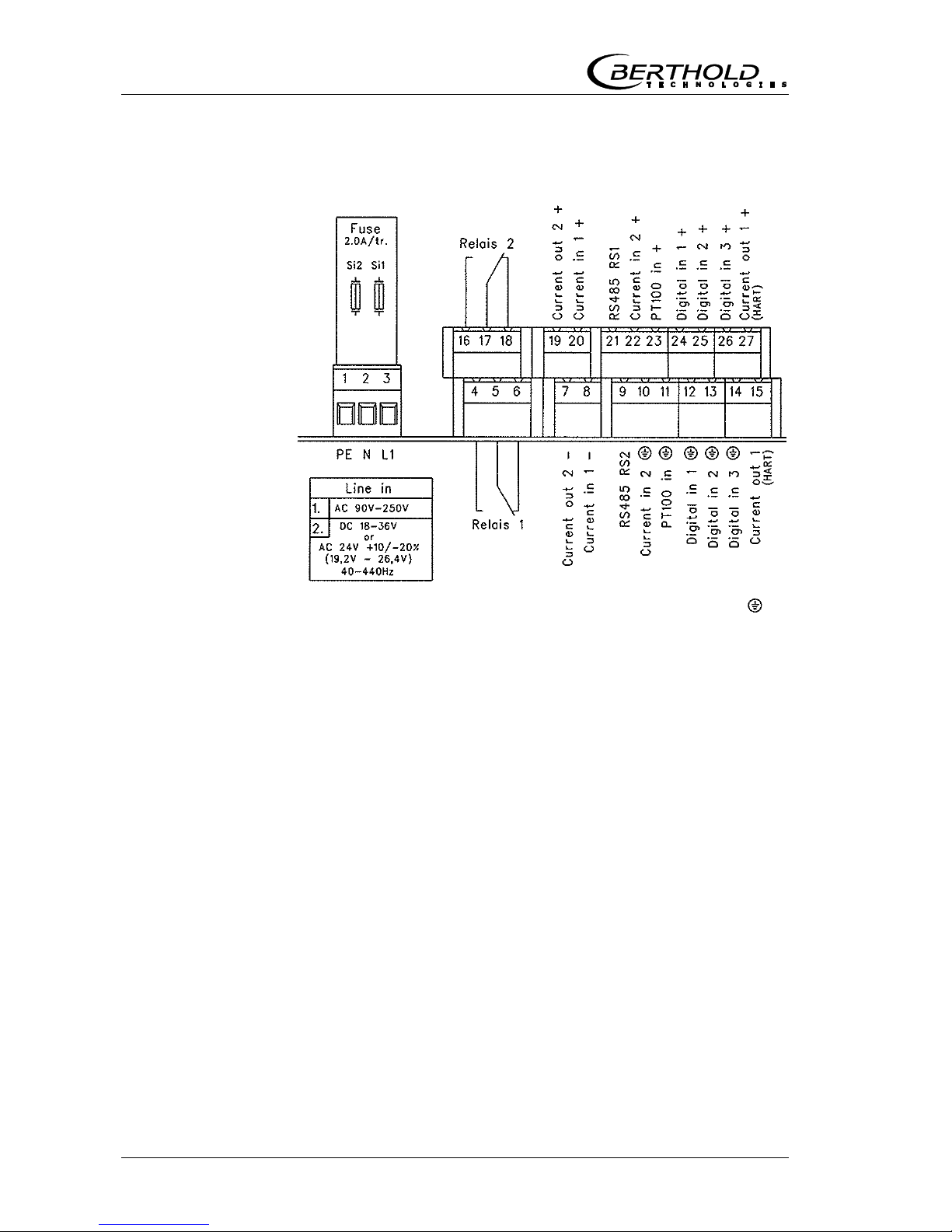

4.5.1 Pin Configuration of the Connector Strip

The connector strip of the evaluation unit includes the following

terminals:

Power supply: Terminals 3 (L1, +), 2 (N, -) and 1 (PE, )

For MicroPolar, depending on device type, see name plate on

the housing outer wall.

1.) 100…240 V AC, 45…65 Hz

2.) 24 V DC: 18…36 V

24 V AC: -20%, +5%, 40…440 Hz

For MicroPolar ++, depending on device type, see name plate

on the housing outer wall.

1.) 100…240 V AC, 45…65 Hz

2.) 24 V DC: 18…36 V, no reverse polarity protection

Current input no. 1 (terminals 20+ and 8-), insulated

Current input no. 2 (terminals 22+ and 10-), not insulated

Input as 0/4 - 20 mA signal. For example, for temperature

compensation or reference signal recording.

Current output no. 1 (terminals 27+ and 15-), insulated

Output as 4 - 20 mA signal. Output options: Concentrations (1 /

2), current input signals (1 / 2), PT100 signal, mass flow

Current output no. 2 (terminals 19+ and 7-), insulated

Output as 0/4 - 20 mA signal. Output options same as for cur-

rent input no. 1.

Figure 4-7:

LB 566 wiring diagram

Chapter 4. Getting Started

MicroPolar (++) LB 566 47

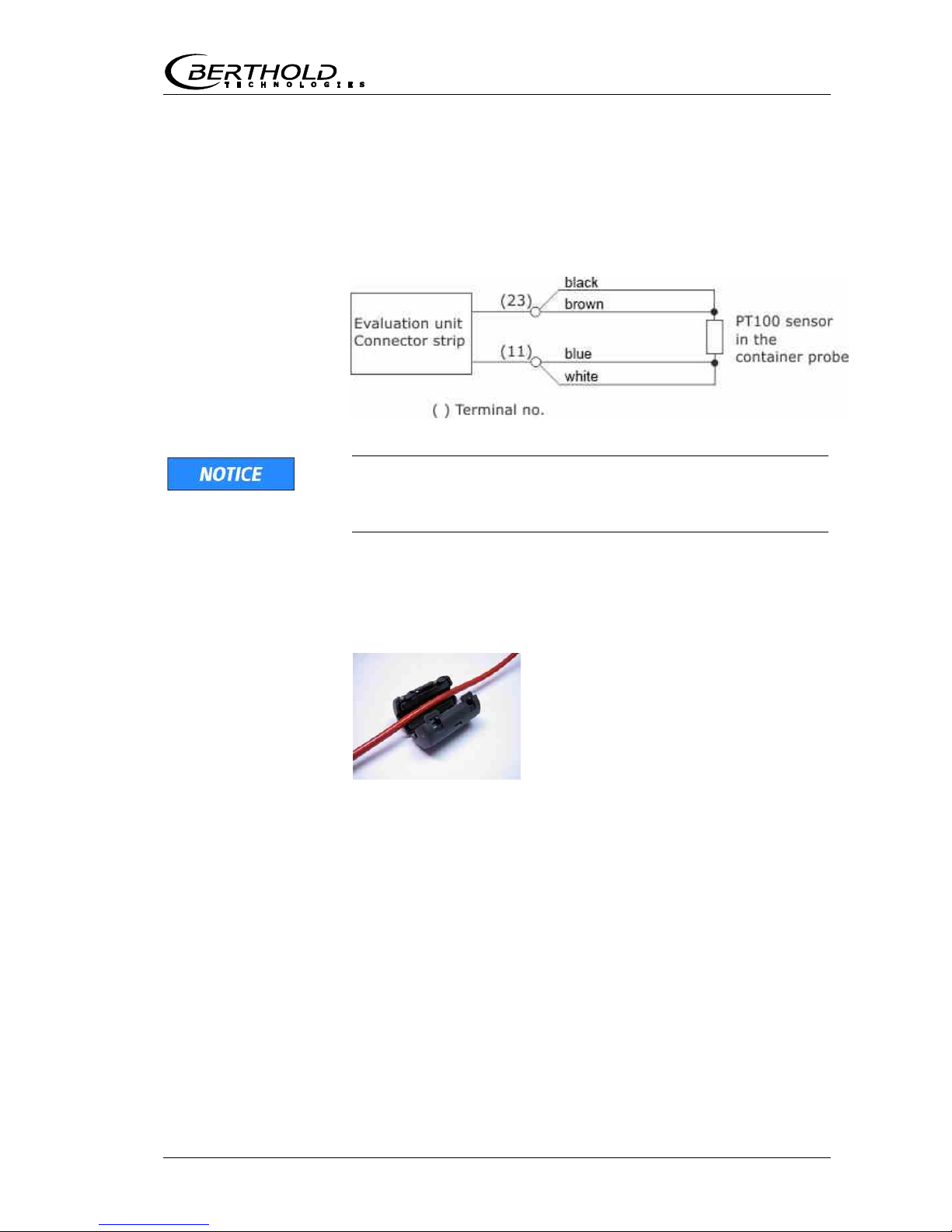

PT100 (terminals 23+ and 11-)

Connection for temperature measurement.

When commissioning the container probe, connect the 4-core

cable of the PT100 to the connector strip of the evaluation (see

fig. 4-8). Connect the other end of the cable with the corresponding plug on the container probe (see fig. 4-6).

In the delivered state, the PT100 cable has a length of 10

meters. We recommend shortening the cable to the required

length.

Combine the two core pairs in accordance with figure 4-8.

After connection of the PT100 cable, the included ferrite core

must be wound around the cable. The applicable position is

within the housing, as close as possible to the cable bushing.

Digital input 1: DI1 (terminals 24+ and 12-)

Configuration options:

No function

Measurement: Start (closed) and stop (open)

Digital input 2: DI2 (terminals 25+ and 13-)

Configuration options:

No function

Average value: hold (closed) and continue averaging (open)

Product selection: product 1 (open) and product 2 (closed)

Figure 4-8:

PT100 connection

container probe

Figure 4-9:

Ferrite core

Chapter 4. Getting Started

48 MicroPolar (++) LB 566

Digital input 3: DI3 (terminals 26+ and 14-)

Configuration options:

No function

Start sampling, open: no action, closed: unique measure-

ment starts

Product selection

Relay 1: (Terminals 4, 5 and 6) and

Relay 2: (Terminals 16, 17 and 18)

Changeover contacts (SPDT), insulated, configuration option:

No function

Error message

Stop measurement

Limit value min. and max.

No product

Below load limit

RS485 interface (terminals 21 (RS1) and 9 (RS2)) and

RS232 interface (on instrument underside)

Serial data interface for output of the live data (all readings for

every sweep (measuring cycle), the protocol and data logs.

Data format: Data transfer rate 38400 baud, 8 data bits, 1 stop

bit, no parity, no handshake

4.5.2 Digital Outputs, Relay

The status of the measurement is output via two relays:

Error

Alarm (alarm min. and max.)

No product

On the Plausibility menu, you can enter a min. attenuation for

pause detection (e.g. for process pause, no product present); if

this value is not reached, „No product“ is signaled via a relay

and the current output drops to 0 or 4 mA.

Measurement stopped

Below load

The respective switching state is also signaled via LEDs on the

front panel (LEDs signal 1 and 2).

Chapter 4. Getting Started

MicroPolar (++) LB 566 49

Relay no. Error, alarm, no product,

measurement stopped,

Below load, currentless

condition

Normal

1

2

The relays with changeover contacts can either be operated as

make contact, terminals 4 & 5 (open at error, alarm ...) or as

break contact, terminals 5 & 6 (closed at error, alarm ...).

com

456

com

161718

com465com1618

17

Chapter 5. Service instructions

MicroPolar (++) LB 566 51

Service instructionsChapter 5.

5.1 General Information

A malfunction of the measuring system is not always due to a

defect in the instrument. Often the error is caused by incorrect

operation, improper installation or irregularities in the product

being measured. If a malfunction occurs, anyway, the measuring system helps you to identify and eliminate errors by displaying error messages on the display, indicating operator errors

and defects of the electronics.

Defective modules of the evaluation unit cannot usually be repaired but must be replaced. The microwave module is firmly

bolted to a screening hood and must not be opened.

For device disposal, please contact the Berthold Service and apply for a recycling passport.

Chapter 5. Service instructions

52 MicroPolar (++) LB 566

5.2 Wear Parts

The evaluation unit does not include any parts that are subject

to wear or components that require special maintenance.

The plastic caps of the measuring rods of the container probes

and the PEEK Microwave window of the flow cell may be subject

to abrasion over the course of time. A low to medium abrasive

influences the measurement only very little and can be compensated for by a calibration. Therefore, check the wear parts in intervals of about 2 years. In case of heavy wear, the plastic caps

of the measuring rods of the container probe and the PEEK Microwave window of the flow cells can be replaced.

The plastic caps of the measuring rods can be replaced on site.

For this purpose, please proceed as follows:

1

Unscrew the two plastic caps from the measuring rods and

remove the four sealing rings (see figure 5-1, yellow arrow).

2

Clean the four grooves of the sealing rings with a lint-free (if

necessary wet) cloth.

3

For each measuring rod, insert two new sealing rings into

the grooves.

4

Screw on the two new plastic caps.

Caps set for container probe

Id.-Nr. 66049-S 2 pieces of PEEK plastic caps with 4 sealing rings

Figure 4-7:

PT100 connection

container probe

Chapter 5. Service instructions

MicroPolar (++) LB 566 53

5.3 Instrument Cleaning

Clean all system components exclusively with a damp cloth with

no chemical cleaning agent. Parts coming into contact with the

product (during regular operation) can be cleaned with warm

water, taking into account the temperature limits, see chapter

6.2 Technical Data Sensors.

5.4 Battery

If the measuring system LB 566 is a long time without power

supply (power failure or disconnected from the mains supply),

the system clock is powered by the lithium battery on the

motherboard.

If the battery voltage is no longer sufficient, the error message

CODE 14 "Battery voltage" appears after a restart of the evaluation unit. After acknowledging the error message, the unit

continues to work properly; however, the date and time should

be checked and corrected, if necessary. Measurement data that

are output via a serial interface can be fatally damaged by incorrect date and time information. We recommend changing the

batteries immediately.

The service life of the battery, even under continuous stress, is

approximately 8 years. Replacement of batteries must be carried out in a device disconnected from mains.

Battery type: 3 Volt lithium cell (button cell), type CR2032

Chapter 5. Service instructions

54 MicroPolar (++) LB 566

5.5 Fuse Replacement

The mains fuses of the LB 566 are located in the wall housing.

Replace the fuses only if the instrument is disconnected from

mains.

Use only fuses with the correct rating, see chapter 6.1

Spare fuses must match the rating specified by the device

manufacturer. Short-circuiting or manipulation is not permitted.

Figure 5-2:

View with open

housing wall

MicroPolar

0

I

Netzteil

Fuses

Line connector

Terminalstrip

(can be pulled off)

Battery

EEprom

(can be pulled off)

Feed-through for

lineconnector

Testswitch Motherboard

Protectivecover

Chapter 6. Technical Data

MicroPolar (++) LB 566 55

Technical DataChapter 6.

General specifications

Method Microwave transmission measurement

Operating frequen-cy2.4 - 2.5 GHz (ISM band), depending on

local regulations

Transmission

power

MicroPolar: < 0.1 mW (< - 10 dB)

MicroPolar ++: < 10 mW (< 10 dBm)

All coaxial line power

Application Concentration / moisture measurement in

containers and pipelines

6.1 Technical Data Evaluation Unit

Evaluation unit

Housing Wall housing made of stainless steel, see

dimensional drawing in chapter 8

MicroPolar:

HxWxD: 300 x 323 x 140 mm

MicroPolar++:

HxWxD: 400 x 338 x 170 mm

Protection type IP 65

Weight MicroPolar: approx. 6.5 kg

MicroPolar ++: approx. 8.0 kg

Ambient conditions

during operation

-20 ... +60 °C ( 253 K ...333 K ),

no condensation

Relative humidity: max. 80 %

Altitude: max. 2000 m

Ambient conditions

during storage

-20 ... +70 °C ( 253 K ...343 K ),

no condensation

Relative humidity: max. 80 %

Achievable

accuracy

0.2 weight % (standard deviation)

depending on product and sensor

Display Dot matrix LC display, 114 mm x 64 mm,

240 x 128 pixels, with back-lighting,

automatic contrast setting

Keyboard Freely accessible foil keypad, light-stable

and weatherproof: alphanumeric key-

board and 4 softkeys (software-assigned

buttons)

Chapter 6. Technical Data

56 MicroPolar (++) LB 566

Power supply For Micro Polar, depending on device type:

1.) 100 ... 240 V AC, 45 ... 65 Hz

2.) 24 V DC: 18...36 V;

24 V AC: -20%, +5%, 40 ... 440 Hz

For MicroPolar++, depending on device type:

1.) 100 ...240 V AC, 45...65 Hz

2.) 24 V DC: 18...36

V, no reverse polarity

protection

Power consumption For Micro Polar:

max. 30 VA (AC/DC), depending on

configuration

For MicroPolar ++:

max. (48/60) VA (AC/DC), depending on

configuration

Fuses For Micro Polar:

2 x 2.0 A / slow-blow

For MicroPolar ++:

2 x 2.0 A / slow-blow at 100 … 240 V AC or

2 x 6.3 A / slow-blow at 24 V DC

Battery type 3 V Lithium button cell, type CR2032

Measured value e.g. concentration, dry matter content

Inputs and outputs

Cable cross-section min. 1.0 mm² (mains supply)

Cable feed-through 2 x M20x1.5 for cable 5...14 mm (depending

on application)

4 x M16x1.5 for cable 5 ...8 mm (depending

on application)

Sensor connection Inputs and outputs for signal and reference

channel, 50 N-socket

HF cable

HF cable

Cable lengths: 2, 4, 6 and 10 m; 50 ; both

sides with 4 N connectors

Current input 2 x current input 0/4 ...20 mA, ohmic

resistance 50 , 1x insulated, 1x instrument

ground

e.g. for temperature compensation

Current output Current output 1: 4...20 mA, ohmic re-

sistance max. 800 , insulated

Current output 2: 0/4...20 mA, ohmic

resistance max. 800 , insulated

e.g. for measured value or temperature

output

PT100 connection Measuring range: -50 ... +200 °C (223 ...

473 K); measurement tolerance: < 0.4 °C

Chapter 6. Technical Data

MicroPolar (++) LB 566 57

Digital input 3 x digital inputs (DI1..3), for floating

connectors

Configuration options:

DI1: none, measurement start/stop

DI2: none, measurement hold, product

selection

DI3: none, sampling, product selection

Function description:

1. Measurement (Start/Stop), open: Measurement stopped, closed:

Measurement

started and/or measurement running

2. Hold measurement, open: measurement

running, closed: measurement stopped,

i.e. average values and current output are

held

3. Product selection via a DI:

open: Product 1 (P1), closed: P2

Product selection via two DI’s:

DI2 & DI3 open: P1

DI2 closed & DI3 open: P2

DI2 open & DI3 closed: P3

DI2 & DI3 closed: P4

4. Start sampling: open: no actions, closed:

single measurement starts

Relay outputs 2 x relays (SPDT), insulated

Configuration options:

- Collective failure message

- Stop measurement

- Limit value (min. and max.)

- No product

- Low load

Load capacity:

AC: max. 400VA

DC: max. 90W

AC/DC: max. 250V, max. 2A, non-inductive

150V: voltage must be grounded

The cable used at the relay output must

correspond to a mains cable.

Restrictions at 24 V AC/DC (DC: 18 ...36 V;

AC: 24 V +5 %, -20 %) mains supply, if the

ground conductor is not connected to terminal

1 (PE):

AC: max. 50 V

DC: max. 70 V

Serial interfaces RS232 on the bottom side

RS485 via terminal strip

Data format: 38400 Bd, no handshake, 8 data

bits, 1 stop bit, no parity

Chapter 6. Technical Data

58 MicroPolar (++) LB 566

6.2 Technical Data Sensors

Flow cells

Application Microwave FlowCell with various nominal diame-

ters and flanges for measurement on pipelines

Material Stainless steel, PEEK microwave window

Process coupling

Two versions:

1. Hygiene milk pipe screw connection DIN 11853

2. Flange according to EN 1092-1 (V flange)

Optional adapter for the V flange version with

clamp nozzles and ASA flange

Process pressure up to 16 bar (relative), depending on nominal

diameter and flange type, see table below

Temperature range Product temperature: 10...130 °C (283...403 K)

Ambient temperature: -20...60 °C (253...333 K)

Storage temperature: 10...80 °C (283...353 K)

Connections 2 x HF connections: N female, 50

for HF cable with max. 10 m length

Versions Nominal pipe widths from 50 ... 150 mm

Dimensions See dimensional drawings in chapter 8.

Overview FlowCells with V flange

Designation ID no. Nominal

width

[mm]

Flange Pressure

[bar]

LB 5660-102-00x 66744-001 50 DN 50 / PN 16 16

Further versions

on request

Overview FlowCells with Hygiene milk pipe screw connection

Designation ID no. Nominal width [mm] Pressure

[bar]

LB 5660-112-00x 66744-002 50 16

Further versions

on request

Chapter 6. Technical Data

MicroPolar (++) LB 566 59

Overview ASA flange adapter

Designation

ID no.

ASA flange adapter set for Flow Cell 50 62324

ASA flange adapter set for Flow Cell 65 62319

ASA flange adapter set for Flow Cell 80 62328

ASA flange adapter set for Flow Cell 100 62331

ASA flange adapter set for Flow Cell 150 62335

The kit consists of two adapters, screws and two seals.

Chapter 6. Technical Data

60 MicroPolar (++) LB 566

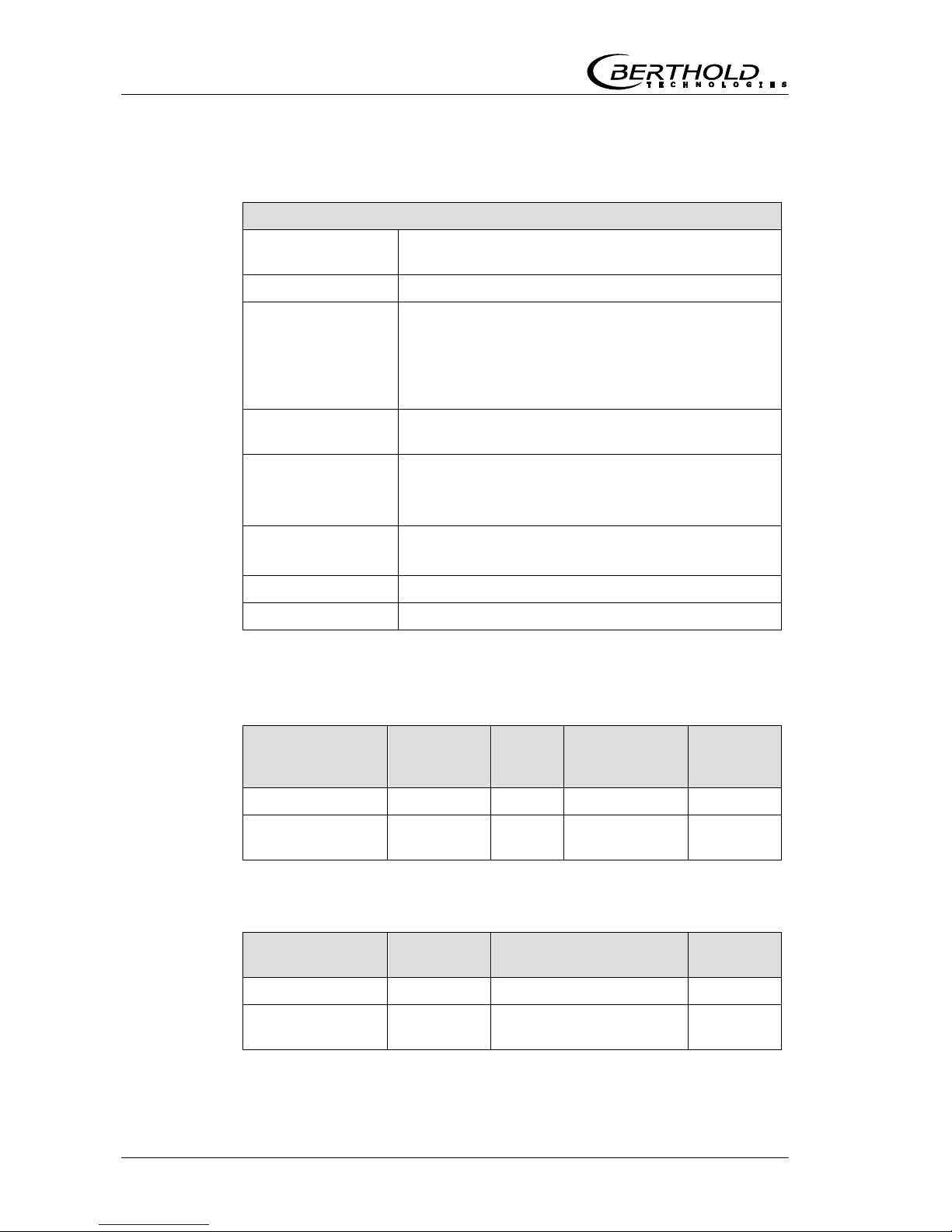

Container Probes

Application Container probes with and without flushing device

for concentration measurement in process

containers and pipelines with nominal width 200

mm.

Material Plastic caps, stainless steel

PT100 connection cable: Silicon / Teflon

Process coupling Flange according to DIN EN 1092 type 05

DN65 / PN6, DN 80, 100, 150 / PN16;

ASA flange 2.5’’ / 150 PSI

(More on request)

Process pressure Up to 16 bar, depending on model

Temperature range Product temperature: 10...120 °C (283...393 K)

Ambient temperature: -20...60 °C (253...333 K)

Storage temperature: 10...80 °C (283...353 K)

Connections 4 x HF connections: N female, 50

for HF cable with max. 10 m length

Dimensions See dimensional drawings in chapter 8.

Accessory sealing washer

Material Klingersil C-4400

Thickness 3 mm

Caps set for container probe

Id.-Nr. 66049-S 2 pieces of PEEK plastic caps with 4 sealing rings

Overview container probes and sealing washers

Designation ID no. Flange

Pressure

[bar]

ID no.

Seals

LB 5650-01 65464-01 DN 65 / PN6 6 32175

LB 5650-02 65464-02 DN 80 / PN16 16 33717

LB 5650-03 65464-03 DN 100 / PN16 16 46661

LB 5650-04 65464-04 DN 150 / PN16 16 46664

LB 5650-05 65464-05 ASA 2.5’’ / 150 PSI 16 46665

LB 5650-09 65464-09 ASA 3’’ / 150 PSI 16 50659

LB 5651-01 65937-01 DN 65 / PN6 6 32175

LB 5651-02 65937-02 DN 80 / PN16 16 33717

LB 5651-03 65937-03 DN 100 / PN16 16 46661

LB 5651-04 65937-04 DN 150 / PN16 16 46664

LB 5651-05 65937-05 ASA 2.5’’ / 150 PSI 16 46665

Chapter 6. Technical Data

MicroPolar (++) LB 566 61

6.3 Technical Data HF Cable

HF cable Quad

Material Corrugated tube: Polyamide (PA6)

Cable sheath: Polyethylene (PE)

Protection type IP 66

Temperature

In operation: -30 ... +70 °C

When installing: -20 ... +70 °C

Cable length [m] ID no.

2 43431

4 43432

6 43433

8 43434

10 43435

HF cable Quad (solid cable)

Material Cable sheath: Polyethylene (PE)

Protection type IP 68 when unscrewed

Temperature

In operation: -40 ... +85 °C

When installing: -40 ... +85 °C

Attenuation

coefficient

about 0.3 dB/m

Cable length [m] ID no.

2.0 11476

2.5 11477

3.0 11478

3.5 11479

4.0 11480

Chapter 6. Technical Data

62 MicroPolar (++) LB 566

6.4 Format of Serial Data Output RS232 and RS485

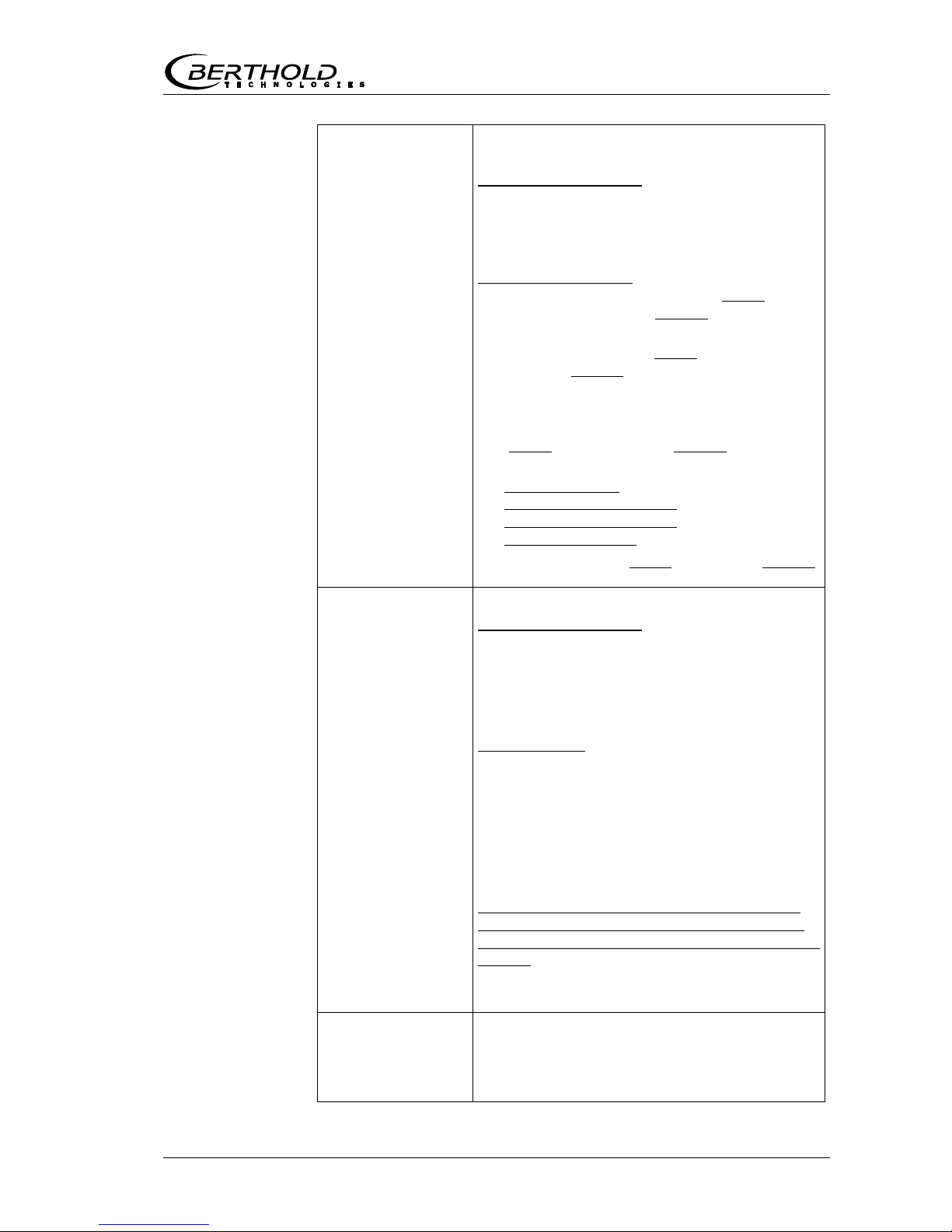

Headline

Date·TimeStateStatusSynchronizerProductAttPhiR2TintIN1IN2PT100

CCmC2C2mMF1MF2

Following lines

01.01.2005·00:00:0000000010.435.300.070.00.00.00.0

1 2 3 4 5 6 7 8 9 10 11 12

75.3675.000.000.000.0000.000¶

13 14 15 16 17 18

Column no. Description Format

1 Date and time DD.MM.YY·HH:MM:SS

2 State 4 digits, HEX

3 Status: Information about the quality of the last

measurement

0 : Measurement OK

< 0 : Error

4 Product synchronization 5: not active

1: still asynchronous

0: all values synchronous

-1: Error

-2: Time too short for syn.

-3: Speed outside range

5 Product number X (1 to 4)

6 Attenuation [dB] X.XX

7 Phase [°/GHz] X.XX

8 Dispersion of the phase regression X.XX

9 Device temperature [temperature unit] X.X

10 Current input 1 [unit of current input] X.X

11 Current input 2 [unit of current input] X.X

12 PT100 temperature [temperature unit] X.X

[…] with selection of the unit g/cm

3

13 Concentration 1 live X.XX [X.XXXX]

14 Concentration 1 averaged X.XX [X.XXXX]

15 Concentration 2 live X.XX [X.XXXX]

16 Concentration 2 averaged X.XX [X.XXXX]

17 Mass flow for concentration 1 X.XXX

18 Mass flow for concentration 2 X.XXX

Special characters

“” Tabulation“¶” Carriage return + Line feed “·” Blank character

Chapter 7. Certificates

MicroPolar (++) LB 566 63

CertificatesChapter 7.

7.1 EC Declaration of Conformity

Chapter 7. Certificates

64 MicroPolar (++) LB 566

Chapter 7. Certificates

MicroPolar (++) LB 566 65

7.2 Frequency License

Chapter 7. Certificates

66 MicroPolar (++) LB 566

Chapter 7. Certificates

MicroPolar (++) LB 566 67

Chapter 7. Certificates

68 MicroPolar (++) LB 566

Chapter 7. Certificates

MicroPolar (++) LB 566 69

Chapter 7. Certificates

70 MicroPolar (++) LB 566

Chapter 7. Certificates

MicroPolar (++) LB 566 71

Chapter 7. Certificates

72 MicroPolar (++) LB 566

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 73

Technical DrawingsChapter 8.

8.1 Dimensions Drawings Evaluation Unit Wall Housing

Chapter 8. Technical Drawings

74 MicroPolar (++) LB 566

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 75

8.2 Electrical Wiring Diagram

Line in for MicroPolar:

1. / 2. depending on

configuration

1.

AC 100-240V, 45-65 Hz

2.

DC 24 V (18-36 V) or

AC 24 V -20/+5%, 40-440 Hz

-------------------------------------------

Line in for MicroPolar ++:

1. / 2. depending on

configuration

Chapter 8. Technical Drawings

76 MicroPolar (++) LB 566

8.3 Dimensional Drawings FlowCell

8.3.1 Type LB 5660-102-00X FlowCell DN 50 VFL. FOA

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 77

8.3.2 Type LB 5660-112-00X FlowCell DN 50 G-BS/M

Chapter 8. Technical Drawings

78 MicroPolar (++) LB 566

8.4 Dimensional Drawings Container Probes

8.4.1 Type LB 5650-01

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 79

8.4.2 Type LB 5650-02

Chapter 8. Technical Drawings

80 MicroPolar (++) LB 566

8.4.3 Type LB 5650-03

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 81

8.4.4 Type LB 5650-04

Chapter 8. Technical Drawings

82 MicroPolar (++) LB 566

8.4.5 Type LB 5650-05

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 83

8.4.6 Type LB 5650-09

Chapter 8. Technical Drawings

84 MicroPolar (++) LB 566

8.4.7 Installation Situation in Pipelines

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 85

8.5 Dimensional Drawings Container Flush Probes

8.5.1 Type LB 5651-01

Chapter 8. Technical Drawings

86 MicroPolar (++) LB 566

8.5.2 Type LB 5651-02

Chapter 8. Technical Drawings

MicroPolar (++) LB 566 87

8.5.3 Type LB 5651-03

Chapter 8. Technical Drawings

88 MicroPolar (++) LB 566

8.5.4 Installation Situation in Pipelines

Index

MicroPolar (++) LB 566 89

Index

A

Accuracy · 55

Adapter flange · 42

ASA flange adapter · 59

Assembly on a container · 33

Assembly on a pipeline · 32

Assembly sheets · 91

B

Battery · 53

C

Cable installation · 39, 43

Calculation of measured values · 18

CE mark · 13

Compatible with foodstuffs · 27

Compensation · 19

Components · 21

Conductive materials · 19

Connector strip · 46

Container probe · 27

Container probe installation · 41

D

Data format RS232 · 62

Data transfer rate · 48

Device disposal · 51

Digital outputs · 48

Distance rail · 38

Distance to metal · 41

E

Evaluation unit · 23

Evaluation unit installation, flow cell · 38

EVU · 15

F

Factory setting · 15

Fitting flange · 41

Flat gasket · 41

Flow cell · 25

Flow cell installation · 36

Flush probe · 15, 29

Flushing parameters · 42

Format RS232 · 62

Frequency license · 12, 65

Fuses · 54

G

Gas inclusions · 14, 36

H

HF cable · 30

HF-cable quad · 30

I

Incrustation · 29

Installation depth · 41

Installation situation in pipelines · 84, 90

Instrument cleaning · 53

L

LED’s · 24, 48

Limitations · 18

M

Mains fuses · 54

O

Overview container probes · 60

Overview flow cells · 58

Index

90 MicroPolar (++) LB 566

Overview sealing washers · 60

P

Pipeline pressure · 36

Power radiation · 14

Power supply · 45

Principle of measurement · 17

R

Recycling passport · 51

Relay · 48

RS232 interface · 48

S

Safety summary · 7

Salt content · 14

Service instructions · 51

Setting up the evaluation unit, container probe · 43

Symbols · 7

Synchronization · 20

T

technical data · 55

Technical data HF cable · 61

Technical data sensors · 58

Technical drawings · 73

Temperature compensation · 19

Throughput calculation · 20

Transmission power · 55

Transport · 35

V

Vertical riser · 36

W

Warning · 7

Wear parts · 52

Wiring diagram · 75

Notes

MicroPolar (++) LB 566 91

Notes

Notes

92 MicroPolar (++) LB 566

Notes

Concentration Meters

MicroPolar (++)

LB 566

User’s Guide

Software Manual

41986BA2

Rev. Nr.: 06-E, 09/2017

MicroPolar (++) LB 566 3

The units supplied should not be repaired by anyone other than Berthold Service engineers or technicians by Berthold.

In case of operation trouble, please address to our central service department (address see below).

The complete user’s guide consists of the hardware manual and the software manual.

The hardware manual comprises the

component description

assembly instructions

electrical installation description

technical data

certificates

dimensional drawings

The software manual comprises the description of the

operation

software functions

calibration

error messages

The present manual is the software description.

Subject to changes without prior notice.

BERTHOLD TECHNOLOGIES GmbH & Co. KG

Calmbacher Str. 22 D-75323 Bad Wildbad

Switchboard: Service:

Phone +49 7081 177 0 Phone +49 7081 177 111