BERTHOLD LB 440 User Manual

Contactless Measurement

of Level

LB 440

PROCESS CONTROL

Level Gauge LB 440

The measuring system LB 440 is used

for the contactless, continuous

measurement of liquids and bulk

materials in reactors, vessels and

bunkers. The measurement is not

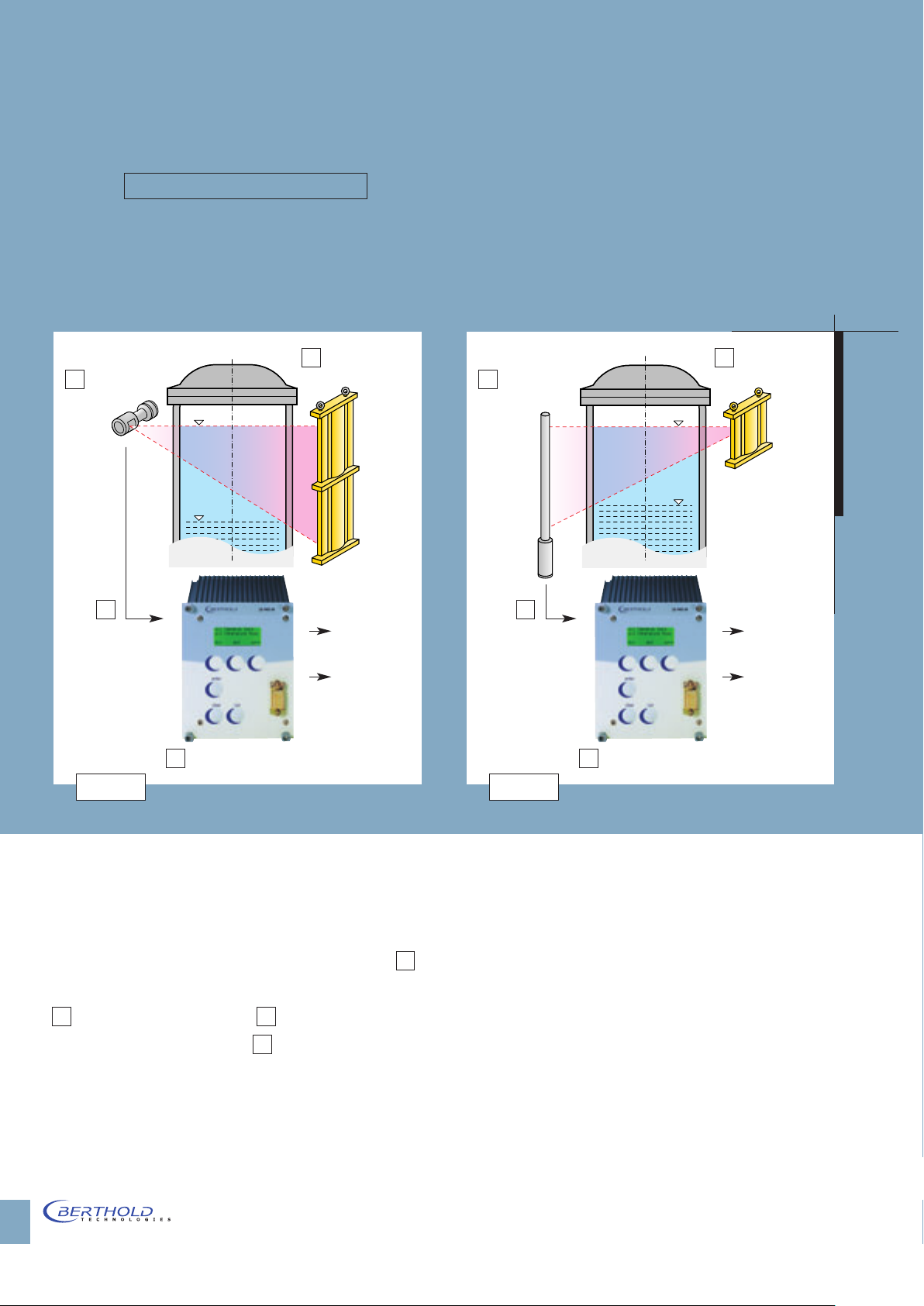

1 Rod Source

2 Point

Detector

Max

Min

with Shielding

affected by the chemical and physical

properties of the product being

measured. The level measurement is

adapted to the specific geometry of

the vessel.

1 Point Source

2 Rod

Detector

Max

Min

with Shielding

3

0/4 ... 20 mA

Alarm

4 Evaluation Unit LB 440

Figure 1 Figure 2

Measuring Arrangement

Figures 1 and 2 show schematic layouts of typical measuring arrangements. It is comprised of the source 1

mounted on the outside of the container, a detector

2 and the connection cable 3 from the detector

to the evaluation unit LB 440 4 . Source and detector

3

0/4 ... 20 mA

Alarm

4 Evaluation Unit LB 440

applications a rod source and rod detector (Fig. 5) can

be used. Which of these options is selected is dependent

upon the measuring geometry, the measuring task,

ambient factors or even considerations of space and

money. For larger measurement ranges several rod

form a radiation field corresponding to the size of the

measuring range. This can be achieved by using a rodshaped source and a point detector (Fig. 3) or a pointshaped source and a rod detector (Fig. 4), for special

detectors can be used together in a line. Signals from

individual detectors are transmitted via slave units to a

master evaluation unit for indication of product level.

Loading...

Loading...