Page 1

Installation, Service and User Instructions

FREESTANDING GAS RANGES

BERTAZZONI

DIMENSIONS: 24’’ (605 mm)(W) x 25

MODEL

X244GGVX [MLS0GTU4X(2 or 5)A]

1/8

’’ (640 mm)(D) x36’’ (911 mm)(H)

310287

Page 2

IMPORTANT - PLEASE READ AND FOLLOW

-Before beginning installation, please read these instructions completely and carefully.

-Do not remove permanently affixed labels, warnings, or plates from the product. This may void the warranty.

-Please observe all local and national codes and ordinances.

-Please ensure that this product is properly grounded.

-The installer should leave these instructions with the consumer who should retain for local inspector's use

and for future reference.

-The electrical plug should always be accessible.

Installation must conform with local codes or in the absence of codes, the National Fuel Gas Code

NSIZ223.1-latest edition. Electrical installation must be in accordance with the National Electrical Code,

ANIS/NFPA70 - latest edition and/or local codes. IN CANADA: Installation must be in accordance with the

current CAN/CGA-B149.1 National Gas Installation Code or CAN/CGA-B 149.2, Propane Installation Code

and/or local codes. Electrical installation must be in accordance with the current CSA C22.1 Canadian

Electrical Codes Part 1 and/or local codes.

Installation of any gas-fired equipment should be made by a licensed plumber. A manual gas shut-off valve

must be installed in the gas supply line ahead of the oven in the gas flow for safety and ease of service.

Warning!

- This range can tip. Injury to persons could result.

- Install anti-tip device shipped with range.

-See Installation Instructions

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR’S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

WARNING: If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage, personal injury

or death.

Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

- Do not light any appliance.

- Do not touch any electrical switch.

- Do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

- If you cannot reach your gas suppliers, call the fire department.

Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

2

Page 3

WARNING

Read this instruction booklet before installing and using the appliance.

The manufacturer will not be responsible for any damage to property or to persons caused by

incorrect installation or improper use of the appliance.

The manufacturer reserves the right to make changes to its products when considered necessary and useful,

without affecting the essential safety and operating characteristics.

This appliance has been designed for non-professional, domestic use only.

Warning: do not use this appliance to heat a room.

Warning: do not place any pot or pan on the open oven door. The door is made of glass and it can

break if loaded with a weight.

Warning: this appliance must be used only with base feet properly installed. See installation

instruction for details.

Installation instructions

This appliance shall only be installed by an authorized person. This appliance shall be installed in

accordance with the manufacturer’s installation instructions, IMPORTANT: this appliance must be

installed in accordance with the norms & standards of the country where it will be installed.

The installation of this appliance must conform to local codes and ordinances. In the absence of

local codes, Installations must conforms to American National Standards, National Fuel Gas Code

ANSI Z223.1 – latest edition** or B149.1.

If local codes permit, a flexible metal appliance connection with the new AGA or CGA certified

design, max. 5 feet (1,5 m) long, ½” I.D. is recommended for connecting this appliance to the gas

supply line. Do not bend or damage the flexible connector when moving the appliance. The pressure

regulator has ½” female pipe thread. The appropriate fitting must be determined based on the size of

your gas supply line, the flexible metal connector and the shutoff valve.

The appliance, when installed, must be electrically grounded in accordance with local codes or, in

the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

The appliance must be isolated from the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply piping system at test pressures equal

to or less than ½ psi (3.5 kPa).

For use with a pressure regulator. The regulator supplied must be used with this appliance; it shall

be properly installed in order to be accessible when appliance is installed in its final location.

The gas appliance pressure regulator must be set for the gas with which the appliance is used.

This appliance can be used with Natural Gas and LP Gas. It is shipped from the factory adjusted for

use with Natural Gas: CONVERSION FIXED ORIFICES ARE LOCATED IN THE LITERATURE PACK

SUPPLIED WITH THE UNIT.

A gas nozzle kit for the change of type of gas are contained inside the package together with the

gas appliance installation kit and instruction booklet.

The maximum inlet gas supply pressure incoming to the gas appliance pressure regulator is 20’’

water column (5 kPa) .

The minimum gas supply pressure for checking the regulator setting shall be at least 1“ w.c. (249 Pa)

above the inlet specified manifold pressure to the appliance (this operating pressure is 4” w.c.

(1.00 kPa) for Natural Gas and 11” w.c. (2.75 kPa for LP Gas).

All opening and holes in the wall and floor, back and under the appliance shall be sealed before

installation of the appliance.

It’s always compulsory to install the riser even for an island installation

3

Page 4

ATTENTION: A manual valve shall be installed in an accessible location in the gas line external to the

appliance for the purpose of turning on or shutting off gas to the appliance

WARNING: Do not use aerosol sprays in the vicinity of this appliance while it is in operation

Requirements

Room ventilation – Location and venting.

ATTENTION: An exhaust fan may be used with the appliance; in each case it shall be installed in

conformity with the appropriate national and local standards.

ATTENTION: Exhaust hood operation may affect other vented appliances; in each case it shall be

installed in conformity with the appropriate national and local standards.

INSTALLATION MANUAL

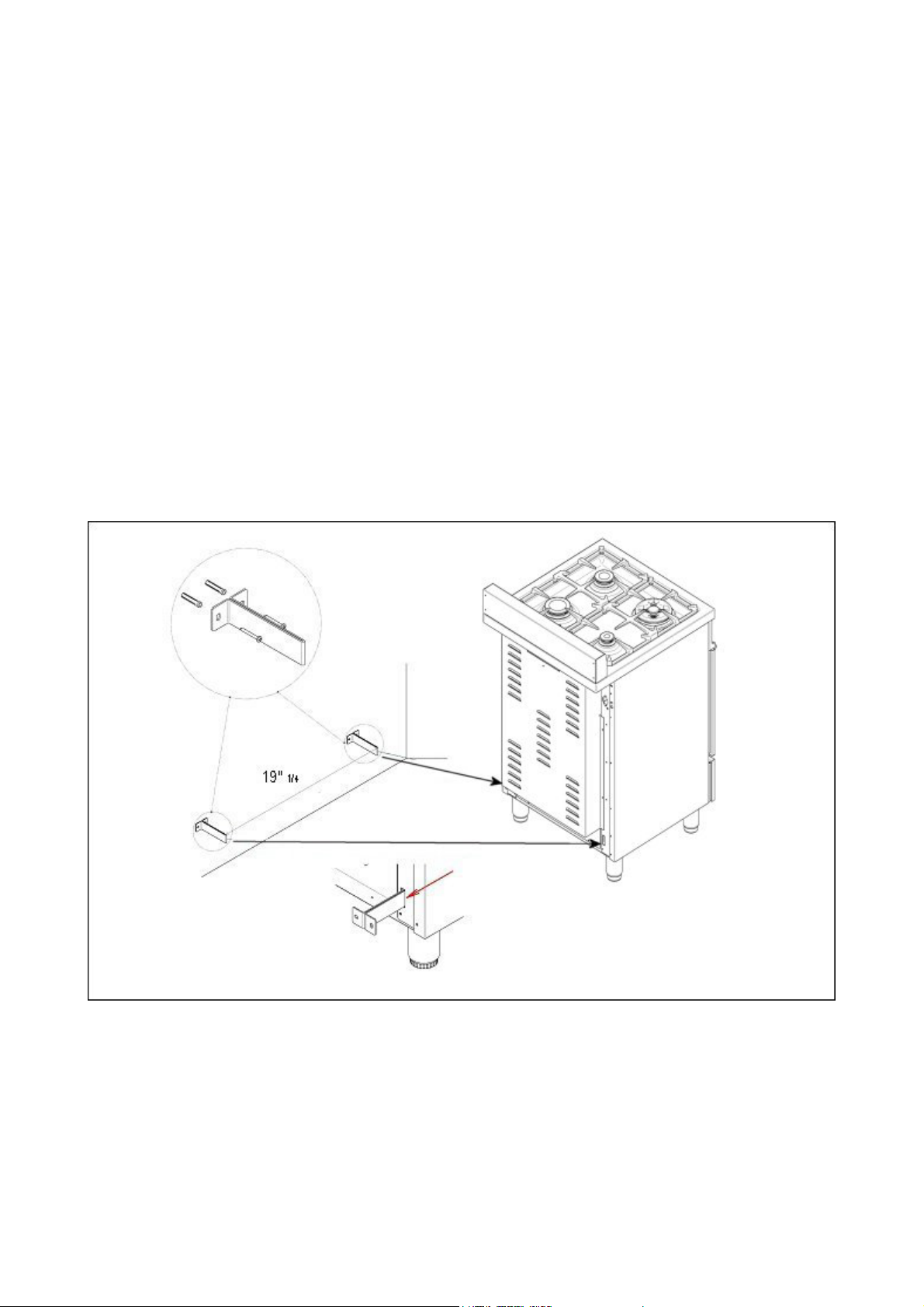

ANTI-TIP STABILlTY DEVICE INSTALLATION INSTRUCTIONS

1. The anti-tip bracket have to be installed to the rear wall as shown. The height for the bracket location from

the floor has to be determined after the range legs have been adjusted to the proper installation height - as

shown in the installation instructions – and after the range has been leveled.

2. Measure from the floor to the bottom of the anti-tip bracket location on the back of the range.

3. Position the two anti-tip brackets on the wall at the measured dimension plus 1/8" (0.32 cm). The brackets

have to be placed at 2”5/16 (6,0 cm) from the side of the range. The distance between the two bracket is

19”1/4 (48,8 cm) clearance. Secure with suitable inserts.

4. Slide the range against the wall until the brackets are fully inserted into the holes on the backside of the

range..

4

Page 5

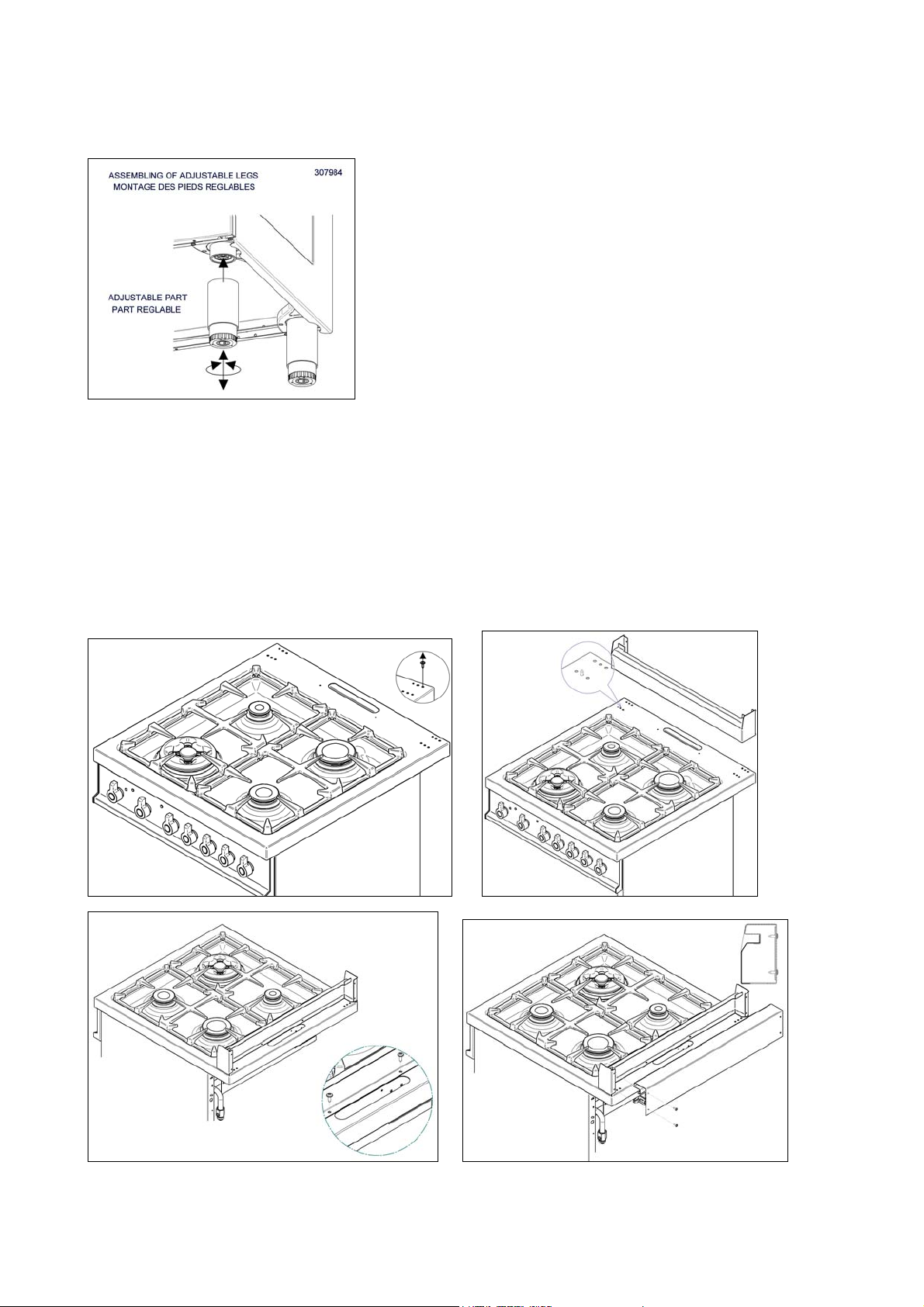

Height adjustable legs:

1. Legs are packed in the top box.

2. Legs should be installed with the appliance being near the location of final installation, they are not secure

for long transport. After unpacking the range, raise it about a foot to insert the legs in their bases assembled

on the lower part of the cooker and lower the range gently to keep any undue strain from legs and mounting

hardware. It is recommended to use a pallet or lift jack instead of tilting the unit.

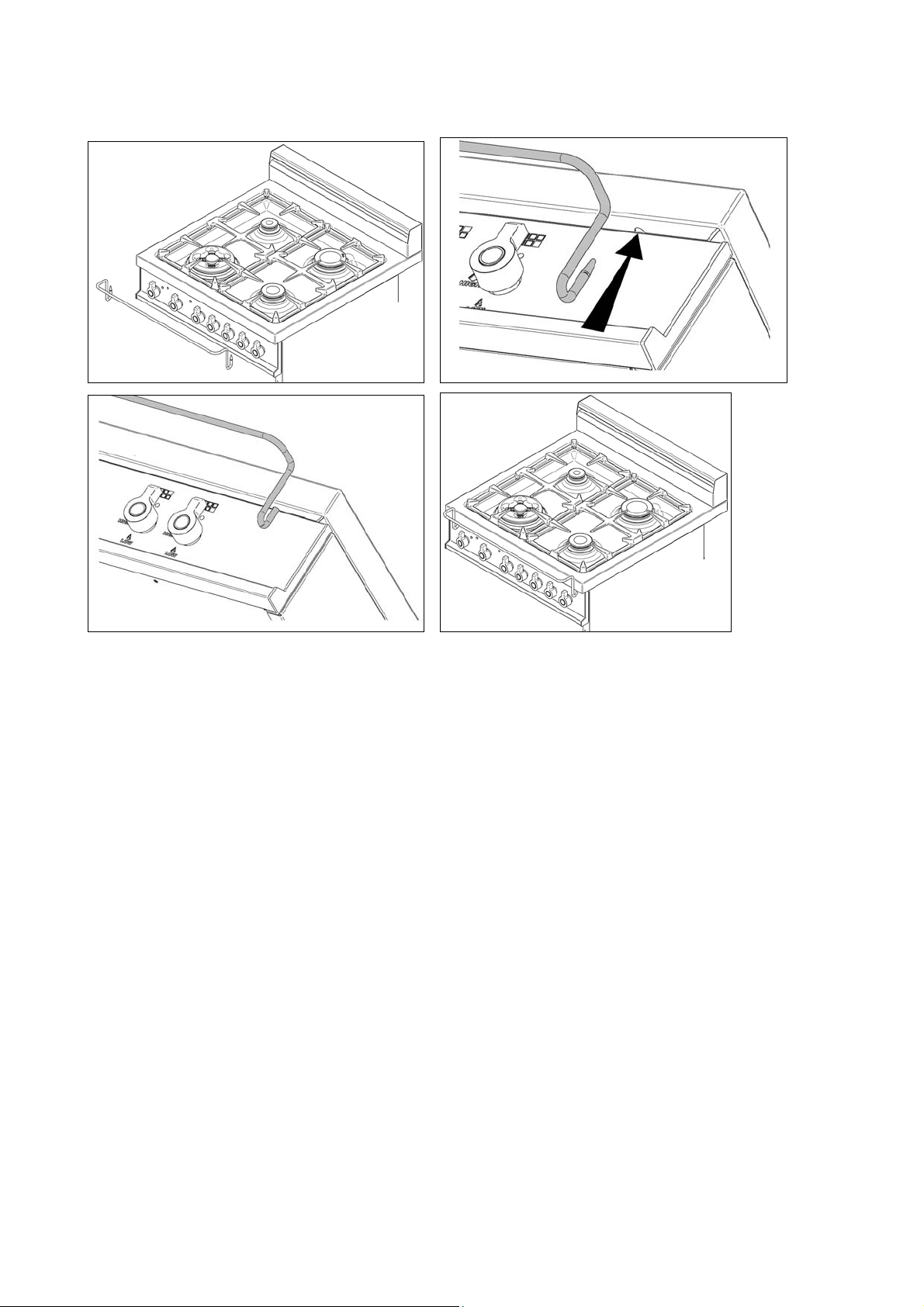

BACKGUARD INSTALLATION INSTRUCTION

It’s always compulsory to installa the riser even for an island installation

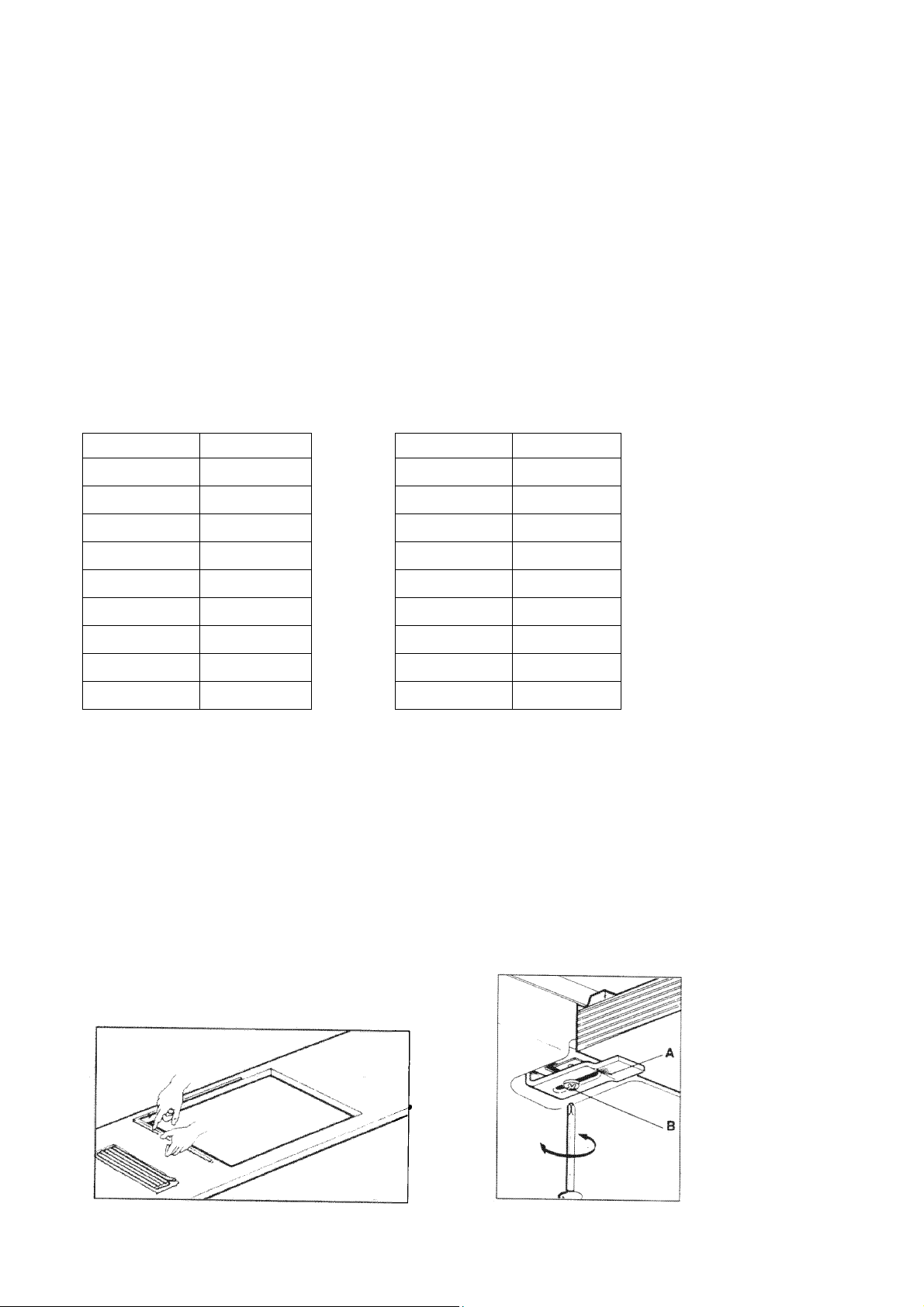

1) Remove n°2 screws fixing worktop as shown in fig.1

2) Place front part of the backguard and attach it from bottom side with the two removed screws (point 2) as shown in

fig .2

3) Fix the front part of the backguard with the screws supplied with the backguard kit (fig.3)

4) Assemble back part with front part of the backguard and fix them with a screws supplied with the backguard kit

(fig.4)

1

2

3

4

5

Page 6

WORKTOP FRONTGUARD INSTALLATION INSTRUCTIONS

In order to increase the clearance between front edge of the worktop and the burners for your safety it is

recomended to install the worktop frontguard supplied with the appliance. For installation instructions follow

the instructions indicated in the following figures

6

Page 7

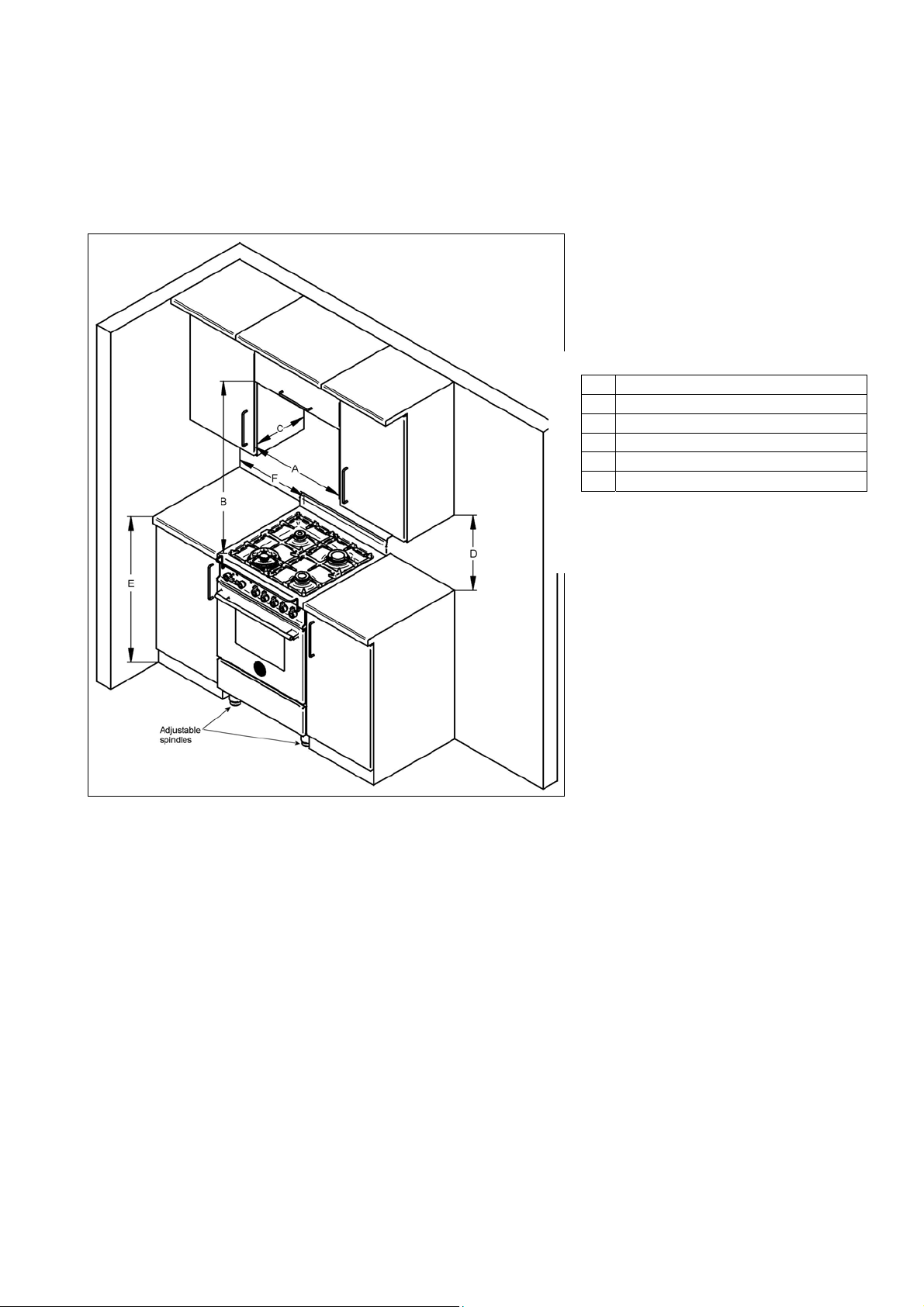

INSTALLATION SIDE-BY-SIDE TO KITCHEN CABINET

1. This range may be installed directly adjacent to existing 36" (91.5 cm) high cabinets. IMPORTANT: The

top border of the worktop should be at the same level of the adjacent

accomplished by raising the unit using the adjustment spindles on the legs.

2. The range CANNOT be installed directly adjacent to sidewalls, tall cabinets, tall appliances, or other vertical

above

3. Within the side clearance to combustible vertical surfaces above 36" (91.5 cm) , the maximum wall cabinet depth must

be 13" (33.0 cm) and wall cabinets within this side clearance must be 18" (45.7

countertop hightness shall be from

36" (91.4 cm) high. There

must be a

minimum of 6" (15.2 cm) side clearance.

35”1/2(90,2 cm) to

37” ¼ (94,6 cm)

cabinet countertop. This can be

cm) above countertop level and

.

A 24” (61 cm)

B 36” (91,5 cm)

C 13” (33,0 cm)

D 18” (45,7 cm)

E 35”1/2(90,2 cm) /

F 6” (15,2 cm)

37” ¼ (94,6 cm)

surfaces

7

Page 8

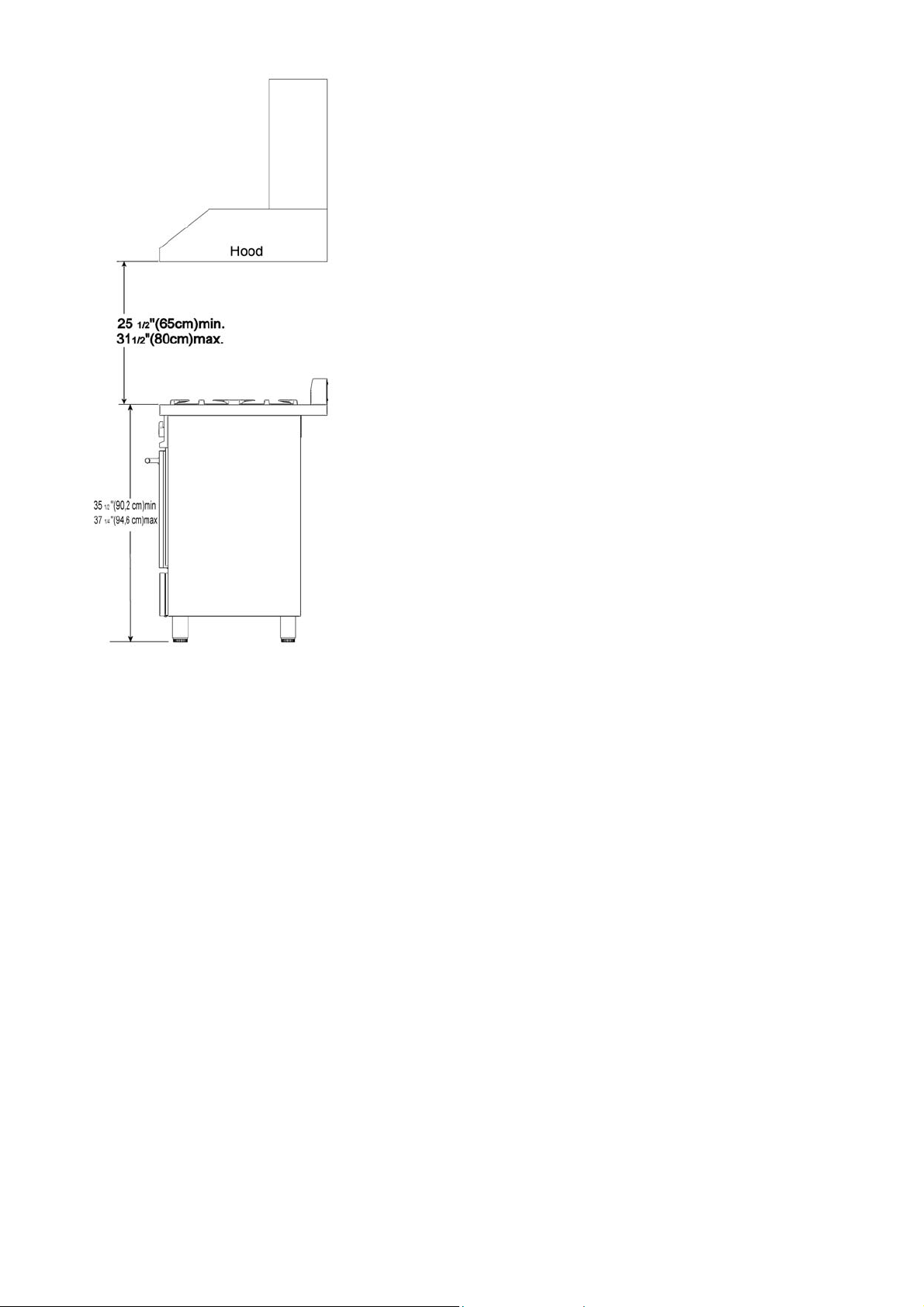

COOKER HOOD INSTALLATION

1/2

The bottom of the hood should be 25

typically result in the bottom of the hood being 61

for other minimum clearance requirements mandated by specific local or regional installation codes. Refer to

the rangehood installation instructions for additional information. These dimensions provide for safe and

efficient operation of the hood.

" (65 cm) min. to 31

1/2

" (156.2 cm) to 67

1/2

" (80 cm) above the countertop. This would

1/2

" (171.5 cm) above the floor. Check

ELECTRICAL CONNECTION

This unit is manufactured for a polarized, grounded 120 volt/60 Hz, 16 amp system. Electric power

consumption is about 150 W. The minimum of 102 VAC is required for proper operation of gas ignition

systems. This circuit must be grounded and properly polarized. The unit is equipped witth a SJT power cord.

In case of replacement, the cable shall be replaced with one of the same type, size and length.

WARNING

Cooling fan failure.

In case of a cooling fan failure the frontal red indicator "Fan Failure" will light up. If this happens, please turn

off the appliance immediately, call the nearest after sale assistance service center and do not use the

appliance until the cooling fan system of the appliance has been properly repaired by a qualified technician.

WARNING

Electrical Grounding Instructions

This appliance is equipped with a three-prong plug for your protection against shock hazard and should be

plugged directly into a properly grounded socket. Do not cut or remove the grounding prong from this plug.

WARNING

ELECTRICAL SHOCK HAZARD

• Disconnect electrical power at the circuit breaker box or fuse box before installing the gas cooker

• Electrically ground gas cooker

•

Use copper conductors only. Failure to follow these instructions could resul in serious injury or death

8

Page 9

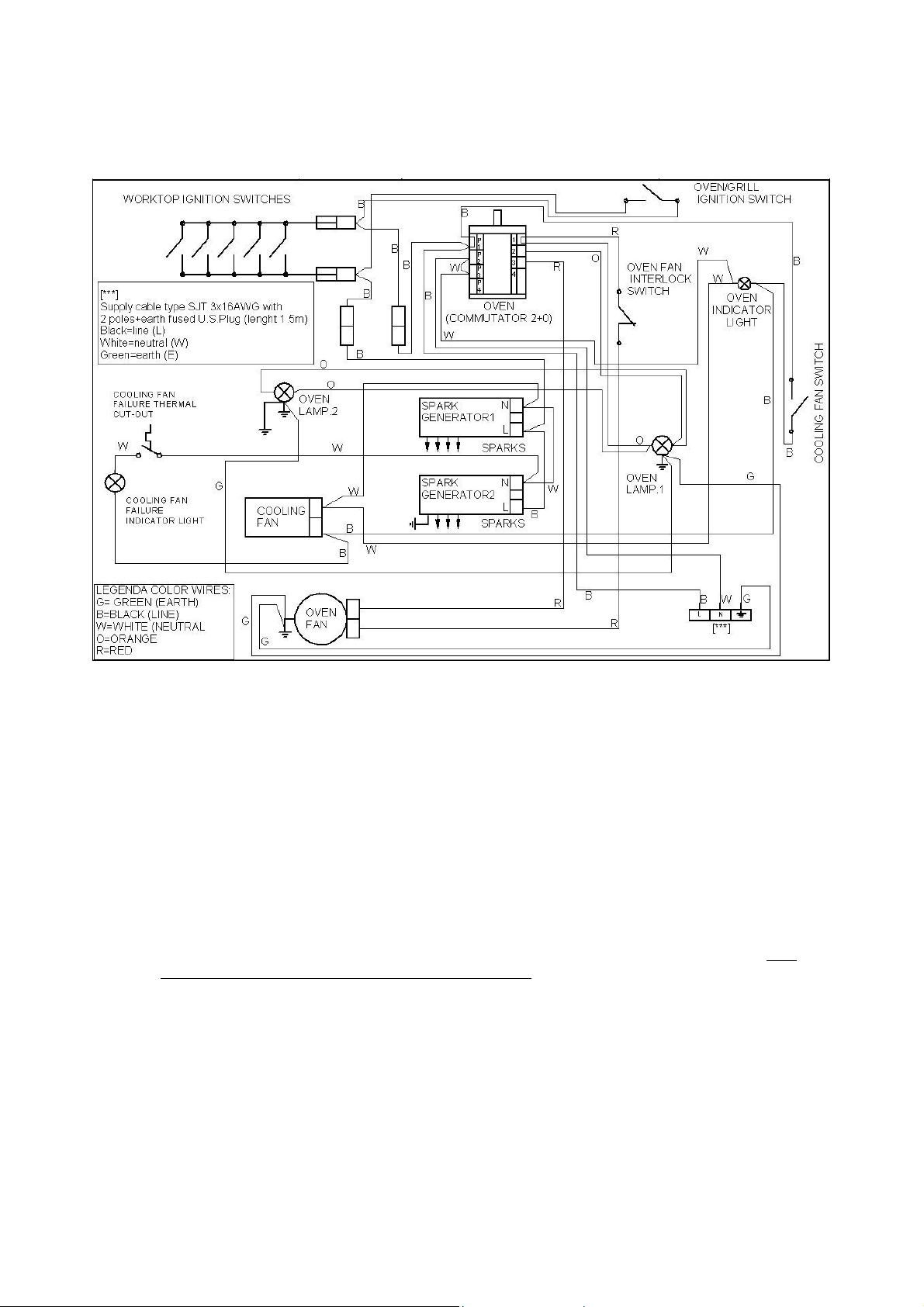

Wiring diagram

For freestanding gas range model X244GGV MLS0GTU4X(2 or 5)A

CAUTION: label all wires prior to disconnection when servicing controls. Wiring errors can cause

improper and dangerous operation.

Verify proper operation after servicing.

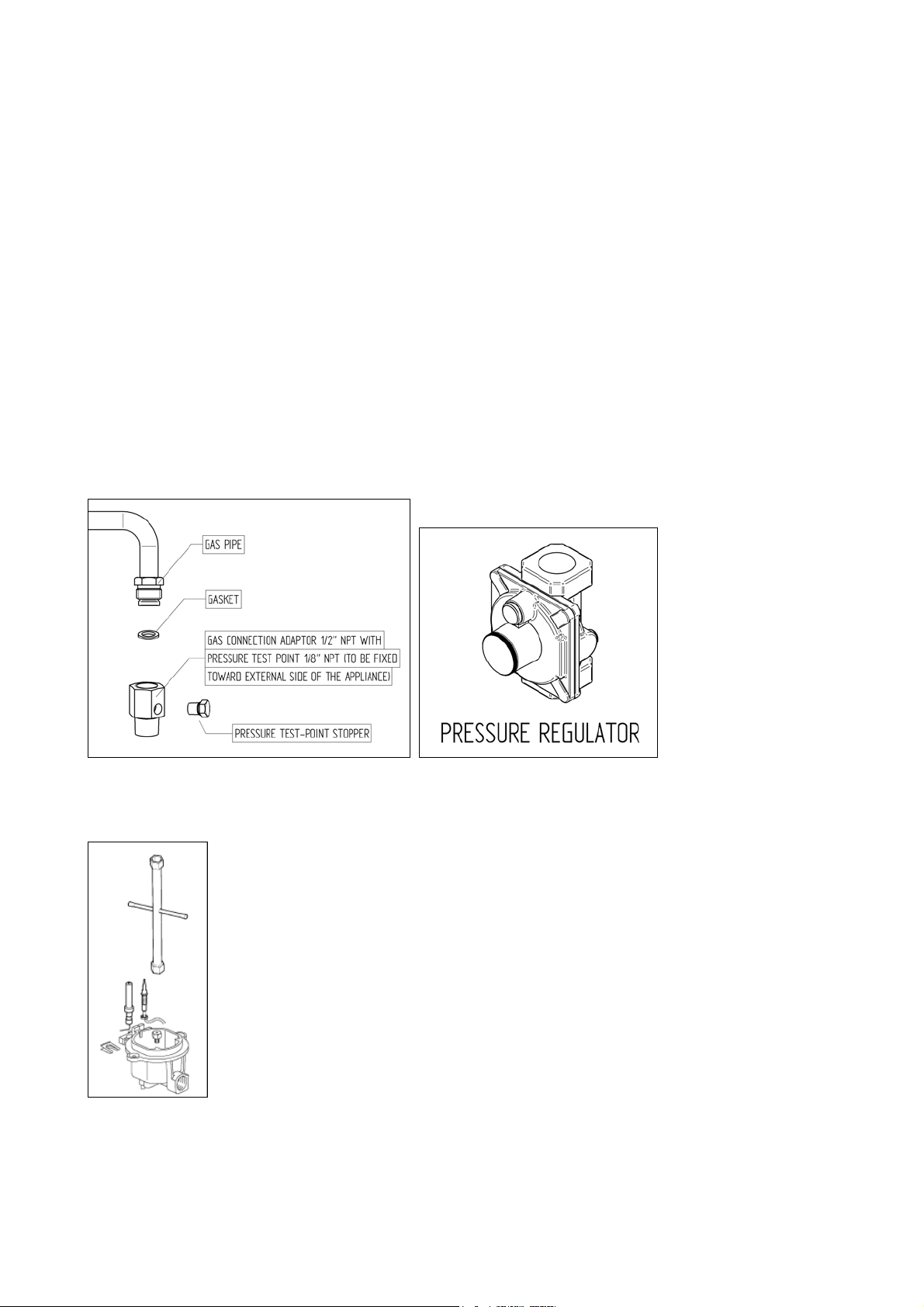

GAS CONNECTION

All gas connections must be made according to national and local codes. The gas supply (service) line must be the same

size or greater than the inlet line of the appliance. This range uses a 1/2" NPT inlet (see fig. in this chapter for details of

gas connections installations).On all pipe joints use sealant resistant to LP gas.

1. Manual Shut-off Valve:

This installer-supplied valve must be installed in the gas service line ahead of the appliance in the gas flow and in a

position where it can be reached quickly in the event of an emergency. The manual shut-off valve shall be installed

properly in order to be accessible when the appliance is installed

2. Pressure Regulator(see fig. in this chapter)

a) All cooking equipment must have a pressure regulator on the incoming service line for safe and efficient

operation, since service pressure may fluctuate with local demand. The pressure regulator is supplied

separately with the appliance; regulator has two female threads ½” NPT; it shall be installed properly in order

to be accessible when appliance is installed in final position.

b) Any conversion required must be performed by your dealer or a qualified licensed plumber or gas service

company. Please provide the service person with this manual before work is started on the range. (Gas

conversions are the responsibility of the dealer or end user.)

c) This range can be used with Natural or LP/Propane gas. It is shipped from the factory adjusted for use with

natural gas.

d) Manifold pressure should be checked with a manometer, natural gas requires 4.0" W.c.P. and LP/Propane

requires 11.0" W.C.P. Incoming line pressure upstream from the regulator must be 1" W.c.P. higher than the

manifold pressure in order to check the regulator. The regulator used on this range can withstand a

maximum input pressure of 1/2 PSI (14.0" W.c.P.) If the line pressure is in excess of that amount, a step-

down regulator will be required.

e) The appliance, its individuai shut-off valve, and pressure regulator must be disconnected from the gas

supply piping system during any pressure testing of that system at pressures in excess of 1/2 psig (3.45

kPa).

f) The appliance must be isolated from the gas supply piping system by closing its individuai manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2

psig (3.45 kPa).

9

Page 10

3. Flexible Connections:

a) If the unit is to be installed with flexible couplings and/or quick disconnect fittings, the installer must use a

heavy-duty, AGA design-certified commerciai flexible connector of at least 1/2" (1.3 cm) ID NPT (with

suitable strain reliefs) in compliance with ANSI Z21.41 and Z21.69 standards.

b) In Canada: CAN 1-6.10-88 metal connectors for gas appliances and CAN 1-6.9 M79 quick disconnect

device for use with gas fuel.

CAUTlON: Leak testing of the appliance shall be conducted according to the manufacturer's instructions. Before placing

the oven into operation, always check for leaks with a soapy water solution or other acceptable method. DO NOT USE

AN

OPEN

FLAME TO CHECK FOR LEAKS!

A 2”( 5 cm)

B 3”(7,6 cm)

D 8”(20,3 cm)

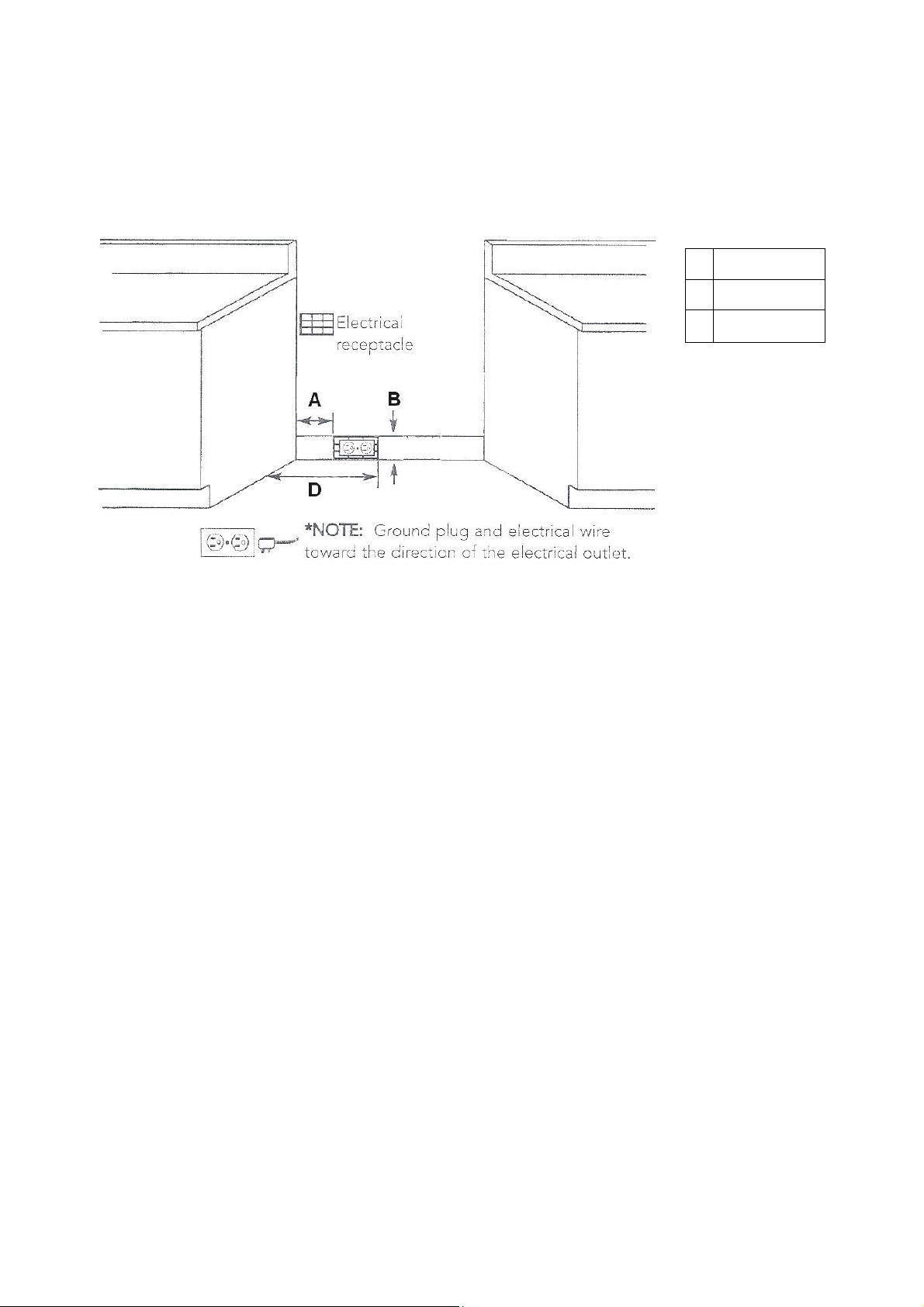

A properly-grounded horizontally- mounted electrical receptacle should be installed no higher than 3" (7.6 cm) above the

floor, no less than

requirements.

An agency-approved, properly-sized manual shut-off valve should be installed no higher than 3" (7.6 cm) above the floor

and no less than

shut-off valve and regulator, use agency-approved, properly sized flexible or rigid pipe. Check all local code

requirements.

2”( 5 cm)

2”( 5 cm)

PERFORMANCE CHECKLlST

All burners are tested before leaving the factory. There are no adjustments for the burners if connected according to the

information on the rating plate. Check each burner for proper operations. Flames should be blue in all settings. If service

is required, contact your dealer for the name of their authorized service agency. Gas conversions and initial installation

are not the responsibility of the manufacturer.

The installer should carry out the following performance checks. Refer to instructions below.

1. Check surface burner ignition.

2. Check air shutter adjustment (only for oven and broiler burner)- sharp blue flame, no yellow tipping, sooting or flame

lifting

3. Check low flame adjustment

4. Check broiler and oven ignition - all burner ports.

5. Check for gas leaks (odors) at all gas connections.

6. Check oven bake and convection bake function.

FINAL PREPARATION

1. Some stainless steel parts may have a plastic protective wrap which must be removed. The interior of the oven

should be washed thoroughly with hot soapy water to remove film residues and any installation dust or debris

before using it for food preparation, then rinsed and wiped dry. Solutions stronger than soap and water are rarely

needed.

2. All stainless steel body parts should be wiped with hot, soapy water and with a liquid cleaner recommended for

use with stainless steel If buildup occurs, do not use steel wool, abrasive cloths, cleaners, or powders! If it is

necessary to scrape stainless steel to remove encrusted materials, soak with hot, wet cloths to loosen the

material, then use a wood or nylon scraper. Do not use a metal knife, spatula, or any other metal tool to scrape

stainless steel! Scratches are almost impossible to remove.

NOTE: These installation instructions should remain with the unit for future reference. The electrical diagram is located in

the backside or the appliance.

and no more than

and no more than

8”(20,3 cm)

8”(20,3 cm)

from the right side (facing product). Check all local code

from the left side (facing product). To connect gas between

10

Page 11

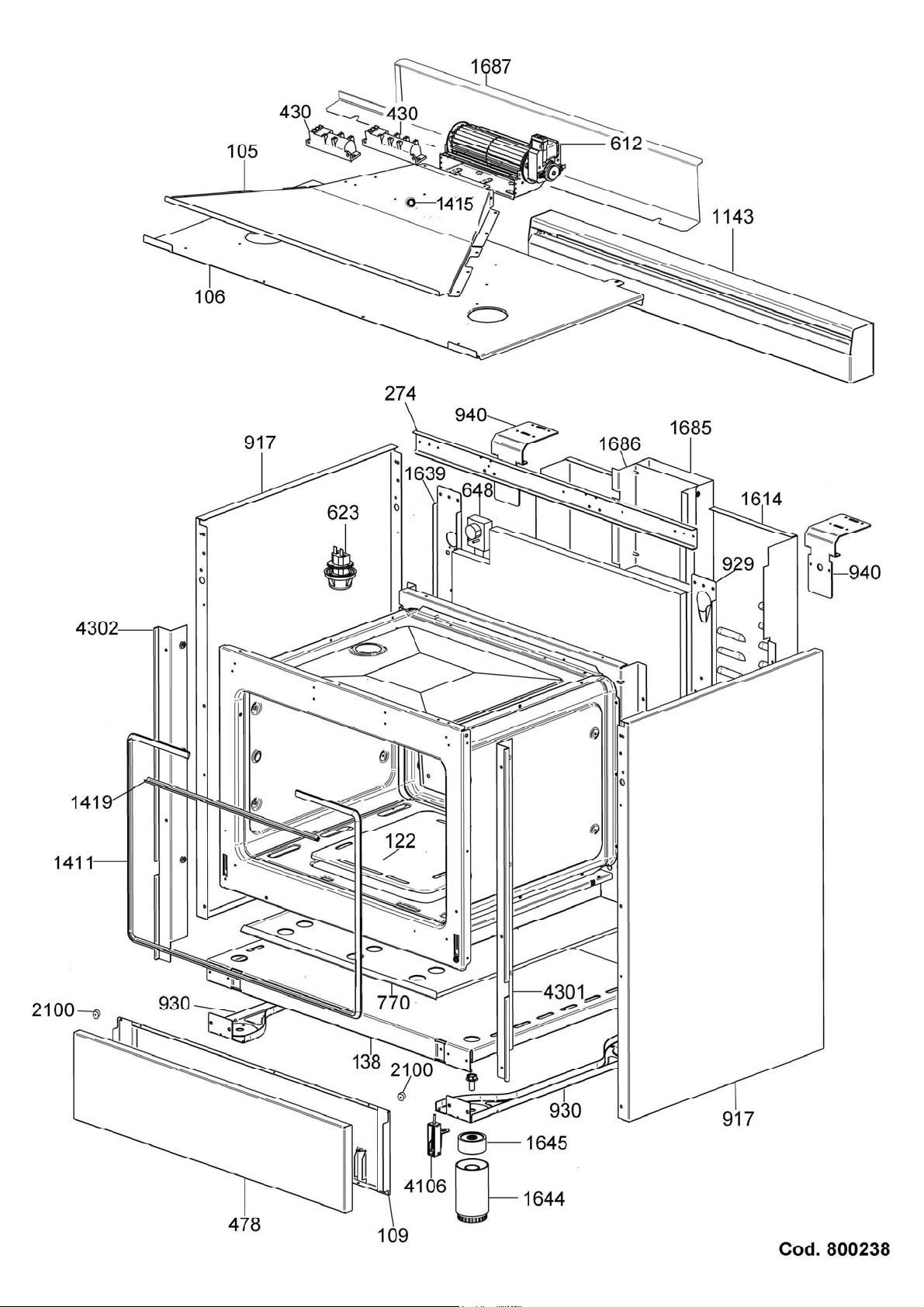

REPLACEMENT PARTS

Only authorized replacement parts may be used in performing service on the appliance. Replacement parts are available

from factory authorized parts distributors.

Conversion to different types of gas

Before carrying out any maintenance work, disconnect the appliance from the gas and electric

supply. For Natural Gas fit regulator assembly described in Fig.

Adaptation of the pressure regulator for use with different type of gas

The pressure regulator supplied with the appliance is a convertible type pressure regulator for use with Natural Gas at a

nominal outlet pressure of 4” w.c. or LP gas at a nominal outlet pressure of 11” w.c. and it is pre-arranged from the

factory to operate with one of these gas/pressure as indicated in the labels affixed on the appliance, package and

Instruction booklet.

To convert the regulator for use with other types of gas follow these instructions:

1) Unscrew by hand the upper metal stopper of the regulator.

2) Unscrew by hand the white plastic piece screwed under the above mentioned metal stopper, afterward screw it again

in opposite way under the metal stopper (for gas reference see the written “LP” and “NAT” with relative indicating arrows

on the white piece).

3) Screw again by hand the metal stopper in the original position on the regulator.

Following these exact instructions the gas regulator is converted for use with the other gas/pressure.

It is essential that the gasket and the pressure test point stopper are properly installed to avoid gas leakage

- CHANGING THE NOZZLES FOR USE WITH OTHER TYPES OF GAS:

To change the nozzles of the burners use the following procedure:

Lift up the burners and unscrew the nozzles ( Fig.) using an adjustable spanner of 7 mm and change the nozzles with

those designed for the new gas supply according to the information given in TABLE shown below.

11

Page 12

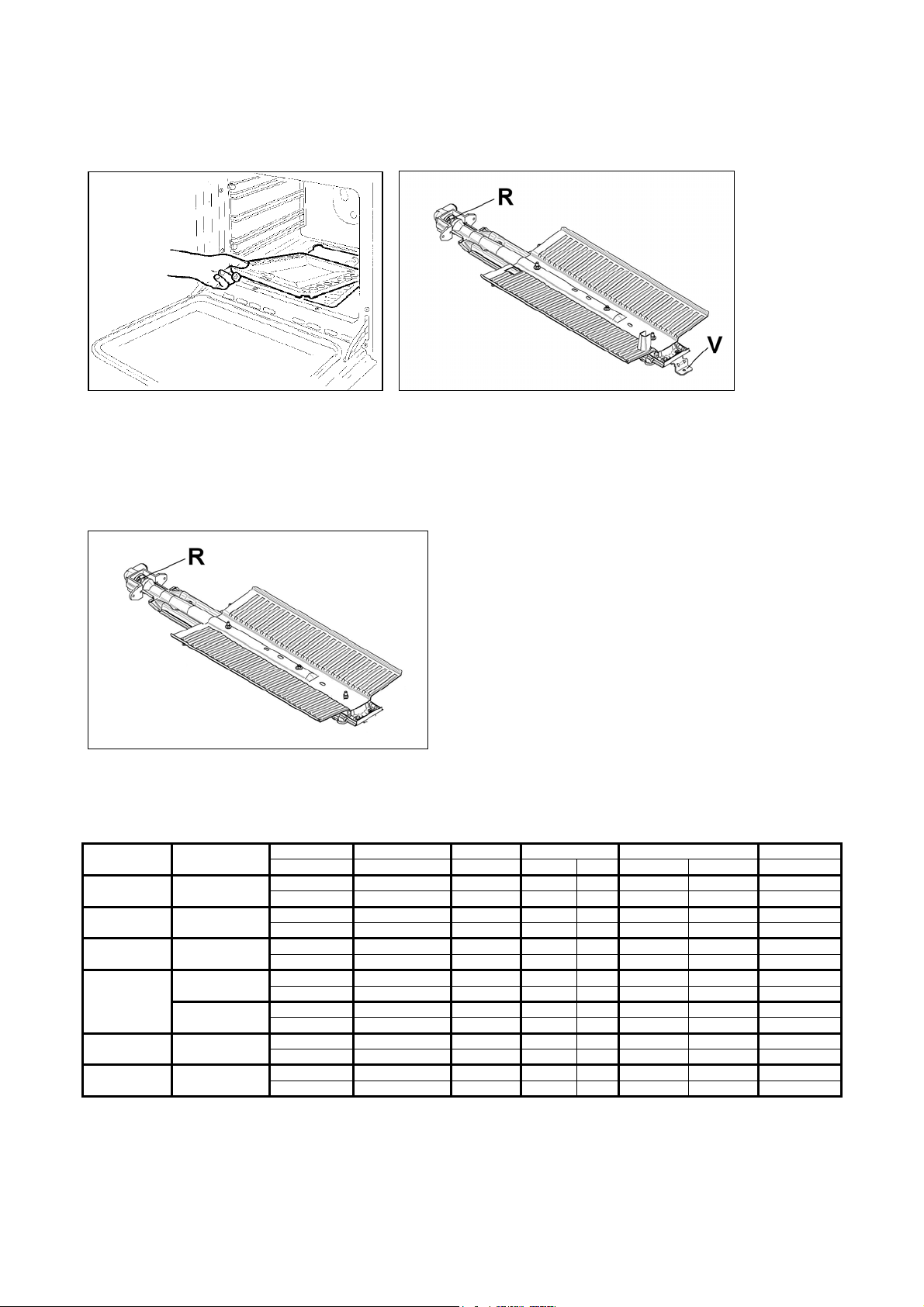

Follow the instructions below to change the oven burner nozzle:

1) Remove the oven level (Fig. 9).

2) Loosen the screw V and pull out the burner from the support being careful not to damage the ignition plug and the

thermocouple (Fig. 10).

3) Unscrew the nozzle R (Fig. 10) using a 7 mm spanner and replace it with the nozzle needed for the new type of gas

according to what is indicated in Table below

4) Re-install all the parts in revers sequence from 3 to 1

(Fig. 9) (Fig. 10)

Follow the instructions below to change the broiler burner nozzle:

1) Loosen the screw and pull out the burner from the support being careful not to damage the ignition plug and the

thermocouple (Fig. 11).

2) Unscrew the nozzle R (Fig. 11) using a 7 mm spanner and replace it with the nozzle needed for the new type of gas

according to what is indicated in Table below.

Models X244GGVX [MLS0GTU4X(2 or 5)A]

Adapting to different types of gas

Burner Position Injector Gas Pressure Max Rate Min Rate By-pass

diam. [mm.] Type [i.w.c.] [BTU/h] [W] [BTU/h] [W] diam. [mm]

Auxiliary Rear L 0,90 NG 4” 3400 996 900 264 Regulated

0,54 LP (Propane) 11” 3400 996 900 264 0,29

Semi-Rapid Front R 1,18 NG 4” 6100 1787 1500 439 Regulated

0,70 LP (Propane) 11” 6100 1787 1500 439 0,36

Rapid Rear R 1,55 NG 4” 10400 3047 2500 732 Regulated

0,92 LP (Propane) 11” 10400 3047 2500 732 0,47

Front L Inner 0,80 NG 4” 2800 820 900 264 Regulated

Dual Burner 0,49 LP (Propane) 11” 2800 820 900 264 0,29

Front L Outer N°2 x 1,15 NG 4” 12000 3516 4500 1318 Regulated

N°2 x 0,70 LP (Propane) 11” 12000 3516 4500 1318 0,65

Oven Oven 1,60 NG 4” 11000 3223 2400 703 Regulated

downside 0,95 LP (Propane) 11” 11000 3223 2400 703 0,48

Broiler Oven 1,50 NG 4” 10000 2930 Only Max Only Max No by-pass

upside 0,90 LP (Propane) 11” 10000 2930 Only Max Only Max No by-pass

CAUTION: save the orifices removed from the appliance for future use

12

Page 13

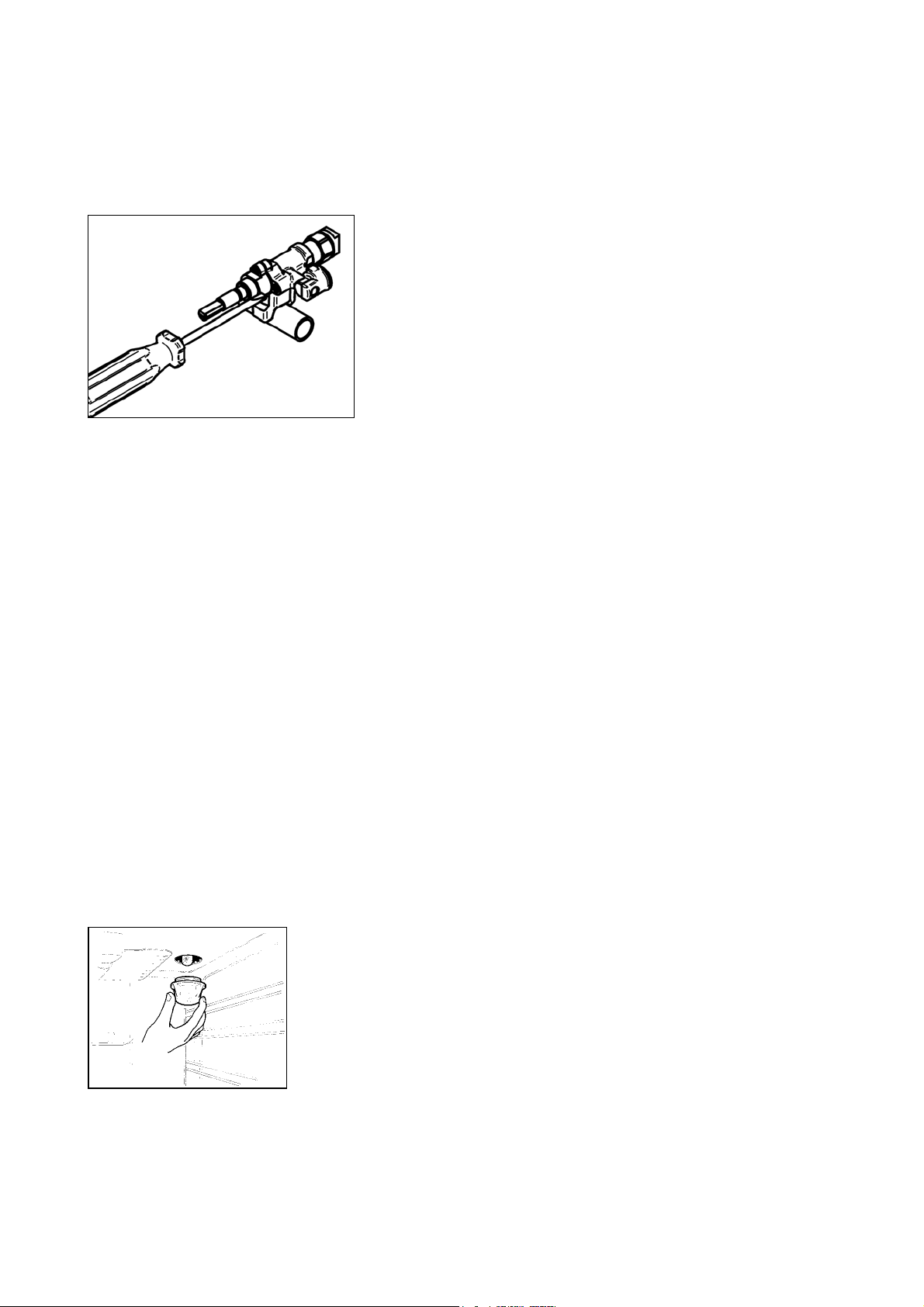

REGULATION OF BURNERS

Work surface burner adjustment: follow the instructions below to adjust the work surface burner minimum:

1) Light the burner and set the knob to the MINIMUM position (small flame).

2) Remove the knob of the valve that is press fit on the rod of that valve.

3) The cooker is equipped with safety valves, use a small slotted screwdriver the choke valve located on the valve body

and turn the choke screw to the right or left until the burner flame is adjusted to minimum

4) Make sure that the flame does not go out when switching quickly from the MAXIMUM to the MINIMUM position.

Oven burner adjustment: follow the instructions below to adjust the minimum:

1) Light the burner setting the knob to the MAXIMUM position.

2) Close the oven door and operate the oven for at least 10 minutes.

3) Set the knob to the MINIMUM position (corresponding to 250°F/120°C) and then remove it.

4) With a slotted screwdriver turn the choking screw (by-pass screw at the left side of the thermostat bar) and, while

observing the flame at the same time through the cooker porthole, evaluate the consistency of the flame so it remains on

when switching quickly from the MINIMUM to the MAXIMUM position.

WARNING: The above-mentioned adjustment should be made only for natural gas, while for operation with

liquid gas the screw must be locked at the end in a clockwise direction. The broiler burner always

operates at maximum and therefore no minimum adjustment is required.

SERVICE & MAINTENANCE INSTRUCTIONS

Service and maintenance only to be carried out by an authorised person

To replace parts such as burners, valves and electric components, the appliance must be open removing the worktop.

Note: if the valves must be replaced, first disassemble the ignitions switches wires.

It is recommended to replace the valve gaskets each time the valve is replaced, thus ensuring a perfect seal between the

body and the gas train.

WARNING: After first installation of the appliance or after any service intervention concerning main gas parts of

the appliance, make the leak test using water with soap on the gas connections in order to verify the correct

installation. Do not use fire for gas leak testing.

To replace the oven bulb, just unscrew the protection cap that projects out inside the oven. (Fig.19) WARNING:

Disconnect power before servicing unit.

In order to remove the oven door make sure to block the ihinges with a screw driver.

Call an autorised service person for this operation that can be dangerous

13

Page 14

USER MANUAL

WARNINGS:

Do not to cover the holes inside the oven with aluminium paper

Do not to cover the burners of cooktop with aluminium paper

Do not store any flammable objects or objects under pressure in the storage compartment

Keeping appliance area clear and free from combustible materials, gasoline and other flammable

vapors and liquid.

Do not store dangerous or flammable material in the cabinet areas above appliance; store them in a

safe place in order to avoid potential hazards.

For safe use of appliance, do not use it for space heating.

Do not use aerosol sprays in the vicinity of this appliance while it is in operation

Do not use oven doors as support or for sit-down.

Do not use oven cavity as storage compartment.

DESCRIPTIONS

14

Page 15

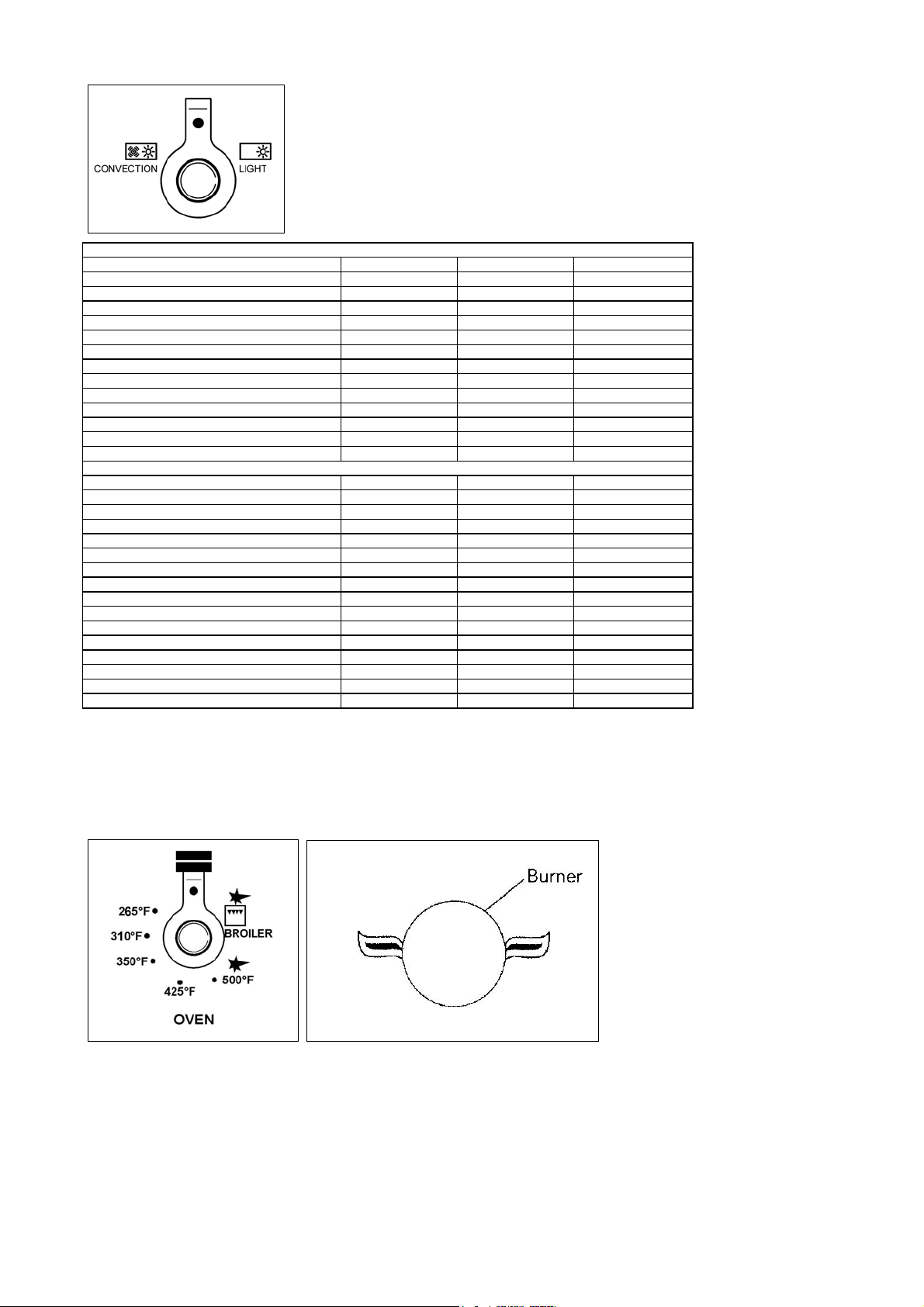

CONTROL PANEL DESCRIPTION

On the control panel, small symbols show the function of each knob or key. Here as follows are the several controls that

a cooker can have:

the symbol shows the disposition of burners on the worktop, the full dot identifies the burner in object (in this

case the front burner on the right).

the symbol shows the running of oven or broiler

the symbol

the symbol

shows the swicth for the oven light

shows the swicth for the oven fan and oven light

USING BURNERS

A diagram is etched on the control panel above each knob which indicates which burner corresponds to that

knob.

(flame)

Manual ignition:

Manual ignition is always possible even when the power is cut off or in the event of prolonged power failure.

Turn the knob that corresponds to the burner selected counterclockwise to the MAXIMUM position at the etched star

(large flame) and place a lit match up to the burner.

Automatic electric ignition:

Turn the knob that corresponds to the burner selected anticlockwise direction to the MAXIMUM position at the etched

star (large flame) and then press the knob down to activate the spark ignition. Once ignited, keep pressing the knob for

about 10 seconds to allow the flame to heat the thermocouple. If the burner does not remain alight after releasing the

knob repeat the above procedure,

Note: It is recommended not to try to ignite the burner if the relative flame cap is not in the correct position

Note: Dual burner is composed by two burner (inside and outside); each one operates under the relative gas valve

indipendently from the other one.

Instructions for the ignition of the dual wok burner: turn on the central burner first, then turn on the external ring.

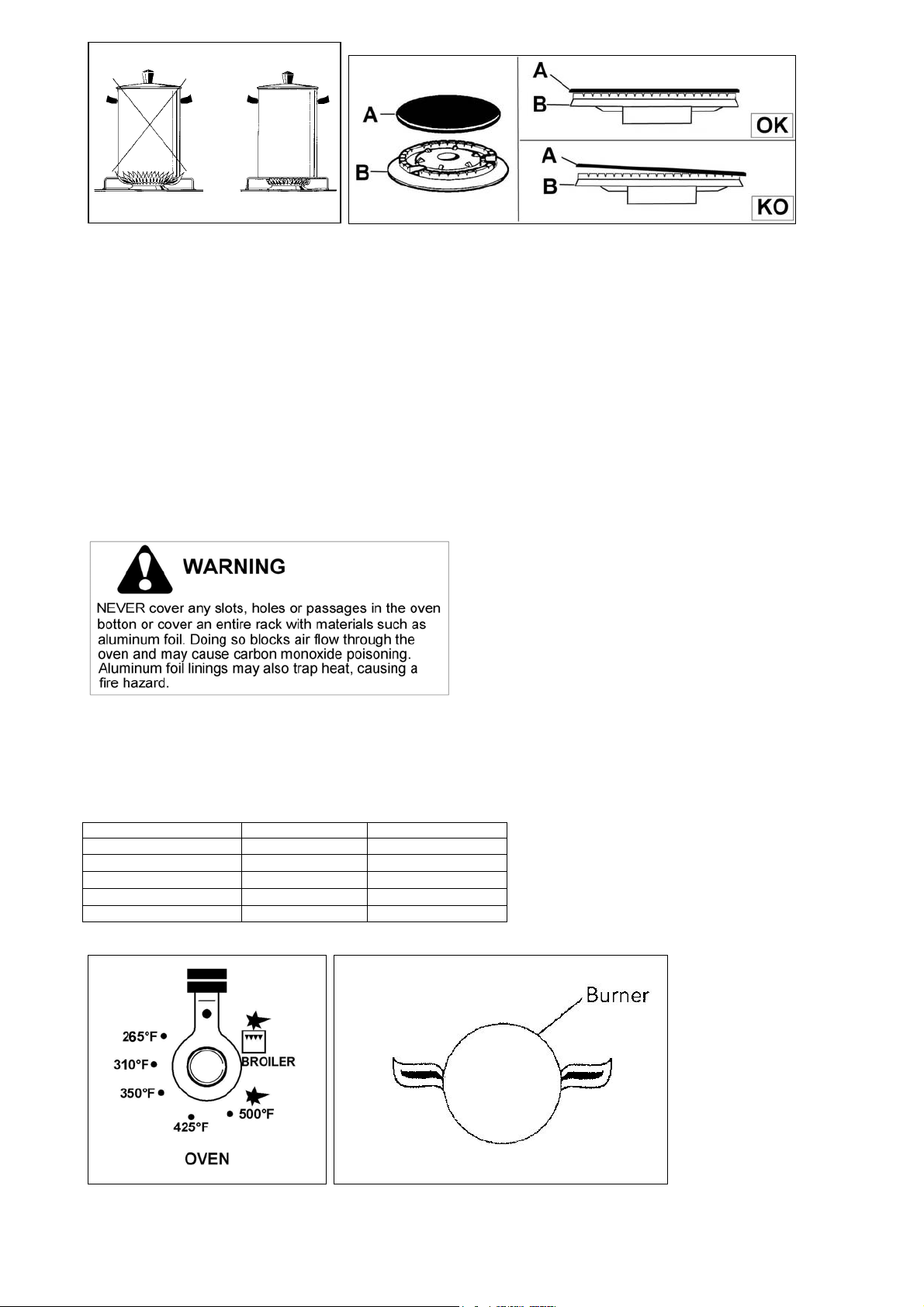

Tips for using burners correctly:

WARNING: During use of each gas burner(s) adjust the burner flame size properly so it does not extend beyond

the edge of the cooking utensil. This is an instruction based on safety considerations

- Use suitable pots for each burner (see Fig. and Table )

- When the liquid is boiling, turn down the knob to the MINIMUM position.

- Always use pots with a cover.

Correct flame aspect: verify that aspect flame of the worktop burners be completely blue and with an aspect as

indicated in figure(flame)

Table

Burner Recommended pan diameters inches (mm)

Small 3½”-5

Medium 5

Large 7

Dual burner 8

1/2

1/8

2/3

”- 10

”- 10

”-10

1/2

”(90 – 140)

1/4

”(140 – 260)

1/4

” (180 – 260)

1/4

” (220 – 260)

15

Page 16

WARNING: check the position of the burner caps before operation.

Correct usage of pans:

- Dry the bottom of the pan before placing it on the hotplate.

- Use pots with a flat, thick bottom, except for wok cooking.

- When using the burners, ensure that the handles of the pans are correctly positioned. Keep children away from the

appliance.

- When cooking foods with oil and fat, which are very flammable, the user should not leave the appliance unattended.

WOK PAN: To use the wok pan, please utilize a suitable wok adaptor grid; wok pan external diameter shall not be less

than 10” (25cm) and not more than 16”(40cm).

WARNING: If the power is cut off, the burners can be lit with matches.

The burners equipped with a safety thermocouple can only be lit when the knob is in the MAXIMUM position (large flame

etching).

USING THE GAS OVEN

All the gas oven cookers are equipped with a thermostat and safety device to adjust the cooking temperature. The oven

temperature is set by turning the knob counterclockwise to match the indicator with the temperature selected. The gas

oven is combined with a gas broiler. See the specific pages for use information.

WARNING: If the burner flames are extinguished accidentally, turn off the control knob and do not try to relight

the oven until after at least 1 minute.

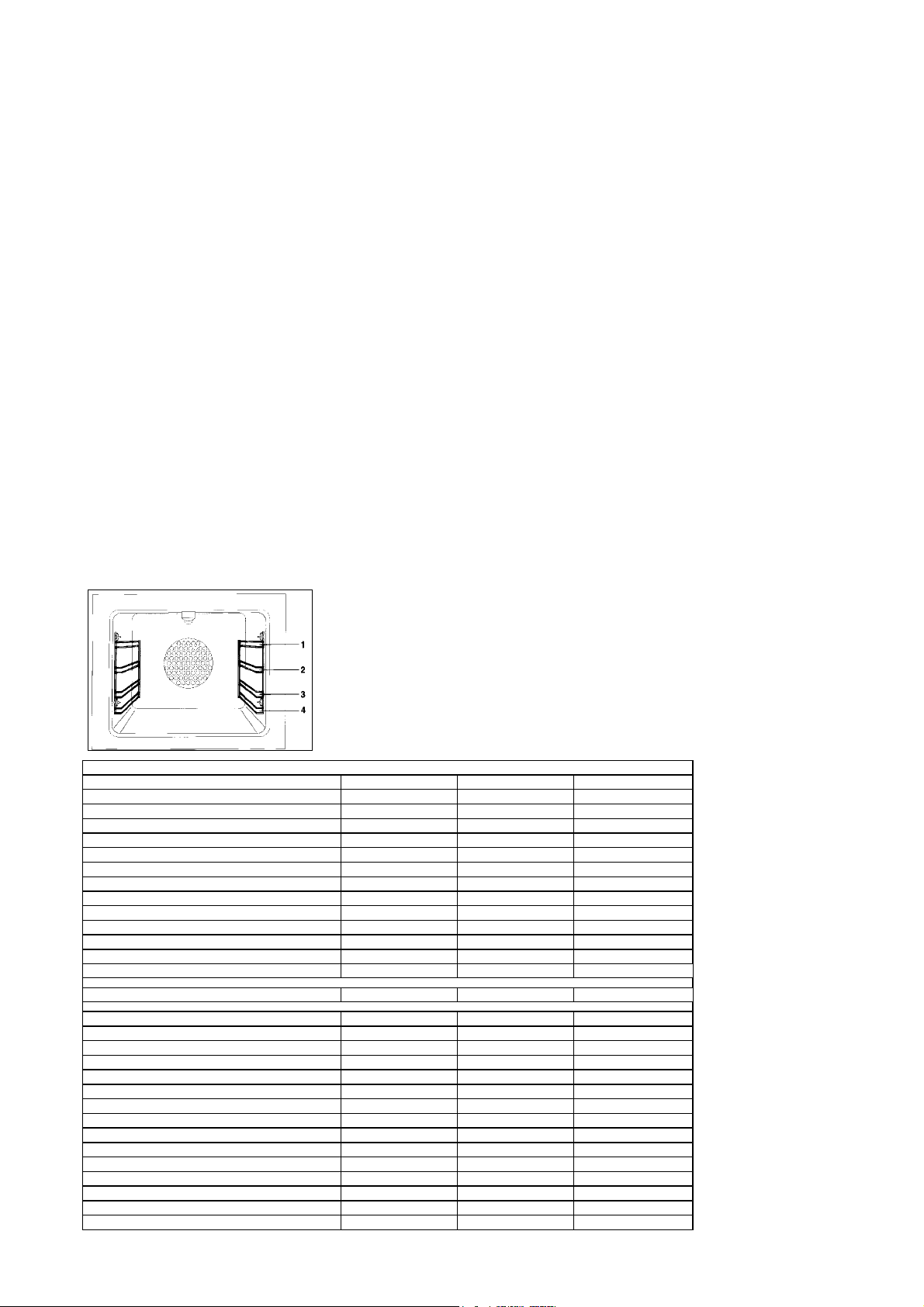

TABLE N°7

THERMOSTAT SETTING TEMPERATURE °F TEMPERATURE °C

MIN.

MED-LOW

MED.

MED-HI

MAX.

265 130

310 155

350 175

425 220

500 260

16

Page 17

The oven burner can be ignited in different ways:

- Manual lighting (it is always possible even when the power is cut off):

To light the oven, open the oven door and turn the knob at maximum position . At the same time put a lit match next to

the ignition tube that is visible on the oven level . Then press the thermostat knob (this makes the gas start to flow) and

keep it pressed, after the burner has been completely lit, for 10 seconds. Release the knob and make sure that the

burner remains on, otherwise repeat the operation.

- Electric ignition

In this case, first open the oven door, then turn the knob to the maximum temperature setting. Then press the thermostat

knob to start the gas flow and the ignition spark. Wait about 10 seconds after the burner has been completely lit and then

release the knob. Make sure that the burner remains on, otherwise repeat the operation.

The ignition device should not be used for more than 15 seconds. If after that period the burner still has not

been lit, do not use the device and open the door of the room or wait at least 60 seconds before trying to light

the oven again.

WARNING: when trying to light the oven, the door must always be open.

The gas oven operation is indicated by a blue light

Verify that aspect flame of the oven burner be completely blue and with an aspect as indicated in figure

NOTICE: when using the oven for the first time it should be operated for 15-30 minutes at a temperature of

about 500°F/260°C without cooking anything inside in order to eliminate any moisture and odours from the

internal insulation.

During normal oven use, after lighting the burner and setting the desired temperature, wait about 15 minutes before

putting in any food to preheat the oven.

The oven is equipped with 4 guides at different heights level which can be used to insert shelves or the tray. To keep the

oven as clean as possible it is recommended to cook meat on the tray or on the shelf that has been inserted inside the

tray. The table below lists the general cooking times and the position of the tray for different types of foods. Personal

experience will help to determine any variations in the values reported in the table. In any case, it is recommended to

follow the instructions of the specific recipe being used.

This type of oven is equipped with a fan. The fan convection creates forced-air circulation in the horizontal direction.

Thanks to this type of operation, the ventilated oven can be used for different types of cooking at the same time, without

changing the taste of each food. Hot-air circulation guarantees a uniform distribution of heat. Pre-heating the oven is not

necessary, but for very delicate pastries, it is recommended to heat the oven before inserting the trays.

The convection system partially changes the various notions about traditional cooking. Meat no longer needs to be

turned while it is cooking and the rotisserie is no longer needed to cook a roast on the spit. Just put the meat directly on

the shelf.

GAS OVEN COOKING TABLE

MEAT

PORK ROAST 430/220 4 60-70

BEEF ROAST (YOUNG STEER) 480/250 4 50-60

BEEF ROAST 465/240 4 60-70

VEAL ROAST 430/220 4 60-70

LAMB ROAST 430/220 4 45-55

ROAST BEEF 445/230 4 55-65

ROAST HARE 450/235 4 40-50

ROAST RABBIT 430/220 4 50-60

ROAST TURKEY 450/235 4 50-60

ROAST GOOSE 450/225 4 60-70

ROAST DUCK 450/235 4 45-60

ROAST CHICKEN 450/235 4 40-45

FISH

PASTRY

FRUIT PIE 390/200 3 35-40

TEA CAKE 375/190 3 50-55

BRIOCHES 345/175 3 25-30

SPONGE CAKE 450/235 3 20

RING CAKE 375/190 3 30-40

SWEET PUFF PASTRIES 430/220 3 20

RAISIN LOAF 430/220 3 15-20

STRUDEL 355/180 3 15-20

SAVOIA COOKIES 375/190 3 15

APPLE FRITTERS 430/220 3 20

SAZOIARDI SANDWICH 430/220 3 20-30

TOAST SANDWICH 480/250 4 5

BREAD 430/220 3 30

PIZZA 430/220 3 20

TEMP °F/ °C HEIGHT MINUTES

390-440/200-225 3 15-25

17

Page 18

To activate the convection fan use the selector placed on control panel.

Turn the knob anti clockwise for activation of the convection fan +light

Turn the knob clockwise to turn on the oven light.

CONVECTION GAS OVEN COOKING TABLE

MEAT

PORK ROAST 320-340/160-170 3 70-100

BEEF ROAST (YOUNG STEER) 340-355/170-180 3 65-90

BEEF ROAST 340-375/170-190 3 40-60

VEAL ROAST 320-355/160-180 3 65-90

LAMB ROAST 285-320/140-160 3 100-130

ROAST BEEF 355-375/180-190 3 40-45

ROAST HARE 340-355/170-180 3 30-40

ROAST RABBIT 320-340/160-170 3 80-100

ROAST TURKEY 320-340/160-170 3 160-240

ROAST GOOSE 320-355/160-180 3 120-160

ROAST DUCK 340-355/170-180 3 100-160

ROAST CHICKEN 355/180 3 70-90

FISH

PASTRY

FRUIT PIE 355-390/180-200 3 40-50

TEA CAKE 390-430/200-220 3 40-45

BRIOCHES 340-355/170-180 3 40-60

SPONGE CAKE 390-445/200-230 3 25-35

RING CAKE 320-355/160-180 3 35-45

SWEET PUFF PASTRIES 355-390/180-200 3 20-30

RAISIN LOAF 445-480/230-250 3 30-40

STRUDEL 320/160 3 25-35

SAVOIA COOKIES 300-355/150-180 3 50-60

APPLE FRITTERS 355-390/180-200 3 18-25

SAZOIARDI SANDWICH 340-355/170-180 3 30-40

TOAST SANDWICH 445-480/230-250 4 7

BREAD 390-430/200-220 4 40

PIZZA 390-430/200-220 3 20

TEMP °F/ °C HEIGHT MINUTES

320-355/160-180 3 / 4

USING THE GAS BROILER

The gas broiler is controlled with the same gas oven knob, but turning it clockwise instead of counterclockwise (see the

gas oven use instructions), matching the symbol with the indicator. The broiler burner always operates at maximum and

therefore there is no minimum position. In addition, it is equipped with a safety device to prevent the flame from going

out. The gas broiler can also be ignited in different ways:

- Manual lighting: Just completely open the oven door, turn the knob so that the relative symbol matches the indicator,

while pressing the knob, and, at the same time, put a lit match next to the burner. Make sure that the burner is

completely lit and after about 10 seconds release the knob. Make sure that the burner remains on, otherwise repeat the

operation.

- Electric ignition: In this case, completely open the oven door, turn the knob so that the relative symbol matches the

indicator and, while keeping the knob pressed, press the knob with the spark symbol. Wait about 10 seconds after the

burner has been completely lit and then release the knob. Make sure that the burner remains on, otherwise repeat the

operation.

ATTENTION: To use broiler please utilize the proper broiler grid installed inside the grid enamelled tray supplied

with the appliance; broiler tray shall be supported by oven grid.

18

Page 19

WARNING: As with the oven, the broiler must be lit with the door completely open.

The gas broiler can be used to broil foods on the oven shelf .

The gas broiler operation is indicated by a blue light

IMPORTANT: when broiling food keep the door closed..

Verify that aspect flame of the broiler burner be completely blue and with an aspect as indicated in figure

Note: The use of a gas cooking appliance produces heat and humidity in the room where it is installed. Therefore, proper

ventilation in the room is needed and natural ventilation openings must remain unobstructed and activating the

mechanical exhaust fan/range hood. Intensive and continuous use of the appliance may require additional ventilation, for

example by opening a window, or increasing the power of the mechanical exhaust fan/range hood, if installed.

Note: the cooker is equipped with the cooling fan that starts operation each time the oven knob is on a position different

from 0 (zero). The fan circulates the air between the control panel and the oven door and also allows the control panel

and the oven door stay at a warm temperature during the appliance operation in any condition.

CLEANING THE APPLIANCE:

Never use abrasive cleaners

Before cleaning the appliance it should be disconnected from the power supply.

Cleaning the work surface: periodically clean the burner heads, the cast iron pan supports and the burner caps using

warm water.

Any spillage must always be removed as soon as possible using a rag.

If it become difficult to open or close a valve, do not force it, but immediately request the assistance of the

technical service personnel.

Cleaning the enamelled parts: Enamelled parts should be cleaned frequently with soapy water. Never use abrasive

powder. Do not leave acidi or alkaline substances on the enamelled parts (such as vinegar, lemon juice, salt, tomato

sauce, etc.) and do not wash the enamelled parts while they are still hot.

Cleaning the stainless steel parts: Clean the parts with soapy water and dry them with a soft cloth. The shine is

maintained by periodically using specific stainless steel cream cleaner. Never use abrasive powders. Use specific

stainless steel cream cleaner to eliminate the glue remains afther the elimination of the blue plastic protection film on the

worktop after installation.

Cleaning the burner caps: Lift the burner caps from the burner heads and wash them in soapy water and dry

thoroughly. Before replacement on the burner head ensure that the holes are not clogged.

Cleaning the inner glass door: Clean the glass with warm soapy water using a sponge. A spatula can be used to

remove burner fat if used gently.

ATTENTION: while cleaning the door make sure to avoid any spillage in the venting holes on the top part of the door. To

clean inside the door it is necessary to disassemble the door through a service engineer.

ATTENTION: for further details about cleaning of the appliance, please contact your applliance retailer.

AFTER SALE SERVICE:

Please note here below details for after save service.

Refer to warranty certificate for warranty condiftions

Dealer /Importer: Name, address, phone

SERVICE CENTERS

Name

Phone

MANUFACTURER:

BERTAZZONI SPA

VIA PALAZZINA, 8 – 42016 – GUASTALLA (REGGIO E.) ITALY

Tel. +39 0522/226411 – telefax +39 0522/226440 – http://www.bertazzoni-italia.com

19

Page 20

SPARE PARTS LIST

NUMBER COMPONENT DESCRIPTION QUANTITY

X24 4 GGV X - GAS COOKER

11 202387 BURNERS FLASK 1

18 202432 PART FOR DUAL WOK AND SEMI RAPID BURNERS 1

38 306003 THERMOSTAT CLIP 2

55 404229 WORKTOP FRONTGUARD 1

80 504160 COVER FOR SMALL FLAME SPREADER 1

81 504161 COVER FOR MEDIUM BURNER 1

82 504162 COVER FOR RAPID BURNER 1

85 504187 COVER IN FOR DUAL BURNER FLAME SPREADER 1

86 504186 COVER OUT FOR DUAL BURNER FLAME SPREADER 1

105 202509 UP SUPPORT FOR AXIAL COOLIN FAN 1

106 202487 DOWN SUPPORT FOR AXIAL COOLIN FAN 1

109 202491 INSIDE FLAP DOOR 1

117 101374 PROTECTION FOR VENTILATED OVEN 1

120 101048 BLACK OVEN DRIP TRAY 1

122 101098 GRILL TRAY 1

138 202492 DISHWARMER BOTTOM 1

160 202262 BRIDLE FOR FIXING GAS VALVES 1

205 410572 PROFILE FOR GLASS DOOR 1

206 410571 PROFILE FOR GLASS DOOR 1

207 308038 BUMPER 2

274 202486 HORIZONTAL VENT 1

311 309010 RING FOR GRID SUPPORT 4

329 309141 INSIDE DOOR SPACER 2

385 306024 SPRING FOR SPARK PLUG 5

424 415071 SPARK PLUG FOR DUAL BURNER 2

425 415054 SPARK PLUG 350MM 3

427 415074 SPARK PLUG FOR OVEN 1

429 415072 SPARK PLUG FOR GRILL 1

430 415064 ACCUMULATOR 4U 2

441 404217 GRID FOR OVEN 1

442 404216 SHELF OVEN 2

443 404497 GRID FOR TRAY 1

444 202407 FLASK HINGE 2

446 405082 OVEN DOOR HINGE 2

447 404218 GRID FOR OVEN 1

473 408069 SIMMER PLATE 1

478 410631 FLAP DOOR 1

544 504203 OVEN BURNER + SPARK PLUG + THERMOC. 1

546 505059 SUPPORT FOR GRILL BURNER NOZZLE 1

561 508025 THERMOCOUPLE MM300 1

562 508021 THERMOCOUPLE MM600 2

564 508036 THERMOCOUPLE 1

566 508034 THERMOCOUPLE ULTRA-RAPID BURNER 2

567 508035 THERMOCOUPLE 1

611 603020 OVEN CONVECTION FAN 1

612 603022 COOLING FAN 1

620 602039 COMMUTATOR 1

623 608046 OVEN BULB WITH HOLDER 1

648 601991 TERMINAL SEPARATOR 1

649 608047 SMALL WARNING LIGHT 1

649 608047 SMALL WARNING LIGHT 1

667 503128 THERMOSTAT 1

670 504128 SMALL FLAME SPREADER 1

671 504129 MEDIUM FLAME SPREADER 1

672 504130 RAPID FLAME SPREADER 1

675 504189 ULTRA RAPID FLAME SPREADER 1

702 408058 ADAPTER FOR WOK BURNER PAN SUPPORT 1

715 604070 DASYCHAIN SWITCH 1

760 510507 SMALL BURNER 1

761 510508 SEMI RAPID BURNER 1

762 510509 RAPID BURNER 1

764 510511 DUAL BURNER 1

Page 21

770 202490 WARMER DROWER UPPERSIDE PROTECTION PANEL 1

881 502148 GAS VALVE BY PASS 036 SEMI-RAPID 1

883 502150 GAS VALVE BY PASS 065 DUAL OUTER 1

884 502179 GAS VALVE BY PASS 029 SMALL/DUAL INNER 2

886 502180 GAS VALVE BY PASS 047 RAPID 1

917 200327 STAINLESS STEEL SIDE 2

929 202493 RIGHT VERTICAL VENT 1

930 202214 FEET SUPPORT 2

940 201168 FIXING FOR WORK TABLE 2

943 308031 BUMPER FOR C.I. GRIDS AND DISHWARMER 4

947 403449 HANDLE TERMINAL 2

965 408063 CAST IRON PAN SUPPORT 2 BURNERS 2

972 202360 WORK TABLE FIXING 4

1041 401904 GAS VALVE KNOB 3

1043 401905 GAS THERMOSTAT KNOB 1

1044 401906 ELECTRIC KNOB 1

1046 401961 DUAL IN KNOB 1

1047 401962 DUAL OUT KNOB 1

1143 910730 UPSTAND KIT 1

1406 403453 OVEN DOOR HANDLE 1

1407 406409 OVEN DOOR GLASS 2

1411 411103 GASKET FOR OVEN FRONT 4 SIDE 1

1415 602044 THERMOSWITCH FOR COOLING FAN 1

1419 411104 GASKET FOR OVEN FRONT ONE SIDE 1

1421 406410 INNER OVEN GLASS 1

1508 410629 STAINLESS STEEL OVEN DOOR 1

1602 210620 CONTROL PANEL 1

1603 309119 BRIDLE FOR FIXING GAS VALVES/THERMOSTAT 1

1608 501778 ALL.TUBE FOR OVEN BURNER 1

1609 505056 SUPPORT FOR OVEN BURNER NOZZLE 1

1614 201182 BACK PANEL 1

1615 202477 CONTROL SUPPORT 1

1617 608045 SMALL BLUE BUD 1

1622 608025 SMALL RED BUD 1

1624 200371 WORK TABLE 1

1627 501777 GAS COLLECTOR 1

1628 501784 TUBE FOR RIGHT FRONT BURNER 1

1631 501785 TUBE FOR RIGHT BACK BURNER 1

1639 202494 LEFT VERTICAL VENT 1

1644 414048 S.STEEL LEG 4

1645 414031 BASE FOR LEGS 4

1646 501779 GRILL THERMOSTAT TUBE 1

1661 202495 OVEN BURNER COMPARTMENT BOTTOM 1

1671 101147 GAS OVEN PANEL M6D2 1

1673 101404 BACK OVEN BODY 1

1674 101406 OVEN TOP PANEL BLACK 1

1677 101405 FRONT PANEL BLACK 1

1679 101190 SIDE PANEL FOR OVEN 2

1685 201175 BACK VENT STACK 1

1686 201176 FRONT VENT STACK 1

1687 202489 BACK ENCLOSURE METAL PANEL 1

1705 410630 OVEN GLASS SUPPORT 1

1801 501783 TUBE FOR LEFT BACK BURNER 1

1803 501787 TUBE FOR EXTERNAL DUAL BURNER 1

1804 501786 TUBE FOR INTERNAL DUAL BURNER 1

2100 308036 BUMPER 2

4106 405078 HINGE FOR FLAP DOOR 2

4301 200376 SIDE PROFILE 1

4302 200377 SIDE PROFILE 1

5140 504202 GRILL BURNER + SPARK PLUG + THERMOC. 1

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Installation, Service and User Instructions

(instruction en francais page 12)

Built-in gas hotplates

DIMENSIONS: 23

Models P24 4 00 X

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR’S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

OBSERVE ALL GOVERNING CODES AND ORDINANCES.

In Massachusetts: All gas products must be installed by a "Massachusetts" license

plumber or gasfitter. A "T" handle type manual gas valve must be installed in the gas

supply line to this appliance.

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

1/4

’’

[P680..T4X5D]

BERTAZZONI

(590 mm)

(W) x 19

2/3

’’

(500 mm)

(D)

Do not store or use gasoline or other flammable vapors and liquid in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch.

- Do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow

the gas supplier’s instructions.

- If you cannot reach your gas suppliers, call the fire department.

Installation and service must be performed by a qualified installer, service agency

or the gas supplier.

Read this instruction booklet before installing and using the appliance.

The manufacturer will not be responsible for any damage to property or to persons caused by

incorrect installation or improper use of the appliance.

The manufacturer reserves the right to make changes to its products when considered necessary and useful,

without affecting the essential safety and operating characteristics.

This appliance has been designed for non-professional, domestic use only.

310295

Page 30

INDEX:

Installation manual……………………………………..……………………………..pag.2

Inserting the hotplate……………………………………………..…………………..pag.3

Requirements……………………………………..……………………………….…..pag.3-4

Attaching the hotplate……………………………………..………………………….pag.4

Gas connection……………………………………..…………………………………pag.4-5-6

Electrical connection……………………………………..……………………….…..pag.6

Wiring diagrams……………………………………..…………………………….…..pag.6

Instructions for assembly of load bearing bottom protection.…………………….pag.6-7

Room ventilation…………………………………….…………………………………pag.7

Location and venting…………………………………….…………………………….pag.7

Replacement of nozzles……………………………………..………………………..pag.7

Regulation of burners……………………………………………...………………….pag.8

Service & maintenance instructions……………………………..…………………..pag.8

User instructions……………………………………………..……………………….. pag.9

Descriptions…………………………………………………………………………….pag.9

Using burners……………………………………………………..……………………pag.9-10

Cleaning the appliance……………………………………………..…………………pag.10

Installation manual

This appliance shall only be installed by an authorized person. This appliance shall be installed in

accordance with the manufacturers installation instructions, IMPORTANT: this appliance must be

installed in accordance with the norms in force of the country concerned.

The installation of this appliance must conform to local codes and ordinances. In the absence of

local codes, Installations must conforms to American National Standards, National Fuel Gas Code

ANSI Z223.1 – latest edition** or B149.1.

If local codes permit, a flexible metal appliance connection with the new AGA or CGA certified

design, max. 5 feet (1,5 m) long, ½” I.D. recommended for connecting this cooktop to the gas supply

line. Do not bend or damage the flexible connector when moving the cooktop. The pressure regulator

has ½” female pipe thread. You will need to determine the fitting required, depending on the size of

your gas supply line, the flexible metal connector and the shutoff valve.

The appliance, when installed, must be electrically grounded in accordance with local codes or, in

the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

The appliance and its individual shutoff valve must be disconnected from the gas supply piping

system any pressure testing of that system at test pressure in excess of ½ psi (3,5 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply piping system at test pressures equal

to or less than ½ psi (3.5 kPa).

For use with a pressure regulator. The regulator supplied must be used with this appliance.

The gas appliance pressure regulator must be set for the gas with which the appliance is used.

This appliance can be used with Natural Gas and LP Gas. It is shipped from the factory adjusted for

use with Natural Gas: CONVERSION FIXED ORIFICES ARE LOCATEDIN THE LITERATURE PACK

SUPPLIED WITH THE UNIT.

Injectors kit for the change of type of gas are contained inside the package jointly with the hob

installation kit and Instruction booklet.

The maximum inlet gas supply pressure incoming to the gas appliance pressure regulator is 20’’

water column (5 kPa) .

The minimum gas supply pressure for checking the regulator setting shall be at least 1“ w.c. (249 Pa)

above the inlet specified manifold pressure to the appliance (this operating pressure is 4” w.c.

(1.00 kPa) for Natural Gas and 11” w.c. (2.75 kPa) for LP Gas).

ATTENTION: A manual valve shall be installed in an accessible location in the gas line external to the

appliance for the purpose of turning on or shutting off gas to the appliance

WARNING: Do not use aerosol sprays in the vicinity of this appliance while it is in operation

2

Page 31

Inserting the hotplate

After having removed the various loose parts from the internal and external packing, make sure that the

hotplate in not damaged and is suitable for the specific gas usage. The gas type label is on the underside of

the hotplate base.

In case of doubt, do not use the appliance and contact skilled personnel.

Keep all the packing parts (polystyrene foam, cardboard, staples, etc.) away from children.

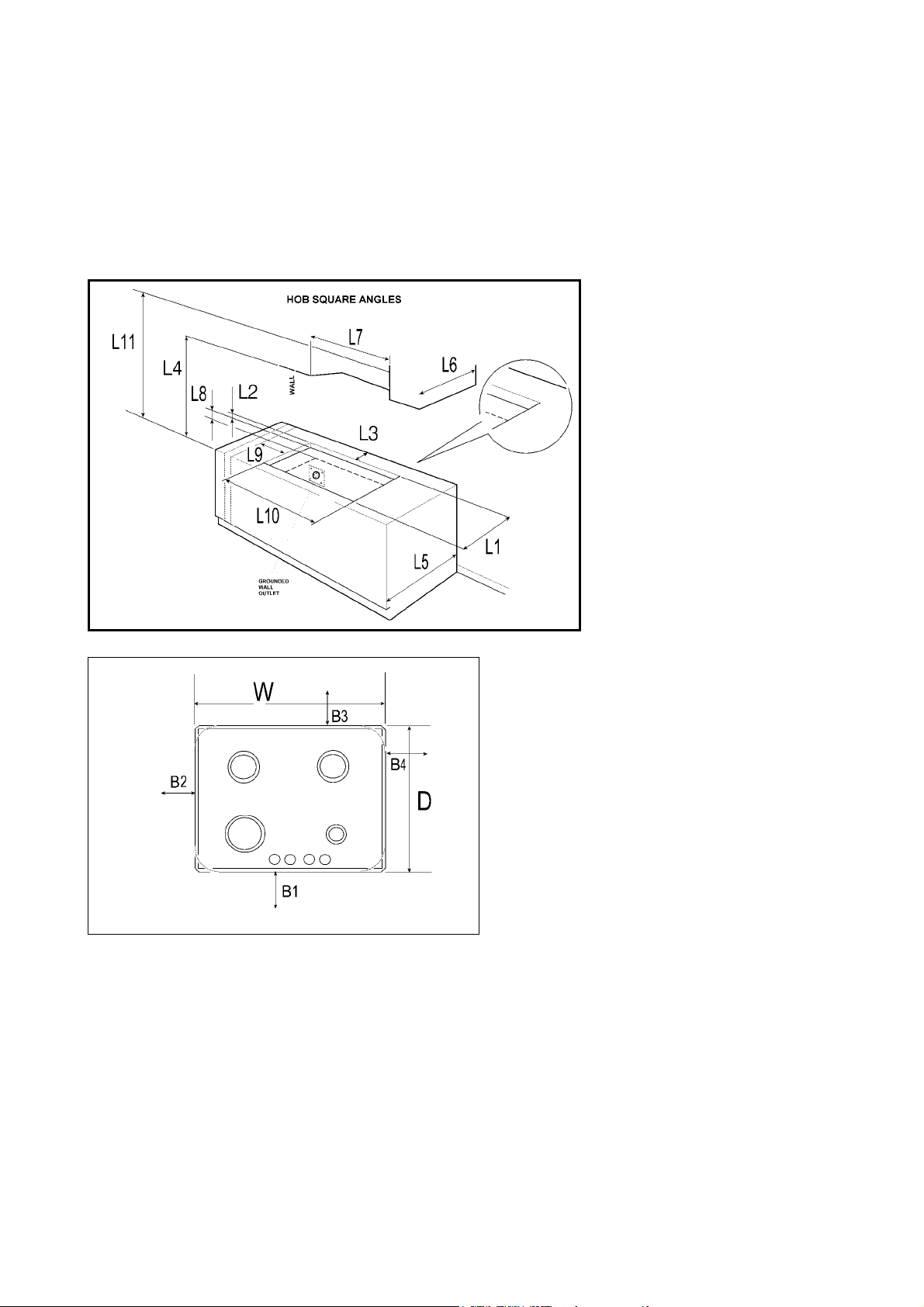

Consider the critical dimensions of the appliance, before making an opening in the top surface of the bench

top. (relative measurements as per Fig 1- 2).

fig.1

fig. 2

Requirements

1. Overhead clearances (Minimum values)

The minimum overhead clearances shall be in accordance with the minimum values indicated in the table

n.1 and are shown and in the fig. 1- 2

Range hoods and exhaust fans shall be installed in accordance with the manufacturer’s instructions.

However, in no case shall the clearance between the top of the highest burner of the cooking appliance and

the range hood be less than 30”( 762mm). See Fig. 1- 2.

Any other downward facing combustible surface less than 600mm above the top of the highest burner shall

be protected for the full width and depth of the cooking surface area.

However, in no case shall this clearance to any surface be less than 17

Maximum depth for the overheads cabinet is 13” (330mm)

3/4

”(450mm.)

3

Page 32

2. Side clearances (Minimum values)

The different side clearances shall be in accordance with the minimum values indicated in the table n.1 and

are shown and in the fig. 1

The cooking surface area is defined as that part of the appliance where cooking normally takes place and

does not include those parts of the appliance containing control knobs.

Table n.1

Min. Clearances inches (mm) Min. Clearances inches (mm)

18

7/8”

L1

L2

L3

1

3

(480)

9/16

“ (40)

3/8

“ (86)

L10

L11

W

22 1/2“ (570)

32“ (813)

23

1/4

“ (590)

L4

L5

L6

L7

L8

L9

18” (457)

24” (610)

13” (330)

23

1/4

“ (590)

3/4

“ (20)

3

15/16

” (100)

D

B1 (*)

B2 (*)

B3 (*)

B4 (*)

R

19

2/3

“ (500)

1

3/8

“ (35)

3

1/2

“ (90)

3” (76)

3 1/2“ (90)

5

1/8

“(135)

(*) Note:

-B1 is the min. clearance between the front edge of the appliance and the front edge of the cabinet.

-B2 and B4 are the min. clearance between the left/right side edge of the appliance and the side wall (if

present).

-B3 is the min. clearance between the back edge of the appliance and the back wall.

Attaching the hotplate

To prevent liquids from leaking accidentally into the underlying storage space, the appliance is equipped with

a special gasket. To apply this gasket, carefully follow the instructions in Fig. 3. Lay out the protective sealing

strips along the edges of the opening in the bench top and carefully overlap the strip end. (See Fig. 3). insert

the hotplate into the bench top opening. With a screwdriver assemble the brackets A to the hotplate bottom

by means of the screws B. (See Fig. 4). Slide the hooks into position and secure them with the screws.

Trim the part of the sealing strips which extend beyond the hotplate base

fig.3 fig.4

Gas connection

Before connecting the appliance to the gas supply, first remove the plastic plug on which is pressfitted into the gas inlet union; to remove, just pull it off.

1. Check the ‘gas type’ sticker attached to the hotplate. Details of the injector sizes used are recorded on the

data plate located on the base of the appliance.

2. This appliance shall be installed in accordance with installation requirements of the local gas authority of

the appropriate installation code.

3. Before installing the hotplate consider the location of the gas supply and routing the gas line.(Refer fig.5B)

4

Page 33

4. For LPG models the gas supply is connected to the regulator which is supplied loose. The inlet connection

has a 1/2” B.S.P. male thread. IT IS ESSENTIAL THAT THE ELBOW ON THE APPLIANCE BE HELD

FIRMLY WITH A SPANNER WHEN CONNECTING THE SUPPLY. DO NOT OVER TIGHTEN. The

regulated pressure For LPG is 11” w.c. (See Fig. 5A).

5. For NG models the gas supply is connected to the regulator which is supplied loose. The inlet connection

has a 1/2” B.S.P. male thread. IT IS ESSENTIAL THAT THE ELBOW ON THE APPLIANCE BE HELD

FIRMLY WITH A SPANNER WHEN CONNECTING THE SUPPLY. DO NOT OVER TIGHTEN. The

regulated pressure For NG is 4” w.c. (See Fig. 5A).

6. For gas inlet position of appliance refer Fig 5A and 5B. After installing the gas supply and making all

connections check thoroughly for possible leaks. Turn all control knobs on the unit to ‘OFF’ position. Open

the valve on the gas supply. Using a soap and water solution check each gas connection one at the time, by

brushing the solution over the connection. Presence of bubbles will indicate a leak. Tighten the fitting and recheck for leaks. If it is not possible to correct the leak, replace fitting. Under no circumstances use matches

or flame for checking leaks.

It is essential that the gasket and the pressure test point stopper are properly installed to avoid gas leakage

Fig.5B

A

B

C

D

Fig.5A

7.To checking inlet pressure at the appliance operate as follow:

8. Turn on appliance control cock and light each burner. Check for a clear blue flame without yellow tipping.

If burners show any abnormalities check that they are located properly and in line with the injector nipple.

a) Disconnect electric power before pressure checking be carried out.

b) Take off one of the gas burner cap and the relative flame spreader in order to get access to the

burner injector.

c) Put in position the pressure detector directly on the burner injector afterward open the relative burner

knob at maximum position keeping it pressed, then measure the outlet pressure from the burner

injector.

d) Once the pressure checking has been carried out, replace the burner cap and flame spreader in the

correct and original position and re-connect electric power to the appliance.

Inches mm

1

9/16

” 45

8 ¼” 210

8 ½” 215

1/8

” 22

5

Page 34

9. Sometimes the burners will not ignite immediately and seem to ‘blow’ slightly when they do ignite. This

usually due to air in the gas lines, which will clear itself within seconds.

10. If after following the instructions given, satisfactory performance cannot be obtained, contact the local

gas authority for advice and assistance.

Electrical connection

The connection of the hobs to mains is effected via the flex and the three pin plug located underneath the

hotplate. The appliance operate at a main voltage of 120V a.c., frequency 60Hz. Electric power absorption is

about 1W.

WARNING: Electrical Grounding Instructions: This appliance is equipped with a (three-prong)

grounding plug for your protection against shock hazard and should be plugged directly into a

properly grounded receptable. Do not cut or remove the grounding prong from this plug.

Wiring diagrams

Wiring diagram description

1. Cable terminal

2. Spark generator

3. Ignition spark

L. Black

N. White

T. Green (earth)

Instructions for assembly of load bearing bottom protection

1 SCREW M5

2 LOAD BEARING

BOTTOM PROTECTION

3 RIVET M5

4 LOAD BEARING

BOTTOM

5 WORK TABLE

After the installation of the hob (5) proceed with the assembly of the load bearing bottom protection (2)

placing it in the position showed in picture and fixing it with screws supplied (1) with inserts (3) present on

the load bearing bottom (4).

6

Page 35

SECTION VIEW OF THE RIGHT ASSEMBLY

Room ventilation – Location and venting.

ATTENTION: An exhaust fan may be used with the appliance; in each case it shall be installed in

conformity with the national standards in force.

ATTENTION: Exhaust hood operation may affect other vented appliances; in each case it shall be

installed in conformity with the national standards in force.

Conversion to different types of gas

Before carrying out any maintenance work, disconnect the appliance from the gas and electric

supply. For Natural Gas fit regulator assembly described in Fig. 5A. For LP Gas fit assembly

described in fig. 5A.

- CHANGING THE NOZZLES FOR USE WITH OTHER TYPES OF GAS:

To change the nozzles of the burners use the following procedure:

Lift up the burners and unscrew the nozzles ( Fig. 6) using an adjustable spanner of 7 mm and change the

nozzles with those designed for the new gas supply according to the information given in TABLE A shown

below.

fig.6 fig.7

TABLE A: Adapting to different types of gas

Gas NATURAL (A) LP (E)

Burner Pressure Inj. size Input Rate Simmer Rate Pressure Inj. size Input Rate Simmer Rate By-pass size

Type [i.w.c.] 1/100mm [BTU/h] [BTU/h] [i.w.c.] 1/100mm [BTU/h] [BTU/h] [1/100mm]

Auxiliary 0,90 3400 900 0,54 3400 900 29

Semi-Rapid 4" 1,18 6100 1500 11" 0,70 6100 1500 37

Triple Ring 1,65 11900 5300 1,02 12300 5300 73

CAUTION: save the orifices removed from the appliance for future use

7

Page 36

Regulation of burners

Regulation of the "MINIMUM" on the burners

To regulate the minimum on the burners carry out the following procedure indicated below:

1) Turn on the burner and put the knob onto position MINIMUM ( small flame ).

2) Remove the knob ( Fig. 7) of the tap which is set for standard pressure. The knob is found on the bar of

the tap itself.

3) Beside the tap bar on the work top, insert a small slotted screwdriver into the hole on the vale rod (Fig. 7)

and turn the choke screw to the right or left until the flame of the burner is regulated in the most suitable way

to MINIMUM.

4) Make sure that that the flame does not go out when changing the position quickly from MAXIMUM to the

MINIMUM position.

ATTENTION: The regulation described above can be carried out only with burners using natural gas,

while with burners using propane gas the screw must be fully screwed in, in a clockwise direction.

Adaptation of the pressure regulator for use with different type of gas

The pressure regulator supplied with the appliance is a convertible type pressure regulator for use with

Natural Gas at a nominal outlet pressure of 4” w.c. or LP gas at a nominal outlet pressure of 11” w.c. and it is

pre-arranged from the factory to operate with one of these gas/pressure as indicated in the pre-arranging

labels affixed on the appliance, package and Instruction booklet.

To convert the regulator for use with the other gas different from which one it is pre-arranged it is enough

perform the following operations:

1) Unscrew by hand the upper metal stopper of the regulator (Fig. 5A).

2) Unscrew by hand the white plastic piece screwed under the above mentioned metal stopper, afterward

screw it again in opposite way under the metal stopper (for gas reference see the written “LP” and “NAT” with

relative indicating arrows on the white piece).

3) Screw again by hand the metal stopper in the original position on the regulator.

Operating in this way the gas regulator is converted for use with the other gas/pressure.

Service & maintenance instructions

Service and maintenance only to be carried out by an authorised person

To replace parts such as burners, valves and electric components, the hotplate must be removed from the

bench top by releasing the attachment hooks, loosening the attachment screws of each burner, unscrewing

the hotplate attachments nuts which are visible at the bottom of the surface, removing the hotplate top and

finally replacing the defective parts.

Note: if the valves must be replaced, first disassemble the ignitions switches wires.

It is recommended to replace the valve gaskets each time the valve is replaced, thus ensuring a perfect seal

between the body and the gas train.

WARNING: Disconnect power before servicing unit.

For the location of the wall receptable for the connection of the three-pin earthed plug of the

appliance, see indications given in Fig. 1- 2

WARNING: After first installation of the appliance or after any service intervention concerning main

gas parts of the appliance, make the leak test using water with soap on the gas connections in order

to verify the correct installation. Do not use fire for gas leak testing.

8

Page 37

User instructions

WARNINGS:

Keeping appliance area clear and free from combustible materials, gasoline and other flammable

vapors and liquid.

Do not store dangerous or flammable material in the cabinet areas above appliance; store them in a

safe place in order to avoid potential hazards.

For safe use of appliance, do not use it for space heating.

Do not use aerosol sprays in the vicinity of this appliance while it is in operation

For description of hotplates refer to installation instructions.

Descriptions

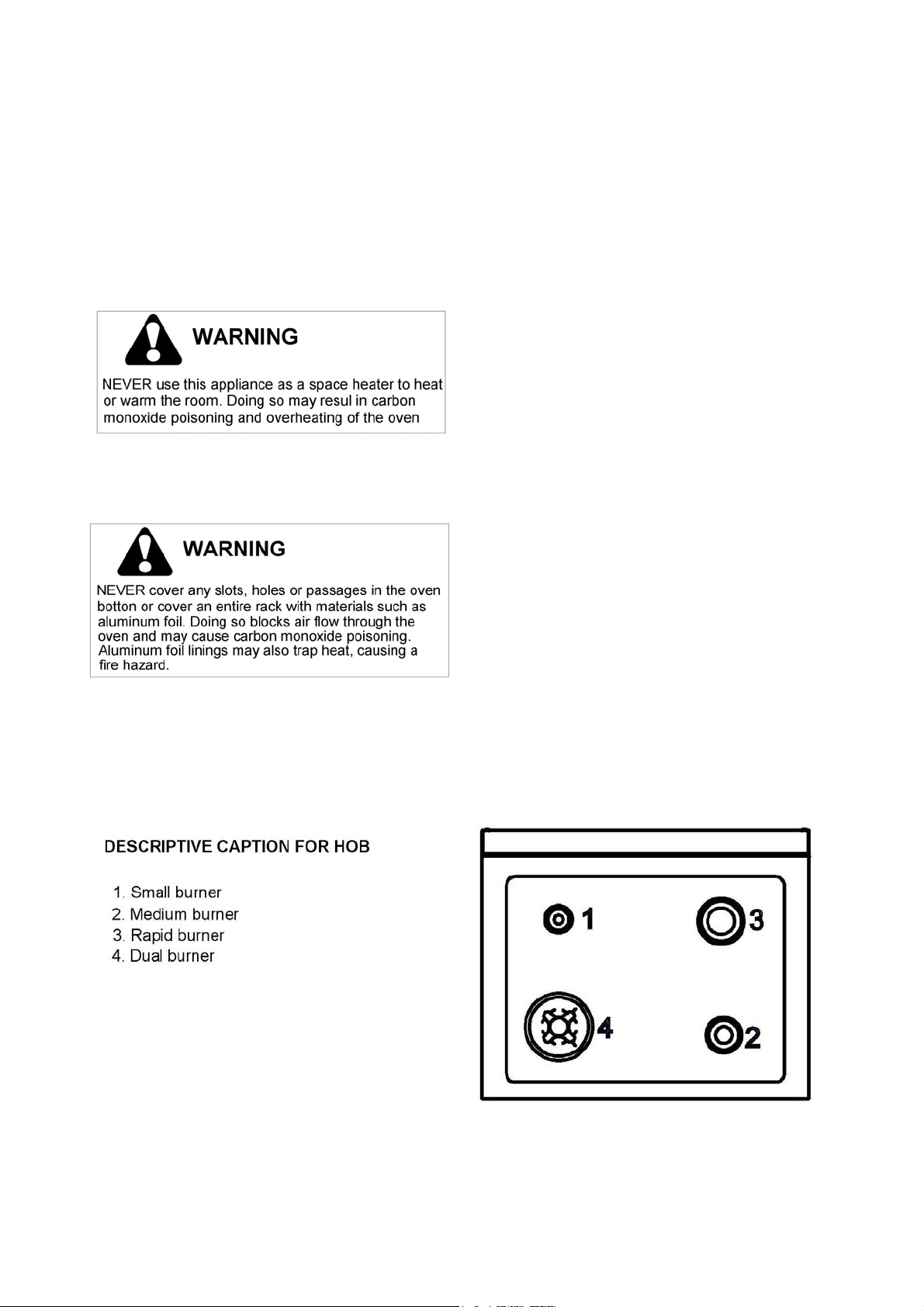

DESCRIPTIVE CAPTION FOR HOB

1. Small Burner

2. Medium burner

3. Double ring (wok) burner

4. Front left side burner control knob

5. Back left side burner control knob

6. Back right side burner control knob

7. Front right side burner control knob

Using burners

A diagram is etched on the control panel above each knob which indicates which burner corresponds to that

knob.

Manual ignition:

Manual ignition is always possible even when the power is cut off or in the event of prolonged power failure.

Turn the knob that corresponds to the burner selected counterclockwise to the MAXIMUM position at the

etched star (large flame) and place a lit match up to the burner.

Automatic electric ignition:

Turn the knob that corresponds to the burner selected counterclockwise to the MAXIMUM position at the

etched star (large flame) and then press the knob down to activate the spark ignition. Once ignited, keep

pressing the knob for about 10 seconds to allow the flame to heat the thermocouple. If the burner does not

remain alight after releasing the knob repeat the above procedure,

Note: It is recommended not to try to ignite the burner if the relative flame cap is not in the correct position

Tips for using burners correctly:

WARNING: During use of each gas burner(s) adjust the burner flame size properly so it does not

extend beyond the edge of the cooking utensil. This is an instruction based on safety considerations

- Use suitable pots for each burner (see Fig. 16 and Table B)

- When the liquid is boiling, turn down the knob to the MINIMUM position.

- Always use pots with a cover.

9

Page 38

Fig.16

Table B

Burner Recommended pan diameters inches (mm)

Small 35½”-55

Medium 55

Double ring (wok) 86

1/8

2/3

”- 102

”-102

1/8

”(90 – 140)

3/8

”(140 – 260)

3/8

” (220 – 260)

Correct usage of pans:

- Dry the bottom of the pan before placing it on the hotplate.

- Use pots with a flat, thick bottom, except for wok cooking.

- When using the burners, ensure that the handles of the pans are correctly positioned. Keep children away

from the appliance.

- When cooking foods with oil and fat, which are very flammable, do not leave the appliance unattended.

WARNING: If the power is cut off, the burners can be lit with matches.

The burners equipped with a safety thermocouple can only be lit when the knob is in the MAXIMUM position

(large flame etching).

Note: The use of a gas cooking appliance produces heat and humidity in the room where it is installed.

Therefore, proper ventilation in the room is needed and natural ventilation openings must remain

unobstructed and activating the mechanical exhaust fan/range hood. Intensive and continuous use of the

appliance may require additional ventilation, for example by opening a window, or increasing the power of

the mechanical exhaust fan/range hood, if installed.

Cleaning the appliance:

Never use abrasive cleaners

Before cleaning the appliance it should be disconnected from the power supply.

Cleaning the work surface: periodically clean the burner heads, the cast iron pan supports and the burner caps using

warm water.

Any spillage must always be removed as soon as possible using a rag.

If it become difficult to open or close a valve, do not force it, but immediately request the assistance of the

technical service personnel.

Cleaning the enamelled parts: Enamelled parts should be cleaned frequently with soapy water. Never use abrasive

powder. Do not leave acidi or alkaline substances on the enamelled parts (such as vinegar, lemon juice, salt, tomato

sauce, etc.) and do not wash the enamelled parts while they are still hot.

Cleaning the stainless steel parts: Clean the parts with soapy water and dry them with a soft cloth. The shine is

maintained by periodically using specific stainless steel cream cleaner. Never use abrasive powders. Use specific

stainless steel cream cleaner to eliminate the glue remains afther the elimination of the blue plastic protection film on the

worktop after installation.

Cleaning the burner caps: Lift the burner caps from the burner heads and wash them in soapy water and dry

thoroughly. Before replacement on the burner head ensure that the holes are not clogged.

ATTENTION: for further details about cleaning of the appliance, please contact your applliance retailer.

10

Page 39

AFTER SALE SERVICE:

Please note here below details for after save service.

Refer to warranty certificate for warranty condiftions

Dealer /Importer: Name, address, phone

SERVICE CENTERS

Name

Phone

MANUFACTURER:

BERTAZZONI SPA

VIA PALAZZINA, 8 – 42016 – GUASTALLA (REGGIO E.) ITALY

Tel. 0522/226411 – telefax 0522/226440 – http://www.bertazzoni-italia.com

11

Page 40

Installation, Service et Instructions pour l’Utilisateur

Tables de cuisson gaz à encastrer

DIMENSIONS: 23

Modèles P24 4 00 X

IMPORTANT: A CONSERVER POUR L’UTILISATION DE L’INSPECTEUR ELECTRIQUE

LOCAL.

LIRE ET CONSERVER CES INSTRUCTIONS POUR LES REFERENCES FUTURES.

OBSERVER TOUS LES CODES ET LES ORDONNANCES PRINCIPAUX.

Dans Le Massachusetts : Tous les produits à gaz doivent être installés par un plombier

ou un préposé au gaz autorisé du "Massachusetts". Un clapet à gaz de poignée à "T"

manuel doit être installé dans la canalisation d'alimentation de gaz à cet appareil.

ATTENTION: Au cas où les informations dans ce manuel ne seraient pas suivies

avec précision, un incendie ou une explosion peuvent se produire en provoquant

des dommages matériels, des blessures ou la mort.

1/4

’’

(590 mm)

BERTAZZONI

(W) x 19

2/3

’’

(500 mm)

[P680..T4X5D]

(D)

Ne pas stocker ou utiliser d’essence, d’autres vapeurs ou liquides inflammables à

proximité de celui-ci ou de n’importe quel autre appareil.

CE QU’ON DOIT FAIRE EN CAS D’ODEUR DE GAZ

- N’essayez d’allumer aucun appareil.

- Ne touchez aucun interrupteur électrique.

- N’utilisez aucun téléphone dans votre établissement.

- Appelez immédiatement votre fournisseur de gaz par le téléphone d’un voisin.

Suivez les instructions du fournisseur de gaz.

- Si vous ne pouvez pas atteindre vos fournisseurs de gaz, appelez les pompiers.

L’installation et le service doivent être exécutés par un installateur qualifié, une

agence de service ou par le fournisseur du gaz.

Lisez ce livret d’instructions avant d’installer ou employer l’appareil.

Le fabricant ne sera responsable d’aucun dommage à la propriété ou aux personnes provoqué par

l’installation incorrecte ou l’utilisation inexacte de l’appareil.

Le fabricant se réserve le droit d’apporter des modifications à ses produits au cas où il le jugerait nécessaire

ou utile, sans influencer les caractéristiques essentielles de sécurité et de fonctionnement.

Cet appareil a été uniquement conçu pour une utilisation non-professionnelle et domestique.

12

Page 41

INDEX:

Manuel pour l’installation..…………………………………..………………………...page 13-14

Insertion de la table de cuisson..………………………………..………………….. .page 14

Exigences…..……………………………………..……………………………….….. page 14

Fixation de la table de cuisson….………………………..………………………….. page 15

Branchement du gaz………………………………..………………………………….page 16

Branchement électrique…………………………………..……………………….…..page 17

Schéma de câblage..………………………………..…………………………….…...page 17

Instructions de montage de la protection du fond portant …..…………….………page 18

Ventilation du local……………………………………………………………… ……page 18

Positionnement et dégazage…………………………….……………………………page 18

Remplacement des becs….…………………………………..………………………page 19

Réglage des brûleurs…. …………………………………………...…………………page 19-20

Instructions de service et d’entretien………………………………..……………....page 20

Instructions pour l’utilisateur……………………………………………..………… . page 20

Descriptions…………………………………………………………………………….page 21

Utilisation des brûleurs…………………………………………..……………………page 21-22

Nettoyage de l’appareil……………………………………………..…………………page 22

Manuel pour l’installation

Cet appareil devra uniquement être installé par une personne autorisée. Il devra être installé selon

les instructions d’installation des fabricants. IMPORTANT: cet appareil doit être installé selon les

normes en vigueur du pays concerné.

L’installation de cet appareil doit se conformer aux codes et aux ordonnances locaux. En l’absence

de codes locaux, l’installation de cet appareil doit se conformer aux Normes Nationales Américaines,

‘’National Fuel Gas Code’’ ANSI Z223.1 – dernière édition** ou B149.1.

Au cas où les codes locaux le permettraient, utilisez un dispositif de raccordement en métal flexible

avec le nouveau dessin certifié AGA ou CGA, de 1,5 mètres de longueur maximum, ½” I.D.

recommandé pour le branchement de cette table de cuisson au conduit d’amenée des gaz. Ne pliez

pas ou n’endommagez pas le connecteur flexible en déplaçant la table de cuisson. Le régulateur de

pression a un filetage au pas du gaz femelle de ½”. Vous devrez déterminer le raccordement

demandé, selon la dimension du conduit d’amenée des gaz, du connecteur en métal flexible et du

robinet d’arrêt.

L’appareil, lorsqu’il est installé, doit être mis à la terre selon les codes locaux ou, en l’absence de

ceux-ci, avec le ‘’National Electrical Code’’, ANSI/NFPA 70.

L’appareil et son robinet d’arrêt individuel doivent être débranchés du système du conduit d’amenée

des gaz pendant tous les essais sous pression de ce système à une pression d’essai supérieure à ½

psi (3,5 kPa).

L’appareil doit être isolé du système du conduit d’amenée des gaz, en fermant son robinet d’arrêt

individuel pendant tous les essais sous pression de celui-ci à une pression égale ou inférieure à ½

psi (3.5 kPa).

Pour l’utilisation avec un régulateur de pression. Le régulateur fourni doit être employé avec cet

appareil.

Le dispositif de réglage de pression doit être prédisposé pour le gaz avec lequel l’appareil est

employé.

Cet appareil peut être utilisé avec Gaz Naturel ou Gaz LP. Il est livré par l’usine et réglé pour

l’utilisation avec Gaz Naturel: LES INJECTEURS FIXE POUR LA CONVERSION DU GAZ SONT PLACE’

DANS L’EMBALLAGE IN DOTATION AVEC L’APPAREIL.

Le kit d’injecteurs pour le changement du type de gaz est contenu dans l’emballage avec le kit

d’installation de la table et le livret d’instructions.

13

Page 42

La pression d’alimentation maximum du gaz en entrée dans le régulateur de pression de l’appareil à

gaz est de 20’’ colonne d’eau (w.c.) (5 kPa)

La pression d’alimentation minimum du gaz pour le contrôle du réglage du régulateur doit être au

moins de 1“ colonne d’eau (w.c.) (249 Pa) au-dessus de la pression du collecteur d’admission à

l’appareil spécifiée (cette pression de fonctionnement est de 4” colonne d’eau (1.00 kPa) pour le Gaz

Naturel et 11” colonne d’eau (2.75 kPa) pour le Gaz LP).

ATTENTION: Une valve manuelle doit être installée dans une position accessible dans la ligne du gaz

externe à l’appareil afin d’ouvrir ou d’arrêter le gaz à l’appareil.

AVERSTISSEMENT: Ne pas utiliser de pulvérisateurs d’aérosol à proximité de cet appareil lorsqu’il

est en fonction.

Insertion de la table de cuisson

Après avoir enlevé les différentes parties libres à l’intérieur et à l’extérieur de l’emballage, assurez-vous que

la table de cuisson ne soit pas endommagée et qu’elle soit appropriée pour l’utilisation du gaz spécifique.