Page 1

REF30PIXL

REF30PIXR

REF30PRL

REF30PRR

REF36PIXL

REF36PIXR

REF36PRL

REF36PRR

INSTALLATION GUIDE

NOTICE D’INSTALLATION

EN

FR

Page 2

IMPORTANT

Dimensions in parentheses are in inches: mm(in).

Weights in parentheses are in pounds: kg (lb).

Temperatures in parentheses are in Fahrenheit degrees: °C(°F)

Page 3

Important Instructions

Installation Guide

Index

Page

10

11

13

14

15

16

3

Important safety instructions

Children safety

Technical Requirements

4

5

6

Appliance features and installation requirements

Installation niche features: Integrated Series (BI)

Installation niche requirements: Stainless Integrated Series (BKI)

Preparing To Install

7

8

Transport to installation site and unpacking

Electrical and Water connection

Levelling

Panels Mounting

Door and Bottom-Drawer overlay panels layout

Overlay panels mounting brackets layout

Panels Dimensions

Mounting the handles on Integrated units

Mounting panels to the door and the drawer of Integrated units

EnglishFrançais

18

19

21

22

23

24

25

Installation

Built-in installation of single appliance

Built-in installation of two or more appliances

Completing The Installation

Anti-tipping safety assembly

Mounting handles on stainless front

Air circulation

Post installation checklist

Start Up

1

Page 4

2

Page 5

Installation Guide

!! ATTENZIONE !! - !! ATTENTION !!

!! ATTENZIONE !! - !! ATTENTION !!

!! ATTENZIONE !! - !! ATTENTION !!

Series: All

Important safely instruction

Symbols used in the Guide

This appliance must be transported in an upright position. If this was

not the case you should leave it upright for 24 hours prior to switch it

on.

Note

Tips for the correct use of the appliance

Important

Directions to avoid appliance damage

Warning

Directions to prevent injury

Children safety

DANGER: Risk of child entrapment. Before you throw away your old

refrigerator or freezer:

• Take off the doors

• Leave the shelves in place so that children may not easily climb

inside.

EnglishFrançais

ATTENTION

Take maximum care during handling to avoid harm to persons and

property.

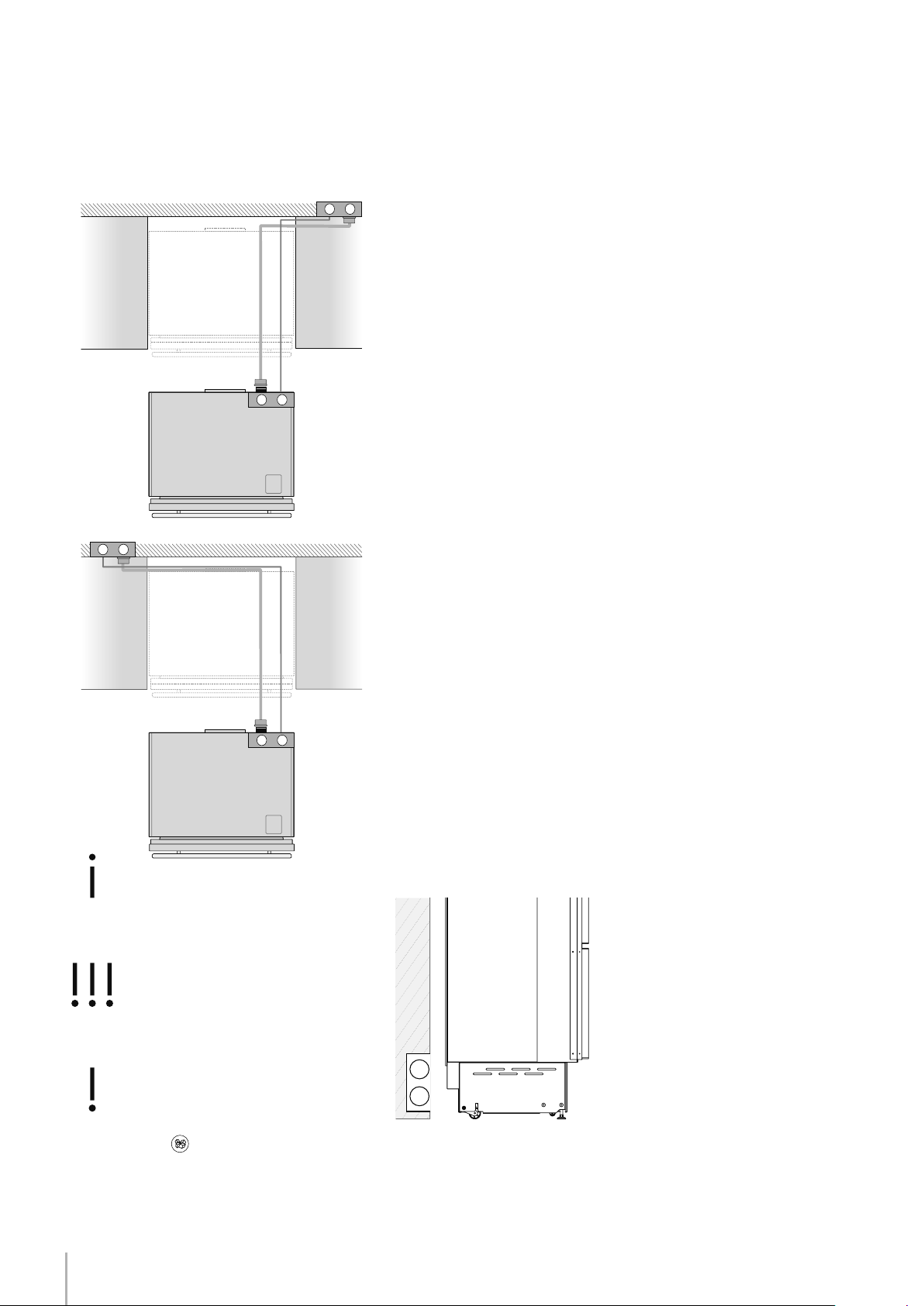

Secure the top of the appliance to the wall with the two brackets

provided with the appliance.

24 h

3

Page 6

Description

Appliance

Fasteners, brackets, screws, wrench for mounting outer panels

Alluminium trims to fill gap between appliance and cabinets

Owner’s Kit (inside the appliance)

StandPlus/

X-pro

Integrated Classic

Description

Water fill hose (only models with Ice Maker)

Water filter (only models with Ice Maker)

Leveling feet

Anti-tipping brackets, fixing plugs and screws

Appliance cleaning kit

User Manual, Installation Guide, Guarantee Certificate

Read the User Manual and the Guide attentively and keep it in a safe place.

Appliance features and installation requirements

Appliance dimensions

Integrated

Appliance dimensions

Stainless Integrated

Appliance dimensions

with packaging

Weight with packaging

BI30 w: 749 mm (29 1/2”)/ h: 2120 mm (83 1/2”)/ d: 610 mm (24”)

BI36 w: 899 mm (35 3/8”)/ h: 2120 mm (83 1/2”)/ d: 610 mm (24”)

BKI30 w: 749 mm (29 1/2”)/ h: 2120 mm (83 1/2”)/ d: 635 mm (25”)

BKI36 w: 899 mm (35 3/8”)/ h: 2120 mm (83 1/2”)/ d: 635 mm (25”)

30” Series w: 800 mm (31 1/2”) / h: 2260 mm (89”) / d: 800 mm (31 1/2”)

36” Series w: 950 mm (37 3/8”) / h: 2260 mm (89”) / d: 800 mm (31 1/2”)

30” Series up to 275 kg (606 lb)

36” Series up to 295 kg (650 lb)

Maker - Models

with Ice Maker

Maker - Models

without Ice

Maker

Voltage

Power supply cable

Potable water supply pressure

Water connection

Provided installation accessories

Additional equipment necessary

Adjusting height of the rear rollers

North America Version: 115V 60Hz

North America Version: 15 A

from 0.05 MPa to 0.5 MPa (0.5 Bar - 5 Bar)

3/4” female attachment

Customized panels mounting Kit

Anti-tipping Kit (B04000200)

Lateral connecting kit (KCLIT/KCLIH)

4 mm (1/8”) allen wrench

Phillips head screwdriver

wood and percussion drill

2.5 mm (1/8”) bit for wood

8 mm (3/8”) bit for walls

17 mm (3/4”) wrench

13 mm (1/2”) socket

Note

Not all models come with an automatic

ice maker. Verify if your model is equipped

with an ice maker to determine if you

require water supply.

4

Page 7

140 (5 ½”) 140 (5 ½”)

min 2134 (84”)

A

610 (24”)

2120 (83 ½”) +25 (1”)

BI36: 1470 (57

)

area to be left clear for the anti-tipping brackets

Niche Height

2134 mm (84”)

Niche Width

BI36: 900 mm (35 1/2”)

BI30: 750 mm (29 5/8”)

Door Swing Clearance

BI36: 1470 mm (57 7/8”)

BI30: 1320 mm (52”)

Installation Guide

Installation niche features: Integrated Series (BI)

Door Opening Angle

105°

Width

BI36: 899 mm (35 3/8”)

BI30: 749 mm (29 1/2”)

Height

2120 mm (83 1/2”) + 25 mm (1”)

Depth with door (without panel)

610 mm (

24”)

100 (4”)

A A

BI36: 900 (35 ½”)

BI30: 750 (29 5⁄8”)

100 (4”)

7⁄8”

992 (39”)

BI30: 1320 (52”)

560 (22”)

610 (24”)

560 (22”)

BI36: 160 (6 3⁄8”)

BI30: 125 (5”)

EnglishFrançais

105°

10 (3⁄8”)

BI36: 899 (35 3⁄8”)

BI30: 749 (29 ½”)

721 (28 3⁄8”) +25 (1”)

500 (19 ¾”)

1293 (50 7⁄8” )

20 (¾”)

474 (18 5⁄8”)

25 (1”)

+ 25 (1”)

) +

)

1⁄8”

¾”

231 (9

248 (9

5

Page 8

1

4

1

2

3

140 (5 ½”) 140 (5 ½”)

min 2134 (84”)

2120 (83 ½”) +25 (1”)

635 (25”)

BKI36: 1470 (57 7⁄8”)

Series: All

Installation niche requirements: Stainless Integrated Series (BKI)

A

area to be left clear for the anti-tipping brackets

Niche Height

2134 mm (84”)

Niche Width

BKI36: 900 mm (35 1/2”)

BKI30: 750 mm (29 5/8”)

Door Swing Clearance

BKI36: 1470 mm (57 7/8”)

BKI30: 1320 mm (52”)

Door Opening Angle

105°

Width

BKI36: 899 mm (35 3/8”)

BKI30: 749 mm (29 1/2”)

Height

2120 mm (83 1/2”) + 25 mm (1”)

Depth with door (without panel)

635 mm (25”)

BKI36: 230 (9”)

BKI30: 195 (7 ¾”)

100 (4”)

A A

BI36: 900 (35 ½”)

BI30: 750 (29 5⁄8”)

100 (4”)

BKI30: 1320 (52”)

560 (22”)

635 (25”)

75 (3”)

560 (22”)

BKI36: 899 (35 3⁄8”)

BKI30: 749 (29 ½”)

105°

10 (3⁄8”)

58 (2 ¼”)

6

1308 (51 ½”)587 (23 1⁄8”)

9 ( 3⁄8”)

732 (28 7⁄8”)+25 (1”)

693 (27 ¼”)

146 (5 ¾”)

+ 25(1”)

Page 9

Installation Guide

Series: All

Preparing the installation

Transport to installation site

and unpacking

2

1

3

4

1

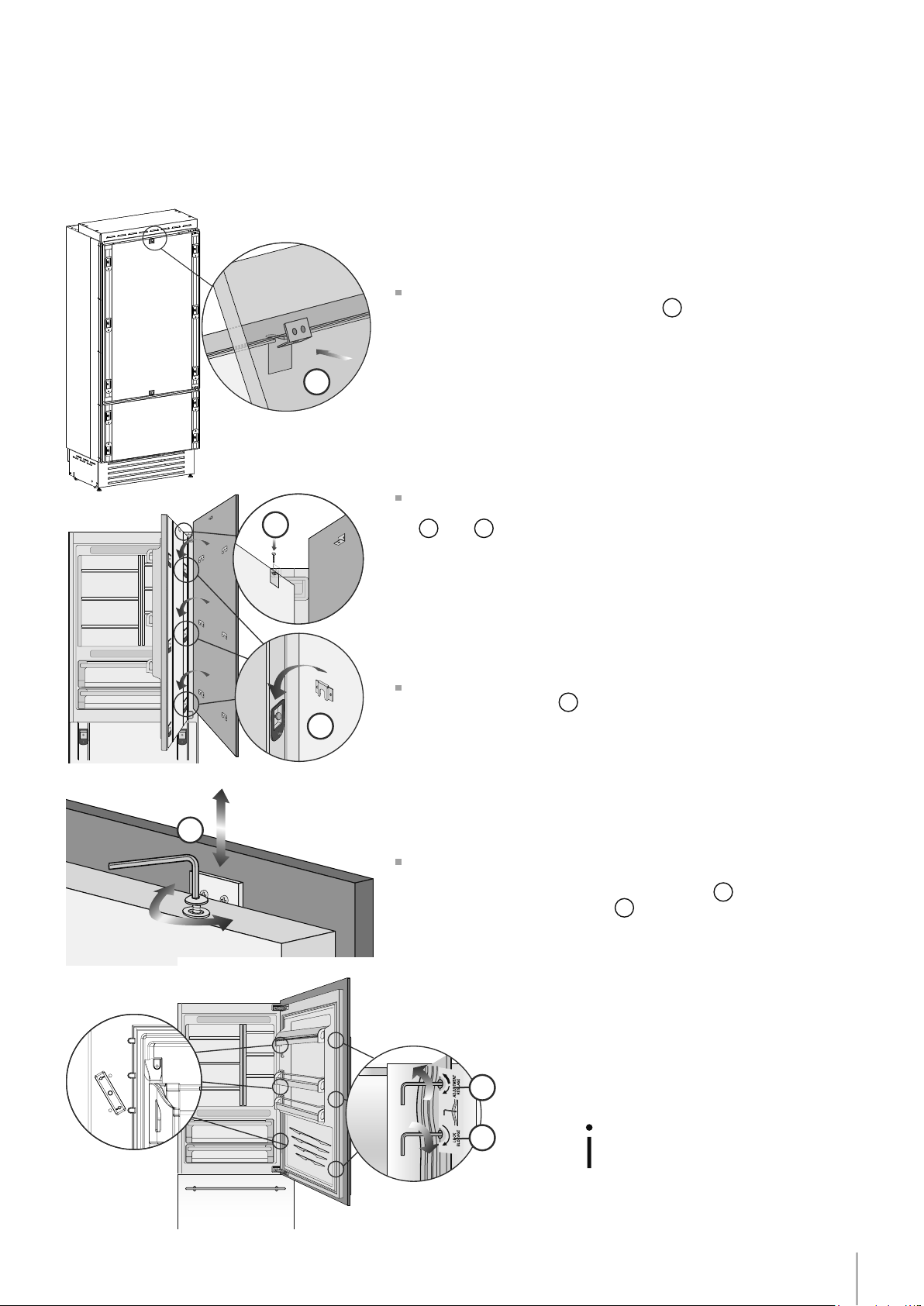

Since this is a large and heavy appliance, before transporting the appliance, check the access to the location where it will be installed

(door size, manoeuvring space in stairwells, etc.).

The appliance is attached to the base of the packaging (pallet)

through four bolts which can be removed using a 17 mm (3/4”) wrench.

It is recommended to use a manual transporting device to move the

appliance to the installation site, and only at this point to remove the

base of the packaging.

The appliance should always be transported in an erect position.

If this is not possible, transport the appliance laying on its rear side.

Once at the installation site, the appliance, which is equipped with four

wheels, can be taken off the pallet and positioned in the installation

area.

Operate as follows:

EnglishFrançais

The appliance is very heavy.

Take maximum care during handling to

avoid injury.

The appliance should always be transported in an erect position.

Avoid at all costs leaning it on its front side.

Take off the four bolts

means of a 17 mm (3/4”) wrench or socket.

Remove the xing brackets 3 and 4.

To remove the front xing bracket 3 , unscrew for one or two turns

the rear wheel adjusting bolt 2 by means of a 13 mm (1/2”) socket,

do not overtighten the nut as it could damage the leveling feet adjusting system.

From the back of the unit and by means of a suitable, high duty hand

trolley, take off the appliance and place it on the oor. Be mindful of

any debris on the oor which could get caught under the rollers and

potentially damage the ooring when moving the appliance.

Be very careful to avoid any damage to oors. Delicate oors should be

protected with plywood, hard cardboard or similar material panels.

securing the appliance to the pallet by

1

7

Page 10

EW

E W

EW

E W

E

W

Series: All

Electrical and Water connection

The appliances are delivered from the factory for operation at 110V120V AC - 60Hz (US and Canada).

Do not connect the refrigerator to any GFCI receptacle.

They are provided with a suitable supply cable and plug to be connected to an appropriate 15A socket (US and Canada) provided

with an effective grounding.

A circuit breaker should also be installed and should be easily accessible so that it can be easily switched off before performing any

installation or maintenance.

To connect to the water supply system (for appliances equipped with

ice makers) a 1/4” waterline with accessible shut-off valve must be

supplied.

The appliance is provided with a water adapter elbow which is suitable for high water pressure and complies the Food Regulations.

The water lter cartridge, which is provided with the appliance,

should be installed according to the accompanying instructions. Use

only the new adapter which is supplied with the appliance. The solenoid connection on the appliance is 3/4” diameter but is metric

threaded. A standard garden hose threaded connector such as a

braided stainless hose found at typical hardware stores will strip or

damage the solenoid threads. Use only the supplied 1/4” quick connect elbow adapter for connecting a 1/4” copper or polyethylene

source water line to the appliance.

Electrical cord length: 2500 mm (98 3/8”)

Water connection line length: 2500 mm (98 3/8”)

Do not use extension cords and/or multiple adapters for the power

supply connection.

Electrical and water supply behind the unit

Integrated Series

The Built-in lter cannot make it safe to

drink any water which is not suitable for human consumption.

The appliance should be connected only to

a drinkable water supply system.

Do not use extension cords or adapters.

Once the appliance is fully installed, connected

to the water supply (if applicable) and operational, in the event that the water supply must be

turned off,(touch the button

to switch it off) before the main water is shut off to

prevent the appliance from entering a ‘NO WATER

IN’ alarm state.

8

on control panel

E

W

Page 11

Electrical connection

Water connection

Installation Guide

Series: All

Back of appliance

Operate as follows:

Unwind the electric cable and connect it directly to the wall socket.

Make sure the appliance is in the Stand-by condition and that all

lights are off; should it be not so press the Unit button to switch it off.

Push the 1/4” source waterline fully into the elbow connector then

thread the elbow adapter to the solenoid at the back of the appliance.

Firmly tighten with ngers - a tool / wrench should not be needed to

make a proper seal. Turn on the water and ensure all connections

are not leaking prior to pushing the unit into the niche.

EnglishFrançais

9

Page 12

Series: All

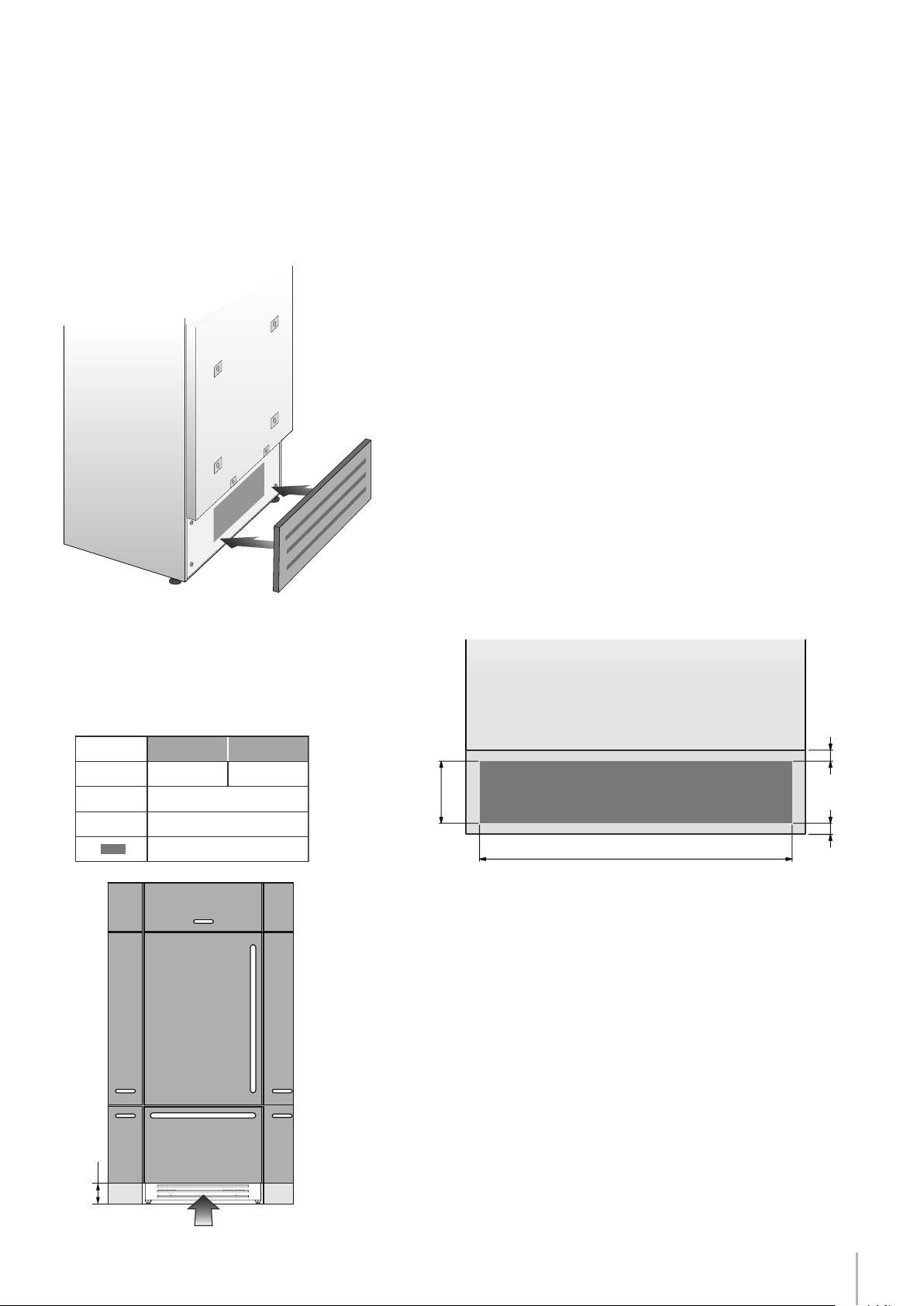

Levelling

2

1

2

1

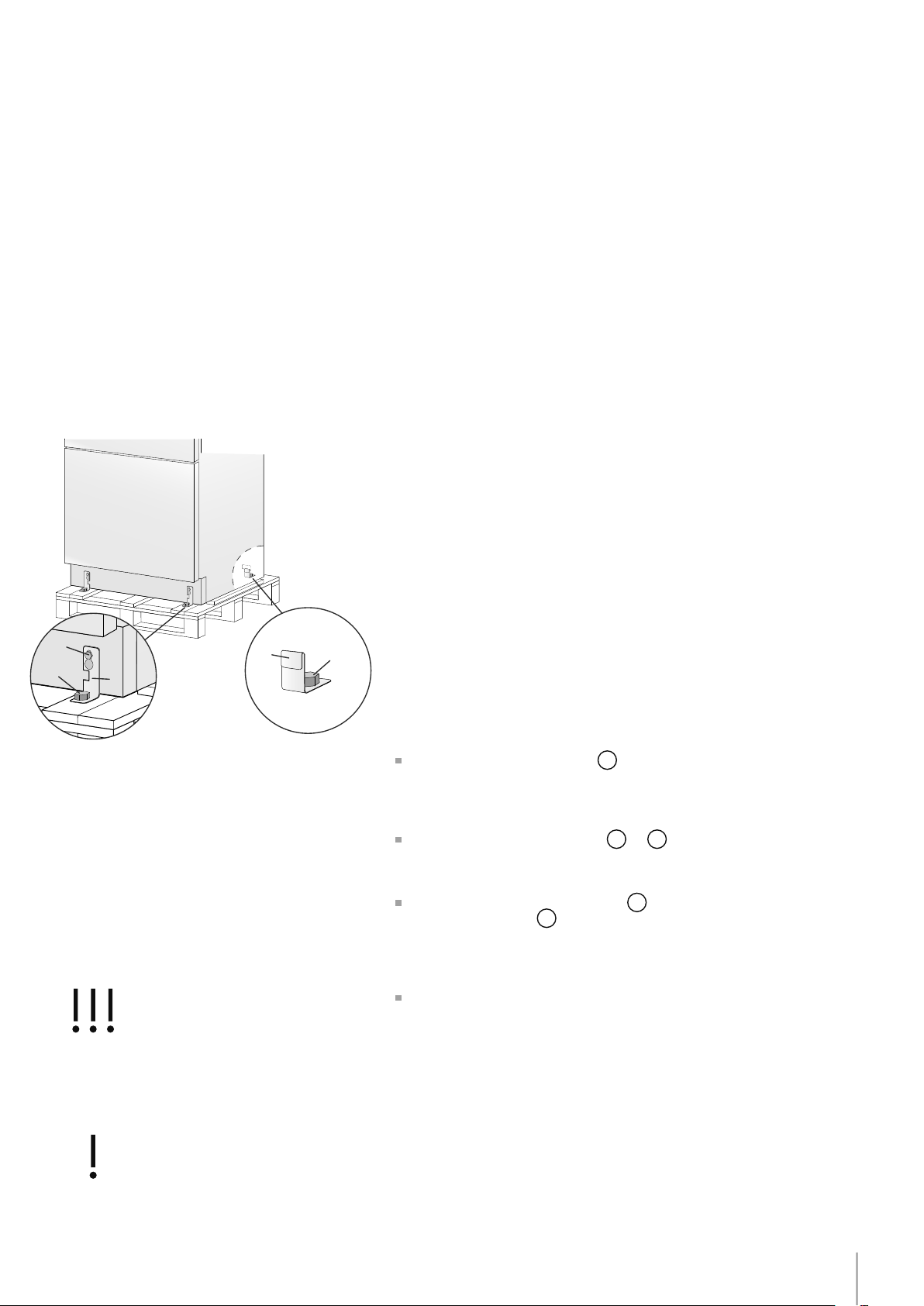

Adjust the appliance level by means of the front levelling feet

and the rear adjustable wheels.

Operate as follows:

The grille should ship taped to the back of the appliance. If by chance

it is already in place, remove the grille (it is kept in position by magnets),

adjust the height of the levelling feet

mm (3/4”) wrench.

Then adjust the height of the rear wheels by turning the front adjusting

bolts

not use power drivers with high torque settings for this step as it could

damage the levelling mechanism)

Mount the lower ventilation grille only after the unit is nally levelled

in the niche.

clockwise or counter-clockwise as it may be required. (Do

2

by means of a 17

1

10

Page 13

Installation Guide

Series: Integrated (BI)

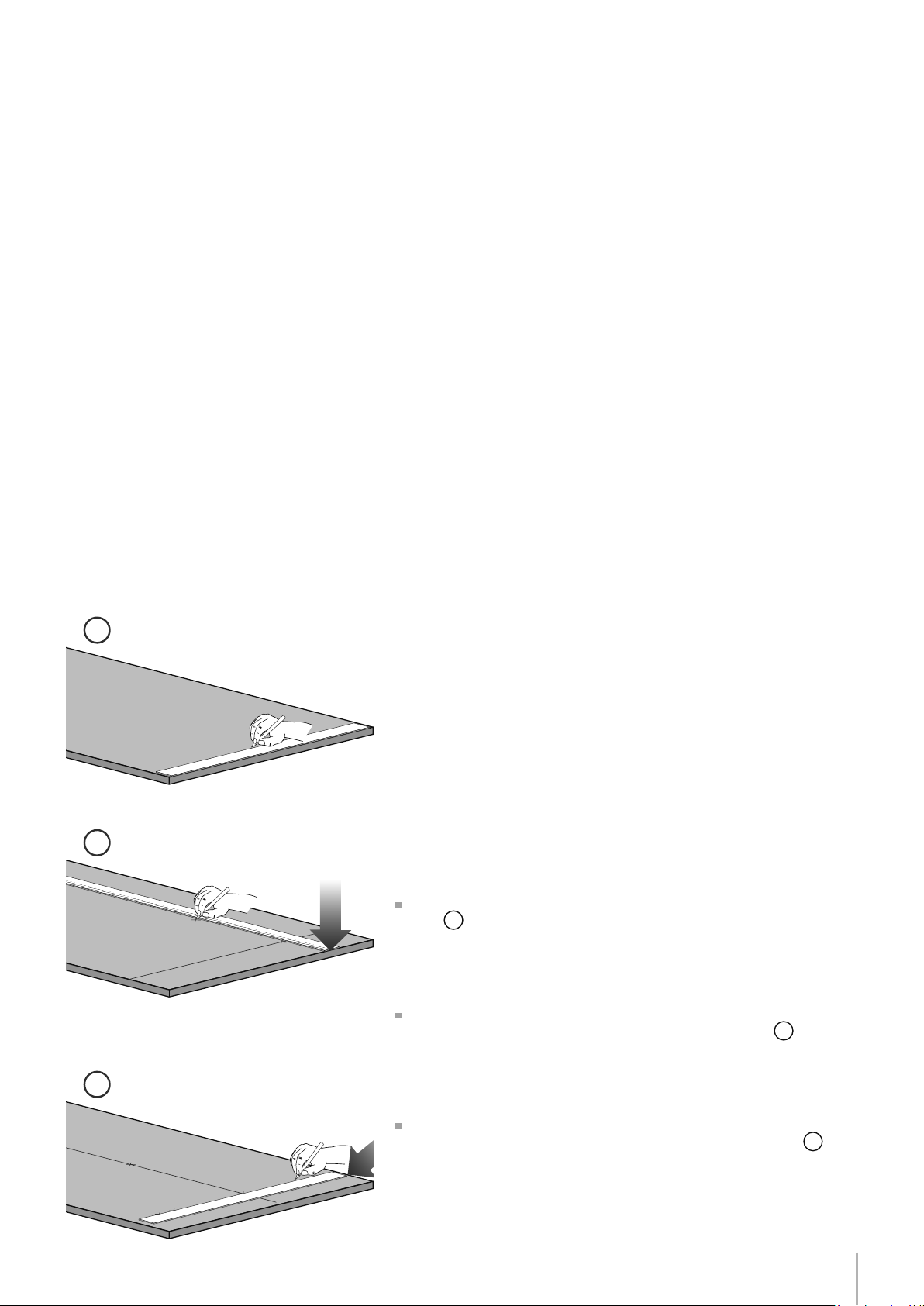

Door and Bottom-Drawer overlay panels layout

The dimensions of the panels are indicated in the table and draw-

ings on pages 13.

Nevertheless, according to the requirements for aligning with other

kitchen structures, the door panel can be higher than the upper

edge of the refrigerator door, and the drawer panel can be lower

than the edge of the drawer.

The panels must be mounted using special braces which attach

to adjustable devices provided on the door and drawer and with

brackets that anchor and adjust the panel’s vertical direction.

Braces, brackets and fixing screws are provided with the appliance

and must be applied to the panel as indicated.

EnglishFrançais

1

Operate as follows:

To prepare the panels to be mounted on the appliance, follow

these steps, working on the back of the panel.

2

Door Panel

Draw a reference center line, dividing the panel width in half 1.

Starting from the bottom edge of the panel, mark the positioning

of the brackets 2.

3

Following the corresponding table, mark the outside and then the

inside hole 3.

11

Page 14

Series: Integrated (BI)

4

5

Position the brackets on each set of marks to make sure they are

aligned 4, you may wish to drill pilot holes (pay close attention to

the panel’s thickness)5.

Screw the brackets in place 6.

Drawer Panel

When preparing the Drawer Panel, follow the same instructions as

per the door panel, but make sure measurements are taken starting

from the top edge 7. The support bracket faces the opposite way

(note imgs 4 and 8).

8

7

8

12

Page 15

A

1273 (50 1⁄8”)

597 (23 ½”)

203.5(8”)

Installation Guide

Series: Integrated

Overlay panels mounting brackets layout

Note: All lateral bracket placement

measurements go from the center line

to the outside bracket hole

Series 36

A

B

C

897 (35

417 (16

354.5 (14”) 279.5 (11”)

Series 30

¼”) 747 (29 3⁄8”)

3⁄8”) 342 (13 ½”)

EnglishFrançais

Holes positions

BB

6,5 (

¼”)6,5 (¼”)

Door panel

34 (1

3⁄8”)

¾”)max 635 (25”)

Back of the panel

A

BB

Back of the panel

34 (1

3⁄8”)

13 (½”)

C C

507.5 (20”)

1163 (45 ¾”)

¼”)

660 (26”)

157 (6

1⁄8”)

100 (4”)

382 (15

Vertical adjustment bracket for

upper door. Note orientation.

Vertical adjustment bracket for

lower drawer. Note orientation.

min 1390 (54

Drawer panel

13

Page 16

2121 (83

") + 25 (1")

B

115 (4 ½”)

min 200 (7 7⁄8”)

135

(5 3⁄8”)

135

(5 3⁄8”)

1075 (42 3⁄8”)

Series: Integrated (BI)

Panels Dimensions

Panels can have thickness ranging between 18 mm (3/4”) and 28 mm (1-1/8“).

Door panels can have a maximum weight 23 kg (51 lbs) and drawer panels may be a maximum weight of 11kg (25 lbs)

Exceeding these weights could void your warranty for any service issues which can be attributed to overweight panels.

The hinging mechanism on appliances is considered to be `Zero-clearance`. The door and drawer widths specified below

assume the minimum niche width is being used and a 3.5mm (1/8”) reveal is desired around the panels. Adjust your panel

dimensions accordingly to your own design criteria considering your niche width and your reveal. Minimum reveal / gap

should not be less than 1.5mm (1/16”).

Series

BI36

BI30

Door/Drawer Width Niche Width

897 (35 1/4”)

747 (29 3/8”)

900 (35 1/2”)

750 (29 5/8”)

1390 (54 ¾”)

Example:

84” niche height

36” niche width

4” toe kick height

1/8” gap desired all around

Door panel:

Width: 35-3/4”

Height: 54-3/4”

Drawer panel:

Width: 35-3/4”

Height: 84”-1/8”-54-3/4”-1/8”-4”=25”

If you want a 6” toe kick height then your

bottom drawer panel height would be 23”

½

14

3 (1⁄8”)

min 540 (21 ¼”)

max 635 (25”)

A

Page 17

Installation Guide

Series: Integrated (BI)

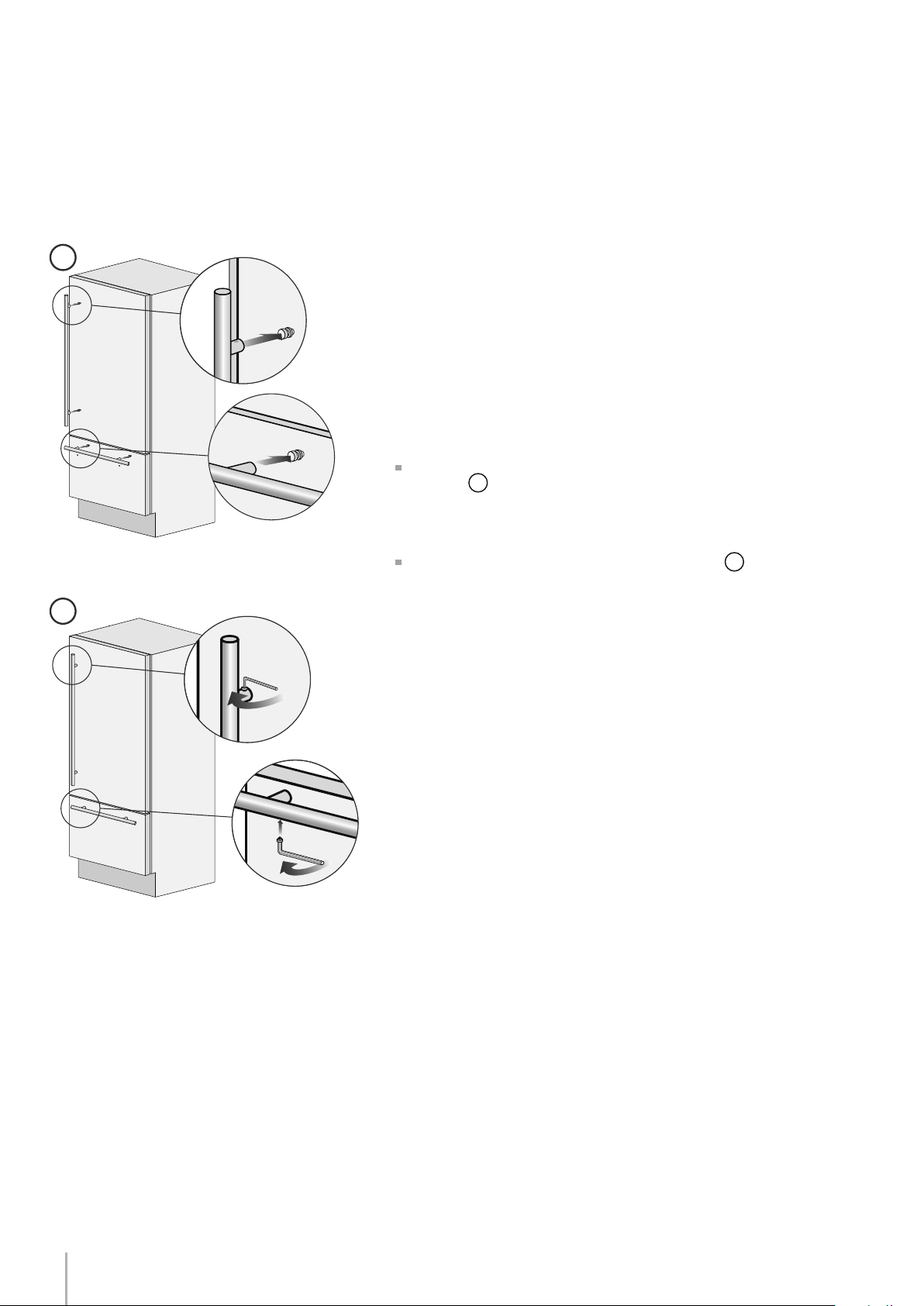

Mounting the handles on Integrated units

1

Handles will have to be mounted on the panels before they are applied to the fridge. For overlay panel mounting, remove the screw

connecting the stand-offs to the handle bar. The overlay screw will

pass through the overlay panel, the stand-off and into the handle

bar.

Operate as follows:

Drill two holes of 5 mm (1/4 “) on the rear side panels, insert the supplied screws to the distance indicated in the

the table below. To center the vertical handle (code HV) to

the center of the door, split into two the height of the panel and make

a hole at -450 mm (-17 3/4”) and one at +450 mm (+17 3/4”) 1.

EnglishFrançais

2

Place the handle on top of the holes and insert the screws through

the panel and into the handle support 2.

Distance between stand-offs X

900 mm

(35 1/2”)

480 mm

(18 7/8”)

490 mm

(19 1/4”)

15

Page 18

Series: Integrated (BI)

Mounting panels to the door and the drawer of Integrated units

Install 1 hanger bolt about 3 threads deep and 1 depth set screw

ush to foam gasket in each mounting cavity.

Once all brackets and small brackets have been applied to the panels, you can begin installing the bottom drawer.

1

Operate as follows:

Partially install the adjustment bolt with washer into the two holes

2

in the bottom of the drawer

.

1

Ensure the L-brackets align with the adjustment bolts on the bottom, place panel against the drawer face with the hanger brackets

above the hanger bolts and allow the panel to drop down. Ensure all

the hanger brackets engage the hanger bolts 2.

It is now possible to align panels to adjacent cabinets in height using the lower alignment brackets,

bolts into position as needed. With the hanger bolts slighty tightened,

move the panel sideways to align it to the other panels on the unit

or other adjacent structures. Tapping the panel with a rubber mallet

3

is a good way to make small adjustments to the X-alignment of the

panel.

Depth alignment: working from the inside of the drawer, after lifting up the magnetic seal, adjust the panel position so it is closer to or

further away from the door using the holes

panel using the holes

Turning in the direction of the thick arrow pulls the panel closer to the

door / drawer face, turning in the direction of the thin arrow pushes

the panel away from the face of the door / drawer.

.

5

tightening or untighteningthe

3

and then secure the

4

4

Once the front panel has been adjusted, check that the gasket has

5

16

been repositioned correctly to assure the door/drawer are closing

correctly and avoid operational errors of the unit.

Page 19

Installation Guide

Series: Integrated (BI)

Ensure the top adjustment L-brackets are aligned and inserted

into the cavities at the top of the door

Make sure all the hanger brackets begin above the hanger bolts

and then lower the panel down checking that each hanger bracket has engaged its corresponding hanger bolt.

6

.

6

At this point, alignment between the panel and adjacent cabi-

7

nets can be adjusted using the alignment brackets and small brackets 7 and 8.

EnglishFrançais

Vertical alignment: tighten or loosen the screw in the brackets to

raise or lower the panel

8

9

Depth alignment: working from the inside of the door, after lifting up the magnetic seal, adjust the panel position so it is closer to

or further away from the door using the holes 10 and then fix the

panel in position using the holes

.

9

.

11

10

11

Once the front panel has been adjusted, check that the gasket has

been repositioned correctly to assure the door/drawer are closing

correctly and avoid operational errors of the unit.

17

Page 20

6,5 (¼”) 6,5 (¼”)

Series: All

Installation in cabinet of this height requires that the back of the cabinet de ventilated through the top. Otherwise,

an additional 2 inches of cabinet height is required for adequate ventilation. Height of custom side panel can be

higher as necessary.

Installation

1

2

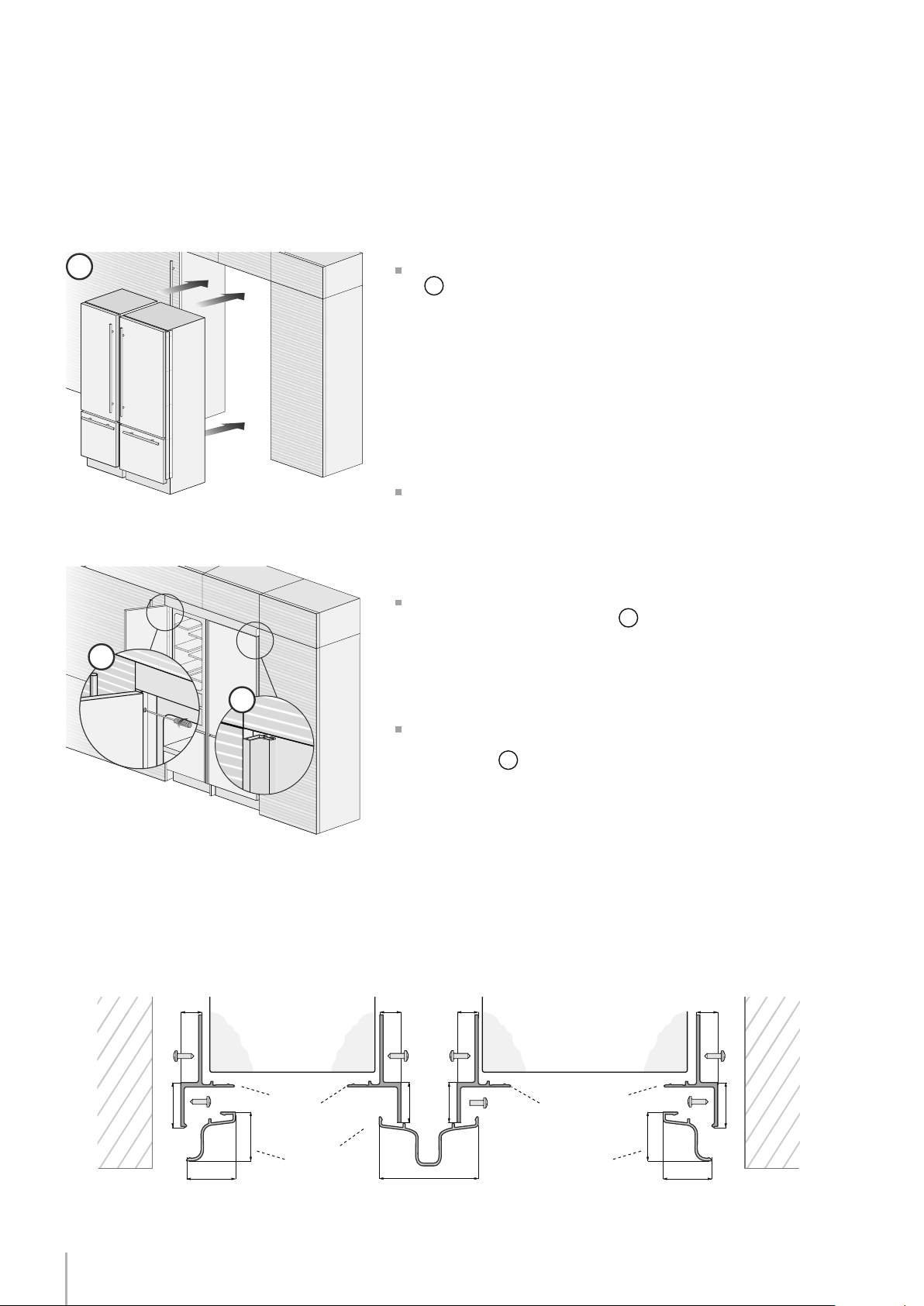

Built-in installation single appliance

For a built-in installation, to close gaps between the appliance and

the adjacent cabinets, special side proles (installed) and aluminum

trim covers (taped to back of appliance) are provided. Side proles

are used for xing the appliance to the niche cabinet and can be

shimmed from the side of the appliance in order to match the niche

width. (Remove screws holding trim to side of appliance and place

washers between prole and appliance and replace screws for example)

Operate as follows:

Push the appliance into the installation niche 1.

If the unit is to be installed inside a niche or within an enclosed

structure, it is not necessary to design a ventilation shaft at the back of

the niche as North American models come with a top ventilation cap

which accommodates sufcient ventilation even though it is behind

the overlay panel.

Ensure panels are mounted (BI Series) prior to pushing the appliance

all the way into the niche as the panel mounting procedure requires

additional height clearance than the niche provides.

If for some reason the top ventilation cap has been removed - a minimum 5mm gap must be provided at the top / back of the cabinetry to

allow warm air to escape.

Check the levelling of the appliance, adjusting its feet and wheels

to correct it.

Using the screws provided, secure the appliance to the adjacent

cabinets through the holes on the prole side trims

.

2

To make this operation easier keep the door and the drawer open.

It may be necessary to hold the door at an approximate 70 degree an-

3

gle to get the easiest access on the hinge side prole with a screwdriver.

Install the prole trim covers: mate with the face of the appliance

and the top of the niche then slide laterally over the prole trims. It will

be necessary to press rmly or use a block and mallet to completely

lock the trims into place until a ‘click’ is heard.

Take care not to damage the soft aluminum trims. Ensure that the full

installation is satisfactory prior to installing the prole trim covers as it is

very difcult to remove them without damaging them after installation

.

3

Side proles mounting

Wall

or

furniture

20 (¾”)

22 (7⁄8”)

22 (7⁄8”) 22 (7⁄8”)

Appliance Wall

A

B

A Connecting element B Alluminium frame

18

or

furniture

20 (¾”)

22 (7⁄8”)

Page 21

Installation Guide

Series: All

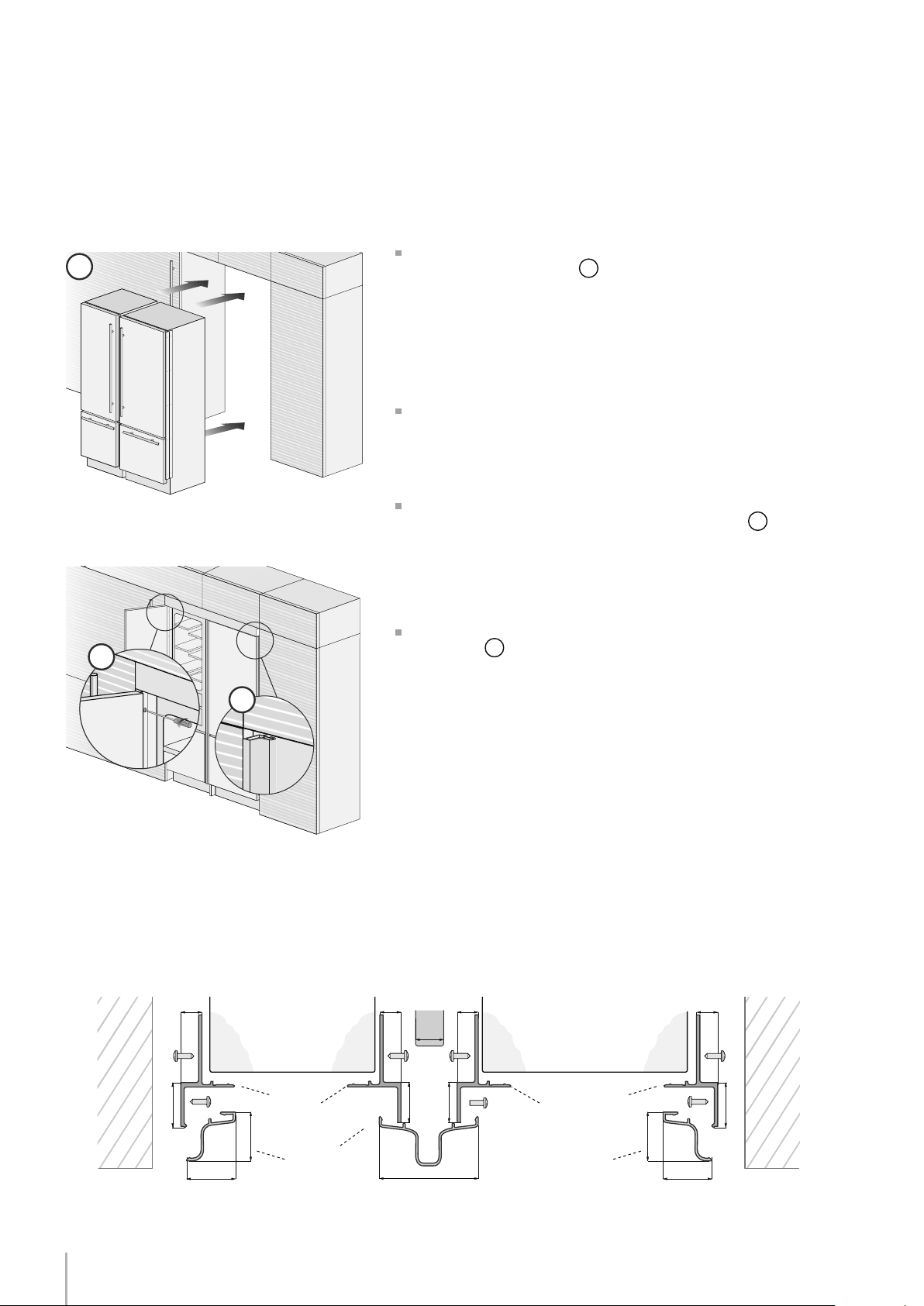

Built-in installation of two or more appliances

Note: top ventilation caps not shown in illustrations

1

2

Required accessories to be ordered separately:

Central connection Kit (KCCITU)

Each appliance comes with its own set of side prole trim covers for

where the appliance connects to the niche side walls. In side-by-side

congurations only 1 side prole trim cover will be needed from each

set. Where the two appliances connect together will be covered

with a central connection trim cover provided in the connection kit

accessory.

Operate as follows:

Position the appliances in front of the installation area, leaving

enugh space to operate at their back 1.

EnglishFrançais

Place the two units side by side, level them with respect to each

other by aligning the screw holes in the side prole trims and then join

them at the front either using pop rivets (supplied with central connection kit) or with 1/4” length #6 screws (not supplied) 2.

3

4

At the back of the appliances mount the connection brackets:

x one side of the top and lower brackets to one of the appliances

and subsequently to the other 3.

Once units are fully installed snap the central cover frame onto the

central connection pro les by rmly pressing toward the front of the

appliance until it clicks 4.

19

Page 22

Series: All

5

Once completed the previous steps, push the units in their nal position 5.

If the units are to be installed inside a niche or within an enclosed

structure, it is not necessary to have additional ventilation at the back

of the niche as North American units come with a factory installed

ventilation cap on top to prevent overheating. Always mount front

panels on door and drawer before pushing the unit into their nal position in the niche as the panels require additional clearance at the top

when being mounted.

Check the levelling of the appliance, adjusting its feet and wheels

to correct it.

Using the provided screws secure the appliance to the adjacent

cabinets through the side proles 6.

To make this operation easier keep the door and the drawer open.

6

7

Wall

or

furniture

Mount the aluminum trim covers onto the side prole trims by mating

with appliance face and niche ceiling and then sliding towards the

niche sidewalls 7.

Press rmly until a click is heard. A wood block and mallet may be

needed to snap into place. Make sure not to damage the trims.

Side and central proles mounting

6,5 (¼”) 6,5 (¼”)

Appliance Appliance

20 (¾”)

A

22 (7⁄8”)

D

6,5 (¼”)6,5 (¼”)

C

13 (½”)

18 (¾”)

18 (¾”)

D

A

22 (7⁄8”)

E

22 (7⁄8”) 22 (7⁄8”)

B

44,4 (1 ¾”)

B

Wall

or

furniture

20 (¾”)

A Connecting element

B Alluminium frame

20

D Connecting element

E Aluminium frame

Page 23

2 x

6 x

2 x

6 x

Installation Guide

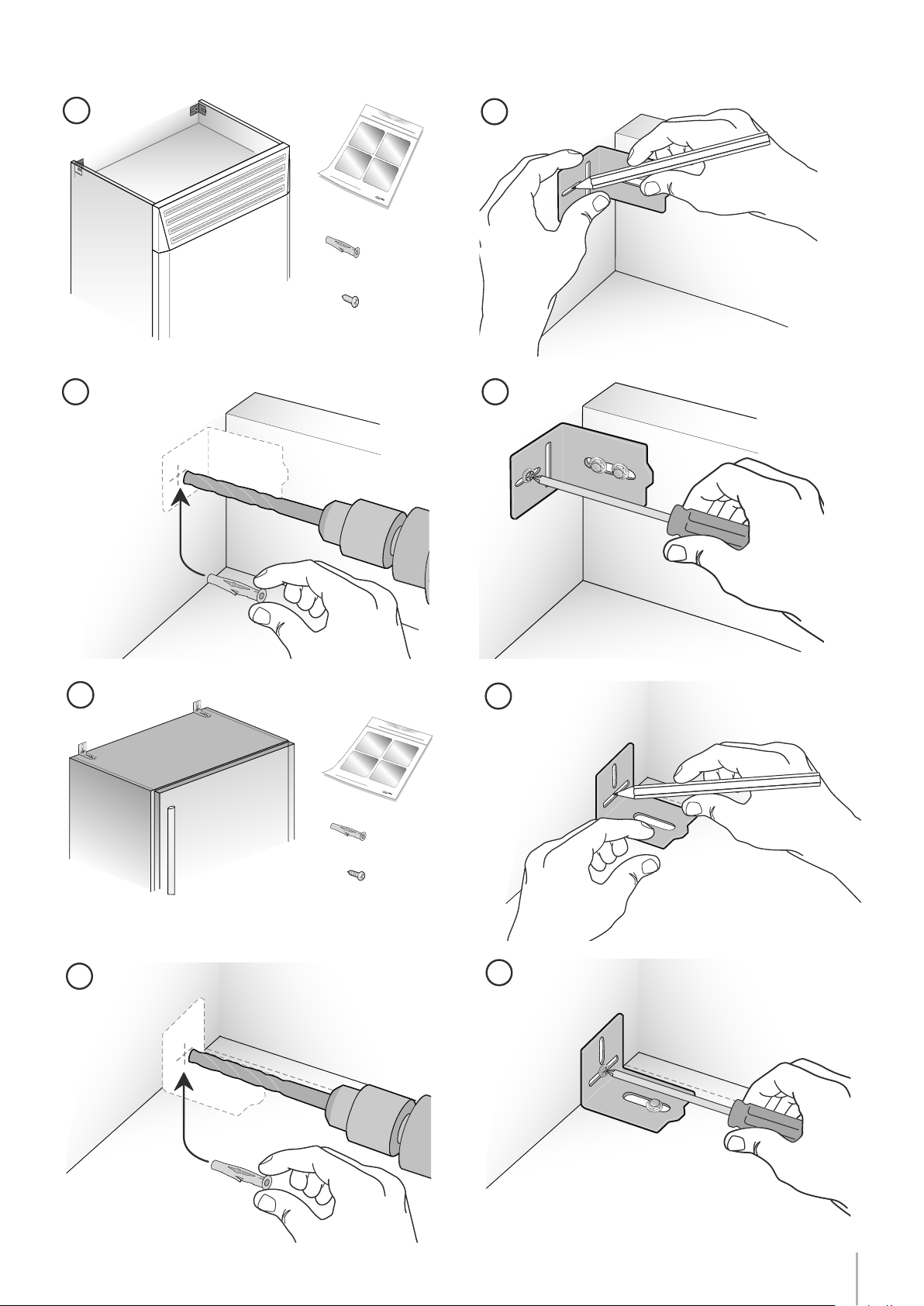

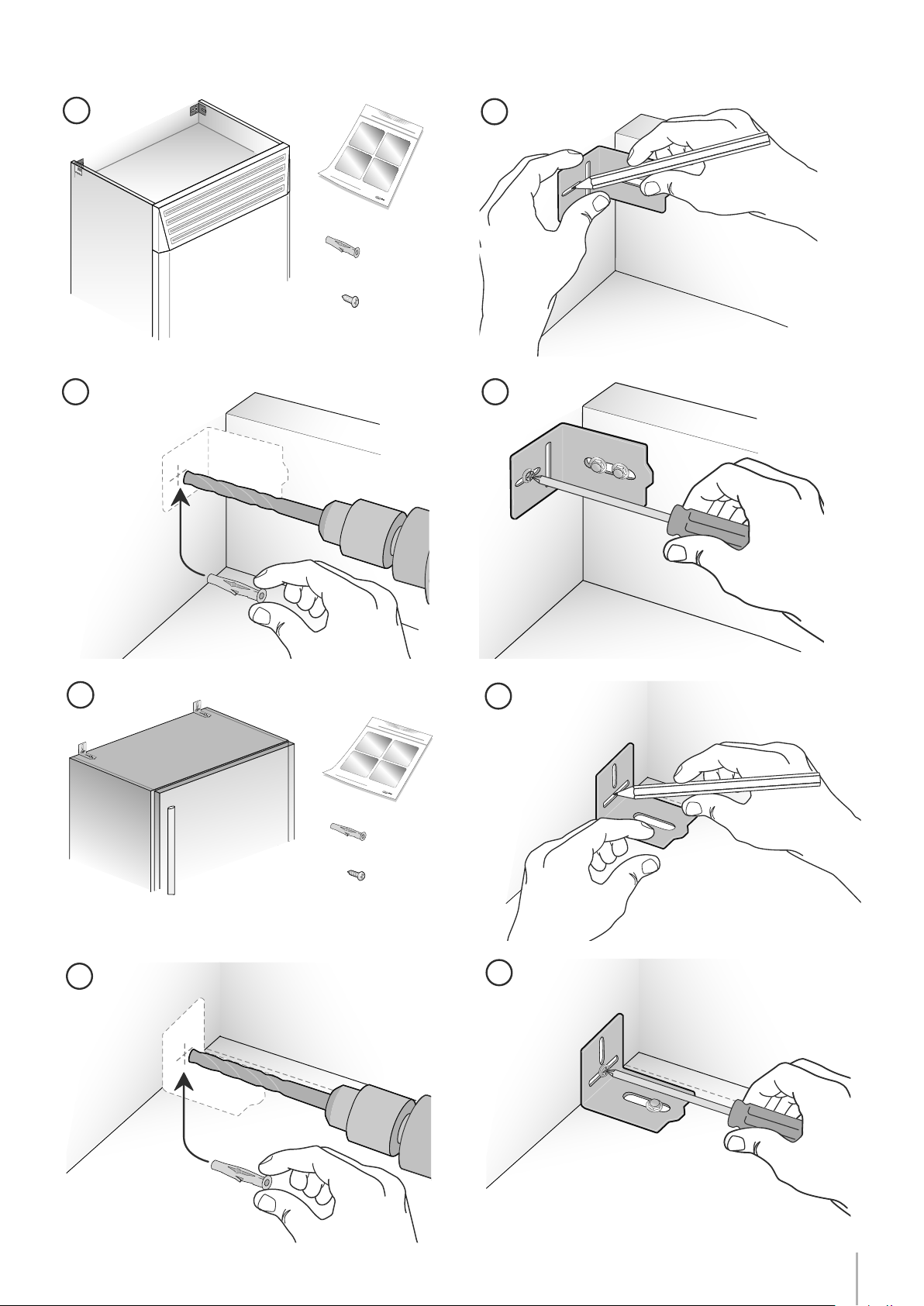

Anti tipping kit installation

1

2

2 x

6 x

3

4

EnglishFrançais

1

2 x

6 x

3

2

4

21

Page 24

Series: Stainless (BKI)

Mounting handles on stainless front

1

To mount the handles onto the door and the drawer operate as follows:

Operate as follows:

Insert the two handle spacers onto the mounting studs already available on the door and the drawer 1. Ensure the mounting studs are

not loose.

Screw in the Allen set-screws pre-installed on the handle 2.

2

The screws must be tightened in by means of a 2.5 mm (1/8”) hex

wrench / Allen key. Take care not to damage or scratch the stainless

panel with the tool.

22

Page 25

Installation Guide

Series: All

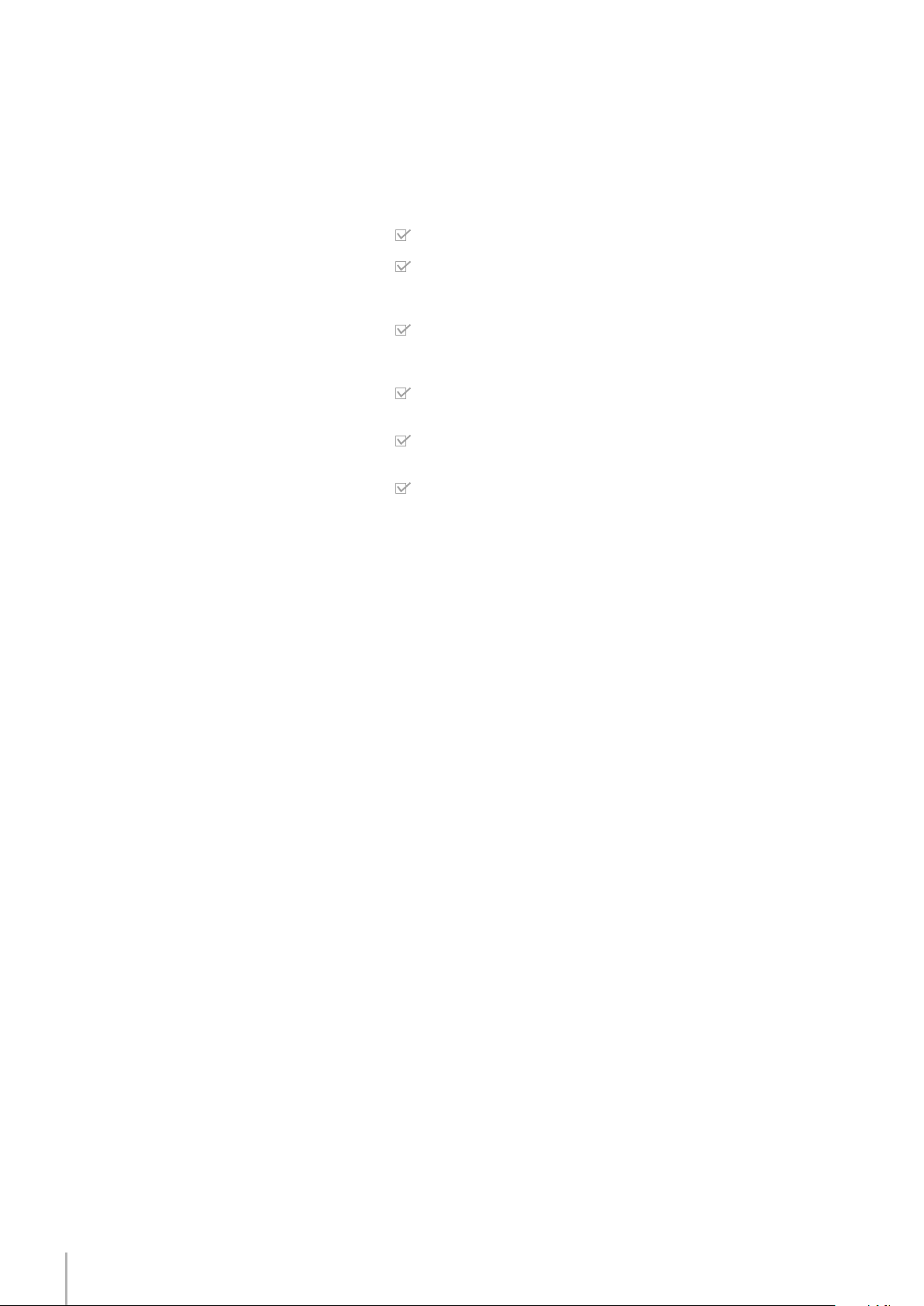

Air circulation

A forced air system assures ventilation through a grille positioned

in the lower front part of the unit. If the kitchen design includes a

kickplate, the latter has to be punched in order to maintain a sati-

sfactory air ow, as described in the drawing. Holes can be in any

shape and size, as long as the total area of the punched part equals

50% of the kickplate are.

In this case, to guarantee a better air ow, it is advisable to remove

the front grille included with the unit. The grille is secured to the unit

with magnetic plates and can be easily removed even by the end

user, to provide for regular cleaning procedures and remove dust.

If the grille is partially covered by the kitchen kickplate, it is advisable

to remove the grille in order to provide for a better airow.

36 Series 30 Series

A 860 (33 7⁄8”) 740 (29 1⁄8”)

B

C

> 100 (4”)

10 (3⁄8”)

50%

EnglishFrançais

C

B

C

A

The air intake and outlet must not be blocked or covered in any way.

They also need to be dusted/cleaned on a regular basis.

100 (4”)

23

Page 26

Series: All

Post installation checklist

Check that the front levelling feet have been properly installed.

Check that the connection to the water system does not have any

leaks and that the closing tap is easily accessible.

Check that the electrical connection is correctly installed and that

the multipole switch and socket are easily accessible.

Check the perfect alignment of the appliance with adjacent

structures.

Check that all adhesive tape and external or internal temporary

protective devices have been removed.

Check the perfect closing of the doors and the smooth sliding of

the drawers and shelves.

24

Page 27

U

NI

T

1234 56798

1 Unit

2 Fridge

3 Menu

Up/down

4

Fridge

5 Display

Up/Down

6

Freezer

(TriMode)

7 Enter

8 Ice maker

9 Alarm

8

E

N

T

R

FR

ID

GE

E

Switches the appliance (all compartments) between ON and STAND BY

(press for three seconds).

Allows switching on and off of only the refrigerator compartment

(press for three seconds).

Allows access to the appliance function menu

Using the Up and Down buttons, it is possible to change the set temperature of the refrigerator and navigate through the interactive menu.

It shows the temperature of the refrigerator and freezer compartments,

the date and time, Menu functions and visual messages.

By selecting Up/Down the preset temperature can be changed according to the selected function mode (freezer, refrigerator, Crisper-Fresco).

Confirms activation or deactivation of the selections made in the

Menu.

Allows activating or deactivating the automatic ice production.

Blinks to signal user alerts such as door left open, also in combination with

a sound signal which can be deactivated by pressing the button.

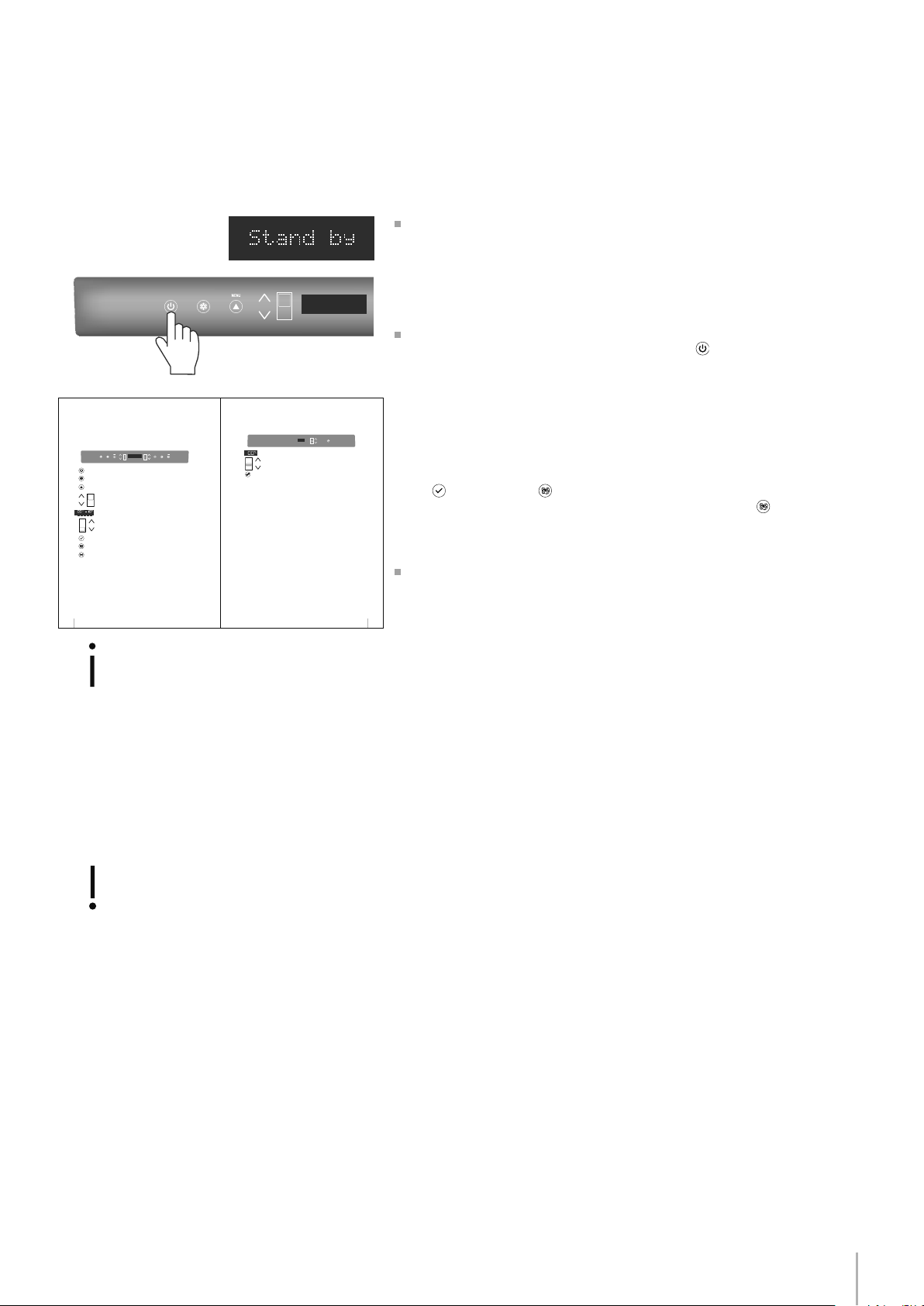

Installation Guide

Series: All

Start up

To start the appliance, connect the plug to the electrical mains: at

this point, when opening the door, the control panel will usually visualize the message “Stand by”, and all the panel keys be off

FRIDGE

UNIT

To turn on all the appliance compartments, press the Unit button

for three seconds. The display will show the message “Initial test” for

approx. 2 minutes. After this phase the compressors will start up and remain on until the default temperature set up in the factory is reached.

Do bear in mind that this condition could last several hours during

which time the display will continue to ash the ‘Start Up Phase’ message.

CR

ISP

E

R

I

CE

MA

K

E

R

11 Display

12 Up/Down

13 Crisper

10 11 12

Shows the temperature of the Crisper-Fresco compartment.

Using the Up and Down buttons, it is possible to change the

temperature set for the Crisper-Fresco compartment.

Allows switching on and off of only the Crisper-Fresco compartment

(press

for three seconds).

If the appliance is provided with an Ice Maker, prior to switching it on

make sure that the water lter cartridge is installed (unless water supply source is already ltered by other means such as reverse osmosis).

English

Purge air from the water lines by enacting the ‘Manual Clean’ function from the Menu->Functions->Water Filter options. You may need to

complete this sequence several times until you stop hearing air sput-

tering from the ice maker ll tube.

Once you are satised that the system is purged of air switch the Ice

Maker on by touching the button which will illuminate.

9

Note: If the TriMode drawer is congured as a Fridge or a Fresco compartment the ice maker will be disabled. Default mode for the TriMode

drawer is Freezer.

EnglishFrançais

If at the rst start - up the message Stand by

does not appear, but other messages appear,

such as Fridge too warm, Fresco too warm,

Freezer too warm, or sound signals are activated, it means, it means that the appliance has

already started the cooling process.

If this is the case, deactivate any possible acoustic signals by pressing the Alarm button, close

the door and wait until the set temperature is

reached.

It is necessary to let the unit reach the correct

temperature before foods are stored inside.

For further information about the appliance operation, refer to the

User Manual.

25

Page 28

Page 29

IMPORTANT

Les dimensions entre parentheses sont en pouces: mm(in).

Les poids entre parenthèses sont en livres: kg(lb).

Les temperatures entre parentheses sont en °F: °C (°F).

Page 30

Page

Indications importantes

3

Indications importantes concernant la sécurité

Pour la sécurité des enfants

Caractéristiques techniques

4

Caractéristiques de l’appareil et conditions requises pour l’installation

5

Caractéristiques de la niche d’installation: Série Integrated (BI)

6

Caractéristiques de la niche d’installation: Série Inox Integrated (BKI)

Préparation à l’installation

7

Transport sur le lieu d’installation et déballage

8

Raccordements électrique et hydraulique

10

Mise à niveau

Notice d’Installation

Sommaire

Montage des panneaux

11

Préparation des panneaux décoratifs pour la porte et Grands bacs

13

Préparation des panneaux décoratifs pour Réfrigérateur avec un Grand bac

14

Dimensions des panneaux

15

Montage des poignées: Série Integrated

16

Fixation des panneaux à la porte et au Grand bac: Série Integrated

Installation dans la niche

18

Encastrement appareil unique

19

Encastrement combinaison

Achèvement de l’installation

21

Montage de la sécurité anti-renversement

22

Montage des poignées sur le devant inoxydable

23

Circulation de l’air

24

Contrôle de n d’installation

25

Mise en marche

EnglishFrançais

1

Page 31

2

Page 32

Notice d’Installation

Indications importantes concernant la sécurité

Symboles utilisés dans le manuel

Important

Indications an d’éviter tout

endommagement de l’appareil

Note

conseils pour une correcte utilisation

de l’appareil

Attention

indications an d’éviter toute

lésion aux personnes

Pour la sécurité des enfants

DANGER : Risque d’enfermement pour les enfants. Avant de jeter un

vieux réfrigérateur ou congélateur :

• Retirer les portes

• Laisser les étagères en place an d’empêcher que des enfants grim-

pent dedans.

EnglishFrançais

3

Page 33

Caractéristiques de l’appareil et conditions requises pour l’installation

Dimensions de l’appareil

Integrated

Dimensions de l’appareil

Inox Integrated

Dimension de enballé

Poids avec emballage

Tension d’alimentation

Câble d’alimentation

Pression d’alimentation de l’eau potable

Tuyau d’alimentation de l’eau

Accessoires pour l’installation fournis

Équipement nécessaire

Réglage de la hauteur des rouleaux arrière

BI30 l: 749 mm (29 1/2”)/ h: 2120 mm (83 1/2”)/ p: 610 mm (24”)

BI36 l: 899 mm (35 3/8”)/ h: 2120 mm (83 1/2”)/ p: 610 mm (24”)

BKI30 l: 749 mm (29 1/2”)/ h: 2120 mm (83 1/2”)/ p: 635 mm (25”)

BKI36 l: 899 mm (35 3/8”)/ h: 2120 mm (83 1/2”)/ p: 635 mm (25”)

Série 30” l: 800 mm (31 1/2”) / h: 2260 mm (89”) / p: 800 mm (31 1/2”)

Série 36” l: 950 mm (37 3/8”) / h: 2260 mm (89”) / p: 800 mm (31 1/2”)

Série 30” max 275 kg (606 lb)

Série 36” max 295 kg (650 lb)

Modèle américain: 115V 60Hz

Modèle américain: 15A

de 0.05 MPa à 0.5 MPa (0.5 Bar - 5 Bar)

fourni, raccord femelle 3/4”, indiqué pour aliments

kit xage des panneaux sur demande

Kit Anti-renversement (B04000200)

kit de raccordement latérale (KCLIT/KCLIH)

clé à six pans de 4 mm (1/8”)

tournevis cruciforme

perceuse à bois et à percussion

pointe pour bois de 2.5 mm (1/8”)

pointe pour mur de 8 mm (3/8”)

clé ouverte de 17 mm (3/4”)

13 mm (1/2”) socket

Note

Modèles ne sont pas tous équipés avec

distributeur de glaçons. Vériez si votre

modèle est équipé d’une machine à

glaçons pour déterminer si vous avez

besoin de le tuyau d’alimentation de l’eau.

4

Page 34

140 (5 ½”) 140 (5 ½”)

min 2134 (84”)

610 (24”)

2120 (83 ½”) +25 (1”)

BI36: 1470 (57

)

Caractéristiques de la niche d’installation: Série Integrated (BI)

A

espace à réserver aux équerres anti-renversement

Hauteur de l’encastrement

2134 mm (84”)

Largeur de l’encastrement

BI36: 900 mm (35 1/2”)

BI30: 750 mm (29 5/8”)

Encombrement avec porte ouverte

BI36: 1470 mm (57 7/8”)

BI30: 1320 mm (52”)

Angle d’ouverture de la porte

105°

Largeur

BI36: 899 mm (35 3/8”)

BI30: 749 mm (29 1/2”)

Hauteur

2120 mm (83 1/2”) + 25 mm (1”)

Profondeur (sans panneau)

610 mm (

24”)

Notice d’Installation

100 (4”)

A A

BI36: 900 (35 ½”)

BI30: 750 (29 5⁄8”)

100 (4”)

7⁄8”

992 (39”)

BI30: 1320 (52”)

560 (22”)

610 (24”)

560 (22”)

BI36: 160 (6 3⁄8”)

BI30: 125 (5”)

EnglishFrançais

105°

10 (3⁄8”)

BI36: 899 (35 3⁄8”)

BI30: 749 (29 ½”)

721 (28 3⁄8”) +25 (1”)

500 (19 ¾”)

1293 (50 7⁄8” )

20 (¾”)

474 (18 5⁄8”)

25 (1”)

+ 25 (1”)

) +

)

1⁄8”

¾”

231 (9

248 (9

5

Page 35

1

4

1

2

3

140 (5 ½”) 140 (5 ½”)

min 2134 (84”)

2120 (83 ½”) +25 (1”)

635 (25”)

BKI36: 1470 (57 7⁄8”)

Caractéristiques de la niche d’installation: Série Inox Integrated (BKI)

A

espace à réserver aux équerres anti-renversement

Hauteur de l’encastrement

2134 mm (84”)

Largeur de l’encastrement

BKI36: 900 mm (35 1/2”)

BKI30: 750 mm (29 5/8”)

Encombrement avec porte ouverte

BKI36: 1470 mm (57 7/8”)

BKI30: 1320 mm (52”)

Angle d’ouverture de la porte

105°

Largeur

BKI36: 899 mm (35 3/8”)

BKI30: 749 mm (29 1/2”)

Hauteur

2120 mm (83 1/2”) + 25 mm (1”)

Profondeur (sans panneau)

635 mm (25”)

BKI36: 230 (9”)

BKI30: 195 (7 ¾”)

100 (4”)

A A

BI36: 900 (35 ½”)

BI30: 750 (29 5⁄8”)

100 (4”)

BKI30: 1320 (52”)

560 (22”)

635 (25”)

75 (3”)

560 (22”)

BKI36: 899 (35 3⁄8”)

BKI30: 749 (29 ½”)

105°

10 (3⁄8”)

58 (2 ¼”)

6

1308 (51 ½”)587 (23 1⁄8”)

9 ( 3⁄8”)

732 (28 7⁄8”)+25 (1”)

693 (27 ¼”)

146 (5 ¾”)

+ 25(1”)

Page 36

Notice d’Installation

Série: tous

Préparation à l’installation

Transport sur le lieu d’installation

et déballage

2

1

3

4

1

S’agissant d’un appareil lourd et de grandes dimensions, avant de

transporter l’appareil, s’informer sur les modalités d’accès au lieu où il

sera installé (dimensions des portes, espaces de mouvement dans les

escaliers, etc.).

L’appareil est xé à la base de l’emballage (palette) moyennant

quatre boulons amovibles avec une clé de 17 mm (3/4”).

Il est conseillé d’utiliser un transporteur manuel pour manutentionner

l’appareil jusqu’à la zone où celui-ci sera installé et seulement alors

retirer la base de l’emballage.

L’appareil devrait toujours être transporté en position verticale.

Si cela n’est pas possible, transporter l’appareil couché sur le dos.

Une fois que l’on a atteint la zone prévue pour l’installation, enlever

les emballages, faire descendre l’appareil de la palette emballages

et faire descendre l’appareil de la palette.

Intervenir de la manière suivante:

EnglishFrançais

L’appareil est très lourd.

Faire très attention durant la manipulation

an d’éviter tout dommage aux personnes

et aux choses.

Transporter l’appareil en position verticale.

Éviter de manière absolue le transport sur la

partie frontale.

Enlever les quatre boulons 1 qui xent l’appareil à la palette en

utilisant une clé ouverte de 17 mm (3/4”).

Retirer les crochets de xation 3 et 4.

Pour retirer le crochet de xation 3 , dévisser pour un ou deux tours

le boulon de réglage 2 de la roue arrière en utilisant une clé à douille

de 13 mm (1/2» in) .

De l’arrière de l’unité et au moyen d’un chariot diable de caractéristiques appropriées, retirer l’appareil et le poser sur le sol.

Faire très attention an d’éviter tout dommage au sol.

Les sols particulièrement délicats doivent être protégés avec des panneaux de faésite, compensé ou autre matériau adéquat.

7

Page 37

EW

E W

EW

E W

E

W

Série: tous

Raccordements électrique et hydraulique

Les appareils sont livrés de l’usine pour le fonctionnement à 230V AC

- 50Hz (Europe, Royaume Uni et autres Pays) ou 115V AC - 60Hz (Etats-

Unis et Canada).

N’utiliser ni rallonges ni adapteurs multiples pour le branchement.

Un câble d’alimentation avec che équipé d’un contact de

terre sont fournis pour la connexion à une prise de 16A (Europe,

Royaume Uni et autres Pays) ou de 15A (Etats-Unis et Canada) .

Un disjoncteur doit également être installé et doit être facilement accessible an de mettre hors tension l’appareil avant d’effectuer toute

installation ou maintenance.

Pour le raccordement hydraulique (pour les appareils équipés de fabricateur de glace) il faut prévoir un robinet avec raccord mâle de

¾”, facilement accessible même lorsque l’appareil est installé.

Pour le raccordement au robinet, utiliser exclusivement le tuyau compris dans le Kit Utilisateur fourni avec l’appareil.

L’appareil doit être raccordé au réseau d’eau potable, en tenant

compte des dispositions en vigueur dans le pays où l’appareil est installé et en ayant soin d’installer la cartouche du ltre à eau, fournie

avec l’appareil, en suivant les instructions jointes.

N’utiliser ni rallonges ni adaptateurs multiples pour le branchement.

Raccordements électrique et hydraulique derrière l’unité

Série Integrated

Le ltre ne peut pas rendre potable de l’eau

qui n’est pas destinée à la consommation alimentaire.

Ne pas utiliser de réductions ou de rallonges.

S’il faut fermer le robinet général, désactiver d’abord l’Ice Maker

re référence au Manuel d’utilisation).

8

à l’aide du Menu Access (fai-

E

W

Page 38

Branchement Électrique

Raccordement Hydraulique

Notice d’Installation

Série: tous

Arrière de l’appareil

Intervenir de la manière suivante:

Dérouler le câble électrique et le brancher directement à la prise

murale.

Contrôler que l’appareil soit en stand-by et que les voyants soient

éteints; dans le cas contraire, appuyer sur la touche Unit

dre l’appareil.

Raccorder le tuyau de l’eau au réfrigérateur dans la zone arrière 1.

Raccorder le tuyau au robinet en utilisant les garnitures comprises à

l’intérieur du Kit Utilisateur

.

2

pour étein-

EnglishFrançais

9

Page 39

Série: tous

Mise à niveau

2

1

Mettre à niveau l’appareil en réglant les pieds et les roues arrière à la

base de l’appareil.

Intervenir de la manière suivante:

Après avoir enlevé le socle (ou grille) inférieur (il est fixé par des

aimants), régler l’hauteur des pieds de mise à niveau 1 en utilisant

une clé ouverte de 17 mm (3/4”).

Ensuite régler l’hauteur des roues arrière en tournant les boulons de

réglage 2 dans le sens horaire ou anti-horaire comme nécessaire.

Remonter le socle (ou grille) inférieur ou la grille.

2

1

10

Page 40

Notice d’Installation

Série: Integrated (BI)

Préparation des panneaux décoratifs pour la porte et Grands bacs

Les dimensions des panneaux sont indiquées dans le tableau et sur les

dessins reportés ci-dessous.

Selon les exigences d’alignement avec d’autres meubles de la cuisine, le panneau de la porte du réfrigérateur peut être plus haut par

rapport à la ligne supérieure de la porte et le panneau inférieur peut

être plus bas par rapport à la ligne inférieure du grand bac.

Les panneaux sont montés moyennant des brides spéciales qui s’accrochent aux dispositifs de xation réglables déjà prévus sur porte et

grand bac et moyennant des équerres qui bloquent et règlent verti-

calement le panneau.

Brides, équerres et vis de xation correspondantes sont fournies avec

l’appareil et sont appliquées au panneau en suivant le schéma de

perçage reporté ci-dessous ou en utilisant le gabarit de perçage

prévu à cet effet et fourni.

EnglishFrançais

1

Intervenir de la manière suivante:

Pour appliquer les brides aux panneaux, procéder de la manière suivante. Il est recommandé de monter les équerres avant de monter la

poignée.

2

Panneau de la porte

Tracer une ligne qui divise verticalement le panneau en deux parties

égales 1.

Partant du bas du panneau, marquer la hauteur à laquelle pratiquer

les trous (pour la distance des trous, voir les pages 14-17) 2.

3

Suivre les données du tableau correspondant au modèle choisi,

marquer d’abord le trou le plus externe et puis le plus interne 3.

11

Page 41

Série: Integrated (BI)

4

5

Vérier la position des trous en appuyant les équerres sur les marques

panneau

Visser les équerres 6.

Panneau du grand bac

puis pratiquer les trous en faisant attention à l’épaisseur du

4

.

5

Pour le montage du panneau du grand bac, faire référence au

montage du panneau de la porte, avec la différence que les mesures

doivent être prises en partant du côté supérieur du panneau et non

pas du côté inférieur comme dans le cas de la porte

tournée de manière spéculaire à celle de la porte

7

et la bride est

.

8

7

8

12

Page 42

A

1273 (50 1⁄8”)

597 (23 ½”)

203.5(8”)

Notice d’Installation

Série: Integrated

Préparation des panneaux décoratifs pour Réfrigérateur avec un Grand bac

Série 36 Série 30

Note: Toutes les mesures de place-

ment du support latéraux vont à la

ligne de centre du trou de support

extérieur

A

B

C

¼”) 747 (29 3⁄8”)

897 (35

417 (16

3⁄8”) 342 (13 ½”)

354.5 (14”) 279.5 (11”)

EnglishFrançais

Positionnement des trous

BB

6,5 (

¼”)6,5 (¼”)

Panneau

de porte

34 (1

3⁄8”)

¾”)max 635 (25”)

Support de réglage vertical de la

porte supérieure. Noter l’orientation.

1163 (45 ¾”)

660 (26”)

1⁄8”)

382 (15

507.5 (20”)

Support de réglage vertical pour le

tiroir inférieur. Noter l’orientation.

Retour du panneau

¼”)

157 (6

BB

Retour du panneau

100 (4”)

34 (1

13 (½”)

A

3⁄8”)

C C

min 1390 (54

Panneau

de tiroir

13

Page 43

2121 (83

") + 25 (1")

B

115 (4 ½”)

min 200 (7 7⁄8”)

135

(5 3⁄8”)

135

(5 3⁄8”)

1075 (42 3⁄8”)

Série: Integrated (BI)

Dimensions des panneaux

Il est possible d’utiliser des panneaux avec des épaisseurs allant entre 18 mm (3/4 in) et 28 mm (1 1/8 in).

Les panneaux de porte avec un poids max de 23 kg (51 lb) et panneaux de grand bac avec poids max de 11 kg (25 lb)

Excéder ces poids pourrait annuler la garantie de tous les problèmes de services qui peuvent être attribués à des panneaux en surpoids.

Le mécanisme de charnière sur les appareils est considéré comme `zéro dégagement`. Les largeurs de portes et de

tiroirs spécifiées ci-dessous supposent la largeur de niche minimum est utilisé et une de 3,5 mm (1/8 “) révèlent l’on

souhaite autour des panneaux. Ajuster les dimensions de votre écran en fonction de vos propres critères de conception

compte tenu de la largeur de votre créneau et votre révèlent. Jeu minimum / écart ne doit pas être inférieure à 1,5 mm

(1/16 “).

Séries

BI36

BI30

Largeur de la porte

et de tiroir

897 (35 1/4”)

747 (29 3/8”)

Largeur

de l’encastrement

900 (35 1/2”)

750 (29 5/8”)

1390 (54 ¾”)

Exemples:

84” hauteur de l’encastrement

36” largeur de l’encastrement

4” hauteur de plinthe

1/8” distance désirée autour

Door panel:

Largeur: 35-3/4”

Hauteur: 54-3/4”

Drawer panel:

Largeur: 35-3/4”

Hauteur: 84”-1/8”-54-3/4”-1/8”-4”=25”

If you want a 6” toe kick height then your

bottom drawer panel height would be 23”

½

14

3 (1⁄8”)

min 540 (21 ¼”)

max 635 (25”)

A

Page 44

Notice d’Installation

Série: Integrated (BI)

Montage des poignées: Sèrie Integrated (BI)

1

Les poignées doivent être montées sur le panneau décoratif de la

porte et du grand bac avant que les panneaux ne soient xés au

réfrigérateur.

Intervenir de la manière suivante:

Après avoir pratiqué deux trous de 5 mm (1/4”) sur le côté arrière

des panneaux, insérer les vis fournies à la distance indiquée sur le tableau, reportée ci-dessous, l’une de l’autre. Pour centrer la poignée

horizontale (code HV) au centre de la porte, diviser en deux la hau-

teur du panneau et pratiquer un trou à -45 cm (-17 3/4”) et un autre

à +45 cm (+17 3/4”) 1.

EnglishFrançais

2

Positionner la poignée au niveau du trou sur le côté avant du panneau; insérer par l’arrière du panneau la vis fournie, à travers le trou,

et la visser à la poignée 2.

Longueur A

Utiliser la même procédure pour le montage des poignées horizontales sur les grands bacs. Pour la mesure de l’entraxe, faire référence

au tableau joint.

900 mm

(35 1/2”)

480 mm

(18 7/8”)

490 mm

(19 1/4”)

15

Page 45

Série: Integrated (BI)

Fixation des panneaux à la porte et au Grand bac: Sèrie Integrated

Aprés avoir appliqué les pattes de xation et les équerres aux panneaux, commencer l’installation par le tiroir du bas.

1

Intervenir de la manière suivante:

2

Serrer les vis que partiellement aux xations inférieures 1.

Fixer le panneau aux support du tiroir à partir des crans de la partie

inférieure de réglage 2

3

À ce point il est possible de régler la hauteur du panneau avec les

crans interieurs pour s’aligner, 3 en serrant ou déssérant la vis. En

tenant la vis un peu desserée, déplacer à droite ou à gauche le pan-

neau pour le centrer au panneau de la porte ou au reste des meubles

de la cuisine.

Alignement en profondeur en travaillant de l’intérieur du tiroir et

après avoir soulevé le joint magnétique, rapprocher ou éloigner le

panneau du tiroir à travers les trous 4 puis xer le panneau toujours

à travers les trous 5.

4

Une fois le panneau avant a été réglé, vériez que le joint a été repo-

5

16

sitionné correctement pour assurer

la porte / tiroir ferment correctement et éviter les erreurs de fonctionnement de l’unité.

Page 46

Notice d’Installation

Série: Integrated (BI)

Accrocher le panneau aux dispositifs de xation en insérant dans les

crans d’alignement supérieurs

6

Il est possible d’ajuster l’alignement du panneau par rapport aux

meubles adjacents à l’aide des pattes et des équerres d’alignement

et 8.

7

.

6

7

EnglishFrançais

Alignement vertical: soulever ou abaisser le panneau 9 en vissant

ou en dévissant la vis à l’équerre.

8

9

Alignement en profondeur en travaillant de l’intérieur de la porte

à après avoir soulevé le joint magnétique, rapprocher ou éloigner le

panneau à sa place toutjours à travers les trous

au à sa place toujours à travers les trous

11

puis xer le panne-

10

.

10

11

Une fois le panneau avant a été réglé, vériez que le joint a été repositionné correctement pour assurer

la porte / tiroir ferment correctement et éviter les erreurs de fonctionnement de l’unité.

17

Page 47

6,5 (¼”) 6,5 (¼”)

Série: tous

Montage dans une armoire de cette hauteur exige que l’arrière de l’armoire de ventilation par le haut. Sinon, un

2” supplémentaires de hauteur de l’armoire est requis pour une ventilation adéquate. Hauteur du panneau latéral

personnalisé peut être plus élevé que nécessaire.

Installation dans la niche

Encastrement appareil unique

Des prols en aluminium peuvent être utilisés pour fermer les espaces

entre l’appareil et les meubles adjacents ou un autre appareil juxtaposé à celui-ci.

1

Intervenir de la manière suivante:

Pousser l’appareil dans la niche d’installation 1.

Si l’appareil doit être installé dans une niche ou à l’intérieur d’une

2

structure fermée, il sera nécessaire de prévoir une cheminée de ventilation à l’arrière de la niche pour garantir une ventilation adèquate. Un écart de 5 mm (1/4”) est sufsant pour éviter tout surchauffement. Assemblez toujours les panneaux frontaux à la porte et aux tiroirs

avant de placer l’appareil dans sa position dénitive dans la niche ou

la structure.

Vérier que les pieds et les roues arrière soient à niveau avant d’encastrer l’appareil.

Fixer l’appareil aux meubles adjacents en vissant à ces derniers les

deux prols latéraux, déjà montés sur l’appareil 2.

3

Schéma de montage prols latéraux

Paroi

ou

meuble

20 (¾”)

22 (7⁄8”)

22 (7⁄8”) 22 (7⁄8”)

A Profil de raccordement B Corniche de couverture en aluminium

18

Pour effectuer facilement l’opération, garder la porte et le grand bac

ouverts.

Monter sur les prols les corniches de couverture, en les insérant

latéralement 3 et puis en poussant avec force jusqu’au “clic”.

Appareil

A

B

Paroi

ou

meuble

20 (¾”)

22 (7⁄8”)

Page 48

Notice d’Installation

Série: tous

Encastrement combinaison

1

2

Accessoires nécessaires à commander séparément:

Kit raccordement central (KCCIT/KCCIH)

Des prols en aluminium peuvent être utilisés pour fermer les espaces

entre l’appareil et les meubles adjacents ou un autre appareil juxtaposé à celui-ci.

Intervenir de la manière suivante:

Positionner les appareils devant la niche en laissant un espace sufsant pour intervenir sur l’arrière des appareils 1.

EnglishFrançais

Passer à l’arrière des appareils pour le montage des équerres de

connexion. Fixer un côté de l’équerre supérieure et inférieure, d’abord

sur un des deux appareils et ensuite sur l’autre 2.

3

4

Visser entre eux les deux prols avec les rivets fournis 3.

Fixer l’équerre supérieure 4 et l’inférieure 5 d’abord sur un appareil

et puis sur l’autre.

Pour effectuer facilement l’opération, garder la porte et le grand bac

ouverts.

Compléter en montant la corniche de couverture centrale en poussant avec force jusqu’au “clic”.

19

Page 49

Série: tous

5

Une fois complétés les passages ci-dessus, poussez les appareils

dans leur position dénitive 6.

Il sera nécessaire de prévoir une cheminée de ventilation à l’arrière

de la niche pour garantir une ventilation adèquate. Un écart de 5 mm

est sufsant pour éviter tout surchauffement. Assemblez toujours les

panneaux frontaux à la porte et aux tiroirs avant de placer l’appareil

dans sa position dénitive dans la niche ou la structure.

Vérier que les pieds et les roues arrière soient à niveau avant d’encastrer l’appareil.

Fixer chaque appareil aux meubles adjacents en vissant à ces derniers les prols latéraux, déjà montés sur les appareils 7.

Pour effectuer facilement l’opération, garder la porte et le grand bac

ouverts.

6

ou

meuble

Monter sur les prols les corniches de couverture, en les insérant

latéralement 8 et puis en poussant avec force jusqu’au “clic” (comme pour l’encastrement de l’appareil unique).

7

Schéma montage prols centraux et latéraux

6,5 (¼”) 6,5 (¼”)

Appareil AppareilParoi

6,5 (¼”)6,5 (¼”)

C

13 (½”)

Paroi

ou

meuble

20 (¾”)

22 (7⁄8”)

22 (7⁄8”) 22 (7⁄8”)

A Profil de raccordement

B Corniche de couverture en aluminium

20

A

D

18 (¾”)

18 (¾”)

D

A

22 (7⁄8”)

20 (¾”)

E

B

44,4 (1 ¾”)

D Prol de raccordement centrale

E Corniche centrale en aluminium de couverture

B

Page 50

2 x

6 x

2 x

6 x

Notice d’Installation

Anti tipping kit installation

1

2

2 x

6 x

3

4

EnglishFrançais

1

2 x

6 x

3

2

4

21

Page 51

Série: Inox Integrated (BKI)

Montage des poignées sur le devant inoxydable

1

Pour xer les poignées à la porte et au grand bac, intervenir comme

indiqué.

Intervenir de la manière suivante:

Insérer les écarteurs sur les deux goujons présents sur la porte et sur le

grand bac 1.

Visser les vis à six pans présentes dans la poignée 2.

2

Les vis de xation seront serrées à fond, en utilisant une clé à six pans

de 2,5 mm (1/8”).

22

Page 52

Notice d’Installation

Série: tous

Circulation de l’air

Un système à air forcé assure la ventilation à travers la grille positionnée

dans la dans la partie inférieure de l’appareil. Si l’aménagement de la

cuisine prévoit une plinthe, cette dernière doit être trouée an de garder un niveau d’aréation satisfaisant, comme expliqué dans le dessin.

Les trous peuvent être de toute sorte de forme et dimension, à condition que la surface totale de la partie trouée est égale au 50% de la

surface de la plinthe.

Dans ce cas, pour permettre une meilleure aération, il est préferable

de retirer la grille frontale de l’ensemble. La grille est accrochée à

l’ensemble avec des plaques magnetiques et peut être facilement

retirée par l’utilisateur nal, an d’être nettoyée régulièrement de la

poussière.

Série 36 Série 30

A 860 (33 7⁄8”) 740 (29 1⁄8”)

B

C

> 100 (4”)

10 (3⁄8”)

50%

EnglishFrançais

C

B

C

A

La grille de ventilation ne doit pas être bloqué ou couvert d’aucune

manière. Il doit aussi être dépoussiéré / nettoyés régulièrement.

100 (4”)

23

Page 53

Série: tous

Contrôle de n d’installation mise en marche

Contrôler que les pieds sont correctement installés.

Contrôler que le raccordement à l’installation hydrique ne présente

pas de fuites d’eau et que le robinet de fermeture est facilement ac-

cessible.

Contrôler que le branchement électrique soit correctement réalisé

et que la che et l’interrupteur omnipolaire dédié soient facilement

accessibles.

Contrôler le parfait alignement de l’appareil avec les meubles ad-

jacents.

Contrôler que chaque ruban adhésif ou protection temporaire in-

terne ou externe soit éliminé.

Contrôler la parfaite étanchéité des portes et le coulissement des

bacs et des clayettes.

24

Page 54

U

NI

T

1234 56798

1 Unit

2 Fridge

3 Menu

Up/down

4

Fridge

5 Display

Up/Down

6

Freezer

(TriMode)

7 Enter

8 Ice maker

9 Alarm

E

N

T

R

FR

ID

GE

E

Switches the appliance (all compartments) between ON and STAND BY

(press for three seconds).

Allows switching on and off of only the refrigerator compartment

(press for three seconds).

Allows access to the appliance function menu

Using the Up and Down buttons, it is possible to change the set temperature of the refrigerator and navigate through the interactive menu.

It shows the temperature of the refrigerator and freezer compartments,

the date and time, Menu functions and visual messages.

By selecting Up/Down the preset temperature can be changed according to the selected function mode (freezer, refrigerator, Crisper-Fresco).

Confirms activation or deactivation of the selections made in the

Menu.

Allows activating or deactivating the automatic ice production.

Blinks to signal user alerts such as door left open, also in combination with

a sound signal which can be deactivated by pressing the button.

Notice d’Installation

Série: tous

Mise en marche

Pour mettre en marche l’appareil, brancher la che au réseau

électrique: lorsque la porte est ouverte, apparaît sur le panneau de

commande le message “Stand-by”, alors que toutes les touches du

panneau sont éteintes.

FRIDGE

UNIT

Pour mettre en marche tous les compartiments de l’appareil, appuyer pendant 3 secondes sur la touche Unit .

Le message “initial test” apparaîtra pendant environ 2 minutes, ensuite

les compresseurs seront actifs jusqu’à attendre la température prévue

en usine par défaut. Veuillez noter que cette opération pourrait durer

plusieurs heures.

CR

ISP

E

R

I

CE

MA

K

E

R

11 Display

12 Up/Down

13 Crisper

10 11 12

Shows the temperature of the Crisper-Fresco compartment.

Using the Up and Down buttons, it is possible to change the

temperature set for the Crisper-Fresco compartment.

Allows switching on and off of only the Crisper-Fresco compartment

(press

for three seconds).

Si l’appareil est fourni avec un appareil à glaçons avant de le mettre

en marche pour la première fois, veuillez vous assurer que la cartouche

du ltre pour l’eau a bien été installée et effectuez un remplissage du

circuit hydraulique. Appuyez donc en même temps sur les touches

Enter et Ice Maker . Après quelques minutes l’appareil à glaçons

English

peut être activé en appuyant sur la touche Ice Maker

.

EnglishFrançais

Pour toute autre information concernant le fonctionnement de

l’appareil, se référer au Mode d’emploi.

8

9

Si lors de la première mise en marche, n’apparaît pas le message Stand-by, mais apparaissent

Fridge too warm, Fresco too warm, Freezer too

warm ou signaux sonores, cela signie que l’appareil a déjà commencé la procédure de refroidissement.

Dans ce cas désactiver les éventuels messages

sonores en efeurant la touche Alarm, refermer la

porte et attendre que les températures programmées soient atteintes.

Il faut laisser l’unité atteindre la température de

fonctionnement vide et avec la porte et un tiroir fermé avant que les aliments sont stockés à l’intérieur.

25

Page 55

Page 56

Loading...

Loading...