Bertazzoni REF30RCPIXR, REF30FCIPIXR, REF30RCPIXL, REF30FCIPIXL, REF30RCPRR Installation Guide

...Page 1

Installation guide

Notice d’installation

Guía de instalación

REF18WCPIXL

REF18WCPIXR

REF18FCIPIXL

REF18FCIPIXR

REF18WCPRL

REF18WCPRR

REF18FCIPRL

REF18FCIPRR

REF24RCPIXL

REF24RCPIXR

REF24WCPIXL

REF24WCPIXR

REF24FCIPIXL

REF24WCPRL

REF24WCPRR

REF24FCIPRL

REF24FCIPRR

REF30RCPIXL

REF30RCPIXR

REF30FCIPIXL

REF30FCIPIXR

REF30RCPRL

REF30RCPRR

REF30FCIPRL

REF30FCIPRR

REF36RCPIXL

REF24FCIPIXR

REF24RCPRL

REF24RCPRR

REF36RCPIXR

REF36RCPRL

REF36RCPRR

Page 2

Page 3

INDEX

1

IMPORTANT INSTRUCTIONS

1.1

Important safety instructions.....................................................................................................................................

1.2

Children safety................................................................................................................................................................

2

TECHNICAL REQUIREMENTS

2.1

Appliance features and installation requiremens................................................................................................

2.2

Installation cutout features: panel ready................................................................................................................

2.3

Installation cutout features: panel installed..........................................................................................................

3

PREPARING THE INSTALLATION

3.1

Transport to installation site and unpacking.........................................................................................................

3.2

Electrical and water connection................................................................................................................................

3.3

Energy: Alternatives and Home Automation.........................................................................................................

3.4

Levelling...........................................................................................................................................................................

4

CUTOUT DIMENSIONS

4.1

Cutout dimensions and installation..........................................................................................................................

4.2

Flush installation with standard trims....................................................................................................................

5

PANELS MOUNTING

5.1

Decorative door panel layout......................................................................................................................................

5.2

Decorative panel for fridge column..........................................................................................................................

5.3

Decorative panels layout for wine column with glass door..............................................................................

5.4

Panel dimensions column models...........................................................................................................................

5.5

Mounting panels to the door.......................................................................................................................................

EN

4

4

4

4

4

6

7

8

8

8

9

9

10

10

10

11

11

13

14

15

16

6

INSTALLATION

6.1

Built-in installation of single appliance...................................................................................................................

6.2

Built-in installation of two or more appliances.....................................................................................................

6.3

Maximum cabinet depth over panel ready appliance with single door panel.............................................

7

COMPLETING THE INSTALLATION

7.1

Anti-tipping safety assembly......................................................................................................................................

7.2

Ventilation........................................................................................................................................................................

7.3

Post installation control...............................................................................................................................................

7.4

Start up.............................................................................................................................................................................

18

18

18

22

23

23

24

25

25

3

Page 4

1. IMPORTANT INSTRUCTIONS

2. TECHNICAL REQUIREMENTS

1.1 Important safety instruction

Symbols used in the Guide:

Note

Tips for the correct use of the appliance

Important

Directions to avoid appliance damage

Warning

directions to prevent injury

1.2 Children safety

DANGER: Risk of child entrapment. Before you throw

away your old refrigerator, freezer or wine cellar:

> Take o the doors

> Leave the shelves in place so that children may not

easily climb inside.

2.1 Appliance features and installation

requirements

Appliance

dimensions

panel ready

Appliance

dimensions

stainless

steel clad

18”

w: 456 mm (17 15/16”)

h: 2120 mm (83 1/2”)

d: 615 mm (24 1/4”)

24”

w: 609 mm (24”)

h: 2120 mm (83 1/2”)

d: 615 mm (24 1/4”)

30”

w: 761 mm (29 15/16”)

h: 2120 mm (83 1/2”)

d: 615 mm (24 1/4”)

36”

w: 913 mm (35 15/16”)

h: 2120 mm (83 1/2”)

d: 615 mm (24 1/4”)

18”

w: 456 mm (17 15/16”)

h: 2120 mm (83 1/2”)

d: 620 mm (24 3/8”)

24”

w: 609 mm (24”)

h: 2120 mm (83 1/2”)

d: 620 mm (24 3/8”)

30”

w: 761 mm (29 15/16”)

h: 2120 mm (83 1/2”)

d: 620 mm (24 3/8”)

36”

w: 913 mm (35 15/16”)

h: 2120 mm (83 1/2”)

d: 620 mm (24 3/8”)

Important!

Dimensions in parentheses are in inches.

Weights in parentheses are in pounds.

Temperatures in parentheses are

in Fahrenheit degrees.

4

Page 5

EN

Weight with

packaging

Voltage AC 110 - 120V 60Hz

Power supply

cable

Dedicated circuit

breaker

Potable water

supply pressure

PSI measurement 7.25psi - 72.5psi

Water connection 3/4” NPT (1/4” elbow adap-

Provided

installation

accessories

18”

up to 150 kg (331 lb)

24”

up to 170 kg (375 lb)

30”

up to 190 kg (419 lb)

36”

up to 200 kg (441 lb)

90° Nema 5-15P

15A

from 0.05 MPa to 0.5 MPa

(0.5 Bar - 5 Bar)

ter included)

- Anti tipping kit Z310113

(in all columns panel ready

and panel installed)

- Joining strip, white

Z310057 (in all columns

panel ready and panel

installed)

- Lateral mounting clips

(10 pieces white) Z310129

(in all columns panel ready

and panel installed)

- Customized panels

mounting kit, fridge and

freezer Z310272 (only in

fridge and freezer columns

panel ready)

- Customized panels

mounting kit, wine cellar

Z310273 (only in wine columns panel ready)

- Central connection kit , for

panel ready models combined installation Z310293

(only in freezer and wine

columns panel ready)

Additional

equipment

necessary

Others provided

accessories

- Central connection kit,

for panel installed models combined installation

Z310287 (only in freezer

and wine columns panel

installed)

- Water connection kit

Z310300 (only in freezer

columns panel ready and

panel installed)

- 4 mm (1/8”) allen wrench

(in all columns panel ready

and panel installed)

- Phillips head screwdriver

- wood drill

- 2.5 mm (1/8”) bit for wood

- 8 mm (3/8”) bit for walls

- 10 mm (3/8”) bit for walls

- 17 mm (11/16”) wrench

- 19 mm (3/4”) wrench

- Cleaning kit Z310284

(in all columns panel ready

and panel installed)

5

Page 6

2. TECHNICAL REQUIREMENTS

36": 1489 (58

24": 1187 (46

565 (22 ¼")

615 (24 ¼")

36": 913 (35

15⁄ 16

")

30": 761 (29

15⁄ 16

")

24": 609 (24")

18": 456 (17

15⁄ 16

")

233 (9

¼”

)

+ 25 (1”)

min 2130 (83 ⅞”)

A A

140 (5 ½”) 140 (5 ½”)

100 (4”)

100 (4”)

S899 / FI36: 914 (36”)

S449 / FI18: 457 (18”)

S599 / FI24: 610 (24”)

S749 / FI30: 762 (30”)

615 (24 ¼”)

565 (22 ¼” )

1808 (71 ¼” )

231 (9

⅛”

) +

25 (1”)

505 (19 ¾”)

2120 (83 ½”) +25 (1”)

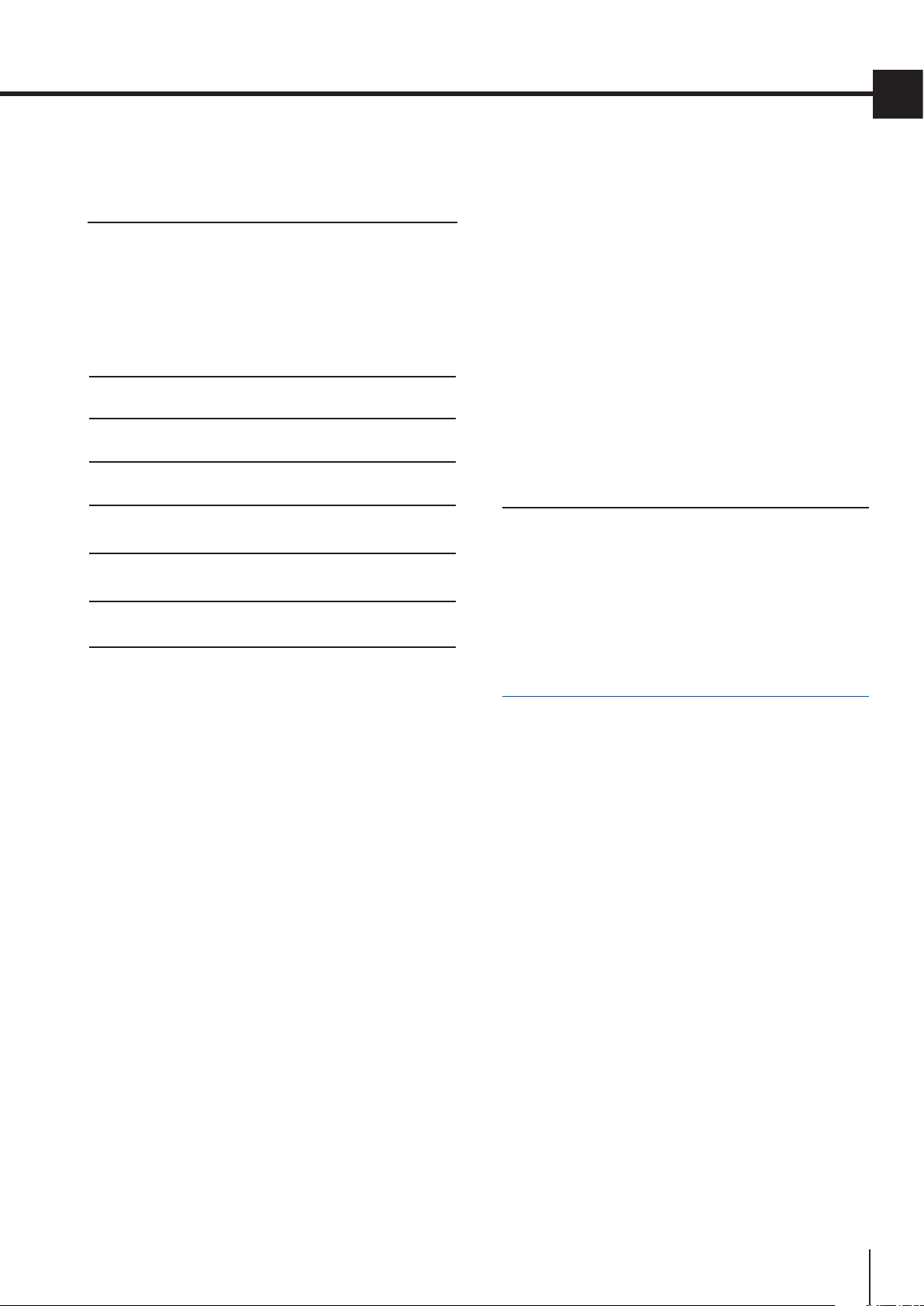

2.2 Installation cutout features:

panel ready

A - area to be left clear for the anti-tipping brackets

Minimum cutout Height

2130 mm (83 7/8”)

127 mm (5") 127 mm (5")

82 mm (3 1/2")

A A

36":914 (36”)

82 mm (3 1/2")

Minimum cutout Width

36”: 914 mm (36”)

30”: 762 mm (30”)

24”: 610 mm (24”)

18”: 457 mm (18”)

Minimum cutout Depth

615 mm (24 1/4”) + panel thickness for flush install

Door hinges do not lock at 90°

Door Swing Clearance

36”: 1489 mm (58 5/8”)

30”: 1338 mm (52 5/8”)

24”: 1187 mm (46 3/4”)

18: 1036 mm (40 3/4”)

Door Opening Angle

100°

Width

36”: 913 mm (35 15/16”)

30”: 913 mm (29 15/16”)

24”: 609 mm (24”)

18”: 456 mm (17 15/16”)

30": 762 (30”)

min 2130 (83 ⅞”)

24": 610 (24”)

18": 457 (18”)

Height

2120 mm (83 1/2”) + 25 mm (1”)

Depth with door (without panel)

615 mm (24 1/4”)

Minimum distance from the wall (hinge side)

36”: 158 mm (6 1/4”)

30”: 132 mm (5 1/4”)

24”: 108 mm (4 1/4””)

18”: 82 mm (3 1/4”)

6

")

¾

¾")

⅝")

18": 1036 (40

30": 1338 (52 ⅝")

565 (22 ¼")

615 (24 ¼")

36": 913 (35

30": 761 (29

24": 609 (24")

18": 456 (17

100°

15⁄ 16

15⁄ 16

15⁄ 16

")

")

")

36": 158 (6 ¼")

30": 132 (5 ¼" )

24": 108 (4 ¼")

18": 82 (3 ¼")

Page 7

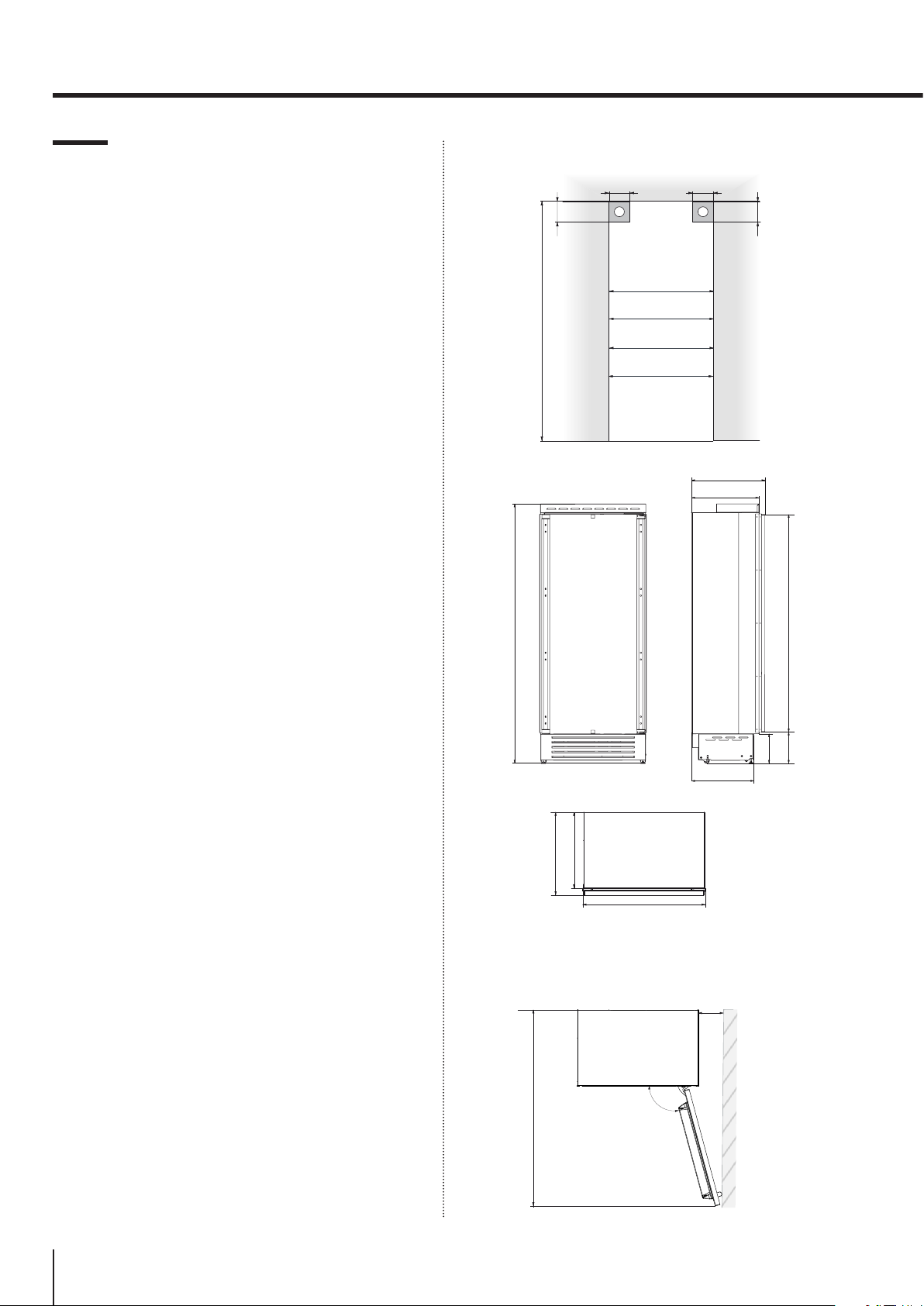

2.3 Installation cutout features:

565 (22 ¼”)

620 (24 ⅜”)

36": 913 m m ( 35

15⁄ 16

")

30": 761 m m ( 29

15⁄ 16

")

24": 609 m m ( 24")

18": 456 m m ( 17

15⁄ 16

")

55 (3 ⅛”)

58 (2 ¼”)

A A

E W E W

140 (5 ½”) 140 (5 ½”)

100 (4”)

100 (4”)

KS899: 900 (35 ½”)

KS599: 600 (23 ¾”)

KS749: 750 (29 ⅝”)

146 (5

+ 25(1”

KS449: 450 (17 ¾”)

100°

36": 1487 (58 ½”)

30": 1336 (52 ⅝”)

24": 1185 (46 ⅝”)

18": 1034 (40 ¾’’)

565 (22 ¼”)

620 (24 ⅜”)

36": 913 m m ( 35

15⁄ 16

")

30": 761 m m ( 29

15⁄ 16

")

24": 609 m m ( 24")

18": 456 m m ( 17

15⁄ 16

")

55 (3 ⅛”)

58 (2 ¼”)

36": 139 (5 ½”)

30": 103 (4 ⅛”)

24": 89 (3 ½”)

18": 63 (2 ½”)

panel installed

A - area to be left clear for the anti-tipping brackets

Minimum Cutout Height

2130 mm (83 7/8”)

127 mm (5") 127 mm (5")

82 mm (3 1/2")

A A

36":914 (36”)

EN

82 mm (3 1/2")

Minimum Cutout Width

36”: 914 mm (36”)

30”: 762 mm (30”)

24”: 610 mm (24”)

18”: 457 mm (18”)

Minimum Cutout Depth

635 mm (25”)

Door hinges do not lock at 90°

Door Swing Clearance

36”: 1487 mm (58 1/2”)

30”: 1336 mm (52 5/8”)

24”: 1185 mm (46 5/8”)

18”: 1034 mm (40 3/4”)

Door Opening Angle

100°

Width

36”: 913 mm (35 15/16”)

30”: 761 mm (29 15/16”)

24”: 609 mm (24”)

18”: 456 mm (17 15/16”)

Height

2120 mm (83 1/2”) + 25 mm (1”)

min 2130 (83 ⅞”)

0F

2120 (83 ½”) +25 (1”)

30": 762 (30”)

24": 610 (24”)

18": 457 (18”)

620 (24 ⅜” )

565 (22 ¼” )

672 (26 ½”)

1904 (75”)

)

¾”)

Depth with door

620 mm (24 3/8”)

Minimum distance from the wall (hinge side)

36”: 139 mm (5 1/2””)

30”: 103 mm (4 1/8”)

24”: 89 mm (25”)

18”: 63 mm (2 1/2”)

7

Page 8

3. PREPARING THE INSTALLATION

Water Filter

EW

E W

EW

E W

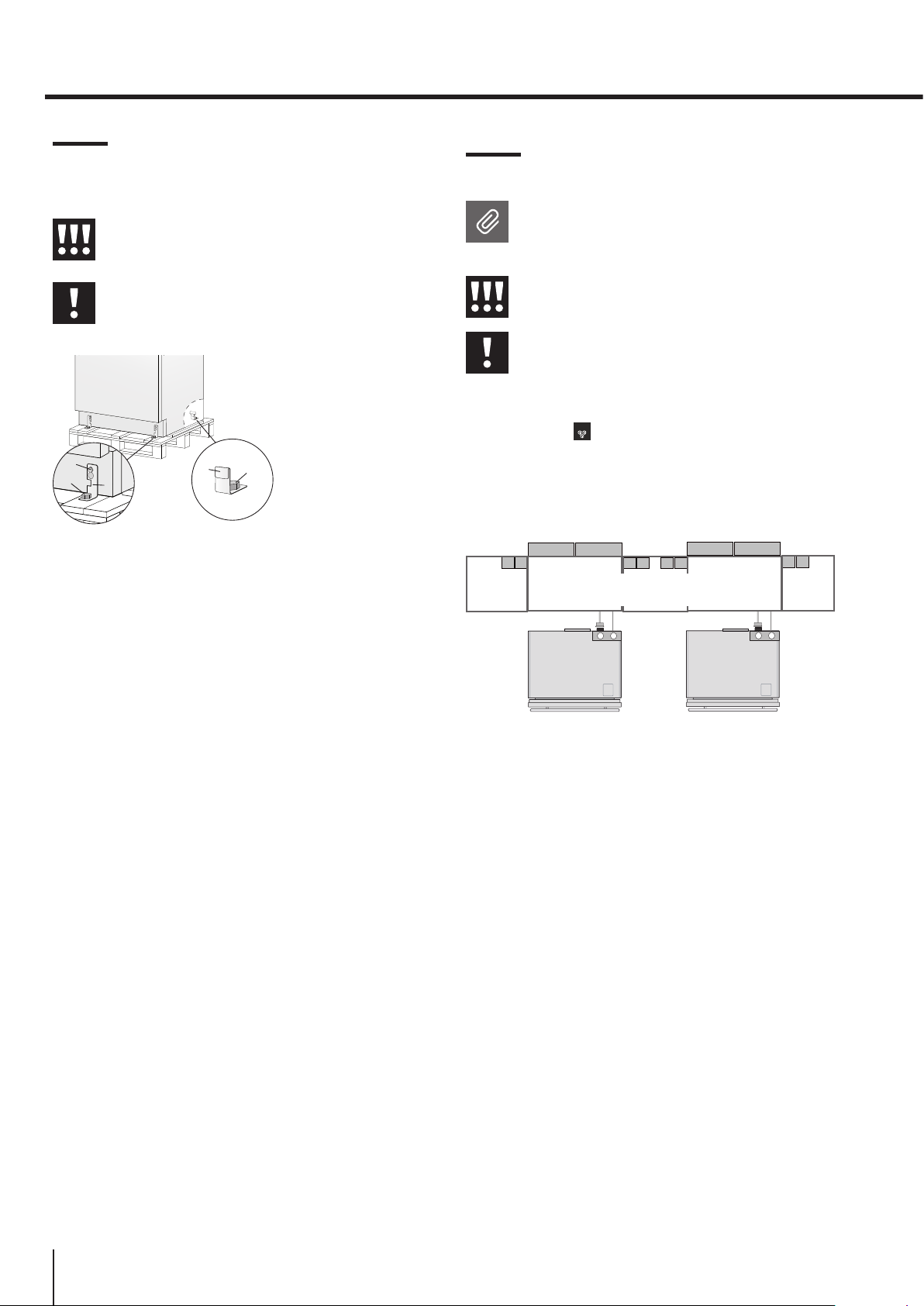

3.1 Transport to installation site

and unpacking

The appliance is very heavy.

Take maximum care during handling

to avoid injury.

The appliance should always be

transported in an erect position.

Avoid at all costs leaning it on its front

side.

2

1

3

Since this is a large and heavy appliance, before transporting the appliance, check the access to the location where it will be installed (door size, maneuvering

space in stairwells, etc.).

The appliance is attached to the base of the packaging

(pallet) through four bolts which can be removed using a 19 mm (3/4”) wrench.

It is recommended to use a manual transporting device to move the appliance to the installation site, and

only at this point to remove the base of the packaging.

The appliance should always be transported in an

erect position.

If this is not possible, transport the appliance laying

on its rear side.

Once at the installation site, the appliance, which is

equipped with four wheels, can be taken o the pallet

and positioned in the installation area.

Operate as follows:

> Take o the four bolts securing [ 1 ] the appliance to

the pallet by means of a 19 mm (3/4”) wrench or socket.

> Remove the fixing brackets [ 3 ] and [ 4 ] .

> To release the front fixing bracket [ 3 ] , unscrew the

rear wheel adjusting bolt [ 2 ] by means of a 13 mm

(1/2”) wrench or socket. Avoid straining this bolt at its

stop points one way or the other so as to not damage

the rear leveling system.

Ensure the front leveling legs are retracted so that all

4 wheels are able to contact the floor for easiest maneuvering.

> From the back of the unit and by means of a suitable, high duty hand trolley, take o the appliance and

place it on the floor.

Be very careful to avoid any damage to floors. Delicate

floors should be protected with plywood, hard cardboard or similar material panels.

4

1

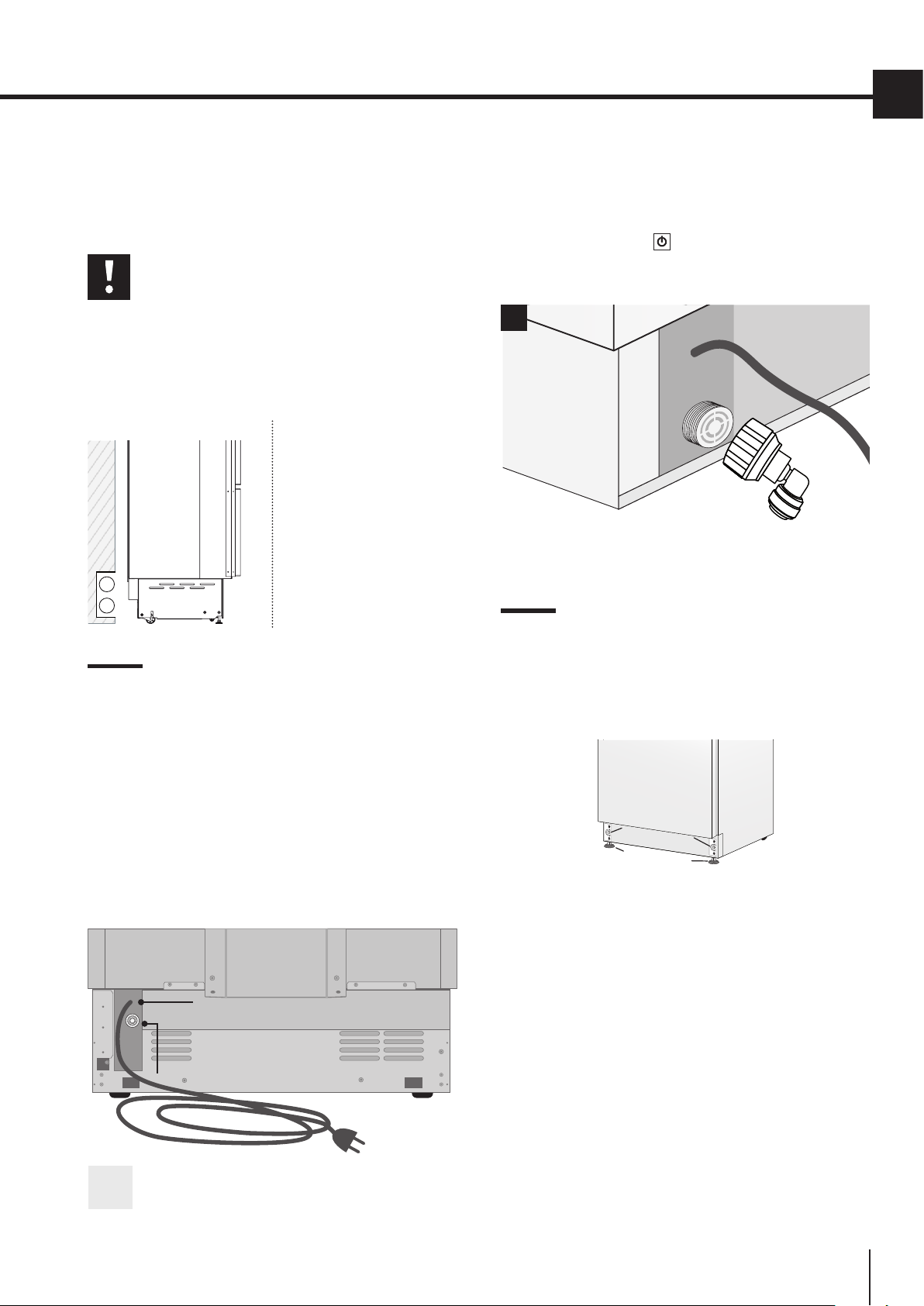

3.2 Electrical and water connection

The Built-in filter cannot make it safe to

drink any water which is not suitable for

human consumption.

The appliance should be connected only

to a potable water supply system.

Do not use extension cords or adapters.

Once the appliance is fully installed, connected to the water supply (if applicable)

and operational, in the event that the water supply must be turned off, (touch the

button

ice maker) before the main water is shut

off to prevent the appliance from entering

a ‘NO WATER IN’ alarm state.

E

W

The appliances are delivered from the factory for operation at 110V-120V AC - 60Hz (US and Canada).

They are provided with a suitable supply cable and

plug to be connected to an appropriate 15A socket

providing an eective grounding.

A dedicated 15A circuit breaker should also be installed and should be easily accessible so that it can

be easily switched o before performing any installation or maintenance.

To connect to the water supply system (for appliances

equipped with ice makers) a 1/4” waterline with accessible shut-o valve must be supplied.

The appliance is provided with a water adapter elbow

which is suitable for the recommended water pressure and complies the applicable food and water regulations.

The water filter cartridge, which is provided with the

appliance, should be installed according to the accompanying instructions. Please refer to water filter

installation instructions contained in the water filter

kit. The solenoid connection on the appliance is 3/4”

diameter but is metric threaded (NPT). A standard

Ice Maker

on control panel to disable the

E

W

E

W

ELECTICAL & WATER

CONNECTION

E

E

W

W

W

E

8

Page 9

EN

E

W

garden hose threaded connector such as a braided

stainless hose found at typical hardware stores will

strip or damage the solenoid threads. It is recommended to use only the supplied 1/4” quick connect

elbow adapter for connecting a 1/4” copper or polyethylene source water line to the appliance.

Do not use extension cords and/or multiple adapters for the power supply connection.

ELECTRICAL AND WATER SUPPLY

BEHIND THE UNIT

E

W

Operate as follows:

> Unwind the electric cable and connect it directly to

the wall socket.

> Make sure the appliance is in the Stand-by condition and that all lights are o; should it be not so

press the Unit button to switch it o.

> Connect the water cable behind the appliance [ 1 ].

1

3.4 Levelling

3.3 Energy: Alternatives and Home Automation

If energy is supplied through an alternative energy power source (solar, geothermal, etc..) or

if home automation systems are installed with

carrier signals in the power lines, it may be necessary to install an isolation transformer (not

supplied) to prevent interference with the appliance’s electronics.

Electrical connection

Water connection

fig.1 Back of appliance

Adjust the appliance level by means of the front

levelling feet and the rear adjustable wheels.

2

1

2

1

Operate as follows:

> If necessary, remove the bottom plinth or grille

(it is kept in position by magnets), adjust the

height of the levelling feet [ 1 ] by means of a 17

mm (11/16”) wrench.

> Then adjust the height of the rear wheels by

turning the front adjusting bolts [ 2 ] clockwise

(raise) or counter-clockwise as it may be required.

Take care if using a power driver for this and

lower the clutch to prevent damaging the leveling

mechanism.

> Remount the bottom plinth or grille.

9

Page 10

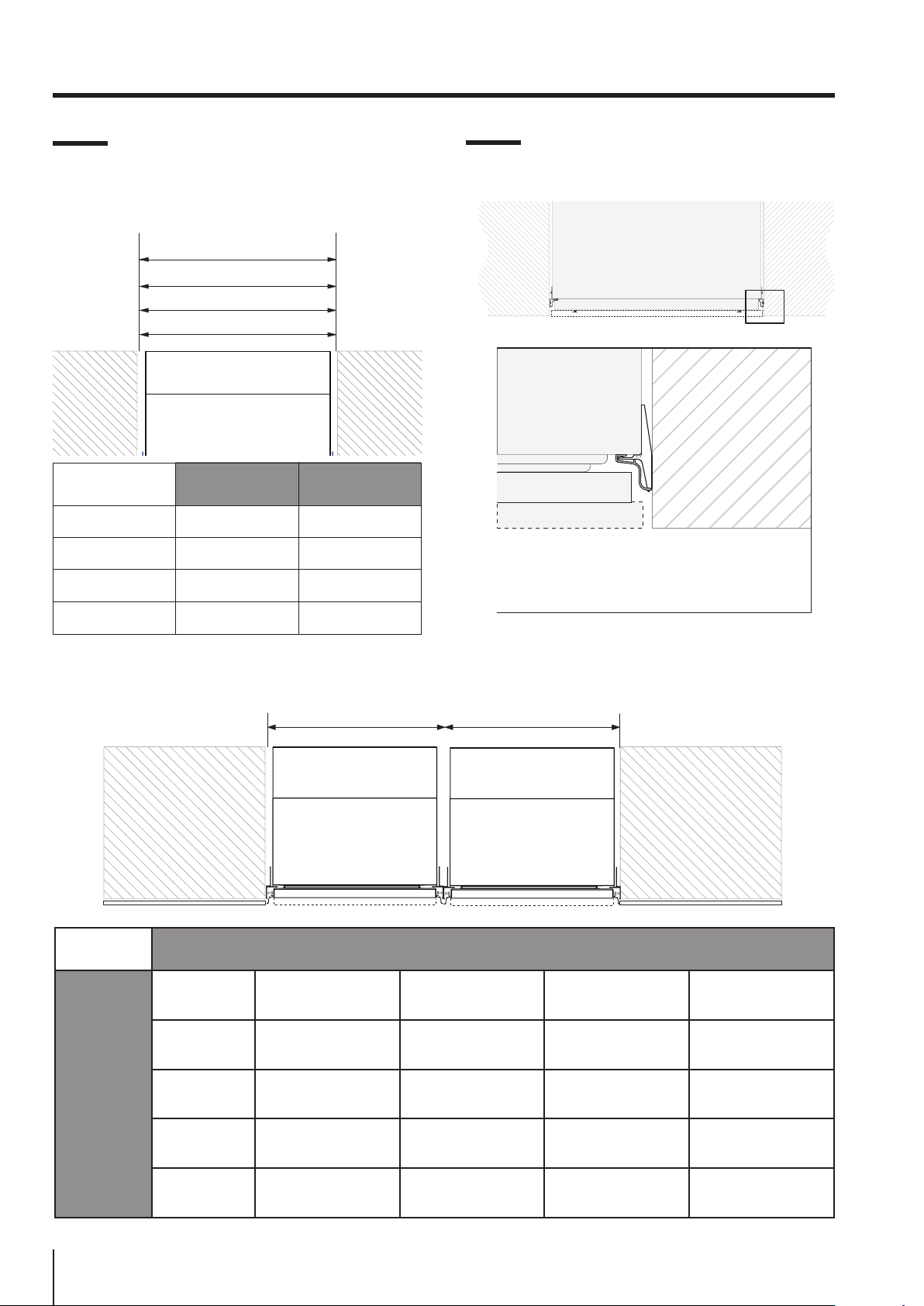

4. CUTOUT DIMENSIONS

A

B

4.1 Cutout dimensions and installation

36": 914 (36”)

30": 762 (30”)

24": 610 (24”)

18": 457 (18”)

Series

36”

30”

24”

762 (30”)

610 (24”)

Panel WidthCutout width

908 (35 3/4”)914 (36”)

756 (29 3/4”)

604 (23 3/4”)

4.2 Flush installation with standard

trims

A

18”

457 (18”)

451 (17 3/4”)

Cutout dimension for combined installation

18” 24” 30” 36”

18” 36”(914mm) 42”(1067mm) 48”(1220mm) 54”(1372mm)

B

A - KCLITU: Lateral connection Kit (included)

A

10

24” 42”(1067mm) 48”(1220mm) 54”(1372mm) 60”(1520mm)

30” 48”(1220mm) 54”(1372mm) 60”(1520mm) 66”(1676mm)

36” 54”(1372mm) 60”(1524mm) 66”(1676mm) 72”(1829mm)

Page 11

5. PANELS MOUNTING

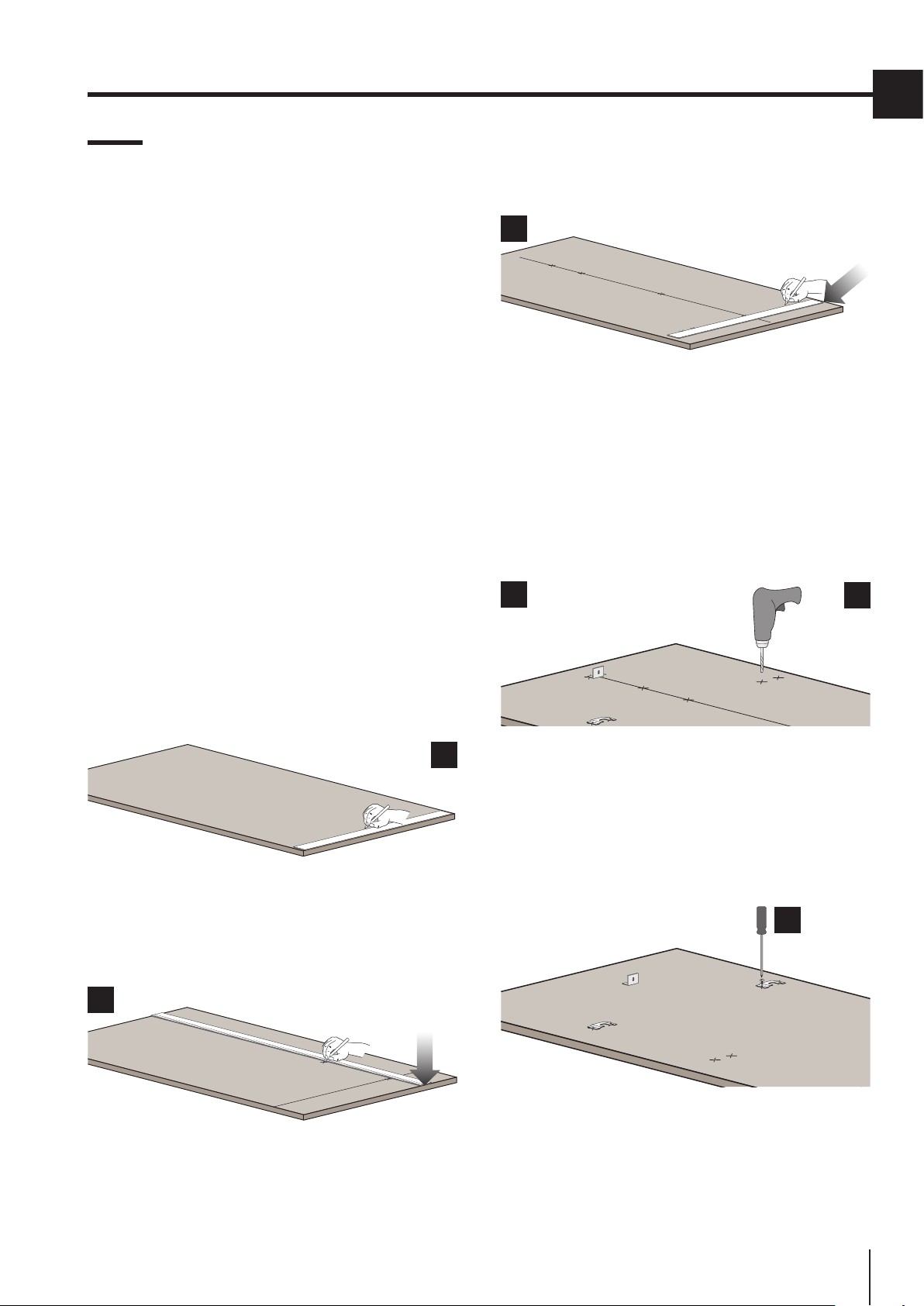

5.1 Decorative door panel layout

EN

> Following the corresponding table, mark the

external and then the internal hole [ 3 ].

The dimensions of the panels are indicated in the

table and drawings on subsequent pages.

Nevertheless, according to the requirements for

aligning with other kitchen structures, the door

panel can be higher than the upper edge of the

refrigerator door.

The panels must be mounted using special brackets which attach to adjustable devices provided

on the door and drawer and with brackets that

anchor and adjust the panel’s vertical direction.

Brackets and fixing screws are provided with the

appliance and must be applied to the panel as indicated.

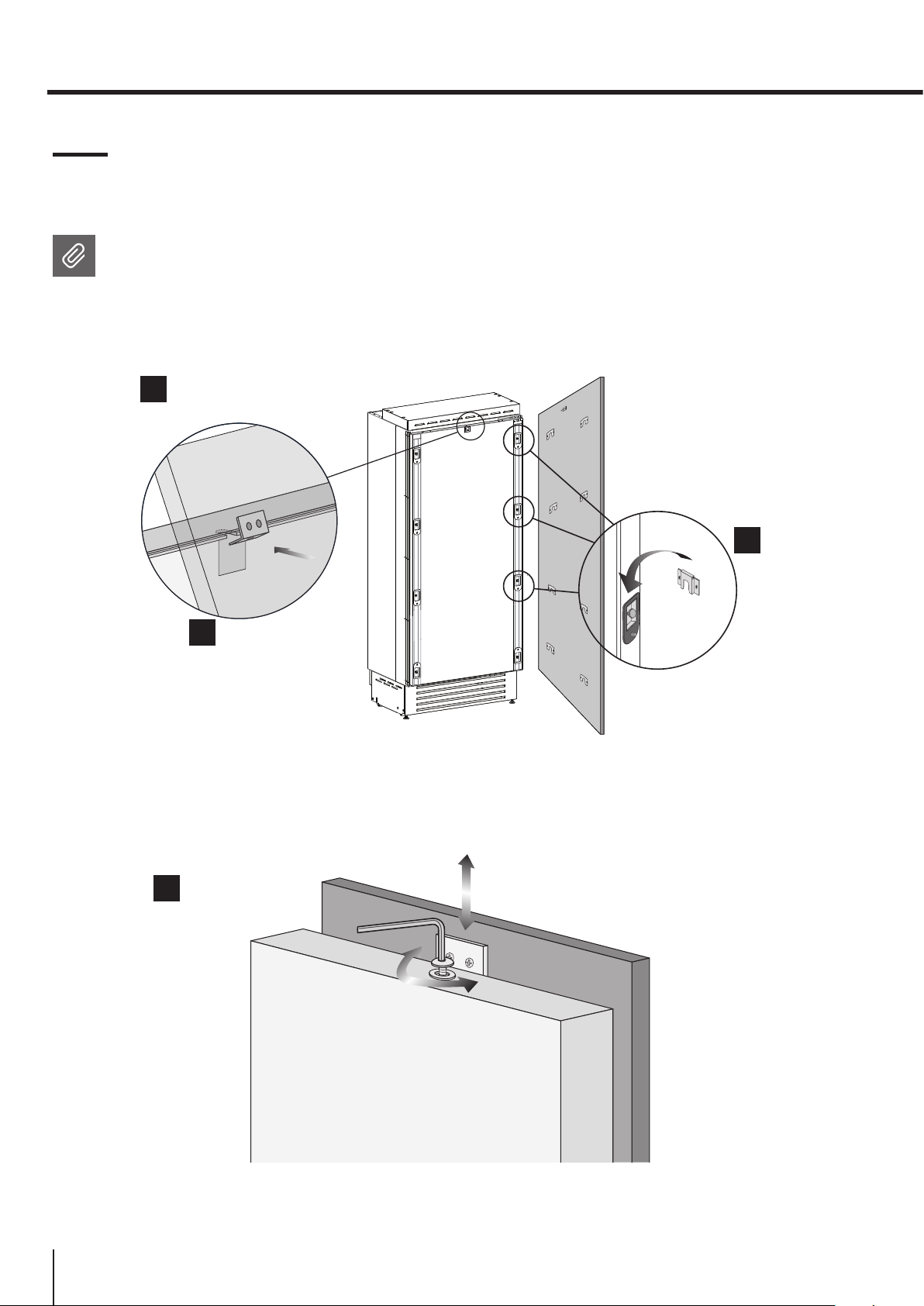

Operate as follows:

To prepare the panels to be mounted on the appliance, follow these steps, working on the back

of the panel.

Door Panel

> Draw a vertical center line on the panel from

top to bottom [ 1 ].

3

> Position the brackets on each set of marks to

make sure they are aligned [ 4 ], if you choose to

drill small pilot holes for the screws pay special

attention to not pass through the panel entirely.

[ 5 ].

4

5

1

> Starting from the bottom edge of the panel,

mark the positioning of the brackets [ 2 ].

2

> Screw the brackets in place [ 6 ].

6

11

Page 12

5. PANELS MOUNTING

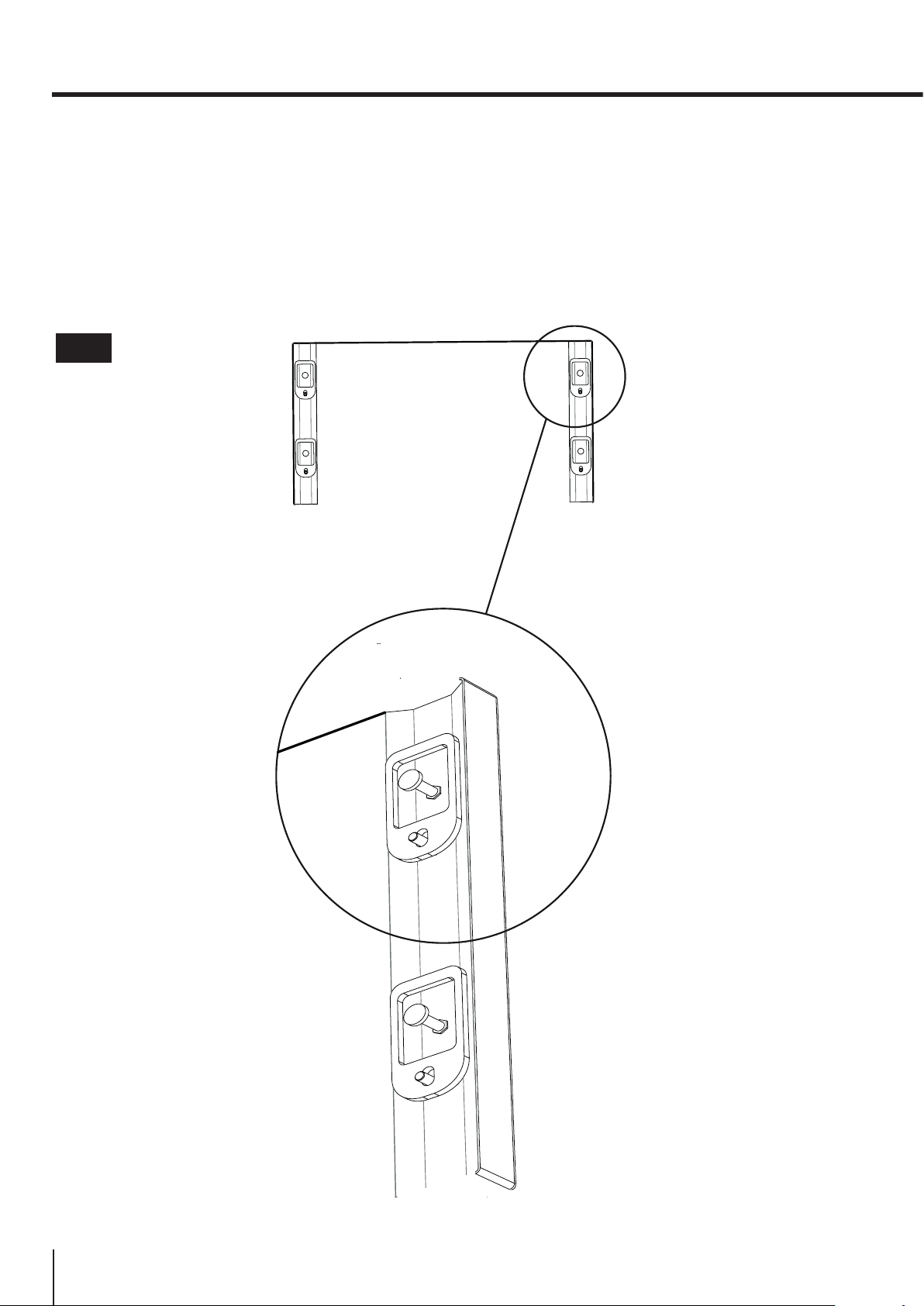

> Prepare the appliance door for panel mounting by threading the shoulder bolts into the recessed receivers and the set screws into the other hole [ 7 ]. Ensure the end with the hex key socket is threaded into

the door and not on the visible end. Thread this in far enough that it is flush with appliance door face so

as not to interferece with hanging the panel. You will adjust these later.

7

12

Page 13

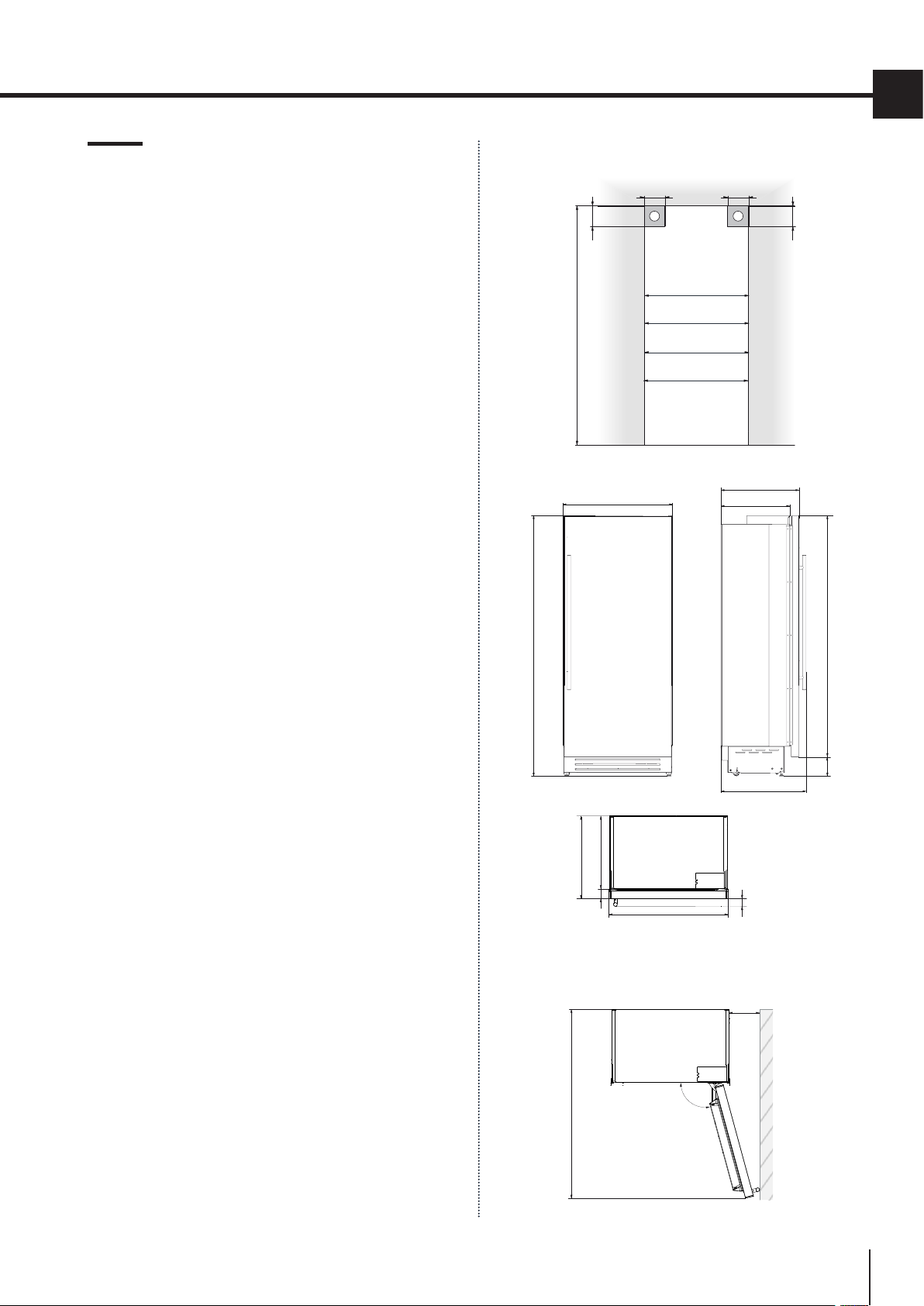

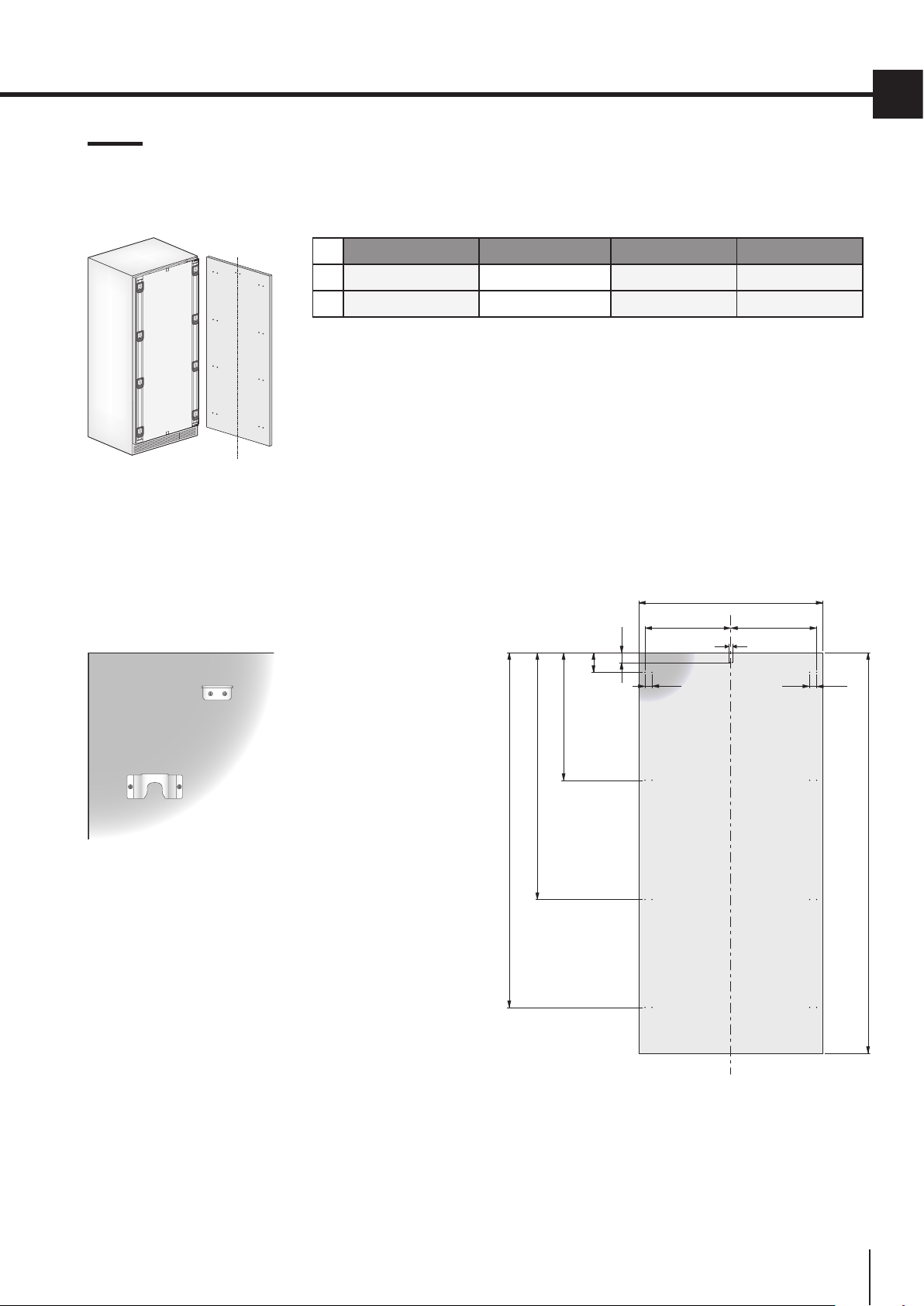

5.2 Decorative panel for fridge column

1797 (70 ¾”)

A

36” 30” 24” 18”

EN

1

A 908 (35 3/4”) 756 (29 3/4”) 604 (23 3/4”) 451 (17 3/4”)

B 418 (16 1/2”) 343 (13 1/2”) 275 (10 7/8”) 200 (7 7/8”)

Holes positions:

B B

¼”)

¼”)

165 (6 ½”)

690,5 (27

6,5 (

34 (1 3⁄8”) 34 (1 3⁄8”)

3⁄8”)

112 (4

6,5 (¼”)

1271,5 (50”)

7⁄8”)

min 1929 (75

13

Page 14

5. PANELS MOUNTING

B B

A

34 (1

3⁄8”

) 34 (1

3⁄8”

)

1797 (70

¾

”)

165 (6

½”

)

1271,5 (50”)

690,5 (27

¼

”)

112 (4

3⁄8”

)

min 1929 (75

7⁄8

”)

6,5 (¼”)

6,5 (

¼”

)

)

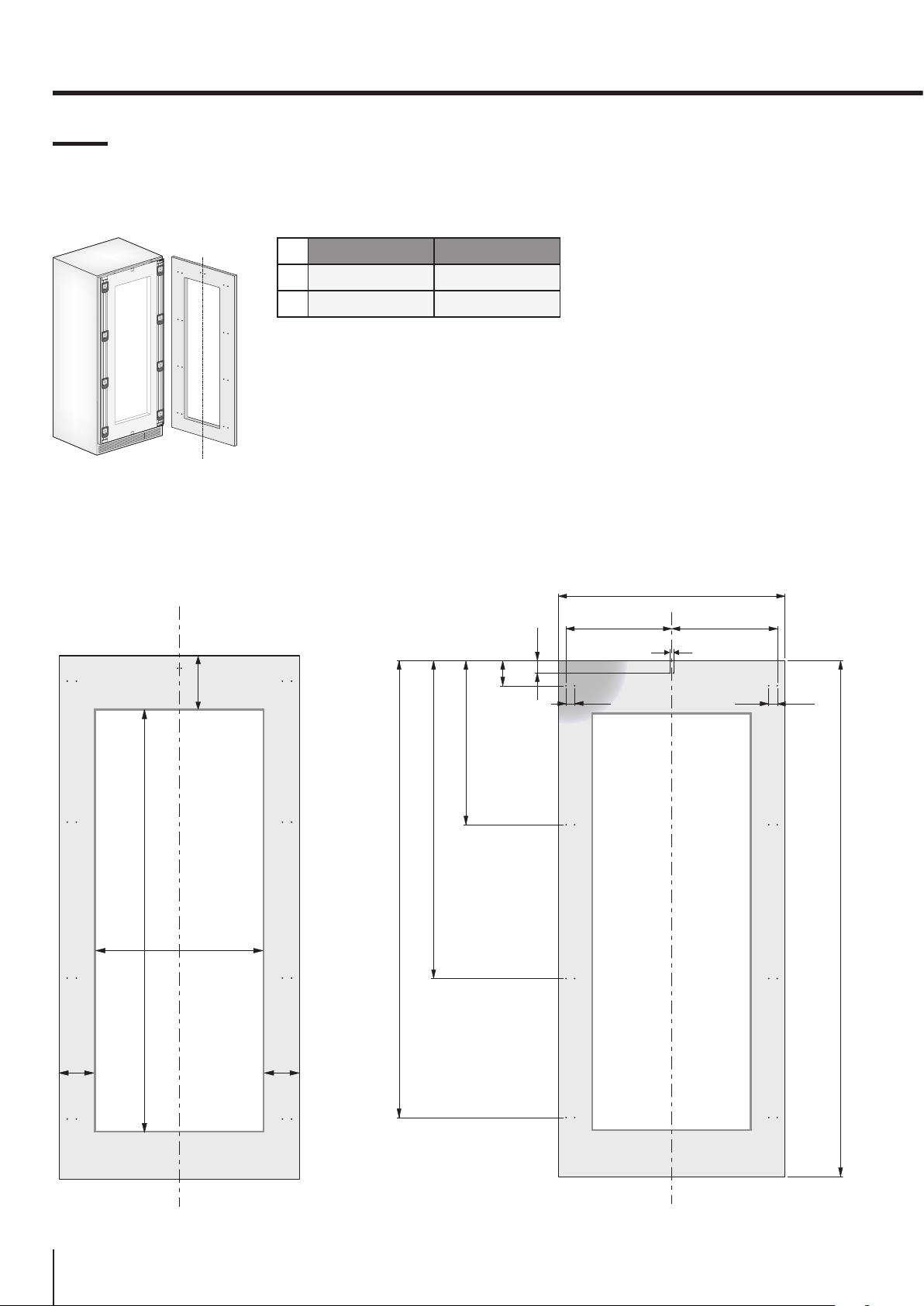

5.3 Decorative panels layout

for wine column with glass door

24” 18”

1

Door window dimensions: Holes positions:

200

7⁄8”)

(7

A 604 (23 3/4”) 451 (17 3/4”)

B 275 (10 7/8”) 200 (7 7/8”)

139 (5 ½”)

1572 (62”)

599: 327 (12

449: 177 (6

)

7⁄8”

7⁄8”)

139 (5

½”

14

Page 15

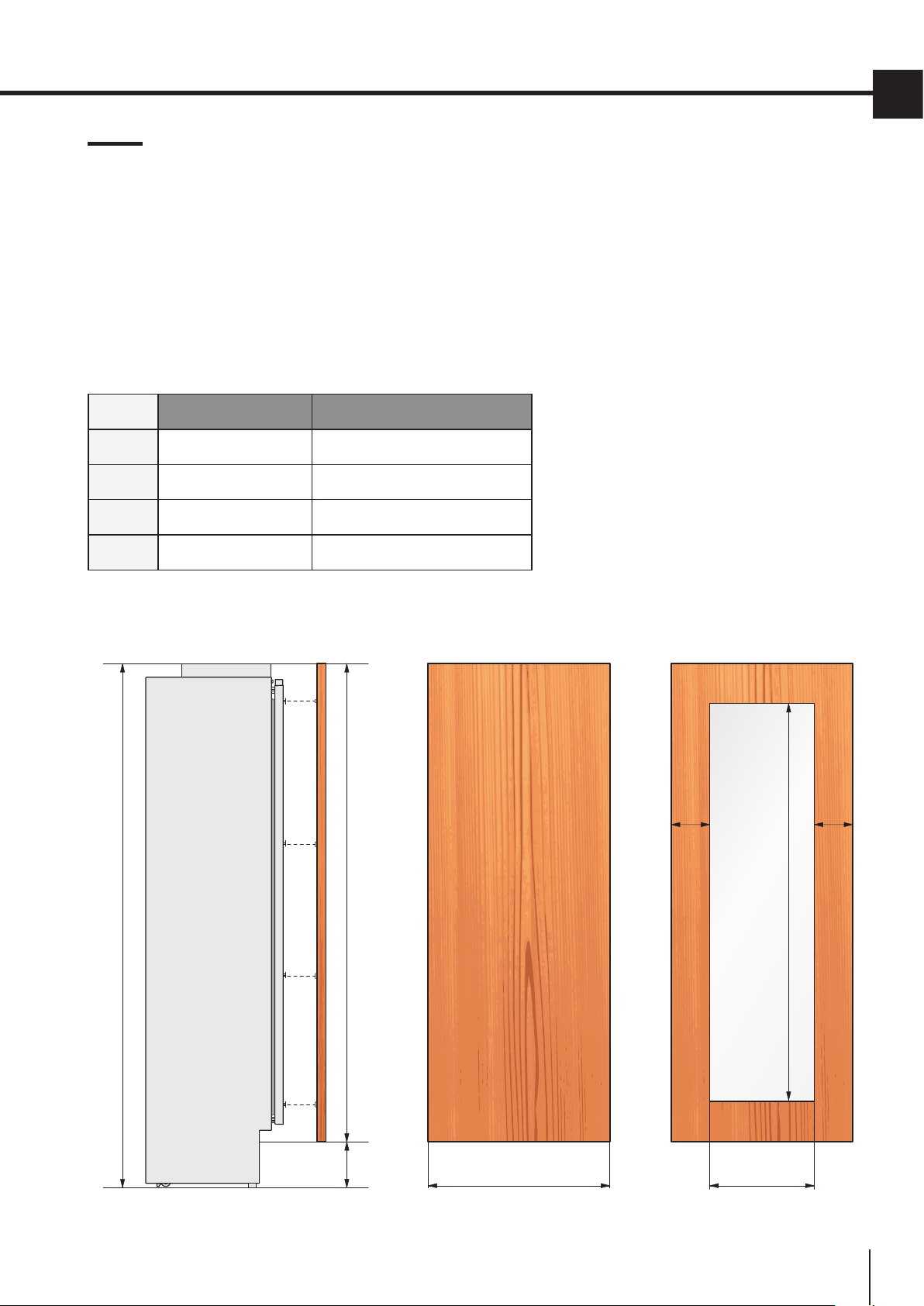

5.4 Panel dimensions column models

min 100 (3

Panels with width ranging between 19 mm (3/4 ”) and 28 mm (1 1/8 ”).

Door panels with weight max of 34 kg (75 lb)

Exceeding these weights could void your warranty for any service issues which can be attributed to

overweight panels.

The hinging mechanism on Bertazzoni appliances is considered to be `Zero-clearance`. The door and

drawer widths specified below assume the minimum cutout width is being used and a 3.5mm (1/8”) reveal

is desired around the panels. Adjust your panel dimensions accordingly to your own design criteria considering your cutout width and your reveal. Minimum reveal / gap should not be less than 1.5mm (1/16”).

SERIES DOOR WIDTH A DOOR GLASS WINDOW WIDTH B

36” 908 (35 3/4”) -

30” 756 (29 3/4”) -

24” 604 (23 3/4”) 327 (12 7/8”)

EN

18” 451 (17 3/4”) 177 (6 7/8”)

)

”

¾”)

min 1929 (75 7⁄8

2120 (83 7/16") + 25 (1")

max 2027 (79

139

(5 ½”)

139

(5 ½”)

1572 (62”)

7⁄8”)

A B

For fridge and freezer columns For wine columns

15

Page 16

5. PANELS MOUNTING

5.5 Mounting panels to the door

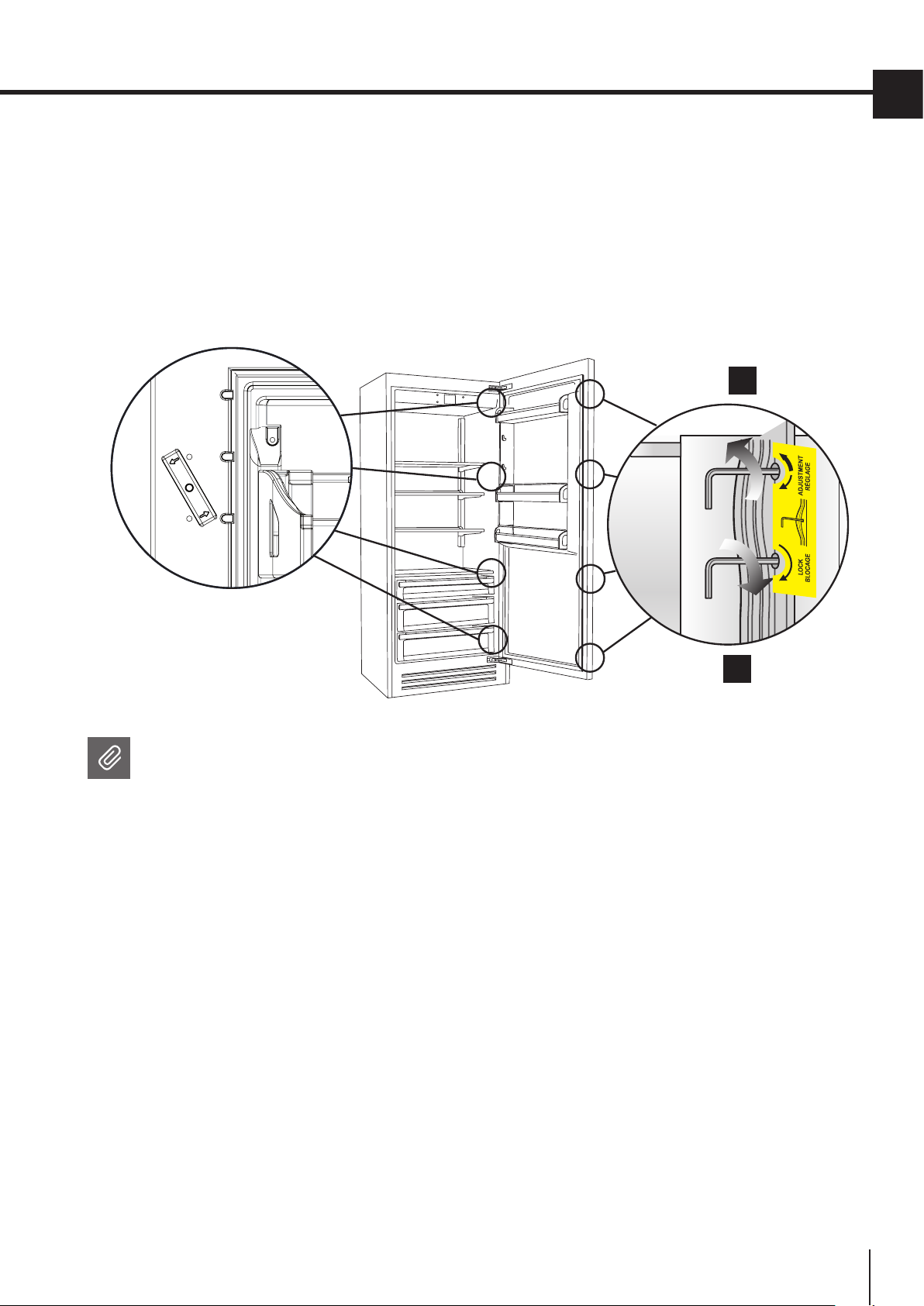

Once all brackets and small brackets

have been applied to the panels, you can

begin installing the bottom drawer.

> Hook the panel to the fixing devices starting

from the top aligning brackets [ 6 ].

6

7

> At this point, alignment between the panel and

adjacent cabinets can be adjusted using the alignment brackets and small brackets [ 7 ] and [ 8 ].

9

8

> Vertical alignment: tighten or loosen the screw

in the brackets to raise or lower the panel [ 9 ].

16

Page 17

> Depth alignment: working from the inside of

the door, after lifting up the magnetic seal on the

handle side and rotating the plastic covers on

the hinge side, adjust the panel position in the

Z-direction by adjusting the shoulder bolts and

setscrews with the 4mm hex key in conjunction

with each other finally locking each mounting position in place. [ 10 & 11 ].

EN

10

Once the front panel has been adjusted,

check that the gasket has been repositioned

correctly to assure the door/drawer are

closing correctly and avoid operational

errors of the unit.

The product handle is not included in the appliace

packaging, but it has to be bought separately. For

handle installation, please refer to the instruction

included in handle’s package.

11

17

Page 18

6. INSTALLATION

B

B

IMPORTANT: The following instruction for installation apply to all Bertazzoni models.

3

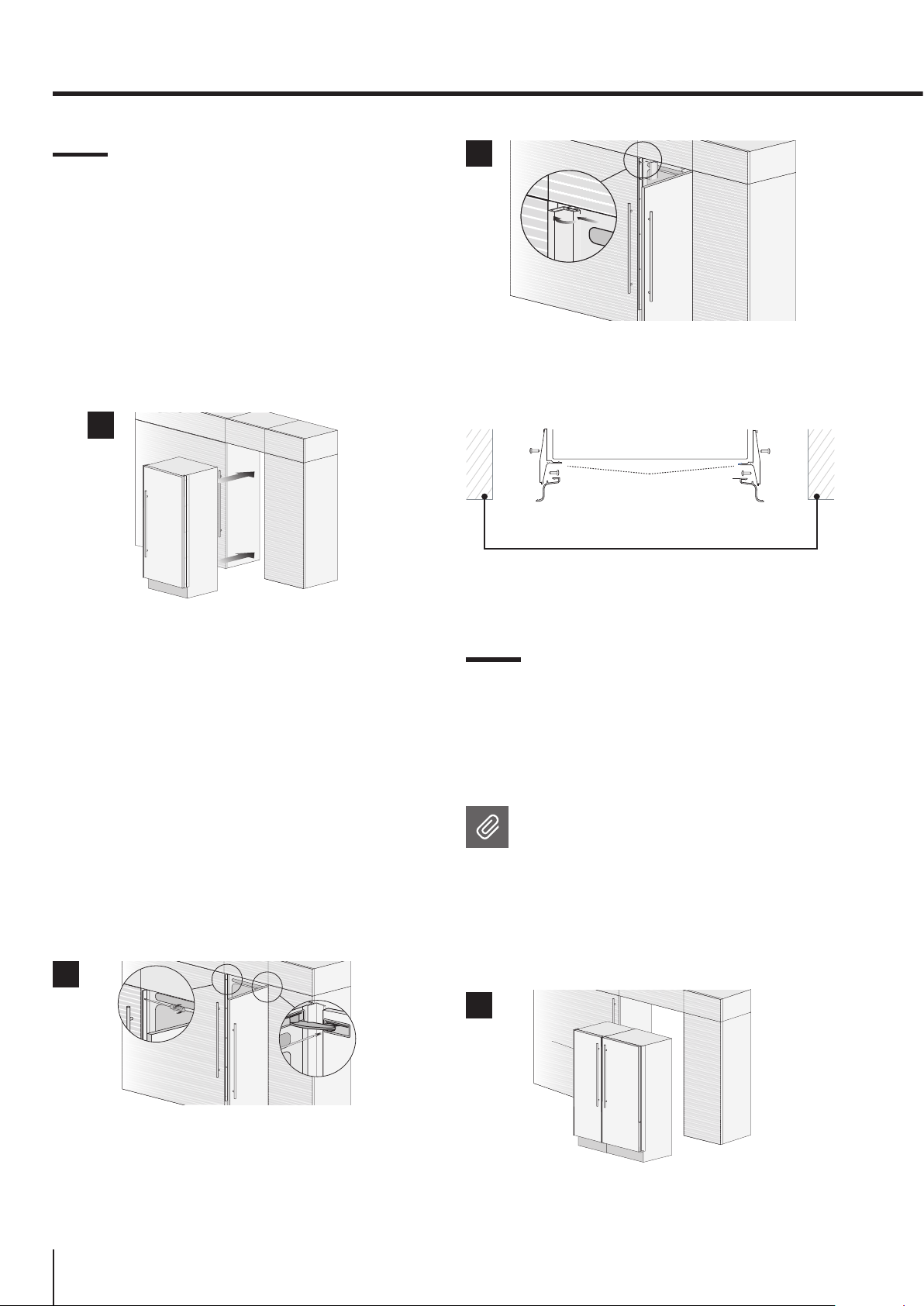

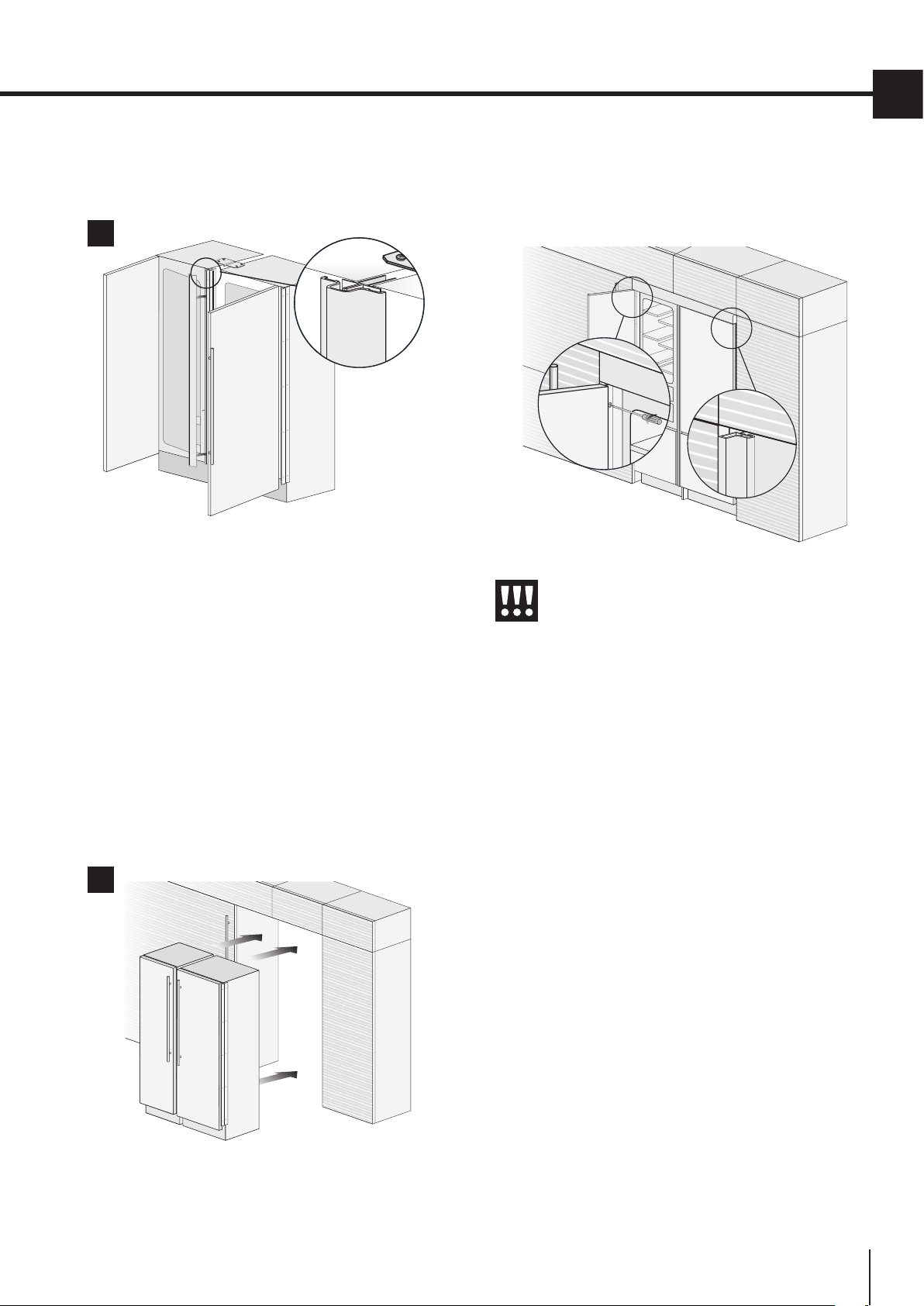

6.1 Built-in installation of

single appliance

For a built-in installation, to cover gaps between

the appliance and the adjacent cabinets, special

side profiles and covering frames are already

factory installed.

Operate as follows:

> Push the appliance into the installation cutout [ 1 ].

Side profiles mounting:

1

Appliance

A

> Always mount front panel on door before pushing the unit into its final position inside the cutout

or structure.

> Check the levelling of the appliance, adjusting

its feet and wheels to correct it.

> Secure the appliance to the adjacent cabinets by

fixing to these the side profiles factory-installed

on the appliance [ 2 ].

To make this operation easier keep the door open.

2

Wall or furniture

A plastic connecting brackets

B Profile trim cover

6.2 Built-in installation of two or

more appliances

> The central profile is provide with freezer and

wine cellar columns.

Special side profiles and plastic covering

frames are provided for closing gaps between the appliance and the adjacent cabinets.

Operate as follows:

> Position the appliances in front of the installation

area, leaving enugh space to operate at their back

[ 1 ].

> Mount the profiles the trim covers: first insert

them laterally and then push firmly until a “click”

is heard [ 3 ].

18

1

Page 19

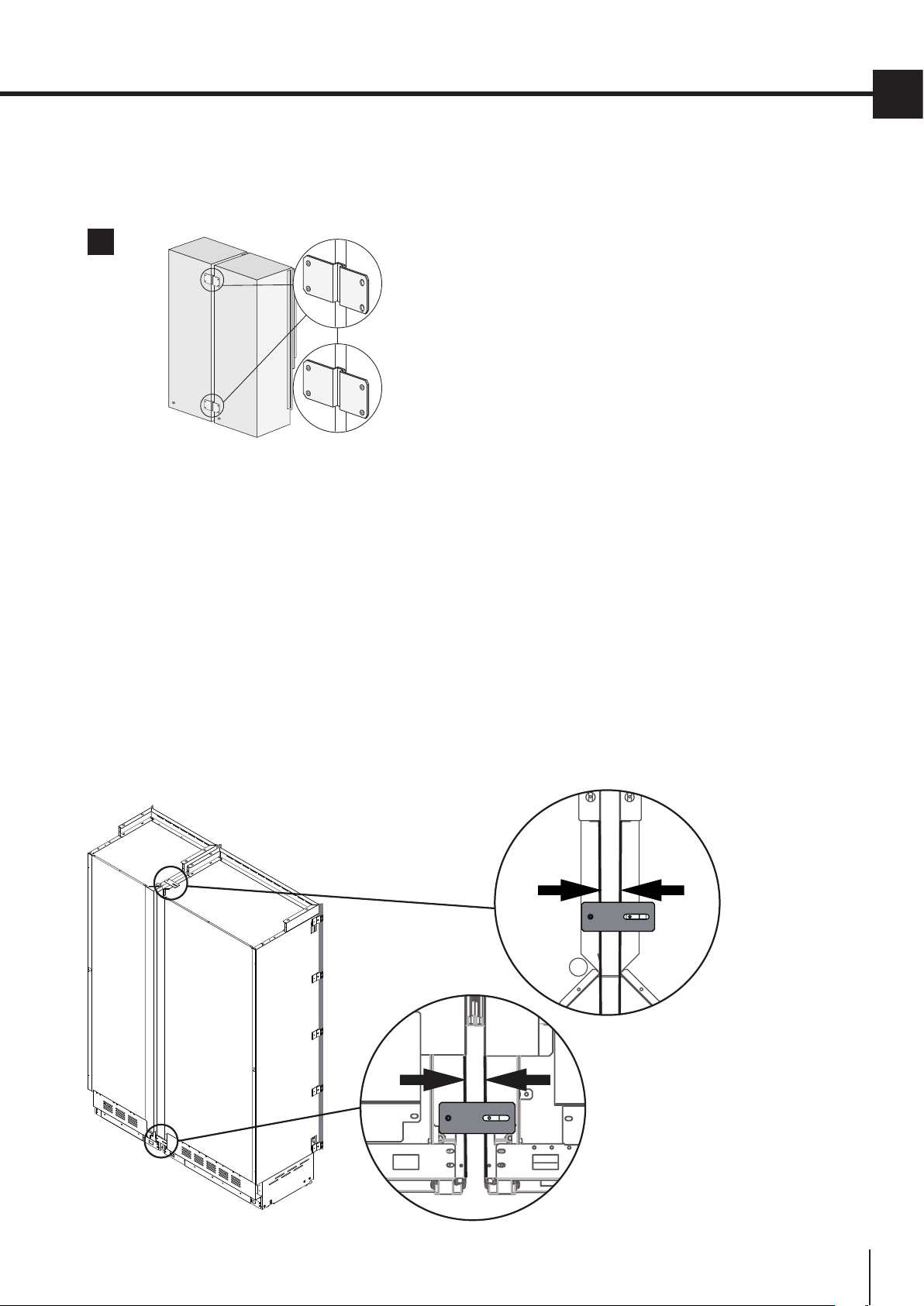

> Access the back of the appliances to mount the

joining brackets: fix one side of the top and lower

brackets to one of the appliances and subsequently

to the other [ 2 ].

2

IMPORTANT: the appliances must be level with

one another.

EN

1 – Attach both units to each other at the front using the 5 white plastic brackets to hold the units

together.

2 – Adjust the units in the back, so that the side panels are perfectly parallel to each other. There are

visual cues that will aid with alignment.

3 – The gap ( C ) between the units must be the

same at the back and top. Measure the gap on all

edges and adjust if not equal.

A

4 – Once the gap is consistent on all edges, secure

the brackets. If the gap between the units is not

even, doors will not align properly.

Gap measurements vary according to the types

of units installed. Please refer to the table below for correct gap measurements.

C

B

C

19

Page 20

6. INSTALLATION

Distance between units (A+B)

A

C

18” 7/8” (22 mm) 15/16” (23,5 mm) 1” (24,5 mm) 1” (25,5 mm)

24” 15/16” (23,5 mm) 1” (25 mm) 1” (26 mm) 1 1/16” (27 mm)

B

30” 1” (24,5 mm) 1” (26 mm) 1 1/16” (27 mm) 1 1/8” (28 mm)

36” 1” (25,5 mm) 1 1/16” (27 mm) 1 1/8” (28 mm) 1 1/8” (29 mm)

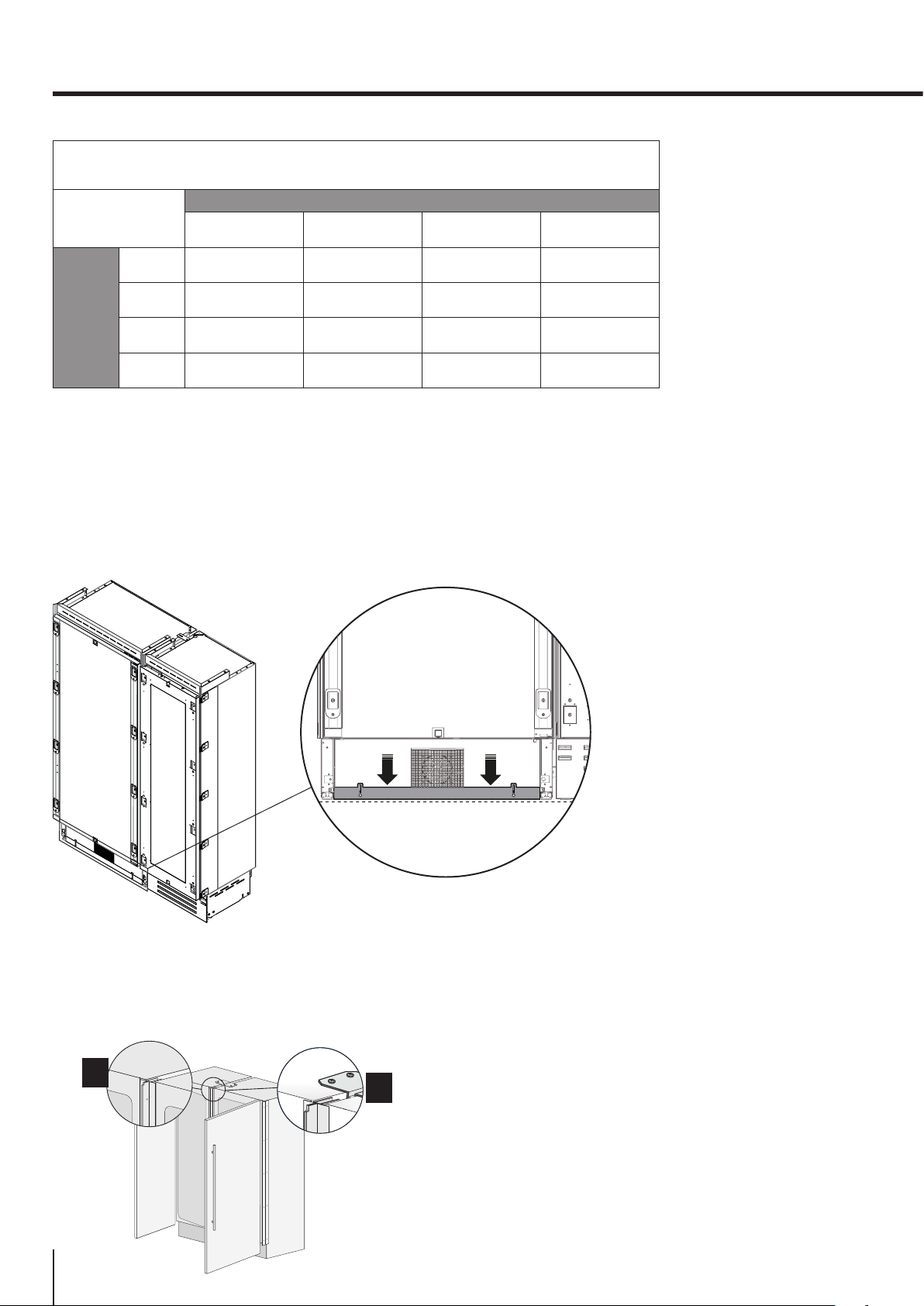

Once the appliances have been adjusted and

properly levelled, loosen the two screws holding

the sealing plate in position.

Lower the plate until flush with the floor, and retighten the screws. This will ensure optimized

airflow through the condenser necessary for proper

operation.

18” 24” 30” 36”

> Next join them at the front attaching the plastic

connecting brackets with the supplied screws [ 3 ] .

Attach the bracket on top of the units (if applicable)

as per figure [ 4 ].

3

20

4

Page 21

EN

> Finish o by mounting the central profile cover

onto the central profiles, by pushing it until a click

is heard [ 5 ].

5

> Once completed, push the units into their final position [ 6 ].

Always mount front panels on door before pushing

the unit into its final position inside the cutout or

structure.

> Check the levelling of the appliance, adjusting its

feet and wheels to correct it.

> Secure the appliance to the adjacent cabinets by

fixing to these the side profiles trims factory-installed on the appliance [ 7 ]. To make this operation

easier keep the door open.

> Mount the covering frames onto the profiles, first

insert them laterally and then push firmly until a

“click” is heard [ 8 ].

7

8

Take care as appliances will be frontheavy and may tip before they are secured to the adjacent furniture.

6

21

Page 22

C

A

B

B

A

A

A

6. INSTALLATION

Side and central profiles mounting:

Appliance

Wall or furniture

A - plastic connecting brackets

B - Profile trim cover (side)

C - Profile trim cover (central).

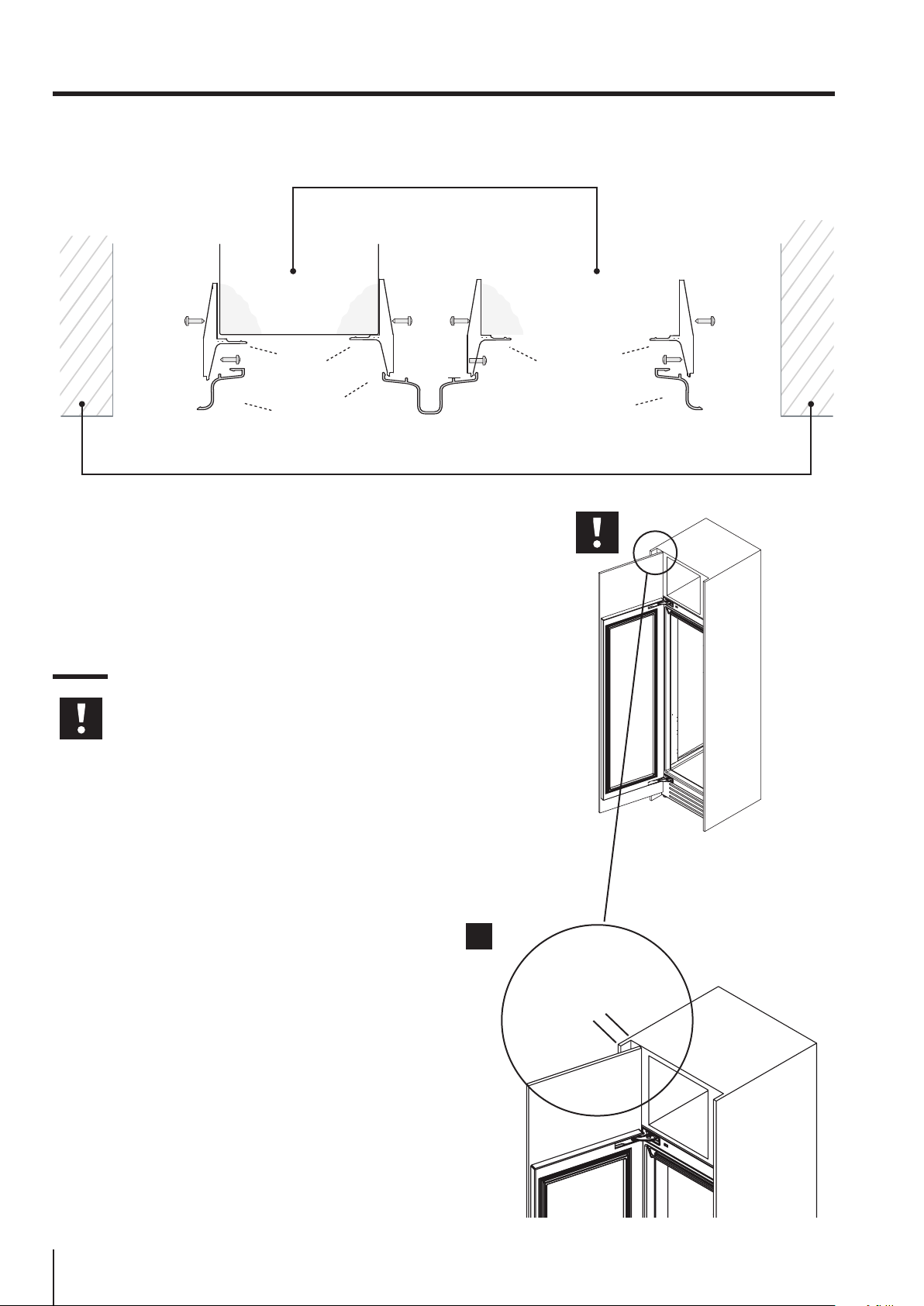

6.3 Maximum cabinet depth

over panel ready appliance with

single door panel

It is possible that the design of the kitchen and,

in particular, of the cutout where the panel ready

appliance is going to be fitted includes a cabinet

right above the refrigerator itself that must be

closed with the same panel mounted on the Panel

ready refrigerator door.”

In this case, the depth of the cabinet above the

appliance must not exceed the depth of the

appliance without the door [ 1 ].

1

This will allow the panel attached to the refrigerator

door to open correctly without interference during

its rotation up to 100°.

22

47 mm (1 7/8”)

Page 23

7. COMPLETING THE INSTALLATION

2 x

59 (

2

3⁄8

”)

”)

> Reposition the bracket and fix it first to the cabi-

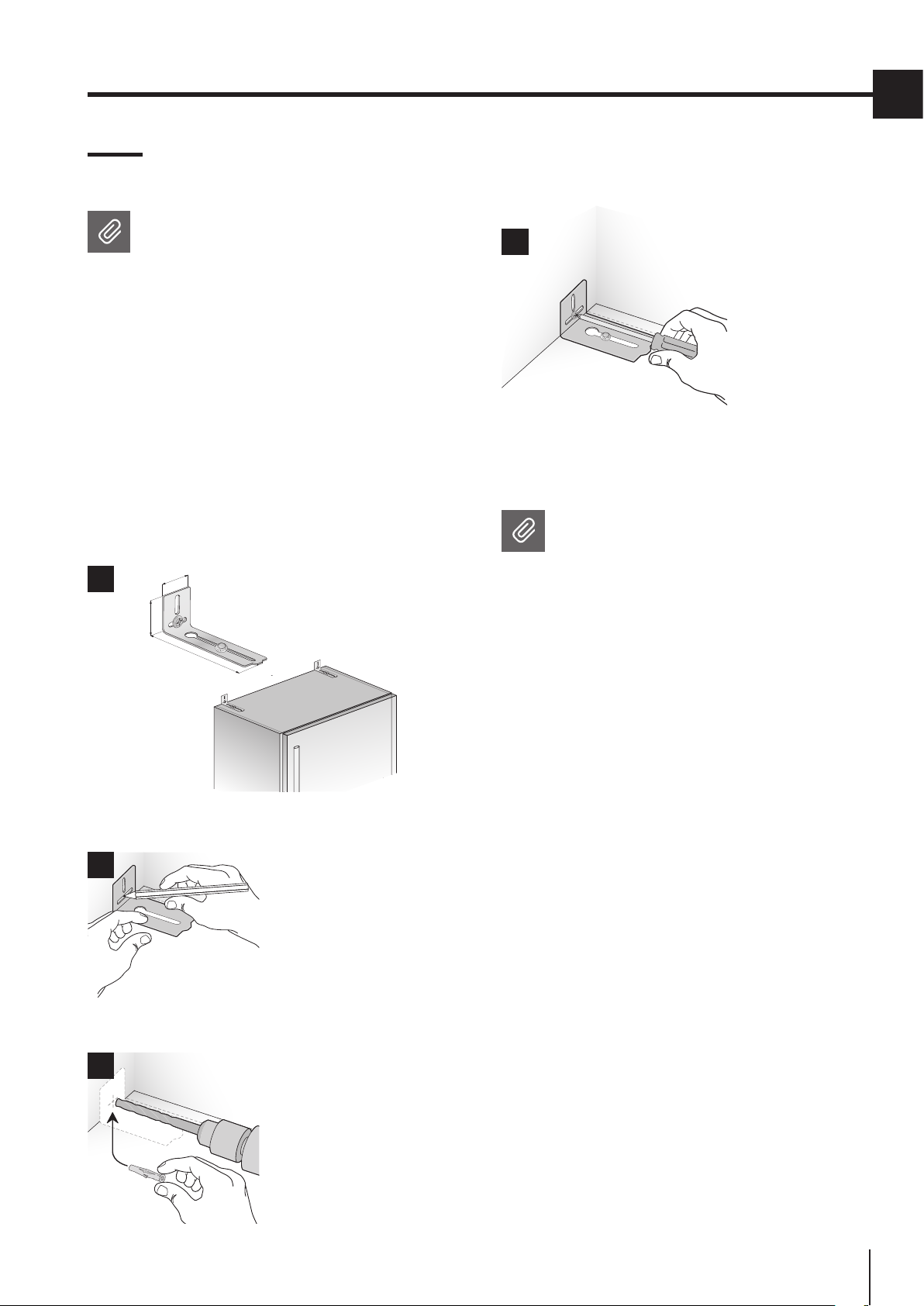

7.1 Anti-tipping safety assembly

If the appliance(s) is not connected through

the side profile trims to secured cabinetry

you must install the anti-tip brackets to ensure the product does not fall forward during use and cause damage or injury. Failing

to secure the appliance(s) securely will void

any warranty claim attributable to a tipping

situation.

Operate as follows:

> The brackets should be applied as illustrated us-

ing the provided screws If using the anti-tip brackets, lag into wood framing or concrete - drywall will

not hold the weight of appliance.

Place a bracket on the top of the appliance in correspondence to the fixing holes and against the wall

[ 1 ].

5⁄8

1

45 (1

net and then to the wall [ 4 ].

4

EN

In order to use the anti-tip brackets on the

top compressor models, it will be necessary to temporarily remove the top, metal

ceiling / shield to access the bolting points

for the brackets./ shield to access the bolting points for the brackets.

152 (6”)

> Mark up the holes position on the wall [ 2 ].

2

> Drill the wall with an 8 mm (3/8”) bit and insert

the expansion plug [ 3 ].

3

23

Page 24

7. COMPLETING THE INSTALLATION

B

C

C

In case of placing a kickplate differently from pic-

7.2 Ventilation

PANEL READY AND PANEL INSTALLED MODELS

A forced air system assures ventilation through a

grille, secured to the unit with magnetic plates,

positioned in the lower front part of the unit [ 1 ].

1

ture (2), the kickplate has to be drill at least of an

area equal to 50% of the area delimited by A and

B dimensions in picture [ 3 ].

3

A

36 ’’ 30 ‘‘ 24 ‘‘ 18 ‘‘

If the kitchen cabinet includes a kickplate, it must be

placed in a way to ensure a better airflow [ 2 ].

2

min 100mm (3 ⅞”)

50mm (1 ⅞”)

A 860 (33 7/8”) 740 (29 1/8”) 560 (22”) 410 (16 1/8”)

B > 100 (4”)

C 10 (3/8”)

The condenser must to be cleaned on a regular

basis. In order to do that, the front grille has to be

accessible [ 4 ].

4

100 (4”)

24

Page 25

7.3 Post installation control

Ice Maker Water Filter

bianco EB 61 - 62 li

Fondo o ultimo passaggio:

passaggio di nero coprente 602 -95 li

forato solo per le parti retro illuminate come da disegno “C”

Nomenclature: Grigio Whirlpool

cambiamento dimensioni foro

56x43mm 29-05-2019

00

°C+

Impostazioni

Funzioni

00

°C+

00

°C-

BISELLATURA SUI 4 LATI

Check that the front levelling feet have been pro-

perly installed.

Check that the connection to the water system

does not have any leaks and that the shut-o valve

is easily accessible.

Check that the electrical connection is correctly

installed and that the socket and / or breaker are

easily accessible.

Check the perfect alignment of the appliance

with adjacent structures.

Check that all adhesive tape and external or internal temporary protective devices have been removed.

Check the perfect closing of the doors and the

smooth sliding of the drawers and shelves.

7.4 Start up

> To start the appliance, connect the plug to the

electrical mains: at this point, when opening the

door, the control panel will usually visualize the

message “Stand by”, and all the panel keys will

be off

EN

> Purge air from the water lines by performing

the ‘Manual Clean’ function from the Menu>Functions->Water Filter options. You may need

to complete this sequence several times until you

stop hearing air sputtering from the ice maker fill

tube (Refer to your Use & Care Manual).

> Once you are satisfied that the system is purged of air switch the Ice Maker on by touching the

button which will illuminate.

> For further information about the appliance

operation, refer to the User Manual.

If at the first start - up the message Stand

by does not appear, but other messages

appear, such as Fridge too warm, Freezer

too warm, or sound signals are activated, it

means that the appliance has already previously started the cooling process. If this is

the case, deactivate any possible acoustic

signals by pressing the Alarm button, close

the door and wait until the set temperature

is reached.

It is necessary to let the unit reach the correct

temperature before foods are stored inside.

Bertazzoni is constantly researching new way to

improve the features and the design of their products, therefore models are often upgraded and

revised.

>To turn on all the appliance compartments,

press the Unit button for three seconds. The

display will show the message “Initial test” for

approximately 2 minutes. After this phase the

compressors will start up and remain on until the

compartment set temperatures are achieved.. Do

bear in mind that this condition could last several

hours during which time the display will continue

to flash the ‘Start Up Phase’ message.

> If the appliance is provided with an Ice Maker,

prior to switching it on make sure that the water

filter cartridge is installed (unless water supply

source is already filtered by other means such as

reverse osmosis).

25

Page 26

Page 27

SOMMAIRE

1

INDICATIONS IMPORTANTES

1.1

Indications importantes concernant la sécurité...................................................................................................

1.2

Pour la sécurité des enfants.......................................................................................................................................

2

CARACTÉRISTIQUES TECHNIQUES

2.1

Caractéristiques de l’appareil et conditions requises pour l’installation......................................................

2.2

Caractéristiques de la niche d’installation: produits encastrables.................................................................

2.3

Caractéristiques de la niche d’installation: produits encastrables avec porte inox...................................

3

PRÉPARATION À L’INSTALLATION

3.1

Transport sur le lieu d’installation et déballage...................................................................................................

3.2

Raccordements électrique et hydraulique.............................................................................................................

3.3

Énergies renouvelables et systèmes domotique.................................................................................................

3.4

Mise à niveau...................................................................................................................................................................

4

DIMENSIONS DE LA NICHE D’ENCASTREMENT

4.1

Dimensions de la niche d’encastrement et installation.....................................................................................

4.2

Montage à fleur avec des garnitures standard.....................................................................................................

5

MONTAGE DES PANNEAUX

5.1

Préparation des panneaux décoratifs pour la porte............................................................................................

5.2

Préparation des panneaux décoratifs pour réfrigérateur..................................................................................

5.3

Préparation des panneaux décoratifs pour cave à vins avec porte vitrée....................................................

5.4

Dimensions des panneaux..........................................................................................................................................

5.5

Fixation des panneaux à la porte..............................................................................................................................

FR

2

2

2

2

2

4

5

6

6

6

7

7

8

8

8

9

9

11

12

13

14

6

INSTALLATION

6.1

Encastrement appareil unique..................................................................................................................................

6.2

Encastrement combinaison de deux appareils....................................................................................................

6.3

Profondeur maximale structure au-dessus du réfrigérateur encastrable à porte unique.....................

7

ACHÈVEMENT DE L’INSTALLATION

7.1

Montage de la sécurité anti-renversement............................................................................................................

7.2

Circulation de l’air..........................................................................................................................................................

7.3

Contrôle de fin d’installation.......................................................................................................................................

7.4

Mise en marche..............................................................................................................................................................

16

16

16

20

21

21

22

23

23

1

Page 28

1. INDICATIONS IMPORTANTES

1.1 Indications importantes concernant

la sécurité

Symboles utilisés dans le manuel:

Note

Conseils pour une correcte utilisation de

l’appareil

Important

Indications afin d’éviter tout

endommagement de l’appareil

Warning

Indications afin d’éviter toute lésion aux

personnes

1.2 Pour la sécurité des enfants

DANGER : Risque d’enfermement pour les enfants.

Avant de jeter un vieux réfrigérateur ou congélateur :

> Retirer les portes

> Laisser les étagères en place afin d’empêcher que

des enfants grimpent dedans.

2.1 Caractéristiques de l’appareil et

conditions requises pour l’installation

Dimensions de

l’appareil encastrable

Dimensions de

l’appareil encastrable avec porte

inox

18”

l: 456 mm (17 15/16”)

h: 2120 mm (83 1/2”)

p: 615 mm (24 1/4”)

24”

l: 609 mm (24”)

h: 2120 mm (83 1/2”)

p: 615 mm (24 1/4”)

30”

l: 761 mm (29 15/16”)

h: 2120 mm (83 1/2”)

p: 615 mm (24 1/4”)

36”

l: 913 mm (35 15/16”)

h: 2120 mm (83 1/2”)

p: 615 mm (24 1/4”)

18”

l: 456 mm (17 15/16”)

h: 2120 mm (83 1/2”)

p: 620 mm (24 3/8”)

24”

l: 609 mm (24”)

h: 2120 mm (83 1/2”)

p: 620 mm (24 3/8”)

30”

l: 761 mm (29 15/16”)

h: 2120 mm (83 1/2”)

p: 620 mm (24 3/8”)

36”

l: 913 mm (35 15/16”)

h: 2120 mm (83 1/2”)

p: 620 mm (24 3/8”)

Important!

Les dimensions entre parentheses sont en

pouces.

Les poids entre parenthèses sont en livres:

kg(lb).

Les temperatures entre parentheses sont

en °F: °C (°F).

2

Page 29

2. CARACTÉRISTIQUES TECHNIQUES

FR

Poids avec

emballage

Tension

d’alimentation

Câble

d’alimentation

Disjoncteur

dévoué

Pression

d’alimentation de

l’eau potable

Tuyau

d’alimentation

de l’eau

Équipement

nécessaire

18”

max 150 kg (331 lb)

24”

max 170 kg (375 lb)

30”

max 190 kg (419 lb)

36”

max 200 kg (441 lb)

AC 110 - 120V 60Hz

90° Nema 5-15P

15A

de 0.05 MPa à 0.5 MPa

(0.5 Bar - 5 Bar)

NPT 3/4” (adaptateur coudé

de 1/4” inclus)

- Kit anti-renversement

Z310113 (dans tous les

modéles encastrables et encastrables avec porte inox)

-Garniture de recouvrement

des profiles, blanc Z310057

(dans tous les modéles encastrables et encastrables

avec porte inox)

- Kit de raccordement

latérale (10 pièces blancs)

Z310129 (dans tous les

modéles encastrables et encastrables avec porte inox)

- Kit fixage des panneaux,

réfrigerateur et congélateur

Z310272 (seulement dans

les modèles réfrigerateurs

et congélateurs encastrables, pas dans les modèles

encastrables avec porte

inox)

- Kit fixage des panneaux,

cave à vins Z310273 (seulement dans les modèles cave

à vins encastrables, pas

dans les modèles encastrables avec porte inox)

- Kit de raccordement centrale, pour l’installation combinée

des modèles encastrables

Z310293 (seulement dans

les modèles cave à vins et

congélateurs encastrables,

pas dans les modèles encastrables avec porte inox)

- Kit de raccordement centrale, pour l’installation combinée

des modèles encastrables

avec porte inox Z310287

(seulement dans les modèles

cave à vins et congélateurs

encastrables avec porte inox,

pas dans les modèles encastrables)

- Kit d’installation du filtre à

eau Z310300 (seulement dans

les congélateurs encastrables

et encastrables avec porte

inox)

- clé à six pans de 4 mm (1/8”)

(dans tous les modèles encastrables et encastrables avec

porte inox)

Réglage de la

hauteur des

rouleaux arrière

Accessoire - Kit de nettoyage Z310284

- tournevis cruciforme

- perceuse à bois

- pointe pour bois de 2.5

mm (1/8”)

- pointe pour mur de 8 mm

(3/8”)

- pointe pour mur de 8 mm

(3/8”)

- pointe pour mur de 10 mm

(3/8”)

- clé ouverte de 17 mm

(11/16”)

- clé ouverte de 19 mm

(3/4”)

(dans tous les modèles encastrables et encastrables

avec porte inox)

3

Page 30

2. CARACTÉRISTIQUES TECHNIQUES

36": 1489 (58

24": 1187 (46

565 (22 ¼")

615 (24 ¼")

36": 913 (35

15⁄ 16

")

30": 761 (29

15⁄ 16

")

24": 609 (24")

18": 456 (17

15⁄ 16

")

233 (9

¼”

)

+ 25 (1”)

min 2130 (83 ⅞”)

A A

140 (5 ½”) 140 (5 ½”)

100 (4”)

100 (4”)

S899 / FI36: 914 (36”)

S449 / FI18: 457 (18”)

S599 / FI24: 610 (24”)

S749 / FI30: 762 (30”)

615 (24 ¼”)

565 (22 ¼” )

1808 (71 ¼” )

231 (9

⅛”

) +

25 (1”)

505 (19 ¾”)

2120 (83 ½”) +25 (1”)

2.2 Caractéristiques de la niche d’installation: produits encastrables

127 mm (5") 127 mm (5")

A - espace à réserver aux équerres anti-renversement

Hauteur de la niche d’encastrement

2130 mm (83 7/8”)

Largeur de la niche d’encastrement

36”: 914 mm (36”)

30”: 762 mm (30”)

24”: 610 mm (24”)

18”: 457 mm (18”)

Profondeur minimale de la niche d’encastrement

615 mm (24 1/4”) + Épaisseur du panneau pour une

installation aeurante

Les charnières de la porte ne se ferment pas à 90°

Encombrement avec porte ouverte

36”: 1489 mm (58 5/8”)

30”: 1338 mm (52 5/8”)

24”: 1187 mm (46 3/4”)

18: 1036 mm (40 3/4”)

Angle d’ouverture de la porte

100°

82 mm (3 1/2")

min 2130 (83 ⅞”)

A A

36":914 (36”)

30": 762 (30”)

24": 610 (24”)

18": 457 (18”)

82 mm (3 1/2")

Largeur

36”: 913 mm (35 15/16”)

30”: 913 mm (29 15/16”)

24”: 609 mm (24”)

18”: 456 mm (17 15/16”)

Hauteur

2120 mm (83 1/2”) + 25 mm (1”)

Profondeur avec la porte (sans panneau)

615 mm (24 1/4”)

Distance minimale du mur (côté de la charnière)

36”: 158 mm (6 1/4”)

30”: 132 mm (5 1/4”)

24”: 108 mm (4 1/4””)

18”: 82 mm (3 1/4”)

565 (22 ¼")

615 (24 ¼")

36": 913 (35

30": 761 (29

15⁄ 16

15⁄ 16

")

")

24": 609 (24")

15⁄ 16

18": 456 (17

")

36": 158 (6 ¼")

30": 132 (5 ¼" )

")

¾

¾")

⅝")

24": 108 (4 ¼")

18": 82 (3 ¼")

100°

18": 1036 (40

30": 1338 (52 ⅝")

4

Page 31

565 (22 ¼”)

620 (24 ⅜”)

36": 913 m m ( 35

15⁄ 16

")

30": 761 m m ( 29

15⁄ 16

")

24": 609 m m ( 24")

18": 456 m m ( 17

15⁄ 16

")

55 (3 ⅛”)

58 (2 ¼”)

A A

E W E W

140 (5 ½”) 140 (5 ½”)

100 (4”)

100 (4”)

KS899: 900 (35 ½”)

KS599: 600 (23 ¾”)

KS749: 750 (29 ⅝”)

146 (5

+ 25(1”

KS449: 450 (17 ¾”)

100°

36": 1487 (58 ½”)

30": 1336 (52 ⅝”)

24": 1185 (46 ⅝”)

18": 1034 (40 ¾’’)

565 (22 ¼”)

620 (24 ⅜”)

36": 913 m m ( 35

15⁄ 16

")

30": 761 m m ( 29

15⁄ 16

")

24": 609 m m ( 24")

18": 456 m m ( 17

15⁄ 16

")

55 (3 ⅛”)

58 (2 ¼”)

36": 139 (5 ½”)

30": 103 (4 ⅛”)

24": 89 (3 ½”)

18": 63 (2 ½”)

2.3 Caractéristiques de la niche d’installation: produits encastrables

avec porte inox

A -espace à réserver aux équerres anti-renversement

127 mm (5") 127 mm (5")

82 mm (3 1/2")

A A

FR

82 mm (3 1/2")

Hauteur de la niche d’encastrement

2130 mm (83 7/8”)

Largeur de la niche d’encastrement

36”: 914 mm (36”)

30”: 762 mm (30”)

24”: 610 mm (24”)

18”: 457 mm (18”)

Profondeur minimale de la niche d’encastrement

635 mm (25”)

Les charnières de la porte ne se ferment pas à 90°

Encombrement avec porte ouverte

36”: 1487 mm (58 1/2”)

30”: 1336 mm (52 5/8”)

24”: 1185 mm (46 5/8”)

18”: 1034 mm (40 3/4”)

Angle d’ouverture de la porte

100°

Largeur

36”: 913 mm (35 15/16”)

30”: 761 mm (29 15/16”)

24”: 609 mm (24”)

18”: 456 mm (17 15/16”)

Hauteur

2120 mm (83 1/2”) + 25 mm (1”)

Profondeur avec la porte

620 mm (24 3/8”)

min 2130 (83 ⅞”)

0F

2120 (83 ½”) +25 (1”)

36":914 (36”)

30": 762 (30”)

24": 610 (24”)

18": 457 (18”)

620 (24 ⅜” )

565 (22 ¼” )

672 (26 ½”)

1904 (75”)

)

¾”)

Distance minimale du mur (côté de la charnière)

36”: 139 mm (5 1/2””)

30”: 103 mm (4 1/8”)

24”: 89 mm (25”)

18”: 63 mm (2 1/2”)

5

Page 32

3. PRÉPARATION À L’INSTALLATION

Water Filter

EW

E W

EW

E W

3.1 Transport sur le lieu d’installation

et déballage

L’appareil est très lourd et peut avoir le

barycentre dans la partie supérieure.

Faire très attention durant la manipulation afin d’éviter tout risque de blessures.

Transporter l’appareil en position verticale. Éviter de manière absolue le transport sur la partie frontale.

2

1

3

S’agissant d’un appareil lourd et de grandes dimensions, avant de transporter l’appareil, s’informer sur

les modalités d’accès au lieu où il sera installé (dimensions des portes, espaces de mouvement dans

les escaliers, etc.). L’appareil est fixé à la base de

l’emballage (palette) moyennant quatre boulons amovibles avec une clé de 19 mm (3/4”).

Il est conseillé d’utiliser un transporteur manuel pour

manutentionner l’appareil jusqu’à la zone où celuici

sera installé et seulement alors retirer la base de

l’emballage.

L’appareil devrait toujours être transporté en position

verticale. Si cela n’est pas possible, transporter

l’appareil couché sur le dos. Une fois que l’on a atteint

la zone prévue pour l’installation, enlever les emballages, faire descendre l’appareil de la palette emballages et faire descendre l’appareil de la palette.

Intervenir de la manière suivante:

> Enlever les quatre boulons [ 1 ] qui fixent l’appareil à

la palette en utilisant une clé ouverte de 19 mm (3/4”).

> Retirer les crochets de fixation [ 3 ] et [ 4 ] .

> Pour libérer le support de fixation avant [ 3 ], desser-

rer le boulon de réglage [ 2 ] des roues arrière au

moyen d’une clé ou douille de 13 mm (1/2”). Éviter

de forcer ce boulon dans son point de butée dans un

sens ou dans l’autre afin d’éviter d’endommager le

système de nivelage arrière.

S’assurer que les pieds de nivellement avant sont

rentrés afin que les 4 roues soient en contact avec le

sol, pour faciliter toute manoeuvre.

> De l’arrière de l’unité et au moyen d’un chariot diable

de caractéristiques appropriées, retirer l’appareil

et le poser sur le sol. Faire très attention afin d’éviter

tout dommage au sol. Il faut protéger les sols particulièrement délicats avec de carton rigide ou un contreplaqué.

4

1

3.2 Raccordements électrique et

hydraulique

Le filtre ne peut pas rendre potable

de l’eau qui n’est pas destinée à la

consommation alimentaire.

L’appareil doit être raccorder uniquement

au système d’eau destinée à la consommation alimentaire.

Ne pas utiliser de rallonges électriques

ou des adaptateurs.

Une fois l’appareil complètement installé,

raccordé au réseau de l’eau (le cas échéant) et opérationnel, en cas de nécessité

de couper l’alimentation d’eau, appuyer

sur le bouton

contrôle pour désactiver la fabrique à

glaçons avant de fermer la conduite principale, afin d’éviter que se déclenche

l’état d’alarme « NO WATER IN » (Absence

d’eau) sur l’appareil.

E

E

W

W

ÉLECTRIQUE ET HYDRAULIQUE

Les appareils sont livrés de l’usine pour une tension

de secteur de 110V-120V AC - 60 Hz (États-Unis et

Canada).

Ils sont fournis avec un câble d’alimentation approprié

et une fiche pour être connectés à une prise de 15 A

assurant une mise à la terre ecace.

Il est recommandé d’installer un disjoncteur dédié

de 15 A, facilement accessible, afin qu’il puisse

être désactivé sans problèmes en cas d’opérations

d’installation ou d’entretien.

Pour le raccordement au réseau de l’eau (en cas

d’appareils équipés de fabrique à glaçons) une ligne

d’eau de 1/4” avec une soupape de fermeture accessible doit être fournie.

L’appareil est livré avec un adaptateur coudé pour

l’alimentation en eau, adapté à la pression recommandée de l’eau et conforme aux réglementations

applicables en matière d’aliments et d’eau.

La cartouche filtrante de l’eau, fournie avec

l’appareil, doit être installée suivant les instructions

qui l’accompagnent. Le raccordement solénoïde à

l’appareil a un diamètre de 3/4”, mais avec filetage

Ice Maker

sur le panneau de

E

E

RACCORDEMENT

W

W

E

W

W

E

6

Page 33

FR

E

W

métrique (NPT). Le connecteur fileté d’un tuyau

d’arrosage standard ainsi qu’un tuyau en acier inox

tressé pouvant être acheté dans une normale quincaillerie peuvent éliminer ou endommager les filetages magnétiques. Il est recommandé d’utiliser

uniquement l’adaptateur coudé rapide de 1/4” pour

le raccordement d’une ligne d’alimentation d’eau à

l’appareil de 1/4” en cuivre ou en polyéthylène.

N’utiliser ni rallonges ni adaptateurs multiple pour le branchement.

RACCORDEMENTS ÉLECTRIQUE ET HYDRAULIQUE

DERRIÈRE L’UNITÉ

E

W

Intervenir de la manière suivante:

> Dérouler le câble électrique et le brancher directe-

ment à la prise murale.

> Contrôler que l’appareil soit en stand-by et que les

voyants soient éteints; dans le cas contraire, appuyer

sur la touche Unit pour éteindre l’appareil.

> Raccorder le tuyau de l’eau au réfrigérateur dans

la zone arrière [ 1 ].

1

3.3 Énergies renouvelables et systèmes

domotique

Si l’alimentation est fournie par une source

d’énergie alternative (solaire, géothermique,

etc.) ou en cas d’installation de systèmes domotiques avec des signaux porteurs dans les lignes

électriques, il peut être nécessaire d’installer un

transformateur d’isolement (non fourni) afin de

prévenir toute interférence avec le circuit électronique de l’appareil.

Raccordement électrique

Raccordement hydraulique

fig.1 Arrière de l’appareil

3.4 Mise à niveau

Mettre à niveau l’appareil en réglant les pieds et

les roues arrière à la base de l’appareil.

2

1

Intervenir de la manière suivante:

> Si nécessaire, déposer le socle ou la grille in-

férieure (il est fixé par des aimants), ajuster la

hauteur des pieds de nivellement [ 1 ] au moyen

d’une clé de 17 mm (11/16”).

> Ajuster ensuite la hauteur des roues arrière

en tournant les boulons de réglage avant [ 2 ]

en sens horaire (pour soulever) ou anti-horaire,

selon le besoin. Faire attention en cas

d’utilisation d’une visseuse électrique et réduire

la puissance afin d’éviter d’endommager le système de nivellement.

> Reposer le socle ou la grille inférieure.

2

1

7

Page 34

4. DIMENSIONS DE LA NICHE D’ENCASTREMENT

A

B

4.1 Dimensions de la niche

d’encastrement et installation

36": 914 (36”)

30": 762 (30”)

24": 610 (24”)

18": 457 (18”)

Series

36”

30”

24”

Largeur de la niche

d’encastrement

762 (30”)

610 (24”)

4.2 Montage à fleur avec des garnitures

standard

A

Largeur de

panneaux

908 (35 3/4”)914 (36”)

756 (29 3/4”)

604 (23 3/4”)

18”

457 (18”)

451 (17 3/4”)

A - KCLITU: Kit raccordement lateral (compris)

Niche d’encastrement pour installation combinée

18” 24” 30” 36”

18” 36”(914mm) 42”(1067mm) 48”(1220mm) 54”(1372mm)

B

A

24” 42”(1067mm) 48”(1220mm) 54”(1372mm) 60”(1520mm)

30” 48”(1220mm) 54”(1372mm) 60”(1520mm) 66”(1676mm)

36” 54”(1372mm) 60”(1524mm) 66”(1676mm) 72”(1829mm)

8

Page 35

5. MONTAGE DES PANNEAUX

5.1 Préparation des panneaux décoratifs

pour la porte

FR

> Suivre les données du tableau correspondant

au modèle choisi, marquer d’abord le trou le plus

externe et puis le plus interne [ 3 ].

Les dimensions des panneaux sont indiquées

dans le tableau et sur les dessins reportés cidessous.

Selon les exigences d’alignement avec d’autres

meubles de la cuisine, le panneau de la porte

du réfrigérateur peut être plus haut par rapport

à la ligne supérieure de la porte.

Les panneaux sont montés moyennant des brides

spéciales qui s’accrochent aux dispositifs de

fixation réglables déjà prévus sur porte et grand

bac et moyennant des équerres qui bloquent et

règlent verticalement le panneau.

Brides, équerres et vis de fixation correspondantes sont fournies avec l’appareil et sont appliquées au panneau en suivant le schéma de

perçage reporté ci-dessous ou en utilisant le gabarit de perçage prévu à cet effet et fourni.

Intervenir de la manière suivante:

Pour appliquer les brides aux panneaux, procéder

de la manière suivante. Il est recommandé de

monter les équerres avant de monter la poignée.

3

> Positionner les équerres sur chaque série de

marques pour vérifier qu’elles sont alignées [ 4 ],

si on choisi de percer des petits trous de guidage

pour les vis, il est recommandé de prêter particulière attention à ne pas traverser complètement

l’épaisseur du panneau [ 5 ].

4

5

Panneau de la porte

> Tracer une ligne qui divise verticalement le

panneau en deux parties égales [ 1 ].

1

> Partant du bas du panneau, marquer la hauteur

à laquelle pratiquer les trous (pour la distance

des trous). [ 2 ].

2

> Visser les équerres [ 6 ].

6

9

Page 36

5. MONTAGE DES PANNEAUX

> Préparer la porte de l’appareil pour le montage des panneaux en enfilant les boulons à épaulement dans sections encastrées et les vis de pression dans l’autre trou [ 7 ]. Vérifier que l’extrémité avec la douille hexagonale

est vissée dans la porte et pas dans la partie visible. Visser susamment jusqu’à les noyer dans la surface de la

porte de l’appareil, afin d’éviter toute interférence avec l’accrochage du panneau. Il sera possible de les ajuster

plus tard.

7

10

Page 37

5.2 Préparation des panneaux décoratifs pour réfrigérateur

1797 (70 ¾”)

A

36” 30” 24” 18”

FR

1

A 908 (35 3/4”) 756 (29 3/4”) 604 (23 3/4”) 451 (17 3/4”)

B 418 (16 1/2”) 343 (13 1/2”) 275 (10 7/8”) 200 (7 7/8”)

Positionnement des trous:

B B

¼”)

¼”)

165 (6 ½”)

690,5 (27

6,5 (

34 (1 3⁄8”) 34 (1 3⁄8”)

3⁄8”)

112 (4

6,5 (¼”)

1271,5 (50”)

7⁄8”)

min 1929 (75

11

Page 38

5. MONTAGE DES PANNEAUX

B B

A

34 (1

3⁄8”

) 34 (1

3⁄8”

)

1797 (70

¾

”)

165 (6

½”

)

1271,5 (50”)

690,5 (27

¼

”)

112 (4

3⁄8”

)

min 1929 (75

7⁄8

”)

6,5 (¼”)

6,5 (

¼”

)

)

5.3 Préparation des panneaux décoratifs

pour cave à vins avec porte vitrée

24” 18”

1

Dimension trou pour porte: Positionnement des trous:

200

7⁄8”)

(7

A 604 (23 3/4”) 451 (17 3/4”)

B 275 (10 7/8”) 200 (7 7/8”)

139 (5 ½”)

1572 (62”)

599: 327 (12

449: 177 (6

)

7⁄8”

7⁄8”)

139 (5

½”

12

Page 39

5.4 Dimensions des panneaux

min 100 (3

Il est possible d’utiliser des panneaux avec des épaisseurs allant entre 19 mm (3/4”) et 28 mm (1 1/8”).

Les panneaux de porte avec un poids max de 34 kg (75 lb).

Excéder ces poids pourrait annuler la garantie de tous les problèmes de services qui peuvent être attribués à des panneaux en surpoids.

Le mécanisme de charnière sur les appareils Bertazzoni est considéré comme `zéro dégagement`.

Les largeurs de portes et de tiroirs spécifiées ci-dessous supposent la largeur de niche minimum est utilisé et une de 3,5 mm (1/8 “) révèlent l’on souhaite autour des panneaux. Ajuster les dimensions de votre

écran en fonction de vos propres critères de conception compte tenu de la largeur de votre créneau et

votre révèlent. Jeu minimum / écart ne doit pas être inférieure à 1,5 mm (1/16 “).

SERIES LARGEUR DE LA PORTE A PORTE: LARGEUR DE LA COUPURE B

36” 908 (35 3/4”) -

30” 756 (29 3/4”) -

FR

24” 604 (23 3/4”) 327 (12 7/8”)

18” 451 (17 3/4”) 177 (6 7/8”)

)

”

¾”)

min 1929 (75 7⁄8

2120 (83 7/16") + 25 (1")

max 2027 (79

139

(5 ½”)

139

(5 ½”)

1572 (62”)

7⁄8”)

A B

Pour réfrigérateur et congélateur Pour cave à vins

13

Page 40

5. MONTAGE DES PANNEAUX

5.5 Fixation des panneaux à la porte

Aprés avoir appliqué les pattes de fixation

et les équerres aux panneaux, commencer l’installation par le tiroir du bas.

Intervenir de la manière suivante:

> Accrocher le panneau aux dispositifs de fixation

en insérant dans les crans d’alignement

supérieurs .

6

7

> Il est possible d’ajuster l’alignement du panneau par rapport aux meubles adjacents à l’aide des

pattes et des équerres d’alignement [ 7 ] e [ 8 ].

9

8

> Il est possible d’ajuster l’alignement du panneau par rapport aux meubles adjacents à l’aide

des pattes et des équerres d’alignement [ 9 ] en

vissant ou en dévissant la vis à l’équerre.

14

Page 41

> Alignement en profondeur : en opérant de

l’intérieur de la porte, après avoir soulevé le joint

magnétique du côté de la poignée et en tournant

les couvercles en plastique du côté de la charnière, ajuster la position du panneau dans la direction Z en ajustant les boulons à épaulement

et les vis de pression en parallèle, au moyen de

la clé hexagonale de 4 mm, et verrouiller finalement toutes les positions de montage en place

[ 10 &11 ].

FR

10

Une fois le panneau avant a été ajusté,

vérifiez que le joint a été repositionné

correctement pour assurer la porte/

tiroir ferment correctement et éviter

les erreurs opérationnelles de l’unité.

La poignée de la porte n’est pas compris dans

l’emballage du produit. Il faut l’acheter à part.

Pour l’installation du poignée, veuillez vous faire

référence aux instructions compris dans l’emballage du poignée.

11

15

Page 42

6. INSTALLATION

B

B

6. INSTALLATION

IMPORTANT: Les instructions suivantes pour l’installation s’appliquent à tous les modèles Bertazzoni.

3

6.1 Encastrement appareil unique

Des profils sont installés pour fermer les espaces

entre l’appareil et les meubles adjacents ou un autre appareil juxtaposé à celui-ci.

Intervenir de la manière suivante:

> Pousser l’appareil dans la niche d’installation

[ 1 ].

Schéma de montage profils latéraux:

1

> Assemblez toujours le panneau frontal à la

porte avant de placer l’appareil dans sa position

définitive dans la niche ou la structure.

> Vérifier que les pieds et les roues arrière soient

à niveau avant d’encastrer l’appareil.

> Fixer l’appareil aux meubles adjacents en vissant à ces derniers les deux profils latéraux, déjà

montés sur l’appareil [ 2 ].

Pour effectuer facilement l’opération, garder la

porte ouverte.

2

Appareil

A

Paroi ou meuble

A Bordure de connexion du profil

B Garniture de recouvrement du profil

6.2 Encastrement combinaison de

deux appareils

> Le profile central est compris dans l’emballage

du congélateur et cave à vins.

Des profils en plastique sont compris et

peuvent être utilisés pour fermer les espaces entre l’appareil et les meubles adjacents ou un autre appareil juxtaposé à

celui-ci.

Intervenir de la manière suivante:

> Positionner les appareils devant la niche en

laissant un espace susant pour intervenir sur

l’arrière des appareils [ 1 ].s.

Schéma montage des profils central et latérals:

> Monter sur les profils les corniches de cou-

verture, en les insérant latéralement et puis en

poussant avec force jusqu’au “clic” [ 3 ].

16

1

Page 43

> Passer à l’arrière des appareils pour le montage

des équerres de connexion. Fixer un côté de

l’équerre supérieure et inférieure, d’abord sur un

des deux appareils et ensuite sur l’autre [ 2 ].

2

IMPORTANT: les appareils doivent être au

même niveau

FR

1 – Fixez les deux unités l’une à l’autre à l’avant, à

l’aide des 5 supports en plastique blanc pour maintenir les unités ensemble.

2 – Ajustez les unités à l’arrière, de sorte que les

panneaux latéraux soient parfaitement parallèles

les uns aux autres. Il existe des indices visuels qui

vous aideront à l’alignement.

3 – L’écart (C) entre les unités doit être le même

à l’arrière, en haut et à l’avant. Mesurez l’écart sur

tous les bords et ajustez s’il n’est pas égal.

4 – Une fois que l’écart est uniforme sur tous les

bords, fixez les supports. Si l’écart entre les unités

n’est pas uniforme, les portes ne s’aligneront pas

correctement.

Les mesures d’écart varient selon les types d’unités

installées. Veuillez vous référer au tableau ci-dessous pour les mesures d’écart correctes.

17

Page 44

6. INSTALLATION

Distances entre unités (A+B)

C

18” 7/8” (22 mm) 15/16” (23,5 mm) 1” (24,5 mm) 1” (25,5 mm)

24” 15/16” (23,5 mm) 1” (25 mm) 1” (26 mm) 1 1/16” (27 mm)

B

30” 1” (24,5 mm) 1” (26 mm) 1 1/16” (27 mm) 1 1/8” (28 mm)

36” 1” (25,5 mm) 1 1/16” (27 mm) 1 1/8” (28 mm) 1 1/8” (29 mm)

Une fois les appareils réglés et correctement mis à

niveau, desserrez les deux vis qui maintiennent la

plaque d’étanchéité en place.

Abaissez la plaque jusqu’à ce qu’elle aeure le

sol et resserrez les vis. Cela garantira un flux d’air

optimisé à travers le condenseur, nécessaire au

bon fonctionnement des appareils.

18” 24” 30” 36”

A

> Ensuite les accoupler sur le devant en fixant

les deux profils avec les vis ou les rivets fournis

[ 3 ]. Fixer le support sur la partie supérieure des

unités (le cas échéant) comme illustré à la figure

[ 4 ].

3

18

4

Page 45

FR

> Fixer l’équerre supérieure l’inférieure [ 5 ].

d’abord sur un appareil et puis sur l’autre. Compléter en montant la corniche de couverture centrale

en poussant avec force jusqu’au “clic”.

> Monter sur les profils les corniches de couverture,

en les insérant latéralement et puis en poussant avec

force jusqu’au “clic” (comme pour l’encastrement

de l’appareil unique) [ 8 ].

7

8

> Une fois complétés les passages ci-dessus, poussez

les appareils dans leur position définitive [ 6 ].

Assemblez toujours le panneau frontal à la porte

avant de placer l’appareil dans sa position définitive dans la niche ou la structure.

> Vérifier que les pieds et les roues arrière soient

à niveau avant d’encastrer l’appareil.

> Fixer chaque appareil aux meubles adjacents

en vissant à ces derniers les profils latéraux, déjà

montés sur les appareils [ 7 ]. Pour eectuer

facilement l’opération, garder la porte ouverte.

6

Faire attention car les appareils ont

la partie avant plus lourde et peuvent

s’incliner avant qu’ils soient fixés aux

meubles adjacents.

19

Page 46

C

A

B

B

A

A

A

6. INSTALLATION

Schéma montage des profils central et latérals:

Appareil

Paroi ou meuble

A - Bordure de connexion du profil

B - Garniture de recouvrement du profil latéral

C - Garniture de recouvrement du profil centrale

6.3 Profondeur maximale

structure au-dessus du

réfrigérateur encastrable à

porte unique

Il est possible que le design de la cuisine et

notamment de la niche où doit être introduit le

réfrigérateur encastrable prévoit un meuble audessus du réfrigérateur, meuble qui doit être fermé

aussi par le panneau de la porte du réfrigérateur

même.

Dans ce cas, la profondeur totale du meuble au-

dessus du réfrigérateur ne doit pas dépasser la

profondeur totale du réfrigérateur même sans la

porte [ 1 ].

1

De cette façon il n’y aura aucune interférence avec

le panneau fixé sur la porte du réfrigérateur, en

assurant ainsi une ouverture correcte pendant la

rotation jusqu’à 100°.

20

47 mm (1 7/8”)

Page 47

7. ACHÈVEMENT DE L’INSTALLATION

2 x

59 (

2

3⁄8

”)

”)

FR

7.1 Montage de la sécurité

anti-renversement

Si l’appareil(s) n’est pas relié par les garnitures des profils latéraux au meuble, il

est nécessaire d’installer les équerres

antirenversement afin d’éviter toute chute

en avant du produit pendant l’utilisation,

pouvant entraîner des dommages ou des

blessures. Toute demande d’intervention

en garantie liée à une situation de renversement sera nulle si l’appareil(s) n’est

pas fixé solidement.

Intervenir de la manière suivante:

> Les équerres devraient être appliquées comme

illustré, en utilisant les vis fournies. En cas

d’utilisation des équerres anti-renversement, il est

recommandé de les fixer dans des charpentes en

bois ou en béton - les plaques de plâtre ne pourraient pas supporter le poids de l’appareil.

Positionner un équerre sur la partie supérieure de

l’appareil en correspondance des trous de fixation

et contre le mur [ 1 ].

> Percer le mur avec une mèche de 8 mm (3/8”) et

insérer la vis tamponnée [ 3 ].

3

> Replacer l’équerre et la fixer d’abord sur la partie supérieure du meuble et, ensuite, au mur [ 4 ].

4

5⁄8

1

45 (1

152 (6”)

> Marquer la position des trous avec un crayon [ 2 ].

2

Pour pouvoir utiliser les équerres anti-renversement sur des modèles avec le compresseur installé sur la partie supérieure,

il est nécessaire de retirer temporairement

la partie supérieure, le plafond métallique

/ panneau de protection, afin d’accéder aux

points de boulonnage des équerres.

21

Page 48

7. ACHÈVEMENT DE L’INSTALLATION

B

C

C

Si la grille est positionnée différemment que le

7.2 Circulation de l’air

MODELS ENCASTRABLES ET ENCASTRABLES

AVEC PORTE INOX:

Un système à air forcé assure la ventilation à travers

la grille, bien fixée à l’appareil par du plaqués magnétiques, positionnée la dans la partie inférieure

de l’appareil [ 1 ].

1

Si l’aménagement de la cuisine prévoit une plinthe,

cette dernière doit être placée d’une manière de garder un niveau d’aréation satisfaisant, comme expliqué

dans le dessin [ 2 ].

dessin [ 2 ], la plinthe doit être trouée au moins

au 50%, comme par les dimensions A et B en bas

[ 3 ].

3

36 ’’ 30 ‘‘ 24 ‘‘ 18 ‘‘

A 860 (33 7/8”) 740 (29 1/8”) 560 (22”) 410 (16 1/8”)

B > 100 (4”)

C 10 (3/8”)

Afin de nettoyer régulièrement le condenseur

de la poussière, la grille doit toujours être accessible [ 4 ].

A

2

4

min 100mm (3 ⅞”)

50mm (1 ⅞”)

100 (4”)

22

Page 49

7.3 Contrôle de fin d’installation

Ice Maker Water Filter

bianco EB 61 - 62 li

Fondo o ultimo passaggio:

passaggio di nero coprente 602 -95 li

forato solo per le parti retro illuminate come da disegno “C”

Nomenclature: Grigio Whirlpool

cambiamento dimensioni foro

56x43mm 29-05-2019

00

°C+

Impostazioni

Funzioni

00

°C+

00

°C-

BISELLATURA SUI 4 LATI

Contrôler que les pieds sont correctement installés.

Contrôler que le raccordement à l’installation

hydrique ne présente pas de fuites d’eau et que le

robinet de fermeture est facilement accessible.

Contrôler que le branchement électrique soit

correctement réalisé et que la fiche et l’interrupteur

omnipolaire dédié soient facilement accessibles.

Contrôler le parfait alignement de l’appareil avec

les meubles adjacents.

> Eliminez l’air des conduites d’eau en activant

la fonction «Nettoyage manuel» du menu - >

Fonctions-> Options de filtre à eau. Vous pourriez

avoir besoin de répeter cette séquence plusieurs

fois jusqu’à ce que vous arrêtez d’entendre l’air

dans le remplissage de la machine à glaçons

(Consulter le Mode d’emploi).

> Une fois que vous êtes convaincu que le système

est purgé d’air, allumez la machine à glaçons en

touchant le

bouton qui s’allume.

FR

Contrôler que chaque ruban adhésif ou protection temporaire interne ou externe soit éliminé.

Contrôler la parfaite étanchéité des portes et le

coulissement des bacs et des clayettes.

7.4 Mise en marche

> Pour mettre en marche l’appareil, brancher la

fiche au réseau électrique: lorsque la porte est

ouverte, apparaît sur le panneau de commande le

message “Stand-by”, alors que toutes les touches

du panneau sont éteintes.

> Pour mettre en marche tous les compartiments

de l’appareil, appuyer pendant 3 secondes sur la

touche Unit .

Le message “initial test” apparaîtra pendant environ 2 minutes, ensuite les compresseurs seront

actifs jusqu’à attendre la température prévue en

usine par défaut. Veuillez noter que cette opération pourrait durer plusieurs heures.

> Si l’appareil est fourni avec un appareil à

glaçons avant de le mettre en marche pour la

première fois, veuillez vous assurer que la cartouche du filtre pour l’eau a bien été installée et

effectuez un remplissage du circuit hydraulique.

> Pour toute autre information concernant le fonctionnement de l’appareil, se référer au Mode

d’emploi.

Si lors de la première mise en marche,

n’apparaît pas le message Stand-by, mais

apparaissent Fridge too warm, Freezer too

warm ou signaux sonores, cela signifie que

l’appareil a déjà commencé la procédure de

refroidissement.

Dans ce cas désactiver les éventuels messages sonores en eeurant la touche

Alarm, refermer la porte et attendre que

les températures programmées soient atteintes.

Il faut laisser l’unité atteindre la température

de fonctionnement vide et avec la porte