Page 1

BERNINA Q 24 | Q 20

Frame Mounting Manual

Page 2

Page 3

Edition notice

Edition notice

Text, Setting and Layout

BERNINA International AG

Photos

Patrice Heilmann, Winterthur

BERNINA International AG, Steckborn

Order number

2019-04 en 0365655.10A.04

Copyright

2018 BERNINA International AG

All rights reserved: For technical reasons and for the purpose of product improvements, changes

concerning the features of the machine can be made at any time and without advance notice. The supplied

accessory can vary depending on the country of delivery.

1

Page 4

Table of Contents

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS ................. 3

1 My BERNINA ........................................................ 5

1.1 Further information ................................................ 5

1.2 Content of these instructions ................................. 5

Explanation of symbols ........................................... 5

1.3 Overview of the quilting frame ............................... 6

1.4 Overview of delivery ............................................... 7

1.5 Overview of large parts .......................................... 7

1.6 Overview of small parts .......................................... 8

2 Quilting frame assembly .................................... 12

2.1 Unpacking and checking the delivery ..................... 12

2.2 Recurring steps ...................................................... 12

Fitting the slot nuts ..................................................... 12

Tightening the socket screws ...................................... 13

2.3 Sequence of assembly steps ................................... 13

2.4 Working height adjustment .................................... 13

2.5 Base frame assembly .............................................. 15

Overview components ................................................ 15

Attachting adjustable levelling feet ............................. 16

Attaching the lower cross bar ..................................... 16

Attaching the back bar ............................................... 18

Attaching the front bar ............................................... 21

2.6 Rail support assembly ............................................. 23

Attaching rail supports ................................................ 23

Adapting the rail support for BERNINAQ20 ............... 24

2.7 Tabletop positioning .............................................. 25

Attaching tabletop brackets ........................................ 25

Positioning tabletops .................................................. 25

2.8 Quilting frame levelling .......................................... 26

2.9 Track assembly ....................................................... 27

Attaching the rear track .............................................. 27

Attaching the front track ............................................ 29

2.12 Machine preparation ............................................... 38

Overview ...................................................................... 38

Getting the machine ready ........................................... 41

Attaching the V-wheel units ......................................... 41

Attaching the front stand profile .................................. 42

Attaching the rear stand profile .................................... 44

Positioning the machine on the carriage ....................... 46

Attaching safety brackets ............................................. 47

Fitting rail covers .......................................................... 49

2.13 Take-up rail and dead bar attachment ..................... 50

Attaching the Take-up rail ............................................ 50

Attaching the handwheel to the take-up rail ................ 52

Attaching the dead bar ................................................ 53

2.14 Leader, side clamp, and storage tray attachment ..... 55

General notes on attaching the leaders ........................ 55

Attaching the Back leader ............................................ 55

Attaching the Take-up leader ....................................... 56

Attaching the Top leader .............................................. 57

Attaching the side clamps ............................................ 58

Attaching the storage trays .......................................... 59

2.15 Front handle attachment ......................................... 60

Attaching the front handle unit .................................... 60

Adjusting the width of the handles .............................. 60

Adjusting the handles .................................................. 61

3 Disposal ................................................................ 62

3.1 Quilting frame disposal ........................................... 62

4 Specifications ....................................................... 63

5 Appendix .............................................................. 64

5.1 Differing information for the "Large" quilting frame

................................................................................

64

5.2 Differing information for the "Small" quilting frame

................................................................................

64

Index ..................................................................... 66

2.10 Top and backing rail assembly ................................ 31

Assembling the top rail ............................................... 32

Assembling the backing rail ........................................ 33

2.11 Carriage and park position magnet alignment ........ 35

2

Page 5

Important safety instructions

IMPORTANT SAFETY INSTRUCTIONS

Please observe the following general safety instructions when assembling the

quilting frame. Before using the quilting frame, also read the operating

instructions for the machine from the BERNINA Q Series carefully.

WARNING

To protect persons from injuries:

• The packaging of the quilting frame and the machine is large and heavy. The

packaging should therefore always be carried by at least two adults

together.

• Position the packaging and individual parts so that they cannot fall over.

• Setting up the quilting frame requires at least two adults.

• During assembly of the individual and small parts, ensure that the parts are

kept out of the reach of small children (risk of suffocation).

• During assembly, ensure that your fingers do not get trapped or caught.

• Only use the quilting frame for the purpose described in these assembly

instructions.

• Do not use the quilting frame as a toy.

• The quilting frame can be assembled by children over the age of 8, as well

as by persons with reduced physical, sensory, or mental capacities or with a

lack of experience and knowledge, as long as they are supervised or have

been made aware of the potential hazards.

• Only use accessories recommended by the manufacturer.

• Do not insert any objects into the openings on the quilting frame.

• Keep fingers away from all moving parts. Special caution is required in the

area of the take-up rail, top rail and backing rail, as well as the carriage.

Availability of the instruction manual

The assembly instructions are part of the quilting frame.

• Store the assembly instructions for the quilting frame in a suitable location

near the quilting frame and keep them available to consult.

• If the quilting frame is passed on to third parties, always include the

assembly instructions with the quilting frame.

3

Page 6

Important safety instructions

Proper use

The quilt frame serves as a support for the machines in the Q series and as a

workplace for long arm quilting. Any other use is not considered proper.

BERNINA assumes no liability for consequences resulting from improper use.

4

Page 7

My BERNINA

1 My BERNINA

1.1 Further information

You can find the latest version of your assembly instructions as well as a lot more information about quilting

on our website at http://www.bernina.com

1.2 Content of these instructions

These assembly instructions describe assembly of the "Classic" quilting frame. With certain differences, the

instructions also apply to assembly of the "Large" and "Small" quilting frames. The differences primarily

concern the number of certain parts. You can find information on these differences in the following section:

• Differing information for the "Large" quilting frame (see page64)

• Differing information for the "Small" quilting frame (see page64)

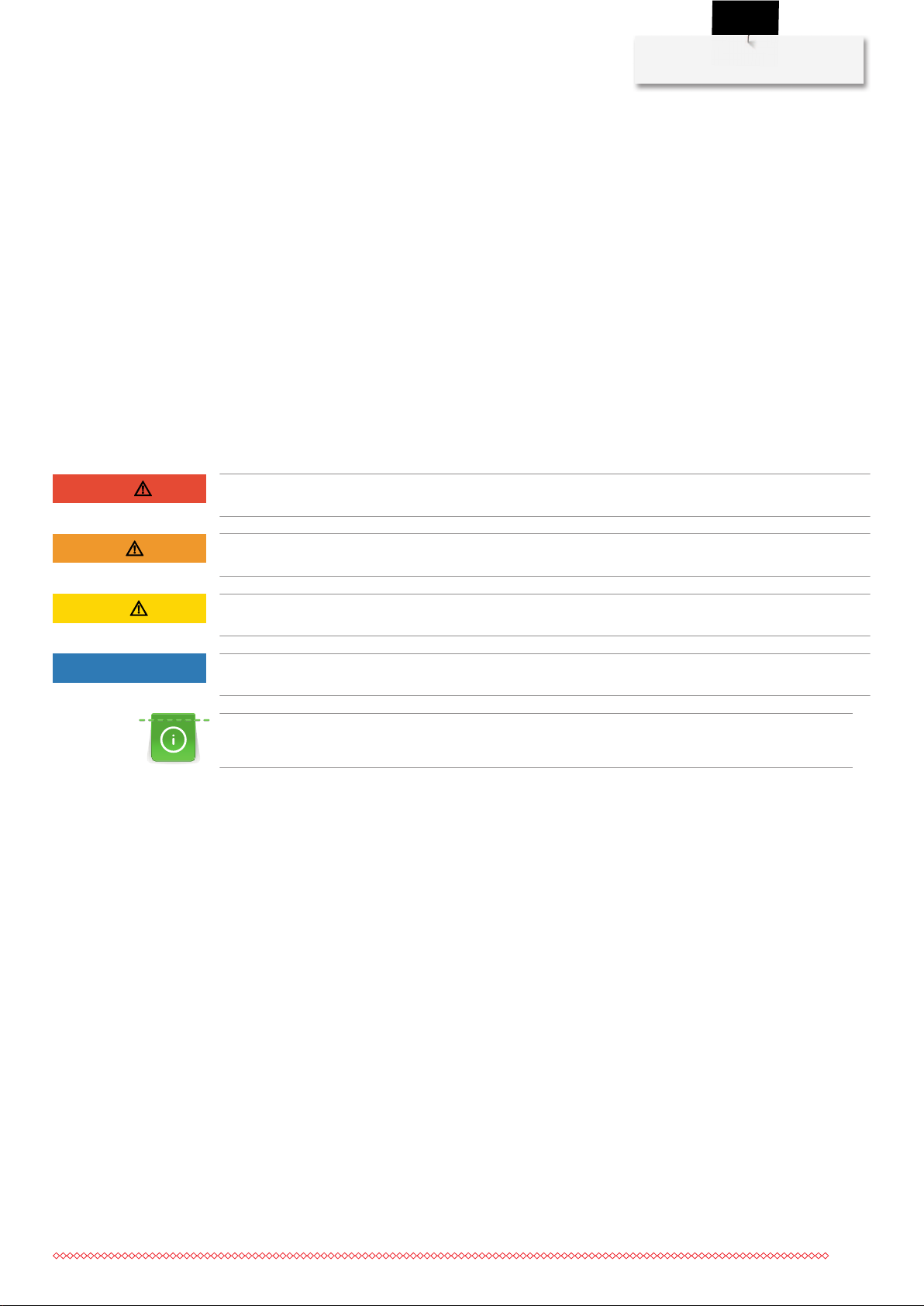

Explanation of symbols

DANGER

WARNING

CAUTION

NOTICE

Labels a high-risk hazard which can lead to serious injuries or potentially even death if not avoided.

Labels a medium-risk hazard which can lead to serious injuries if not avoided.

Labels a low-risk hazard which can lead to minor or moderate injuries if not avoided.

Labels a hazard which can lead to material damage if not avoided.

Tips from BERNINA quilt experts can be found next to this symbol.

Example images are used in these operating instructions for the purposes of illustration. The machines shown

in the images and the accessories shown therefore do not always match the actual items included with your

machine.

5

Page 8

My BERNINA

1

2

3

4

11

10

17

9

14

12

6

5

7

13

1518 16

8

1.3 Overview of the quilting frame

1 Legs, left 10 Cross bar, rear

2 Tabletops 11 Rail support, right

3 Rail support, left 12 Top rail

4 Backing rail 13 Cross bar, bottom

5 Dead bar 14 Legs, right

6 Machine 15 Track, front

7 Take-up rail 16 Legs, center

8 Storage tray 17 Carriage

9 Track, rear 18 Cross bar, front

6

Page 9

My BERNINA

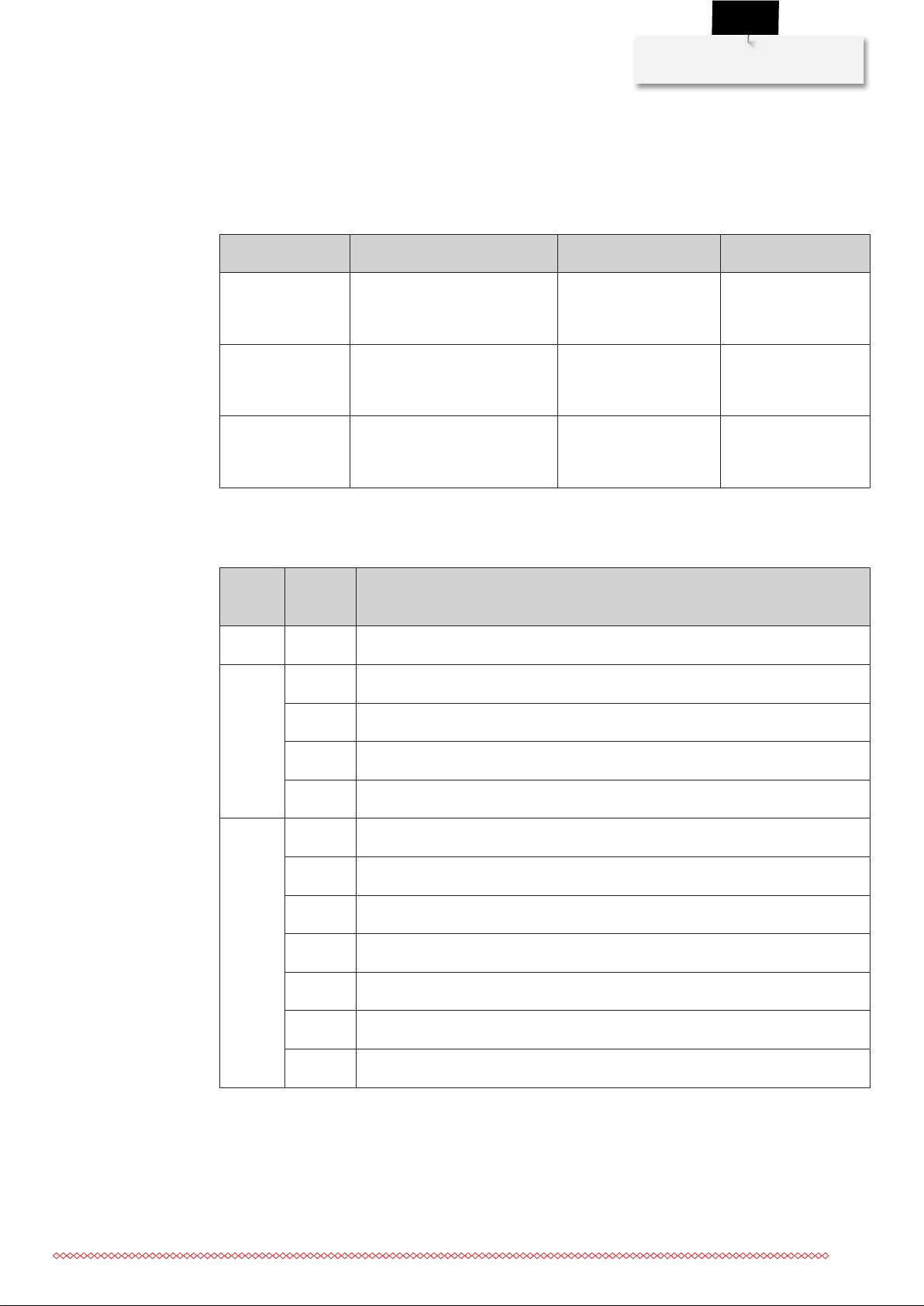

1.4 Overview of delivery

The machines in the BERNINA Q Series for quilting frames are delivered in three packages. Any special

accessories ordered additionally will be supplied in separate packages. These accessories are not taken into

account in these assembly instructions.

Cardboard box Content Size in cm (in) Weight in kg (lb)

1 Q Series machine, including

standard accessories

2 Large parts, tools and

accessories

3 Long parts Approx. 350 × 30 × 24

Approx. 112 × 77 × 42

(44.1 × 30.3 × 16.5)

Approx. 120 × 80 × 70

(47.2 × 31.5 × 27.6)

(137.8 × 11.8 × 9.5)

1.5 Overview of large parts

The delivery contains the following large parts:

Cardbo

ard box

1 1 Machine

2 3 Tabletops

Number Large parts

1 Carriage

Approx. 40

(88.2)

Approx. 75

(165.4)

Approx. 66

(145.5)

3 Legs: Right, left, center

2 Rail supports: Right, left

3 1 Cross bar, bottom

2 Cross bars: Rear, front

2 Tracks: Rear, front

1 Top rail

1 Backing rail

1 Take-up rail

1 Dead bar

7

Page 10

My BERNINA

1.6 Overview of small parts

All small parts such as screws, nuts, washers, etc. that are required for assembly of the standard quilting

frame can be found in cardboard box 2.

The parts are packaged in bags or boxes. We recommend unpacking all parts and then sorting them based

on type. You can use the following tables to check the scope of delivery.

For identification purposes, each part has a code that is included in the list of parts required for the

respective task in the assembly instructions.

Note: The number of items included with the small and the large quilting frame can differ from the details

provided in the following tables. The differences are listed in the appendix. (see page64)

All rights reserved: Changes with regard to the equipment of the machine can be made at any time and

without advance notice for technical reasons and for the purpose of improving the product. The accessories

supplied can also be subject to changes, depending on the country of delivery.

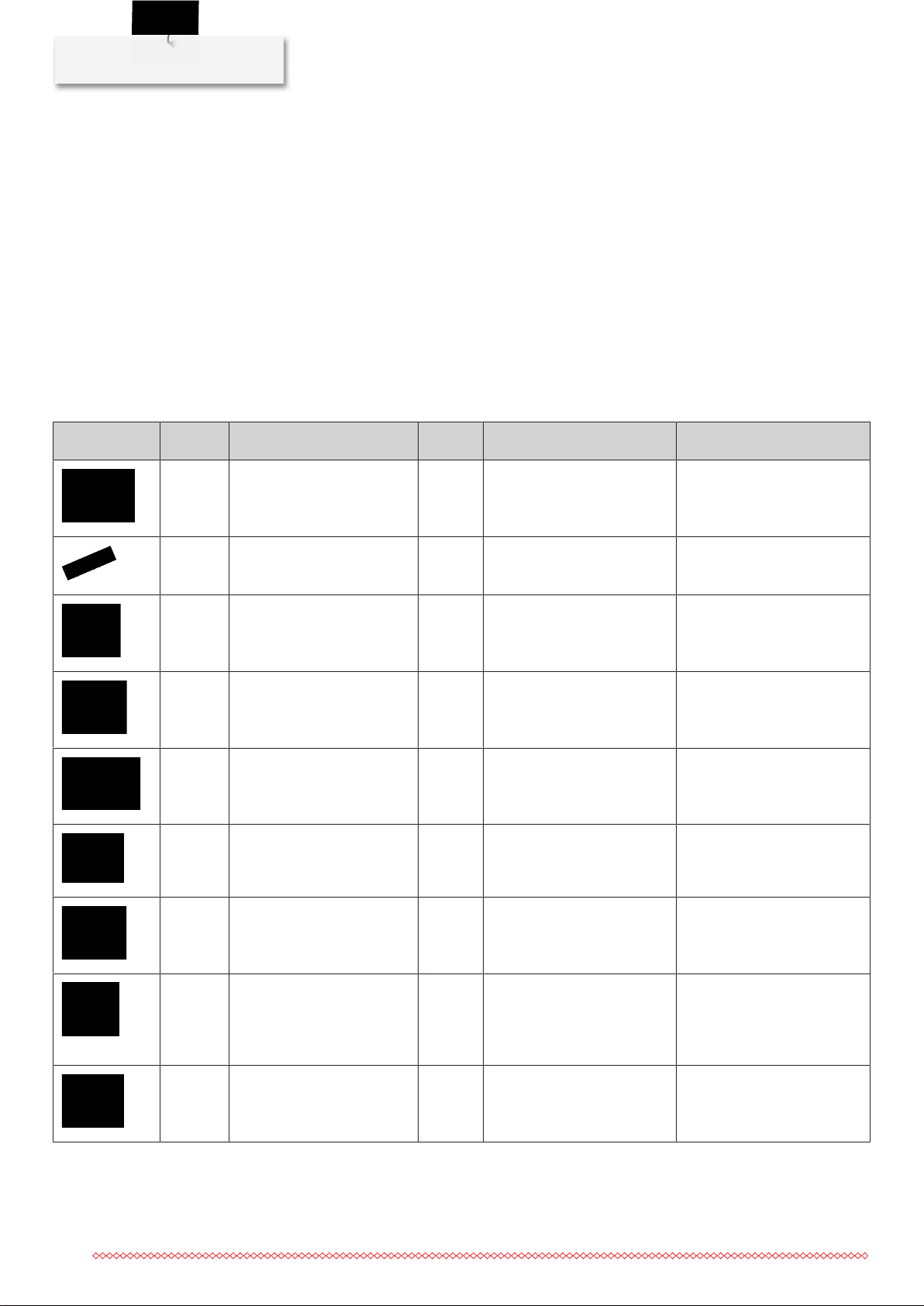

Figure Number Designation Code Tool Use

9 Head cap screw, M8×40 S1 Allen key no.6 Rail support assembly (8 pcs)

Carriage alignment (1 pc.)

3 Head cap screw, M8×50 S2 Torx T30 screwdriver Attaching the lower cross bar

1 Countersunk screw, M5×10 S3 Allen key no.3 Attaching the Take-up rail

2 Head cap screw, M8×50 S4 Allen key no.5 Assembling the Top rail

1 Countersunk screw, M4×45,

black

16 Head cap screw, M4×16 S6 Allen key no.3 Track assembly

4 Button head screw, M5×12 S7 Allen key no.3 Attaching the storage trays

S5 Allen key no.3 Carriage alignment

10 Countersunk screw, M8×14,

black

2 Button head screw, M6×12 S9 Torx T30 screwdriver Carriage alignment

8

S8 Allen key no.5 Positioning tabletops (8 pcs)

Attaching the dead bar (2

pcs)

Page 11

Figure Number Designation Code Tool Use

4 Head cap screw, M5×16 S10 Torx T25 screwdriver Carriage alignment

4 Head cap screw, M6×50 S11 Allen key no.5 Attaching the front bar

My BERNINA

2 Button head self-tapping

S12 Torx T30 screwdriver Attaching the front track

screw, 6.3×22

10 Slot nut, M6, comprising a

SN1 Allen key no.5 Attaching the rear bar

square nut, an M6 serrated

washer and a head cap

screw (M6×12)

Tab.1: Overview of screws

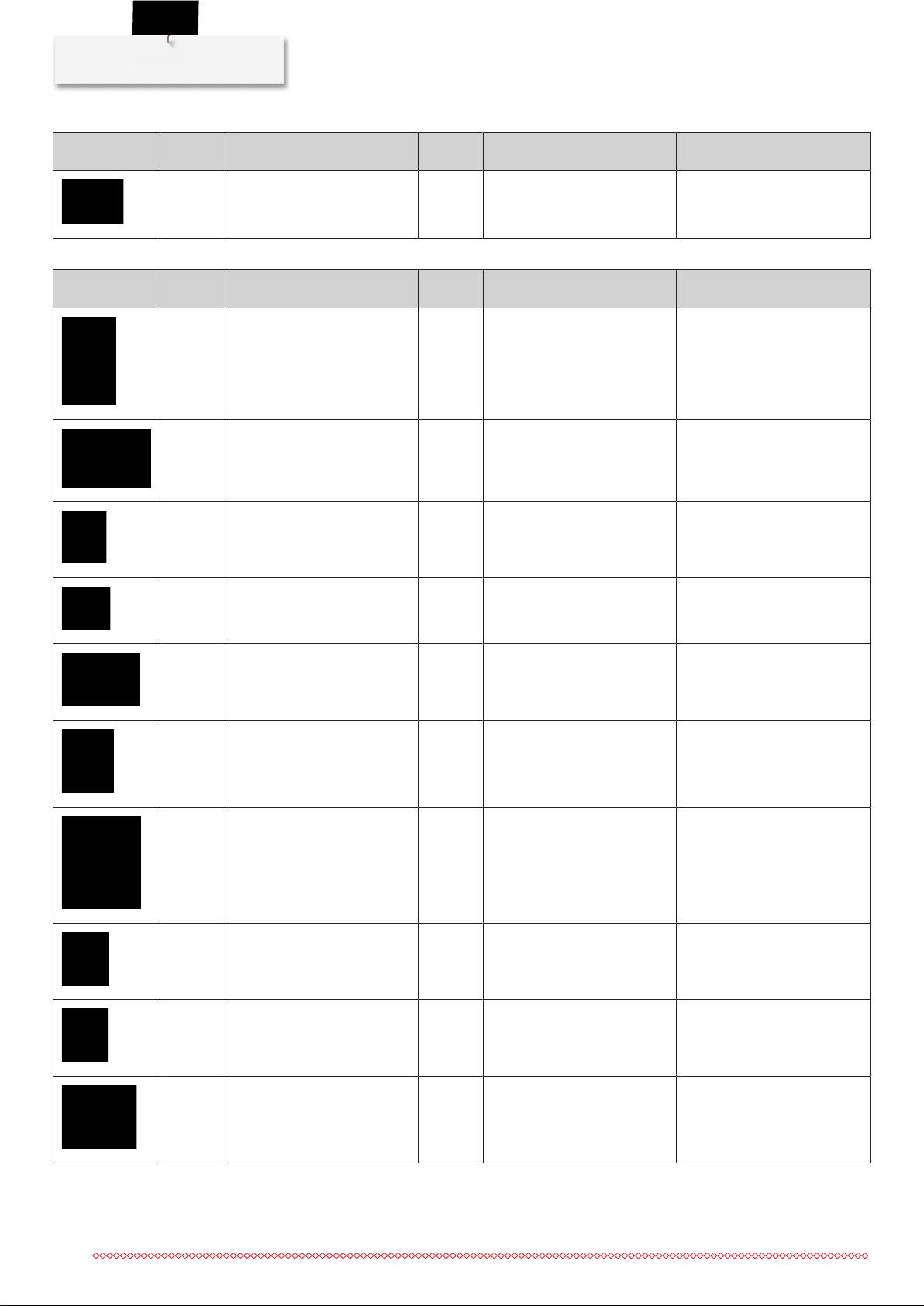

Figure Number Designation Code Tool Use

1 Nut, M4 N1 Carriage alignment

4 Hex nut, M5 N2 Carriage alignment

6 Washer, M10 W1 Attaching adjustable leveling

Attaching the front bar

feet

8 Serrated washer, M8 W2 Rail support assembly

3 Washer, M8 W3 Attaching the lower cross bar

1 Countersunk washer, D25 W4 Attaching the Take-up rail

4 Serrated washer, M6 W5 Attaching the front bar

4 Washer, 5.3/10×1 W6 Carriage alignment

9

Page 12

My BERNINA

Figure Number Designation Code Tool Use

2 Serrated lock washer, M6 W7 Carriage alignment

Tab.2: Overview of washers, nuts

Figure Number Designation Code Tool Use

6 Leveling foot M1 Open-ended wrench no.14 Attaching adjustable leveling

2 Storage tray, black M2 – Attaching the storage trays

feet

1 Handwheel, black, sticker/

M3 Allen key no.3 Attaching the Take-up rail

cover label

1 Locking piece M4 – Attaching the Take-up rail

1 Winder bolt M5 Allen key no.4 Attaching the Take-up rail

2 Setting collar (with three

M6 Allen key no.2 Attaching the backing rail

screwed-in grub screws)

Attaching the Take-up rail

3 Ratchet wheel (with three

M7 Allen key no.2 Attaching the backing rail

screwed-in grub screws)

Attaching the Take-up rail

Attaching the Top rail

1 Magnet, circular M8 – Carriage alignment

10

1 Rubber cap for magnet,

M9 – Carriage alignment

black

8 Metal bracket, black M10 – Positioning tabletops

Page 13

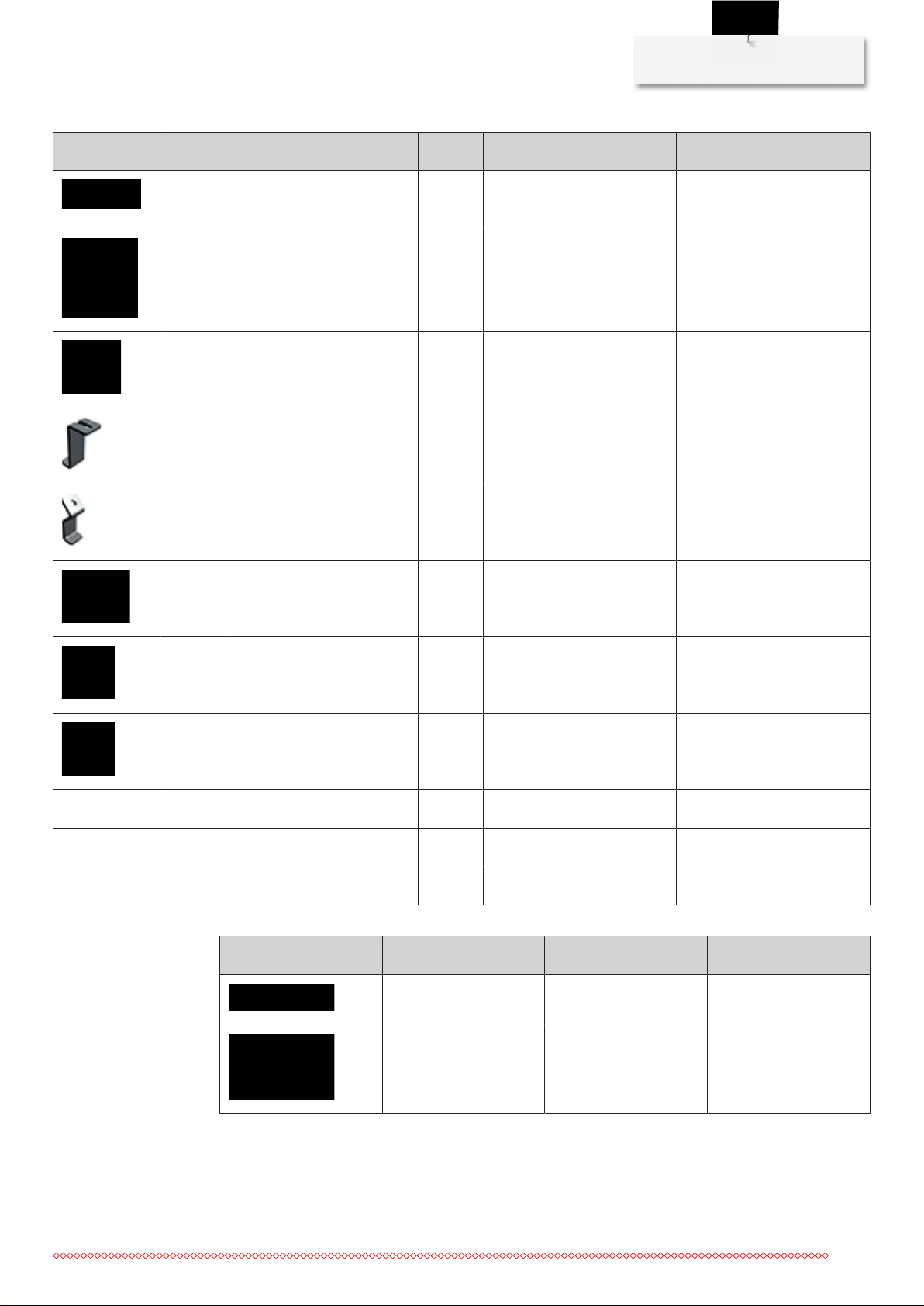

Figure Number Designation Code Tool Use

My BERNINA

14 Self-adhesive felt strips,

black

4 Cover cap for Y rails M12 – Carriage alignment

4 Cover cap for X rails M13 – Carriage alignment

4 Y safety bracket M14 – Carriage alignment

2 X safety bracket M15 – Carriage alignment

4 Bungee cord M16 – Attaching the side clamps

M11 – Positioning tabletops

4 Safety clips M17 – Attaching the side clamps

1 Double-sided adhesive tape M18 – Attaching the side clamps

– 1 Back leader – – Attaching the side clamps

– 1 Top leader – – Attaching the side clamps

– 1 Take-up leader – – Attaching the leaders

Tab.3: Overview of various parts

Figure Number Designation Code

1 Allen key set, nine-piece T1

3 Open-ended wrench:

6×7, 12×14, 13×17

T2

Tab.4: Tools supplied

11

Page 14

Quilting frame assembly

2 Quilting frame assembly

2.1 Unpacking and checking the delivery

> Open the packaging and unpack the individual parts.

> Check the individual parts for damage.

> Check that the delivery is complete.

> If parts are missing or if you have any questions about the assembly, contact your specialist BERNINA

2.2 Recurring steps

The following instructions describe steps that you need to perform repeatedly during assembly of the quilting

frame. These steps are not described in detail each time in the assembly instructions.

Fitting the slot nuts

Slot nuts can be used to securely connect the components of the base frame to one another. A set of slot

nuts (SN1) comprises the slot nut that fits into the slot on the component, a serrated washer and a screw.

> Unscrew the screw from the slot nut.

> Insert the slot nut into the slot near the joint. Ensure that the spring is inside and that the thread can be

dealer immediately.

seen from the outside.

12

> Use the Allen key to slide the slot nut in the slot so that it comes to rest precisely behind the borehole on

the counterpart.

> Place the washer onto the screw.

Page 15

Quilting frame assembly

> Insert the screw through the borehole and screw it into the slot nut.

> Tighten the screw, holding the Allen key by the long end.

Tightening the socket screws

> Always hold the Allen key by the long end when tightening the SN1, S1, S3, S4, S5, S8, and S11 screws.

2.3 Sequence of assembly steps

1. Working height adjustment. (see page13)

2. Base frame assembly. (see page15)

3. Rail support attachment. (see page23)

4. Tabletop positioning. (see page25)

5. Quilting frame levelling. (see page26)

6. Track assembly. (see page27)

7. Top and backing rail assembly. (see page32)

8. Carriage and park position magnet alignment. (see page35)

9. Machine preparation. (see page38)

10.Take-up rail and dead bar attachment. (see page53)

11.Leader, side clamp and storage tray attachment. (see page55)

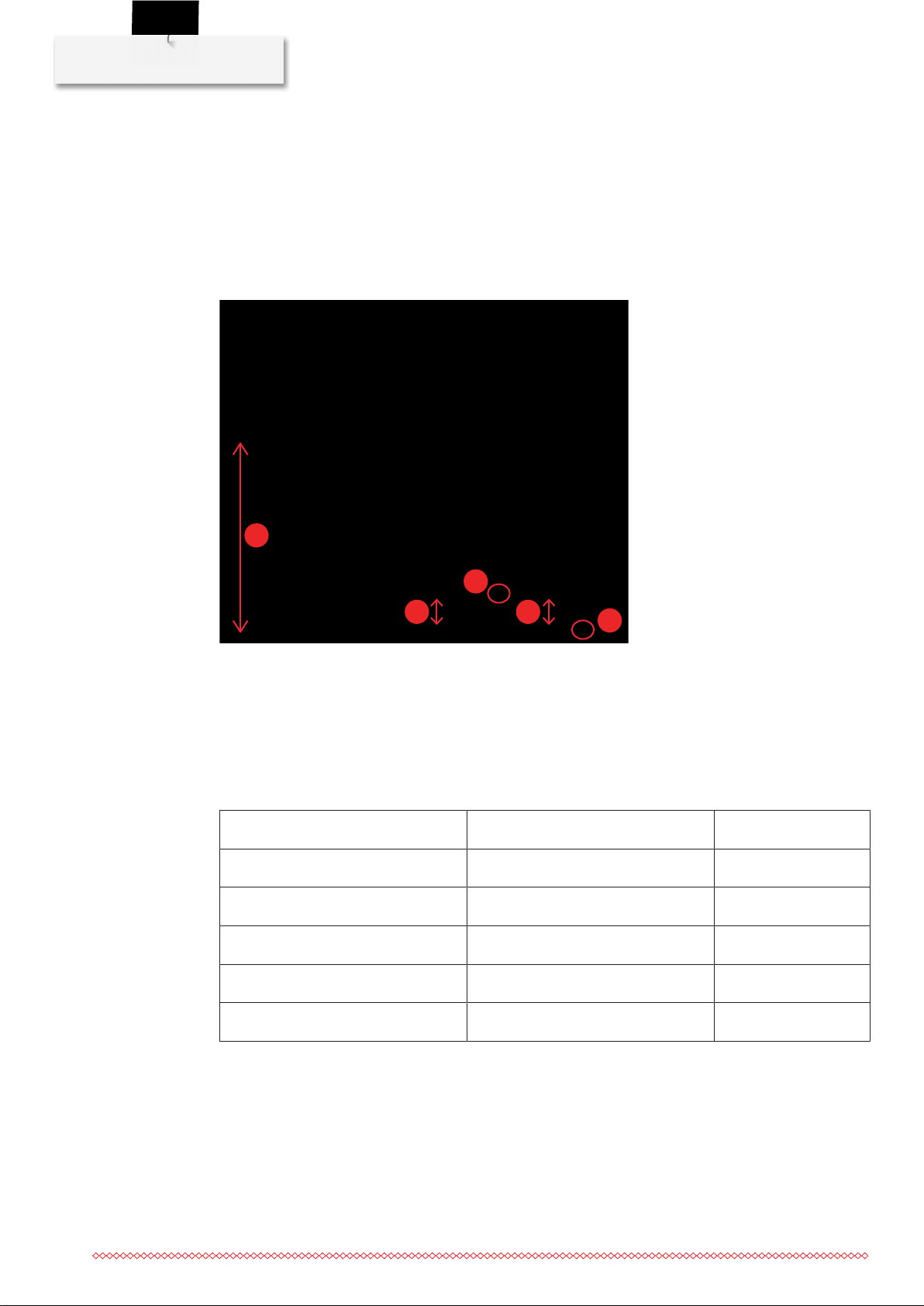

2.4 Working height adjustment

For optimal ergonomics and the best possible quilt quality, the height of the quilting frame can be adjusted.

To adjust the quilting frame to the optimal working height, the legs must be adjusted to the correct length

before assembling the frame.

13

Page 16

Quilting frame assembly

b

a a

2

1

CAUTION!Do not adjust the height of the quilting frame using the height-adjustable levelling feet.

These are only intended for horizontal alignment of the quilting frame.

Determining the optimal working height

The optimal working height (b) is the height of the lower edge of your elbow when your arm is bent at right

angles. For most people, this is around the height of the navel. The height of the quilting frame must be set

so that the stitch plate on the machine is located at the optimal working height (b).

To adjust the quilting frame to the optimal working height, the legs must be adjusted to the correct length

before

assembling the frame.

On delivery, the quilting frame is set to a working height that suits persons with a height of approximately

162 to 167 cm (5'4" to 5'6").

> For other heights, measure the distance from the lower edge of the elbow to the floor (b) with the arms

at right angles.

> The following table lists the suitable leg lengths for this.

Elbow height b (cm / inches) Leg length a (cm / inches)*

95 / 37 5 / 2

100 / 39 10 / 4 Delivery state

105 / 41 15 / 6

110 / 43 20 / 8

115 / 45 25 / 10

*) Length of the protruding leg profile (without levelling feet).

Comment

Adjusting the leg length

Each leg of the quilting frame comprises two leg segments that can be moved against one another.

14

Page 17

Required parts and tools:

a

a

1

2

3

4

5

• Allen key no.6 (T1)

• Tape measure (not included in the scope of delivery)

Prerequisite:

• The optimal leg length is determined.

> Undo the two locking screws on each leg.

– The two leg segments can be moved against one another.

> Move the lower leg segment until it reaches the leg length determined.

Quilting frame assembly

> Tighten the locking screws.

2.5 Base frame assembly

Overview components

The following figures show the most important pre-assembled parts and components for quilting frame

assembly.

1 Rail support, left 4 Legs, right

2 Legs, left 5 Rail support, right

3 Legs, center

15

Page 18

Quilting frame assembly

Attachting adjustable levelling feet

The adjustable levelling feet are used to level the quilting frame (see page26). To ensure sufficient scope

for precision adjustment of the height, the levelling feet must not be screwed in as far as they can go.

Required parts and tools:

> Place one washer (W1) on each levelling foot (M1).

> Screw one levelling foot onto each leg. To ensure that there is sufficient scope for precision adjustment

• Legs, center

• Legs, left

• Legs, right

• 6× levelling feet (M1)

• 6× washers (W1)

• Open-ended wrench no. 14 (T2)

of the height, set a distance of 5cm (1.96inches) between the lower edge of the profile and the lower

edge of the foot.

Attaching the lower cross bar

Required parts and tools:

• Cross bar, bottom

• Legs, center

• Legs, right

• Legs, left

• 3× head cap screws M8 × 50 (S2)

• 3× washers M8 (W3)

• Allen key no.6 (T1)

Prerequisite:

• Leg length is set.

16

Page 19

Quilting frame assembly

> Lay out large parts in approximately the right position on the floor.

> Place the lower cross bar onto the lower longitudinal bar of the central leg in such a way that the central

borehole is located precisely above the pre-fitted slot nut.

> Place a washer (W3) onto a head cap screw (S2). Tighten the screw.

> Place the left-hand edge of the cross bar onto the lower longitudinal bar of the left leg in such a way that

the borehole is located precisely above the pre-fitted slot nut.

17

Page 20

Quilting frame assembly

> Place a washer (W3) onto a head cap screw (S2). Tighten the screw.

> Place the right-hand edge of the cross bar onto the lower longitudinal bar of the right leg in such a way

that the borehole is located precisely above the pre-fitted slot nut.

> Place a washer (W3) onto a head cap screw (S2). Tighten the screw.

Attaching the back bar

Required parts and tools:

• Cross bar, rear

• 8x slot nuts (SN1)

• Allen key no.5 (T1)

Moving the upper longitudinal bar on the central leg

The upper longitudinal bar on the central leg must be moved so that the rear cross bar can be fitted.

> Use the Allen key (T1) to undo the two screws in the lower slot on the right and left of the front leg and

then push the longitudinal bar slightly forward.

18

Page 21

Quilting frame assembly

Positioning the rear cross bar

> Place the cross bar onto the central leg in such a way that the inserted slot nuts are located in the lower

slot and point inward. The "TOP" sticker faces upward.

> Move the inserted slot nuts in such a way that there are the same number of slot nuts to the right and

the left of the central leg.

> Insert the rear cross bar into the slot of the left leg in such a way that the upper edges of the rear cross

bar and the left-hand longitudinal bar are at the same height.

19

Page 22

Quilting frame assembly

> Insert the rear cross bar into the slot of the right leg in such a way that the upper edges of the rear cross

Attaching the rear cross bar to the right and left leg

Carry out the following tasks on both sides.

> Attach a slot nut (SN1) to the top edge of the cross bar. (see page12)

> Check to ensure that the cross bar and longitudinal bar are at the same height.

> If necessary, align the rear cross bar.

> Tighten the screw. (see page13)

bar and the right-hand longitudinal bar are at the same height.

20

> Attach a slot nut (SN1) to the bottom edge of the cross bar.

Page 23

Quilting frame assembly

Attaching the rear cross bar to the central leg

> Push the upper longitudinal bar on the central leg backward again so that it fits into the lower slot on the

internal surface of the cross bar.

> Attach one slot nut (SN1) each in the lower slot of the cross bar to the right and the left of the

longitudinal bar.

> Attach one slot nut (SN1) each in the slot on the lower edge of the cross bar to the right and the left of

the central leg.

Attaching the front bar

Required parts and tools:

• Cross bar, front

• 2× slot nuts (SN1)

• 4× head cap screws M6×50 (S11)

• 4× serrated washers M6 (W5)

• Allen key no.5 (T1)

Positioning the front cross bar

> Place the cross bar onto the central leg in such a way that the inserted slot nuts are located in the lower

slot and point inward. The "TOP" sticker faces upward.

21

Page 24

Quilting frame assembly

> Move the inserted slot nuts in such a way that there are the same number of slot nuts to the right and

Attaching the front cross bar to the right and left leg

Carry out the following tasks on both sides.

> Place one serrated washer (W5) onto each of two head cap screws (S11).

> On the upper longitudinal bar, push one head cap screw into the top front borehole from the outside.

> Guide the screw into the lateral edge of the cross bar and tighten it (see page13).

> Guide the second head cap screw through the lower borehole and secure it in the lateral edge of the

the left of the central leg.

cross bar.

22

Attaching the front cross bar to the central leg

> Attach one slot nut (SN1) each in the lower slot of the cross bar to the right and the left of the

longitudinal bar.

Page 25

Quilting frame assembly

2.6 Rail support assembly

Attaching rail supports

Required parts and tools:

• Rail support, left

• Rail support, right

• 8× head cap screws M8×40 (S1)

• 8× serrated washers M8 (W2)

• Allen key no.6 (T1)

Carry out the following tasks on both sides.

> Hold the rail support against the leg from the outside in such a way that the head cap screws(S1) can be

screwed into the pre-fitted slot nuts on the rail support.

> Place one serrated washer (W24) onto each of the four head cap screws (S1).

> Screw the head cap screws(S1) into the screw holes on the leg from the inside and only tighten them to

the point where the rail support can still be moved.

> Slide the rail support downward and forward until the two metal brackets (M10) rest on the longitudinal

bar of the leg.

23

Page 26

Quilting frame assembly

> Tighten the head cap screws(S1) (see page13).

Adapting the rail support for BERNINAQ20

Required parts and tools:

Carry out the following tasks on both sides.

> Undo the two screws on the top of the rail support.

• Allen key no.6 (T1)

24

> Push the front part of the movable bar toward the vertical profile as far as it will go.

> Tighten the two screws.

Page 27

Quilting frame assembly

2.7 Tabletop positioning

Attaching tabletop brackets

Attach a total of eight metal brackets as supports for the tabletops, comprising four in the rear cross bar and

four in the front cross bar.

Required parts and tools:

• 8× metal brackets (M10)

• 8× countersunk screws M8×14 (S8)

• Allen key no.5 (T1)

Carry out the following tasks for all metal brackets.

> Hold the metal bracket (M10) in front of a slot nut in the cross bar so that the screw hole is positioned

directly above the thread.

> Insert a countersunk screw(S8) into the screw hole and tighten it, but only to the point where the metal

bracket (M10) can still be moved.

Positioning tabletops

Required parts and tools:

• 14× felt strips (M11)

• 3× tabletops

• Allen key no.5 (T1)

> Attach felt strips(M11) to all metal brackets(M10), including the pre-assembled ones on the legs.

> Attach two felt strips to the upper longitudinal bar of the central leg.

25

Page 28

Quilting frame assembly

> Position the metal brackets(M10) so that two tabletops rest on each bracket. Tighten the screws (see

> Place the tabletops onto the metal brackets(M10) so that the tabletops are stable.

page13).

> If necessary, carefully undo the metal brackets(M10) and reposition them.

2.8 Quilting frame levelling

To allow the machine to move smoothly on the quilting frame, the quilting frame must be aligned perfectly

horizontally using the levelling feet after assembly.

Required parts and tools:

• Open-ended wrench no. 17 (T2)

• Spirit level (not included in the scope of delivery)

> Move the quilting frame into the final position for quilting.

> Screw in the levelling feet(M1) on the central leg until they no longer touch the floor.

> Use the spirit level to check the horizontal alignment of the quilting frame. If necessary, shorten the

lateral leg lengths by screwing in the levelling feet(M1) or extend them by unscrewing the feet.

> As soon as the quilting frame has been levelled, unscrew the levelling feet(M1) on the central leg so that

they touch the ground firmly and the quilting frame is well supported.

26

Page 29

> Tighten the counternuts on all six legs.

2.9 Track assembly

Attaching the rear track

Quilting frame assembly

Required parts and tools:

• 8x head cap screws M4×16 (S6)

• 1× track

• 2× black plastic inserts

• Allen key no.3 (T1)

> Pull the two black plastic inserts out of the tracks.

> Insert the head cap screws(S6) into the holes on the track one after the other.

27

Page 30

Quilting frame assembly

> Push the two black plastic inserts back into the track.

> Place the track onto the rear cross bar so that the screw holes(1) are precisely above the threads(2) of

the pre-fitted rail and the flat part of the track is pointing inward.

> Only tighten the inserted head cap screws(S6) to the point that the track can still be moved.

28

Page 31

Quilting frame assembly

> To ensure that the carriage later rests optimally on the tracks, pull the track outwards and then tighten all

head cap screws(S6).

Attaching the front track

Required parts and tools:

• 8× head cap screws M4×16 (S6)

• 2× button head self-tapping screws 6.3×22 (S12)

• 1× track

• 2× black plastic inserts

• Allen key no.3 (T1)

• Torx screwdriver no.T30 (included in the box with the machine)

> Pull the two black plastic inserts out of the tracks.

> Insert the head cap screws(S6) into the holes on the track one after the other.

29

Page 32

Quilting frame assembly

> Push the two black plastic inserts back into the track.

> Place the track onto the front cross bar so that the screw holes(1) are precisely above the threads(2) of

the pre-fitted rail and the flat part of the track is pointing inward.

> Only tighten the inserted head cap screws(S6) to the point that the track can still be moved.

30

Page 33

Quilting frame assembly

1

2

1

2

3

3

> To ensure that the carriage later rests optimally on the tracks, pull the track outwards and then tighten all

head cap screws(S6).

> Screw in one button head self-tapping screw (S12) on each of the two sides of the track.

2.10 Top and backing rail assembly

The top rail and backing rail are fitted to the rail supports at the front.

1 Support, top rail 2 Support, backing rail

3 Support, take-up rail

NOTICE!Leaders are already fitted in some of the following images. In these assembly instructions,

attaching the leaders is only described later. Always attach the rails without leaders.

31

Page 34

Quilting frame assembly

Assembling the top rail

Required parts and tools:

> Push the ratchet wheel(M7) over the right-hand end of the top rail so that the teeth are pointing

• Top rail

• Ratchet wheel (M7)

• 2× head cap screws M8×50 (S4)

• Allen key no.2 and no.6 (T1)

forward when viewed from the front of the quilting frame.

> Hold the top rail and inner bar with the pre-fitted plastic cap precisely in front of the screw hole on the

lower rail bracket of the right-hand rail support.

> Insert the head cap screw(S4) through the screw hole and tighten it.

32

> Repeat the last two steps on the left-hand side.

> Push the ratchet wheel(M7) under the pawl as close as possible to the rail support. However, the ratchet

wheel must not brush against the rail support.

Page 35

Quilting frame assembly

> Tighten the pre-fitted grub screws so that the rail and ratchet wheel are securely connected to one

another.

Assembling the backing rail

Required parts and tools:

• Backing rail

• 1× setting collar (M6)

• 1× ratchet wheel (M7)

• Allen key no.2 (T1)

> Push the setting collar (M6) over the left-hand end of the backing rail.

33

Page 36

Quilting frame assembly

> Push the ratchet wheel(M7) over the right-hand end of the backing rail so that the teeth are pointing

> Push both ends of the backing rail into the upper rail brackets of the rail supports.

> Align the backing rail centrally.

> Push the setting collar(M6) up close to the left-hand rail support. The setting collar must not, however,

> Tighten the pre-fitted grub screws so that the rail and setting collar are securely connected to one

backward when viewed from the front of the quilting frame.

brush against the rail support.

another.

> Push the ratchet wheel(M7) under the pawl as close as possible to the rail support. However, the ratchet

wheel must not brush against the rail support.

> Tighten the pre-fitted grub screws so that the rail and ratchet wheel are securely connected to one

another.

34

Page 37

Quilting frame assembly

2.11 Carriage and park position magnet alignment

Positioning the carriage

Required parts and tools:

• Carriage

> Position the carriage on the tracks so that the hole for the park position magnet(M8) is pointing to the

left when viewed from the front.

> Guide the carriage along the tracks, while checking the contact of the wheels to the tracks with your

fingers.

> If the carriage does not slide smoothly over the tracks, or if not all wheels are in contact with the tracks

at all times, the carriage needs to be realigned.

Aligning the carriage

Required parts and tools:

• Allen key no.4 (T1)

35

Page 38

Quilting frame assembly

> Undo the four screws to align the carriage.

> Align the carriage so that it slides smoothly over the tracks along the entire length of the quilting frame

> Tighten the screws.

Attaching the park position magnet

and all wheels are in contact with the tracks at all times.

Required parts and tools:

• Magnet, circular (M8)

• Rubber cap, black (M9)

• 1x head cap screw M8×40 (S1)

• Countersunk screw M4×45 (S5)

• Nut M4 (N1)

• Allen keys no.2.5 and no.6 (T1)

• Open-ended wrench no.7 (T2)

> Push the countersunk screw(S5) first through the magnet (M8) and then through the rear hole. Position

the nut(N1) from the other side and hold it in place with the open-ended wrench. Tighten the screw.

36

Page 39

Quilting frame assembly

> Press the black rubber cap (M9) over the magnet (M8).

> Screw the head cap screw(S1) into the pre-mounted slot nut in the rear vertical profile of the left-hand

rail support, but only tighten it slightly so that it can still be moved.

> Push the carriage into the park position. Check whether the park position magnet(M8) touches the head

cap screw(S1).

> If necessary, adjust the height of the head cap screw(S1) and then tighten it.

37

Page 40

Quilting frame assembly

2.12 Machine preparation

Overview

Required parts and tools:

• BERNINA Q Series machine

• 2× stand profiles

• Accessories for stand profiles

• 4× V-wheel units (P16) (carriage accessories, cardboard box 2)

• Allen key no.5 (T1)

• Torx screwdrivers (T20 and T25) (included in the box with the BERNINA Q Series machine)

• Slotted screwdriver, medium-sized (not included in the scope of delivery)

Figure NumberDesignation Code Tool Use

1 Stand profile, front P1 Attaching the front stand

profile

1 Stand profile, rear P2 Attaching the rear stand

profile

1 Damping mat P3 Attaching the front stand

profile

1 Aluminum plate P4 Attaching the rear stand

profile

1 Circular sleeve P5 Attaching the front stand

profile

1 Threaded bolt, short P6 Attaching the front stand

profile

1 Spring washer P7 Attaching the front stand

profile

38

1 Washer P8 Attaching the front stand

profile

1 Serrated lock washer P9 Attaching the rear stand

profile

Page 41

Quilting frame assembly

Figure NumberDesignation Code Tool Use

1 Head cap screw P10 Torx T25 screwdriver Attaching the rear stand

profile

1 Head cap screw P11 Allen key no.5 (T1) Attaching the front stand

profile

2 Head cap screw P12 Torx T20 screwdriver Attaching the rear stand

profile

1 Washer, thick, small P13 Attaching the front stand

1 O-ring P14 Attaching the front stand

1 Washer, thick, large P15 Attaching the front stand

4 V-wheel units P16 Allen key no.4 (T1) Attaching the V-wheel units

Tab.5: Overview of parts for machine assembly

profile

profile

profile

39

Page 42

Quilting frame assembly

P15

P13

P3

P6

P7

P1

P11 P8 P16P16 P10 P9

P2

P4

P12

P12

P16P16 P14P5

Overview of assembly

40

Important notes on the stand profiles

Both stand profiles have a round hole on one side and a slotted opening on the other side for attaching the

V-wheels. The slotted opening allows the V-wheels to be subsequently aligned, so that they rest perfectly on

the tracks of the carriage. Please therefore make sure that the slotted opening on both stand profiles is on

the same side of the machine after assembly.

The front stand profile differs from the rear stand profile due to a plastic stud on the underside, i.e. the stand

profile with the plastic stud must be fitted at the front of the machine.

Page 43

Sequence of assembly steps

1. Getting the machine ready (see page41)

2. Attaching the V-wheel units (see page41)

3. Attaching the front stand profile (see page42)

4. Attaching the rear stand profile (see page44)

5. Positioning the machine on the carriage (see page46)

6. Attaching safety brackets (see page47)

7. Fitting rail covers (see page49)

Getting the machine ready

Quilting frame assembly

CAUTION

The machine can easily tip over without stand profiles

Risk of injury and damage to the machine.

> Carefully put the machine in a position where it is stable.

> Lay the machine down on its side at the edge of a fixed base, such as a tabletop.

Attaching the V-wheel units

Attach the V-wheel units to both stand profiles.

Required parts and tools:

• 4x V-wheel units (P16)

• Stand profile, front (P1)

• Stand profile, rear (P2)

• Allen key no.4 (T1)

• Tape measure (not included in the scope of delivery)

Perform the following work for both stand profiles.

> Remove the screws and washers from the V-wheel units(P16).

41

Page 44

Quilting frame assembly

> Position the V-wheel unit under the outer round hole, insert the screw from above and then tighten it.

> On the other side of the profile, position the V-wheel unit(P16) below the slot so that the distance from

> Insert the screw and washer from above, but only tighten the screw slightly so that the V-wheel unit can

the left-hand screw head to the right-hand screw head is approximately28cm(11inches).

still be moved.

NOTICE

Attaching the front stand profile

Machine damage due to undoing screws on the underside of the machine

Parts of the machine can fall out.

> Do not undo any screws on the underside of the machine.

Assembling the front stand profile

Required parts and tools:

• Stand profile, front (P1)

• Damping mat (P3)

• Circular sleeve (P5)

• Threaded bolt (P6)

• Spring washer (P7)

• Washer (P8)

• Head cap screw (P11)

• Washer, thick, small (P13)

• O-ring (P14)

• Washer, thick, large (P15)

42

Page 45

Quilting frame assembly

• Slotted screwdriver, medium-sized (not included in the scope of delivery)

> Push the spring washer(P7) over the thread on the short threaded bolt(P6).

> Screw the threaded bolt into one of the two smaller holes in the center of the front stand profile and

tighten it using the slotted screwdriver.

> Hold the long screw (P11) by its head and then push the washer (P8), black O-ring (P14) and circular

sleeve(P5) onto the screw (P11) one by one in sequence. Position the circular sleeve(P5) so that the

chamfer points downward toward the head of the screw (P11).

> Guide the long screw into the large hole in the plastic stud on the stand profile from below.

> Place the blue damping mat(P3) onto the screw from above so that the lateral recess encircles the

threaded bolt.

> Push the large, thick washer(P15) and the small, thick washer(P13) onto the screw in sequence.

Attaching the front stand profile

Required parts and tools:

43

Page 46

Quilting frame assembly

Prerequisite:

• The machine is on its side (see page41).

> Screw the screw(P11) into the thread on the front slot nut, but only tighten it slightly so that the profile

> Move the stand profile so that the arrow tip printed on the machine profile touches the edge of the

> Tighten the screw(P11).

• Assembled stand profile

• Allen key no.5 (T1)

can still be moved.

damping mat(P3).

NOTICE

Attaching the rear stand profile

Machine damage due to undoing screws on the underside of the machine

Parts of the machine can fall out.

> Do not undo any screws on the underside of the machine.

Required parts and tools:

• Stand profile, rear (P2)

• Aluminum plate (P4)

• Washer (P9)

• Head cap screw (P10)

• 2x head cap screws (P12)

• Torx T20 and T25 screwdrivers

> Place the aluminum plate(P4) onto the center of the rear stand profile from above.

44

Page 47

Quilting frame assembly

> Insert the two screws(P12) on the right and the left and tighten them using the Torx T20 screwdriver.

> Push the screw(P10) with the washer (P9) through the central hole from below.

> Align the stand profile so that the V-wheel unit which is fitted in the slotted hole is on the same side as

with the front stand profile (top or bottom).

> Use the T25 Torx screwdriver to screw the screw into the thread on the rear slot nut, but only tighten it

slightly so that the profile can still be moved.

> Check to ensure that the two heads of the screws(P12) are sunk in the slot on the underside of the

machine.

– The stand profile can still be moved, but not rotated.

> Move the stand profile so that the arrow tip printed on the machine profile touches the edge of the

aluminum plate (P4).

> Tighten the screw(P10).

45

Page 48

Quilting frame assembly

Positioning the machine on the carriage

CAUTION

Risk of injury from improper transport

Risk of injury and damage to the machine.

> Position the machine on the carriage with the help of another person.

> Leave the machine in the park position until the dead bar and take-up rail have been fitted.

Required parts and tools:

• Machine with stand profiles fitted

• 4x lateral cover caps (M13)

• Allen key no.4 (T1)

> Position the machine on the carriage with the help of another person.

> Check to ensure that the machine can be moved freely along the entire length of the carriage and that

all wheels are in contact with the carriage at all times.

> If necessary, readjust the position of the V-wheel units(P16) and then tighten the screws.

> Attach the lateral cover caps(M13) to the ends of the stand profiles.

46

Page 49

Quilting frame assembly

> Carefully push the machine up to the left-hand rail support and into the park position.

Attaching safety brackets

The machine is secured from tipping over with two types of safety brackets:

• Y safety brackets secure the machine on the carriage and are fitted to the machine's stand profiles.

• X safety brackets secure the carriage on the quilting frame and are fitted to the carriage.

Attaching Y safety brackets

Attach the four Y safety brackets to the two stand profiles of the machine on both sides.

Required parts and tools:

• 4× Y safety brackets (M14)

• 4× washers 5.3/10×1 (W6)

• 4× head cap screws Torx M5×16 (S10)

• 4× hex nuts M5 (N2)

• Torx screwdriver (T25)

• Open-ended wrench no.8 (T2)

> Guide one head cap screw (S10) with washer attached (W6) through the borehole behind the rail in the

stand profile from above.

> Push one Y safety bracket (M14), with the slot facing upward, over the screw from below.

47

Page 50

Quilting frame assembly

1mm

> Loosely tighten the hex nut (N2) from below, with the ribbed surface facing upward.

> Push the Y safety bracket (M14) all the way up to the rail and then pull it approximately 1 mm back.

– The Y safety bracket does not touch the rail.

48

> Hold the threaded nut securely with the open-ended wrench and then tighten the head cap screw (S10).

> Attach the other three Y safety brackets (M14) the same way.

Page 51

Quilting frame assembly

Checking the position of the Y safety brackets

> Move the machine forward and backward.

> Check whether the Y safety brackets (M14) brush against the wheels.

> If they do, pull the Y safety brackets approximately 1 mm away from the wheels.

> Check whether the wheels become jammed.

> If they do, undo the head cap screw (S10) slightly.

> Check whether the machine can be lifted off the carriage.

> If it can, move the Y safety brackets closer to the wheels.

Attaching X safety brackets

Required parts and tools:

• 2× X safety brackets (M15)

• 2× serrated lock washers M6 (W7)

• 2× button head screws Torx M6×12 (S9)

• Torx screwdriver (T30)

> Push the serrated lock washer (W7) over the button head screw (S9). Screw down one X safety bracket

(M15) vertically to the carriage in the center at the back.

> Push the serrated lock washer (W7) over the button head screw (S9). Screw down the second X safety

bracket (M15) vertically to the carriage in the center at the front.

Checking the position of the X safety brackets

> Push the machine along the entire length of the quilting frame.

> Check whether the X safety brackets (M15) brush against anything.

> If they do, undo the button head screw (S9) slightly.

> Check whether the machine can be lifted off the quilting frame with the carriage.

> If it can, tighten the button head screw (S9) further.

Fitting rail covers

The rail covers are used to prevent your fingers getting caught or trapped.

Required parts and tools:

• 4x rail covers (M12)

49

Page 52

Quilting frame assembly

> Attach the rail covers to the ends of the rail pair brackets on the carriage, pressing them as far as they

2.13 Take-up rail and dead bar attachment

Attaching the Take-up rail

will go.

CAUTION

Risk of injury from falling machine

Risk of injury and damage to the machine.

> Leave the machine in the park position until the dead bar and the take-up rail have been fitted.

> Always take care when moving the machine or carriage.

Required parts and tools:

• Take-up rail

• 1x setting collar (M6)

• 1× ratchet wheel (M7)

• Allen key no.2 (T1)

> Push the setting collar (M6) over the left-hand end of the take-up rail.

50

Page 53

Quilting frame assembly

> Push the ratchet wheel(M7) over the right-hand end of the take-up rail so that the teeth of the ratchet

wheel are pointing backward when viewed from the front of the quilting frame.

> Guide the take-up rail through the neck of the machine.

> Guide the two ends of the take-up rail through the rear rail brackets of the rail supports.

> Align the take-up rail centrally.

> Push the setting collar(M6) up close to the left-hand rail support. The setting collar must not, however,

brush against the rail support.

> Tighten the pre-fitted grub screws so that the rail and setting collar are securely connected to one

another.

> Slide the ratchet wheel(M7) under the pawl as close as possible to the rail support.

51

Page 54

Quilting frame assembly

> Tighten the pre-fitted grub screws so that the rail and ratchet wheel are securely connected to one

Attaching the handwheel to the take-up rail

Required parts and tools:

another.

• Handwheel (M3)

• Locking piece (M4)

• Winder bolt (M5)

• Countersunk screw M5x10 (S3)

• Countersunk washer D25 (W4)

• Sticker, round (included with the M3 handwheel)

• Allen keys no.3 and no.4 (T1)

> Remove and dispose of the yellow plastic cap from the right-hand end of the take-up rail.

> Insert the locking piece(M4) into the recess on the end of the take-up rail.

> Attach the handwheel(M3) precisely to the protruding end.

52

Page 55

Quilting frame assembly

> Push the countersunk screw washer(W4) onto the countersunk screw(S3).

> Insert the screw into the screw hole and tighten it carefully.

> Cover the countersunk screw(S3) with a sticker.

CAUTION

> Screw the winder bolt (M5) to the handwheel (M3).

Attaching the dead bar

Risk of injury from falling machine

Risk of injury and damage to the machine.

> Leave the machine in the park position until the dead bar and the take-up rail have been fitted.

> Always take care when moving the machine or carriage.

Required parts and tools:

• Dead bar

53

Page 56

Quilting frame assembly

> Guide the dead bar through the neck of the machine with the rounded off side facing backward.

> Carry out the following tasks on both sides.

> Position the dead bar behind the pre-fitted rail support bracket so that the slot nut in the dead bar sits

• 2x countersunk screws M8x14 (S8)

• Allen key no.5 (T1)

precisely behind the screw hole in the bracket.

> Insert the countersunk screw(S8) into the screw hole and tighten it.

Checking/adjusting the height of the dead bar

The dead bar must be attached at the correct height relative to the machine.

If the dead bar is attached too low, the machine will brush when moving. If it is attached too high, the

distance between the material and the BSR sensors is too great. The sensors cannot measure the movement

of the machine correctly and the stitch length is not adjusted correctly.

The dead bar is attached at the optimal height when a no. 6 (T1) Allen key just fits between the dead bar

and the machine.

54

Required parts and tools:

• Allen key no.5 (T1)

• Allen key no.6 (T1)

> To check the height of the dead bar, first move the machine to the left-hand edge of the quilting frame.

> Place Allen key no. 6 (T1) between the machine and the dead bar.

> If the distance between the dead bar and the Allen key is too great or too small, adjust the height of the

dead bar.

> To adjust the height of the dead bar, undo the countersunk screw on the pre-fitted bracket in the rail

support until the bracket can be moved.

> Move the bracket so that the dead bar just touches the no. 6 Allen key (T1) on the machine.

Page 57

Quilting frame assembly

TOP

BACK

TAKE-UP

1

2

3

4

> Tighten the countersunk screw.

> Remove Allen key no.6 (T1).

> Move the machine to the right-hand edge of the quilting frame.

> Repeat the test and height adjustment process.

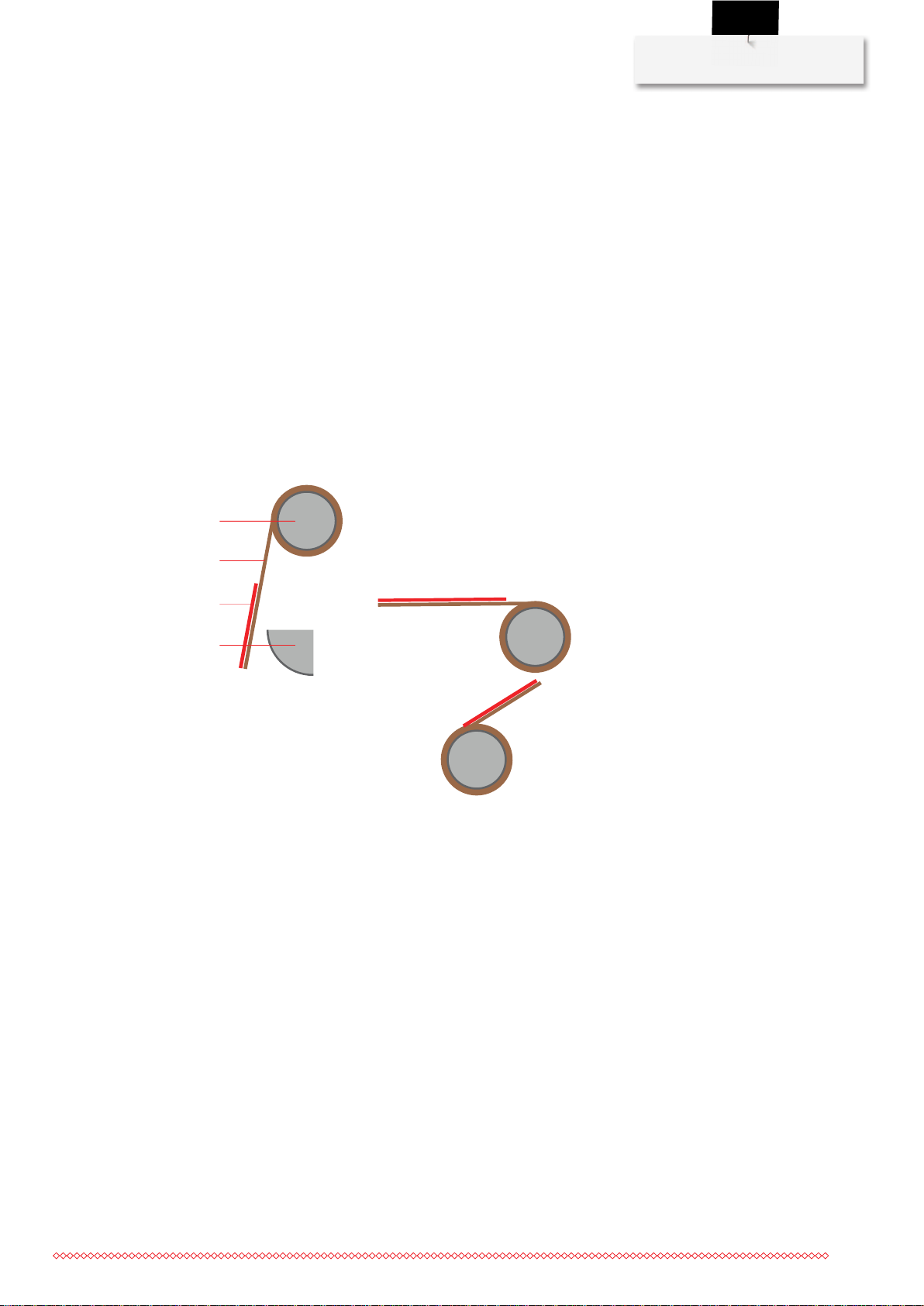

2.14 Leader, side clamp, and storage tray attachment

General notes on attaching the leaders

• Each leader has one printed and one unprinted side.

• Each leader must be attached securely to the center of the respective rail.

• All leaders are attached using double-sided adhesive tape.

• The leaders are wound onto the rails in different directions.

Check the following figure to see how the various leaders need to be attached to their respective rails.

Printed side facing up or down, clockwise or anticlockwise winding direction.

Fig.1: Rails, viewed from the left-hand side of the quilting frame

1 Rail 3 Printed side (red)

2 Leader 4 Dead bar

Sequence of assembly steps

Attach the leaders in the following sequence:

1. Attaching the back leader

2. Attaching the take-up leader

3. Attaching the top leader

Attaching the Back leader

Required parts and tools:

• Back leader

• Double-sided adhesive tape (M18)

• Pencil (not included in the scope of delivery)

• Tape measure (not included in the scope of delivery)

55

Page 58

Quilting frame assembly

> Determine the center of the backing rail using the tape measure and mark this position with a pencil.

> Measure and then use a pencil to mark out a point 155 cm(61inches) to the left and the right of the

> Attach double-sided adhesive tape (M18) from the left-hand marking all the way to the right-hand

marked center.

marking. Be sure to attach the tape straight without any kinks.

> Remove the protective film on the top of the adhesive tape.

> Unfold the back leader so that the material is suspended between the rail and the quilting frame and the

printed side is pointing backward toward the quilting frame.

> Position the center line of the back leader (dark broken line) on the marked center of the backing rail.

> Attach the leader to the adhesive tape, working from the center outward to the left and right. Make sure

you guide the edge of the material precisely along the edge of the adhesive tape.

> Press the leader firmly onto the adhesive tape and roll it up.

> Trim any excess adhesive tape.

56

Attaching the Take-up leader

Required parts and tools:

• Take-up leader

• Double-sided adhesive tape (M18)

• Pencil (not included in the scope of delivery)

• Tape measure, quilting guide or ruler (not included in the scope of delivery)

Page 59

Quilting frame assembly

> To mark the center of the take-up rail, unroll the back leader. Using a quilting guide, first transfer the

center of the back leader onto the dead bar and from there onto the take-up rail. Make sure that

everything is aligned correctly at right angles.

> Fit the take-up leader from the back of the quilting frame.

> Measure and then use a pencil to mark out a point 155 cm(61inches) to the left and the right of the

marked center.

> Attach double-sided adhesive tape (M18) from the left-hand marking all the way to the right-hand

marking. Be sure to attach the tape straight without any kinks.

> Remove the protective film on the top of the adhesive tape.

> Unfold the take-up leader so that the material is suspended between you and the rail and the printed

side is pointing toward you.

> Position the center line of the take-up leader (dark broken line) on the marked center of the take-up rail.

> Attach the leader to the adhesive tape, working from the center outward to the left and right. Make sure

you guide the edge of the material precisely along the edge of the adhesive tape.

> Press the leader firmly onto the adhesive tape and roll it up.

> Check to ensure that the center of the take-up leader and the back leader line up precisely. If necessary,

reposition the take-up leader.

> Trim any excess adhesive tape.

Attaching the Top leader

Required parts and tools:

• Top leader

• Double-sided adhesive tape (M18)

• Pencil (not included in the scope of delivery)

• Tape measure (not included in the scope of delivery)

> Fit the top leader from the front of the quilting frame.

> To mark the center of the top rail, unroll the back leader and pull it straight to the top rail.

57

Page 60

Quilting frame assembly

> Transfer the center position of the unrolled back leader onto the top rail.

> To make it easier to fit the top leader, swing the top rail upward.

> Measure and then use a pencil to mark out a point 155 cm(61inches) to the left and the right of the

> Attach double-sided adhesive tape (M18) from the left-hand marking all the way to the right-hand

> Unfold the top leader so that the material is suspended between you and the rail and the printed side is

> Position the center line of the top leader (dark broken line) on the marked center of the top rail.

> Attach the leader to the adhesive tape, working from the center outward to the left and right. Make sure

> Press the leader firmly onto the adhesive tape and roll it up.

> Check to ensure that the center of the top leader and the back leader line up precisely. If necessary,

> Trim any excess adhesive tape.

> Swing the top rail back down again.

marked center.

marking. Be sure to attach the tape straight without any kinks.

pointing toward you.

you guide the edge of the material precisely along the edge of the adhesive tape.

reposition the top leader.

Attaching the side clamps

Required parts and tools:

• 4x bungee cords (M16)

• 4x safety clips (M17)

> Guide the bungee cord(M16) through the bracket on the left-hand rail support from inside to outside.

> Attach the safety clip (M17) to the end of the bungee cord (M16).

58

Page 61

> Fix the bungee cord (M16) in the bracket.

> Fit the remaining side clamps in the same way.

Attaching the storage trays

Required parts and tools:

• 2× storage trays (M2)

• 4× button head screws M5x12 (S7)

• Allen key no.3 (T1)

Quilting frame assembly

Two slot nuts are pre-fitted in the slot below the brackets of the side clamps.

Carry out the following tasks on both sides.

> Hold the storage tray (M2) in front of the slot.

> Slide the two pre-fitted slot nuts so that they are behind the holes on the storage tray.

> Insert two button head screws (S7) into the holes on the storage tray and tighten them.

59

Page 62

Quilting frame assembly

1

2.15 Front handle attachment

Attaching the front handle unit

> Screw the handle unit behind the head of the machine with the two screws from below so that the

locking levers point backward.

> Insert the cable of the handle unit into the connection at the back on the head of the machine.

Adjusting the width of the handles

NOTICE!To ensure that the thread does not get caught up on the locking lever when winding,

always adjust the locking levers so that they point vertically downward when clamped.

Carry out the following tasks on both sides.

> Swing up the locking lever on the bracket of the handle.

> Move the handle to the side until the required handle width has been reached.

> Adjust the inclination of the handle so that the handle is at a suitable height.

> Only tighten the locking ring (1) to a point where the locking lever can still be swung down with force.

60

Page 63

> Swing the locking lever down.

– The handle is now fixed and the locking lever is pointing downward.

Adjusting the handles

> To adjust the handles, swing up the locking lever on both sides.

Quilting frame assembly

> To adjust the length of the handle, pull the handle out of the bracket or push it into the bracket.

> To adjust the angle of the handle, rotate the handle until a comfortable angle has been reached.

> Close the locking lever.

61

Page 64

Disposal

3 Disposal

3.1 Quilting frame disposal

BERNINA International AG is committed to environmental protection. We make every effort to increase the

environmental friendliness of our products by continually improving their design and production technology.

If you no longer require your quilting frame, please clean it, sort the components according to material and

then dispose of these in line with local regulations and legislation.

Do not dispose of the quilting frame in household waste. If you are in any doubt, first dismantle the quilting

frame and then take it to your nearest BERNINA specialist.

62

Page 65

4 Specifications

B

C

Dimensions of the quilting frame

Specifications

"Classic" quilting frame "Large" quilting frame "Small" quilting frame

Length (A) 12' (3.60 m) 13' (4 m) 9' (2.75 m)

Width (B) 3.9' (1.20 m) 3.9' (1.20 m) 3.9' (1.20 m)

Height (C) 5.6' (1.70 m) 5.6' (1.70 m) 5.6' (1.70 m)

63

Page 66

Appendix

5 Appendix

5.1 Differing information for the "Large" quilting frame

Overview of large parts (see page7)

5x tabletops: 3× large, 2× small

Overview of small parts (see page8)

• 12x metal brackets (M10)

• 16x felt strips (M11)

• 12x countersunk screws M8x14 (S8)

Attaching tabletop brackets (see page25)

> Fit the 12 metal brackets (M10) with 12 countersunk screws M8x14 (S8).

Positioning tabletops (see page25)

> Attach the 16 felt strips (M11).

> Position three large tabletops in the center, with one small tabletop each on the right and the left.

Attaching the leaders (see page55), (see page56), (see page57)

In the step entitled «Measure and then use a pencil to mark out a point 155 cm/61inches to the left and the

right of the marked center.»

, use the following values: 170cm/67inches

5.2 Differing information for the "Small" quilting frame

General overview (see page6)

Point 16 «Legs, center» is no longer applicable.

Overview of large parts (see page7)

Just two legs, on the right and the left

Overview of small parts (see page8)

• 12× head cap screws M4×16 (S6)

• 2× head cap screws M8 × 50 (S2)

• 4× slot nuts (SN1)

• 4× washers (M10)

• 2× washers M8 (W3)

• 4× leveling feet

Attaching adjustable leveling feet (see page16)

64

No legs, center, only four leveling feet (M1) and washers (W1)

Overview of assemblies (see page15)

Point 3 «Legs, center» is no longer applicable

Attaching the lower cross bar (see page16)

Just two legs, on the right and the left

Page 67

Appendix

Just two head cap screws M8 × 50 (S2)

Just two washers M8 (W3)

Do not perform any steps in the instructions that affect the central leg.

Attaching the rear cross bar (see page18)

• Just four 4× slot nuts (SN1) are required

• Do not carry out the tasks described in the instructions entitled «Moving the upper longitudinal bar on

the central leg»

• Work described in the instructions entitled «Positioning the rear cross bar»: Do not perform steps 1 and

2.

Step 4 new: «

are located in the lower slot and point inward, and the "TOP" sticker faces upward. ....»

• Do not perform the work described in the instructions entitled «Fitting the rear cross bar on the central

leg»

.

.

Insert the rear cross bar into the slot on the left leg in such a way that the inserted slot nuts

Attaching the front cross bar (see page21)

• No slot nuts required.

• Do not carry out the tasks described in the instructions entitled «Fitting the front cross bar on the central

leg»

.

Quilting frame levelling (see page26)

Do not carry out the tasks described in step 2 or step 4 of the instructions.

Attaching the rear track (see page27) | Attaching the front track (see page29)

12× head cap screws M4×16 (S6) required.

Attaching the leaders (see page55), (see page56), (see page57)

In the step entitled «Measure and then use a pencil to mark out a point 155 cm/61inches to the left and the

right of the marked center»

, use the following values: 108cm/43inches.

65

Page 68

Index

Index

A

Adjusting the handles 61

Adjusting the working height 13

Assembling the base frame 15

Assembling the machine 38

Attaching side clamps 58

B

Backing rail

Attaching the leaders 55

Fitting 33

C

Carriage

Alignment 35

Positioning 35

Checking the scope of delivery 12

Cross bar

Front, attaching 21

Lower, attaching 16

Rear, attaching 18

D

Dead bar

Attaching 53

Checking/adjusting the height 54

L

Levelling feet attachment 16

Levelling the quilting frame 26

M

Machine

Attaching V-wheel units 41

Positioning on the carriage 46

Safety brackets 47

Stand profile, attaching at the front 42

Stand profile, rear attaching 44

O

Overview of the quilting frame 6

P

Park position magnet 36

Preparing the machine

For assembly 41

Q

Quilting frame

Dimensions 63

Disposal 62

Overview 6

R

E

Explanation of symbols 5

F

Fitting rail covers 49

Front track

attaching 29

H

Handles

Adjusting 60

Attaching 60

Height adjustment 13

66

Rail supports

Adapting for Q 20 24

Attachment 23

Rear track

attaching 27

S

Safety brackets 47

Specifications 63

Stand profile

Front, attaching 42

Rear, attaching 44

Storage tray 59

Page 69

T

Tabletops

Attaching brackets 25

Positioning 25

Take-up rail

Attaching 50

Attaching handwheel 52

Attaching the leaders 56

Top rail

Attaching 32

Attaching the leaders 57

U

Unpacking the delivery 12

Index

67

Page 70

Page 71

Page 72

Loading...

Loading...