Page 1

Page 2

Page 3

Table of Contents

Table of Contents

Tabl e of Cont ents

Introduction .............................................................................. 4

Machine Parts ....................................................................................................5

Display and Selection keys............................................................................6

Select Mode Arrows ....................................................................................7

Align Mode Arrows .....................................................................................7

Sewing Mode Arrows .................................................................................7

Accessories .........................................................................................................9

Optional Tools ................................................................................................. 10

Operation ..................................................................................11

Preparing to Embroider .............................................................................. 11

Bobbin Winding ........................................................................................ 11

Installing the Bobbin ............................................................................... 14

Threading the Machine .......................................................................... 15

Thread the Needle Using the Needle Threader ............................. 16

Hooping ....................................................................................................... 18

Using the Template .................................................................................. 19

Attaching the Hoop to the Machine .................................................. 23

Selecting a Design ........................................................................................ 24

Selecting a Design from Internal Memory ...................................... 24

Selecting a Design from a Memory Card ......................................... 25

Align Design .................................................................................................... 26

Sewing the Design ........................................................................................ 27

Trace the Design ....................................................................................... 27

Sew the Design .......................................................................................... 28

Thread Tension adjustment ....................................................................... 30

Adjust Upper Thread Tension ............................................................... 30

Bobbin Tension Adjustment ................................................................. 31

Changing a Needle ....................................................................................... 33

Thread Breaks ................................................................................................. 35

Bobbin Thread Breaks .................................................................................. 36

Removing Hoop from Machine ................................................................ 37

Table of Contents

Machine Cleaning and Oiling ..........................................37

Error Codes and Troubleshooting ................................. 39

Error Codes ...................................................................................................... 39

Troubleshooting ............................................................................................ 41

H79_Manual.indd 3H79_Manual.indd 3 10/6/2008 4:28:53 PM10/6/2008 4:28:53 PM

Model H79

3

Page 4

Introduction

Introduc t ion

Introduction

®

bernette

for

Introduction

Welcome to the exciting and fun world of machine embroidery.

Your Model H79 Embroidery Machine should give you many,

many hours of fun and creativity. To familiarize yourself with

the machine and how it works, it is recommended that you read

through this manual. Your experience will be much more fun if

you are familiar with the parts of the machine, what each one does

and where to reference it again when you need more information.

Use supplies recommended for use with embroidery. Many

products look the same but are not made especially for machine

embroidery. Needles, threads and stabilizers are the main

products you will want to keep on hand to make your embroidery

experience easier. When you have the products handy and ready

to use, you’ll be more apt to use your machine more often. It will

be great for gifts for family and friends. They’ll be so impressed

with your new talent when you make special gifts for them.

Enhance your home décor with pillows, towels, even wall hangings

and quilts. Use your machine for scrap-booking or card making.

Your cards will be extra special! There is no limit to your creativity!

Best of all, you’ll have many hours of relaxation and fun!

Every e ort has been made to make your Model H79 User’s Guide accurate and as easy to understand as possible. Bernina, Inc. is not

responsible for any errors or ommissions.

4

H79_Manual.indd 4H79_Manual.indd 4 10/6/2008 4:29:01 PM10/6/2008 4:29:01 PM

Model H79

Page 5

Know your machine

Intr o duct i on

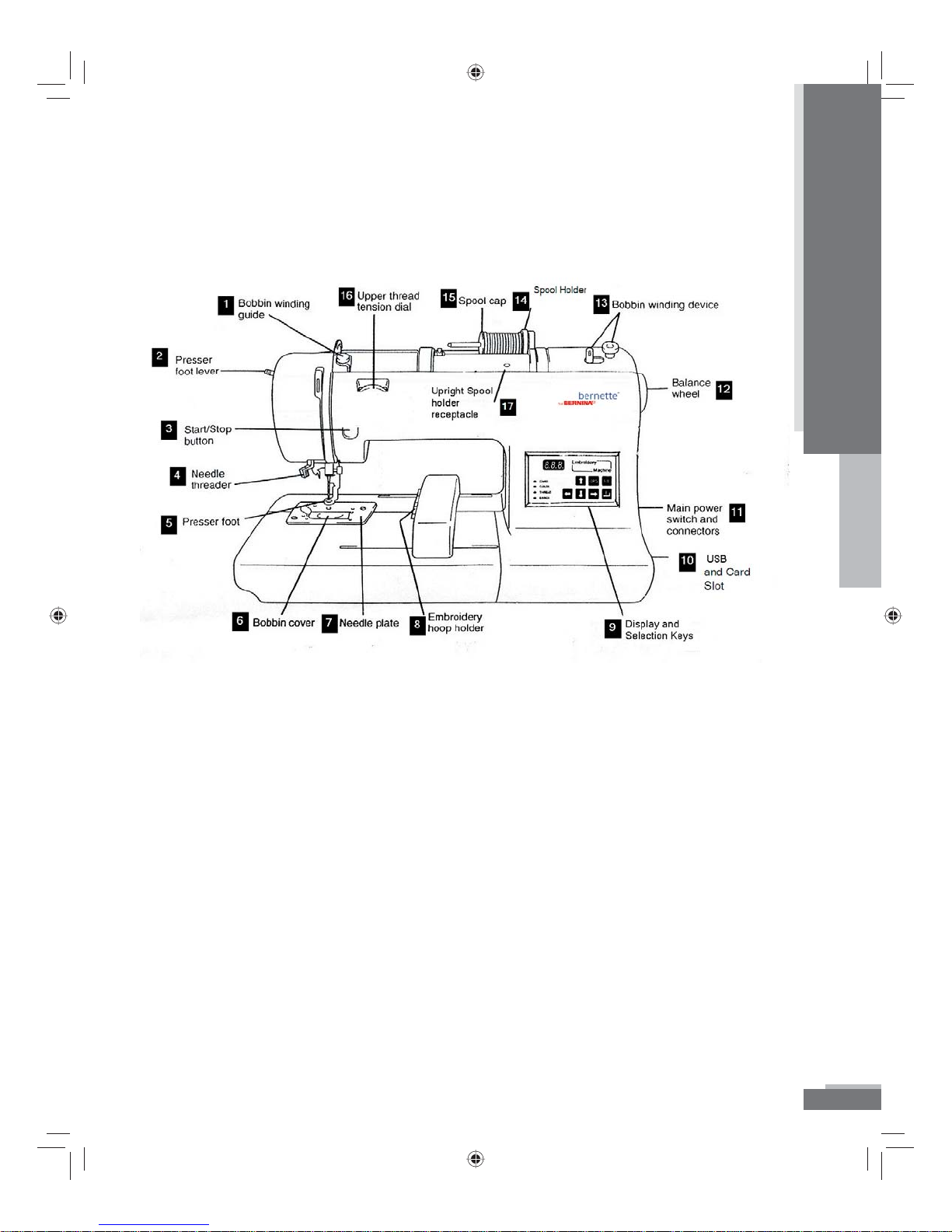

Machine Parts

Introduction

1. Bobbin Winding Guide 10. USB Outlet and Card Slot

2. Presser Foot Lever 11. Main Power Switch and Connectors

3. Start/Stop Button 12. Balance Wheel

4. Needle Threader 13. Bobbin Winding Device

5. Presser Foot 14. Spool Holder

6. Bobbin Cover 15. Spool Cap

7. Needle Plate 16. Upper Thread Tension Dial

8. Embroidery Hoop Holder 17. Upright Spool Holder Receptacle

9. Display and Selection Keys

Model H79

5

H79_Manual.indd 5H79_Manual.indd 5 10/6/2008 4:29:02 PM10/6/2008 4:29:02 PM

Page 6

Intr o duct i on

Introduction

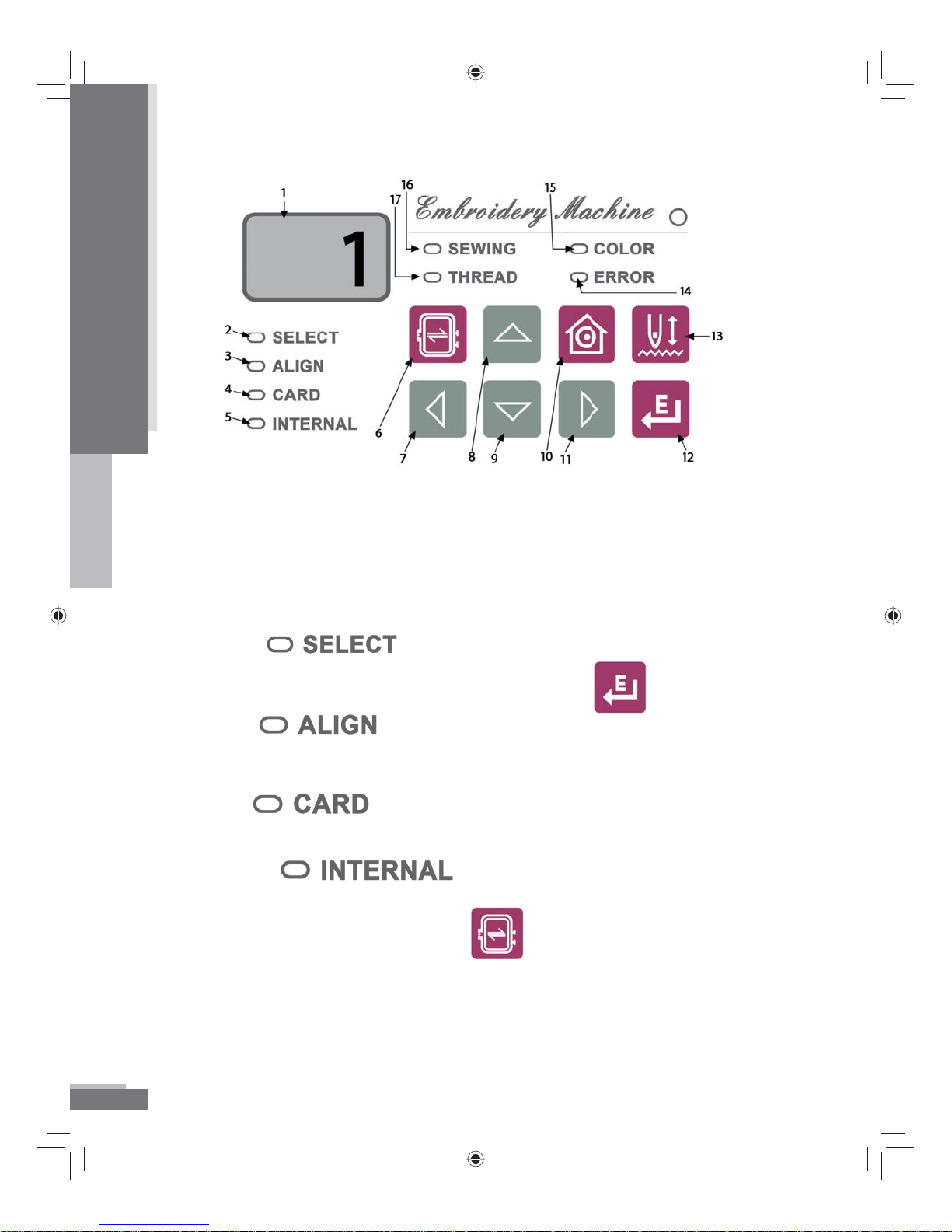

Display and Selection Keys

1. LED Screen – Displays functions

a. Design Number (## for design from Internal Memory or C##

for design on Memory Card)

b. Color Number (i.e. c01, c02)

c. Error message codes—see Error codes, p. 39 - 40.

2. Select is lit when you are in the process of selecting

a design. To make your selection press the

button.

3. Align lights after you have selected a design.

Design can now be embroidered or needle position moved in the

hoop.

4. Card lights to indicate you are accessing designs

from a Memory Card.

5. Internal lights to indicate you are accessing

designs from the Internal Memory of the machine.

6. Only available in align mode, traces the four corners of the

perimeter of the design in the hoop.

7. The arrow keys perform di erent functions depending on which

mode has been accessed.

6

Model H79

H79_Manual.indd 6H79_Manual.indd 6 10/6/2008 4:29:02 PM10/6/2008 4:29:02 PM

Page 7

Select Mode Arrows

Intr o duct i on

Goes backward through the list of designs one design at a time.

Introduction

Card Memory.

or Card Memory.

Advances 10 designs at a time in the Internal Memory or

Goes backward 10 designs at a time in the Internal Memory

Goes forward through the list one design at a time.

Align Mode Arrows

Moves needle position closer to the left of the hoop.

Moves needle position closer to the top of the hoop (toward

the back of the machine).

Moves needle position closer to the bottom of the hoop

(toward the front of the machine).

Moves needle position closer to the right of the hoop.

Sewing Mode Arrows

Moves backward through the design one stitch at a time.

NOTE: The Up and Down arrows are not functional in Sewing Mode.

H79_Manual.indd 7H79_Manual.indd 7 10/6/2008 4:29:03 PM10/6/2008 4:29:03 PM

Moves forward through the design one stitch at a time.

Model H79

7

Page 8

Intr o duct i on

Introduction

8. To center a selected design in the hoop press .

9. To enter or accept a design number shown in the LED window

press

.

10. Toggles between Internal memory and a Memory Card.

## will be displayed on the LED when the Internal memory of

the machine is accessed. C## signi es Card Memory has been

accessed.

11. When lit, indicates an error—see LED for error

number. In some cases you may have to press the START/STOP

button to see which error has occurred.

12. When lit, indicates machine power is on.

13. When lit, indicates a color change—see LED

for color change number. This will be displayed as a lower case “c”

followed by the number of the sequence of the color.

14. When lit, indicates thread break.

15. When lit, indicates machine is in sewing mode.

8

H79_Manual.indd 8H79_Manual.indd 8 10/6/2008 4:29:04 PM10/6/2008 4:29:04 PM

Model H79

Page 9

Accessories

Intr o duct i on

Introduction

1. Cleaning Brush 8. Large Spool Cap

2. Needle Pack 9. Small Spool Cap

3. Hoop 10. Oiler

4. Seam Ripper 11. Bobbins (4)

5. Thread Nippers 12. Power Cord

6. 3-Way Screwdriver Tool 13. USB - AB Cable

7. Upright Spool Holder 14. Thread Hook

H79_Manual.indd 9H79_Manual.indd 9 10/6/2008 4:29:04 PM10/6/2008 4:29:04 PM

Model H79

9

Page 10

Intr o duct i on

Introduction

Optional Tools

To get the most from your Model H79 Embroidery Machine you

will want to connect it to a Personal Computer. By using the

eXplorations Lite software, you can add more designs to your

collection as well as many other great features. The software gives

you the ability to connect to the Internet and get more designs,

ideas for projects, and new information about your machine.

You do not need to be connected to the internet to use the software.

With the eXplorations Lite software you can see your design before you

sew it. You can size, rotate and mirror image the design as well

as add lettering to personalize your projects. Changing colors of

the design is simple. Using the eXplorations Lite software simply

changes the color of the design on the screen and sees what the

design will look like with the new colors, without having to sew out

the design.

Note:

With the included Navigator, you can see the design sew on the

computer screen as it is sewing on the machine. This is really

helpful if you happen to want to skip part of the design. Simply

stop the machine from the Navigator software, go forward through

the design and then tell the machine to move to that point. If your

machine has a problem you can also back up through the design

using the Navigator. This can be a real time saver as well as being

much easier than backing up with the arrow keys on the machine.

(See Quick Start Guide for more information).

The eXplorations Lite software is very powerful, fun and easy to

use. You can even get more from your machine by upgrading

your eXplorations Lite software to eXplorations Basic software

or eXplorations Galaxy. You can create new designs as well as

edit pre-digitized designs plus have many more features at your

ngertips.

10

H79_Manual.indd 10H79_Manual.indd 10 10/6/2008 4:29:05 PM10/6/2008 4:29:05 PM

Model H79

Page 11

Operation

Operat i on

Operation

Operation

The operation of the Model H79 Embroidery Machine is simple.

However, there are some guidelines to follow to make your

embroidery experience a good one. To prepare to sew your rst

design, there are a few steps you’ll need to take.

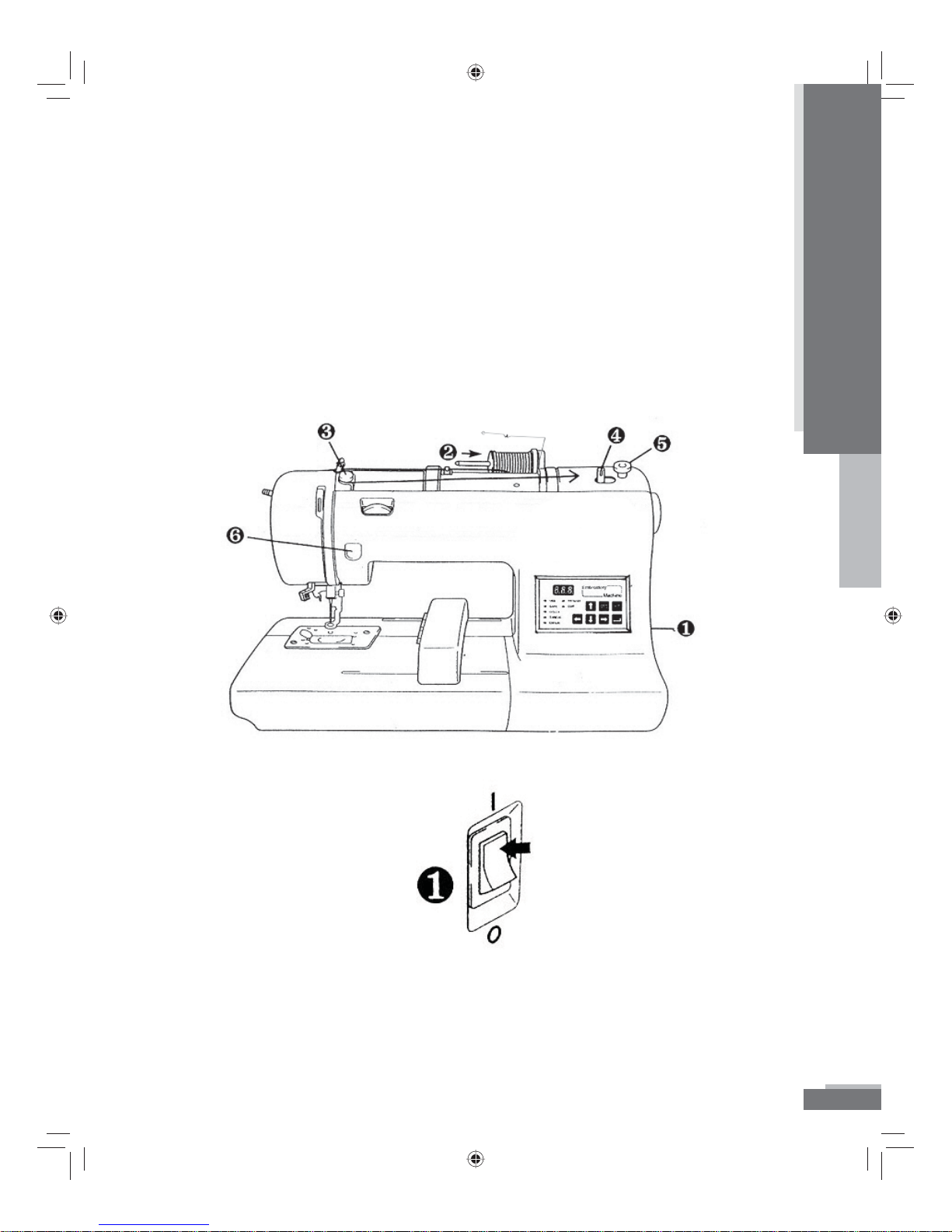

Preparing to Embroider

Bobbin Winding

1. Connect the machine to the power supply and turn on the main

power.

H79_Manual.indd 11H79_Manual.indd 11 10/6/2008 4:29:05 PM10/6/2008 4:29:05 PM

Model H79

11

Page 12

Operat i on

Operation

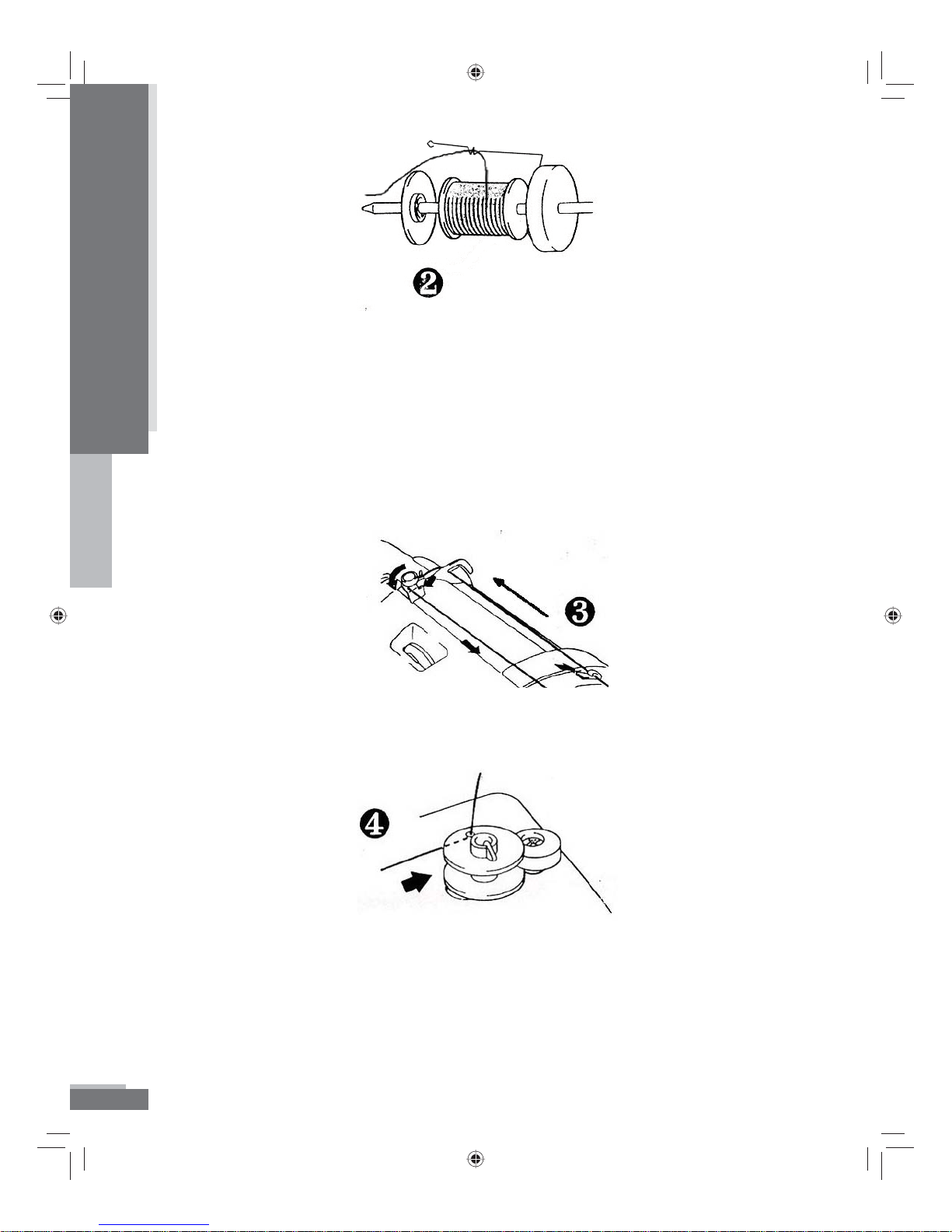

2. Place the spool of thread, the suitable spool cap and the wire

thread guide on spool pin. To attach the thread guide, clamp it

onto the spool pin prior to sliding on the spool of thread. NOTE:

Bobbin thread should always be used for normal embroidery.

Bobbin thread is thread speci cally made for embroidery and

usually comes in white or black. An exception is when stand alone

lace is embroidered. Use the same thread in the bobbin as is

threaded on top when embroidering stand alone lace.

3. Bring the thread through the guides and around the bobbin

winder guide. (Follow thread path illustration on top of machine).

4. Place an empty bobbin on the bobbin spindle. Put the thread

through the small hole in the side of the bobbin from the inside.

Match the groove of the bobbin with the spring on the shaft and

press the bobbin onto the shaft. Push the bobbin winder shaft to

the right. The word “bob” will be displayed in the LED screen. This

tells you when the bobbin winder is engaged.

12

H79_Manual.indd 12H79_Manual.indd 12 10/6/2008 4:29:05 PM10/6/2008 4:29:05 PM

Model H79

Page 13

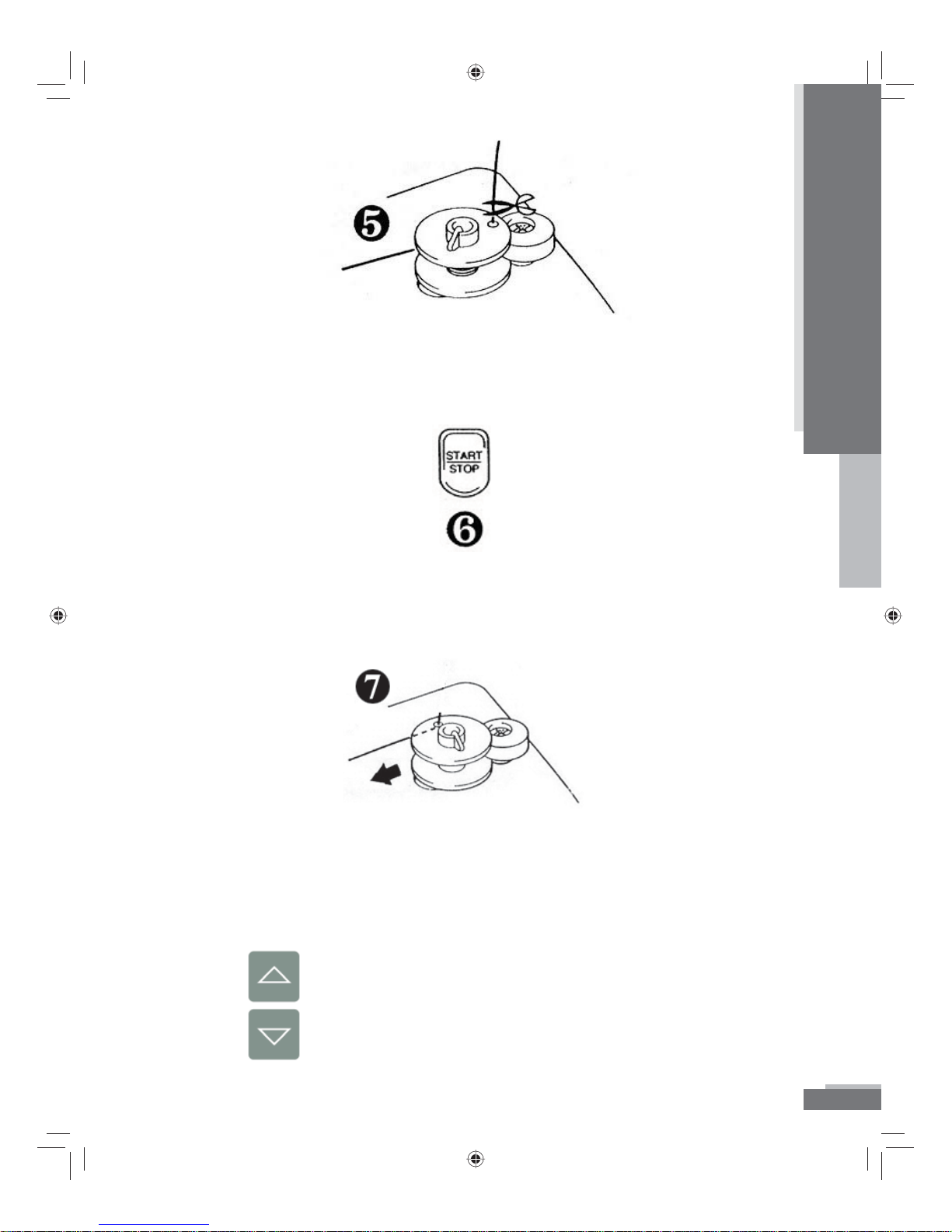

5. Holding the thread end, press the START/STOP button. After the

Operat i on

thread has wound a few times, press the START/STOP button to

stop the machine. Trim thread from top of bobbin.

Operation

6. Press START/STOP button to nish winding bobbin. Winding will

stop automatically when the bobbin is full. Press the START/STOP

button to stop the machine.

7. Push the bobbin shaft to the left and remove the bobbin by lifting

it up from the spindle. Clip the thread. NOTE: The machine will not

embroider until the shaft is returned to the left.

8. The winder speed can be increased and decreased by pushing

either buttons.

H79_Manual.indd 13H79_Manual.indd 13 10/6/2008 4:29:05 PM10/6/2008 4:29:05 PM

Model H79

13

Page 14

Operat i on

Operation

Installing the Bobbin

To put the bobbin in the machine, follow these steps:

1. Slide open the bobbin cover by sliding the small black slide bar to

the right. Remove the plastic cover. If the clear plastic cover does

not ip up, slide it to the right a bit.

2. Insert the bobbin into the shuttle with the thread direction as

noted in the etching under the bobbin cover.

3. Guide the thread around the nger of the machine through the

channel toward the back, and then pull the thread toward you to

cut the thread end. The thread will be cut at the end of the channel

and be ready for use.

14

H79_Manual.indd 14H79_Manual.indd 14 10/6/2008 4:29:06 PM10/6/2008 4:29:06 PM

Model H79

Page 15

4. Replace the bobbin cover by placing the left end in place and

Operat i on

pressing down lightly on the right end to snap in place.

NOTE: There is no need to pull up the lower thread, as it is done automatically.

TIP: It’s a good idea to have several full bobbins before starting a new project.

Threading the Machine

Operation

1. Raise the presser foot lever. (If the presser foot is not raised, the upper

thread cannot be threaded properly)

2. Turn the balance wheel toward you to raise the needle to its

highest position.

3. Guide the thread through the thread path, following the arrows

and number sequence on the machine. (See dotted line in

illustration).

4. Lower the presser foot.

5. Thread the needle using the needle threader or thread manually.

CAUTION: Always be sure to raise the presser foot before removing upper thread

to prevent damage to the thread tension system.

H79_Manual.indd 15H79_Manual.indd 15 10/6/2008 4:29:06 PM10/6/2008 4:29:06 PM

Model H79

15

Page 16

Operat i on

Operation

Thread the Needle Using the Needle Threader

1. Lower the presser foot at this time. Lower the needle threader lever

until it stops. Hook the thread into the threader guide and pull the

thread to the right.

2. Push the needle thread lever toward the back to swing threader

into place.

3. Check to be sure that the hook has passed through the eye of the

needle and route the thread through the metal guides and under

the hook. Pull the thread toward you and check that it is being

held by the thread hook.

16

H79_Manual.indd 16H79_Manual.indd 16 10/6/2008 4:29:06 PM10/6/2008 4:29:06 PM

Model H79

Page 17

4. While gently holding the thread, pull the needle threader lever

Operat i on

forward.

Operation

5. Release the thread from the needle threader lever.

6. Pull the upper thread through the needle eye from front to back

toward the rear of the machine.

NOTE: Replace the needle often. Discard used needles, do not reuse.

H79_Manual.indd 17H79_Manual.indd 17 10/6/2008 4:29:07 PM10/6/2008 4:29:07 PM

Model H79

17

Page 18

Operat i on

Operation

Hooping

Inner Hoop

Fabric

Stabilizer

Outer Hoop

Make sure fabric, threads and stabilizer are compatible for laundering.

1. Place stabilizer on the wrong side of the fabric in the area to be

embroidered.

2. Loosen the adjusting screw on the outer hoop, place the stabilizer

(must be larger than the hoop) and fabric on top of the outer hoop

with the right side of the fabric up. Always put stabilizer in the

hoop with the fabric. Stabilizer must be larger that the hoop to

adequately stabilize the fabric.

18

3. Place the inner hoop into the outer hoop to clamp the fabric and

stabilizer. Fabric and stabilizer should be smooth in the hoop, but

do not stretch or distort it. Smooth the fabric but do not stretch it.

Push the inner hoop into the outer hoop. Clamp securely so that

the edges of the outer hoop and inner hoop are even.

4. Firmly tighten the adjusting screw.

NOTE: Stabilizer provides body and control to fabric and aids in ensuring that stitches go

where they should go. Stabilizers can be bonded fabric, liquid, or water soluble and can be

sewn on, applied with spray adhesive or ironed on. Di erent blends of fabric react di erently

when water or heat is applied or when tearing or cutting stabilizer away from your nished

design. Always have an assortment of stabilizer on hand to match with various fabrics.

Always stitch a test design on actual fabric and stabilizer. Remove stabilizer gently and

carefully to avoid distorting your design.

Model H79

H79_Manual.indd 18H79_Manual.indd 18 10/6/2008 4:29:07 PM10/6/2008 4:29:07 PM

Page 19

Using the Template

Operat i on

In order to hoop a garment straight, you may need to make some marks

on the garment. Draw a + sign in the center where you want the

design to be with chalk, a water soluble, air soluble or temporary

marker that will wash out easily.

On the inner hoop there are four arrows, at the top and bottom and

both sides. By lining up the marked center with the arrows at the

top, bottom and sides, you will get a straight embroidery that is

lined up with your markings.

Operation

To make this process much easier, a duplicatable

template has been included in this manual on

page 22.

You may print as many templates as you need.

Print the template on clear transparency lm,

such as that used for overhead projectors,

to create a reusable template. If you do not

have a printer and want to make copies, take this entire book

to the copy shop. This will inform the copy shop that you have

permission to make copies of the template.

H79_Manual.indd 19H79_Manual.indd 19 10/6/2008 4:29:07 PM10/6/2008 4:29:07 PM

Model H79

19

Page 20

Operat i on

Operation

The template is ruled in 1 inch squares with the sewing eld of the

machine subdivided by ¼” squares. Cut out the template along

the outside edge of the diamond shape. You may want to use a

hole punch to punch out the circles. To get to the center circle, just

barely fold the template so you can punch it. Or you can use a craft

knife and make cross cuts at each circle. These will indicate the

outside edge of the sewing eld and the center where the design

will start. You may also want to make a small notch in the top,

bottom and both sides to denote the horizontal and vertical center

lines. These horizontal and vertical center lines correspond with

the arrows of the hoop.

NOTE: The sewing eld of your Model H79 Embroidery Machine is 100mm x 100mm or 3.93

inches. The template is marked in inches, therefore the design will always t within this area.

Mark the horizontal and vertical lines for the center of the design on the

garment to be embroidered. Use the template to make sure the

centers are lined up with the center of the sewing eld.

20

H79_Manual.indd 20H79_Manual.indd 20 10/6/2008 4:29:07 PM10/6/2008 4:29:07 PM

Model H79

Page 21

You can use the template to mark the placement of the design on fabric

Operat i on

or a garment.

Operation

1. Place the template over the section of the garment where you

want the design to be. With an erasable marker, chalk, air dry

marker, or water soluble marker, mark the four corner holes and the

center. You may also want to mark the vertical and horizontal lines

at the edge of the template.

2. Remove the hoop and connect the lines with your erasable marker.

3. Place the outer hoop under the garment and the stabilizer

and place the inner hoop in the area you have marked for the

placement of the design.

4. Place the template in the inner hoop. The small ledges of the inner

hoop should hold the template in place. The lines on the template

should line up with the arrows on the inner hoop.

5. Adjust the inner hoop on the garment to get it placed according to

your markings. (This is why the transparency lm is a good choice).

When using a paper template, cut along the lines and fold back to

see the markings you have made on the fabric.

6. Once the inner hoop is lined up, adjust the outer hoop to t. Press

the inner hoop into the outer hoop and check the template again

for proper placement.

Proceed with the hooping instructions on page 18.

H79_Manual.indd 21H79_Manual.indd 21 10/6/2008 4:29:08 PM10/6/2008 4:29:08 PM

Model H79

21

Page 22

Operat i on

Operation

©Bernina of America, Inc. You have permission to make as many copies of this template as needed.

22

H79_Manual.indd 22H79_Manual.indd 22 10/6/2008 4:29:08 PM10/6/2008 4:29:08 PM

Model H79

Page 23

Operat i on

Attaching the Hoop to the Machine

Operation

1. Raise the presser foot to its highest position.

2. Pass the embroidery hoop under the presser foot with the

mounting pins on the right side and the fabric right side up. NOTE:

It is easier to slide the embroidery hoop under the presser foot if

you lift the presser foot all the way to its highest position with your

left hand as you slide the hoop under the presser foot with your

right hand.

3. Align the two pins on the embroidery hoop and rmly press

straight down into the hoop holder until a soft click is heard.

NOTE: Do not push too hard as you attach the hoop. Use caution

so as not to move the hoop holder in any direction as you attach

the hoop.

NOTE: Be sure to insert both pins. If only one pin is inserted, the result may be poor

quality embroidery.

Model H79

H79_Manual.indd 23H79_Manual.indd 23 10/6/2008 4:29:08 PM10/6/2008 4:29:08 PM

23

Page 24

Operat i on

Operation

Selecting a Design

In the Model H79 Embroidery Machine you have Internal Memory as

well as Card Memory. Designs can be accessed from both places.

Selecting a Design from Internal Memory

In order to use the Internal Memory of the Model H79 Embroidery

Machine to its fullest, you must have it connected to a Personal

Computer with the software installed. This allows you to save

designs to the Internal Memory of the machine. The Internal

Memory will hold up to 99 designs or one million stitches,

whichever comes rst. You must use the eXplorations Lite software

and the Navigator to view, save or delete designs in the internal

memory.

To select a design from Internal Memory you must use the

on the keypad. This button toggles back and forth from Internal

Memory (designs that show as ## in the LED screen) to Card

Memory (designs that show as C## in the LED screen). When you

have Internal Memory selected, the light next to “Internal” will be

illuminated.

To move through the selections in the Internal Memory you will use the

arrow buttons on the keypad.

The Right Arrow button will take you forward through the list of

designs (higher numbers) one design at a time.

button

The Left Arrow button

(lower numbers) one design at a time.

The Up Arrow button

The Down Arrow button will take you backwards 10 designs at a time.

24

H79_Manual.indd 24H79_Manual.indd 24 10/6/2008 4:29:09 PM10/6/2008 4:29:09 PM

will take you backward through the list

will advance 10 designs at a time.

Model H79

Page 25

Once you have the design you wish to sew selected, press the Enter

Operat i on

button .

Selecting a Design from a Memory Card

Card Memory (designs that show as C## in the LED screen) are designs

that are on a pre-programmed Memory Card. The search features

are the same as above for Internal Memory.

To select a design from a Memory Card you must rst have a card

inserted.

Operation

To insert the Memory Card into the machine simply insert the card in

the card slot until it softly clicks. It should go in easily. Do not force

the card. If it does not go in easily, you may have the card reversed.

Forcing the card into the slot could bend the connector pins inside

the machine.

Use the

button on the keypad to access the Memory Card designs.

This button toggles back and forth from Internal Memory (designs

that show as ## in the LED screen) to Card Memory (designs that

show as C## in the LED screen). When you have a Memory Card

selected, the light next to “Card” will be illuminated.

When you nd the design you want to select, press the Enter button

.

H79_Manual.indd 25H79_Manual.indd 25 10/6/2008 4:29:09 PM10/6/2008 4:29:09 PM

Model H79

25

Page 26

Operat i on

Operation

Align Design

Designs, in most cases, start and stop at the center of the design. The

Model H79 Embroidery Machine is programmed to start and stop

in the center unless you specify otherwise in eXplorations Lite

software. When hooping your fabric to be embroidered you will

need to mark where you want the center of the design to start.

If you don’t get the fabric centered exactly in the hoop, you can

reposition the needle in the hoop to some degree depending on

the size of the design.

Once you have selected your design, you will see that the illumination

has changed on the keypad from Select to Align allowing you to

use the arrow keys to move the needle position of the start of the

design around in the hoop. You must have the presser foot lever in

the upper position to move the needle position. (E15 will appear

in the LED screen if the presser foot lever is in the lower position.

Raise the presser foot and Press the arrow button again).

26

To center the design in the center of the hoop, use the Home button .

This positions the hoop so that the needle is in the center of the

hoop.

To move the needle position to the left in the hoop, use the Left Arrow

If you try to move too far, you will get an error (E25). This means

that the machine cannot sew the design any further to the left. If

the design needs to start closer to the left, you will need to re-hoop

the fabric.

To move the needle position to the right in the hoop, use the Right

Arrow

This means that the machine cannot sew the designs any further

to the right. If the design needs to start closer to the right, you will

need to re-hoop the fabric.

. If you try to move too far, you will get an error (E26).

Model H79

.

H79_Manual.indd 26H79_Manual.indd 26 10/6/2008 4:29:10 PM10/6/2008 4:29:10 PM

Page 27

To move the needle position to the bottom of the hoop, use the Down

Operat i on

Operation

Arrow

This means that the machine cannot sew the design any further to

the bottom. If the design needs to start closer to the bottom, you

will need to re-hoop the fabric.

To move the needle position to the top of the hoop, use the Up Arrow

If you try to move too far, you will get an error (E28). This means

that the machine cannot sew the design any further to the top.

If the design needs to start closer to the top, you will need to rehoop the fabric.

. If you try to move too far, you will get an error (E27).

Sewing the Design

Trace the Design

After selecting the design you wish to sew, it is always advisable to

trace the design. Make sure you are in the Align Mode by checking

to see that Align is illuminated.

.

OR

Make sure the presser foot is in the up position. Press the Trace button

. The hoop will begin to move to all four corners of the outer

perimeter of the design and then back to the center. You can still

reposition the needle if necessary. If you move the hoop, you

should trace the design again.

Model H79

H79_Manual.indd 27H79_Manual.indd 27 10/6/2008 4:29:10 PM10/6/2008 4:29:10 PM

27

Page 28

Operat i on

Operation

Sew the Design

Now that you have the hoop positioned where you want the design to

start you are ready to sew the design.

1. After threading the needle, place the thread through the hole in

the presser foot from top to bottom and gently pull the end of the

thread (See gure 1 above).

2. Lower the presser foot and hold the thread in your left hand. If you

do not hold the thread taut, you may get a thread break error (E13).

Press the START/STOP button to start the machine. After sewing

5-6 stitches, stop the machine by pressing the START/STOP button

and raise the presser foot again. Clip the beginning thread tail

close to the fabric. Do this when starting each color.

TIP: Make sure you are trimming the thread tail and not the sewing thread closest to the needle.

28

H79_Manual.indd 28H79_Manual.indd 28 10/6/2008 4:29:10 PM10/6/2008 4:29:10 PM

Model H79

Page 29

3. After trimming, lower the presser foot and press the START/STOP

Operat i on

button again to start the machine. The machine will stop when

it completes all the stitching with this thread color. During the

sewing process, the display will read =## signifying the percentage

of completion of the design. For example, =22 is displayed in the

LED means that the design is 22% complete.

4. When the color is complete, the LED screen will display c## (c02

for the second color in the design, c03 for third color in the design,

etc). depending on the sequence of the color. This lets you know

which color to change to according to the code sheet of the

design.

5. To change the color of the upper thread, raise the presser foot and

clip the upper thread close to the embroidery AND at the thread

spool. Pull the upper thread from the needle to remove and

discard it.

6. Thread the machine with the new color.

Operation

7. Lower the presser foot. While holding the thread tail, press START/

STOP to sew the next color section.

8. Repeat until the design is completed. The LED will show 100 to

represent 100% completion when the design is complete.

Model H79

29

H79_Manual.indd 29H79_Manual.indd 29 10/6/2008 4:29:10 PM10/6/2008 4:29:10 PM

Page 30

Operat i on

Operation

Thread Tension Adjustment

Thread tension can be adjusted from either the top thread tension

adjustment or the bobbin case screw adjustment. If you see

bobbin thread on top, you may need to adjust the tension.

However, before you adjust anything, check to see if the thread

may be caught and not feeding properly. Next, check to see if the

machine is threaded correctly. Change the needle. This could also

a ect the tension. Adjust the tension only if these suggestions do

not correct the problem.

Adjust Upper Thread Tension

When making tension adjustments, always start with the top thread. If

bobbin thread is showing on the top of the design, this means that

the tension on the top thread is too tight or the bobbin adjustment

is too loose. To loosen the top thread tension, rotate the Thread

Tension knob to the left (to a lower number).

If the stitches are not setting properly in the fabric or if loops appear,

you may need to adjust the tension so that it is tighter. First check

to see if the machine is threaded correctly before making any

adjustments. If threading is correct, turn the Thread Tension knob

to the right (to a higher number).

The standard position of the tension should be between 4 and 6 as

noted in the dark area of the Thread Tension knob.

30

H79_Manual.indd 30H79_Manual.indd 30 10/6/2008 4:29:10 PM10/6/2008 4:29:10 PM

Model H79

Page 31

To check to see if your machine has proper tension, look at the wrong

Operat i on

side of the embroidery. Proper tension should be where the

bobbin thread is covering the middle 3rd of the back of the

embroidery. The image below shows di erent tensions from

the wrong side of the embroidery stitches. You should see

approximately 1/3 of the top thread on either side of the bobbin

thread. The column on the far left shows proper bobbin and top

thread tension. The column in the middle shows the bobbin

tension too tight and/or the top thread too loose. Sometimes

the bobbin thread is barely showing. If this happens it is very

likely that the bobbin thread may break during wear and tear

and the embroidery will come loose. The column on the right

shows the bobbin tension too loose and/or the top tension too

tight. The bobbin thread could be showing on the right side of

the embroidery in some places and it is very likely that the stitches

could become loose during wearing.

Proper Tension

Top too loose

and/or bobbin

too tight

Operation

Top too tight

and/or bobbin

too loose

Bobbin Tension Adjustment

Adjusting the bobbin is a little more di cult. Only adjust the bobbin if

you cannot achieve a proper tension with the adjustments to the

top thread tension.

Remove the bobbin cover from the machine.

Using the 3-Way Screwdriver Tool provided in the accessory pouch,

remove the two screws from the stitch plate and lift up the stitch

plate.

Model H79

H79_Manual.indd 31H79_Manual.indd 31 10/6/2008 4:29:11 PM10/6/2008 4:29:11 PM

31

Page 32

Operat i on

Operation

Remove the bobbin and the bobbin case.

If too much bobbin thread is showing on top of the embroidery, the

bobbin tension needs to be tightened. On the side of the bobbin

case there is a tiny screw (bobbin tension adjustment screw).

Using the small end of the 3-way screwdriver tool, rotate the screw ¼

turn to the right to tighten the tension.

32

H79_Manual.indd 32H79_Manual.indd 32 10/6/2008 4:29:11 PM10/6/2008 4:29:11 PM

Model H79

Page 33

If not enough bobbin thread is showing on the wrong side of the

Operat i on

embroidery, turn the screw ¼ turn to the left to loosen the tension.

Replace the bobbin case. The Hook Tab should be to the left of the

Hook with the fuzzy part under the bar. Replace the stitch plate.

Make sure the screws are in as far as they will go. Tighten hand

tight. Do not use any mechanical devices to screw in the screws.

Put the bobbin back in the bobbin case according to the image on the

bobbin case and replace the plastic cover onto the stitch plate.

Test the embroidery again to see if further adjustments are needed.

Never adjust more than ¼ turn at a time.

Changing a Needle

If you break a needle while sewing, stop the machine immediately.

Change the needle according to the instructions below.

Operation

Use embroidery needles with your Model H79 Embroidery Machine.

Embroidery needles are made for the higher speeds of embroidery

machines. Regular sewing needles are not recommended, but

will not damage your machine. We recommend Organ Brand

embroidery needles, which are included with the machine.

Changing the needle should also be done at regular intervals to keep

your Model H79 Embroidery Machine running well and your

embroidery looking good. A good time to change the needle

is when you start a new project. Needles should be changed at

intervals no longer than four to six hours of sewing time. (You can

gure your sewing time by dividing the number of stitches by 500.

This will give you the number of approximate minutes it will take

the machine to sew out the design, i.e. 5000 stitches divided by 500

is 10. The design will take approximately 10 minutes to sew out).

To change the needle in your Model H79 Embroidery Machine, you will

need the 3-way screwdriver tool that came with your machine or a

short at blade screwdriver.

Model H79

33

H79_Manual.indd 33H79_Manual.indd 33 10/6/2008 4:29:11 PM10/6/2008 4:29:11 PM

Page 34

Operat i on

Operation

1. It is a good idea to turn o the power if you are not in the middle

of an embroidery design. If you have to change the needle in the

middle of a design, be very careful not to push the START/STOP

button during the process of changing the needle.

2. Lower the presser foot to its lowest position and raise the needle to

its highest position by turning the balance wheel toward you. This

will facilitate the removal and replacement of the needle.

3. With the 3- way screwdriver tool provided in the accessory kit,

loosen the needle screw (counterclockwise) until the needle can be

removed from the machine.

34

H79_Manual.indd 34H79_Manual.indd 34 10/6/2008 4:29:11 PM10/6/2008 4:29:11 PM

Model H79

Page 35

4. Remove the needle by pulling straight down. Once the needle is

Operat i on

free from the machine, discard it. Do not reuse old needles.

5. Insert a new needle into the machine with the at side of the

needle away from you and toward the back of the machine. Push

the needle up as far as it will go. Tighten the screw as tight as you

can (clockwise).

NOTE: Use only Embroidery needles. These are made for the high speeds of embroidery

machines. Use sharp point needles for woven fabrics and ball point needles for knit fabrics.

TIP: Titanium needles will last much longer than standard steel needles which make them a

good value.

Operation

Thread Breaks

In the event of a thread break, the machine will stop. When the

machine stops, you may have to push the START/STOP key to see

which error has occurred. Check the needle to see if the thread is

broken. If the thread is not broken at the needle, the thread has

either gotten out of one of the guides or is caught on something. If

the thread is broken, re-thread the machine and the needle.

Using the Left Arrow key

the design until you reach the point at which the thread broke. By

pressing the

you need to back up quite a bit hold the button down, it will then

start backing up in larger increments. If you only need to back up

a few stitches, press the

it again. This will allow you to keep backing up 1 stitch at a time.

Press the START/STOP key to restart the embroidery. Remember

to hold on to the thread to keep the thread taut until ve or six

key, it will start backing up 1 stitch at a time. If

on the key pad, you can back up through

key and then lift your nger and press

Model H79

35

H79_Manual.indd 35H79_Manual.indd 35 10/6/2008 4:29:12 PM10/6/2008 4:29:12 PM

Page 36

Operat i on

Operation

stitches are sewn. Stop the machine and trim the thread tail close

to the fabric.

When the machine is backed up to the point of the thread break, the

display shows the percent that has been completed. When START/

STOP is pushed, it will change to the percent of completion where

the thread break occurred.

Thread breaks happen occasionally but are not necessarily a warning

sign that something is wrong unless they are frequent. If thread

breaks occur very often, change the needle. Many times the

needle can become dull or have a spur or just be a tiny bit bent.

Replacing the needle is the easiest x.

If changing the needle does not eliminate the frequent thread breaks

there may be a small piece of thread in the bobbin case. Clean the

bobbin case thoroughly using a small soft brush.

Old sewing thread is not recommended for use with your machine. Use

good quality embroidery thread such as Isacord or Poly Sheen.

Some specialty threads will work with your machine but may have

frequent thread breaks.

Bobbin Thread Breaks

Rarely does the bobbin thread break. But if it does break, carefully

remove the hoop from the machine. Check the bobbin to see if

there is thread on the bobbin. An empty bobbin can register a

thread break. Replace with a lled bobbin.

In the unlikely event that the bobbin thread is broken, remove the

bobbin and reinsert it or put in a full bobbin following the diagram

on the bobbin case.

36

H79_Manual.indd 36H79_Manual.indd 36 10/6/2008 4:29:12 PM10/6/2008 4:29:12 PM

Model H79

Page 37

Removing Hoop from Machine

Machine Cleaning and Oiling

Operat i on / Cle a ning and Oili n g

1. Raise the presser foot.

2. Remove the embroidery hoop from the machine by gently pushing

the Hoop release lever to the right.

3. Raise the presser foot to its highest position to slide the hoop

under it to remove it from the machine.

4. When cutting the lower thread, leave about 10 cm. (4 inches)

of bobbin thread outside the needle hole in the needle plate.

(Cutting o the thread at the edge of the machine should be

adequate).

Operation / Cleaning and Oiling

Machine Cleaning and Oiling

**Always unplug machine prior to performing any maintenance**

Machine cleaning, oiling and maintenance is very important to ensure a

long lasting, enjoyable machine. Keep dirt and dust away from the

machine as much as possible. Small bits of thread can cause huge

problems. Keep the bobbin case free of dust and thread pieces.

Remove the needle plate and bobbin case and clean entire area

(pg. 32).

To keep your machine running smoothly you will want to do regular

cleaning followed by oiling (use sewing machine oil only). The

following graphic shows the points at which you should add one

drop of oil each time you clean your machine. A clean machine

is a happy machine. And a well oiled machine is a well running

machine. Approximately once a week, or after approximately 20

hours of sewing you should take the machine head cover o by

loosening the screw just to the right of the presser foot lifter. Take

o the plastic cover to expose the inner workings of the machine.

Model H79

37

H79_Manual.indd 37H79_Manual.indd 37 10/6/2008 4:29:12 PM10/6/2008 4:29:12 PM

Page 38

Clea n ing a nd O ilin g

Cleaning and Oiling

Clean the areas shown on the diagram with a clean soft brush.

Follow by adding one drop of oil at each location on the diagram.

Replace the plastic cover and the screw. Sew out a design on a scrap

piece of fabric to test the machine and work in the oil. This will also

remove any excess oil.

38

H79_Manual.indd 38H79_Manual.indd 38 10/6/2008 4:29:13 PM10/6/2008 4:29:13 PM

Model H79

Page 39

Error Codes and Troubleshooting

Error Codes and Troubleshooting

Erro r Co d es a n d Troub l esho otin g

Error Codes and Troubleshooting

Error Codes

Error

11

12

13

14

Problem

Needle is in the fabric and

the hoop cannot move.

Card was removed.

Upper thread broken.

Presser foot needs to be

lowered.

Solution

Turn the Balance Wheel until

the needle is at its highest

point.

Do not remove the card

while the machine is on.

Re-thread the needle or

check to see if the thread is

not in all the tensioners. If

this happens at the beginning of the design, hold the

thread taut when you press

the START/STOP button.

Lower the presser foot with

the presser foot lever

15

16

22 & 23

25

bob

Presser foot needs to be up.

Bobbin Winder is engaged.

Design is too large to sew.

-X limit reached.

Bobbin winder engaged.

Model H79

Raise the presser foot with

the presser foot lever.

Push the Bobbin winder to

the left to disengage it.

Choose another design or

make the design smaller using the software.

Start design in center of

hoop and trace to make sure

design will t and restart

design.

Move bobbin winder to the

left to disengage it.

continued on next page

39

H79_Manual.indd 39H79_Manual.indd 39 10/6/2008 4:29:13 PM10/6/2008 4:29:13 PM

Page 40

Erro r Co d es a n d Troub l esho otin g

Error Codes and Troubleshooting

Error Problem Solution

26

+X limit reached.

Start design in center of

hoop and trace to make sure

design will t and restart

design.

27

28

36

40

53

-Y limit reached.

+Y limit reached.

No design selected.

The main motor has stalled.

Not enough available free

space.

Start design in center of

hoop and trace to make sure

design will t and restart

design.

Start design in center of

hoop and trace to make sure

design will t and restart

design.

Select a design.

Check for obstructions or

thread nests.

Delete some designs in the

internal memory using Navigator.

40

H79_Manual.indd 40H79_Manual.indd 40 10/6/2008 4:29:13 PM10/6/2008 4:29:13 PM

Model H79

Page 41

Troubleshooting

Erro r Co d es a n d Troub l esho otin g

If you are having di culty with a certain part of the embroidery process,

review that section of the manual to make sure you are performing the

task properly. Some common problems that you might encounter are:

Error Codes and Troubleshooting

Common Problem

Thread breaks.

Bobbin thread

breaks.

Possible Cause and Solution

1. Check the thread to see if it is properly

threaded in all the guides.

2. Make sure you are using embroidery

thread recommended by the manufacturer

of the machine.

3. Change the needle.

4. Check to see if the bobbin thread has run

out.

5. Check the needle to see that it has been

inserted properly.

1. Check to see if the correct bobbin thread

is being used. Use bobbin thread recommended by the manufacturer. Use spun

Poly or continuous lament bobbin thread.

2. Bobbin thread has not been wound properly. Review the bobbin winding section of

the manual.

3. Bobbin has not been inserted properly.

Take out the bobbin and reinsert it following the guidelines in the manual and the

image on the stitch plate.

(Isacord Polyester or Poly Sheen)

Puckered fabric

around embroidery

design.

H79_Manual.indd 41H79_Manual.indd 41 10/6/2008 4:29:13 PM10/6/2008 4:29:13 PM

1. Review the Hooping section of the manual

to see if you are following all the instructions.

2. Improper stabilizer used.

3. Improper thread tension.

4. Screw on hoop was not tight enough to

hold fabric.

continued on next page

Model H79

41

Page 42

Erro r Co d es a n d Troub l esho otin g

Error Codes and Troubleshooting

Common Problem

Bobbin thread is

showing on the top

of the design.

Possible Cause and Solution

1. Check the top thread to see if it has gotten

caught and not feeding properly.

2. Re-thread the machine and pull the thread

with one hand at the spool and one at the

needle at the same time to make sure all

the guides have been threaded properly.

3. Adjust tension on the bobbin case by tightening the screw one quarter turn at a time.

(See the section on adjusting the bobbin

tension).

Thread loops on

top.

Thread break errors

when starting a

new color.

Outline of design is

o .

1. Adjust the tension tighter on the top

thread.

2. Change the needle.

3. Re-thread the machine and pull the thread

with one hand at the spool and one at the

needle at the same time to make sure all

the guides have been threaded properly.

1. Hold onto the thread tail as you start the

machine. The thread needs to be taut to

avoid registering a thread break.

1. Make sure you have attached the hoop to

the machine properly. If the hoop is not

attached at both pins, the design could be

distorted.

2. Follow all hooping instructions in the

Hooping section of the manual.

3. The inner hoop may not have been pushed

all the way into the outer hoop.

Skipped stitches

or machine not

sewing.

42

H79_Manual.indd 42H79_Manual.indd 42 10/6/2008 4:29:13 PM10/6/2008 4:29:13 PM

1. Probably a bent or improperly inserted

needle. Make sure the needle isn’t bent by

laying it on a at surface with the at side

down and make sure it is straight.

2. Needle may have been inserted backwards. Take the needle out and reinsert it.

3. Needle may be dull. Replace with a new

needle.

Model H79

Page 43

Loading...

Loading...