Page 1

my

my

city

bernette

Chicago 7

Instruction Manual

Page 2

502020.83.11_2013_06_bernette chicago 7_EN

Page 3

Contents

502020.83.11_2013_06_bernette chicago 7_EN

Safety Instructions 3

All rights reserved 4

Machine Overview 5

Details of the sewing machine 5

Accessories 6

– Optional 6

Machine Setup 7

Connecting the Machine 7

– Polarized plug information 7

Foot Control 7

Sewing Table 8

Winding the Bobbin 9

Inserting the Bobbin 11

Threading the Upper Thread 12

Needle Threader 14

Replacing the Needle 15

Thread Cutter 15

Thread Tension 16

Altering Presser Foot Pressure 17

Raising or Dropping the Feed dog 17

Changing the Presser Foot 18

Two-Step Presser Foot 18

Important Sewing Information 19

Needle, Fabric, Thread Selection Guide 19

Presser Foot Application Chart 21

Display Explanation & Operating Functions 22

Buttons Explanation 22

Information on the LCD Display 23

– Normal Mode 23

– Memory Mode 24

– Embroidery Mode 25

Function Buttons 26

– Start/Stop button 26

– Reverse/Exit button 26

– Auto-Lock/Trace button 26

– Needle up/down button 27

– Speed Dial 27

– Arrow buttons 28

– OK button 28

– Direct pattern selection 28

– Number buttons 28

– Mirror image button 29

– Elongation/Resize button 29

– Double needle/Rotate button 29

– Stitch length adjustment/ Stitch forward/backward button

30

– Stitch width adjustment/ Colour forward/backward button

30

– Memory/Setup button 31

– Clear/Return button 31

– Pattern group selection/Colour setup button 31

How to select a stitch 32

Stitches Overview 33

Stitches 33

Basic Sewing Procedures 36

Reverse 36

Free arm 36

Sewing corners 36

Sewing on the heavy fabric 37

Straight Stitches and Needle Position 38

– Changing the needle position 38

– Altering the stitch length 38

Zig-zag Stitches 38

– Altering the stitch width 38

– Altering the stitch length 38

Triple Straight Stretch Stitch 39

Overlock Stitches 40

Using the All- purpose foot 40

Blind Hem 41

Button Sewing-on 42

Buttonhole Stitching 43

– Buttonholes on stretch fabrics 47

– Bartack stitch 48

Eyelet Stitch 49

Darning Stitch 50

Zipper Insertion* 52

– Inserting a centered zipper 52

– Inserting a side zipper 53

– Invisible zipper insertion 54

Narrow Hemming 55

Cording 56

– Single cording 56

– Triple cording 56

Satin Stitch Sewing 57

Quilting 58

– Patchwork stitching 58

– Hand look quilting 59

– Blanket (Quilting Applique) 59

– Patchwork stitching 59

Fagoting 60

Scallop Stitch 60

Gathering 61

– Gathered fabric 61

– To gather and attach gathered fabric in one step 61

– Smoking 62

Free Motion Darning, Embroidery and Monogramming 63

– Darning 63

– Embroidery 64

– Monogramming 64

Walking Foot 65

1

Page 4

Contents

502020.83.11_2013_06_bernette chicago 7_EN

Special Functions 66

Mirror image stitch pattern 66

Elongation 67

Double Needle Sewing 68

Memory 70

Overview Memory Enter Mode 71

– Enter a sequence of stitch patterns in Memory Enter

Mode 71

Overview Memory Review/Edit Mode 74

– Review stored stitches 74

Switch from Memory Mode to the Normal Mode 76

– Sew memorized patterns 76

Memory Editing functions - Add a sequence of stitches 77

Memory Editing functions - Change a stored stitch or its

parameters 79

Memory Editing functions - Insert an additional stitch 80

Memory Editing functions - Delete a stored stitch 82

Memory Editing functions - Delete ALL 83

Embroidery 84

Important Embroidery information 85

– Embroidery threads 85

– Lower threads 86

Embroidery Setup 87

Details of Embroidery module 87

Attaching the embroidery foot 88

Connecting the embroidery module 89

Removing the embroidery unit 90

Embroidery hoop 91

– Hooping the fabric 92

– Using embroidery templates 93

Attaching the embroidery hoop 94

Removing the embroidery hoop 94

Stabilizer 95

– Tear-away stabilizers 95

– Cut-away stabilizers 95

Adhesive Spray 96

– Spray starch for additional stiffening 96

Iron-on interfacing 97

– Paper-backed adhesive stabilizer 97

– Water soluble stabilizer 97

Embroidery Selection 98

Embroidery Design types 98

– Built-in Embroidery Designs 99

– Built-in Embroidery Letters 100

– Designs from USB stick 101

Starting to embroider 102

Editing the Embroidery Design 104

– Basic setting 104

– Embroidery hoop 104

– Mirroring the Design 104

– Resizing the Design 105

– Rotating the Design 106

– Single/ Multi color 106

– Advanced settings 107

– CutWork Tool 107

– Inch/mm options 107

– Embroidery maximum speed 107

– Software version information 107

– Acoustic signal 108

– Embroidery arm return 108

Load a Design after interruption 109

BERNINA CutWork Tool* 111

– Preparation 111

– Switch from Embroidery Mode to Cutting Mode 112

– Start to Cut 113

Warnings 114

Warning functions 114

– Warning message 114

– Warning display 114

– Warning sound 119

Maintenance 120

Cleaning the display 120

Cleaning the sewing machine surface 120

Cleaning the hook 120

Environmental protection 121

Trouble Shooting 122

Trouble shooting guide 122

Stitches Overview 127

A - Group Stitches 127

B - Group Stitches 130

Embroidery Design Overview 133

Start Screen 133

Seasons 134

Sports 138

Decoration 140

Flowers 142

Children 145

Animals 148

2

Page 5

Safety Instructions

502020.83.11_2013_06_bernette chicago 7_EN

IMPORTANT

When using an electrical appliance, basic

safety precautions should always be followed,

including the following:

Read all instructions before using this sewing

machine. Keep the instruction at a suitable

place close to the machine, and hand it over if

you give the machine to a third party.

When the sewing-/embroidery machine is

not in use, it should be disconnected from

the electricity supply by removing the plug

from the outlet.

WARNING!

To reduce the risk of burns, fire, electric shock

or injury to persons:

1. This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

or instruction concerning use of the appliance by a person responsible for their

safety.

2. Do not allow this machine to be used as a

toy. Close attention is necessary when

this appliance is used by or near children

and infirm persons.

3. Use this appliance only for its intended

use as described in this manual. Use only

attachments recommended by the manufacturer as contained in this manual.

4. Children should be supervised to ensure

that they do not play with the appliance.

5. Never operate this appliance if it has a

damaged cord or plug, if it is not working

properly, if it has been dropped or damaged, or dropped into water. Return the

appliance to the nearest authorized dealer

or service center for examination, repair,

electrical or mechanical adjustment.

6. Never operate the appliance with any air

openings blocked. Keep ventilation open-

DANGER!

To reduce the risk of electric shock:

1. An appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the

electric outlet immediately after using and

before cleaning.

3. LED RADIATION: Do not view directly with

optical instruments Class

ings of the sewing machine and foot control free from accumulation of lint, dust,

and loose cloth.

7. Keep fingers away from all moving parts.

Special care is required around the sewing machine needle.

8. Always use the proper Stitch plate. The

wrong plate can cause the needle to

break.

9. Do not use bent needles.

10. Do not pull or push fabric while stitching.

It may deflect the needle causing it to

break.

11. Switch the sewing machine off («O») when

making any adjustments in the needle

area, such as threading needle, changing

needle, threading bobbin, or changing

presser foot, and the like.

12. Always unplug sewing machine from the

electrical outlet when removing covers,

lubricating, or when making any other

user servicing adjustments mentioned in

the instruction manual (pull power plug).

13. Never drop or insert any object into any

opening.

14. Do not use outdoors.

15. Do not operate where aerosol spray products are being used or where oxygen is

being administered.

3

Page 6

Safety Instruction

502020.83.11_2013_06_bernette chicago 7_EN

16. To disconnect, turn all controls to the off

(«O») position, then remove plug from outlet.

17. Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

18. If the supply cord fixed with foot controller

is damaged, it must be replaced by the

manufacturer or its service agent or a

similar qualified person in order to avoid a

hazard.

19. Never place anything on the foot control.

20. This sewing machine is provided with

double insulation (except U.S.A/Canada).

Use only identical replacement parts. See

instructions for Servicing of double-insulated products.

SERVICING OF DOUBLEINSULATED PRODUCTS

In a double-insulated product, two systems of

insulation are provided instead of grounding.

No grounding means is provided on a doubleinsulated product nor should a means for

grounding be added to the product. Servicing

a double-insulated product requires extreme

care and knowledge of the system and should

only be done by qualified service personnel.

Replacement parts for a double-insulated product must be identical to those parts in the

product. A double insulated product is marked with the words «DOUBLE INSULATION»

or «DOUBLE INSULATED».

The symbol

product.

may also be marked on the

SAVE THESE INSTRUCTIONS!

AtteNtioN!

This sewing machine is intended for household use only. If

used intensively or commercially, regular cleaning and

especially attentive care is required.

Signs of wear and tear owing to intensive or commercial use

are not covered automatically, even if they occur within the

warranty period. The decision on how to deal with any such

cases rests with the local authorised servicing staff.

If the sewing machine is stored in a cold room, it should be

brought to a warm room about one hour before use.

All rights reserved

For technical and product improvement reasons, the sewing computer‘s features, parts and accessory are subject to unannounced changes and alterations at any time. The accessory included can differ from country to country.

Note

4

Page 7

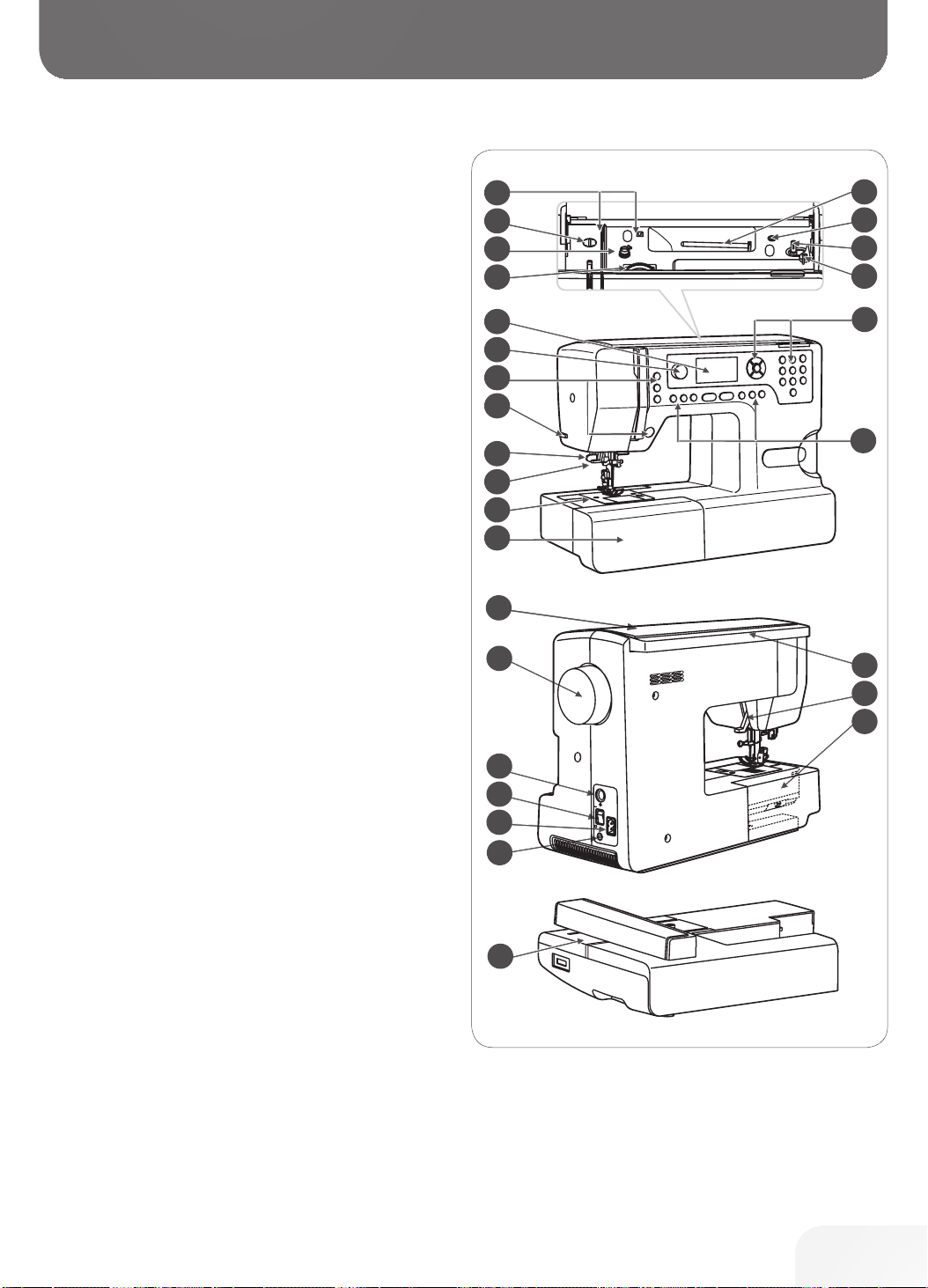

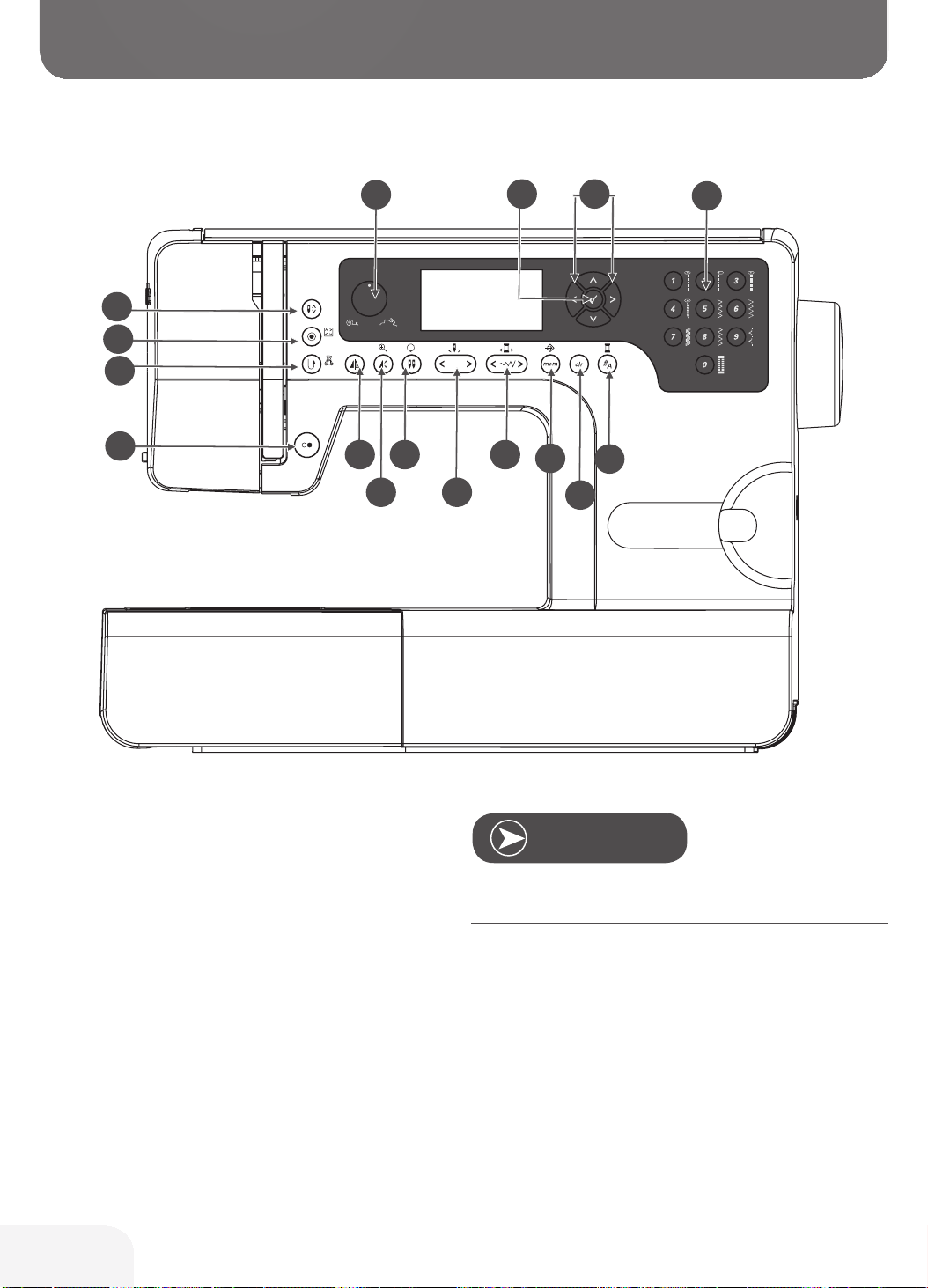

Details of the sewing machine

1

3

4

2

9

11

12

10

13

15

16

14

20

19

28

22

23

24

21

25

27

26

5

6

7

8

17

18

502020.83.11_2013_06_bernette chicago 7_EN

1 Thread guide

2 Presser foot pressure

3 Bobbin winder pre-tension

4 Thread tension dial

5 Spool pin

6 Hole for second spool pin

7 Bobbin winder spindle

8 Bobbin winder stopper

9 LCD display

10 Speed dial

11 Operation buttons

12 Thread cutter

13 One-step buttonhole lever

14 Needle threader

15 Stitch plate cover

16 Sewing table and accessory box

17 Selection buttons

18 Function buttons

19 Top cover

20 Handwheel

21 Embroidery module connector

22 Power switch

23 Power cord

24 Foot control connector

25 Handle

26 Presser foot lever

27 Feed dog lever

28 Embroidery module

(for details refer to separate section on page 87)

Machine Overview

5

Page 8

Machine Overview

502020.83.11_2013_06_bernette chicago 7_EN

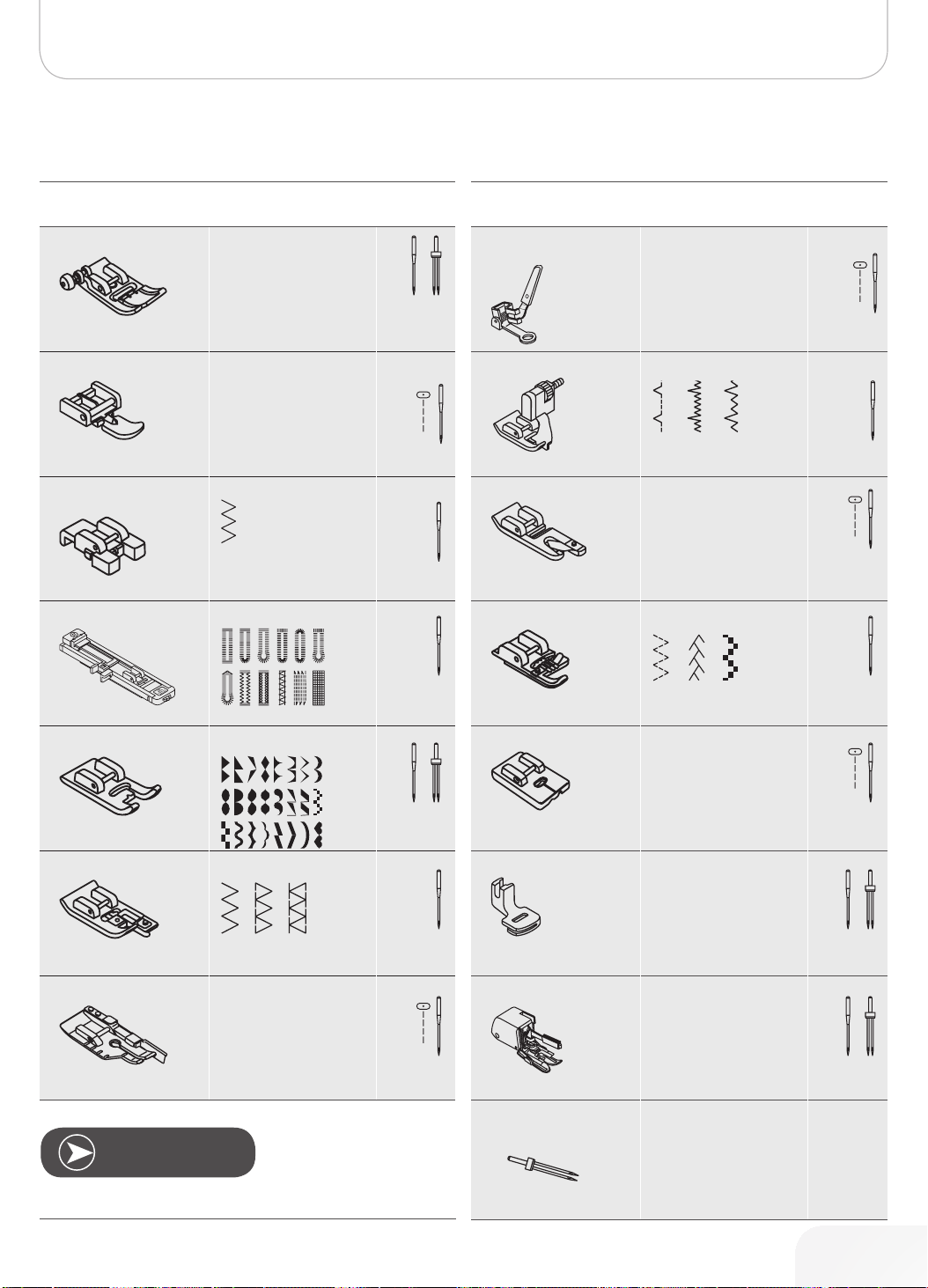

Accessories

1 All-purpose foot (T)

2 Buttonhole foot (D)

3 Blind hem foot (F)

4 Button sewing foot (H)

5 Overcasting foot (E)

6 Satin stitch foot (A)

7 Zipper foot (I)

8 Simple embroidery foot

9 Darning/Embroidery foot

10 Brush & Seam ripper

11 Needle Set (3 pcs)

12 Bobbin

13 Screwdriver

14 Seam guide/Quilting bar

15 L – Screw driver

16 Spool pin long (V)

17 Spool pin felt

18 Spool holder (large)

19 Spool holder (small)

20 Dust Cover

21 Spool net

22 Embroidery hoop (L-110x170mm)

23 Scissors

502020.69.03

502020.73.08

502020.59.21

502020.59.20

1 4

502020.70.20

5 9

502020.60.06

10 14

502020.74.87

15

502020.76.49

20

2

6

11

16

21

502020.59.99

502020.81.81

502020.70.90

502020.60.09

7

502020.81.80

12

502020.76.53

17

502020.76.50

22

3

502020.59.98

8

502020.80.84

13

502020.59.24

18

502020.59.27

19

23

Optional

24 Cording foot (M)

25 Gathering foot

26 Hemmer foot (K)

27 Double needle

28 ¼“ Quilting foot (P)

29 Walking foot

30 Invisible Zipper foot

31 Embroidery hoop (M-100x100mm)

32 Embroidery hoop (S-40x40mm)

6

502020.81.82

502020.60.05

502020.70.65

24

29

502020.79.37

502020.60.01

502020.70.53

25

30

502020.79.37

502020.60.10

502020.81.84

502020.81.85

26

502020.62.91 502020.70.52

27

31

32

502020.83.23

28

Page 9

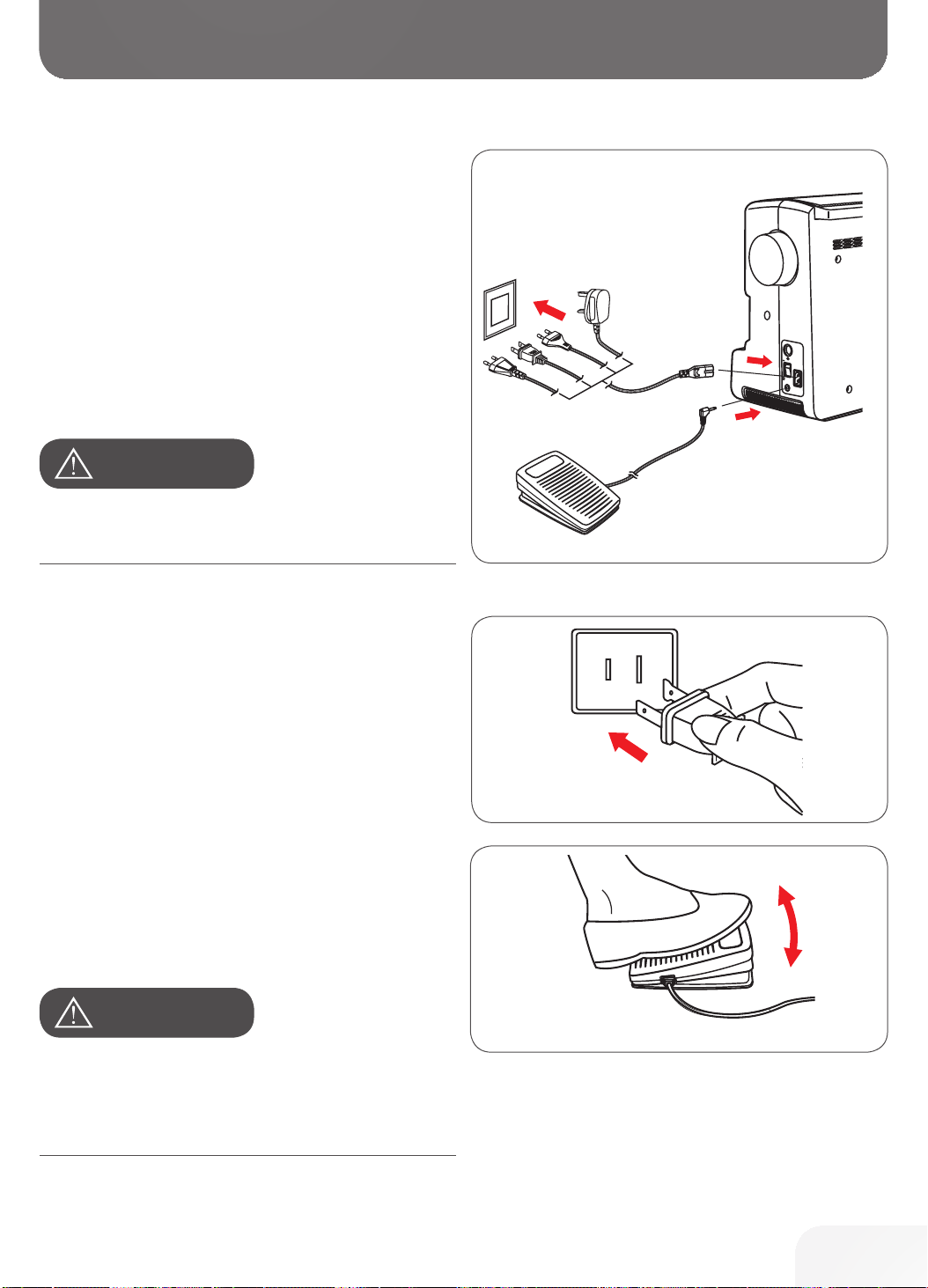

Connecting the Machine

502020.83.11_2013_06_bernette chicago 7_EN

Before connecting the power supply, make sure that the voltage and frequency shown on the rating plate is conforming

with your mains power.

• Place the machine on a stable table.

• Connect the power line cord to the machine by insert-

ing the 2-hole plug into the mains plug socket.

• Connect the power line plug to the wall outlet.

• Turn on the power switch.

– The sewing lamp will light up when the switch is

turned on.

AtteNtioN!

Always make sure that the machine is unplugged from

power source and the main switch is on «O». When the

machine is not in use and before inserting or removing parts.

Machine Setup

Polarized plug information

This appliance has a polarized plug (one blade wider than the

other), to reduce the risk of electrical shock; this plug will fit in

a polarized outlet only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not modify

the plug in any way.

Foot Control

With the sewing machine turned off, insert the foot control

plug into its connector on the sewing machine.

• Turn on the sewing machine, and then slowly depress

the foot control to start sewing.

• Release the foot control to stop the sewing machine.

AtteNtioN!

Consult a qualified electrician if in doubt as how to connect

the machine to the power source. Unplug the power cord

when the machine is not in use. Use only foot control type

C-9000 manufactured by CHIEN HUNG TAIWAN., LTD. with

sewing machine.

7

Page 10

Machine Setup

502020.83.11_2013_06_bernette chicago 7_EN

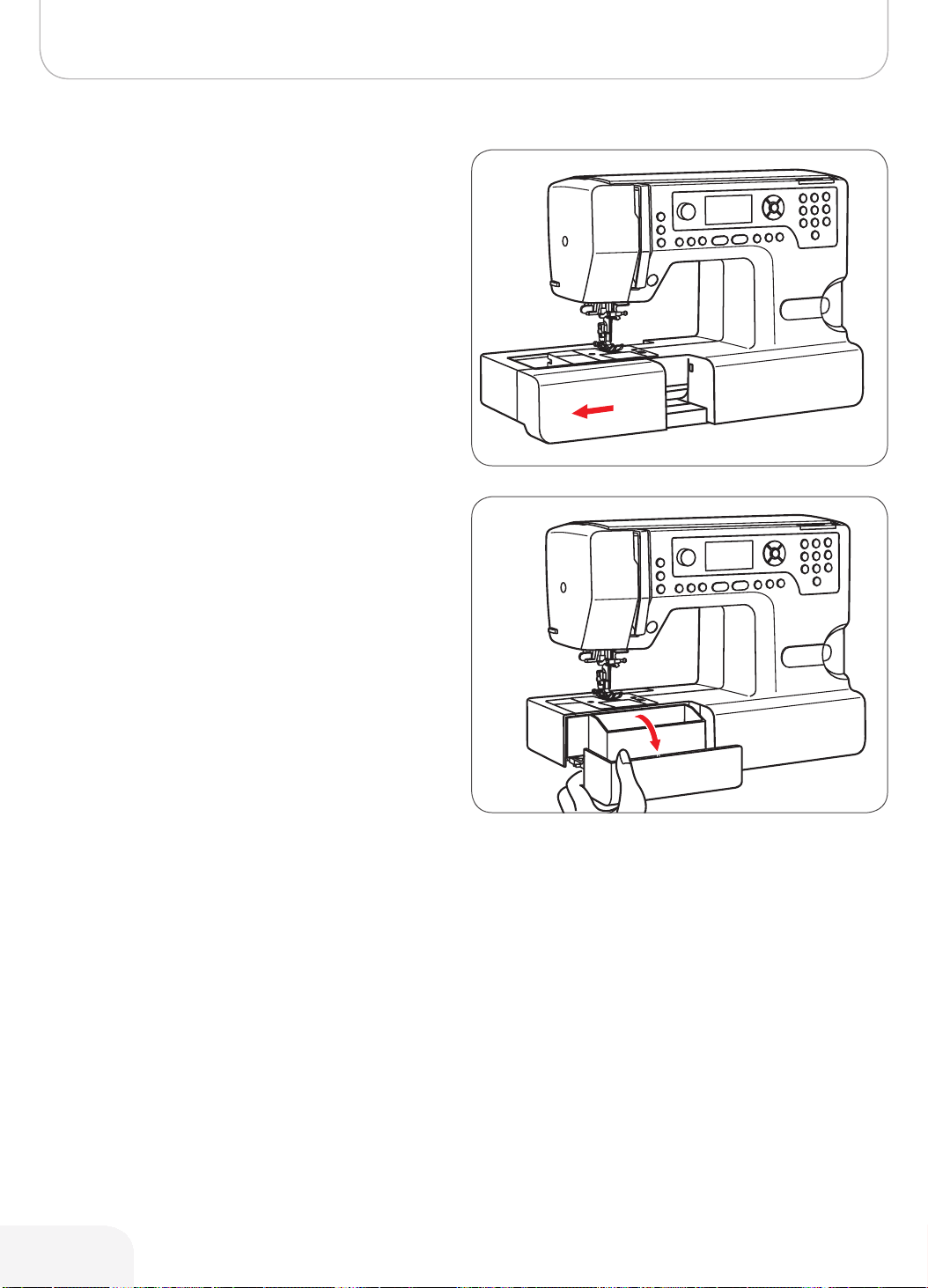

Sewing Table

• Keep the snap-in sewing table horizontal, and pull it in

the direction of the arrow.

The inside of the snap-in sewing table is used as an accessory box.

•

8

Page 11

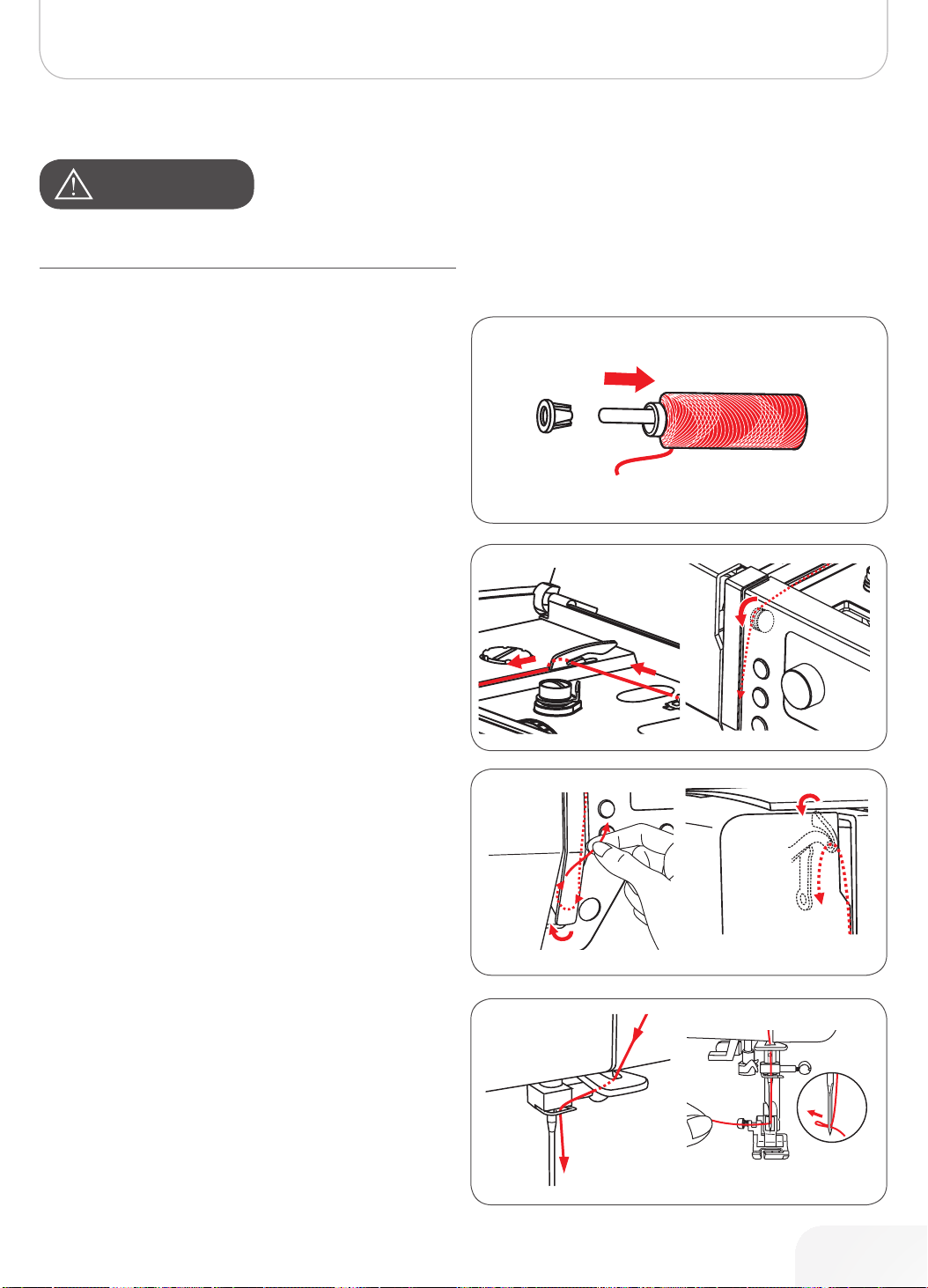

1

2

3

4

5 -

11

502020.83.11_2013_06_bernette chicago 7_EN

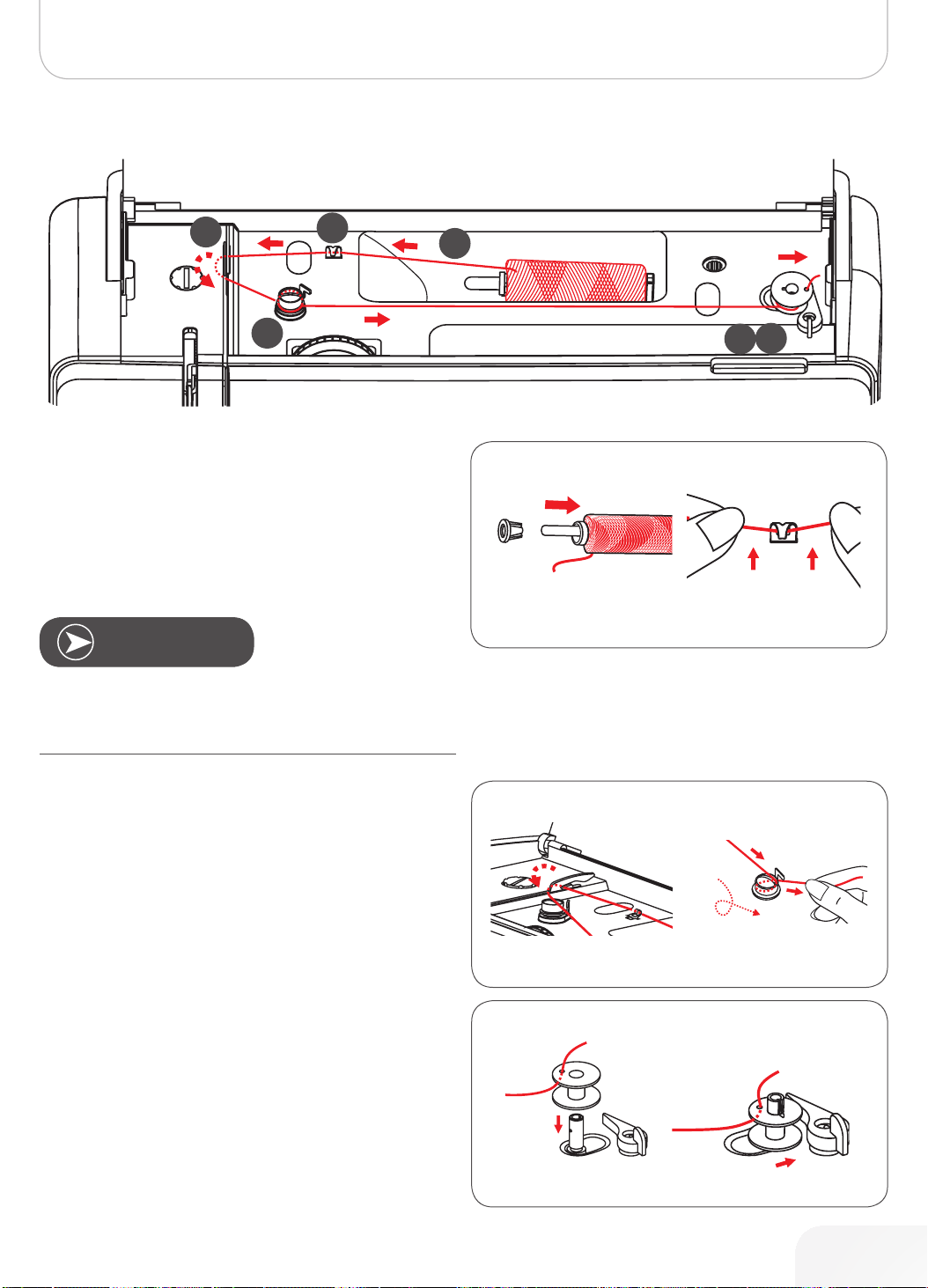

Winding the Bobbin

• Place the thread and spool holder onto the spool pin.

For smaller spools of thread use the small spool holder.

• Snap the thread into the upper thread guide.

Machine Setup

Note

If using special thread which winds quickly off the spool

attach a net to the spool before using and use the larger

spool holder. Reduce the thread tension if necessary.

• Wind the thread clockwise around the bobbin winder

tension disc.

• Insert the thread end through one of the inner holes in

the bobbin as illustrated and place the empty bobbin

on the spindle.

• Push the bobbin to right.

9

Page 12

Machine Setup

502020.83.11_2013_06_bernette chicago 7_EN

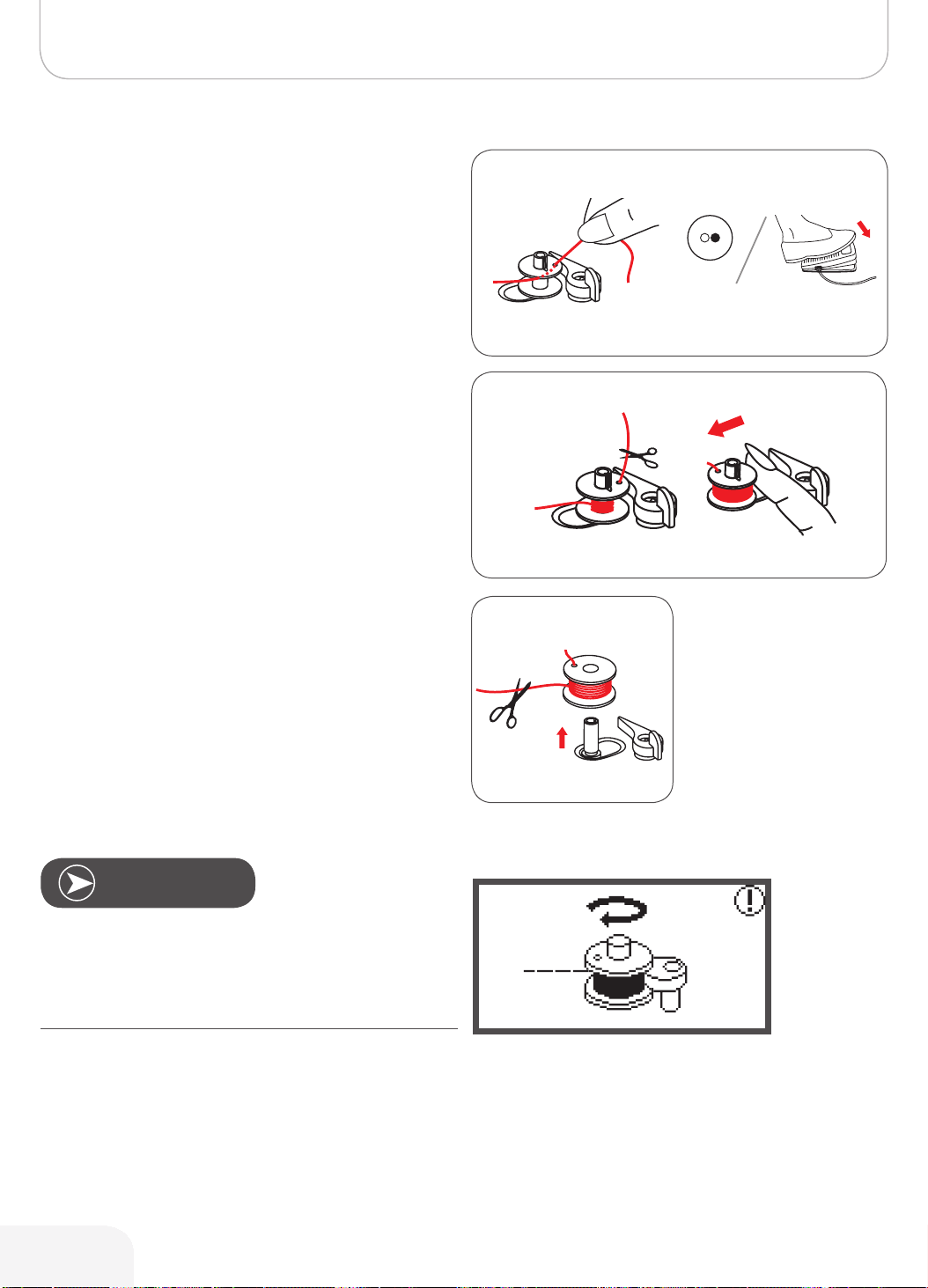

• Hold the thread tail securely in one hand.

• Press on the foot control or the Start/Stop button to

start winding the bobbin.

– After the bobbin has wound a few turns, stop the

machine.

• Cut the thread near the hole of the bobbin.

• Continue filling the bobbin until it is full.

– The motor stops automatically when the bobbin is

full.

• Press the Start/Stop button or release the foot control

to stop the machine.

• Push the bobbin winder spindle to left.

• Cut the thread and then remove the bobbin.

Note

When the bobbin winder spindle is pushed to the right

(bobbin winding position), this message is shown on the

LCD display. It will disappear from the LCD display when the

bobbin winder spindle is pushed back to the left into the

sewing position.

10

Page 13

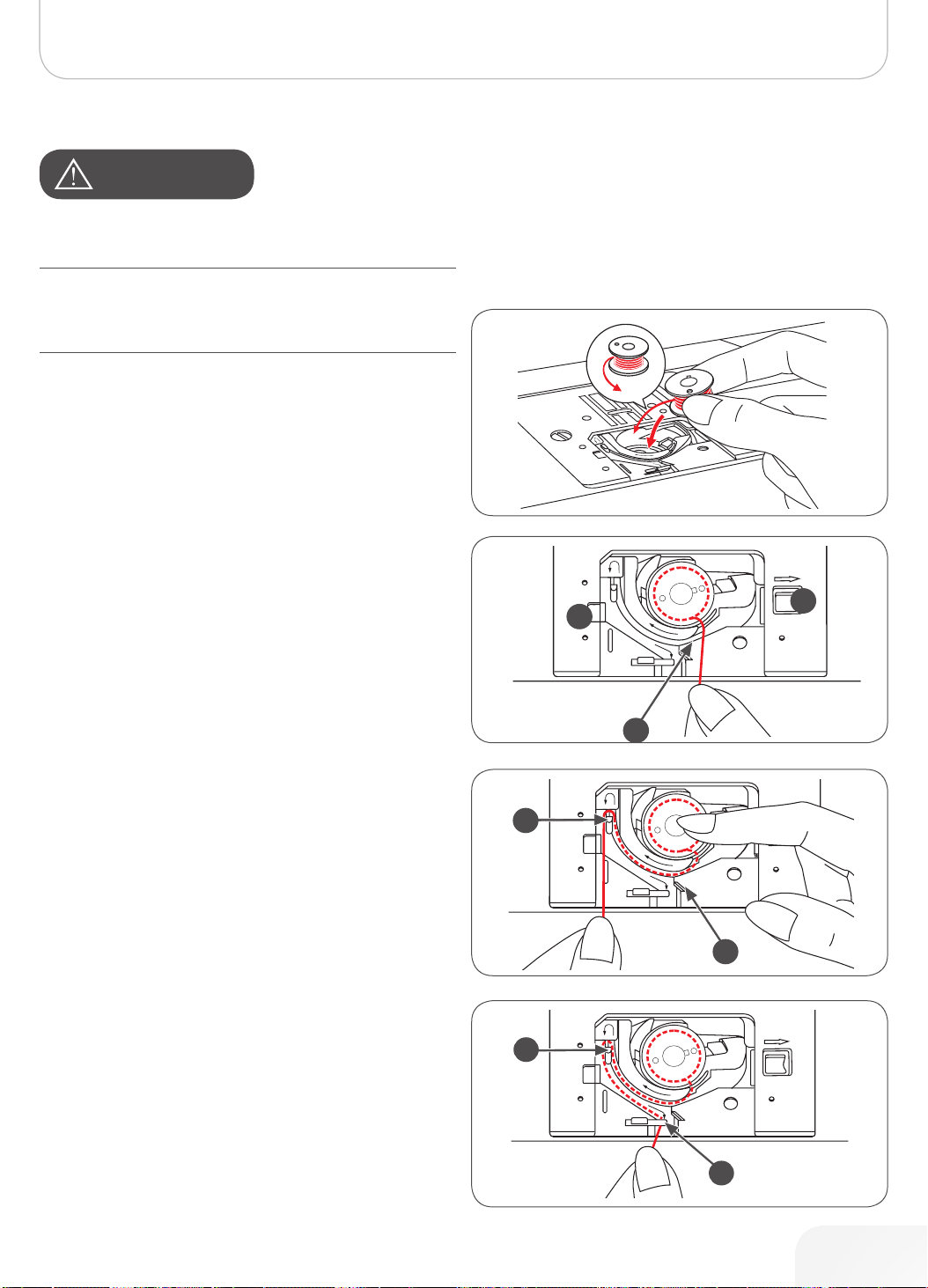

Inserting the Bobbin

A

1

2

A

B

C

B

502020.83.11_2013_06_bernette chicago 7_EN

AtteNtioN!

AtteNtioN!

Turn power switch to «O» before threading or unthreading

the machine.

The thread take-up lever must be in the highest position

when threading. Incorrect threading can cause damages to

the machine!

• When pushing the locking knob (1), the bobbin cover

opens.

• The bobbin cover can be pulled out of the guide (2).

• Inserting the bobbin in the bobbin holder with the

thread running in counter-clockwise direction.

• Pull the thread along the arrow marking through the slit

under the finger (A) as far as the pulley (B).

Machine Setup

• To make sure that the thread is pulled into the tension

spring of the bobbin holder, press a finger slightly onto

the bobbin while pulling. As a check you must feel a

resistance in the thread feed.

• Pull the thread at the arrow markings into the stitch

plate thread guide from (B) to (C).

– To cut off excess thread pull the thread back over

the cutting-off blade at point (C).

– When closing, insert the lid in the guide (2) on the

left. Afterwards press down on the right until the

locking knob (1) engages.

11

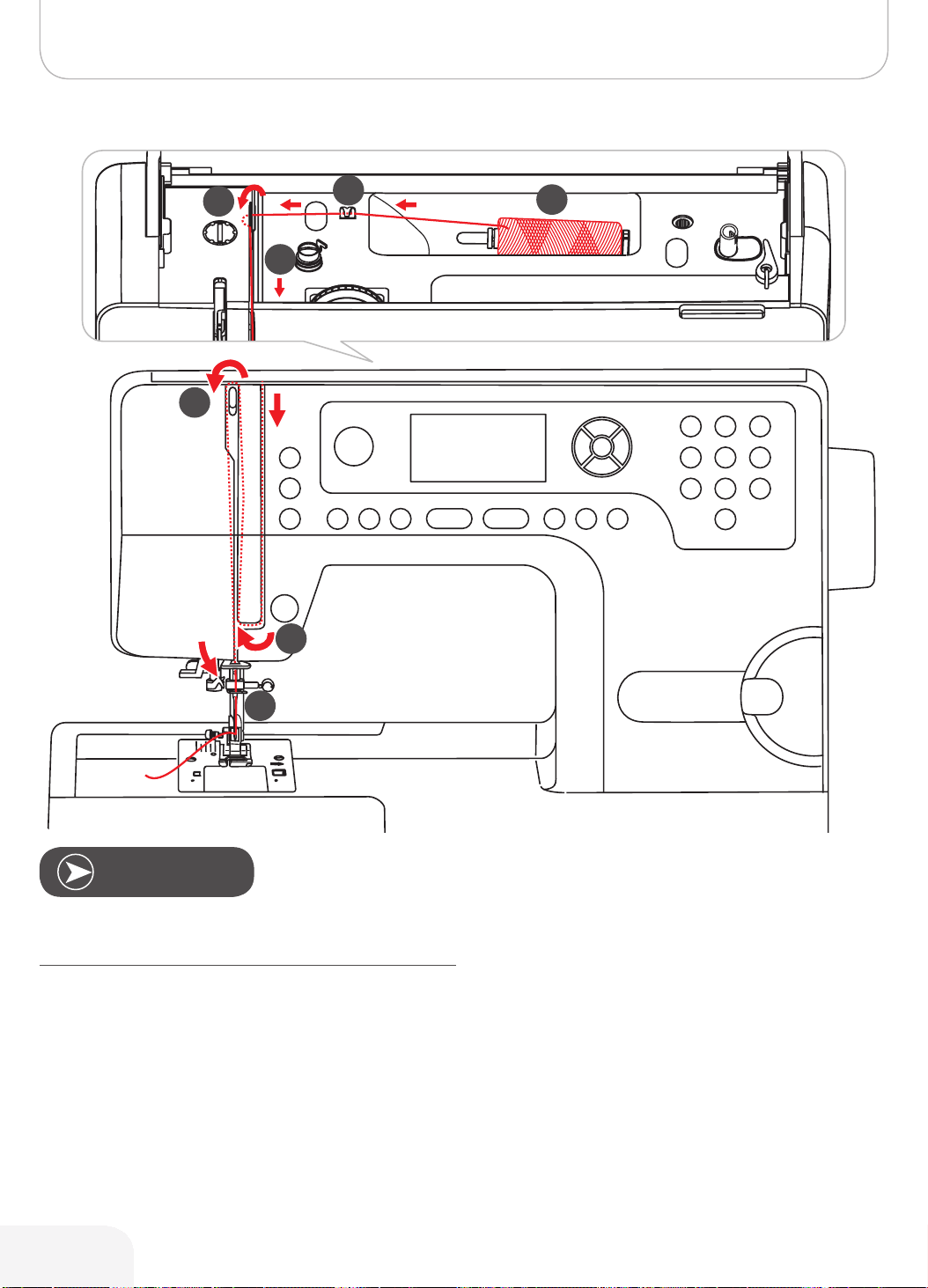

Page 14

Machine Setup

1

2

3

4

6

5

7

502020.83.11_2013_06_bernette chicago 7_EN

Threading the Upper Thread

Note

It is important to carry out the threading correctly as by not

doing so several sewing problems can occur.

12

Page 15

502020.83.11_2013_06_bernette chicago 7_EN

AtteNtioN!

Start by raising the needle to its highest point, and also raise

the presser foot to release the tension discs.

• Place the thread spool on the spool pin so that the

thread comes from the front of the spool, then place

the spool cap at the end of the spool pin.

• Pull the thread from the spool through the upper thread

guide.

• Guide the thread around the thread guide pulling the

thread through the pre-tension spring as illustrated

Machine Setup

• Then lead it further down and around the bottom part

of the take-up lever cover.

• Pull it up and insert the thread from the right to the left

through the slotted eye of the take-up lever and then

take it downwards again.

• Guide the thread through the wire loop.

• Pull the end of the thread through the needle from the

front to the rear, and pull out about 10 cm of thread.

• Use the face plate thread cutter to cut excess needle

thread.

• Use the needle threader to thread the needle (refer to

next page for instruction).

13

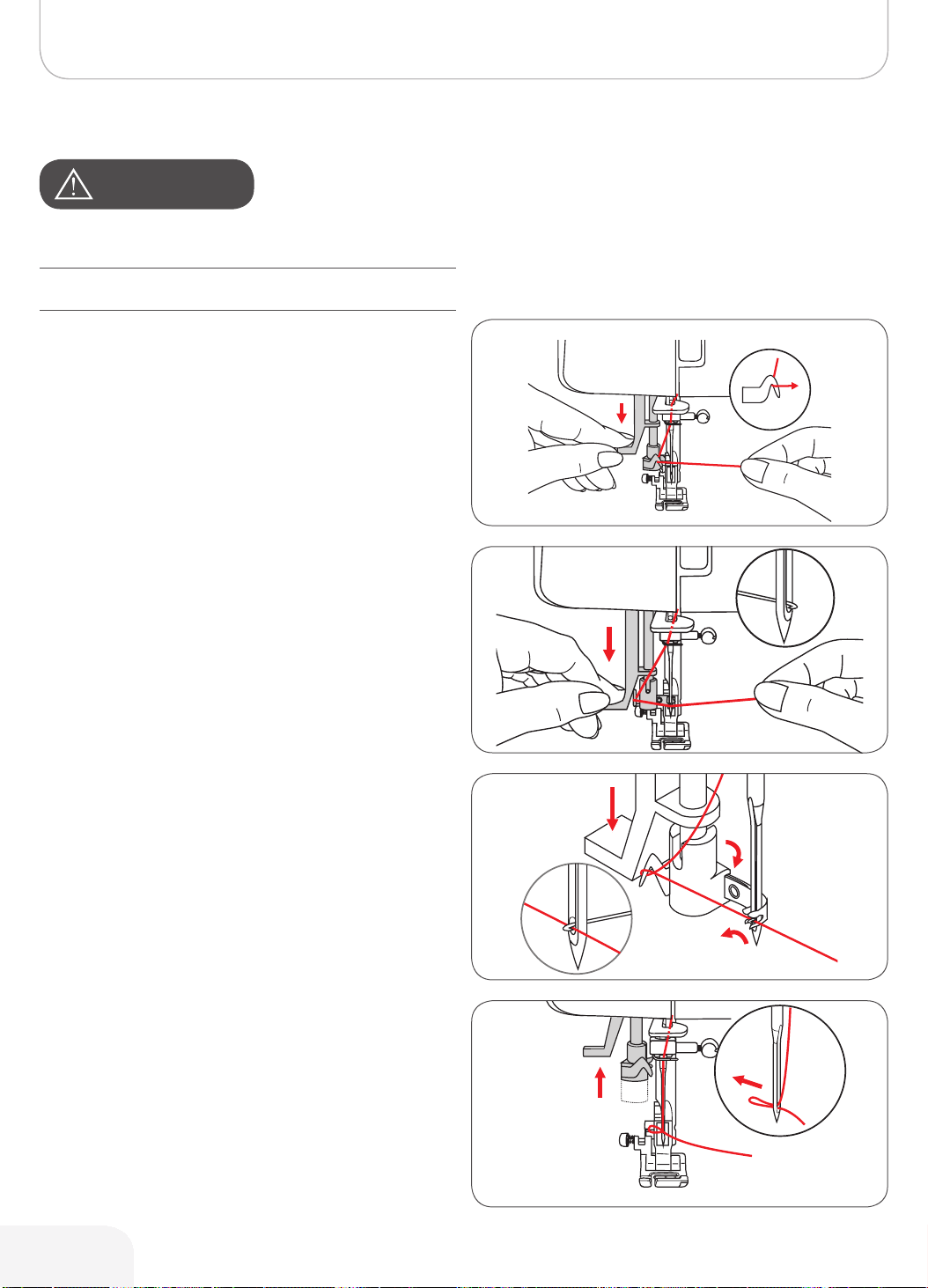

Page 16

Machine Setup

502020.83.11_2013_06_bernette chicago 7_EN

Needle Threader

AtteNtioN!

AtteNtioN!

Raise the needle to its highest position and lower the

presser foot.

Turn power switch to the off position «O»!

• Lower the needle threader lever slowly and pull the

thread through the thread guide as illustrated and then

to the right.

• The needle threader automatically turns to the thread-

ing position and the hook pin passes through the

needle eye.

• Pull the thread to the right, guiding it to the front of the

needle

• Hold the thread loosely and release the lever slowly.

– The hook will turn and pass the thread through the

needle eye forming a loop.

– Pull the thread through the needle eye.

14

Page 17

502020.83.11_2013_06_bernette chicago 7_EN

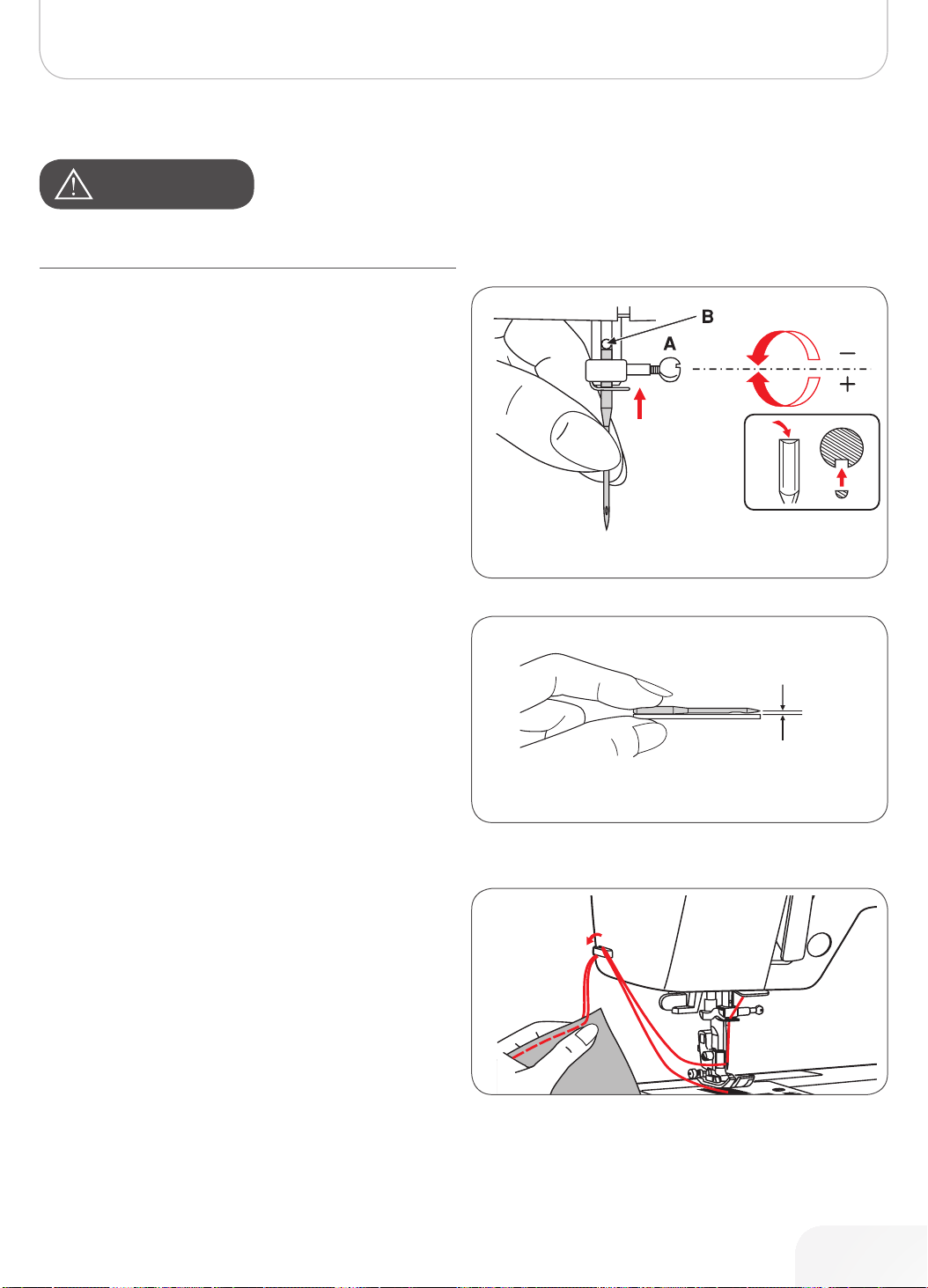

Replacing the Needle

AtteNtioN!

Turn power switch to off («O») when carrying out the

following operation!

Change the needle regularly, especially if it is showing signs of

wear and tear or of it is causing problems.

Insert the needle following the illustrated instructions.

A Loosen the needle clamp screw and tighten it again

after inserting the new needle. The flat side of the shaft

must be at the back.

B Insert the needle as far up as it will go.

Machine Setup

Needles must be in perfect condition

Problems can occur with:

– Bent needles

– Blunt needles

– Damaged points

Thread Cutter

The thread cutter serves two purposes:

1. Cut the thread after threading the needle

2. Cut the thread after finishing a seam.

• To cut the thread after completing your work raise the

presser foot.

• Remove the fabric, draw the threads to the left side of

the face cover and cut using the thread cutter.

• The threads are cut at the proper length to start the

next seam.

15

Page 18

Machine Setup

502020.83.11_2013_06_bernette chicago 7_EN

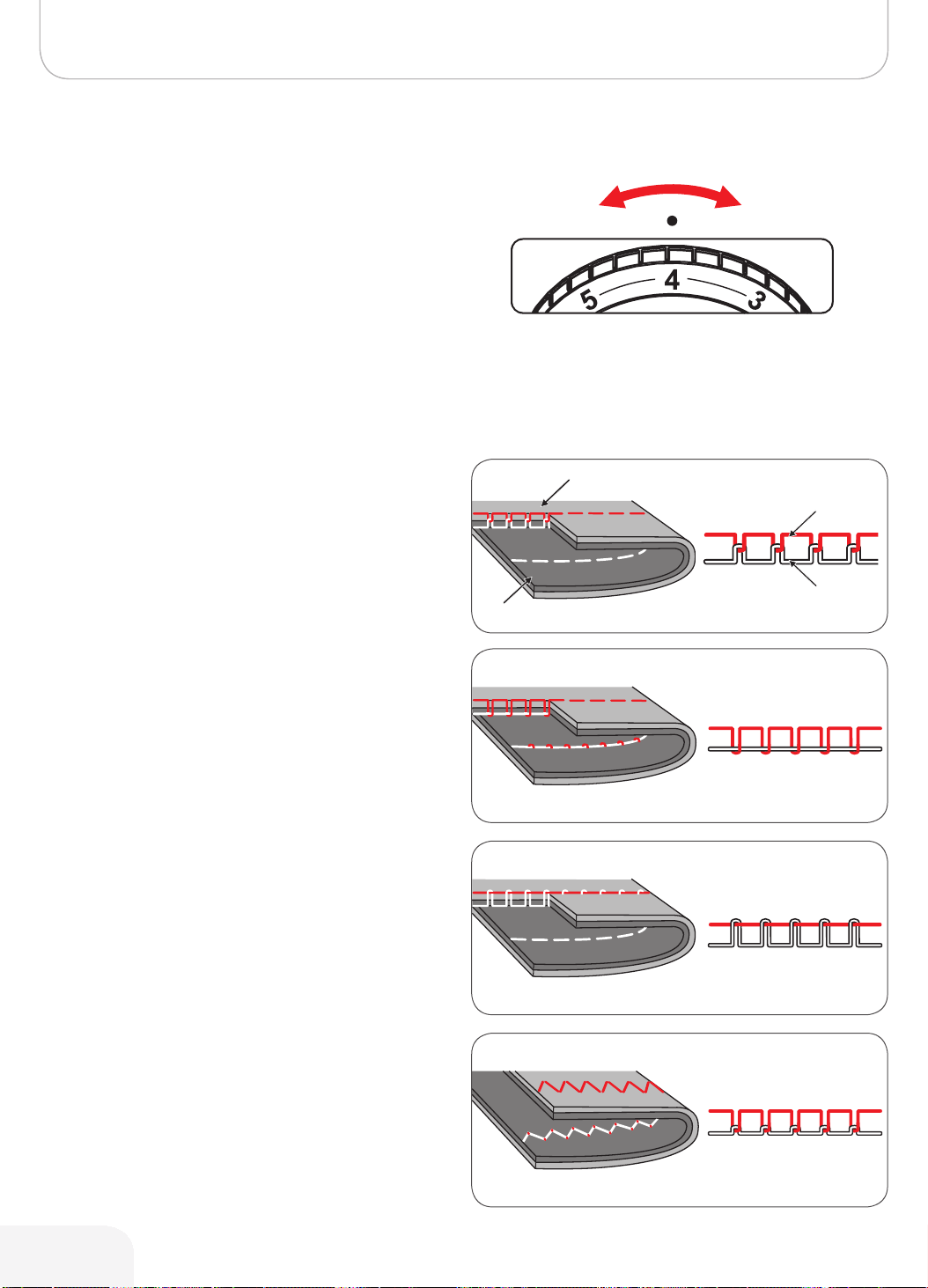

Thread Tension

Basic thread tension setting: «4»

• To increase the tension, turn the dial to the next num-

ber up.

• To reduce the tension, turn the dial to the next number

down.

Appropriate setting of tension is important to good sewing.

With any decorative sewing you will always obtain a nicer

stitch formation and less fabric puckering when the upper

thread appears on the wrong side of your fabric.

tight

loose

Normal thread tension for straight stitch sewing.

Thread tension is too loose for straight stitch sewing.

• Turn dial to higher number.

Thread tension is too tight for straight stitch sewing.

• Turn dial to lower number.

Surface

Reverse side

Upper thread

Bobbin thread

Normal thread tension for zig-zag and decorative sewing.

16

Page 19

b

a

b

a

502020.83.11_2013_06_bernette chicago 7_EN

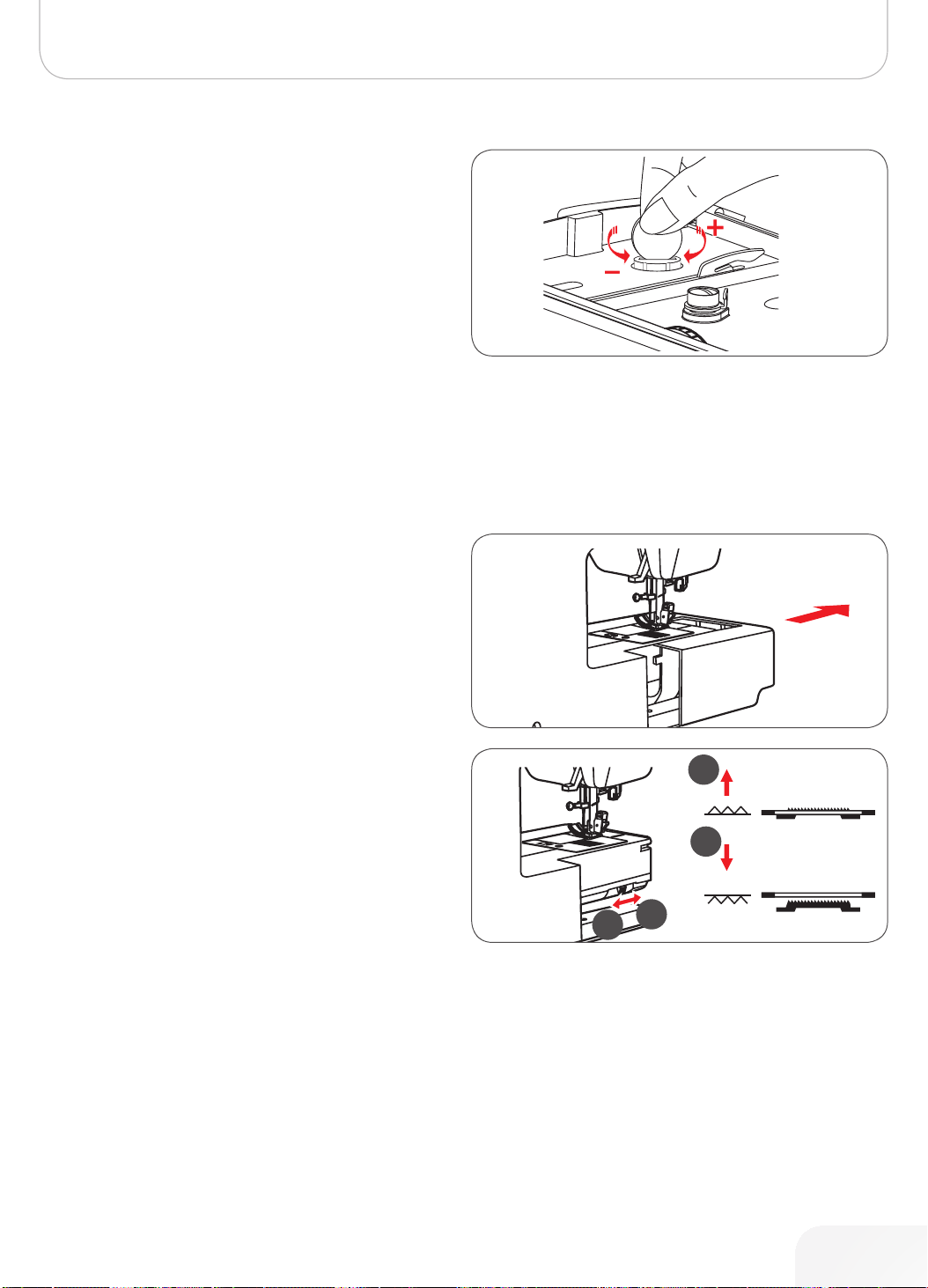

Altering Presser Foot Pressure

The presser foot pressure of the machine has been pre-set

and requires no particular re-adjustment according to the type

of fabric (light-or-heavy weight).

However, if you need to alter the presser foot pressure, turn

the presser foot pressure adjusting screw using a coin.

• For sewing very thin fabric, loosen the pressure by

turning the screw counter-clockwise, and for heavy

fabric, tighten by turning it clockwise.

• To return to initial pressure foot setting turn the presser

foot pressure adjusting screw to become flush with the

face cover.

Raising or Dropping the Feed dog

With the sewing table detached, the feed dog lever can be

located on the back of the free arm.

Machine Setup

Sliding the lever to position (b) will lower the feed dog, for

example during button sewing or freehand embroidery.

• If you wish to continue sewing normally, slide the lever

to position (a) in order to raise the feed dog.

• The feed dog will not be raised if you do not turn the

handwheel, even if the lever is slid to the right.

• Make a complete turn to raise the feed dog.

17

Page 20

Machine Setup

b

d

c

f

e

a

b

e

g

502020.83.11_2013_06_bernette chicago 7_EN

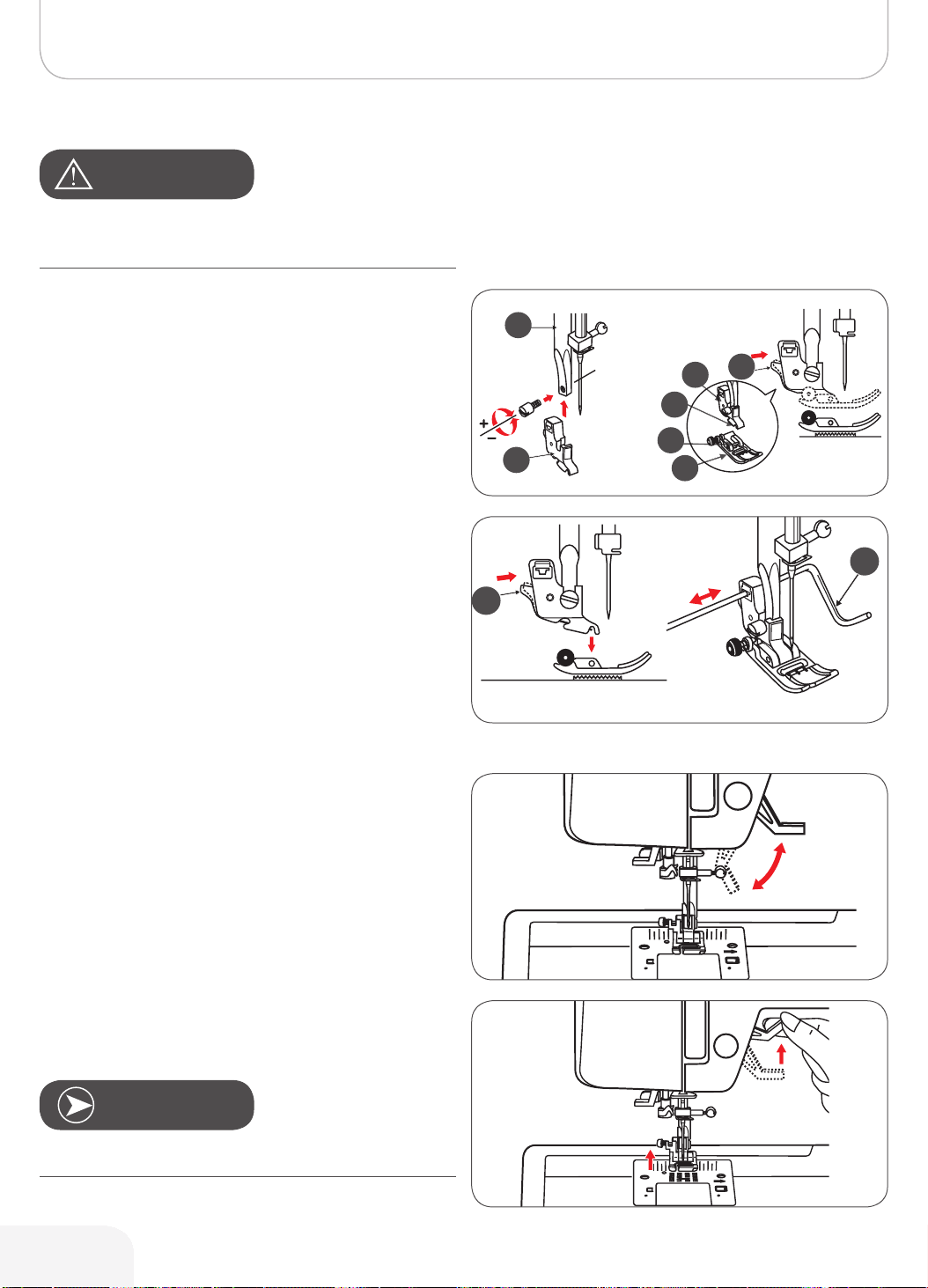

Changing the Presser Foot

AtteNtioN!

Turn power switch to off («O») when carrying out any of the

following operations!

Attaching the presser foot holder

• Raise the presser foot bar (a).

• Attach the presser foot holder (b) as illustrated.

Attaching the presser foot

• Lower the presser foot holder (b) until the cut-out (c) is

directly above the pin (d).

• Press the black lever (e).

• Lower the presser foot holder (b) and the presser foot

(f) will engage automatically.

Removing the presser foot

• Raise the presser foot.

• Press the black lever (e) and the foot will disengages.

Attaching the edge/quilting guide

• Attach the edge/quilting guide (g) in the slot as illus-

trated.

• Adjust according to the need for hems, pleats, etc.

Two-Step Presser Foot

There are two raising levels of the presser foot. Lifting the foot

up to the first level is used to place the fabric under the foot

for sewing.

The second level is only used in embroidery mode to remove

the hoop easily.

Note

The needle must always be at the highest position.

18

Page 21

Important Sewing Information

502020.83.11_2013_06_bernette chicago 7_EN

Needle, Fabric, Thread Selection Guide

Note

The thread is chosen according to the purpose. For a perfect sewing result, thread and fabric quality play an important role.

It is recommended to use quality brands.Care must be taken when choosing needle and thread. The correct needle size

depends on the selected thread and fabric. The fabric weight and type determine the thread weight, needle size and point

form.

Needle size Fabrics Thread

9-11/65-75

12/80 Medium-weight fabrics such as cotton, satin,

14/90 Medium-weight fabrics-cotton duck, woolen,

16/100 Heavy-weight fabrics such as canvas,

18/110 Heavy woolens, overcoat fabrics, upholstery

Light-weight fabrics such as thin cottons,

voile, serge, silk, muslin, Qiana, interlocks,

cotton knits, tricots, jerseys, crepes, woven

polyester, shirt & blouse fabrics.

kettleclote, sailcloth, double knits, lightweight

woolens.

heavier knits, toweling, denims.

woolens, outdoor tent and quilted fabrics,

denims, upholstery material (light to medium).

fabrics, some leathers and vinyls.

Light-weight thread in cotton, nylon or

polyester.

Most threads sold are medium size and

suitable for these fabrics and needle

sizes.

Use polyester threads on synthetic

materials and cotton on natural woven

fabrics for best results.

Always use the same thread for upper

and lower thread.

Heavy-weight thread, carpet thread. (Use

heavy foot pressure with large numbers.)

19

Page 22

Important Sewing Information

502020.83.11_2013_06_bernette chicago 7_EN

Note

Double needles can be purchased for utility and decorative work. European needles show sizes 65, 70, 80 etc. American

and Japanese needles show size 9, 11, 12 etc.Replace needle regularly (approximately after every second garment ) and/or

when thread breakage or skipped stitches occur.

Needles Explanation Type of fabric

HA x 1

15 x 1

15 x 1/130/ 705H

15 x 1/ 130/705H (SUK)

130PCL/705H-LR/LL

Standard sharp needles.

Sizes range thin to large.

9 (65) to 18 (110)

Semi-ball point needle, large eye.

9 (65) to 18 (110)

Full ball point needle.

9 (65) to 18 (110)

Leather needles.

12 (80) to 18 (110)

Natural woven fabrics-wool, cotton, silk,

etc. Qiana. Not recommended for double

knits.

Natural and synthetic woven fabrics,

polyester blends. Knits-polyesters,

interlocks, tricot, single and double knits.

Can be used instead of 15 x 1 for sewing

all fabrics.

Sweater knits, Lycra, swimsuit fabric,

elastic.

Leather, vinyl, upholstery. (Leaves smaller

hole than standard large needle.

20

Page 23

502020.83.11_2013_06_bernette chicago 7_EN

Presser Foot Application Chart

The double needle is being suggested with certain stitches for more creativity

Important Sewing Information

Presser Foot Application Needle

All-purpose foot (T)

Zipper foot (I) Inserting zippers

Button sewing-on

foot

Buttonhole foot (D) Buttonhole sewing

General sewing,

Patchwork stitches,

Decorative stitching,

Smoking, Fagoting,

etc.

Button sewing-on

Presser Foot Application Needle

Darning/Embroidery

foot

Blind hem foot (F) Blind hem stitching

Hemmer foot (K)*

Cording foot (M)*

Darning, Free

embroidery Monogramming

Narrow hemming

Cording

Satin stitch foot (A) Satin stitch sewing

Overlcasting foot (E) Overcasting

1/4“ Quilting foot* Quilting and Patch-

work sewing

Note

* Available as optional accessories

Invisible Zipper foot*

Gathering foot*

Walking foot*

Double needle*

Inserting invisible

zippers

Gathering

This foot helps to

prevent uneven

feeding with very

delicate fabrics

21

Page 24

Display Explanation & Operating Functions

502020.83.11_2013_06_bernette chicago 7_EN

Buttons Explanation

5

6

7

8

4

3

2

1

9

11 13

10

12

14

16

15

1 Start/Stop button

2 Reverse/Exit button

3 Auto-lock/Trace button

4 Needle up/down button

5 Speed dial

6 OK button

7 Arrow buttons

8 Direct pattern selection and Number buttons

9 Mirror image button

10 Elongation/Resize button

11 Double needle/Rotate button

12 Stitch length adjustment/Stitch forward/back button

13 Stitch width adjustment/Colour forward/back button

14 Memory/Setup button

15 Clear/Return button

16 Pattern group selection/Colour setup button

22

Note

The icon on the button is for sewing mode, and the icon on

the side of the button is for embroidery mode.

Page 25

1

21

20

18

19

2

4

8

15

22

5

11

7

10

6

9

3

17

16

1413

12

24

23

502020.83.11_2013_06_bernette chicago 7_EN

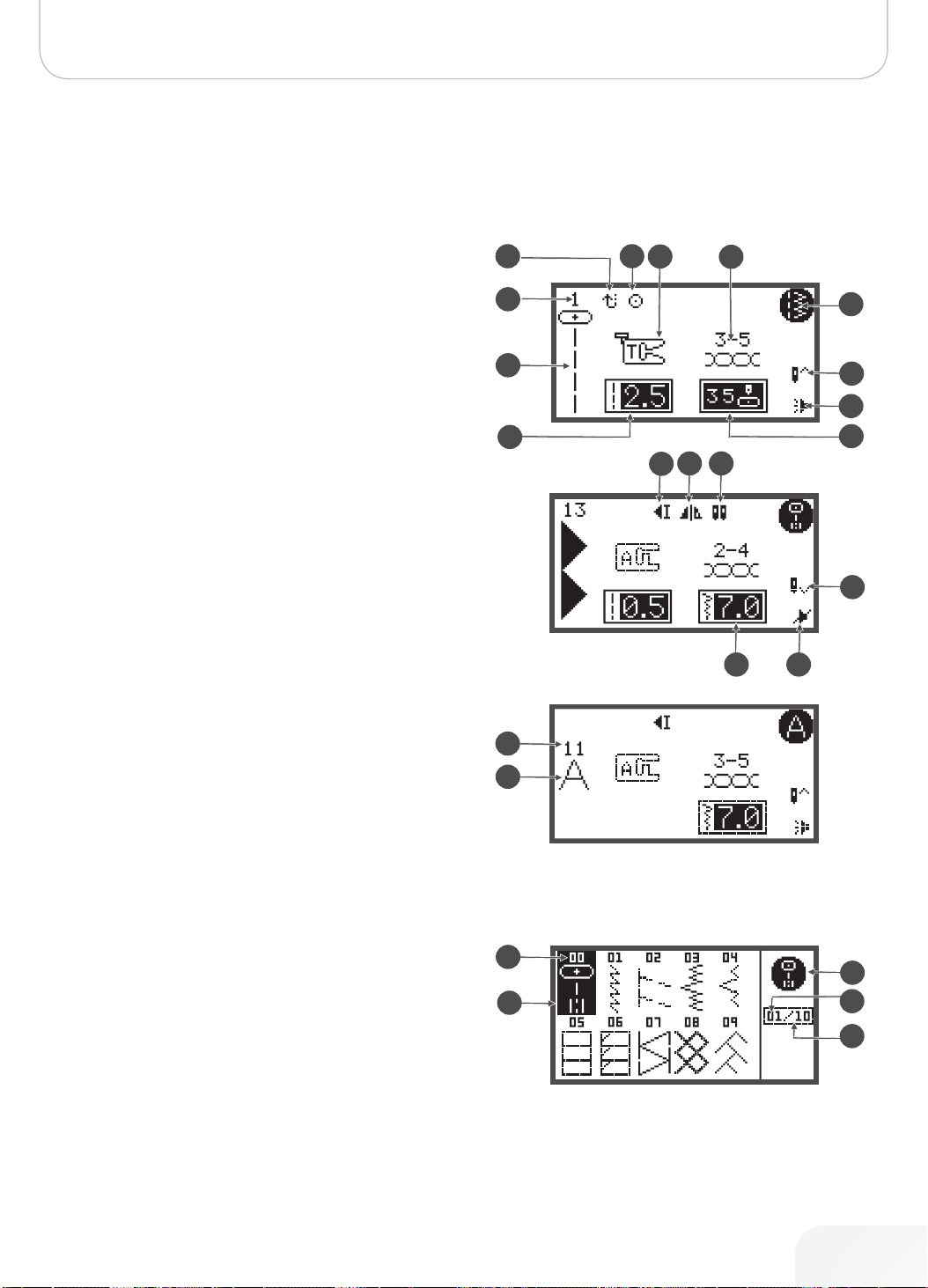

Information on the LCD Display

Normal Mode

Normal mode display

1 Pattern

2 Pattern number

3 Reverse

4 Auto-lock

5 Recommended presser foot

6 Recommended tension

7 Pattern group

8 Needle up position

9 Stitch length

10 Needle position

11 Sound on

12 Auto-stop

13 Mirror image

14 Double needle

15 Needle down position

16 Stitch width

17 Sound off

18 Alphabet number

19 Alphabet

Display Explanation & Operating Functions

Normal Mode display - pattern browser display

20 Pattern

21 Pattern number

22 Pattern group

23 Current page

24 Total page

23

Page 26

Display Explanation & Operating Functions

13

14

15

18

17

9

11

19

10

4

2

12

16

7

8

6

5

21

22

20

1

3

502020.83.11_2013_06_bernette chicago 7_EN

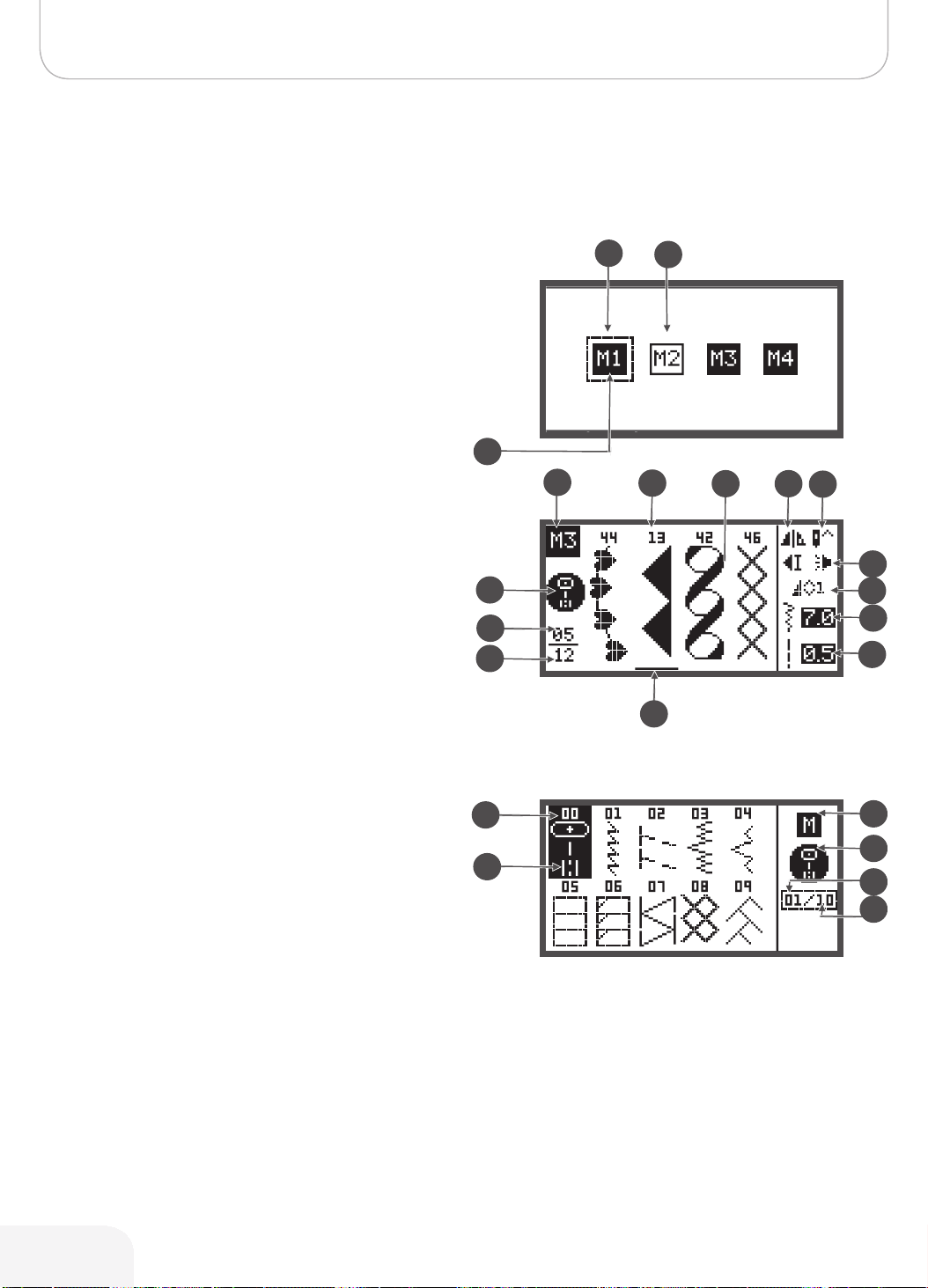

Memory Mode

Memory mode display

1 Selected memory (framed)

2 Memory containing stitches

3 Empty memory

4 Current memory

5 Pattern number and pattern

6 Auto-stop

7 Mirror image

8 Needle up position

9 Sound on

10 Elongation

11 Stitch width

12 Stitch length

13 Pattern group

14 Current memory unit

15 Total of memory units

16 Memory cursor

Memory Mode display - pattern browser display

17 Pattern

18 Pattern number

19 Memory model

20 Pattern group

21 Current page

22 Total page

24

Page 27

1 2 3

6

7

4

18

20

5

13

9

8

12

11

10

19

17

16

15

14

502020.83.11_2013_06_bernette chicago 7_EN

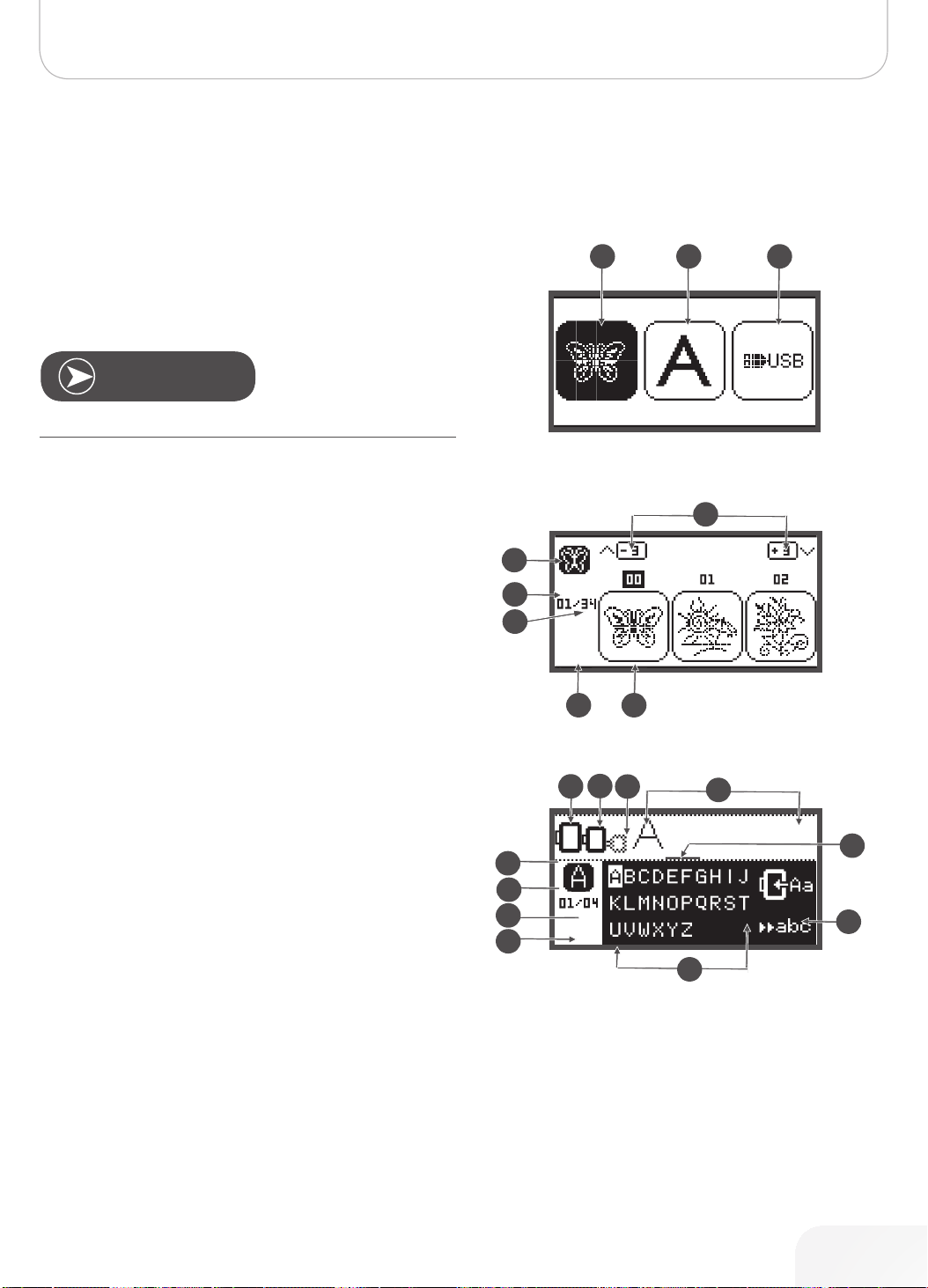

Embroidery Mode

Embroidery mode display - type selection display

1 Built-in Embroidery Designs

2 Built-in Embroidery Letters

3 Designs from USB

Note

This embroidery machine reads .exp format only

Embroidery mode display - type selection display

4 Type mode

5 Indication - select page up/down

6 Current design

7 Total design

8 Operation indication

9 Embroidery design number and design

Display Explanation & Operating Functions

Embroidery mode display - Built-in Embroidery letters

10 Embroidery hoop size L-110*170mm

11 Embroidery hoop size M-100*100mm

12 Embroidery hoop size S-40*40mm* While the hoop

icon is flashing the is adjusting the size or the current

size will change.

13 Editing area

14 Cursor

15

16 Current page

17 Total page

18 Operation indication

19 Embroidery letters

20 Letter type font

25

Page 28

Display Explanation & Operating Functions

502020.83.11_2013_06_bernette chicago 7_EN

Function Buttons

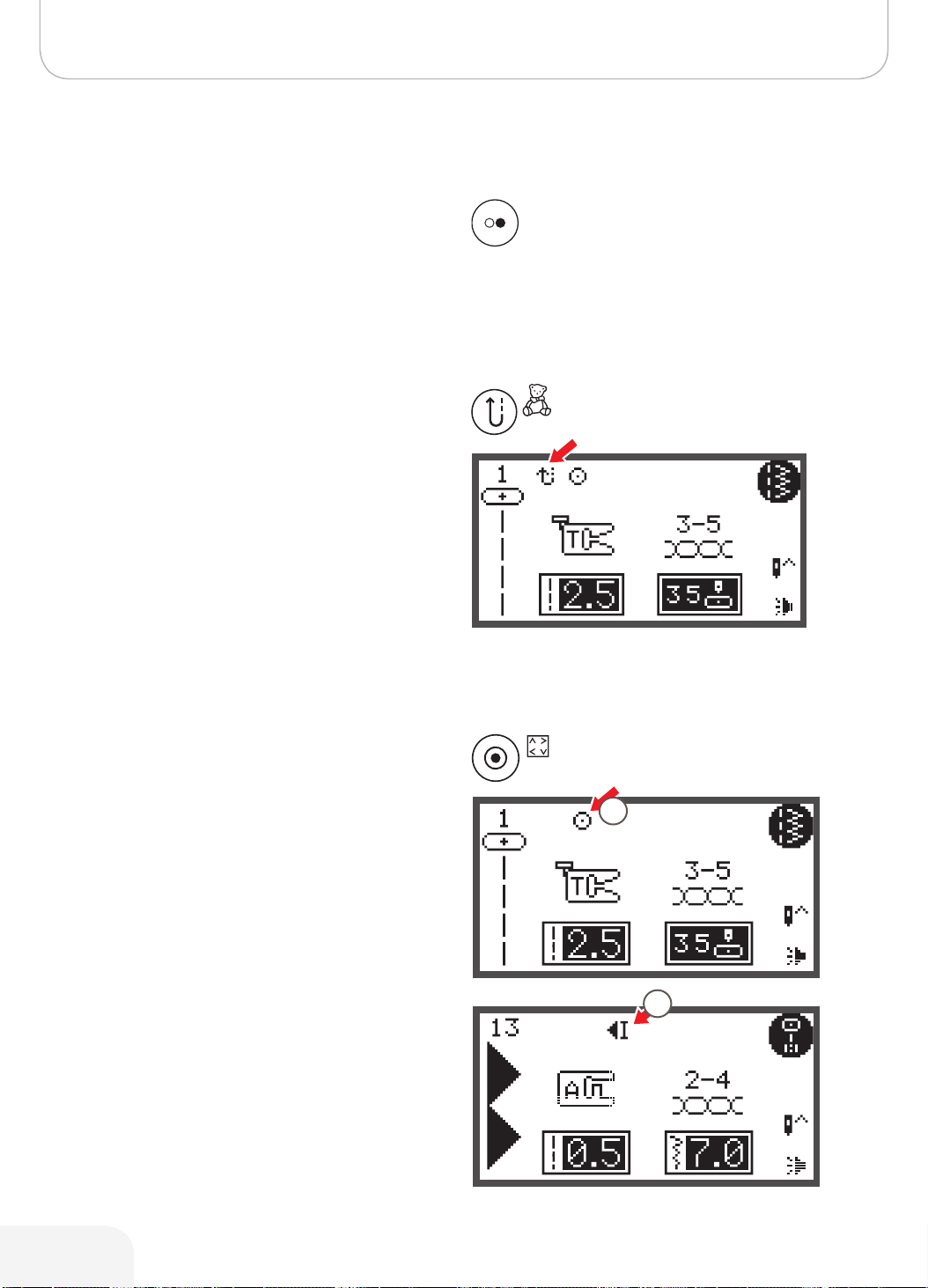

Start/Stop button

• Press the Start/Stop button to start the machine. Press

again to stop it. The machine will move slowly at the

start of sewing.

– This way you may operate the machine without foot

control.

Reverse/Exit button

Reverse is pressed to sew in reverse.

The icon «Reverse» on the LCD indicates reverse sewing.

Only the Direct Group Patterns 1 – 5 and A Group Patterns

00 can be sewn in reverse.

• If you press the Reverse/Exit button before starting to

sew

– the machine will permanently sew in reverse. Press

the button again to sew forward.

• If you press the reverse button during sewing

– it will sew in reverse as long as the reverse buttons

is pressed.

In Embroidery Mode press this button to return to the type

selection display, the selected pattern is canceled.

Auto-Lock/Trace button

When the Direct Group Patterns 0 and A Group Patterns

13-26 are selected, the machine will immediately sew 3

securing stitches when the Auto-Lock button is pressed, then

it will stop automatically.

1 The LCD display shows the symbol until the machine is

stopped.

Except for Direct Group Pattern 0 and A Group Patterns

13-26, press the Auto-Lock button, the machine will sew 3

securing stitches at the end of the current pattern and then

stop automatically.

2 The LCD display shows the symbol until the machine is

stopped.

The function will be cancelled if you press the button once

again or select another pattern.

1

2

26

Page 29

Display Explanation & Operating Functions

502020.83.11_2013_06_bernette chicago 7_EN

Needle up/down button

• By pressing the needle up/down button

– the needle will either stop in the up position or in the

material when stop sewing.

1 Press the button so the arrow on the LCD points

upward

– the needle moves to the highest position and will

stop there after sewing.

2 Press the button so the arrow on the LCD points

downwards

– the needle moves to the lowest position and will

stop there after sewing.

1

2

Note

During sewing, press the needle up/down button, the

machine will stop automatically.

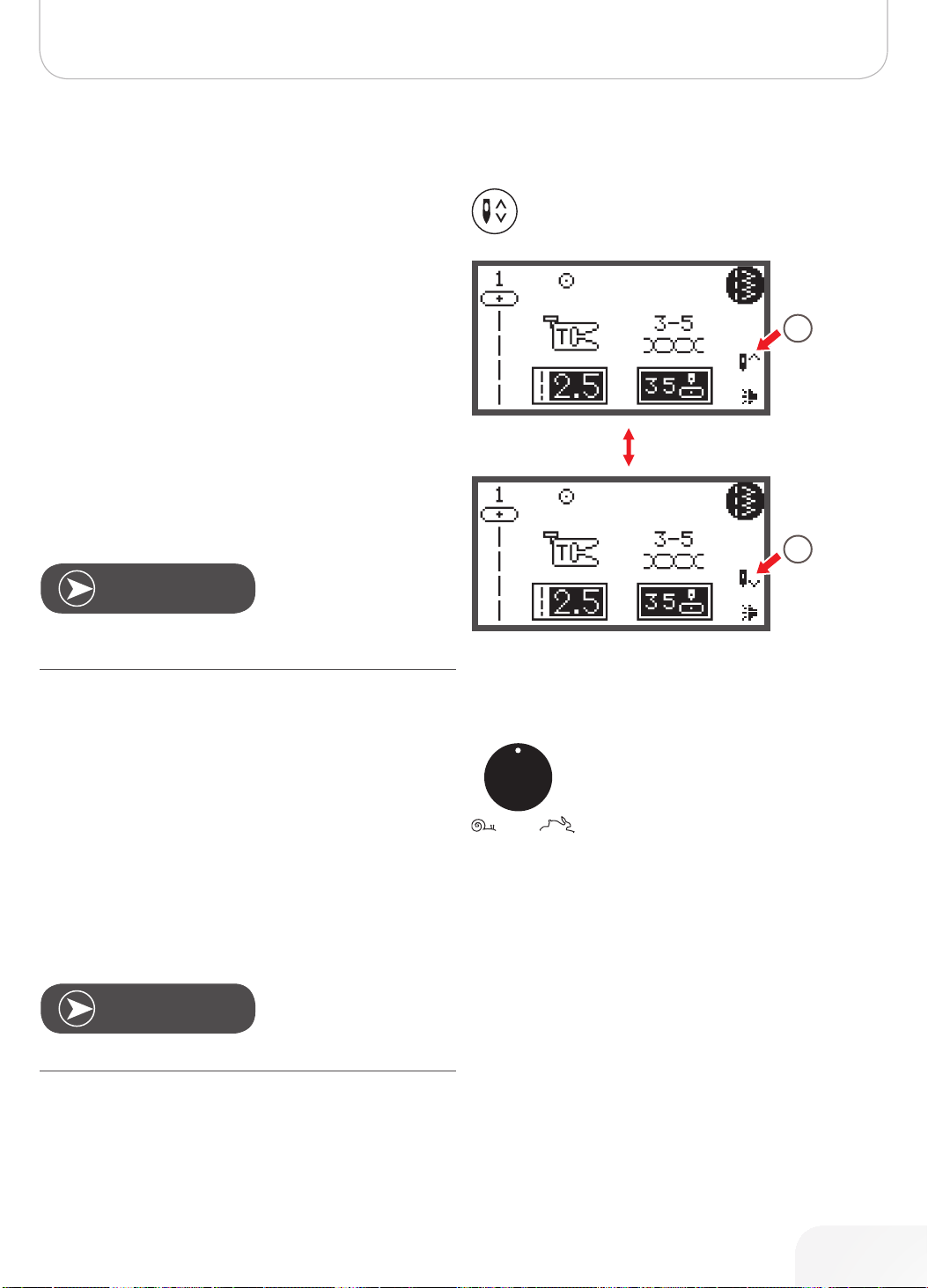

Speed Dial

• By adjusting the position of the speed dial

– the top speed during sewing may be limited.

The position of the speed dial defines the sewing speed when

the foot control is pressed down completely.

• For higher speed: Turn the dial clockwise

• For slower speed: Tu r n the dial counter-clockwise

When the machine is run via the Start/Stop button the position of the speed dial defines the actual sewing speed.

Note

Speed setting is applied exclusively in sewing mode.

27

Page 30

Display Explanation & Operating Functions

502020.83.11_2013_06_bernette chicago 7_EN

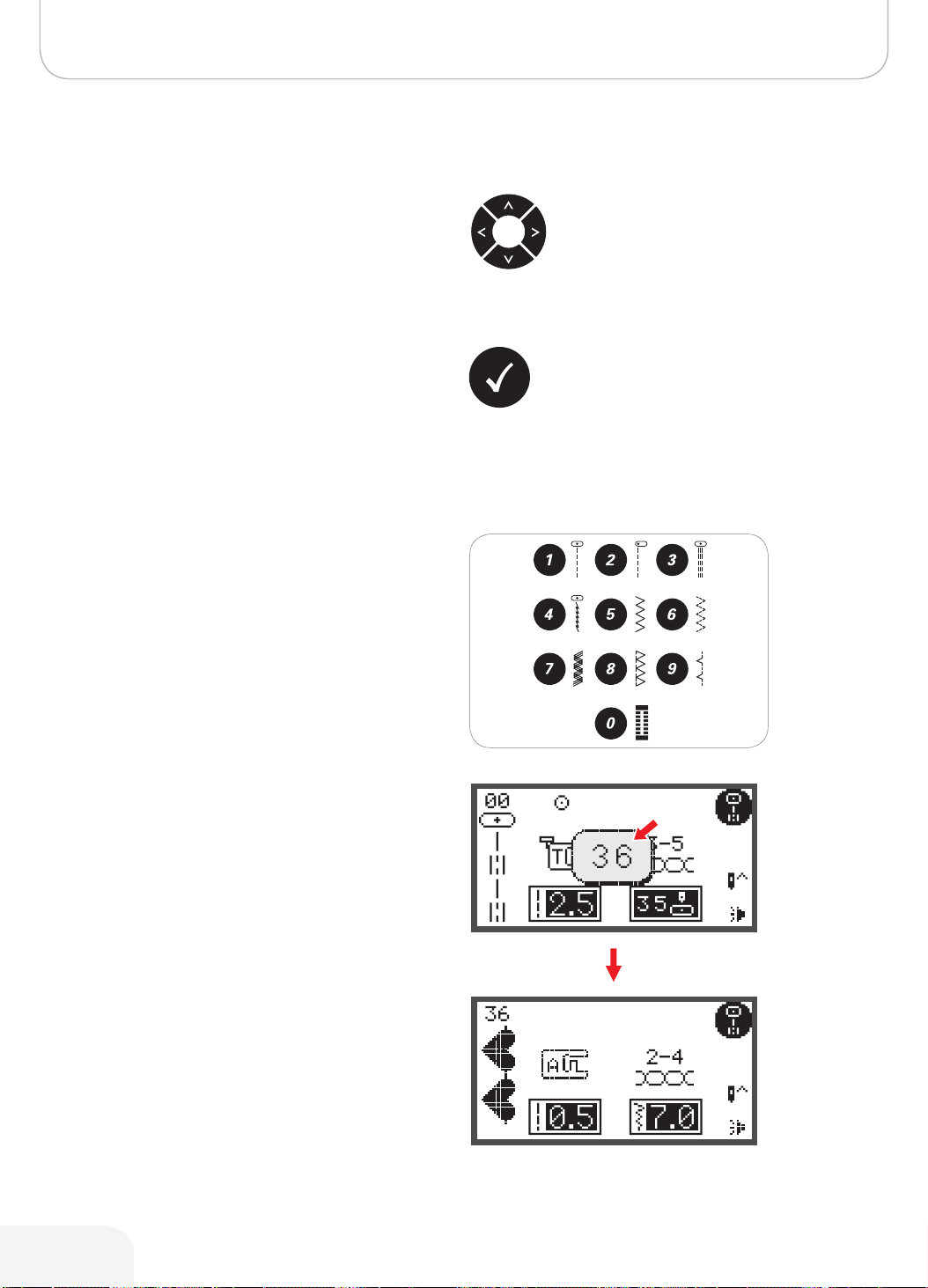

Arrow buttons

Use the buttons to select desired pattern, function… etc.

OK button

• Press this button to confirm the selection.

– In the Normal Mode press the button to enter the

pattern browser.

– In the Memory Mode press the button to enter the

pattern browser.

Direct pattern selection

• Press the buttons to select the practical stitch patterns

shown beside the numbers when the Direct Mode is

set.

Number buttons

• Press the buttons to select the practical stitch patterns

at set Pattern Group directly.

28

Page 31

Display Explanation & Operating Functions

B

A

502020.83.11_2013_06_bernette chicago 7_EN

Mirror image button

• Except for Direct Group Pattern 0 and the A Group

patterns 86-99, the other patterns can be mirrorimaged by pressing the mirror immage button.

– The machine will continue to sew the mirrored pat-

tern until the mirror button is pressed again.

– The mirror function will also be canceled if the pat-

tern is changed.

A Normal pattern

B Mirror-imaged pattern

Elongation/Resize button

• A Group Patterns 13-36 can be elongated up to five

times its normal length by pressing the elongation but-

ton.

When the width or length of the stitch is changed, a greater

variety of patterns is available.

• In Embroidery Mode, press this button to open the

resize display.

Double needle/Rotate button

Except for the Direct Group Patterns 0 and the A Group patterns 86-99, the patterns can be sewn in two parallel lines of

the same stitch using the double needle.

• Press the double needle button and the machine auto-

matically reduces the maximum width for double needle sewing.

• Press the button again to return to single needle sew-

ing.

• In Embroidery Mode, press this button to rotate the

embroidery design.

29

Page 32

Display Explanation & Operating Functions

502020.83.11_2013_06_bernette chicago 7_EN

Stitch length adjustment/ Stitch forward/backward button

When you select a stitch, the machine will automatically set

the recommended stitch length which will be indicated by

numbers on the LCD display.

• The stitch length can be altered by pressing the stitch

length adjustment button.

• To shorten the stitch length, press the «-» button (left).

For a longer stitch length, press the «+» button (right).

The stitch length can be altered from «0.0 to 4.5». Certain stitches have a limited stitch length.

• In Embroidery Mode, press this button to move forward

or backward within the design stitch by stitch.

Stitch width adjustment/ Colour forward/backward button

When selecting a stitch, the machine will automatically set the

recommended stitch width, which will be indicated by numbers on the LCD display.

• The stitch width can be regulated by pressing the stitch

width adjustment button.

• For a narrower stitch, press the button left.

• For a wider stitch, press the button right.

– The stitch width can be altered from «0.0 to 7.0».

Certain stiches have a limited stitch width.

When Direct Patterns 1-4 and A Group Pattern 00 are

selected, the needle position is regulated by the stitch width

adjustment buttons.

• Press the button left and the needle moves to the left.

• Press the button right and the needle moves to the

right.

– The number will be changed from left position «0.0»

to extreme right position «7.0».

– The pre-set center needle position will be indicated

as «3.5».

• In Embroidery Mode, press this button to move forward

or backward in the colour part.

30

Page 33

Display Explanation & Operating Functions

502020.83.11_2013_06_bernette chicago 7_EN

Memory/Setup button

• Press the memory button to enter the Memory Mode

and program the combinations of characters or decorative stitches.

– The Direct Group Patterns and the A Group pat-

terns 86-99 can’t be programed.

• In Embroidery Mode, press this button to enter the set-

ting program.

Clear/Return button

• If an incorrect pattern or memory file is selected, press

this button to clear it or to return to the previous display.

Pattern group selection/Colour setup button

The LCD display shows the Direct Group Patterns when you

turn on the machine.

• Press the pattern group selection button, the LCD dis-

play enters the pattern group selection display automatically. Use the arrow buttons to select the desired

group of stitches.

• In Embroidery Mode, press this button to set the single

or multi colour for embroidery designs.

– Direct Group Patterns

– A Group Patterns

– B Group Patterns

– C1 Group Patterns: Block Style Alphabet

– C2 Group Patterns: Script Style Alphabet

31

Page 34

Display Explanation & Operating Functions

502020.83.11_2013_06_bernette chicago 7_EN

How to select a stitch

The LCD display shows the Direct Group Patterns when

switching on the machine.

• Press number buttons to select a pattern shown next

to the number buttons or press the pattern group

selection button to select the desired pattern group.

• Use the arrow buttons to select the desired pattern

group and press the OK button.

• Use either the arrow buttons or the number buttons to

select the desired pattern.

• When using the arrow buttons, press the OK button

after the desired stitch was selected to go back to

Sewing Mode.

• When using the number buttons, the machine will

automatically set the stitch and go back to Sewing

Mode.

32

Page 35

Stitches

134 5678902

37 38

41

43 44 45

51 52 53

54 55

46

47

48 49 50

58 59

72

62

63 64

65

66

67 68

69

70 71

60 61

75

74

73

78 79 80 81 82 83 4867

77

85

90 91 92 9386 87 88 89

94

502020.83.11_2013_06_bernette chicago 7_EN

Direct Patterns

A - Group Patterns

Utility stitches

00 02 03 04 05 06 07 08 09 10

01 12

Stitches Overview

11

Satin stitches

Decorative Satin

stitches

Cross stitches

Quilt stitches

Decorative stitches

Buttonhole stitches

13

14

56 57

16 17 18

15

39 40

19 20 21 22 23 24 25 26

42

29 30 31 32 33 34 35 362827

Bar tack stitches

33

Page 36

Stitches Overview

9989

502020.83.11_2013_06_bernette chicago 7_EN

A - Group Patterns

Eyelet stitches

Button sewing

stitches

Darning stitches

B - Group Patterns

Decorative stitches

6959

79

00 02 03 04 05 06 07 08 09 10

01

12 13 14 15 16 17 18 19 20 21 22 23 24

11

25

30 32

3126 27 28 29

52 54 55 56 57 58 5953

78 79 80 81 82 83 84

33 34 35 36 37 38 39

60 62 63 64 65 66 67 68 69 70

61

85

86 87 88 89

41 42 43 44 45 46 47 48 49 50 51

40

73 74 75 76 77

72

71

92 93 94 95 96 97 98 99

9190

34

Page 37

502020.83.11_2013_06_bernette chicago 7_EN

C - Group Patterns

C1 Group Patterns:

Block Style Alphabet

C2 Group Patterns:

Script Style Alphabet

Stitches Overview

35

Page 38

Basic Sewing Procedures

1

2

3

4

5

502020.83.11_2013_06_bernette chicago 7_EN

Reverse

Reverse stitching is used to secure the threads at the beginning and at the end of a seam.

• Press the reverse button and sew 4-5 stitches.

– The machine will sew forward when the button is

released.

Free arm

Free-arm sewing is convenient for sewing tubular areas such

as pant hems and cuffs.

Sewing corners

1 Stop the sewing machine when you reach a corner.

2 Lower the needle into the fabric manually or by press-

ing the needle up/ down button once.

3 Raise the presser foot.

4 Use the needle as a pivot and turn the fabric.

5 Lower the presser foot and resume sewing.

36

Page 39

A

502020.83.11_2013_06_bernette chicago 7_EN

Sewing on the heavy fabric

The black button on the left side of the presser foot will lock

the presser foot in a horizontal position if you push it in before

lowering the presser foot. This ensures even feeding at the

beginning of a seam and helps when sewing multiple layers of

fabric such as sewing over seams when hemming jeans.

When you reach the point of an increased thickness, lower

the needle and raise the presser foot.

• Press the toe of the foot and push in the black button,

then lower the foot and continue sewing.

The black button releases automatically after sewing few

stitches.

You can also place another piece of fabric with the same

thickness at the back of the seam. Or support the presser

foot while feeding by hand and sewing towards the folded

side.

Basic Sewing Procedures

A Cardboard or thick fabric

37

Page 40

Basic Sewing Procedures

4 A-0012

3

4 A-0012

3

4 A-0012

3

56

7

502020.83.11_2013_06_bernette chicago 7_EN

Straight Stitches and Needle Position

Changing the needle position

These settings apply to the Direct Group Pattern 1-4 and the

A Group Pattern 00 only.

The pre-set position is «3.5», center position.

• Press the stitch width button to enter the stitch width

adjustment mode.

• When you turn the selector wheel counter-clock-

wise, the needle position will move to the left.

• When you turn the selector wheel clockwise, the

needle position will move to the right.

Altering the stitch length

• Press the stitch length button to enter the stitch length

adjustment mode.

• To shorten the stitch length, turn the selector

wheel counter-clockwise.

• For a longer stitch length, turn the selector wheel

clockwise.

In general, the thicker the fabric, thread and needle, the longer

the stitch should be.

Zig-zag Stitches

3

4 A-0012

Altering the stitch width

The maximum zig-zag stitch width for zig-zag stitching is

«7.0»; however, the width can be reduced with any patterns.

• Press the stitch width button to enter the stitch width

adjustment mode,

– the stitch width can be altered from «0.0 to

7.0mm».

Altering the stitch length

The density of zig-zag stitches increase- as the setting of

stitch length approaches «0.3».

Neat zig-zag stitches are usually achieved at «1.0-2.5».

Closed up zig-zag stitches (close together) look like satin

stitches.

56

7

38

Page 41

1

2

34

7

1

2

34

7

1

2

34

7

502020.83.11_2013_06_bernette chicago 7_EN

Triple Straight Stretch Stitch

Basic Sewing Procedures

The triple straight stretch stitch is strong and flexible and

ensures a durable seam without breaking.

Suitable for highly elastic and knit fabrics but also for heavy

fabrics such as denim.

These stitches can also be used as a decorative top stitching.

The triple straight stretch stitch is used to add triple reinforcement to stretch and hardwearing seams.

1 Triple straight stretch stitch

2 Straight stitch

The triple zig-zag stretch stitch is suitable for firm fabrics like

denim, poplin, duck, etc.

34

7

39

Page 42

Basic Sewing Procedures

2.5~4.52.0-3.0

6 A-02

2.5~4.52.0-3.0

6 A-02

2.5~4.52.0-3.0

502020.83.11_2013_06_bernette chicago 7_EN

Overlock Stitches

Change the presser foot to the overlock foot (E).

Sew the fabric with the fabric edge against the guide of the

overlock foot.

AtteNtioN!

The overlock foot should be used to sew with Direct Group

Patterns 5 and 8 only. Do not set the stitch width narrower

than «5.0». It is possible that the needle could hit the presser

foot and break when sewing other patterns and width.

Using the All- purpose foot

Change the presser foot to the All-purpose foot (T).

When sewing the overlock using the All-purpose foot, sew

along the edge of the fabric so that the needle drops over the

edge of the fabric on the right side.

6 A-02

2.5~4.52.0-3.0

40

Page 43

A

B

A

a

b

B

A

a

b

B

A

a

b

B

502020.83.11_2013_06_bernette chicago 7_EN

Blind Hem

9 : Blind hem/ lingerie for firm fabrics

A-03 : Blind hem for stretch fabrics

A-04 : Blind hem for stretch fabrics

Fold the fabric as illustrated with the wrong side up.

First perform an overlock stitch as shown in left picture.

Note

It takes practice to sew blind hem. Always sew a test

sample first.

Basic Sewing Procedures

• Place the fabric under the foot.

• Turn the handwheel forward manually until the needle

swings fully to the left.

– It should just pierce the fold of the fabric.

• If it does not, adjust the stitch width accordingly.

• Adjust the guide (b) by turning the knob (a) so that the

guide just rests against the fold.

• Sew slowly, guiding the fabric carefully along the edge

of the guide.

A Wrong side of the fabric

B Right side of the fabric

• Sew slowly, guiding the fabric carefully along the edge

of the guide.

• Turn over the fabric.

41

Page 44

Basic Sewing Procedures

b

b

a

a

b

b

a

a

b

b

a

a

b

a

b

a

502020.83.11_2013_06_bernette chicago 7_EN

Button Sewing-on

Change the presser foot to the button sewing-on foot.

• Move the feed dog control to lower the feed dog (b).

• Position the work under the foot.

• Place the button in the desired position, lower the foot.

• Select zig-zag pattern.

• Adjust the stitch width to «2.5-4.5» according to the

distance between the two holes of the button.

• Turn the handwheel to check that the needle goes

cleanly into the left and right holes of the button.

• Before sewing, press the Auto-lock button to sew

securing stitches automatically at the beginning and at

the end of the stitch.

• If a shank is required, place a darning needle on top of

the button and sew.

• For buttons with 4 holes, sew the front two holes first,

push the work forward and then sew the back two

holes.

Note

After having finished the work

42

Page 45

0

A-87

A-91

A-92

A-93

A-90

A-86

A-88

A-89

2.5~7.00.3~1.0

2.5~5.5

5.5~7.0

3.0~7.01.0~2.0

3.0~7.01.0~3.0

0.3~1.0

0.3~1.0

DD

0

A-87

A-91

A-92

A-93

A-90

A-86

A-88

A-89

2.5~7.00.3~1.0

2.5~5.5

5.5~7.0

3.0~7.01.0~2.0

3.0~7.01.0~3.0

0.3~1.0

0.3~1.0

DD

0

A-87

A-91

A-92

A-93

A-90

A-86

A-88

A-89

2.5~7.00.3~1.0

2.5~5.5

5.5~7.0

3.0~7.01.0~2.0

3.0~7.01.0~3.0

0.3~1.0

0.3~1.0

DD

A

502020.83.11_2013_06_bernette chicago 7_EN

Buttonhole Stitching

Basic Sewing Procedures

0 : For thin or medium fabric

A-86 : For thin or medium fabric

A-87 : For suits or overcoats

A-88 : For horizontal buttonholes on thick fabrics

A-89 : For thin or medium fabric

A-90 : For thick coats

A-91 : For jeans or trousers

A-92 : For jeans or stretch fabric with a coarse weave

Note

Before sewing a buttonhole on your project, practice on a

scrap piece of the same type of fabric.

• Mark the positions of the buttonhole on the fabric.

The maximum buttonhole length is 3cm (1 3/16 inch). (Total of

diameter + thickness of button.)

A-86

A-87

A-92

A-93

0

DD

A-88

A-90

A-89

0.3~1.0

A-91

0.3~1.0

2.5~7.00.3~1.0

2.5~5.5

5.5~7.0

3.0~7.01.0~2.0

3.0~7.01.0~3.0

• Attach the buttonhole foot, then pull out the button

• The size of the buttonhole is determined by the button

• The thread should be passed through the hole in the

• Select the buttonhole stitch.

• Adjust the stitch width and the stitch length to the

A Starting point

holder plate and insert the button.

inserted in the button plate.

presser foot, then be placed under the foot.

desired width and density.

43

Page 46

Basic Sewing Procedures

A-87

A-91

A-90

A-92 A-93

A-86 A-88 A-89

0

502020.83.11_2013_06_bernette chicago 7_EN

• Position the fabric under the presser foot so that the

centerline‘s mark is aligned with the center of the buttonhole foot.

• Lower the buttonhole lever.

Note

The buttonhole stitch was selected and the Start/Stop

button was pressed while the buttonhole lever is raised, the

LCD will display the warning massage to remind you to

lower the buttonhole lever.

• Hold the upper thread slightly and start sewing.

Note

Gently feed the fabric by hand. Before stopping, the

machine will automatically sew a securing stitch after the

buttonhole is sewn.

44

Page 47

502020.83.11_2013_06_bernette chicago 7_EN

0

A-86 A-88 A-89

Basic Sewing Procedures

A-87

A-90

A-92 A-93

A-91

Buttonholes are sewn from the front of the presser foot to the back, as shown.

45

Page 48

Basic Sewing Procedures

A-87

A-91

A-90

A-92 A-93

A-86 A-88 A-89

0

A-87

A-91

A-90

A-92 A-93

A-86 A-88 A-89

0

502020.83.11_2013_06_bernette chicago 7_EN

• Raise the presser foot and cut the thread.

• To sew over same buttonhole, raise the presser foot (it

will return to original position).

• After sewing the buttonhole, raise the buttonhole lever

until it stops.

Note

When having finishing and another stitch is selected (other

than the buttonhole, bartack or darning stitch) and the Start/

Stop button is pressed while the buttonhole lever is lowered,

the LCD will display the warning message which reminds

you to raise the buttonhole lever.

• Cut the slit of the buttonhole being careful not to cut

any stitches on either side.

• Use a pin as a stopper at the bartack so you do not cut

too much.

46

Page 49

502020.83.11_2013_06_bernette chicago 7_EN

Buttonholes on stretch fabrics

When sewing buttonholes on stretch fabric, hook a heavy

thread or a cord under the buttonhole foot.

• Attach the buttonhole foot and hook the cord at the

back of the presser foot.

• Bring the two cord ends to the front of the foot and

insert them in the grooves, then temporarily tie them

there. Lower the presser foot and start sewing.

• Set the stitch width to match the diameter of the cord.

• Once the sewing is completed, pull the cord gently to

remove any loose parts, then trim off any excess.

Basic Sewing Procedures

Note

It is recommended to use stabilizer on the backside of the

fabric.

47

Page 50

Basic Sewing Procedures

1.0~3.00.4~1.0

A-94

D

1.0~3.00.4~1.0

A-94

D

A

1.0~3.00.4~1.0

A-94

D

A

1.0~3.00.4~1.0

A-94

D

A

502020.83.11_2013_06_bernette chicago 7_EN

Bartack stitch

A-94

• Extend the button guide plate and set to the desire

bartack length.

• Adjust the stitch width and stitch length to personalize

the stitches.

• Position the fabric so that the needle is 2mm (1/16

inch) in front of the pocket opening and then lower the

presser foot lever.

A Starting point

• Lead the upper thread down through the hole in the

presser foot.

• Pull down the buttonhole lever and position it behind

the bracket on the buttonhole foot.

• Gently hold the end of the upper thread in your left

hand and start sewing.

D

1.0~3.00.4~1.0

Sewing procedure for bartack is illustrated.

This is an example of sewn bartacks at pocket corners.

48

Page 51

A B

C

A

A-95 A-96

A B

C

A

A-95 A-96

A B

C

A

A-95 A-96

502020.83.11_2013_06_bernette chicago 7_EN

Eyelet Stitch

Basic Sewing Procedures

* The eyelet punch tool is not included with the machine.

Select pattern 60 to obtain the eyelet stitch.

Attach the satin stitch foot (A).

• Press the «-» or «+» stitch width adjustment button to

select the eyelet size.

Size of eyelet:

A Small: 5.0mm (3/16 inch)

B Medium: 6.0mm (15/64 inch)

C Large: 7.0mm (1/4 inch)

• Position the needle in the fabric at the beginning of the

stitching, and then lower the presser foot lever.

– Once the sewing is completed, the machine sews

the securing stitches automatically, then stopps.

A-95 A-96

A

• Make a hole at the center using an eyelet punch tool.

Note

If thin thread is used, the stitching may be too loose. If this

occurs, sew the eyelet twice one on top of the other.

49

Page 52

Basic Sewing Procedures

A-98

A-99

E

A-98

A-99

E

A

B

C

D

D

A-98

A-99

E

502020.83.11_2013_06_bernette chicago 7_EN

Darning Stitch

A-98: Simple darning stitch in thin and medium fabrics

A-99: Reinforced darning stitch in heavy fabrics

• Select the A Group Patterns 98 or 99 to obtain the

darning stitch.

• Change to the buttonhole foot.

Baste the upper fabric and the under fabric together.

• Select the needle position.

• Lower the presser foot over the center of the tear.

• Pull the button holder to rear.

• Adjust the button guide plate on the buttonhole foot to

the desired length.

A-98

A-99

E

The size of one darning sequence is variable.

However, the maximum sewing length is 2.6cm (1 inch) and

the maximum sewing width is 7mm (9/32 inch).

A The length of sewing.

B The width of sewing.

C Start

D Stop

50

Page 53

A

B

C

D

D

A-98

A-99

E

502020.83.11_2013_06_bernette chicago 7_EN

Position the fabric so that the needle is 2mm (1/16 inch) in

front of the area to be darned, and then lower the presser

foot.

When lowering the presser foot, do not push the front of the

presser foot, otherwise the darning will not be sewn in the

correct size.

Note

• Lead the upper thread down through the hole in the

presser foot.

• Pull down the buttonhole lever.

• The buttonhole lever is positioned behind the bracket

on the buttonhole foot.

• Gently hold the end of the upper thread in your left

hand, and then start sewing.

Basic Sewing Procedures

Darning stitches are sewn from the front of the presser foot to

the back, as shown.

• If the sewing range is too big to sew,

– then we recommend to sew the area several times

(or cross sew) to get better sewing result.

51

Page 54

Basic Sewing Procedures

502020.83.11_2013_06_bernette chicago 7_EN

Zipper Insertion*

AtteNtioN!

The zipper foot should be used for sewing with center

needle position, straight stitch only. It is possible that the

needle could hit the presser foot and break when sewing

other patterns.

Inserting a centered zipper

Baste the zipper opening on the garment.

• Press open the seam allowance.

• Place the zipper face down on the seam allowance

with the coils against the seam line.

• Baste the zipper tape.

• Attach the zipper foot.

• Attach the right side of the presser foot pin to the

holder when sewing the left side of the zipper.

• Attach the left side of the presser foot pin to the

presser foot holder when sewing the right side of the

zipper.

Stitch the left side of the zipper from top to bottom.

• Stitch across the lower end and right side of the zipper.

• Remove the basting and close the zipper.

52

Page 55

502020.83.11_2013_06_bernette chicago 7_EN

Inserting a side zipper

Baste the zipper opening on the garment.

• Fold seam allowance back to the left.

• Form a 3mm-fold of the right seam allowance.

• Attach the zipper foot.

• Attach the right side of the presser foot pin to the

holder when sewing the left side of the zipper.

• Attach the left side of the presser foot pin to the

presser foot holder when sewing the right side of the

zipper.

Basic Sewing Procedures

Stitch the left side of zipper from the bottom to the top.

• Turn the fabric right side out, stitch across the lower

end and right side of zipper.

• Stop about 5cm (2 inches) from the top of zipper.

• Remove the basting and open the zipper.

• Stitch the remaining seam.

53

Page 56

Basic Sewing Procedures

1.0~3.0 3.5

1

A

1.0~3.0 3.5

1

A

B

A

502020.83.11_2013_06_bernette chicago 7_EN

Invisible zipper insertion

* The invisible zipper foot accessory is optional. It is not included with this machine.

This foot is used to insert invisible zippers so that they are

covered by the seam, and therefore hidden.

• Attach the invisible zipper foot to the machine.

• Adjust needle center position and select the straight

stitch.

– The stitch length depends on the fabric.

• Vary from 1,0 to 3,0mm.

• Place the open zipper face - down on right side of

fabric as shown in the picture.

• Align the fabric edge with the 5/8 inch marking line on

the stitch plate.

• Place the zipper 6mm (1/4 inch) below raw edge of

garment.

• With right-hand groove of the foot over the zipper coils,

sew along the zipper until the foot hits the zipper pull.

• Remove the garment from the machine.

To attach the other half of the zipper, align the fabric edge with

the 5/8 inch marking line on the stitch plate as shown in the

picture.

With the left-hand groove of the foot over the zipper coils, sew

along the zipper until the foot hits the zipper pull.

• Close zipper.

• Fold the fabric that the zipper is on the right hand side

out of the way as shown in the picture.

• Use a pin to fix the fabric.

• Change to the regular sewing foot and sew along the

zipper as closely as possible using straight stitch.

• At last secure with some forward and reverse stitches.

1

1.0~3.0 3.5

A Right side of the fabric

B Wrong side of the fabric

54

Page 57

502020.83.11_2013_06_bernette chicago 7_EN

Narrow Hemming

* The hemmer foot accessory is optional. It is not included with this machine.

• Fold the edge of the fabric over about 3mm, then fold

it over again 3mm for about 5cm along the edge of the

fabric.

• Position the needle in the fold by turning the handwheel

towards you, and lower the presser foot.

• Sew several stitches and raise the presser foot.

• Insert the fabric fold into the spiral opening of the hem-

mer foot.

• Move the fabric back and forth until the fold forms a

scroll shape.

Basic Sewing Procedures

• Lower the presser foot and start sewing slowly guiding

the raw edge of the fabric in front of the hemmer foot

evenly into the opening of the foot.

55

Page 58

Basic Sewing Procedures

N

5

N

5

6 A-09 A-28

N

5

6 A-09 A-28

502020.83.11_2013_06_bernette chicago 7_EN

Cording

* The cording foot accessory is optional. It is not included with this machine.

Sew over one strand of cording to create a pretty swirled

design on a jacket or vest or sew over three strands of cording for border trims. Pearl cotton, knitting yarn, embroidery

floss, lace thread, fine wool or lily yarn can be used for cording.

Single cording

• Mark the design on the fabric. Insert the cord in the

center groove of the cording foot from the right side

opening.

• Pull the cord about 5cm (2 inches) behind the foot.

• The grooves under the foot will hold the length of the

cord in place while the stitches are being formed over

the cord.

• Select the stitch and adjust the stitch width so that the

stitches just cover the cord.

• Lower the foot and sew slowly, guiding the cord over

the design.

5

N

6 A-09 A-28

Triple cording

• Push the sewing thread to the left and insert three

cords into the grooves of the foot and pull about 5cm

(2 inches) of the cords behind the foot.

• Select the desired pattern and adjust the stitch width

so that the stitches just cover the cords. Lower the foot

and sew slowly guiding the cords.

56

Page 59

0.3~2.0

A-15 A-16 A-17 A-18 A-19 A-20 A-21 A-22 A-23 A-24

A-25 A-26 A-27 A-28 A-29

A-30 A31

A-32

A-33

A-34 A-35 A-36

31 - A41 -A

2.5~7.0

5

502020.83.11_2013_06_bernette chicago 7_EN

Satin Stitch Sewing

Basic Sewing Procedures

5

A-15 A-16 A-17 A-18 A-19 A-20 A-21 A-22 A-23 A-24

31 - A41-A

A-25 A-26 A-27 A-28 A-29

A-30 A31

A-32

A-33

A-34 A-35 A-36

Use the satin stitch foot for satin stitching and sewing decorative stitches. This foot has a full indentation on the sole which

allows both easy sewing over the thickness of the stitches

formed by closely spaced zig-zag stitches and even feeding

of the fabric.

• To tailor the satin or decorative stitch pattern, you may

adjust the length and width of the pattern by pressing

the stitch length and width adjustment buttons.

– Experiment with fabric scraps until you get the

desired length and width.

Note

When working with thin fabrics it is recommended to

reinforce the wrong side using a stabilizer.

0.3~2.0

2.5~7.0

57

Page 60

Basic Sewing Procedures

502020.83.11_2013_06_bernette chicago 7_EN

Quilting

* The 1/4“ quilting foot accessory is optional. It is not included with this machine.

Patchwork stitching

Align the edges of the fabric with the inside edge of the guide

on the side of the foot for accurate 1/4“ piercing of the needle.

Note

Only the straight stitch in center position can be used.

The inside of the toes provides an accurate 1/8“ seaming

guide.

The foot has 1/4“ markings both behind the needle and in

front of the needle for accurate pivoting of corners.

Using the edge/quilting guide

• Insert the edge/quilting in the presser foot holder as

illustrated and set the space as you desire.

• Sew the first row and move over the fabric to sew sub-

sequent rows with the guide riding along the previous

row of stitching.

58

Page 61

502020.83.11_2013_06_bernette chicago 7_EN

Hand look quilting

You can imitate the look of a hand look quilt stitch by using

monofilament thread in the needle, 30 or 40 weight cotton

thread in the bobbin, and by increasing the thread tension.

The thread tension depends on the thickness of your batting.

Blanket (Quilting Applique)

For all fabrics and all types of work.

Basic Sewing Procedures

Patchwork stitching

• Place the two pieces of fabric with the right side

together and sew with the straight stitch.

• Open the seam allowance and press it flat.

• Place the center of the presser foot on the seam line of

the joined pieces of fabric and sew over the seam.

59

Page 62

Basic Sewing Procedures

A-11

A

B

A-07

A-11

A-11

502020.83.11_2013_06_bernette chicago 7_EN

Fagoting

Separate the folded edges of the fabric pieces with a gap of

4mm (1/8 inch) and baste them onto a piece of thin paper or

water-soluble stabilizer sheet.

Align the center of the presser foot with the center of the two

pieces of fabric and begin sewing.

After sewing, remove the paper.

A Thin paper

B Basting

Scallop Stitch

• Stitch along the edge of the fabric, making sure not to

sew directly on the edge of the fabric.

– For better results, apply spray starch onto the fabric

• Trim along the stitches.

• Be careful not to cut the stitches.

and press with a hot iron before it is sewn.

A-07

A-11

60

Page 63

3.54.5

1

3.54.5

1

3.54.5

1

502020.83.11_2013_06_bernette chicago 7_EN

Gathering

Basic Sewing Procedures

* The gathering foot accessory is optional. It is not included

with this machine.

Gathered fabric

• Remove the presser foot holder and attach the gather-

ing foot, lowering the tension setting to below 2.

• Place the fabric to be thered under presser foot to the

right of the presser foot.

• Sew a row of stitches, keeping the raw edge of fabric

aligned with the right edge of the foot.

– The stitches make the fabric gather automatically.

– Suitable for light to medium weight fabrics.

To gather and attach gathered fabric in one

step

Look closely at the gathering foot to see a slot on the bottom.

When using the slot, you can gather the bottom layer of the

fabric while attaching it to a flat top layer, such as the waistband on a dress bodice.

• Remove the presser foot holder and attach the gather-

ing foot.

• Place the fabric to be gathered with the right side up

under the foot.

• Place the top layer of the fabric with the right side down

in the slot.

• Guide the two layers as illustrated.

1

3.54.5

Note

When testing the machine for adjustments to achieve

desired density, work with an extra 10“ allowance of the

fabric, trims or elastic.This makes it easier to determine the

necessary adjustments and how much change is needed for

your project. Always test on your project fabric and on the

same grainline which will be used in your finished project.

Using the crossgrain of the fabric will make prettier pleats

than the straight of grain.Sew at slow to medium speed for

better fabric control.

61

Page 64

Basic Sewing Procedures

502020.83.11_2013_06_bernette chicago 7_EN

Smoking

• Adjust the stitch length to 4mm and loosen the thread

tension.

• Use the All-purpose foot to sew straight lines 1cm (3/8

inch) apart from each other, across the area to be

smoked.

• Knot the threads along one edge.

• Pull the bobbin thread and spread the pleats evenly.

Secure the threads at the other end.

• Reduce the tension, if necessary and sew decorative

pattern stitches between the straight seams.

• Pull out the gathering stitches.

62

Page 65

b

b

c

b

a

a

a

b

b

c

b

a

a

a

b

a

b

a

502020.83.11_2013_06_bernette chicago 7_EN

Free Motion Darning, Embroidery and Monogramming

• Move the feed dog control to lower the feed dog (b).

Basic Sewing Procedures

• Remove the presser foot holder, and attach the darning

foot to the presser foot holder bar.

• The lever (a) should be behind the needle clamp screw

(b). Press the darning foot on firmly from behind with

your index finger and tighten the screw (c).

Darning

• First sew around the edges of the hole (to secure the

threads).

• Working from left to right, sew over the hole in a con-

stant and continuous movement.

• Turn the work by 1/4 (90°) and sew over the first stitch-

ing moving the work slowly over the hole to separate

the rows and to avoid big gaps between them.

Note

Free motion darning is accomplished without the internal

feed system of the sewing machine. The movement of the

fabric is controlled by the operator. It is necessary to

coordinate sewing speed and movement of fabric.

63

Page 66

Basic Sewing Procedures

502020.83.11_2013_06_bernette chicago 7_EN

* The embroider hoop is not included with the machine.

Embroidery

• Select the zig-zag stitch pattern and alter the stitch

width as desired.

• Stitch along the outline of the pattern by moving the

embroidery hoop.

– Make sure to maintain a constant speed.

• Fill in the pattern working from the outline towards the

inside.

– Keep the stitches close together.

You will get longer stitches by moving the hoop faster and

shorter stitches by moving the hoop slower.

• Finish with securing stitches at the end by pressing the

Auto-lock button.

Monogramming

• Select the zig-zag stitch pattern and alter the stitch

width as desired.

• Sew at a constant speed, moving the hoop slowly

along the lettering.

• When the letter is finished, finish with securing stitches

at the end by pressing the Auto-lock button.

64

Page 67

a

b

c

a

b

c

502020.83.11_2013_06_bernette chicago 7_EN

Walking Foot

* The walking foot accessory is optional. It is not included with

this machine.