Page 1

Page 2

Table of Contents

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS.............................................................................................. 5

Important information .................................................................................................................... 7

1 My bernette Embroidery................................................................................................................. 8

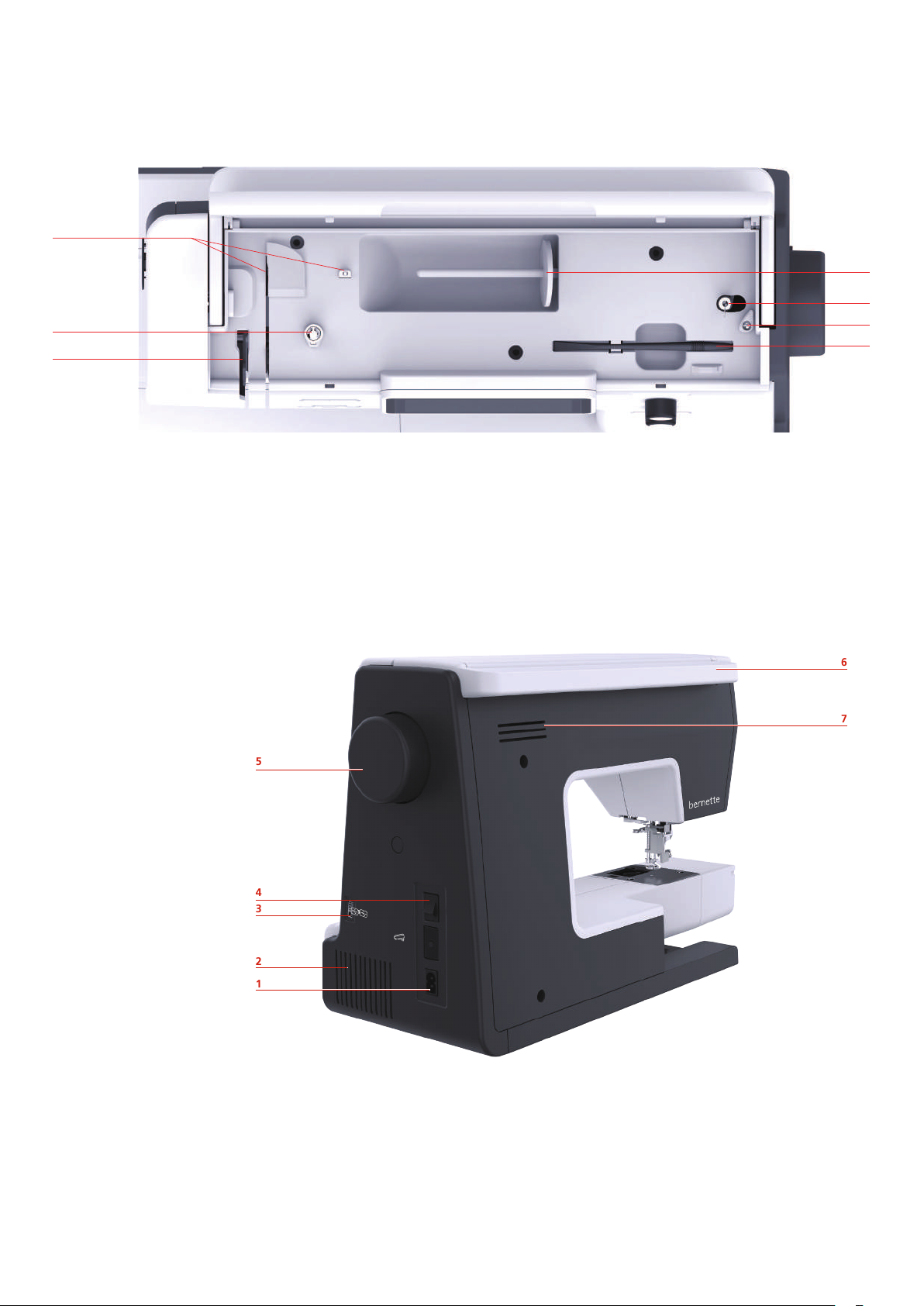

1.1 Overview Machine ................................................................................................................ 8

Overview front controls ..................................................................................................... 8

Overview front .................................................................................................................. 10

Overview top..................................................................................................................... 11

Overview back................................................................................................................... 11

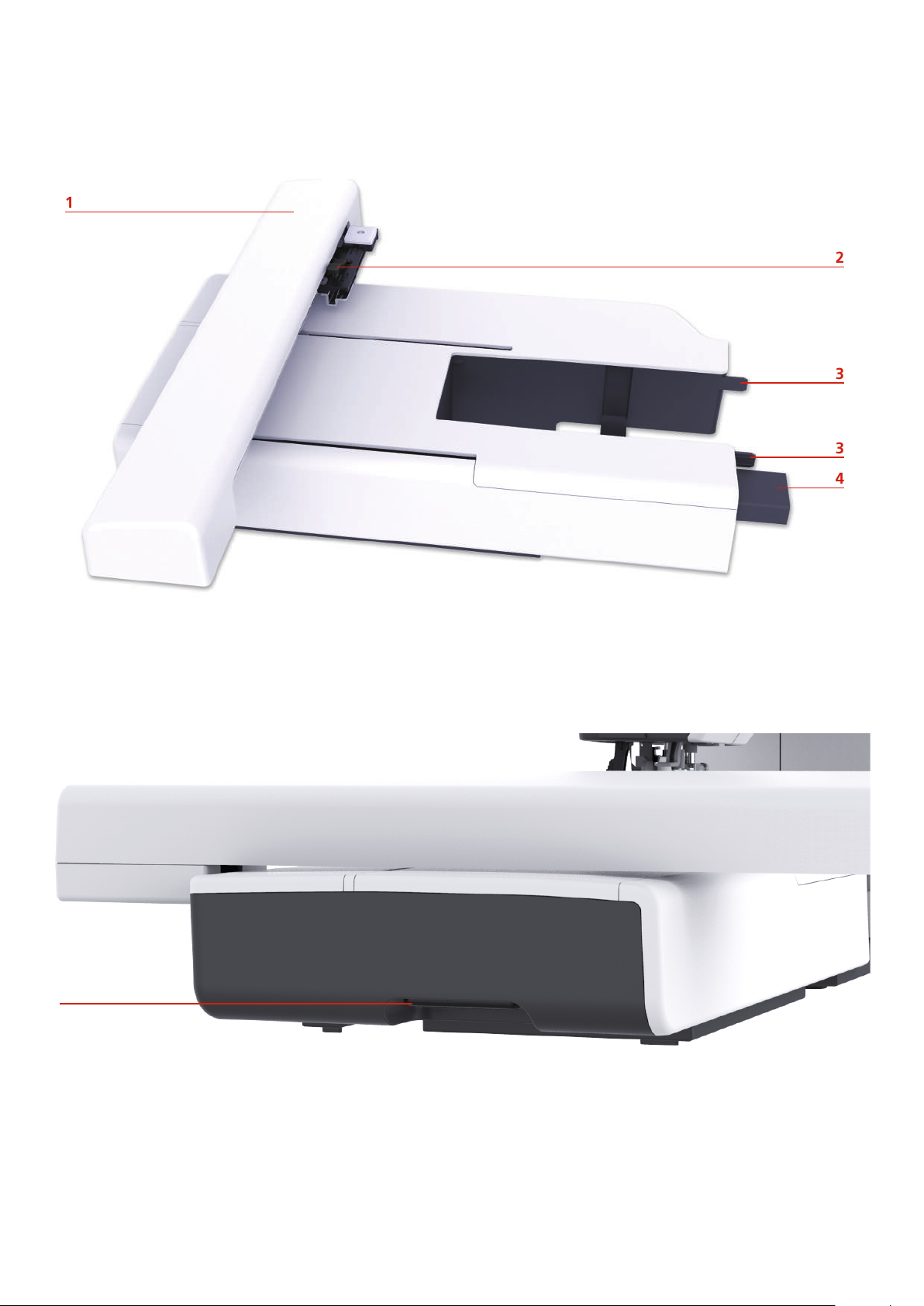

Overview Embroidery module ............................................................................................ 12

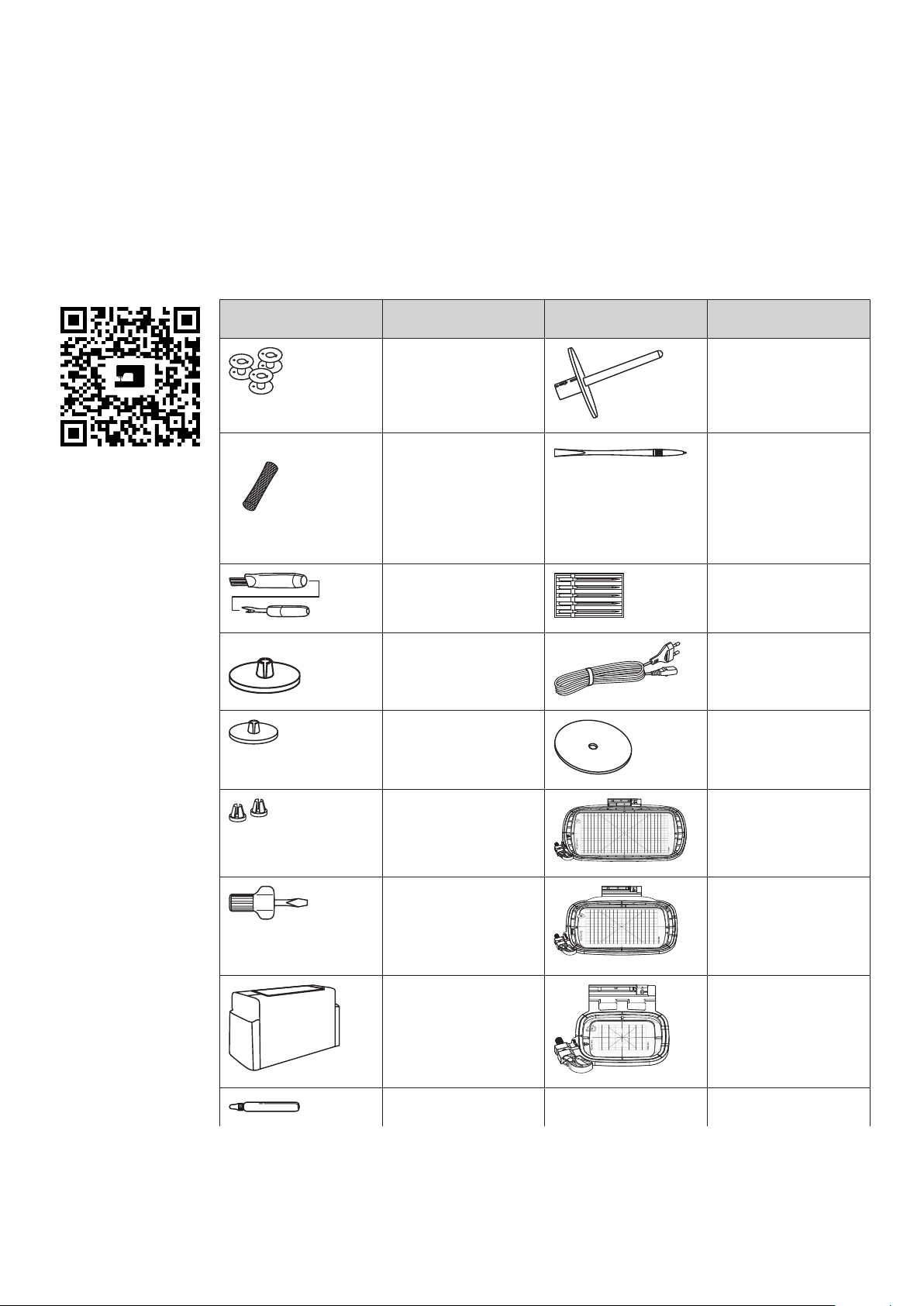

1.2 Accessory.............................................................................................................................. 13

Included accessories .......................................................................................................... 13

Overview presser feet ........................................................................................................ 14

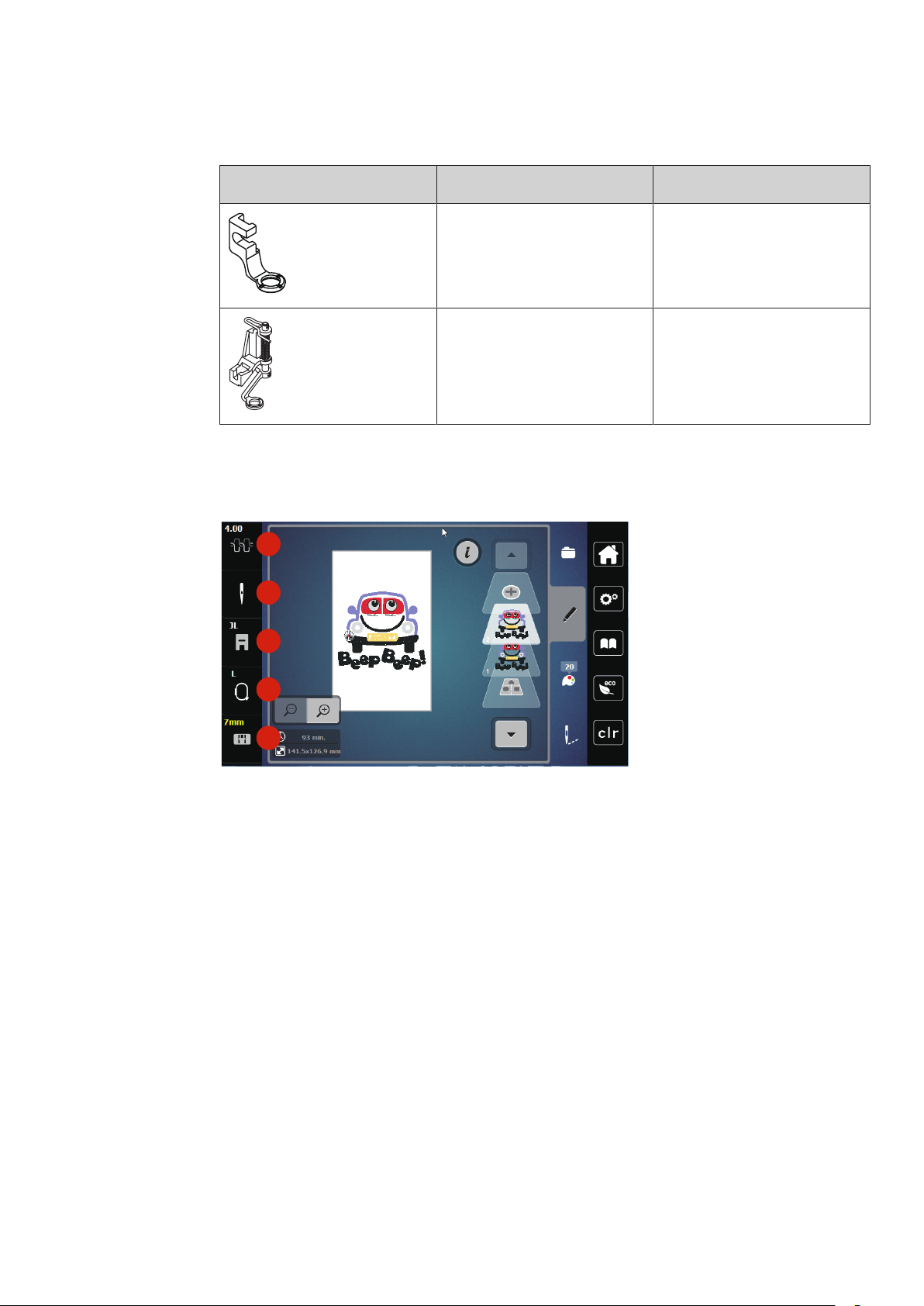

1.3 Overview User Interface ........................................................................................................ 14

Overview functions/visual information ............................................................................... 14

Overview System settings .................................................................................................. 15

Overview Selection menu embroidery ................................................................................ 15

Overview Functions and Views........................................................................................... 15

1.4 Needle, Thread, Fabric........................................................................................................... 17

Overview Needles .............................................................................................................. 17

Example for needle description .......................................................................................... 17

Thread selection ................................................................................................................ 17

Needle/thread combination ............................................................................................... 18

1.5 Important Embroidery information ........................................................................................ 18

Upper thread..................................................................................................................... 18

Bobbin thread ................................................................................................................... 19

Choosing the embroidery motif ......................................................................................... 19

Embroidery test ................................................................................................................. 19

Embroidering motifs by third-party providers ..................................................................... 19

Underlay stitches ............................................................................................................... 20

The size of the embroidery motif ....................................................................................... 20

Satin or Leaf stich .............................................................................................................. 20

Step stitch ......................................................................................................................... 20

Connecting stitches ........................................................................................................... 21

2 Embroidering preparation .............................................................................................................. 22

2.1 Connection and Switching on ............................................................................................... 22

Connecting the machine ................................................................................................... 22

Use of the power cable (only USA/Canada)........................................................................ 22

Switching the machine on ................................................................................................. 22

Fixing the touchscreen pen ................................................................................................ 22

2019-02 EN 5020070.00A.04

2.2 Spool pin .............................................................................................................................. 23

Horizontal spool pin .......................................................................................................... 23

Second spool pin ............................................................................................................... 23

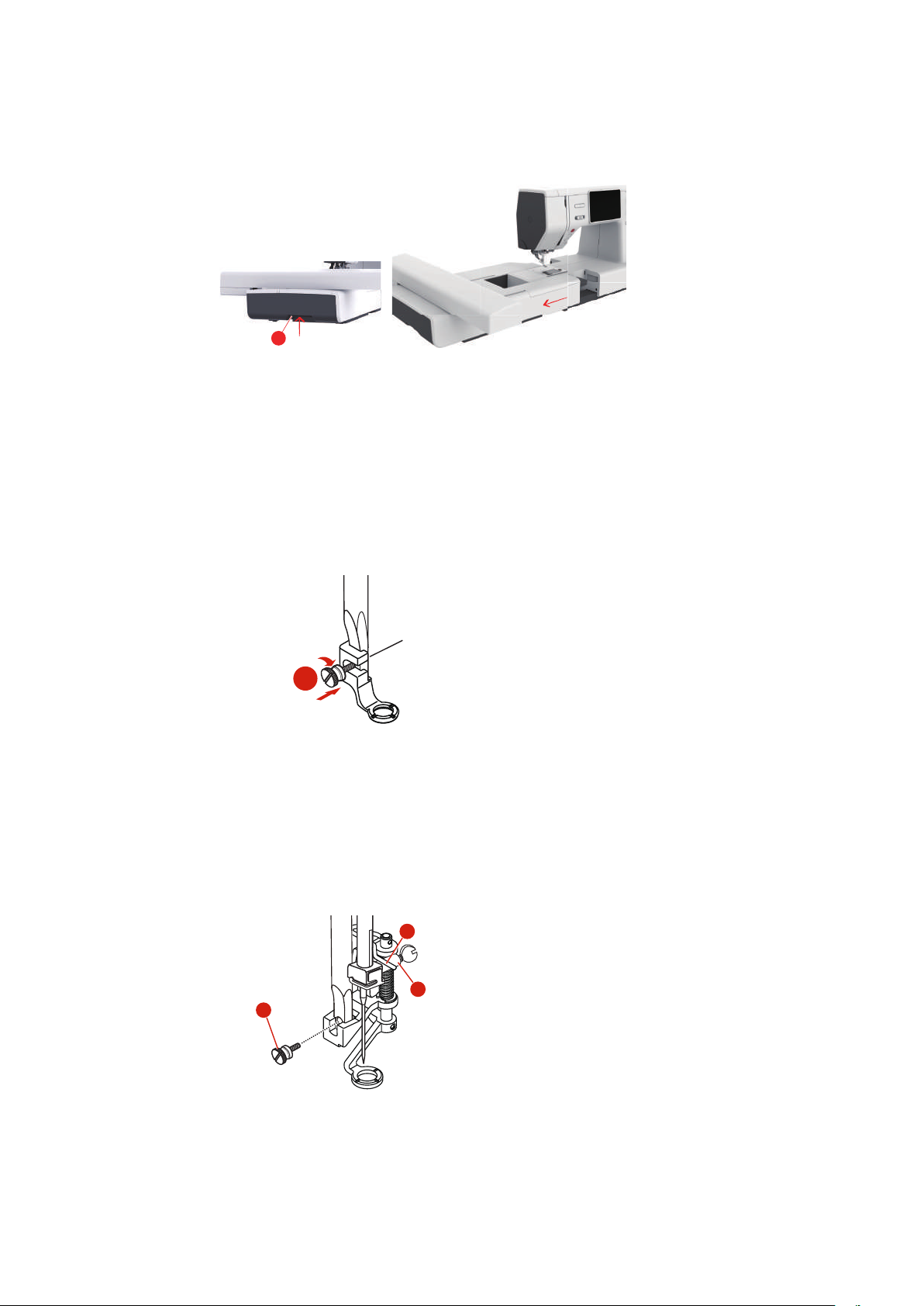

2.3 Attaching the Module ........................................................................................................... 24

2.4 Embroidery foot .................................................................................................................... 25

Attaching the embroidery foot .......................................................................................... 25

1

Page 3

Table of Contents

2.5 Needle .................................................................................................................................. 26

Inserting the embroidery needle ........................................................................................ 26

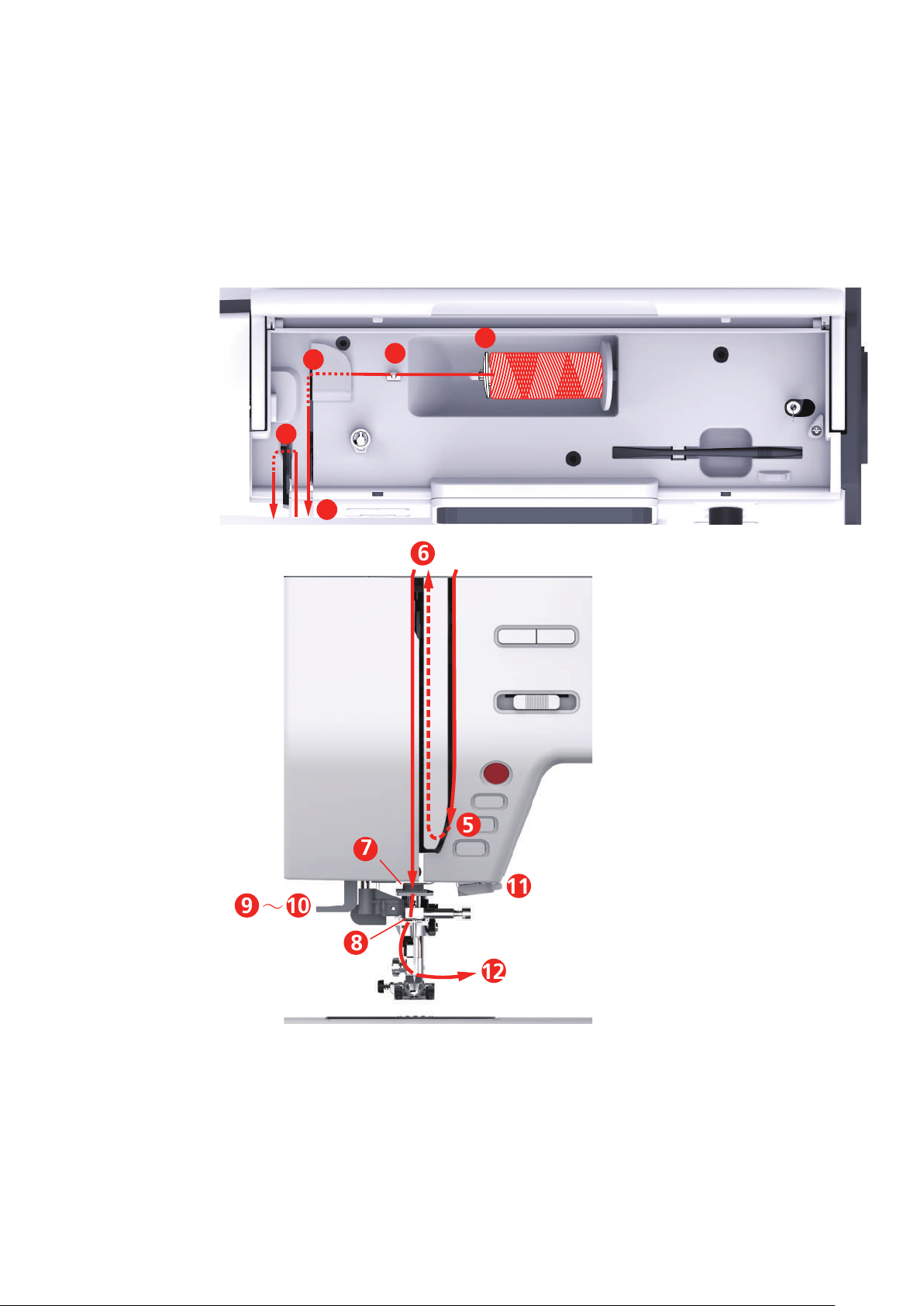

2.6 Threading ............................................................................................................................. 27

Threading preparation ....................................................................................................... 27

Threading the upper thread............................................................................................... 27

Winding the bobbin thread ............................................................................................... 31

Threading the bobbin thread ............................................................................................. 32

2.7 Selecting the embroidery motif ............................................................................................. 34

2.8 Embroidery hoop .................................................................................................................. 34

Overview embroidery hoop selection ................................................................................. 34

Selecting the embroidery hoop .......................................................................................... 35

Tear-away stabilizers.......................................................................................................... 35

Cut-away stabilizers........................................................................................................... 35

Using adhesive spray ......................................................................................................... 35

Using spray starch ............................................................................................................. 35

Using iron-on interfacing ................................................................................................... 36

Using paper-backed adhesive stabilizer .............................................................................. 36

Using water-soluble stabilizer ............................................................................................ 36

Preparing the embroidery hoop ......................................................................................... 36

Attaching the hoop ........................................................................................................... 38

Overview Embroidery functions ......................................................................................... 39

Locating the center of the embroidery motif...................................................................... 39

Center the needle to the embroidery hoop ........................................................................ 39

Embroidery arm return ...................................................................................................... 40

Grid on/off ........................................................................................................................ 40

3 Setup Program ................................................................................................................................. 41

3.1 Embroidery settings............................................................................................................... 41

Adjusting the upper thread tension ................................................................................... 41

Adjusting the maximum embroidering speed..................................................................... 41

Calibrating the embroidery hoop ....................................................................................... 41

Deactivating securing stitches ............................................................................................ 42

Adjusting the thread cut.................................................................................................... 42

Adjusting the height of the embroidery presser foot .......................................................... 43

3.2 Selecting personal settings .................................................................................................... 43

3.3 Monitoring functions ............................................................................................................ 44

Activating the upper thread indicator ................................................................................ 44

Activating the bobbin thread indicator............................................................................... 44

3.4 Sound on/off......................................................................................................................... 44

3.5 Machine settings................................................................................................................... 44

Adjusting the brightness of the display .............................................................................. 44

Calibrating the display ....................................................................................................... 45

Back to basic setting.......................................................................................................... 45

Updating the machine Firmware........................................................................................ 46

Checking the firmware version .......................................................................................... 46

Reviewing the total number of stitches .............................................................................. 46

Selecting a language ......................................................................................................... 47

4 System settings................................................................................................................................ 48

4.1 Calling up the tutorial ........................................................................................................... 48

2

2019-02 EN 5020070.00A.04

Page 4

Table of Contents

4.2 Using eco mode .................................................................................................................... 48

4.3 Cancelling any alterations with «clr» ..................................................................................... 48

5 Creative embroidering .................................................................................................................... 49

5.1 Overview embroidering ......................................................................................................... 49

5.2 Selecting and changing the embroidery motif ....................................................................... 49

5.3 Checking the embroidery time and the embroidery motif size ............................................... 49

5.4 Regulating the speed ............................................................................................................ 49

5.5 Editing the embroidery motif................................................................................................. 50

Overview Editing embroidery motif.................................................................................... 50

Scaling up the embroidery motif view................................................................................ 50

Downsizing the embroidery motif...................................................................................... 50

Moving the embroidery motif view .................................................................................... 51

Moving the embroidery motif in enlarged view.................................................................. 51

Moving the embroidery motif ............................................................................................ 52

Rotating motif ................................................................................................................... 52

Altering the embroidery motif size proportionally .............................................................. 52

Mirroring embroidery motifs.............................................................................................. 53

Checking the size and the position of the embroidery motif .............................................. 53

Deleting an embroidery motif ............................................................................................ 54

5.6 Creating lettering.................................................................................................................. 54

Overview embroidery alphabets......................................................................................... 54

Creating words/sentences.................................................................................................. 54

Editing words/sentences .................................................................................................... 55

Bending the text................................................................................................................ 56

Altering the stitch density .................................................................................................. 56

5.7 Combining embroidery motifs............................................................................................... 56

Combining embroidery motifs ........................................................................................... 56

Deleting a single embroidery motif .................................................................................... 57

5.8 Changing the colors of the embroidery motif ........................................................................ 57

Overview changing the color ............................................................................................. 57

Changing the colors .......................................................................................................... 57

Changing the thread brand ............................................................................................... 58

5.9 Embroidering the embroidery motif....................................................................................... 58

Overview Embroidery menu............................................................................................... 58

Adding basting stitches ..................................................................................................... 59

Moving the hoop............................................................................................................... 59

Embroidery sequence control when thread breaks ............................................................. 59

Cutting connecting stitches ............................................................................................... 60

Multi-colored embroidery motif on/off............................................................................... 60

Color indication................................................................................................................. 61

2019-02 EN 5020070.00A.04

3

Page 5

Table of Contents

5.10 Administering embroidery motifs .......................................................................................... 61

Administering embroidery motifs....................................................................................... 61

Saving embroidery motifs in the personal memory............................................................. 61

Saving the embroidery motif on the USB stick.................................................................... 62

Overwriting the embroidery motif in the personal memory ................................................ 62

Overwriting the embroidery motif in the personal memory ................................................ 62

Loading an embroidery motif from the personal memory................................................... 63

Loading an embroidery motif from the USB stick ............................................................... 63

Deleting an embroidery motif from the personal memory .................................................. 63

Deleting an embroidery motif from the USB stick............................................................... 63

6 Embroidery....................................................................................................................................... 64

6.1 Embroidering via the button «Start/Stop» ............................................................................. 64

6.2 Adjusting the upper thread tension ....................................................................................... 64

7 BERNINA CutWork Tool................................................................................................................... 66

7.1 Changing the CutWork Tool ................................................................................................. 66

7.2 Start to cut............................................................................................................................ 67

8 Attachment ...................................................................................................................................... 68

8.1 Maintencance and cleaning................................................................................................... 68

Cleaning the display .......................................................................................................... 68

Cleaning the hook............................................................................................................. 68

Oiling the needle bar ......................................................................................................... 69

8.2 Troubleshooting.................................................................................................................... 70

8.3 Error messages...................................................................................................................... 73

8.4 Technical data....................................................................................................................... 76

9 Overview stitch patterns ................................................................................................................ 77

9.1 Overview Embroidery motifs.................................................................................................. 77

Editing the embroidery motif ............................................................................................. 77

Embellishment................................................................................................................... 77

Quilt motifs ....................................................................................................................... 80

Borders and Lace ............................................................................................................... 81

Children ............................................................................................................................ 82

Flowers.............................................................................................................................. 84

Seasons ............................................................................................................................. 86

Asia................................................................................................................................... 88

Sport/Hobby ...................................................................................................................... 88

Animals ............................................................................................................................. 91

Cutwork............................................................................................................................ 93

Campaign ......................................................................................................................... 94

Index................................................................................................................................................. 95

4

2019-02 EN 5020070.00A.04

Page 6

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

Please be aware of the following basic safety instructions when using your

machine. Before using this machine, read instruction manual carefully.

DANGER!

To reduce the risk of electrical shock:

• Never leave the machine unattended as long as it is plugged in.

• Always unplug the machine from the electrical outlet immediately after

using.

Protection against LED radiation:

• Do not view the LED light directly with optical instruments (e.g. magnifier).

The LED light corresponds with protection class 1M.

• When the LED light is damaged or defective, contact your bernette specialist

dealer.

WARNING

To reduce the risk of burns, fire, electric shock or injury to persons:

• To operate the machine always use the supplied power cable. USA and

Canada only: Do not connect power plug NEMA 1-15 to circuits exceeding

150 volt-to-ground.

• Use this machine only for purposes as described in this manual.

• Only use the machine in dry rooms.

• Do not use the machine in a damp condition or in a damp environment.

• Do not use this machine as a toy. Close attention is necessary when this

machine is used by or near children.

• The machine can be used by children older than 8 or by people with reduced

physical, sensory or mental capabilities or if there is a lack of experience and

knowledge how to operate the machine as long as they are supervised or

have been given instruction concerning the responsible use of the appliance

and are aware of the involved risks.

2019-02 EN 5020070.00A.04

• Children are not allowed to play with this machine.

• Cleaning and maintencance work must not be carried out by children unless

they are supervised.

• Never operate this machine if it has a damaged cord or plug, if it is not

working properly, if it has been dropped or damaged, or dropped into

water. Contact the nearest authorized bernette dealer to arrange further

details.

5

Page 7

IMPORTANT SAFETY INSTRUCTIONS

• Only use accessory recommended by the manufacturer.

• Don't use this machine when the ventilation openings are blocked. Keep the

• Never insert any objects into any openings of the machine.

• Do not place any objects on the foot control.

• Always use the machine with a foot control of this type -.

• Do not operate the machine where aerosol products (sprays) or oxygen are

• Keep fingers away from all moving parts. Special care is required around the

• Neither pull nor push the fabric while sewing. This can cause needle

• When making any adjustments in the needle area – such as such as

ventilation openings and the foot control free from the accumulation of lint,

dust and loose cloth.

being used.

needle.

breakage.

threading the needle, changing the needle, threading the hook or changing

the presser foot – turn power switch to «0».

• Do not use bent needles.

• Always use the original bernette stitch plate.The wrong stitch plate can

cause needle breakage.

• To disconnect, turn power switch to «0» and then remove the plug from the

outlet. Do not unplug by pulling the cord, instead grasp the plug to pull it

from the outlet.

• Always disconnect the power plug from the electrical outlet when the covers

are removed or opened, when the machine is lubricated or during any other

maintenance adjustments mentioned in the instruction manual.

• This machine is provided with double insulation (except USA, Canada and

Japan). Use only identical replacement parts. See instructions for Servicing of

double-insulated products.

• The sound pressure level is lower than 70dB(A) under normal conditions.

6

2019-02 EN 5020070.00A.04

Page 8

Important information

Important information

Availability of the digital instruction manual

The instruction manual of the machine are provided exclusively as a PDF.

> «www.mybernette.com» in the Internet Browser.

> Select desired machine model.

> Download the instruction manual under «Download».

Appropriate use

Your bernette machine is conceived and designed for private household use. It answers the purpose to quilt

fabrics as it is decribed in this instruction manual. Any other use is not considered appropriate.bernette

assumes no liability concerning consequences resulting from an inappropriate usage.

Servicing of double-insulated products

In a double-insulated product two systems of insulation are provided instead of groanding. No groanding

means is provided on a doubleinsulated product, nor should a means for groanding be added to the

product. Servicing a double-insulated product requires extreme care and knowledge of the system and

should be done only by qualified service personnel. Replacement parts for a double-insulated product must

be identical to the original parts in the product. A double-insulated product is marked with the words:

«Double insulation» or «double-insulated».

The symbol may also be marked on the product.

Environmental Protection

BERNINA is committed to the protection of the environment. We strive to minimize the environmental impact

of our products by continuously improving product design and our technology of manufacturing.

The machine is labeled with the symbol of the crossed-out wastebin. This means that the machine must not

be disposed of with the household waste when the machine is no longer needed. Improper disposal can

result in dangerous substances getting into the groundwater and thus into our food chain, damaging our

health.

The machine must be returned free of charge to a nearby collection point for waste electrical and electronic

equipment or to a collection point for the reuse of the machine. Information on the collection points can be

obtained from your local administration. When purchasing a new machine, the dealer is obliged to take back

the old machine free of charge and dispose of it properly.

If the machine contains personal data, you are responsible for deleting the data yourself before returning the

machine.

2019-02 EN 5020070.00A.04

7

Page 9

My bernette Embroidery

1

2

3

4

5

6

7

8

9

10

1 My bernette Embroidery

1.1 Overview Machine

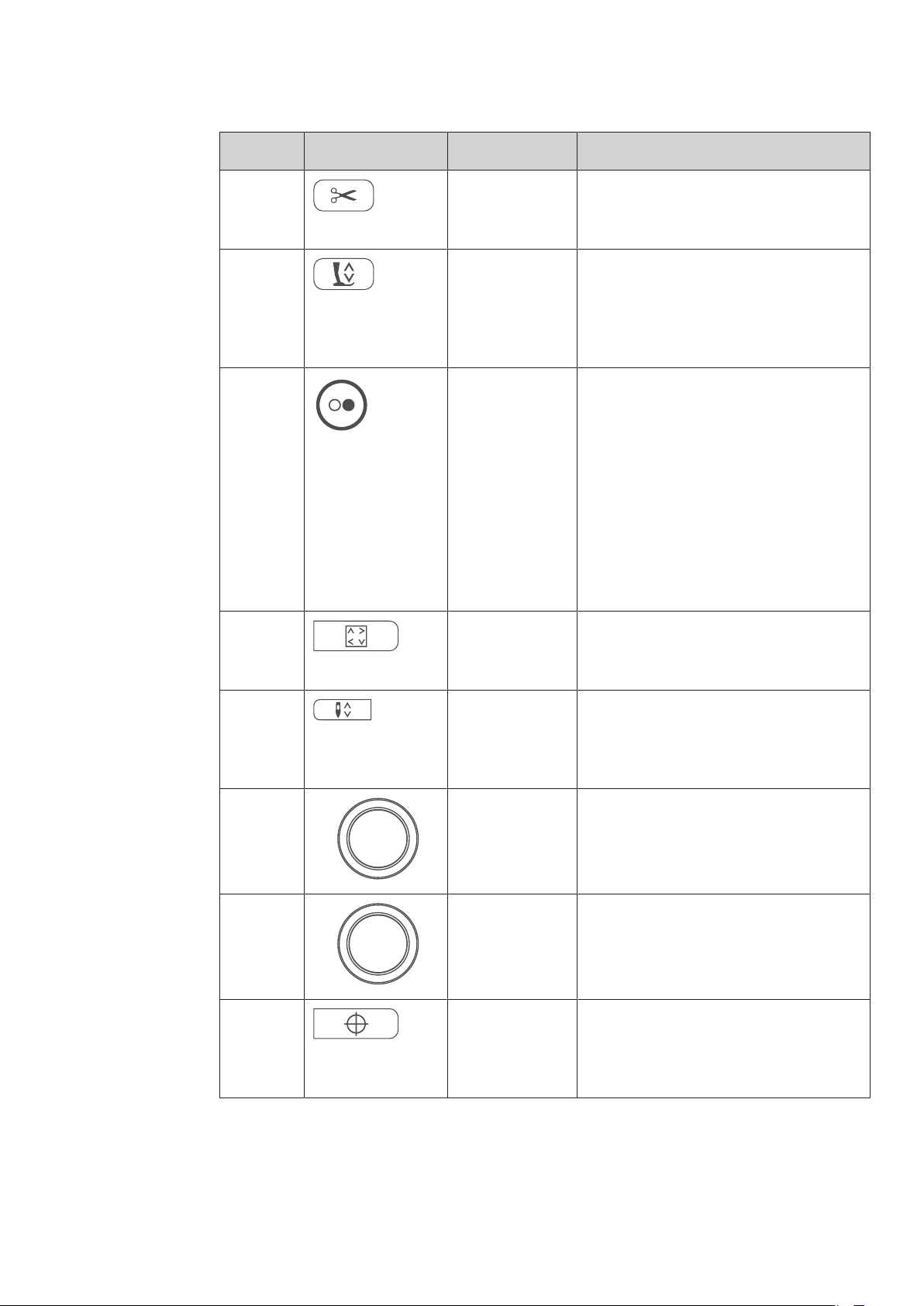

Overview front controls

1 Sewing light 6 Needle up/down

2 Thread cutter 7 Upper Multifunctional knob

3 Presser foot up/down 8 Lower Multifunctional knob

4 Start/Stop 9 Motif center

5 Checking motif size 10 Center the needle to the embroidery hoop

Operation buttons

Number Buttons Name Purpose

1 Sewing light To switch the sewing light on or off, press the

button «Sewing light».

8

2019-02 EN 5020070.00A.04

Page 10

My bernette Embroidery

Number Buttons Name Purpose

2 Thread cutter > Press the «Thread cutter» button in order

to cut the upper and lower threads

automatically.

3 Presser foot up/

down

> Press the button «Presser foot up/down

»to raise the presser foot into hovering

position.

> Push the button «Presser foot up/down»

to raise the presser foot.

4 Start/Stop The button «Start/Stop» serves the purpose

to change the presser foot position and to

start the machine.

> To start the machine, keep the button

«Start/Stop» pressed for 2seconds.

> To bring the presser foot to its highest

position, quickly press «Start/Stop» in the

embroidery mode.

> Press the button «Presser foot up/down»

again to move the presser foot into

hovering position.

5 Checking motif

size

> To position the hoop on the display

according to the needle position, press

the icon «Checking motif size».

6 Needle up/down > Push the button «Needle up/down» to

lower the needle.

> Push the «Needle up/down» button again

to raise the needle.

2019-02 EN 5020070.00A.04

7 Upper

Multifunctional

knob

8 Lower

Multifunctional

knob

With the «Upper Multifunction knob» setting

values can be changed in the embroidering

and the Setup Program.

With the «Lowerr Multifunction knob»

setting values can be changed in the

embroidering and the Setup Program.

9 Motif center > Touch the icon «Center of the embroidery

motif» to position the hoop so that the

needle is placed exactly over the center of

the embroidery motif.

9

Page 11

My bernette Embroidery

2

3

4

6

7

8

9

11

10

1

5

Number Buttons Name Purpose

10 Center the needle

to the embroidery

hoop

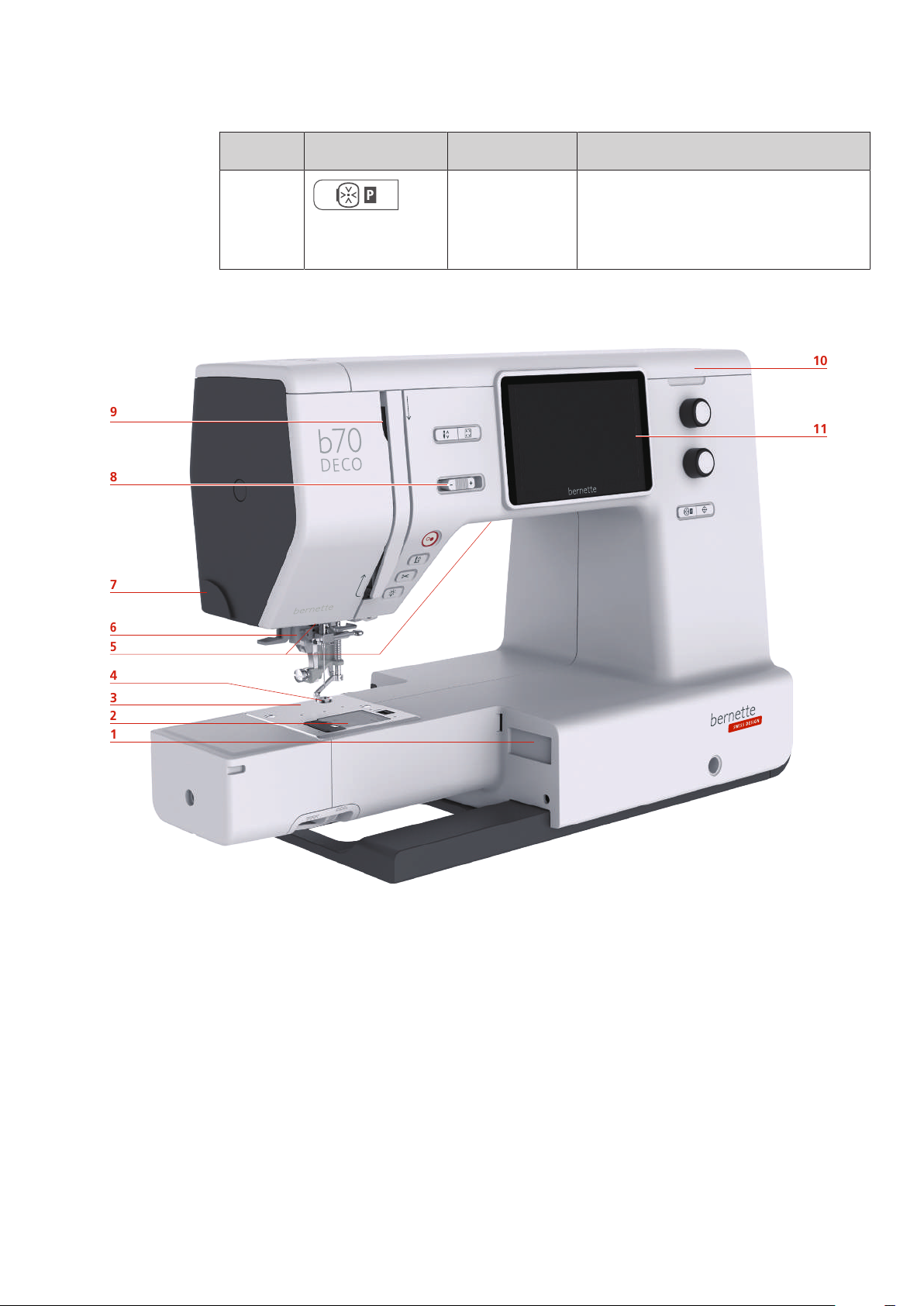

Overview front

> To facilitate threading the needle and to

get enough clearance from the needle to

the hoop, press the icon «Center

embroidery hoop to the needle».

1 Connection for embroidery module 7 Thread cutter

2 Stitch plate cover 8 Slide speed control

3 Stitch plate 9 Thread take-up lever

4 Embroidery foot 10 Top cover

5 Sewing light 11 LCD Display

6 Needle threader

10

2019-02 EN 5020070.00A.04

Page 12

My bernette Embroidery

3

2

1

4

5

7

6

1

2

3

4

5

6

7

Overview top

1 Thread take-up lever 5 Bobbin winding unit and holder for second

spoolpin

2 Thread pretension 6 Bobbin winding stopper

3 Thread guide 7 Touchscreen pen

4 Spool holder

Overview back

1 Connection for power cable 5 Handwheel

2019-02 EN 5020070.00A.04

2 Air vents 6 Carrying handle

3 USB port 7 Air vents

4 Power switch

11

Page 13

My bernette Embroidery

1

2

3

3

4

5

Overview Embroidery module

1 Embroidery arm 4 Connection to the machine

2 Bracket for attaching the embroidery hoop 5 Embroidery unit release button

3 Guide rails for the machine

12

2019-02 EN 5020070.00A.04

Page 14

My bernette Embroidery

1.2 Accessory

All rights reserved: For technical reasons and for the purpose of product improvements, changes

concerning the features of the machine can be made at any time and without advance notice. The supplied

accessory can vary depending on the country of delivery.

Included accessories

Visit www.mybernette.com/accessories for more accessory information.

Illustration Name Illustration Name

Bobbin (3x) Second spool pin

Spool net Touchscreen pen

Brush/ Seam ripper Selection of needles

Spool disc large Power cable

Spool disc middle (1x) Felt disc

Spool disc small Embroidery hoop large,

160 x 260 mm with

embroidery template

Screwdriver Embroidery hoop

medium, 120 x 180 mm

with embroider

template

Dust cover Embroidery hoop small,

50x70 mm with

embroidery template

2019-02 EN 5020070.00A.04

Lubricator

13

Page 15

My bernette Embroidery

1

2

3

4

5

Overview presser feet

Illustration Name Purpose

Embroidery foot (JL) For embroidering, darning and

free-motion quilting.

Hopper embroidery foot (JX) For embroidering, darning and

free-motion quilting.

1.3 Overview User Interface

Overview functions/visual information

1 Upper thread tension 4 Embroidery hoop display/Embroidery hoop

selection

2 Needle selection 5 Stitch plate selection

3 Presser foot display

14

2019-02 EN 5020070.00A.04

Page 16

Overview System settings

1

2

3

4

5

1

2

3

4

1 Home 4 eco mode

2 Setup Program 5 Back to default setting

3 Tutorial

My bernette Embroidery

Overview Selection menu embroidery

1 Selection embroidery motifs 3 Color information

2 Editing embroidery motifs 4 Embroidery

Overview Functions and Views

Illustration Name Purpose

Close The display is closed and the

previously made adjustments are

saved.

2019-02 EN 5020070.00A.04

Icons «-/+» By touching the icons «-» and

«+» the setting values are

Confirm Confirms the previously adjusted

changed.

alterations. The display is closed.

15

Page 17

My bernette Embroidery

Illustration Name Purpose

Cancel The process is canceled. The

display is closed and the

previously made adjustments are

not saved.

Slide By moving the slide the setting

values are changed.

Switch Activates or deactivates

functions.

Process navigation With the process navigation, you

can return from any display to

the previous the display.

Machine To load or save motifs on the

machine.

USB stick To load or save embroidery

motifs on the USB stick.

USB storage space The percentage of used USB

storage (%) will be displayed in

the green bar icon.

Swipe function By swiping the display using the

touchscreen pen or the finger

upwards or downwards, further

functions can be displayed.

Yellow-framed icon Touch the yellow-framed icon to

reset the alterations to default

setting.

16

2019-02 EN 5020070.00A.04

Page 18

My bernette Embroidery

2

1

5

3

4

1.4 Needle, Thread, Fabric

In the course of time a needle wears out. Therefore, the needle should be replaced regularly. Only a perfect

point results in a good stitching result. In general it can be said: the thinner the thread, the finer the needle.

The illustrated needles are either standard or optional accessory, depending on the machine.

• Needle sizes 70, 75: for light-weight fabrics.

• Needle sizes 80, 90: for medium fabrics.

• Needle sizes 100: for heavy fabrics.

Overview Needles

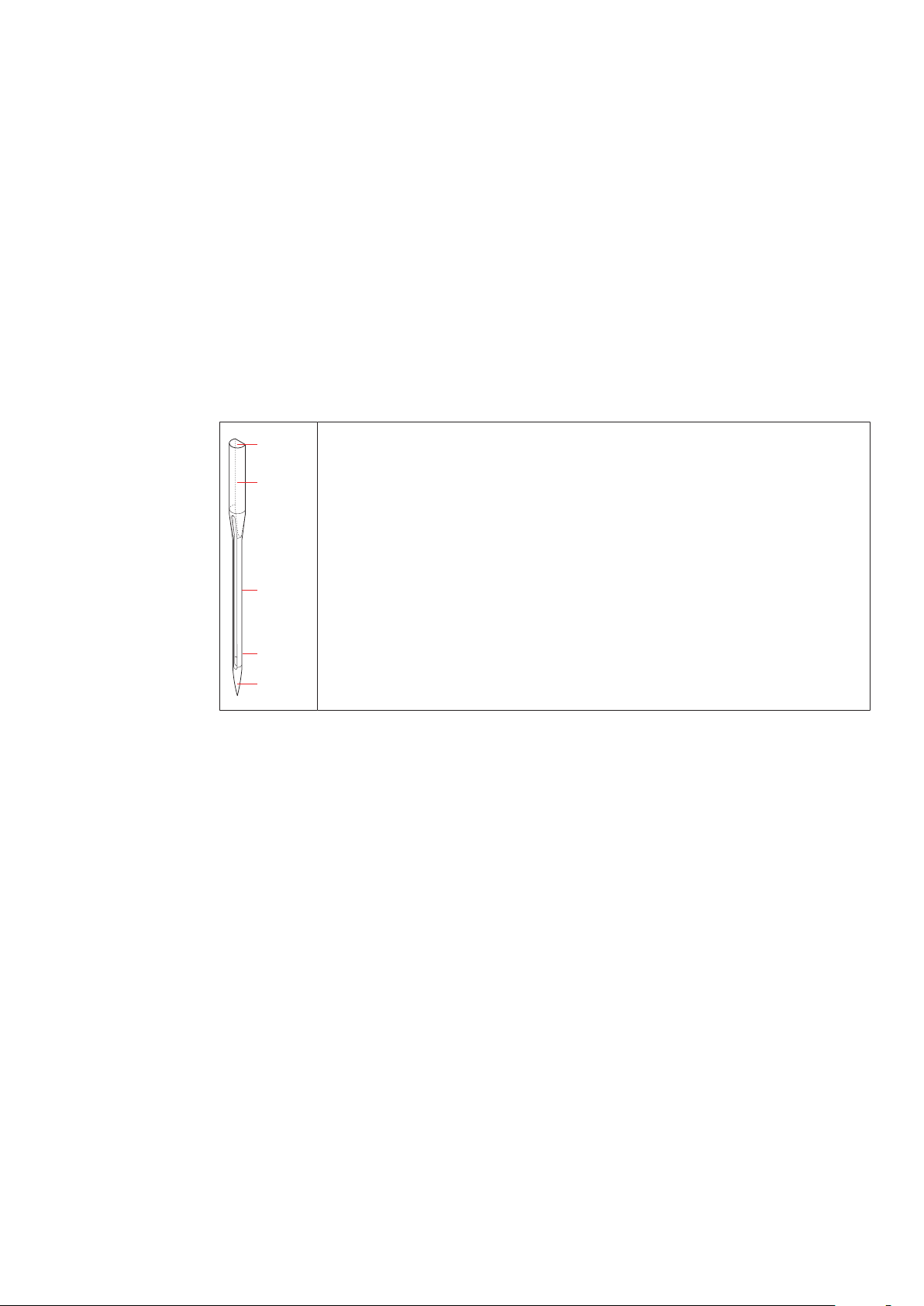

Example for needle description

The 130/705 system, which is the most common for household machines, is explained by the following

picture of a Jersey/Stretch needle.

130/705 H-S/70

130 = Shank length (1)

705 = Flat shank (2)

H = Needle scarf (3)

S = Needle point (here medium ball point) (4)

70 = Needle size 0.7 mm (5)

Thread selection

For a perfect sewing result, thread and fabric quality play an important role.

We recommend purchasing quality threads to achieve good sewing results.

• Cotton threads have the advantage of being a natural fiber and therefore are especially suitable for

sewing cotton fabrics.

• Mercerized cotton threads have a slight sheen that is not lost with washing.

• Polyester threads have a high tensile strength and is particularly colorfast.

• Polyester threads are more flexible and are recommended where a strong and elastic seam is required.

• Rayon threads are made of natural fibers and have a brilliant sheen.

• Rayon threads are suitable for decorative stitches and achieve a more beautiful effect.

2019-02 EN 5020070.00A.04

17

Page 19

My bernette Embroidery

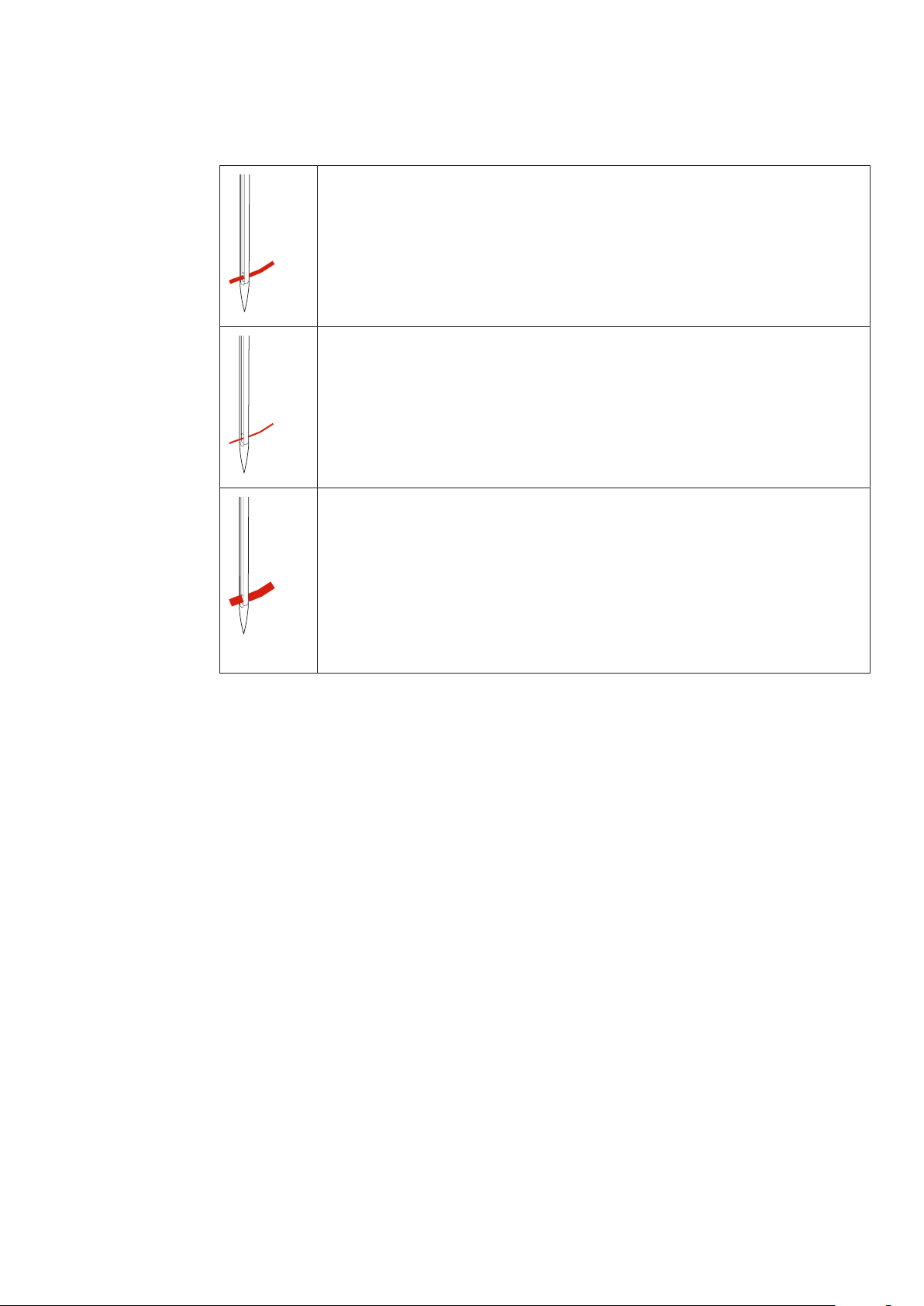

Needle/thread combination

The needle/thread combination is correct, when the thread fits perfectly into the long

groove and goes easily through the needle eye. The thread can be optimally sewn.

The thread can break and cause skipped stitches if there is too much play in the long

groove or eye of the needle.

The thread can break and become jammed if it frays on the edges of the long groove and

is not guided optimally through the eye of the needle.

1.5 Important Embroidery information

Upper thread

A good quality thread (brand manufacturer) is essential for embroidery so that the embroidery is not affected

negatively because of poor thread or thread breakage.

Embroidery is particularly effective if you use 40wt glossy rayon or polyester embroidery threads as upper

threads. They are available in a wide range of colors for beautiful embroidery.

• Glossy polyester with a brilliant sheen is a hard wearing, colorfast thread and has a high tensile strength

which is suitable for all types of embroidery.

• Rayon is a soft viscose fiber with a brilliant sheen and suitable for fine, delicate embroidery, or items that

will not receive excessive wear and tear.

• Metallic thread is a light to medium-weight thread suitable for special effects in embroidery.

• When working with metallic threads, the automatic bobbin thread cutter should be deactivated. The

other thread cutters shouldn't be used either because the knives are likely to wear off very quickly.

18

2019-02 EN 5020070.00A.04

Page 20

My bernette Embroidery

• When using metallic threads, the speed and the upper thread tension should be reduced.

Bobbin thread

In most cases black or white bobbin thread is used for embroidering. When both sides should have the same

look, it is recommended to use the same color for bobbin and upper thread.

• Bobbin Fill is an especially soft and light polyster thread which is suited well to be used as bobbin thread.

This special bobbin thread ensures a steady thread tension and an optimal intertwining of the upper and

bobbin thread.

• Darning and embroidery threads are fine mercerized cotton threads which are suitable for embroidery on

cotton.

2019-02 EN 5020070.00A.04

Choosing the embroidery motif

Simple motifs with a low stitch count are suitable for embroidery on fine material. Densely embroidered

motifs, e.g. embroidered motifs with multiple color and embroidery direction changes, are suitable for

medium and heavy-weight material.

Embroidery test

For the embroidery test, always use the original material reinforced with the same stabilizer as will be used

later. For the embroidery test it is recommended to use the same colors, threads and needles which are

planned to be used for the embroidery project.

Embroidering motifs by third-party providers

bernette recommends uploading embroidery motifs of any file format via the free program ««ART-Link»» to

the machine or a USB stick. Using «ART-Link» ensures that the embroidery motif can be read and

embroidered correctly. «ART-Link» can be downloaded for free at www.bernina.com.

19

Page 21

My bernette Embroidery

Underlay stitches

Underlay stitches are the foundation of a motif and are used to stabilize the base material and hold it in

shape. They also prevent the covering stitches of the motif from sinking into the knit or the nap of the

material.

The size of the embroidery motif

Embroidery motifs can be enlarged or downsized on the embroidery machine or on the PC using the

BERNINA Embroidery software (optional accessory). Enlargements or reductions up to 20% achieve the best

results.

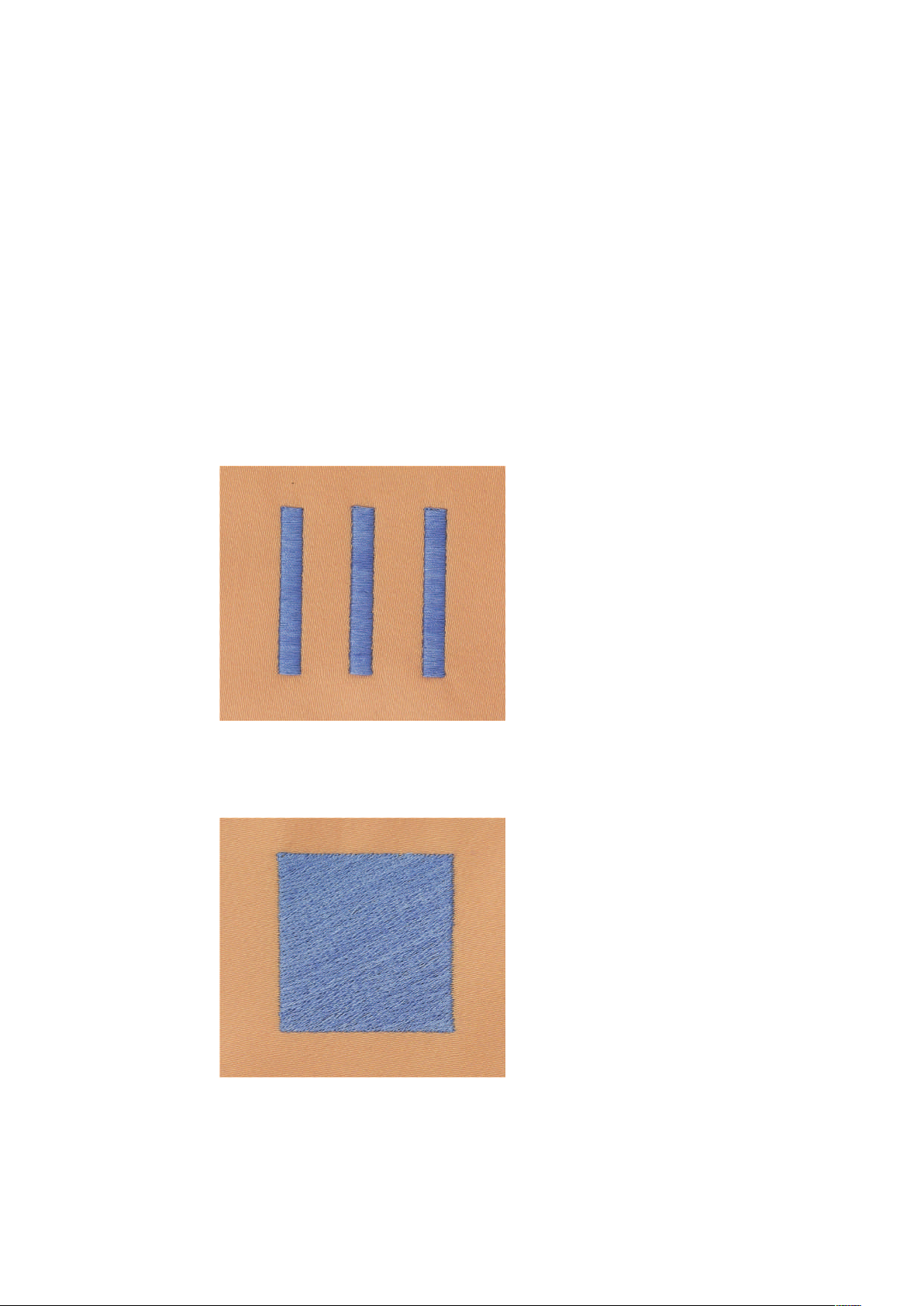

Satin or Leaf stich

The needle moves left to right and vice versa. The result is a very dense, covering zig zag stitching to fill the

shape. Satin stitching fills are ideal for narrow and small shapes. Satin stitching is, however, not suitable for

larger areas, since wide stitches are too loose and do not cover the fabric properly. In addition there is the

risk that with too long stitches the threads could catch on something which would damage the embroidery.

Step stitch

Many short, equally long stitches are embroidered in offset rows closely next to each other which results in a

densesly filled area.

20

2019-02 EN 5020070.00A.04

Page 22

My bernette Embroidery

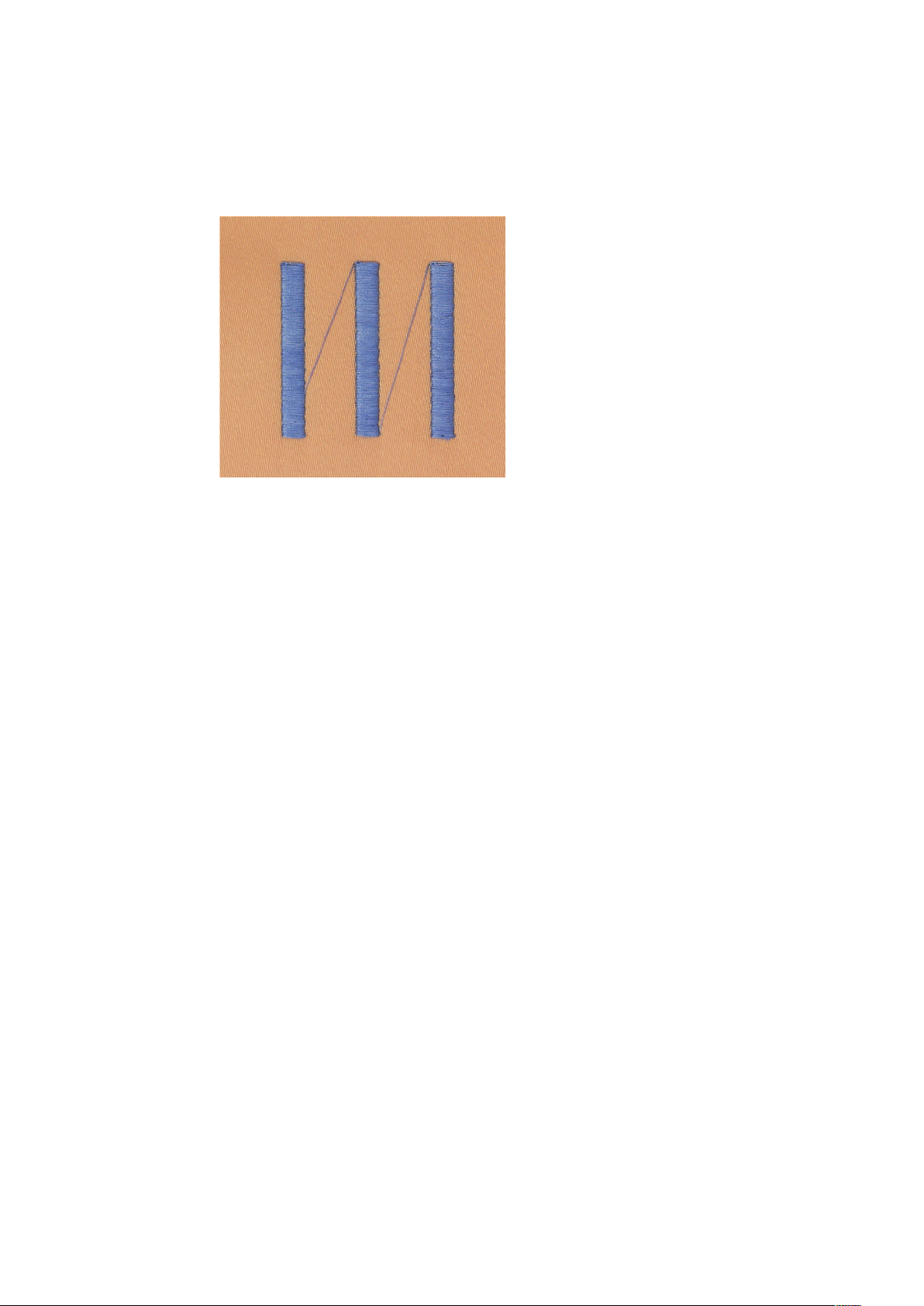

Connecting stitches

Long stitches which are used to get from one part of the motif to the next. Before and after the connecting

stitch securing stitches are sewn. Connecting stitches are trimmed.

2019-02 EN 5020070.00A.04

21

Page 23

Embroidering preparation

2 Embroidering preparation

2.1 Connection and Switching on

Connecting the machine

> Insert the power cable into the power cord connection.

> Insert the power cable into the power cord connection.

Use of the power cable (only USA/Canada)

The machine has a polarized plug (one blade wider than the other). To reduce the risk of electrical shock, this

plug is intended to fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse

the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the

plug in any way!

Switching the machine on

> Switch on the machine at the main switch to «I».

Fixing the touchscreen pen

> Store the touchscreen pen on the top holder.

22

2019-02 EN 5020070.00A.04

Page 24

Embroidering preparation

1

2

3

2.2 Spool pin

Horizontal spool pin

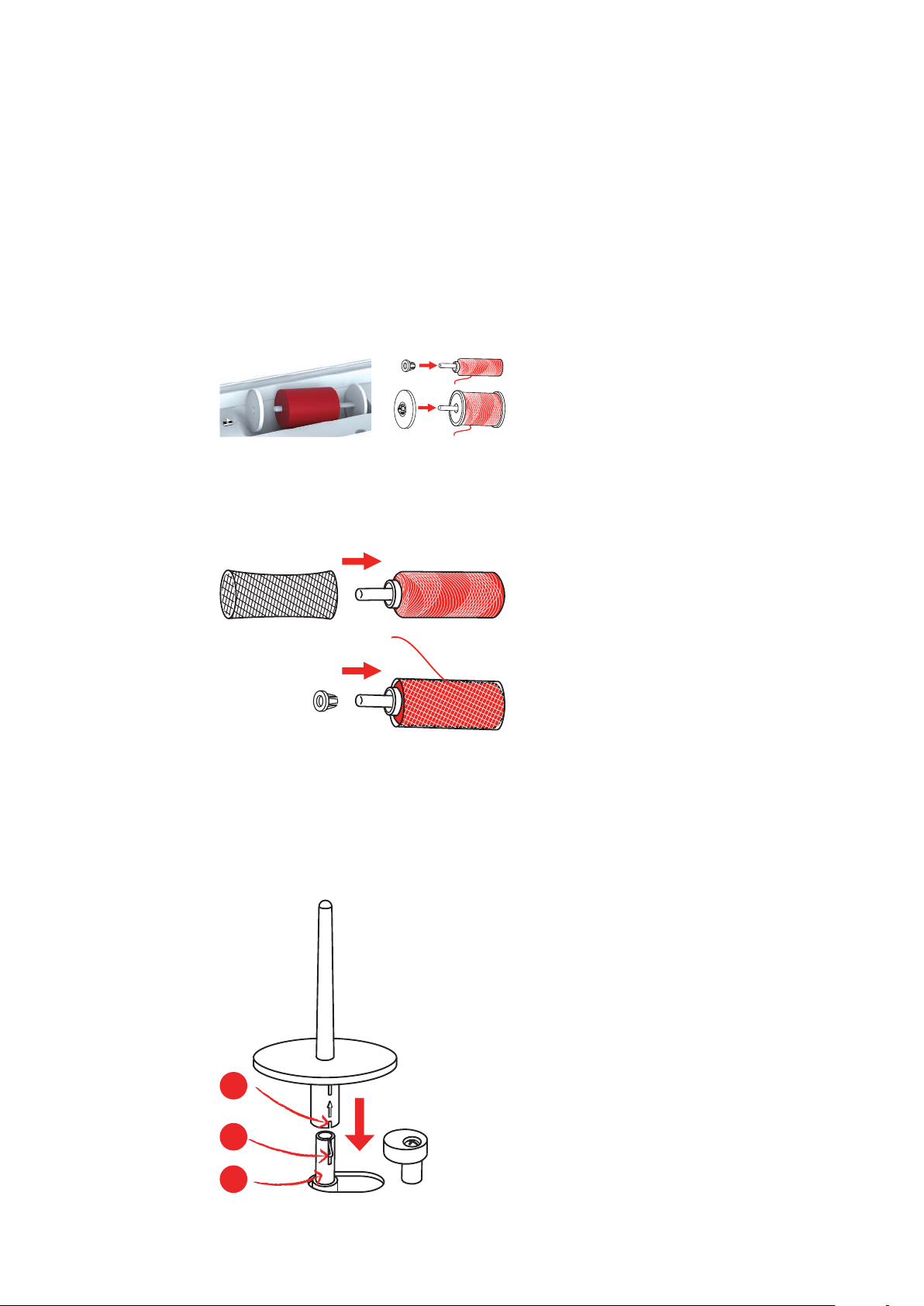

Placing the thread spool and the thread disc

Spool discs hold the thread spool in place for proper release of thread from the spool. The thread disc is only

used with the horizontal spool holder.

> Place the thread spool on the spool holder.

> Position the appropriate spool disc on the spool holder so that there is no space between the spool disc

and the thread spool.

Using a spool net

The spool net provides an even unwinding of the thread from the thread spool and prevents the thread from

knotting and breaking. The spool net is only used with the horizontal spool holder.

> Pull the spool net over the thread spool.

Second spool pin

Installing the second spool pin

The second spool pin is necessary when several threads are sewn.

> Insert the second spool pin onto the end of the bobbin winding unit(1).

> Align the notch (2) with the spring (3) on the bobbin winding unit.

2019-02 EN 5020070.00A.04

23

Page 25

Embroidering preparation

1

1

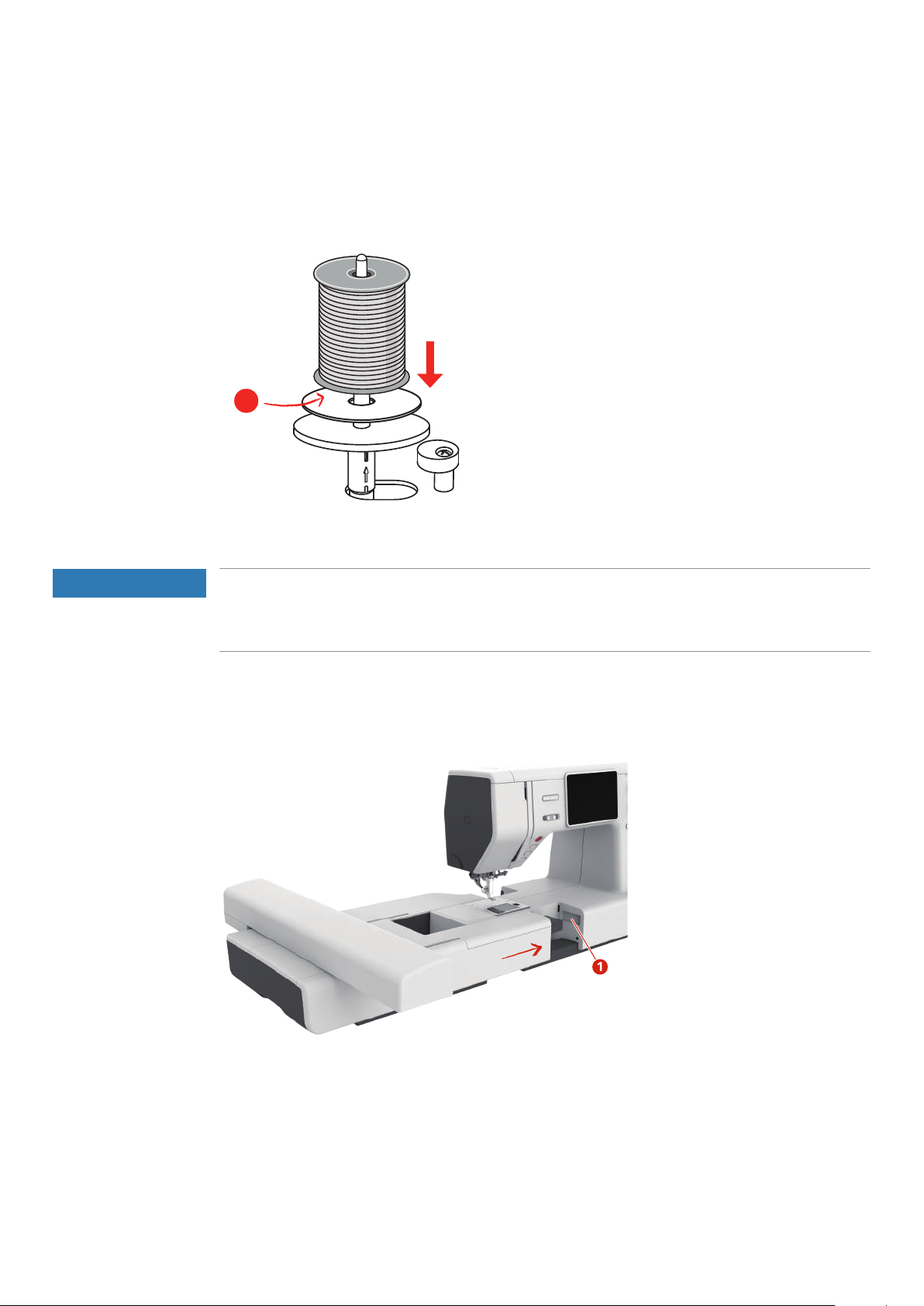

Inserting thread spool

The felt disc prevents the thread from getting hooked at the second spool pin.

> Place the felt disc (1) on the second spool pin.

> Place the thread spool on the second spool pin.

NOTICE

2.3 Attaching the Module

Transporting the embroidery module

Damage to the embroidery module connection and machine.

> Remove the embroidery module before transporting the machine.

> Make sure that the module and the machine are placed on a stable, even surface.

> Make sure that there is enough space around to allow the unimpeded movement of the embroidery arm.

> Lift the embroidery module on the left.

> Carefully push the module from left to right into the embroidery module connection (1) of the machine.

24

2019-02 EN 5020070.00A.04

Page 26

Embroidering preparation

2

1

4

3

1

> To remove, hold the embroidery module and press the release button (2), then slide left the embroidery

module out of the machine arm.

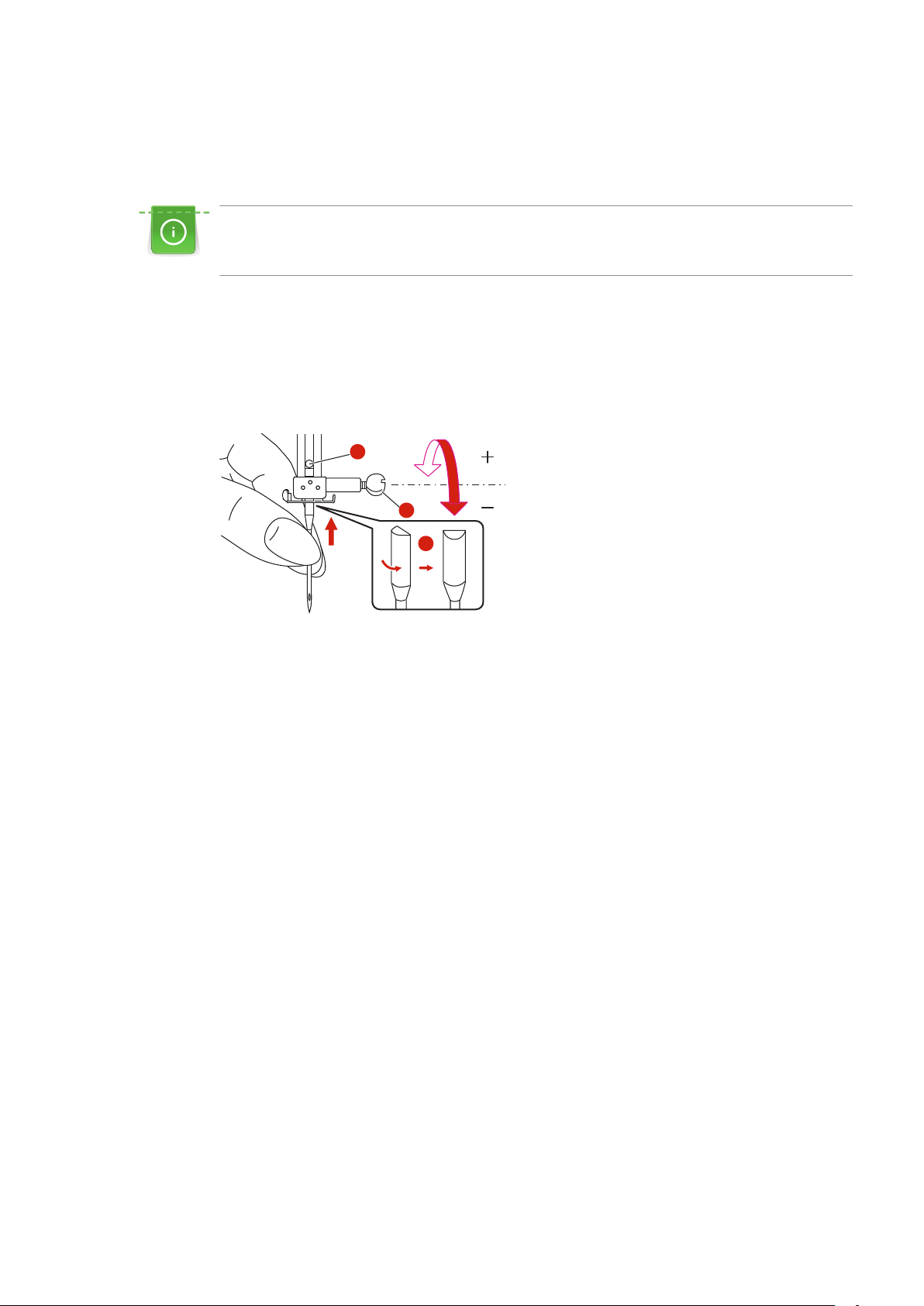

2.4 Embroidery foot

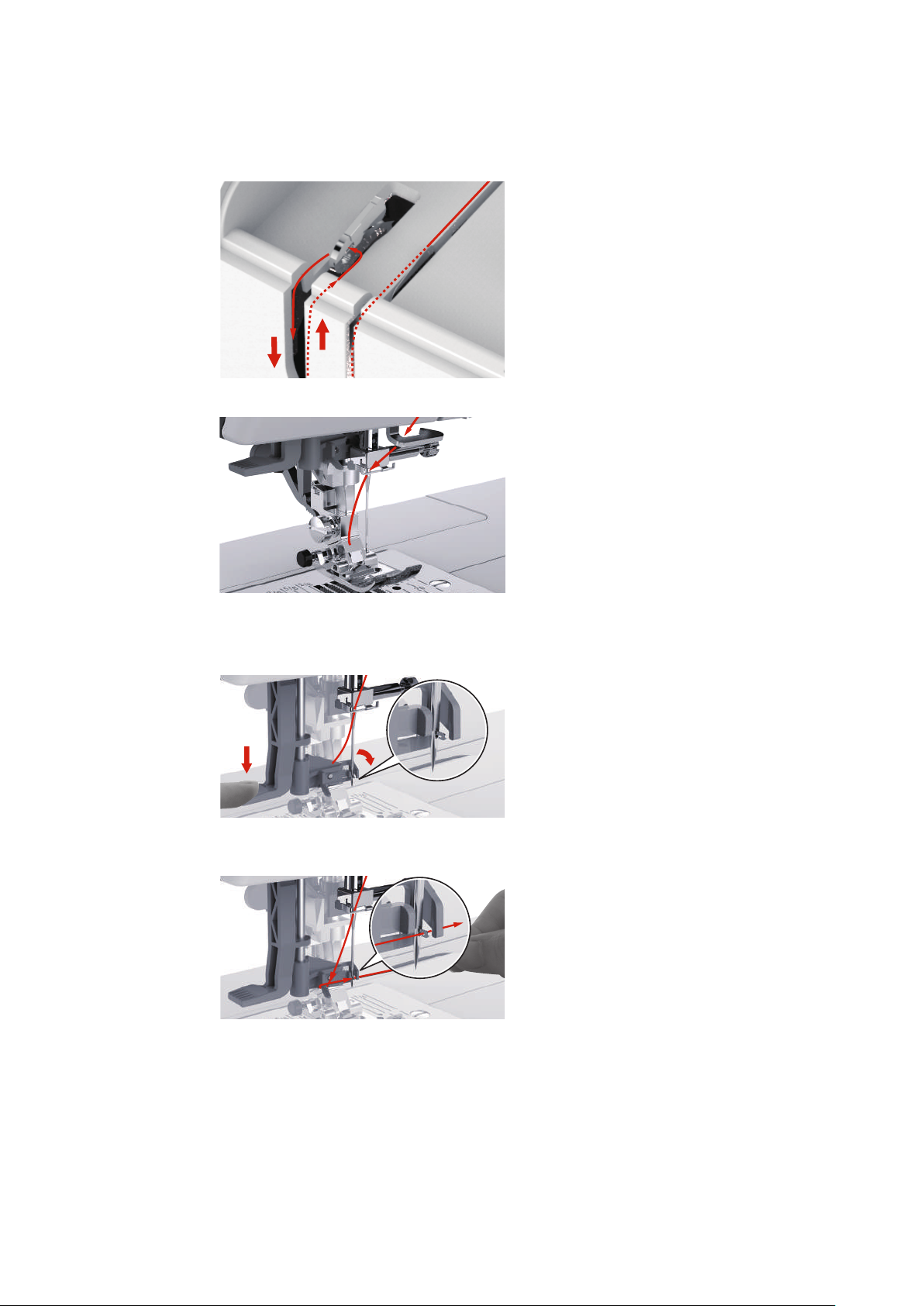

Attaching the embroidery foot

Mount the embroidery foot

> Raise the needle.

> Raise the presser foot.

> Switch the machine off and disconnect it from the power supply system.

> Attach the embroidery foot (JL) from the back with the index finger to the presser foot bar and tighten

the screw (1).

2019-02 EN 5020070.00A.04

Mount the hopper embroidery foot

> Raise the needle.

> Raise the presser foot.

> Switch the machine off and disconnect it from the power supply system.

> Mount the hopper embroidery foot (JX) on the presser foot rod, making sure that the spring (3) is above

the needle fixing screw (4).

> Tighten the screw (1).

25

Page 27

Embroidering preparation

1

3

2

2.5 Needle

Inserting the embroidery needle

Embroidery needles of the type 130/705 H-SUK provide a larger eye and are slightly rounded. This avoids

thread abrasion when using Rayon- and cotton embroidery thread. Depending on the embroidery thread

use a size No. 70-SUK to No. 90-SUK needle.

> Raise the needle.

> Switch the machine off and disconnect it from the power supply system.

> Remove the attached foot.

> Loosen the needle clamp screw (1) using the screwdriver and remove the needle.

> Hold the needle with the flat side (2) to the back.

> Insert the needle as far up as it will go (3).

> Tighten the needle clamp (1) screw using the screwdriver.

26

2019-02 EN 5020070.00A.04

Page 28

2.6 Threading

1

2

4

6

3

5

6

9 10

12

11

7

8

∼

Threading preparation

> Press the button «Presser foot up/down» to raise the presser foot.

> Raise the presser foot.

Threading the upper thread

Embroidering preparation

2019-02 EN 5020070.00A.04

1 Spool disc 7 Guides

2 Thread guide 8 Guides

3 Thread guide 9 Needle threader lever

4 Silver discs 10 Hook pin

5 Thread take-up lever cover 11 Thread cutter

6 Thread take-up lever 12 Thread

27

Page 29

Embroidering preparation

> Place the thread spool on the spool holder so that the thread unwinds clockwise.

> Add the appropriate spool disc.

> Guide the thread from the spool through the upper thread guide (2).

> Guide the thread from the spool through the upper thread guide (3).

> Place the thread end downwards along the duct.

> Then, down and around the check spring holder.

28

2019-02 EN 5020070.00A.04

Page 30

Embroidering preparation

> At the top of this movement pass the thread from right to left through the slotted eye of the take-up

lever and then downwards again.

> Guide the thread through the guides above the presser foot.

> Press the lever to the very bottom until it clicks in.

– The hook pin passes through the needle eye (9).

– To prevent the threader from being damaged, the presser foot is lowered automatically.

> Guide the thread around thread guide.

> Guide the thread in front of the needle and under the hook pin.

2019-02 EN 5020070.00A.04

29

Page 31

Embroidering preparation

> To cut the excess thread, take thread end and gently pull it over the thread cutter.

> To thread the needle, lift the threader lever.

– The hook retreats and passes the thread through the needle eye where a loop is formed.

> Pull the thread through the needle eye.

30

2019-02 EN 5020070.00A.04

Page 32

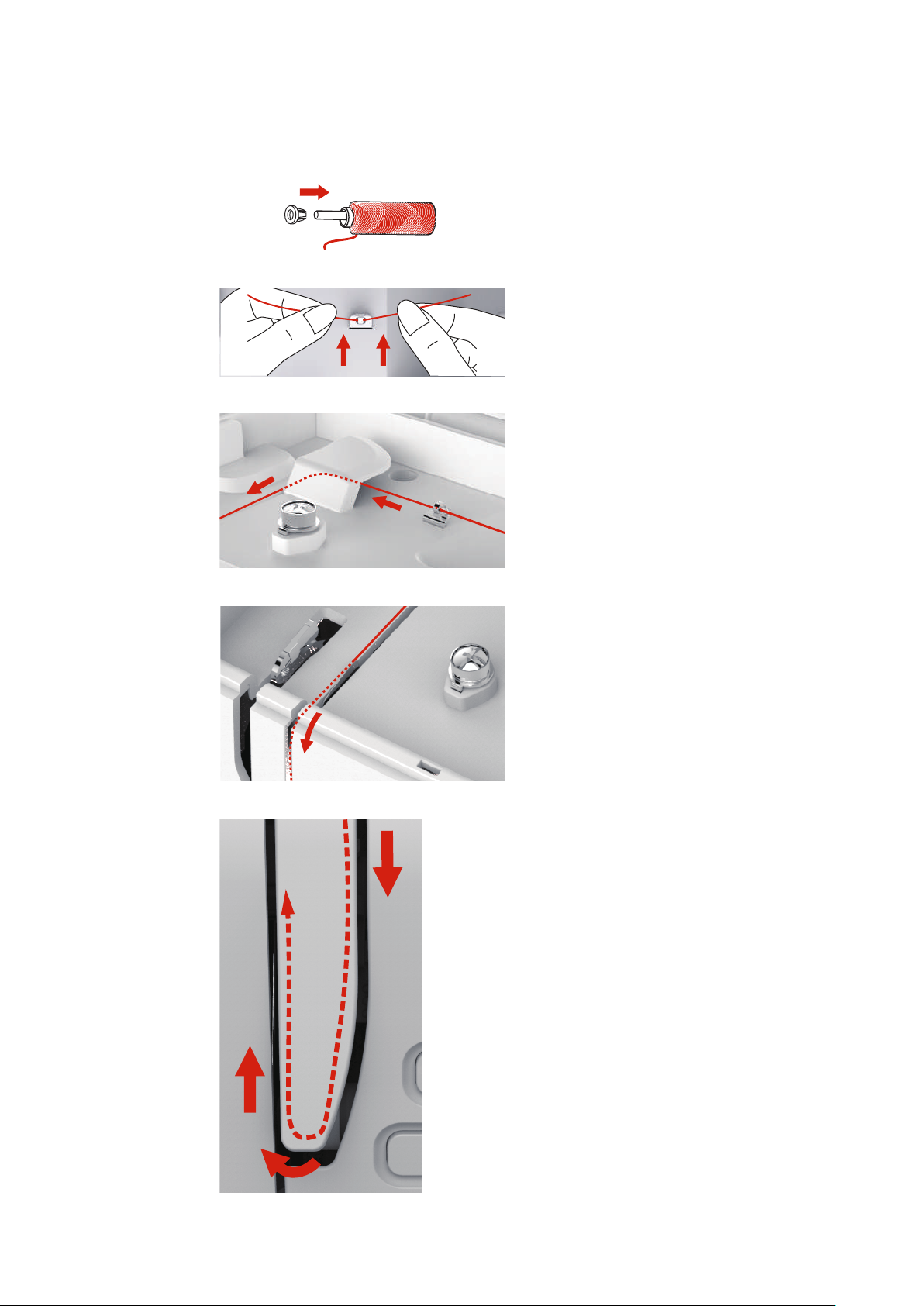

Winding the bobbin thread

1

2

4

3

1 Spool disc 3 Thread pretension

2 Thread guide 4 Spool pin

Embroidering preparation

> Place the thread spool and the appropriate spool disc on the spool holder.

> For small thread spools use the spool disc.

> In order to prevent tangling of the thread, please use a spool net.

> Guide the thread through the upper thread guide.

> Guide the thread around the thread pretension clockwise.

2019-02 EN 5020070.00A.04

> Place the thread end through one of the inner holes and place the empty bobbin on the winding unit.

31

Page 33

Embroidering preparation

> Push the bobbin to the right.

> The button «Start/Stop» flashes and the display for winding appears.

> Hold the thread end with one hand.

> To start the winding process for a few rotations and then stop, push the button «»Start«/Stop», so that

the thread is held tight on the bobbin.

> Cut the thread end next to the inner hole.

> To continue the winding process, push the button «Start/Stop» or press the foot control.

> To stop the winding process, push the button «Start/Stop» or press the foot control.

> Remove the bobbin and cut the thread.

Threading the bobbin thread

Prerequisite:

• The needle is raised.

• The presser foot is raised.

• The machine is switched off.

> Open the bobbin cover by pushing the release button to the right.

32

2019-02 EN 5020070.00A.04

Page 34

Embroidering preparation

1

2

> Insert the new spool so that the thread is wound in the counterclockwise direction.

> Pull the thread into the slit (1).

> Press gently on the bobbin.

> Follow the arrow markings to bring the thread into the bobbin thread guide.

> To cut excess thread, take the thread end and pull over the thread cutter (2).

> Close the bobbin cover.

2019-02 EN 5020070.00A.04

33

Page 35

Embroidering preparation

1

2 3

1

2 3

1

2.7 Selecting the embroidery motif

All embroidery motifs can be embroidered directly or they can be altered using the various functions the

embroidery machine provides. You can find all embroidery motifs at the end of the instruction manual. In

addition to that, embroidery motifs can be downloaded from the personal memory or from the USB stick

(optional accessory).

> Touch the icon «Home».

> Select an alphabet, an embroidery motif, a stitch pattern or a personal embroidery motif from one of the

files.

1 Embroidery Alphabet 3 Personal Embroidery motif

2 Embroidery motif

2.8 Embroidery hoop

Overview embroidery hoop selection

1 Hoop selection

34

2019-02 EN 5020070.00A.04

Page 36

Embroidering preparation

đ

Selecting the embroidery hoop

The best embroidery result is achieved when the smallest possible embroidery hoop for the embroidery motif

is selected.

The embroidery motif has a pre-set size which is displayed.

Prerequisite:

• The embroidery motif is selected.

> Touch the icon «Embroidery hoop display/Embroidery hoop selection».

– The presently attached embroidery hoop is displayed.

– The machine selects the optimal embroidery hoop according to the size of the embroidery motif

automatically.

– If the preset embroidery hoop is not available, another desired embroidery hoop can be selected.

– When an embroidery hoop is attached which does not correspond with the selected one, the attached

hoop is considered active and the embroidery motif area is displayed accordingly.

> Select the desired embroidery hoop.

Tear-away stabilizers

Using a stabilizer ensures more stability of the embroidery project. A tear-away stabilizer suits all woven and

non-stretch materials. 1–2layers can be used. Stabilizers are available in different weights. With larger

embroidered areas the stabilizer will remain under the embroidery thread. The stabilizer is applied to the

wrong side of the fabric with temporary adhesive spray. Carefully tear away excess stabilizer after

embroidering.

Cut-away stabilizers

Using a stabilizer ensure more stability of the embroidery project. A cut-away stabilizer suits all elastic

materials. 1–2layers can be used. Stabilizers are available in different weights. With larger areas to be

embroidered the stabilizer will remain under the embroidery thread. The stabilizer is applied to the wrong

side of the fabric with temporary adhesive spray. Carefully cut away excess stabilizer after embroidering.

Using adhesive spray

The application of spray adhesive is recommended for stretch and smooth materials and knitware. It prevents

the fabric from losing shape and slipping. Appliqués can be exactly positioned with spray adhesive. The spray

adhesive shouldn't be used near the machine to avoid contamination.

> Use the adhesive spray carefully at a distance 25 – 30 cm (9–12inch) when spraying the stabilizer.

> Adhere the sprayed stabilizer to the wrong side of the fabric carefully, smoothing material so there are

no puckers.

> Position smaller parts such as pocket flaps or collars on the stabilizer.

> To avoid the possibility of getting hoop marks when working with napped materials or fleece, don't hoop

the parts but spray the stabilizer and hoop it.

> Adhere the fabric to be embroidered.

> Remove any adhesive residue before starting the machine.

2019-02 EN 5020070.00A.04

Using spray starch

Spray starch is ideal for additional stiffening fine, loosely woven materials. Always use an additional stabilizer

on the wrong side of the material.

> Spray the area to be embroidered.

> Let it dry or press gently with a warm iron if necessary.

35

Page 37

Embroidering preparation

Using iron-on interfacing

Iron-on interfacings are available in a variety of weights. It is recommended to use an iron-on interfacing

which is easily removable from the basic fabric. An Iron-on interfacing suits all materials that are easily

distorted like stretch fabric such as tricot and jersey.

> Iron-on interfacings are ironed to the wrong side of the material using a warm iron.

Using paper-backed adhesive stabilizer

Paper-backed adhesive stabilizers are intended to be used for fabrics such as jersey and silk as well as for

embroidery projects which are not suited to be hooped in the embroidery hoop.

> Place the stabilizer in the hoop, so that the paper side is up.

> Use a a pair of scissors to score the paper and remove paper in the hoop area.

> Position the fabric to be embroidered on the stabilizer and press it on place.

> Remove any adhesive residue before starting the machine.

Using water-soluble stabilizer

For lace embroidery it is recommended to hoop 1 – 3 layers of water-soluble stabilizer in the embroidery

hoop. As the embroidery motif is not embroidered on the fabric, only the thread embroidered motif is

left. The embroidery motifs should be combined with short stitches otherwise the individual motifs may

fall out.

Water-soluble stabilizers are ideal for fine, sheer fabrics where other stabilizers may show through the

embroidery stitches as well as for lace embroidery. The stabilizer dissolves in water. Water-soluble stabilizers

are an ideal protection for looped pile fabrics preventing the loops from being damaged. It prevents threads

from sinking into the material and keeps the fabric pile from poking though the embroidery.

> Place the stabilizer on the underside of the material.

> Use adhesive spray to adhere stabilizer if necessary.

> For material with a pile, reinforce with additional, suitable stabilizer on the wrong side.

> Place all the layers together into the embroidery hoop.

> After dissolving, lay the motif down flat and let dry.

Preparing the embroidery hoop

The embroidery hoop consists of an outer and an inner hoop. There is an embroidery template for each

hoop. The area to be embroidered is marked in 1 cm (0,39 in) squares. The center is marked with hole and

cross lines. The required marks can be transferred to the material.

36

2019-02 EN 5020070.00A.04

Page 38

> Loosen the screw (1) or open the quick release device (2) on the outer hoop.

1

2

1

– If a new type of fabric is used, the pressure must be adjusted by turning the screw.

> Remove the inner hoop.

Embroidering preparation

> Place the template (1) in the inner hoop, so the bernette logo is at the front edge, and make sure the cut

outs click into place.

> Place fabric under the inner frame so that it is at least 2 cm above the hoop.

> Line up the marked center point on the center of the template.

> Place the material and the inner hoop on the outer hoop so that the arrows of both hoops match.

2019-02 EN 5020070.00A.04

> Fit the hoops into each other; ensure that the material does not move.

37

Page 39

Embroidering preparation

1

3

2

1

> Hoop the fabric to be embroidered tightly.

> Close the quick release device (2). If necessary, tighten screw (1).

> The inner hoop should protrude about 1 mm on the underside, this prevents the hoop from sticking to

the stitch plate.

> The quick release device (2) is for changing the same type (thickness) fabric easily and quickly.

> Remove the template (3) from the hoop.

Attaching the hoop

> Raise the needle.

> Raise the embroidery foot.

> Position the embroidery hoop under the embroidery foot.

> Push the embroidery hoop into the embroidery module until it clicks into place.

– The hoop is attached.

> To remove the hoop, press the securing lever and pull the hoop backwards.

38

2019-02 EN 5020070.00A.04

Page 40

Overview Embroidery functions

1

2

3

4

đ

1 Center the needle to the embroidery hoop 3 Grid on/off

2 Embroidery arm return 4 Motif center

Locating the center of the embroidery motif

Embroidering preparation

The embroidery hoop is positioned so that the needle is exactly above the center of the embroidery motif or

the motif begin.

> Touch the icon «Embroidery hoop display/Embroidery hoop selection».

> Touch the icon «Center of the embroidery motif» to position the hoop so that the needle is placed

exactly over the center of the embroidery motif.

> Touch the icon «Center of the embroidery motif» again to position the hoop so that the needle is placed

exactly over the motif start.

Center the needle to the embroidery hoop

Relocating the embroidery hoop facilitates threading when the needle is close to the embroidery hoop.

> Touch the icon «Embroidery hoop display/Embroidery hoop selection».

> > Touch the icon «Center the needle to the embroidery hoop» to move the hoop to the center.

> Thread the upper thread.

> Push the button «Start/Stop» to move the hoop back to its previous position.

2019-02 EN 5020070.00A.04

39

Page 41

Embroidering preparation

đ

đ

Embroidery arm return

The embroidery arm can be positioned to store the embroidery module.

> Touch the icon «Embroidery hoop display/Embroidery hoop selection».

> Remove the hoop.

> Touch the icon «Embroidery arm return» the embroidery arm travels horizontally to the left to the park

position.

> Push the button «Start/Stop» to move the embroidery arm to the last position.

Grid on/off

When the center of the hoop and the grid are displayed, the embroidery motif can be positioned more

exactly.

> Touch the icon «Embroidery hoop display/Embroidery hoop selection».

> Touch the icon «Grid on/off» to display the center of the hoop on the display.

> Touch the icon «Grid on/off» again to display the grid.

> Touch the icon «Grid on/off» again so that the center of the hoop and the grid disappear.

40

2019-02 EN 5020070.00A.04

Page 42

Setup Program

RPM

3 Setup Program

3.1 Embroidery settings

Adjusting the upper thread tension

Alterations of the upper thread tension in the Setup Program affect all embroidery motifs.

> Touch the icon «Setup Program».

> Touch the icon «Embroidery settings».

> Touch the icon «Alter the upper thread tension».

> Move the slide using the touchscreen pen/finger or touch the icons «+» or «-» to alter the upper thread

tension.

Adjusting the maximum embroidering speed

By using this function, the maximum speed can be reduced.

> Touch the icon «Setup Program».

> Touch the icon «Embroidery settings».

> Touch the icon «Alter the maximum speed».

> Move the slide using the touchscreen pen/finger or touch the icons «+» or «-» to alter the maximum

speed.

Calibrating the embroidery hoop

The calibration of the embroidery hoop is the coordination of the needle to the center of the embroidery

hoop.

Prerequisite:

• The embroidery module is connected and the embroidery hoop with the appropriate embroidery

template is attached.

> Touch the icon «Setup Program».

2019-02 EN 5020070.00A.04

> Touch the icon «Embroidery settings».

> Touch the icon «Calibrate the embroidery hoop».

– The machine recognizes the size of the attached embroidery hoop automatically and moves to the

center of the hoop.

41

Page 43

Setup Program

> Center the needle via the arrow icons on the display and confirm.

Deactivating securing stitches

> «»Touch the icon «Setup Program».

> Touch the icon «Embroidery settings».

> Touch the icon «Securing stitches on/off».

> Touch the switch in the lower left corner of the display to deactivate the securing stitches.

– No securing stitches will be sewn and the bobbin thread needs to be brought up manually and held

when embroidering is started.

> Touch the switch again to activate the securing stitches.

Adjusting the thread cut

> Touch the icon «Setup Program».

> Touch the icon «Embroidery settings».

> Touch the icon «Thread cut settings».

> To deactivate the automatic thread cut before changing a thread, press the switch in the upper section of

the display (1).

> To activate the automatic thread cut before changing a thread, press the switch in the upper section of

the display (1) again.

> Touch the switch in the lower section of the display (2) to deactivate the automatic thread cut after

starting embroidering.

– The machine won't stop for a manual thread cut.

> To activate the manual thread cut after embroidering, press the switch in the lower section of the display

(2).

– The machine will stop after about 7 stitches.

42

2019-02 EN 5020070.00A.04

Page 44

> Cut the remaining thread with scissors.

1

2

Adjusting the height of the embroidery presser foot

> Touch the icon «Setup Program».

Setup Program

> Touch the icon «Embroidery settings».

> Touch the icon «Adjust the height of the embroidery presser foot».

> Turn the «Upper Multifunction knob» or the «Lower Multifunction knob» or touch the icons «-» or «+»

to adjust the distance between the stitch plate and the presser foot.

3.2 Selecting personal settings

> Touch the icon «Setup Program».

> Touch the icon «Personal settings».

> Select the desired display color.

2019-02 EN 5020070.00A.04

43

Page 45

Setup Program

3.3 Monitoring functions

Activating the upper thread indicator

> Touch the icon «Setup Program».

> Touch the icon «Monitoring settings».

> Touch the switch in the upper portion of the display to deactivate the upper thread indicator.

> Touch the switch again to activate the upper thread indicator.

Activating the bobbin thread indicator

> Touch the icon «Setup Program».

> Touch the icon «Monitoring settings».

> Touch the switch in the lower section of the display to deactivate the bobbin thread indicator.

> Touch the switch again to activate the bobbin thread indicator.

3.4 Sound on/off

> Touch the icon «Setup Program».

> Touch the icon «Sound on/off» to deactivate any audio signals in general.

> Touch the icon «Sound on/off» again to deactivate any audio signals in general.

3.5 Machine settings

Adjusting the brightness of the display

The brightness of the display can be adjusted corresponding to the personal preferences.

> Touch the icon «Setup Program».

> Touch the icon «Machine settings».

44

> Touch the icon «Adjust the brightness».

> Move the slide in the upper portion of the display using the touchscreen pen/finger or touch the icons

«+» or «-» to alter the brightness of the display.

2019-02 EN 5020070.00A.04

Page 46

Setup Program

Calibrating the display

Please find further information on this topic in the chapter attachment below troubleshooting at the end of

the instruction manual.

> Touch the icon «Setup Program».

> Touch the icon «Machine settings».

> Touch the icon «Calibrate the display».

> Touch the crosses in sequence using the touchscreen pen.

Back to basic setting

ATTENTION: Using this function will delete all individually made settings.

> Touch the icon «Setup Program».

> Touch the icon «Machine settings».

> Touch the icon «Default settings».

> Touch the icon «Default setting embroidery».

> Touch the icon «Confirm» and restart the machine to restore all default settings.

2019-02 EN 5020070.00A.04

45

Page 47

Setup Program

Updating the machine Firmware

The latest firmware of the machine and a detailed step-by-step instruction for updating processes can be

downloaded at www mybernette.com . Personal data and settings are automatically transferred during a

firmware update.

NOTICE

USB stick (optional accessory) has been removed too early

Firmware has not been updated and the machine cannot be used.

> Remove the USB stick (Optional accessory) only after the saved data has been transferred successfully.

> Insert the BERNINA USB Stick (optional accessory), FAT32 formatted, providing the latest software into

the port.

> Touch the icon «Setup Program».

> Touch the icon «Machine settings».

> Touch the icon «Firmware version».

> Touch the icon «Update» to start the update of the firmware.

Checking the firmware version

The firmware version of the machine is displayed.

> Touch the icon «Setup Program».

> Touch the icon «Machine settings».

> Touch the icon «Firmware version».

Reviewing the total number of stitches

The total number of stitches of the machine as well as the number of stitches since the last service carried

out by the specialized dealer are displayed.

> Touch the icon «Setup Program».

> Touch the icon «Machine settings».

> Touch the icon «Firmware version».

46

2019-02 EN 5020070.00A.04

Page 48

Setup Program

Selecting a language

The User Interface can be programmed in different languages according to the customer’s wish.

> Touch the icon «Setup Program».

> Touch the icon «Machine settings».

> Touch the icon «Language selection».

> Select a language.

2019-02 EN 5020070.00A.04

47

Page 49

System settings

4 System settings

4.1 Calling up the tutorial

The tutorial provides information and explanations on different sections concerning embroidering.

> Touch the icon «Tutorial».

> Select the desired topic to get information.

4.2 Using eco mode

During a longer interruption of work the machine can be set into a power save mode. Nothing can be

selected in the display and the machine cannot be started.

> Touch the icon «eco» again.

– The display goes to sleep. The power consumption is reduced and the sewing light is off.

> Quickly click the green icon «eco» on the screen.

– The machine is ready for use.

4.3 Cancelling any alterations with «clr»

Any alterations to motifs can be reset to default setting. Exceptions are saved motifs which have been filed in

the personal memory and monitoring functions.

> Touch the icon «clr».

48

2019-02 EN 5020070.00A.04

Page 50

5 Creative embroidering

1

2

3

4

1

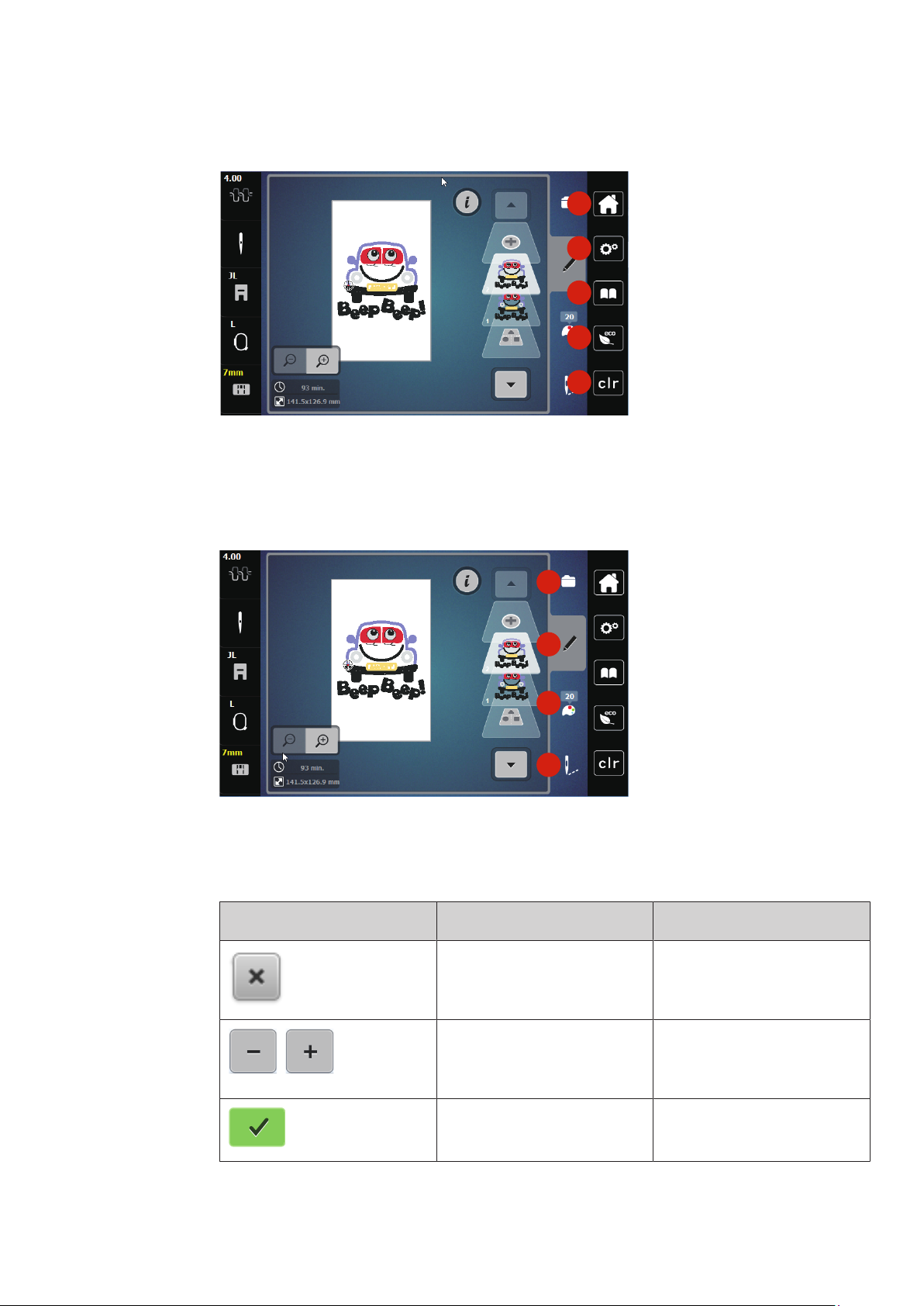

5.1 Overview embroidering

Creative embroidering

1 Scaling up, downsizing and moving the

embroidery motif view

2 Embroidery time/Embroidery motif size in mm 4 «i»-Dialog

3 Area to be embroidered

5.2 Selecting and changing the embroidery motif

> Touch the icon «Selection».

> Touch the icon «Upload embroidery motif».

> Select a new embroidery motif.

5.3 Checking the embroidery time and the embroidery motif size

In the selection menu «Editing» the estimated embroidery time in minutes as well as the width and height of

the embroidery motif is indicated at lower left (1).

2019-02 EN 5020070.00A.04

5.4 Regulating the speed

The sewing speed can be adjusted infinitely variable with the slide.

> Move the slide to the left to reduce the sewing speed.

> Move the slide to the right to increase the sewing speed.

49

Page 51

Creative embroidering

1

2 3

4

5

6

6

7

8

9

10

11

12

13

14

5.5 Editing the embroidery motif

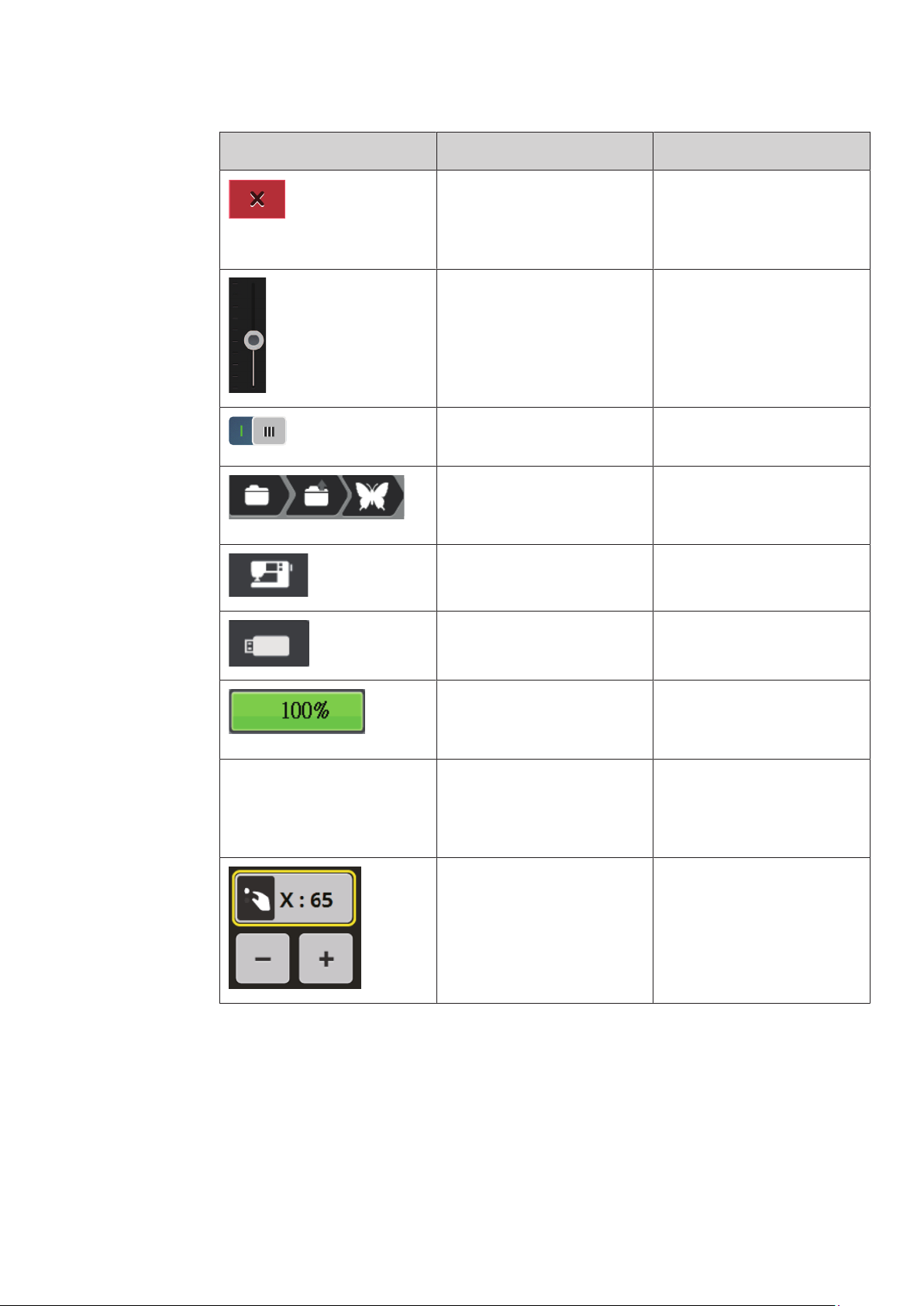

Overview Editing embroidery motif

1 Preview all 8 Rotating motif

2 Moving the view 9 Checking motif size

3 Moving the view of the motif 10 Bending the text

4 Zoom out 11 Mirror image left/right

5 Zoom in 12 Mirror image up/down

6 Moving the embroidery motif 13 Deleting

7 Altering the motif proportionally 14 Altering the stitch density

Scaling up the embroidery motif view

The view of the embroidery motif can be scaled up. In addition to that, the view can be adjusted with or

without changing the embroidery position.

> Select an embroidery motif.

> Touch the icon «Zoom in» to edit the view of the embroidery motif.

> Touch the icon «Zoom in» 1to 9 times to enlarge the view of the embroidery motif gradually.

> Touch the icon «Zoom out» 1to 9 time to get back to the Edit Mode.

Downsizing the embroidery motif

The view of the embroidery motif can be downsized. In addition to that, the view can be adjusted with or

without changing the embroidery position.

> Select an embroidery motif.

> Touch the icon «Zoom in» to scale up the embroidery motif.

> To downsize the enlarged embroidery motif view by each one step, touch the icon «Zoom out» 1to 9x.

50

2019-02 EN 5020070.00A.04

Page 52

Creative embroidering

Moving the embroidery motif view

The view of the embroidery motif can be moved. In addition to that, the embroidery motif position won’t be

changed.

> Select an embroidery motif.

> Touch the icon «Zoom in» to edit the view of the embroidery motif.

> Touch the icon «Move the view».

– The icon turns dark gray.

> Move the view of the embroidery motif using the touchscreen pen/finger.

– Touch the icon «Zoom out» again to return to previous view.The embroidery position is not altered.

> To return to the previous view, touch the icon «Zoom out» again .

Moving the embroidery motif in enlarged view

The view of the embroidery motif can be moved when the embroidery position is changed.

> Select an embroidery motif.

> To activate the icon «Relocating the motif», touch the icon «Zoom in».

> Touch the icon «Move the motif».

– The icon turns dark gray.

> Move the embroidery motif using the touchscreen pen/finger.

– The embroidery motif position is altered.

> To return to the previous view, touch the icon «Zoom out» again .

2019-02 EN 5020070.00A.04

51

Page 53

Creative embroidering

+90

Moving the embroidery motif

> Select an embroidery motif.

> Touch the icon «i»-Dialog.

> Touch the icon «Move the motif».

> Turn the Upper Multifunction knob to move the embroidery motif horizontally.

> Turn the «Lower Multifunction knob» to move the embroidery motif vertically in 0.5-mm steps or touch

the «+»/«-» icon or touch the embroidery motif, keep it pressed and move it as you like.

– The relocation is indicated in the yellow-framed icons.

> Touch the icon «Center of the embroidery motif».

– The embroidery motif is repositioned in the center of the embroidery hoop.

Rotating motif

> Select an embroidery motif.

> Touch the icon «i»-Dialog.

> Touch the icon «Rotate the motif».

> Turn the ««Upper Multifunction knob»» or the «Lower Multifunction knob» to the right or touch the

«+» icon to rotate the embroidery motif clockwise.

> Turn the «Upper Multifunction knob» or the «Lower Multifunction knob» to the left or touch the «-»

icon to rotate the embroidery motif counter-clockwise.

> Touch the icon «Rotate the motif +90°» to rotate the embroidery motif in 90°-steps.

Altering the embroidery motif size proportionally

The alteration is limited to +/- 20%.

> Select an embroidery motif.

> Touch the icon «i»-Dialog.

52

2019-02 EN 5020070.00A.04

Page 54

Creative embroidering

> Touch the icon «Alter the embroidery motif proportionally».

> To increase the size of the embroidery motif proportionally, turn the «Upper Multifunction knob» or the

«Lower Multifunction knob» to the right or touch the icon ««+»».

> To decrease the size of the embroidery motif proportionally, turn the «Upper Multifunction knob» or the

«Lower Multifunction knob» to the left or touch the ««-»» icon .

Mirroring embroidery motifs

Embroidery motifs can be mirror-imaged both vertically and horizontally.

> Select an embroidery motif.

> Touch the icon «i»-Dialog.

> Touch the icon «Mirror image left/right» to mirror the embroidery motif vertically.

> Touch the icon «Mirror image up/down» to mirror the embroidery motif horizontally.

Checking the size and the position of the embroidery motif

It can be checked whether or not the embroidery motif matches the designated position/location on the

fabric.

> Select an embroidery motif.

> Touch the icon «i»-Dialog.

> Touch the icon «Checking the size of the embroidery motif».

– The embroidery hoop travels all the way until the needle is at the position as it is indicated in the

display.

– If the embroidery motif hasn't been positioned correctly yet, the position can be altered via the

«Upper/Lower Multifunction knobs» and the complete embroidery positions can be checked again.

2019-02 EN 5020070.00A.04

> Touch the icon «Embroidery motif center» to bring the needle to the center of the embroidery motif.

> Turn the «Upper Multifunction knob» to move the embroidery motif horizontally.

> Turn the «Lower Multifunction knob »to move the embroidery motif vertically.

53

Page 55

Creative embroidering

Deleting an embroidery motif