Page 1

HUHAAFC Series

Modular Unit Heaters

Installation, Operation & Maintenance Instructions

Specifications

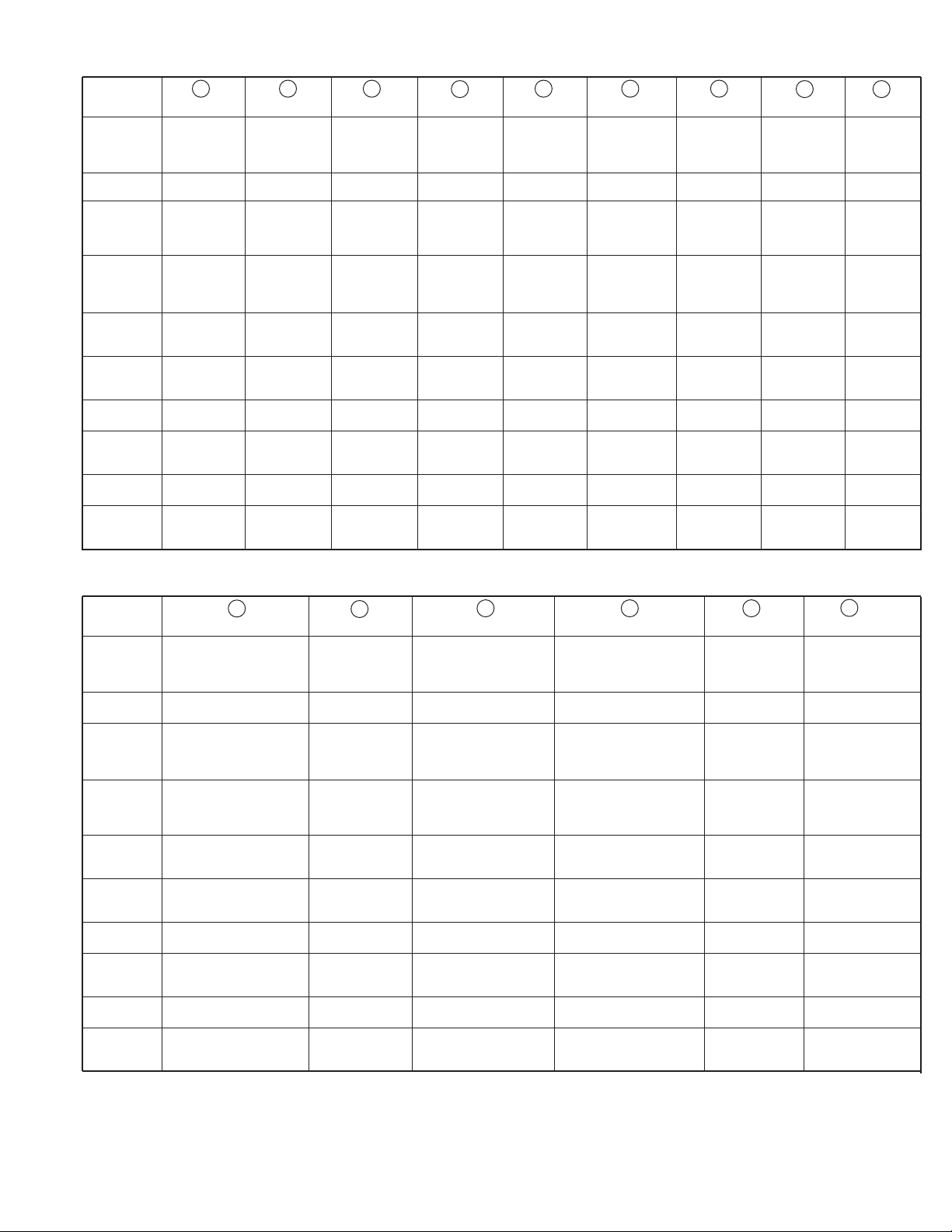

Basic Model Height Width Depth Weight Compartment

No. in (mm) in. (mm) in. (mm) lbs. (kg) Volume

HUHAA320FC

HUHAA324FC

HUHAA327FC

HUHAA348FC

HUHAA520FC

16 14 7

(406.4) (355.6) (190.5)

HUHAA524FC

HUHAA527FC

HUHAA548FC

HUHAA724FC

HUHAA720FC

HUHAA727FC

HUHAA748FC

HUHAA1020FC

3

/

4

19 71/

21

(552.5) (482.6) (190.5) (1639 cm

HUHAA1024FC

HUHAA1027FC

HUHAA1048FC

Mounting Wiring

27 (12.2)

27 (12.2)

27 (12.2)

30 (13.6)

1

/

2

27 (12.2)

27 (12.2)

27 (12.2)

30 (13.6)

38 (17.2)

38 (17.2)

2

38 (17.2)

38 (17.2)

38 (17.2)

38 (17.2)

38 (17.2)

38 (17.2)

90 in

(14.70 cm

100 in

3

3

)

3

3

)

Basic Mode Height Width Depth Weight Compartment

No. in (mm) in. (mm) in. (mm) lbs. (kg) Volume

HUHAA1520FC

HUHAA1524FC

HUHAA1548FC

HUHAA2020FC

HUHAA2024FC

HUHAA2048FC

HUHAA2524FC

HUHAA2548AFC

HUHAA3020FC

HUHAA3024FC

HUHAA3048AFC

HUHAA4024FC

HUHAA4048FC

HUHAA5024FC

HUHAA5020FC

HUHAA5048FC

3

/

4

19 123/

5

/

113/

8

5

/

171/

8

21

(552.5) (482.6) (323.9)

30 26

(76.2) (676.4) (298.5) (8260 cm

30 26

(76.2) (676.4) (435.1) (10620 cm

4

4

4

54 (24.5)

50 (22.7)

50 (22.7)

60 (27.2)

55 (24.9)

55 (24.9)

89 (40.4)

89 (40.4)

89 (40.4)

89 (40.4)

89 (40.4)

119 (54.0)

119 (54.0)

119 (54.0)

119 (54.0)

119 (54.0)

140 in

(2295 cm

504 in

648 in

Mounting Wiring

3

3

)

3

3

)

3

3

)

ECR 41912 07/19 5200-11106-004

Page 2

IMPORTANT INSTRUCTIONS

WARNING

WHEN USING ELECTRIC APPLIANCES, BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE

RISK OF FIRE, ELECTRIC SHOCK, AND INJURY TO PERSONS, INCLUDING THE FOLLOWING:

1. Read all instructions before installing or using this heater.

2. This heater is a commercial/industrial product not intended

for use in a residential setting.

3. This heater is hot when in use. To avoid burns, do not let

bare skin touch hot surfaces. Keep combustible materials,

such as furniture, pillows, bedding, papers, clothes, etc. and

curtains at least 3 feet (0.9 m) from the front of the heater.

4. Extreme caution is necessary when any heater is used by or

near children or invalids and whenever the heater is left

operating and unattended.

5. This heater has hot and arcing or sparking parts inside and

is not intended for use in hazardous atmospheres where

flammable vapors, gases, liquids or other combustible

atmospheres as defined in the National Electrical Code are

used or stored. Failure to comply can result in explosion or

fire.

6. Do not operate any heater after it malfunctions. Disconnect

power at service panel and have heater inspected by a reputable electrician before using.

!

7. Do not use outdoors.

8. To disconnect heater, turn controls to off, and turn off power

to heater circuit at main disconnect panel.

9. Do not insert or allow foreign objects to enter any ventilation

or exhaust opening as this may cause an electric shock, fire,

or damage to the heater.

10. To prevent a possible fire, do not block air intake or exhaust

in any manner.

11. Use this heater only as described in this manual. Any other

use not recommended by the manufacturer may cause fire,

12. This heater is not intended for use in special environments.

Do not use in damp or wet locations such as marine or

greenhouse or in areas where corrosive or chemical agents

are present.

13. When installing, see INSTALLATION INSTRUCTIONS for

additional warnings and precautions.

14. For safe and efficient operation, and to extend the life of your

heater, keep your heater clean - See MAINTENANCE

INSTRUCTIONS.

SAVE THESE INSTRUCTIONS

INSTALLATION INSTRUCTIONS

WARNING

To prevent a possible fire, injury to persons or damage to the

heater, adhere to the following:

1. Disconnect all power coming to heater at main service panel

before wiring or servicing.

Important Note: This heater must be installed by a qualified

person.

2. All wiring procedures and connections must be in accordance with the National and Local Codes having jurisdiction

and the heater must be grounded.

3. Verify the power supply voltage coming to heater matches

the ratings as shown on the heater nameplate.

CAUTION: ENERGIZING HEATER AT A VOLTAGE GREATER

THAN THE VOLTAGE PRINTED ON THE NAMEPLATE WILL

DAMAGE THE HEATER AND VOID THE WARRANTY AND

COULD CAUSE A FIRE.

Heater Location Instructions

Arrange units so that discharge air streams:

a. are subjected to a minimum of interference from columns,

machinery and partitions;

b. wipe exposed walls without blowing directly at them;

c. are directed away from room occupants in comfort heating;

d. are directed along the windward side when installed in a

building exposed to a prevailing wind.

!

4. To reduce the risk of fire, do not store or use gasoline or

other flammable vapors and liquids in the vicinity of the

heater.

5. The ceiling or wall mounting structure and the anchoring

provisions must be of sufficient strength to support the combined weight of the heater and mounting bracket.

6. All built-in thermostats: If the heater is used to prevent piping or liquids from freezing, and if the thermostat is set

below 45° F (7°C), the fan must run continuously.

7. The heater must be mounted at least 7’ (2134 mm) above

the floor to avoid accidental contact with the fan blade which

could cause injury.

8. Keep at least 5’ clearance in front of the heater. Refer to

Table 1 for side, top and back clearance requirements.

9. Do not mount mercury type thermostat directly on unit.

Vibration could cause heater to malfunction.

Locate thermostats approximately 5' (1524mm) above the floor

on interior partition walls or post away from cold drafts, internal

heat sources and away from heater discharge air streams.

Small rooms can be heated by one unit heater.

Large rooms require multi-unit installations. Number and capaci-

ty of units will be determined by volume of building and square

feet of floor area to be heated. Arrange units to provide perimeter

air circulation where each unit supports the air stream from

another.

2

Page 3

Mounting the Heater - General

The heater may be mounted to discharge the heated air either

horizontally or vertically. When the heater is mounted for vertical

discharge, it is recommended that the heater be positioned so

that the access door will open away from the wall to provide

greater access to the wiring and control compartment. If the

heater is to be mounted with the access door facing a wall, the

heater must be mounted far enough from that wall to allow full

opening of the access door (a distance approximately equal to

the width of the heater, check clearance before installing). Refer

to Table 1 for wall and ceiling clearances before mounting heater.

The heater may be mounted for either vertical or horizontal discharge by the use of th

ed rod sizes required.) Observe the detailed procedures in the

following installation instructions.

The heater may also be suspended from the wall or ceiling by

means of an optional mounting bracket (type MMB or MCMB)

which permits horizontal pivoting of the heater.

After the heater is installed, the louvers may be positioned to

direct the heated air in the desired direction. When the heater is

installed for horizontal discharge, the louvers should direct the

air either straight ahead or downward. Directing the air upward

may cause the heated air to remain in the ceiling area and waste

energy.

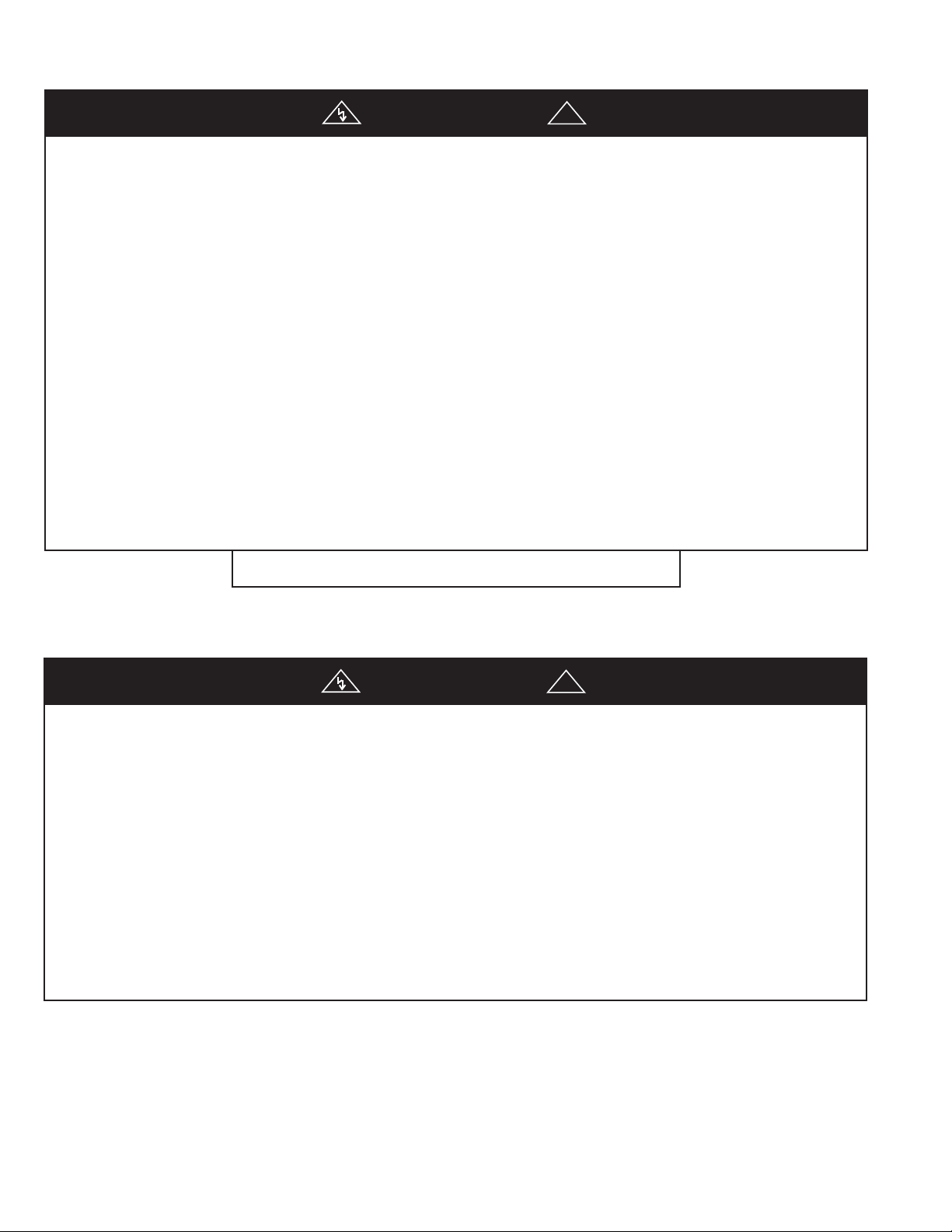

Table 1. Wall and Ceiling Clearance, inches (mm)

Minimum Floor to Bottom of heater clearance is 7 feet

Unit Discharge Ceiling Side Wall Back Wall

Horiz. 2 (50.8) 6 (152.4) 9 (228.6)

3 & 5 kW

Vert. 6 (152.4) 18 (457.2) 18 (457.2)

Horiz. 6 (152.4) 6 (152.4) 13 (330.2)

7.5 to 10 kW

Vert. 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 6 (152.4) 9 (228.6) 12

15 to 20 kW

Vert 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 16 (406.4) 12 (304.8) 18

25 to 50 kW

MOUNTING

ROD

LOCK NUT

B

A

C

K

W

A

L

L

Vert. 12 (304.8) 36 (914.4) 39 (914.4)

CEILING

Figure 1. Horizontal Discharge Mounting and Spacing.

Table 2. Rod Thread and Spacing Dimensions, inches (mm)

for Horizontal Discharge

Rod Thread

Unit Type A B C D

3 - 5 kW

7.5 - 10 kW

15 - 20 kW

25 - 30 kW

40 - 50 kW

readed rods. (Refer to Table 2 for thread-

BACK WALL

B

(TOP VIEW)

6 4

(152.4) (103.1) (19.0)

87/

(225.6) (130.3) (19.0)

14 - 12 63/

14 - 12 63/

51/

8

5

/16- 18

3

/8- 16

THREADED

MOUNTING

HOLES

A

UNIT HEATER

61/

16

(153.9)

3

/

11

8

(289.0)

9

/

10

16

(268.2) (368.3) (157.2) (16.0)

1515/

16

(404.9) (368.3) (157.2) (16.0)

1

/

16

8

16

16

1

/2(317.5)

1

/2(470.0)

D

C

3

3

5

5

S

I

D

E

W

A

L

L

/

4

/

4

/

8

/

8

Horizontal Discharge (Rod-mount from Ceiling)

1. Install four threaded mounting rods in the threaded holes and

in place using lock nuts. (See Table 2).

secure

2. Securely attach the four mounting rods to the ceiling. (Refer

to Table 1 for wall and ceiling clearances, and Table 2 for

mounting rod spacing).

Table 3. Rod Thread and Spacing Dimensions, inches (mm)

for Vertical Discharge

Rod Thread

Unit Type E F G H

3 - 5 kW

7.5 - 20 kW

25 - 30 kW

ACCESS

DOOR

B

A

C

K

W

A

L

L

5

/16- 18

3

/8- 16

CEILING

LOCK NUT

CLEARANCE EQUAL TO WIDTH OF

HEATER TO PERMIT FULL OPENING OF THE ACCESS DOOR

THREADED

MOUNTING

HOLES

/

4

145/

211/

G

(TOP VIEW)

6 9

(152.4) 247.7) (50.8) (103.1)

7

/

8

8

(225.6) (371.6) (50.8) (130.3)

1

/

14

2

(368.3) (539.8) (56.0) (157.2)

MOUNTING

ROD (4)

8

4

2 41/

2 51/

23/

16

BACK WALL

E

63/

F

H

3

Figure 2. Vertical Discharge Mounting and Rod Spacing

Vertical Discharge (Rod-Mount from Ceiling)

1. Remove bolts from the threaded holes in the back of the

heater.

2. Install four threaded mounting rods in the threaded holes and

and secure in place using lock nuts.

3. Securely attach the four mounting rods to the ceiling. (Refer

to Table 1 for wall and ceiling clearances, and Table 3 for

mounting rod spacing dimensions.)

Wiring Branch Circuit (Power)

1. Connect heater only to the voltage, amperage and frequency

specified on the namep

2. Field wiring must be properly sized to carry the amperage in

accordance with the NEC.

3. The access door is hinged. There are either one or two screws

accessible from the side that must be loosened to gain access.

These screws are the captive type; do not try to remove them.

4. A knockout is provided in the back of the heater close to the

power terminal block and the control terminal board. The contr

ol terminal board knockout is 1/2 inch (12.7 mm) conduit size.

The power terminal block knockout is multiple diameter. Use

the diameter that fits the required conduit size.

5. A ground terminal is provided near the power terminal board.

The ground wire should be connected before other connections

are made.

6. The power terminal block is equipped with box terminals sized

to accept the correct size power supply wi

wire rated min 600V, 60° C is acceptable for heaters rated up to

80 amps. For heaters rated more than 80 amps, branch circuit

wire must be rated at least 75°C. Either aluminum or copper

wire is satisfactory for connection to the heater power terminal

block box terminal. Copper wire is recommended and must be

used with built-in disconnect switch.

3

late.

re. Branch circuit

16

8

16

S

I

D

E

W

A

L

L

Page 4

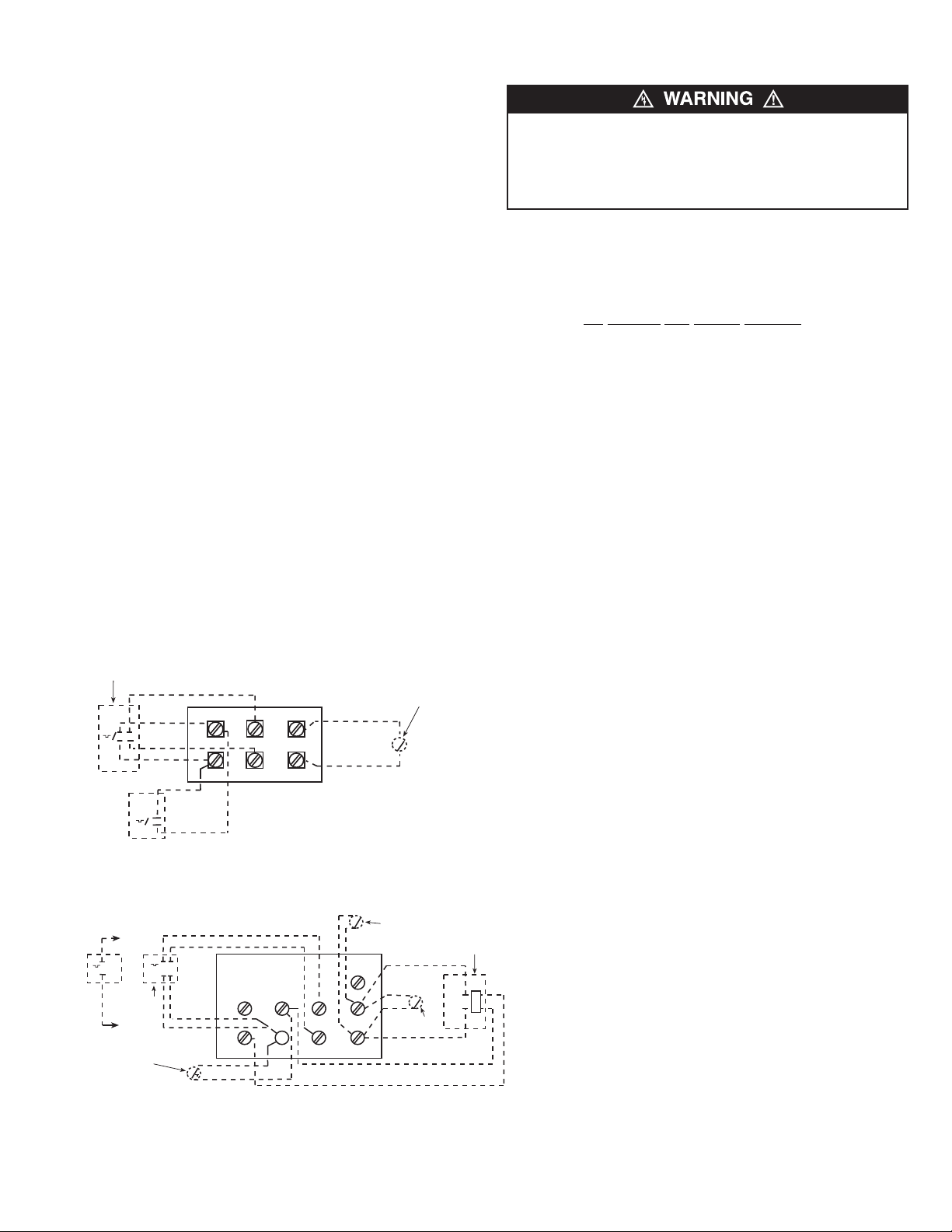

7. Each heater has a wiring diagram affixed to the inside of the

LEAD WIRE

3 PHASE BLOCK

C

1

D

1

D

1

C

1

C

1

D

1

D

1

C

1

access door. Consult this diagram before making any field

connections.

Important Note - Installation Screw Lug Torque:

During transportation it is possible screw lug connections can

loosen. After installation, before power is turned on to the heater,

check all screw lug connections for tightness to a recommended

minimum torque of 35 in-lbs. (3.9 N-m). Loose connections may

present a hazard.

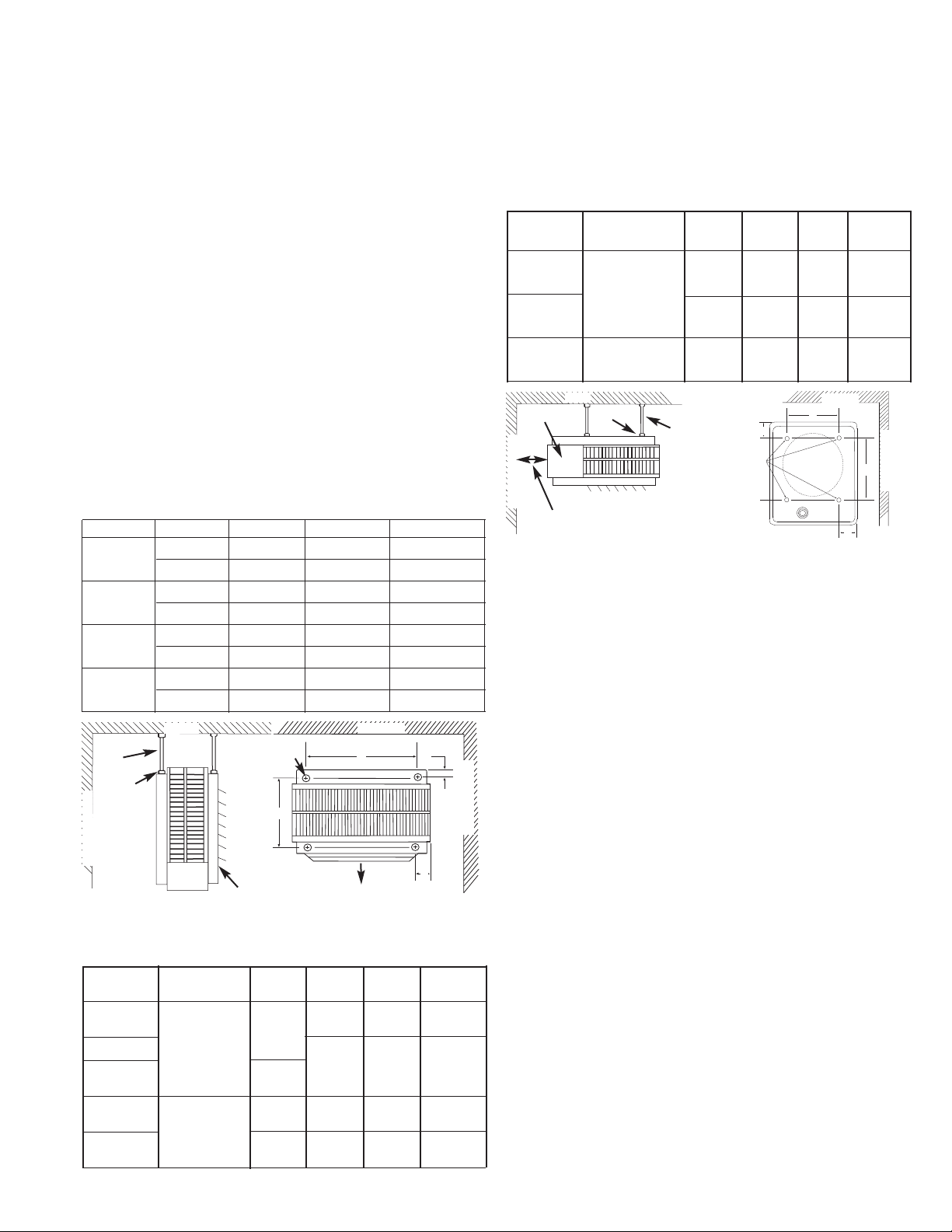

8. Single or three-phase power connections may be used with

heater models HUHAA524FC, HUHAA520FC, HUHAA720FC,

HUHAA724FC, HUHAA1024FC, HUHAA1020FC,

and

HUHAA1520FC. These units are factory wired for single-phase

operation. If these heaters are for use with three-phased power,

reconnect the wires as indicated in the wiring diagram attached

to the heater.

the wi

ring illustrations in Figures 3a and 3b and following the

Additional information can be found by looking at

directions shown below.

On models HUHAA524FC, HUHAA520FC, HUHAA724FC,

HUHAA720FC, HHUHAA1520FC, HUHAA1024FC,

and

HUHAA1020FC, (Figure 3a), move only the two wires marked

“A1”and marked “B1”; do not move or change any other wiring.

The element lead wire marked “B1” which is factory connected

to the power terminal block (terminal located closest to the

elements) must be moved to terminal “B” on the three-phase

terminal block.

HEATER FRONT

"A1"

3 PHASE BLOCK

HEATER FRONT

LEAD WIRE

"A1"

LEAD WIRE

"B1"

TO ELEMENTS

CONTACTOR

(OR P2)

B

A

POWER TERMINAL BLOCK

ELEMENTS

LEAD WIRE

"B1"

TO ELEMENTS

CONTACTOR

(OR P2)

B

A

ELEMENTS

POWER TERMINAL BLOCK

FACTORY-WIRED FOR SINGLE-PHASE POWER FIELD-WIRED FOR THREE-PHASE POWER

Figure 3a. Wiring Connections for Single-Phase and Three-Phase Power(HUHAA524FC, HUHAA520FC, HUHAA724FC,

HUHAA720FC, HUHAA1024FC, HUHAA1020FC

B

C

D

3 PHASE BLOCK

B

C

D

B

C

B

C

D

3 PHASE BLOCK

D

3 PHASE BLOCK

FACTORY-WIRED FOR SINGLE-PHASE POWER

FIELD-WIRED FOR THREE-PHASE POWER

Figure 3b. Wiring Connections for Single-Phase and Three -Phase Power (HUHAA1520FC)

4

3 PHASE BLOCK

Page 5

The relay (contactor) lead wire “A1” must be moved from the end

terminal of the power terminal block (terminal closest to the contactor or control terminal board) to the “A” terminal of the lower

terminal block (center terminal).

Model HUHAA1520FC (Figure 3b) has two three-phase terminal

blocks located adjacent to the relays (contactors). Move only the

two wires marked “C1” and “D1” on each of these two three-phase

terminal blocks to terminal “B”. Do not move or change any other

wires.

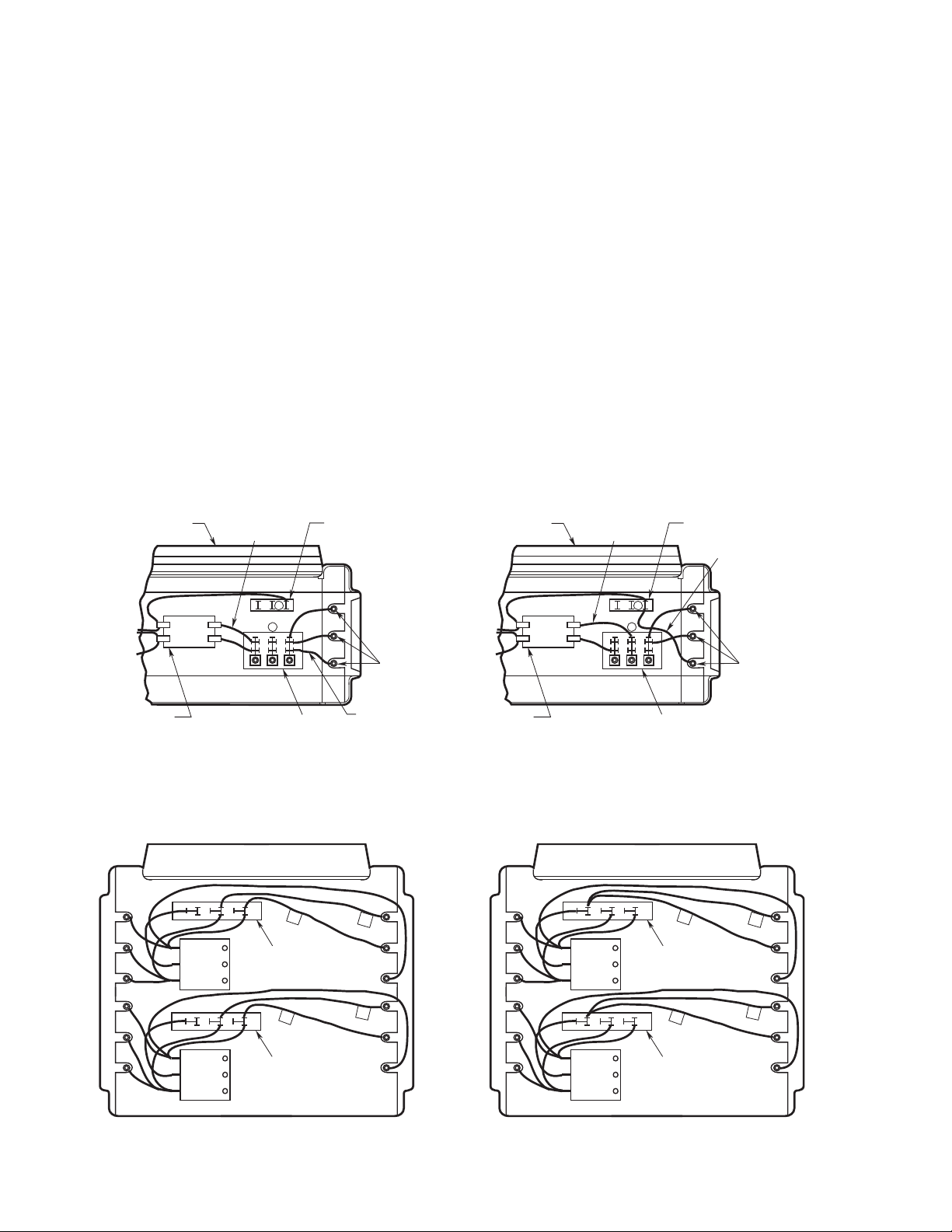

9. Electrical Accessories, either kits or factory-installed

options, are shown connected by a dash line on the heater

wiring diagram.

10. 208/240 VOLT HEATER: The heaters are wired for 240V

from factory. When

heater is to be connected to 208V supply, the transformer leads MUST BE interchanged. For units

rated 30/40kW or higher, interchange ORANGE and RED

primary leads. The black colored lead is the COMMON for

the transformer (50VA) provided with the high wattage units.

For lower kW rated heaters, interchange BLACK and RED

primary leads. The WHITE colored lead is the COMMON for

the control transformer provided with these heaters. Always

refer to the wiring diagram on the cover of the heater before

making this reconnection of tranformer primary leads.

Control Wiring

LINE VOLTAGE IS PRESENT ON SOME OF THE TERMINALS

ON THE CONTROL TERMINAL BOARD. ALWAYS DISCONNECT THE POWER FROM THE HEATER BEFORE MAKING

ANY CONNECTIONS TO THE CONTROL BOARD TO PREVENT ELECTRIC SHOCK HAZARD.

1. Use min. 600 volts, NEC Class 1 insulated wire for all control

circuit wiring.

2. Use a crimp-on type fork terminal on the wire ends that

attach to the control terminal board if more than one connection is to be made under the terminal screw.

3. On units not

provided with internal contactor (3 & 5 KW),

refer to Figure 4 for wiring diagram.

NOTE: Thermostat and control circuit wiring must be suitable to

handle the full load of the heater (example HUHAA520FC is

rated 24amps)

4. On units provided with internal contactor (units rated 7 KW

and higher) refer to Figure 5 for wiring diagram. Control

wiring must be rated minimum 18 AWG.

OPERATING

CAUTION: To prevent a possible fire or damage to heater,

if a two stage thermostat is provided, it MUST be wired so

Stage 1 turns the rear heating element (where fan control is

located) on first and off last. Stage 2 MUST turn on

elements other than the rear element as the need for

additional heat is required and will turn on last and off first.

2-STAGE

INTERNAL

THERMOSTAT

MT-2

BLACK

MT-1

RED

BLACK

RED

H1

H2

F 2

P1

F 1

P2

IMPORTANT! FOR 2 STAGE THERMOSTATS, USE:

1. H1 AND P1 FOR STAGE 1 CONNECTIONS

2. H2 AND P2 FOR STAGE 2 CONNECTIONS

REMOTE SUMMER

FAN SWITCH (MRFS-1)

OR SUMMER FAN

SWITCH MCFS (MANUAL)

S

INSTRUCTIONS

1. Heater must be properly installed before operation.

2. Turn power supply to heater “ON” at main switch panel.

3. Where applicable, refer to control accessory instructions

Figure 4. Control Terminal Board (for Heaters Without Contactors)

REMOTE SUMMER FAN

S

T R

F 1

F 2

SWITCH (MRFS-1)

S

SUMMER

FAN

SWITCH

FAN RELAY

(FOR MRFS-2 AMD MHRT)

BLACK TO W1

T

MT-1

2-STAGE

INTERNAL

THERMOSTAT

RED TO R

MHRT HEAT RECOVERY

THERMOSTAT OR

REMOTE FAN

SWITCH (MRFS-2)

RED

BLACK

T

MT-2

BLACK

RED

T

G

W2

R W1

C

regarding proper operation of any controls or accessories

used with the heater.

NOTES:

1. THIS STYLE CONTROL TERMINAL BOARD USED WITH MODELS HUHAA324FC,

HUHAA327FC, HUHAA320FC, HUHAA524FC, HUHAA527FC, AND HUHAA520FC.

2. WHEN UNIT IS WIRED FOR SINGLE-PHASE, JUMPER H1 TO H2. IF SINGLEPOLE THERMOSTAT IS USED WITH SINGLE-PHASE UNIT, CONNECT

THERMOSTAT LEADS TO P1 AND H1.

3. EXTERNAL LINE VOLTAGE THERMOSTATS SHOULD BE TREATED AS

SINGLE STAGE ONLY.

NOTES:

1. THIS STYLE CONTROL TERMINAL BOARD USED WITH MODELS

EXCEPT HUHAA324FC, HUHAA327FC, HUHAA320FC, HUHAA524FC,

HUHAA527FC, AND HUHAA520FC.

2. REMOVE JUMPER W1 TO W2 WHEN 2-STAGE THERMOSTAT IS USED.

3. *ONLY ONE OF THESE ACCESSORIES MAY BE INSTALLED IN A

SINGLE HEATER.

4. EXTERNAL LINE VOLTAGE THERMOSTATS SHOULD BE TREATED AS

SINGLE STAGE ONLY.

IMPORTANT! FOR 2 STAGE THERMOSTATS, USE:

1. W1 AND R FOR STAGE 1 CONNECTIONS

2. W2 AND R FOR STAGE 2 CONNECTIONS

Figure 5. Control Terminal Board (for Heaters With Contactors)

5

Page 6

How to Reset Manual Reset Safety Limit

(Factory Installed Option Only)

The manual reset switch is located internally on the rear of the

heater. On the 3KW and 5KW models, the access to the reset

button is on the right side (when facing rear of heater); on all

other models it is near the top rear of the heater.

The manual reset limit is in series with the automatic recycling

protector (limit). The manual reset limit will not reset until the

heater has cooled and the button is pushed in.

DO NOT TAMPER WITH OR BYPASS ANY SAFETY LIMITS

INSIDE HEATER.

CAUTION - DO NOT CONTINUE TO ATTEMPT TO USE THE

HEATER IF THE SAFETY CONTROL REPEATEDLY OPERATES AFTER BEING RESET. TO DO SO COULD PERMANENTLY DAMAGE THE HEATER OR CREATE A FIRE OR

SAFETY HAZARD.

It is important to keep this heater clean. Your heater will give you

years of service and comfort with only minimum care. To assure

efficient operation follow the simple instructions below.

ALL SERVICING BEYOND SIMPLE CLEANING THAT

REQUIRES DISASSEMBLY SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

MAINTENANCE

INSTRUCTIONS

It is important to keep this heater clean. Your heater will give you

of service and comfort with only minimum care. To assure

years

efficient operation follow the simple instructions below.

ALL SERVICING BEYOND SIMPLE CLEANING THAT

REQUIRES DISASSEMBLY SHOULD BE PERFORMED BY

QUALIFIED SERVICE PERSONNEL.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK OR

INJURY, DISCONNECT ALL POWER COMING TO HEATER

AT MAIN SERVICE PANEL AND CHECK THAT THE ELEMENT

IS COOL BEFORE SERVICING OR PERFORMING

MAINTENANCE.

User Cleaning Instructions:

1. After the heater has cooled, a vacuum cleaner with brush

attachment may be used to remove dust and lint from exterior

surfaces of the heater including the grille openings.

2. With a damp cloth, wipe dust and lint from grille and exterior

surfaces.

3. Return power to heater and check to make sure it is operating properly.

TO REDUCE RISK OF FIRE AND ELECTRIC SHOCK OR

INJURY, DISCONNECT ALL POWER COMING TO HEATER

AT MAIN SERVICE PANEL AND CHECK THAT THE ELEMENT

IS COOL BEFORE SERVICING OR PERFORMING

MAINTENANCE.

User Cleaning Instructions:

1. After the heater has cooled, a vacuum cleaner with brush

attachment may be used to remove dust and lint from exterior

surfaces of the heater

2. With a damp cloth, wipe dust and lint from grille and exterior

surfaces.

3. Return power to heater and check to make sure it is operating properly.

including the grille openings.

Maintenance Cleaning Instructions:

(To be performed only by Qualified Service Personnel)

At least annually, the heater should be cleaned and serviced by

a qualified service person to assure safe and efficient operation.

This should include as necessary, vacuuming dust and debris

from the elements and fan, and checking all screw lug connections for tightness to a recommended minimum torque of 35 inlbs. (3.9 N-m). After completing the cleaning and servicing, the

heater should be fully reassembled and checked for proper

operation.

6

Page 7

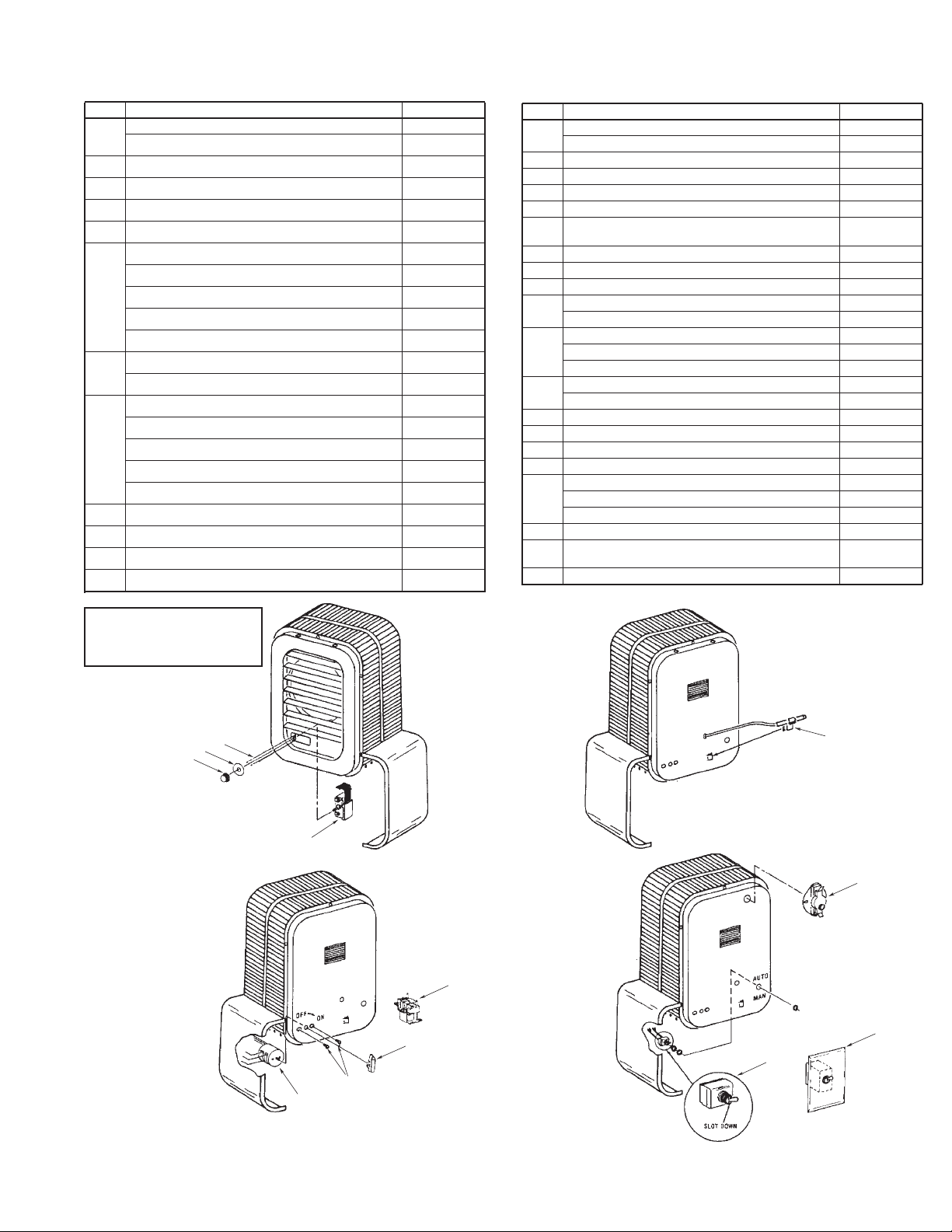

HUHAA FC

Built-in Controls

Key No. Description Part Number

1 Thermostat, One Pole (MT-1) 5813-0036-000

Thermostat, Two Stage (MT-2) 5813-0035-000

2 Knob, Thermostat 3301-0060-000

3 Label, Thermostat 3502-1781-000

4 Screws, Fl. Hd., 6-32 x 1/4 5202-7009-021

5 Clip, Thermostat 1403-0041-000

6 Switch, 25A, OEM 5216-0132-000

Switch, 25A, K & N 5216-0204-000

Switch, 63A, OEM 5216-0131-000

Switch, 63A, K & N 5216-0203-000

Switch 25A, Electro 5216-0200-000

7 Screw, M4 x 10, Rd. Hd., (25A) —

Screw, 63A, M5 x 16, Rd. Hd. —

8 Knob, 25A, OEM “T1” OEM “T1”

Knob, 25A, K & N

Knob, 63A, OEM OEM “S4”

Knob, 63A, K & N

Knob, Electro EI 141747

9 Switch, Toggle, 600V 5216-0130-000

10 Relay, Fan, 24V Coil 5018-0008-000

11 Switch Assembly 5216-0199-000

12 Manual Reset Limit 4520-0012-000

K & N S1B 6001

K & N S2B G001

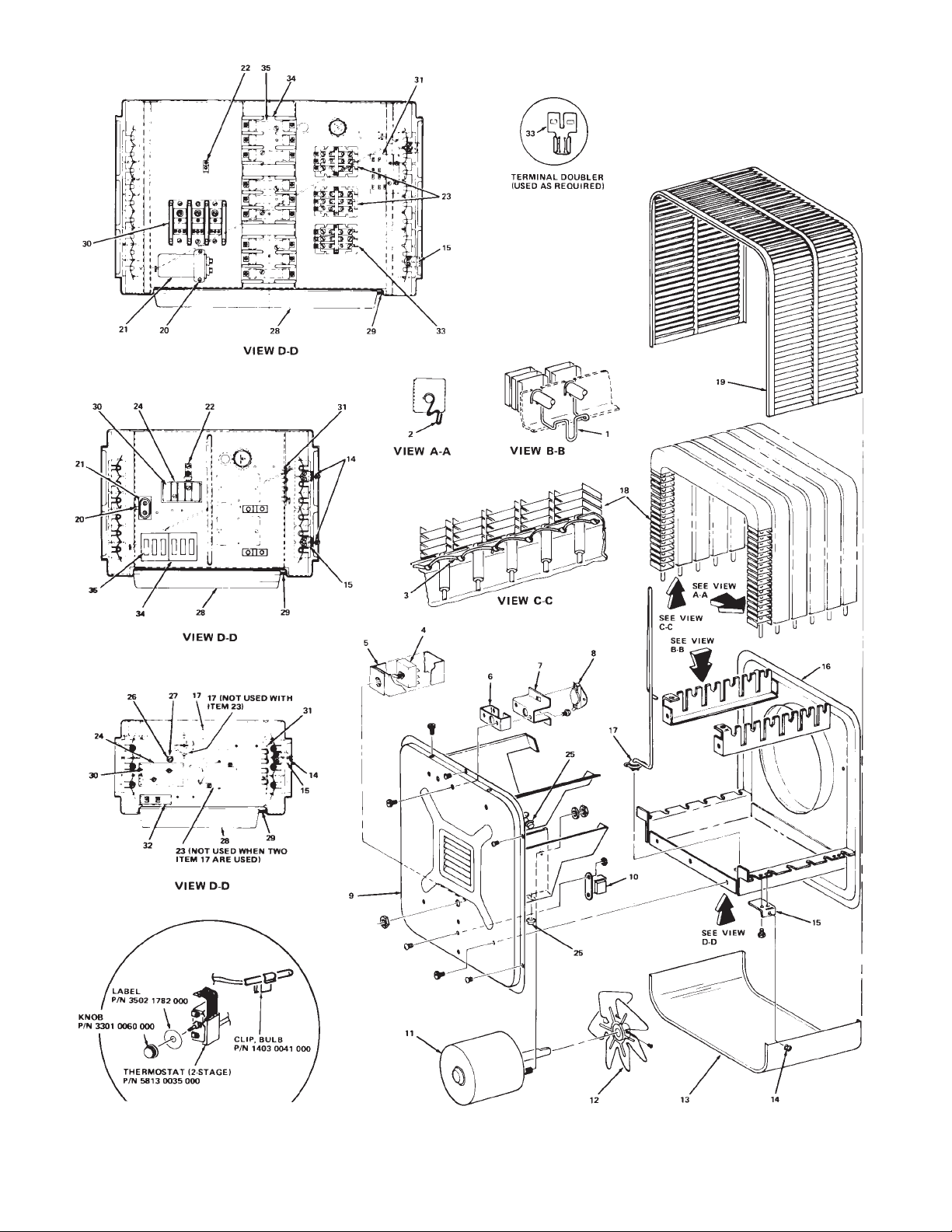

Heater Replacement Parts

Key No. Description Part Number

1 Spring, Element (used on 20kW and below only) 5208-0073-000

Spring, Element (used on 25kW and below only) 5208-0073-001

2 Spring, Capillary Tube 5208-0072-000

3 Spring, Element Retainer 5208-0074-000

4 Switch (used on 25kW thru 50kW only) 5216-7076-001

5 Insulator (used on 25kW thru 50kW only) 2900-0031-000

6 Bracket Extension

(used on 15kW, 20kW, 40kW and 50kW only) 1215-0282-000

7 Switch Bracket 1215-0256-000

8 Fan Delay 4520-0010-000

14 Speed Nut 4100-7036-026

15 Bracket, Captive Screw (used on 3kW thru 20kW only) 1215-0291-000

Bracket, Captive Screw (used on 25kW thru 50kW only) 1215-0289-000

17 Protector, Linear Limit (used on 3kW thru 5kW only) 4520-0011-000

Protector, Linear Limit (used on 7kW thru 20kW only) 4520-0011-001

Protector, Linear Limit (used on 25kW thru 50kW only) 4520-0011-002

20 Clamp (used on 20kW thru 50kW only) 1417-5004-000

Bracket, Mounting Capacitor (used on 20kW, 208v only) 1215-0314-000

22 Terminal Lug (used on 7kW thru 50kW only) 3504-7002-001

25 Bushing (used on 20kW thru 50kW only) 25221-60131

26 Washer, Ground (used on 3kW thru 5kW only) 6401-0084-000

27 Screw, Ground (used on 3kW thru 5kW only) 5202-0290-002

28 Louver (used on 3kW thru 5kW only) 3503-0036-000

Louver (used on 7kW thru 20kW only) 3503-0036-001

Louver (used on 25kW thru 50kW only) 3503-0036-002

29 Spring, Louver 5208-7005-001

32 Terminal Block, 3-Phase (used where models

can be 1 or 3 phase) 5823-0003-000

33 Terminal Doublers (used where required) 5819-7012-005

BUILT-IN CONTROLS —

Made-to-Order Units Only

4

3

2

POWER

DISCONNECT

SWITCH

SINGLE-POLE

THERMOSTAT, TWO-STAGE

THERMOSTAT, HEAT

RECOVERY THERMOSTAT

5

1

12

SUMMER

FAN

10

8

SWITCH

11

9

7

6

9

7

Page 8

25KW THRU 50KW ONLY

7KW THRU 20KW ONLY

3KW THRU 5KW ONLY

THESE PARTS ARE USED ON

FACTORY 2T OPTION ONLY

8

Page 9

9 10 11 12 13 16 18 19 21

Model No. Back Case Transformer** Motor Fan Blade Cover Front Case Element Assy. Element Guard Capacitor

HUHAA324FC

HUHAA348FC

HUHAA327FC

HUHAA320FC

HUHAA548FC

HUHAA527FC

HUHAA724FC

HUHAA720FC

HUHAA748FC

HUHAA727FC

HUHAA1024FC

HUH

AA1027FC

HUHAA1048FC

HUHAA1020FC

HUHAA1524FC

HUHAA1548FC

HUHAA1520FC

HUHAA2024FC

HUHAA2048FC

HUHAA2020FC

HUHAA2524FC

HUHAA2548AFC

HUHAA3024FC

HUHAA3048AFC

HUHAA3020FC

HUHAA4024FC

HUHAA4048FC

HUHAA5020FC

HUH

AA5024FC

HUHAA5048FC

1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-000 2504-0011-000 –

1425-2004-000 5814-0003-002 3900-2005-000 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-002 2504-0011-000 –

1425-2004-000 – 3900-2002-007 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-001 2504-0011-000 –

1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-024 2504-0011-000 –

1425-2004-000 5814-0003-002 3900-2005-000 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-005 2504-0011-000 –

1425-2004-000 – 3900-2002-007 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-004 2504-0011-000 –

1425-0010-004 5814-0003-000 3900-2014-002 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-006 2504-0013-001 –

1425-0010-004 5814-0003-000 3900-2014-001 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-031 2504-0013-001 –

1425-0010-004 5814-0003-002 3900-0347-005 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-008 2504-0013-001 –

1425-0010-004 5814-0003-001 3900-2014-003 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-007 2504-0013-001 –

1425-0010-004 5814-0003-000 3900-2014-002 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-031 2504-0013-001 –

1425-0010-004 5814-0003-001 3900-2014-003 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-010 2504-0013-001

1425-0010-004 5814-0003-002 3900-0347-005 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-011 2504-0013-001 –

1425-0010-004 5814-0003-000 3900-2014-001 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-036 2504-0013-001 –

1425-0014-000 5814-0003-000 3900-0361-000 1210-0090-001 1402-0339-003 1425-0009-017 1802-0087-012 2504-0012-001 –

1425-0014-000 5814-0003-002 3900-0361-001 1210-0090-001 1402-0339-003 1425-0009-017 1802-0087-013 2504-0012-001 –

1425-0014-000 5814-0003-000 3900-0361-002 1210-0090-001 1402-0339-003 1425-0009-017 1802-0087-031 2504-0012-001 –

1425-0013-000 5814-0003-000 3900-0362-000 1210-0096-000 1402-0339-003 1425-0009-017 1802-0087-014 2504-0012-001 1432-0002-003

1425-0013-000 5814-0003-002 3900-0362-001 1210-0096-000 1402-0339-003 1425-0009-017 1802-0087-015 2504-0012-001 1432-0002-003

1425-0013-000 5814-0003-000 3900-0362-002 1210-0096-000 1402-0339-003 1425-0009-017 1802-0087-026 2504-0012-001 1432-0002-003

1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-016 2504-0014-001 1432-0002-001

1425-0011-003 5814-0003-002 3900-0363-001 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-017 2504-0014-001 1432-0002-003

1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-018 2504-0014-001 1432-0002-001

1425-0011-003 5814-0003-002 3900-0363-000 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-019 2504-0014-001 1432-0002-003

1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0009-017 1802-0087-028 2504-0014-001 1432-0002-001

1425-0011-001 5814-0003-000 3900-0350-000 1210-0097-000 1402-0340-003 1425-0012-006 1802-0087-020 2504-0015-001 1432-0002-004

1425-0011-001 5814-0003-002 3900-0350-001 1210-0097-000 1402-0340-003 1425-0012-006 1802-0087-021 2504-0015-001 1432-0002-004

1425-0011-001 5814-0003-000 3900-0350-000 1210-0097-000 1402-0340-003 1425-0012-006 1802-0087-022 2504-0015-001 1432-0002-004

1425-0011-001 5814-0003-000 3900-0350-000 1210-0097-000 1402-0340-003 1425-0012-006 1802-0087-022 2504-0015-001 1432-0002-004

1425-0011-001 5814-0003-002 3900-0350-001 1210-0097-000 1402-0340-003 1425-0012-006 1802-0087-023 2504-0015-001 1432-0002-004

–

23 24 30 31 34 35

Model No. Relay*** Insulator Terminal Block, Power Terminal Block, Control Fuse Block Fuse

HUHAA324FC –– 5823-0004-000 5823-0001-000 – –

HUHAA348FC 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 – –

HUHAA327FC – 2900-0030-000 5823-0004-000 5823-0001-000 – –

HUHAA320FC –– 5823-0004-000 5823-0001-000 – –

HUHAA548FC 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 – –

HUHAA527FC – 2900-0030-000 5823-0004-000 5823-0001-000 – –

HUHAA720FC

HUHAA724FC 5018-0003-000 5823-0004-000 5823-0002-000

HUHAA748FC 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 – –

HUHAA727FC 5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 – –

HUHAA1024FC

HUH 5018-0003-000 2900-0030-000 5823-0004-000 5823-0002-000AA1027FC

HUHAA1048FC

HUHAA1020FC

HUHAA1524FC

HUHAA1548FC

HUHAA1520FC

HUHAA2024FC

HUHAA2048FC

HUHAA2020FC

HUHAA2524FC

HUHAA2548FC

HUHAA3024FC

HUHAA3048AFC

HUHAA3020FC

HUHAA4024FC

HUHAA4048FC

HUHAA5020FC

HUH 5018-0006-000 5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-080AA5020FC

HUHAA5048FC

* Two relays are used: 35A relay P/N 5018-0004-000 and 40A relay P/N 5018-0006-000.

** 24V secondary shown. For 120V secondary, increase last digit by 3. (i.e. for MUHAA348FC, 24V secondary use 5814-0003-002; for 120V secondary use 5814-0003-005.)

*** 24V H.C. shown. For 120 H.C., increase last digit by 1. (i.e.: for HUHAA348FC, 24V H.C. use 5018-0004-000; for 120V H.C. use 5018-0004-001.)

5018-0003-000 –

5018-0003-000 – 5823-0004-000 5823-0002-000 –

5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 – –

5018-0004-100 – 5823-0004-000 5823-0002-000 – –

5018-0005-004 – 5823-0004-001 5823-0002-000 – –

5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 – –

5018-0005-008 – 5823-0004-003 5823-0002-000 2025-0002-000 2019-0007-010

5018-0006-000 – 5823-0004-002 5823-0002-000 – –

5018-0004-100 2900-0030-000 5823-0004-000 5823-0002-000 – –

5018-0005-000 – 5823-0004-002 5823-0002-000 2025-0002-000 2019-0007-008

5018-0005-004 – 5823-0004-002 5823-0002-000 2025-7002-000 2019-7008-077

5018-0005-004 2900-0030-000 5823-0004-001 5823-0002-000 – –

5018-0005-004 – 5823-0004-003 5823-0002-000 2025-7002-000 2019-7008-079

5018-0005-004 2900-0030-000 5823-0004-001 5823-0002-000 – –

5018-0006-000 – 5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-080

5018-0005-004 – 5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-079

* 2900-0030-000 5823-0004-002 5823-0002-000 2025-7002-000 2019-7008-079

5018-0005-004 –

* 2900-0030-000 5823-0004-002 5823-0002-000 – –

–

–

5823-0004-000 5823-0002-000 – –

5823-0005-000 5823-0002-000 2025-7002-000 2019-7008-080

– –

–

–

–

9

Page 10

Maintenance Cleaning Instructions:

(To be performed only by Qualified Service Personnel)

At least annually, the heater should be cleaned and serviced by

a qualified service person to assure safe and efficient operation.

This should include as necessary, vacuuming dust and debris

from the elements and fan, and checking all screw lug connections for tightness to a recommended minimum torque of 35 inlbs. (3.9 N-m). After completing the cleaning and servicing, the

heater should be fully reassembled and checked for proper

operation.

All products manufactured by Marley Engineered Products are warranted against defects in workmanship and materials for one year from date of installation, except

LIMITED WARRANTY

heating elements which are warranted against defects in workmanship and materials for five years from date of installation. This warranty does not apply to damage from

accident, misuse, or alteration; nor where the connected voltage is more than 5% above the nameplate voltage; nor to equipment improperly installed or wired or

maintained in violation of the product’s installation instructions. All claims for warranty work must be accompanied by proof of the date of installation.

The customer shall be responsible for all costs incurred in the removal or reinstallation of products, including labor costs, and shipping costs incurred to return products to

Marley Engineered Products Service Center. Within the limitations of this warranty, inoperative units should be returned to the nearest Marley authorized service center

or the Marley Engineered Products Service Center, and we will repair or replace, at our option, at no charge to you with return freight paid by Marley. It is agreed that such

repair or replacement is the exclusive remedy available from Marley Engineered Products.

THE ABOVE WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE AFORESAID EXPRESSED WARRANTIES ARE HEREBY DISCLAIMED AND EXCLUDED FROM THIS

AGREEMENT. MARLEY ENGINEERED PRODUCTS SHALL NOT BE LIABLE FOR CONSEQUENTIAL DAMAGES ARISING WITH RESPECT TO THE

PRODUCT, WHETHER BASED UPON NEGLIGENCE, TORT, STRICT LIABILITY, OR CONTRACT.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above exclusion or limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

For the address of your nearest authorized service center, contact Marley Engineered Products in Bennettsville, SC, at 1-800-642-4328. Merchandise returned to the factory must be accompanied by a return authorization and service identification tag, both available from Marley Engineered Products. When requesting return authorization,

include all catalog numbers shown on the products.

HOW TO OBTAIN WARRANTY SERVICE AND

WARRANTY PARTS PLUS GENERAL INFORMATION

1. Warranty Service or Parts 1-800-642-4328

2. Purchase Replacement Parts 1-800-654-3545

3. General Product Information www.marleymep.com

Note: When obtaining service always have the following:

1. Model number of the product

2. Date of manufacture

3. Part number or description

10

470 Beauty Spot Rd. East

Bennettsville, SC 29512 USA

Page 11

Serie HUHAAFC

Unidades calefactoras

modulares

Instrucciones de instalación, operación y mantenimiento

Especificaciones

Modelo pulg. pulg. pulg. montaje compartimiento

básico Nº (mm) (mm) (mm) lb (kg) de cables

HUHAA320FC

HUHAA324FC

HUHAA327FC

HUHAA348FC

HUHAA520FC

HUHAA524FC

HUHAA527FC

HUHAA548FC

HUHAA724FC

HUHAA720FC

HUHAA727FC

HUHAA748FC

HUHAA1020FC

HUHAA1024FC

HUHAA1027FC

HUHAA1048FC

Altura, Ancho, Prof., Peso de Volumen del

27 (12.2)

27 (12.2)

27 (12.2)

30 (13.6)

16 14 7

(406.4) (355.6) (190.5)

1

/

2

27 (12.2)

90 pulg

(14.70 cm

27 (12.2)

27 (12.2)

30 (13.6)

38 (17.2)

38 (17.2)

38 (17.2)

3

/

4

19 71/

2

38 (17.2)

38 (17.2)

21

(552.5) (482.6) (190.5) (1639 cm

100 pulg

38 (17.2)

38 (17.2)

38 (17.2)

3

3

3

Modelo pulg. pulg. pulg. montaje compartimiento

básico Nº (mm) (mm) (mm) lb (kg) de cables

HUHAA1520FC

HUHAA1524FC

HUHAA1548FC

HUHAA2020FC

3

HUHAA2024FC

)

HUHAA2048FC

HUHAA2524FC

HUHAA2548AFC

HUHAA3020FC

HUHAA3024FC

HUHAA3048AFC

HUHAA4024FC

)

HUHAA4048FC

HUHAA5024FC

HUHAA5020FC

HUHAA5048FC

Altura, Ancho, Prof., Peso de Volumen del

54 (24.5)

50 (22.7)

3

/

4

19 123/

21

(552.5) (482.6) (323.9)

50 (22.7)

4

60 (27.2)

140 pulg

(2295 cm

55 (24.9)

55 (24.9)

89 (40.4)

5

/

30 26

(76.2) (676.4) (298.5) (8260 cm

113/

8

89 (40.4)

4

89 (40.4)

504 pulg

89 (40.4)

89 (40.4)

119 (54.0)

5

/

30 26

(76.2) (676.4) (435.1) (10620 cm

171/

8

4

119 (54.0)

119 (54.0)

648 pulg

119 (54.0)

119 (54.0)

3

3

)

3

3

)

3

3

)

ECR 41912 07/19 5200-11106-004

Page 12

INSTRUCCIONES IMPORTANTES

ADVERTENCIA

AL UTILIZAR ARTEFACTOS ELÉCTRICOS, PARA REDUCIR EL

RIESGO DE INCENDIO, CHOQUE ELÉCTRICO Y LESIONES PERSONALES DEBEN OBSERVARSE SIEMPRE ALGUNAS PRECAUCIONES BÁSICAS, COMO LAS SIGUIENTES:

1. Lea todas las instrucciones antes de instalar o utilizar este calefactor.

2. Este calefactor es un producto comercial/industrial, que no está

destinado a su empleo en un entorno residencial.

3. Cuando está en funcionamiento, el calefactor está muy caliente.

Para evitar quemaduras, no deje que su piel haga contacto directo

con las superficies calientes. Mantenga los materiales combustibles

como muebles, almohadas, ropas de cama, papeles, ropas, cortinas, etc. a 0.9 m (3 pies) como mínimo del frente del calefactor.

4. Se necesita extremo cuidado al utilizar cualquier calefactor junto a

o cerca de niños o inválidos, y en todo momento en que el calefactor quede funcionando y desatendido.

5. Este calefactor tiene en su interior piezas calientes y piezas en las

que se producen arcos o chispas, y no está destinado a su empleo

en atmósferas peligrosas en las que se usen o almacenen vapores,

gases o líquidos inflamables u otras atmósferas combustibles como

las define el Código Eléctrico Nacional de los EE. UU. Si no se

cumple esto puede producirse una explosión o incendio.

6. No opere ningún calefactor después de que haya tenido una falla

de funcionamiento. Desconecte la alimentación eléctrica en el

!

tablero de servicio y haga revisar el calefactor por un electricista

calificado antes de usarlo.

7. No use el equipo en exteriores.

8. Para desconectar el calefactor, lleve los controles a la posición

Apagado (OFF) y desconecte la alimentación del circuito del calefactor en el tablero de desconexión principal.

9. No inserte ni permita que entren objetos extraños en ninguna abertura de ventilación o de descarga, porque esto puede ser causa de

choque eléctrico, incendio o daño al calefactor.

10. Para evitar un posible incendio, no bloquee de ningún modo la

entrada ni la descarga de aire.

11. Utilice este calefactor únicamente de la manera descrita en este

manual. Todo otro uso no recomendado por el fabricante puede

originar un incendio.

12. Este calefactor no está destinado a su empleo en entornos especiales. No lo use en lugares húmedos o mojados como zonas marítimas o invernaderos, ni en áreas en las que estén presentes

agentes químicos o corrosivos.

13. Al realizar la instalación, vea las advertencias y precauciones adicionales en las INSTRUCCIONES DE INSTALACIÓN.

14. Para asegurar una operación segura y eficiente, y para extender la

vida útil de su calefactor, manténgalo limpio. Vea las INSTRUCCIONES DE MANTENIMIENTO.

GUARDE ESTAS INSTRUCCIONES

INSTRUCCIONES DE INSTALACIÓN

ADVERTENCIA

Para evitar un posible incendio, lesiones personales o daños al calefactor,

observe lo siguiente:

1. Antes de proceder a tareas de conexionado o de reparación del calefactor, desconecte toda la alimentación eléctrica que llega al mismo

desde el tablero principal de servicio.

Nota importante: este calefactor debe ser instalado por personal calificado.

2. Todos los procedimientos de cableado y conexiones deben hacerse de

conformidad con los códigos nacionales y locales que tengan jurisdicción, y el calefactor debe estar conectado a tierra.

3. Verifique que la tensión de alimentación provista al calefactor coincida

con la tensión nominal indicada en la placa de características del

mismo.

ATENCIÓN: SI SE ENERGIZA UN CALEFACTOR CON UNA TENSIÓN

MAYOR QUE EL VALOR DE TENSIÓN IMPRESO EN LA PLACA DE CARACTERÍSTICAS, SE DAÑARÁ EL CALEFACTOR, SE ANULARÁ LA

GARANTÍA, Y PODRÍA PRODUCIRSE UN INCENDIO.

Instrucciones sobre la ubicación del calefactor

Disponga las unidades de manera que las corrientes de aire de

descarga:

a. Estén sujetas a un mínimo de interferencia a causa de columnas,

maquinaria y tabiques;

b. Se deslicen por las paredes expuestas sin impactar directamente contra

ellas.

c. Se dirijan lejos de los ocupantes de la habitación en aplicaciones de

calefacción ambiental;

d. Se dirijan a lo largo del lado de donde viene el viento, cuando se instalan

!

4. Para reducir el riesgo de incendio, no almacene ni use gasolina u otros

vapores y líquidos inflamables en las cercanías del calefactor.

5. La estructura de montaje en el cielorraso o la pared, así como los

medios de anclaje, deben tener la resistencia suficiente para soportar el

peso combinado del calefactor y del soporte de montaje.

6. Todos los termostatos incorporados: si el calefactor se usa para prevenir

el congelamiento de tuberías o líquidos y el termostato se ajusta por

debajo de 7 ºC (45 ºF), el ventilador debe funcionar continuamente.

7. El calefactor debe montarse al menos a 2134 mm (7’) encima del piso

para evitar el contacto accidental con la paleta del ventilador, lo que

podría causar lesiones.

8. Mantenga un espacio libre de 1524 mm (5’) como mínimo delante del

calefactor. Para ver los requisitos de espacio libre lateral, superior y posterior consulte la Tabla 1.

9. No monte un termostato de mercurio directamente sobre la unidad. La

vibración podría hacer que el calefactor funcione mal.

en un edificio expuesto a un viento preponderante.

Localice los termostatos aproximadamente 1524 mm (5’) por encima del

piso, en paredes divisorias interiores, o colóquelos lejos de corrientes de

aire frío, fuentes de calor internas y de las corrientes de aire de descarga

de calefactores.

Las habitaciones pequeñas pueden usar una unidad calefactora única.

Las habitaciones grandes requieren instalaciones de unidades múltiples.

La cantidad y la capacidad de las unidades se determinará de acuerdo

con el volumen del edificio y el área de piso (pies cuadrados) a calefaccionar. Disponga las unidades para proporcionar una circulación de aire

perimetral, en la que cada unidad soporte la corriente de aire de otra.

12

Page 13

Montaje del calefactor - Generalidades

El calefactor puede montarse para descargar el aire caliente horizontalmente o verticalmente. Cuando el calefactor se monta para descarga

vertical, se recomienda posicionarlo de manera que la puerta de acceso

se abra en sentido contrario a la pared, a fin de proporcionar mayor

acceso al compartimiento de cables y control. Si el calefactor se va a

montar con la puerta de acceso enfrentada a una pared, debe montarse

lo suficientemente lejos de esa pared a fin de permitir la apertura plena

de la puerta (una distancia aproximadamente igual al ancho del calefactor; verifique el espacio libre antes de la instalación). Para ver los espacios libres en relación con las paredes y el cielorraso antes de montar el

calefactor, consulte la Tabla 1.

El calefactor puede montarse para descarga vertical u horizontal, mediante el uso de varillas roscadas. (Para ver los tamaños de varillas

roscadas requeridos, consulte la Tabla 2). Observe los procedimientos

detallados en las instrucciones de instalación siguientes.

El calefactor puede también ir suspendido de la pared o del cielorraso

por medio de un soporte de montaje opcional (tipo MMB o MCMB) que

le permite pivotar horizontalmente.

Después de instalar el calefactor, las celosías pueden posicionarse para

orientar el aire caliente en la dirección deseada. Cuando el calefactor

se instala para descarga horizontal, las celosías deben dirigir el aire en

línea recta hacia adelante, o hacia abajo. La orientación hacia arriba

puede hacer que el aire

con lo que se desperdicia energía.

Tabla 1. Espacio libre en relación con las paredes y el

cielorraso, pulgadas (mm)

La distancia mínima entre el piso y el fondo del calentador es de 7 pies

Unidad Descarga Cielorraso Pared lateral Pared posterior

Horiz. 2 (50.8) 6 (152.4) 9 (228.6)

3 y 5 kW

Vert. 6 (152.4) 18 (457.2) 18 (457.2)

Horiz. 6 (152.4) 6 (152.4) 13 (330.2)

7.5 a 10 kW

Vert. 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 6 (152.4) 9 (228.6) 12

15 a 20 kW

Vert 6 (152.4) 24 (609.6) 24 (609.6)

Horiz. 16 (406.4) 12 (304.8) 18

25 a 50 kW

VARILLA DE

MONTAJE

P

A

R

E

D

TUERCA DE

SEGURIDAD

P

O

S

T

E

R

I

O

R

Vert. 12 (304.8) 36 (914.4) 39 (914.4)

CIELORRASO

Figura 1. Montaje y espaciado de varillas para descarga horizontal

Tabla 2. Dimensiones de espaciado y rosca de las varillas,

pulgadas (mm), para descarga horizontal

Tipo de rosca

Unidad de las varillas A B C D

3 - 5 kW

7.5 - 10 kW

15 - 20 kW

25 - 30 kW

40 - 50 kW

caliente permanezca en el área del cielorraso,

PARED POSTERIOR

B

1

51/

/

16

8

16

16

6 4

(152.4) (103.1) (19.0)

87/

8

(225.6) (130.3) (19.0)

14 - 12 63/

14 - 12 63/

UNIDAD CALEFACTORA

5

/16- 18

3

/8- 16

AGUJEROS

DE MONTAJE

ROSCADOS

A

(VISTA SUPERIOR)

61/

16

(153.9)

3

/

11

8

(289.0)

9

/

10

16

(268.2) (368.3) (157.2) (16.0)

1515/

16

(404.9) (368.3) (157.2) (16.0)

1

/2(317.5)

1

/2(470.0)

D

C

P

A

R

E

D

L

A

T

E

R

A

L

3

/

4

3

/

4

5

/

8

5

/

8

Descarga horizontal (montaje con varillas desde el cielorraso)

1. Instale cuatro varillas roscadas de montaje en los agujeros roscados,

y asegúrelas en su posición mediante tuercas de seguridad (vea la

Tabla 2).

2. Fije firmemente las cuatro varillas de montaje al cielorraso. (Para ver

los espacios libres en relación con las paredes y el cielorraso consulte la Tabla 1, y para ver el espaciado de las varillas de montaje

consulte la Tabla 2).

Tabla 3. Dimensiones de espaciado y rosca de las varillas,

pulgadas (mm), para descarga vertical

Tipo de rosca

Unidad de las varillas

3 - 5 kW

5

/16- 18

7.5 - 20 kW

3

TUERCA DE

SEGURIDAD

/8- 16

25 - 30 kW

PUERTA DE ACCESO

CIELORRASO

P

A

R

E

D

P

O

S

T

E

R

ESPACIO LIBRE IGUAL AL ANCHO

I

DEL CALEFACTOR, PARA PERMITIR

LA APERTURA PLENA DE LA PUERTA

O

DE ACCESO

R

E F G H

3

6 9

(152.4) 247.7) (50.8) (103.1)

7

/

8

8

(225.6) (371.6) (50.8) (130.3)

1

/

14

2

(368.3) (539.8) (56.0) (157.2)

VARILLA DE

MONTAJE (4)

/

4

145/

211/

G

AGUJEROS

DE MONTAJE

ROSCADOS

(VISTA SUPERIOR)

8

4

2 41/

2 51/

23/

16

PARED POSTERIOR

E

H

Figura 2. Montaje y espaciado de varillas para descarga vertical

Descarga vertical (montaje con varillas desde el cielorraso)

1. Quite los pernos de los agujeros roscados que están en la parte

trasera del calefactor.

2. Instale cuatro varillas roscadas de montaje en los agujeros roscados,

y asegúrelas en su posición mediante tuercas

de seguridad.

3. Fije firmemente las cuatro varillas de montaje al cielorraso. (Para ver

los espacios libres en relación con las paredes y el cielorraso consulte la Tabla 1, y para ver las dimensiones de espaciado de las varillas de montaje consulte la Tabla 3).

Cableado del circuito de derivación (alimentación)

1. Conecte el calefactor únicamente a un circuito apto para la tensión (V),

corriente (A) y frecuencia (Hz) especificadas en la placa de características.

2. El cableado de campo debe estar dimensionado correctamente para la

corriente (A) que debe conducir, de acuerdo con el NEC.

3. La puerta de acceso está abisagrada. Existen uno o dos tornillos

accesibles desde el costado, que deben aflojarse para tener acceso.

Estos tornillos son del tipo prisionero; no intente quitarlos.

4. Se ha provisto un prepunzonado en la parte posterior del calefactor,

cerca de las borneras de alimentación eléctrica y de control. El

prepunzonado para la bornera de control es para un tamaño d

e

conducto de 12.7 mm (1/2 pulgada). El prepunzonado para la bornera

de alimentación eléctrica es de diámetro múltiple. Use el diámetro que

corresponda al tamaño de conducto necesario.

5. Se ha provisto un terminal de masa cerca de la bornera de

alimentación eléctrica. El cable de masa debe conectarse antes de

hacer las otras conexiones.

6. La bornera de alimentación eléctrica está equipada con terminales

dimensionados para aceptar el cable de alimentación eléctrica de

calibre correcto. El cable para circuitos de derivación con especificación

de 600 V, 60 °C, es aceptable para los calefactores que consumen

hasta 80 A. Para los calefactores que consumen más de 80 A, el cable

del circuito de derivación debe tener una especificación de 75 °C como

mínimo. Para la conexión a los terminales de la bornera de

alimentación eléctrica del calefactor pueden usar

se tanto cables de

cobre como de aluminio. Se recomiendan los cables de cobre, y

deben usarse con un interruptor de desconexión incorporado.

13

63/

F

16

8

16

P

A

R

E

D

L

A

T

E

R

A

L

Page 14

7. Cada calefactor tiene un diagrama de conexionado fijado en el interi-

LEAD WIRE

3 PHASE BLOCK

C

1

D

1

D

1

C

1

C

1

D

1

D

1

C

1

or de la puerta de acceso. Consulte este diagrama antes de hacer

las conexiones de campo.

Nota importante – Par de apriete de los terminales de

tornillo en la instalación:

Durante el transporte es posible que las conexiones de los terminales

de tornillo se aflojen. Después de la instalación, antes de conectar la alimentación eléctrica al calefactor, revise las conexiones de los terminales

de tornillo para verificar que cumplan con el valor de par de apriete

recomendado de 3.9 N·m (35 lb·pulg.). Las conexiones flojas pueden

ser riesgosas.

8. En los modelos de calefactor HUHAA524FC, HUHAA520FC,

HUHAA724FC, HUHAA720FC, HUHAA1024FC, HUHAA1020FC, y

HUHAA1520FCpueden

Estas unidades

calefacto

estos

los cables según se indica en el diagrama de conexionado fijado al

calefactor. Puede encontrarse información adicional en las

ilustraciones de conexionado de las Figuras 3a y 3b, y en las

instrucciones que siguen a continuación.

En los modelos HUHAA524FC, HUHAA520FC, HUHAA724FC,

HUHAA720FC, HUHAA1520FC, HUHAA1024FC y HUHAA1020FC

(Figura 3a), mueva sólo los dos cables marcados ‘A1’ y ‘B1’;

no mueva ni cambie ninguna otra conexión. El cable de conexión

bornera de alimentación eléctrica (terminal más cercano a los

elementos calefactores), debe moverse al terminal ‘B’ de la bornera

de conexiones trifásicas.

FRENTE DEL CALEFACTOR

HEATER FRONT

usarse conexiones monofásicas o trifásicas.

están cableadas en fábrica para operación monofásica. Si

res van a usarse con alimentación trifásica, reconecte

al a acirbáf ne odatcenoc átse euq ,’1B‘ odacram rotcafelac otnedelm

CABLE DE

CONEXIÓN 'A1'

"A1"

BORNERA DE

3 PHASE BLOCK

CONEXIONES

TRIFÁSICAS

El cable de conexión ‘A1’ del relé (contactor) debe moverse del terminal

extremo

de la bornera de alimentación eléctrica (terminal más cercano

al contactor o a la bornera de control) al terminal ‘A’ de la bornera inferior

(terminal central).

El modelo HUHAA1520FC (Figura 3b) tiene dos borneras de conexiones

trifásicas ubicadas adyacentes a los relés (contactores). Mueva únicamente

los dos cables marcados 'C1' y 'D1' en cada una de las dos borneras de

conexiones trifásicas, al terminal 'B'. No mueva ni cambie ningún otro

cable.

9. Los accesorios eléctricos, ya sea kits u opciones instaladas en

fábrica, se muestran conectados por una línea de trazos en el diagrama de conexionado del calefactor.

10. CALEFACTOR DE 208/240 VOLTS: los calefactores están cablead-

os de fábrica para 240 V. Cuando conecte el calefactor a una

de alimentación de 208 V DEBE intercambiar los cables de

fuente

conexión del transformador. Para unidades con una especificación

de 30/40 kW o mayor, intercambie los cables de conexión NARANJA y ROJO del primario. El cable de conexión de color NEGRO es

el COMÚN (retorno) del transformador (50 VA) suministrado con

las unidades de alta potencia (watts). Para calefactores con una

especificación más baja de potencia (kW), intercambie los cables

de conexión NEGRO y ROJO del primario. El cable de conexión de

color BLANCO es el COMÚN (retorno) del transformador de control

suministrado con estos calefactores. Antes de realizar esta reconexión de los cables de conexión del primario del transformador, consulte siempre el diagrama de conexionado en

la cubierta del cale-

factor.

FRENTE DEL

HEATER FRONT

CALEFACTOR

CABLE DE

LEAD WIRE

CONEXIÓN 'A1'

"A1"

BORNERA DE

CONEXIONES

TRIFÁSICAS

CABLE DE

LEAD WIRE

CONEXIÓN 'B1'

"B1"

B

A

TO ELEMENTS

CALEFACTORES

A LOS ELEMENTOS

CONTACTOR

CONTACTOR

(Ó P2)

(OR P2)

CABLEADO EN FÁBRICA PARA ALIMENTACIÓN MONOFÁSICA CABLEADO EN CAMPO PARA ALIMENTACIÓN TRIFÁSICA

FACTORY-WIRED FOR SINGLE-PHASE POWER FIELD-WIRED FOR THREE-PHASE POWER

BORNERA DE

POWER TERMINAL BLOCK

ALIMENTACIÓN ELÉCTRICA

ELEMENTOS

ELEMENTS

CALEFACTORES

CABLE DE

LEAD WIRE

CONEXIÓN 'B1'

"B1"

TO ELEMENTS

CALEFACTORES

A LOS ELEMENTOS

CONTACTOR

CONTACTOR

(Ó P2)

(OR P2)

ALIMENTACIÓN ELÉCTRICA

B

A

BORNERA DE

POWER TERMINAL BLOCK

ELEMENTOS

ELEMENTS

CALEFACTORES

Figura 3a. Conexiones de cables para alimentación monofásica y trifásica (HUHAA524FC, HUHAA520FC, HUHAA724FC,

HUHAA720FC, HUHAA1024FC, HUHAA1020FC)

B

C

B

C

D

BORNERA DE

3 PHASE BLOCK

CONEXIONES

TRIFÁSICAS

D

B

C

D

BORNERA DE

3 PHASE BLOCK

CONEXIONES

TRIFÁSICAS

B

C

D

BORNERA DE

3 PHASE BLOCK

CONEXIONES

TRIFÁSICAS

CABLEADO EN FÁBRICA PARA ALIMENTACIÓN MONOFÁSICA CABLEADO EN CAMPO PARA ALIMENTACIÓN TRIFÁSICA

FACTORY-WIRED FOR SINGLE-PHASE POWER

FIELD-WIRED FOR THREE-PHASE POWER

BORNERA DE

3 PHASE BLOCK

CONEXIONES

TRIFÁSICAS

Figura 3b. Conexiones de cables para alimentación monofásica y trifásica (HUHAA1520FC)

14

Page 15

Conexionado de control

EN ALGUNOS TERMINALES DE LA BORNERA DE CONTROL ESTÁ PRESENTE LA TENSIÓN DE LÍNEA.

DESCONECTE SIEMPRE LA ALIMENTACIÓN ELÉCTRICA

DEL CALEFACTOR ANTES DE HACER CONEXIONES A LA

PLACA DE CONTROL, A FIN DE EVITAR UN RIESGO DE

CHOQUE ELÉCTRICO.

1. Use para el cableado del circuito de control cables aislados, NEC

Clase 1, 600 volts como mínimo.

2. Si se va a hacer más de una conexión bajo el tornillo de un terminal

de la bornera de control, use un terminal tipo horquilla engarzado a

presión en los extremos de cable.

3. Para ver el diagrama de conexionado de las unidades no provistas

de contactor interno (3 y 5 kW), consulte la Figura 4.

NOTA: el cableado del termostato y del circuito de control deben ser

aptos para manejar la carga plena del calefactor (por ejemplo, el consumo nominal del HUHAA520FC es 24 A).

4. Para ver el diagrama de conexionado de las unidades provistas de

contactor interno (unidades de 7 kW y mayores), consulte la Figura

5. El cableado de control debe tener un calibre 18 AWG como mínimo.

INSTRUCCIONES DE

OPERACIÓN

1. El calefactor debe instalarse correctamente antes de ponerlo en

funcionamiento.

2. Conecte la alimentación eléctrica al calefactor en el tablero de

distribución principal.

3. Donde sea aplicable, para ver la operación correcta de los controles

y accesorios que pueda utilizar el calefactor consulte las

instrucciones de los accesorios de cont

TERMOSTATO

INTERNO DE

2 ETAPAS

MT-2

NEGRO

MT-1

ROJO

NEGRO

ROJO

H1

H2

P1

P2

¡IMPORTANTE! PARA TERMOSTATOS DE 2 ETAPAS, UTILICE:

Figura 4. Bornera de control (para calefactores sin contactor)

¡IMPORTANTE! PARA TERMOSTATOS DE 2 ETAPAS, UTILICE:

1.

NEGRO, a W 1

T

MT-1

TERMOSTATO

INTERNO DE

2 ETAPAS

ROJO, a R

TERMOSTATO DE

RECUPERACI ÓN

DE CALOR MHR T O

INTERRUPTOR DE

VENTILADO R REMOTO

(MRFS-2)

T

MT-2

NEGRO

ROJO

T

ROJO

NEGRO

C

Figura 5. Bornera de control (para calefactores con contactor)

F 2

F 1

G

R W1

rol.

INTERRUPTOR DE VENTILADOR

REMOTO PARA VERANO (MRFS-1)

INTERRUPTOR DE VENTILADOR

PARA VERANO

S

INTERRUPTOR DE VENTILADOR

S

REMOTO PARA VERANO (MRFS-1)

RELÉ DE VENTILADOR

(PARA MRFS-2 Y MHRT)

T R

W2

F 1

F 2

S

INTERRUPTOR

DE VENTILADOR

PARA VERANO

PRECAUCIÓN: para evitar un posible incendio o daño en el

calentador, en el caso que se proporciona un termostato de

dos etapas, se DEBE conectar a modo que la Etapa 1

enciende primero el elemento trasero de calefacción (donde

se encuentra el control del ventilador) y lo apaga de último.

La Etapa 2 DEBE encender los elementos distintos del

elemento trasero conforme se requiere calefacción adicional

y se encenderá de último y se apagará de primero.

1. LA BORNERA DE CONTROL DE ESTE TIPO SE USA CON LOS MODELOS HUHAA324FC, HUHAA327FC, HUHAA320FC, HUHAA524FC,

HUHAA527FC, Y HUHAA520FC.

2. CUANDO LA UNIDAD SE CABLEA PARA CONEXIÓN MONOFÁSICA,

PUENTEE H1 CON H2. SI SE USA UN TERMOSTATO UNIPOLAR CON

LA UNIDAD MONOFÁSICA, CONECTE LOS CABLES DE CONEXIÓN

DEL TERMOSTATO A P1 Y H1.

3. LOS TERMOSTATOS PARA TENSIÓN DE LÍNEA EXTERNA DEBEN CONSIDERARSE COMO DE UNA ETAPA ÚNICAMENTE.

NOTAS:

1. LA BORNERA DE CONTROL DE ESTE TIPO NO SE USA CON LOS

MODELOS HUHAA324FC, HUHAA327FC, HUHAA320FC, HUHAA524FC,

HUHAA527FC, NI HUHAA520FC.

2. CUANDO USE UN TERMOSTATO DE 2 ETAPAS, QUITE EL PUENTE

QUE UNE W1 Y W2.

3. *SÓLO UNO DE ESTOS ACCESORIOS PUEDE INSTALARSE EN UN

CALEFACTOR ÚNICO.

4. LOS TERMOSTATOS PARA TENSIÓN DE LÍNEA EXTERNA DEBEN

CONSIDERARSE COMO DE UNA ETAPA ÚNICAMENTE.

15

Page 16

Cómo restablecer el Restablecimiento manual del

límite de seguridad (opción instalada de fábrica

solamente)

El interruptor de límite se encuentra internamente en la parte posterior

del calentador. En los modelos de 3 kW y de 5 kW, el acceso al botón

de reposición es por el lado derecho (al mirar a la parte trasera del

calefac-tor); en todos los demás modelos está cerca de la parte superior

trasera del calefactor.

El límite de reposición manual está en serie con el protector (límite) de

reciclado automático. El límite de reposición manual no se repondrá

hasta que el calefactor se haya enfriado y se oprima el botón.

NO ALTERE NI PUENTEE NINGÚN LÍMITE DE SEGURIDAD

INTERNO DEL CALEFACTOR.

ATENCIÓN: SI EL CONTROL DE SEGURIDAD SE ACTIVA

REPETIDAMENTE DESPUÉS DE LA REPOSICIÓN, NO

VUELVA A INTENTAR USAR EL CALEFACTOR. SI LO HACE,

EL CALEFACTOR PUEDE SUFRIR DAÑOS PERMANENTES,

O PROVOCAR UN INCENDIO O RIESGO PARA LA

SEGURIDAD.

Es importante mantener limpio este calefactor. Su calefactor le brindará

muchos años de servicio y confort con sólo un mínimo de cuidado. Para

asegurar un funcionamiento eficiente, observe las instrucciones simples

que se indican a continuación.

TODO SERVICIO, MÁS ALLÁ DE UNA SIMPLE LIMPIEZA,

QUE REQUIERA UN DESMONTAJE DEBE SER REALIZADO

POR PERSONAL DE SERVICIO CALIFICADO.

INSTRUCCIONES DE

MANTENIMIENTO

Es importante mantener limpio este calefactor. Su calefactor le brindará

muchos años de servicio y confort con sólo un mínimo de cuidado. Para

asegurar un funcionamiento eficiente, observe las instrucciones simples

que se indican a continuación.

TODO SERVICIO, MÁS ALLÁ DE UNA SIMPLE LIMPIEZA,

QUE REQUIERA UN DESMONTAJE DEBE SER REALIZADO

POR PERSONAL DE SERVICIO CALIFICADO.

PARA REDUCIR EL RIESGO DE INCENDIO Y DE CHOQUE

ELÉCTRICO O LESIONES, DESCONECTE TODA LA ALIMENTACIÓN ELÉCTRICA QUE LLEGA AL CALEFACTOR EN

EL TABLERO PRINCIPAL DE SERVICIO Y VERIFIQUE QUE

EL ELEMENTO CALEFACTOR ESTÉ FRÍO ANTES DE

PRESTAR SERVICIO O DE REALIZAR EL MANTENIMIENTO.

Instrucciones de limpieza para el usuario:

1. Después de que el calefactor se haya enfriado, puede utilizarse una

aspiradora con accesorio de cepillo para eliminar el polvo y la

pelusa de las superficies exteriores del calefactor, incluidas las aberturas de la rejilla.

2. Con un paño húmedo, elimine el polvo y la pelusa de la rejilla y las

superficies exteriores.

3. Vuelva a conectar la alimentación eléctrica al calefactor y asegúrese

de que funcione correctamente.

PARA REDUCIR EL RIESGO DE INCENDIO Y DE CHOQUE

ELÉCTRICO O LESIONES, DESCONECTE TODA LA ALIMENTACIÓN ELÉCTRICA QUE LLEGA AL CALEFACTOR EN

EL TABLERO PRINCIPAL DE SERVICIO Y VERIFIQUE QUE

EL ELEMENTO CALEFACTOR ESTÉ FRÍO ANTES DE

PRESTAR SERVICIO O DE REALIZAR EL MANTENIMIENTO.

Instrucciones de limpieza para el usuario:

1. Después de que el calefactor se haya enfriado, puede utilizarse una

aspiradora con accesorio de cepillo para eliminar el polvo y la

pelusa de las superficies exteriores del calefactor, incluidas las aberturas de la rejilla.

2. Con un paño húmedo, elimine el polvo y la pelusa de la rejilla y las

superficies exteriores.

3. Vuelva a conectar la alimentación eléctrica al calefactor y asegúrese

de que funcione correctamente.

Instrucciones de limpieza de mantenimiento:

(a realizarse únicamente por personal de servicio calificado)

Al menos una vez por año, un técnico de servicio calificado debe limpiar

y prestar servicio al calefactor para asegurar un funcionamiento seguro

y eficiente. Esto debe incluir, según sea necesario, la aspiración del

polvo y los desperdicios de los elementos calefactores y del ventilador, y

la revisión de las conexiones de los terminales de tornillo para verificar

que cumplan con el valor de par de apriete recomendado de 3.9 N·m

(35 lb·pulg.). Después de terminada la limpieza y servicio, el calefactor

debe volver a montarse completamente y verificarse que funcione co

rectamente.

r-

Instrucciones de limpieza de mantenimiento:

(a realizarse únicamente por personal de servicio calificado)

Al menos una vez por año, un técnico de servicio calificado debe limpiar

y prestar servicio al calefactor para asegurar un funcionamiento seguro

y eficiente. Esto debe incluir, según sea necesario, la aspiración del

polvo y los desperdicios de los elementos calefactores y del ventilador, y

la revisión de las conexiones de los terminales de tornillo para verificar

que cumplan con el valor de par de apriete recomendado de 3.9 N·m

(35 lb·pulg.). Después de terminada la limpieza y servicio, el calefactor

debe volver a montarse completamente y verificarse que funcione correctamente.

16

Page 17

12

11

HUHAA FC

Controles integrales

Nº clave Descripción Nº de pieza

Termostato unipolar (MT-1)

1 Thermostat, One Pole (MT-1) 5813-0036-000

Termostato, dos etapas (MT-2)

Thermostat, Two Stage (MT-2) 5813-0035-000

Perilla termostato

2 3301-0060-000

Etiqueta termostato

3 3502-1781-000

Tornillos cab. plana, 6-32 x 1/4

4 5202-7009-021

Clip termostato

5 1403-0041-000

Interruptor 25 A, OBM

6 5216-0132-000

Interruptor 25 A, K&N

Interruptor 63 A OBM

Interruptor 63 A, K&N

Interruptor 25 A Electro

Tornillo M4 x 10, cab. red. (25 A)

Tornillo 63 A M5 x 16, cab. red.

Perilla 25 A OBM "T1"

8 OEM “T1”

Perilla 25 A, K&N

Perilla 63 A OBM

Perilla 63 A, K&N

Perilla Electro

Interruptor basculante 600 V

9 5216-0130-000

Relé ventilador, bobina 24 V

10 5018-0008-000

Conj. interruptor

11 5216-0199-000

Límite reposición manual

12 4520-0012-000

5216-0204-000

5216-0131-000

5216-0203-000

5216-0200-000

—7

—

K & N S1B 6001

OEM “S4”

K & N S2B G001

EI 141747

Piezas de repuesto del calentador

Nº clave Descripción Nº de pieza

1

Resorte elemento (utilizado solo en 20kW y menos)

Resorte elemento (utilizado solo en 25kW y menos)

2

Resorte tubo capilar

3

Resorte retenedor elemento

4

Interruptor (utilizado solo en 25kW a 50kW)

5

Aislador (utilizado solo en 25kW a 50kW)

6

Extensión del soporte

(utilizado solo en 15kW, 20kW, 40kW y 50kW)

7

Soporte de interruptor

8

Retardo del ventilador

14

Tuerca velocidad

15

Soporte tornillo imperdible (utilizado solo en 3kW a 20kW)

Soporte tornillo imperdible (utilizado solo en 250W a 50kW)

17

Protector límite lineal (utilizado solo en 3kW a 20kW)

Portector límite lineal (utilizado solo en 7kW a 20kW)

Portector límite lineal (utilizado solo en 25kW a 50kW)

20

Abrazaderar (utilizado solo en 20kW a 50kW)

Soporte montaje capacitor (utilizado solo en 20kW a 208v)

22

Orejeta terminal (utilizado solo en 7kW a 50kW)

25

Buje (utilizado solo en 20kW a 50kW)

26

Arandela pulida (utilizado solo en 3kW a 5kW)

27

Tornillo pulido (utilizado solo en 3kW a 5kW)

28

Persiana (utilizado solo en 3kW a 5kW)

Persiana (utilizado solo en 7kW a 20kW)

Persiana (utilizado solo en 25kW a 50kW)

29

Resorte persiana

32

Regleta terminales trifásica (utilizado donde los modelos

pueden ser de 1 o 3 fases)

33

Dobladores terminales (utilizado según se requieran)

5208-0073-000

5208-0073-001

5208-0072-000

5208-0074-000

5216-7076-001

2900-0031-000

1215-0282-000

1215-0256-000

4520-0010-000

4100-7036-026

1215-0291-000

1215-0289-000

4520-0011-000

4520-0011-001

4520-0011-002

1417-5004-000

1215-0314-000

3504-7002-001

25221-60131

6401-0084-000

5202-0290-002

3503-0036-000

3503-0036-001

3503-0036-002

5208-7005-001

5823-0003-000

5819-7012-005

CONTROLES INTEGRALES –

Unidades hechas por encargo

solamente

4

3

2

INTERRUPTOR

DE POTENCIA

TERMOSTATO UNIPOLAR,

TERMOSTATO DE DOS ETA-

PAS, TERMOSTATO DE TER-

MORECUPERACIÓN

5

1

INTERRUPTOR

DEL

10

VENTILADOR DE

VERANO

8

9

7

6

9

17

Page 18

DOBLADOR TERMINAL

UTILIZAR SEGÚN SE REQUIER

A

(MUH -25 HASTA MUH 50 SOLAMENTE)

25KW A 50KW SOLAMENTE

VISTA D-D

VISTA D-D

(MUH-07 HASTA MUH-20 SOLAMENTE)

7KW A 20KW SOLAMENTE

17 (NO SE USA CUANDO

SE USAN DOS ITEMES 23)

VISTA A-A

VISTA-B-B

VER VISTA

VISTA-C-C

VER VISTA

VER VISTA

23 (NO SE USA CUANDO SE USAN

DOS ITEMES 17)

VISTA D-D

(MUH-03 HASTA MUH-05 SOLAMENTE

3KW A 5KW SOLAMENTE

ETIQUETA

PERILLA

TERMOSTATO (2 ETAPAS)

ESTAS PIEZAS SE USAN SOLO

ESTAS PIEZAS SE USAN EN

EN LA OPCIÓN DE FÁBRICA 2T

EL MODELO MUH05-21T SOLAMENTE

VER VISTA

BOMBILLA CON CLIP

18

Page 19

9 10 11 12 13 16 18 19 21

Nº de modelo Caja trasera Transformador** Motor Paleta del ventilador Cubierta Caja delantera Conj. elemento Protector elemento Capacitor

Model No. Back Case Transformer** Motor Fan Blade Cover Front Case Element Assy. Element Guard tor

HUHAA324FC

HUHAA348FC

HUHAA327FC

HUHAA320FC

HUHAA548FC

HUHAA527FC

HUHAA724FC

HUHAA720FC

HUHAA748FC

HUHAA727FC

HUHAA1024FC

HUHAA1027FC

HUHAA1048FC

HUHAA1020FC

HUHAA1524FC

HUHAA1548FC

HUHAA1520FC

HUHAA2024FC

HUHAA2048FC

HUHAA2020FC

HUHAA2524FC

HUHAA2548AFC

HUHAA3024FC

HUHAA3048AFC

HUHAA3020FC

HUHAA4024FC

HUHAA4048FC

HUHAA5020FC

HUHAA5024FC

HUHAA5048FC

1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-000 2504-0011-000 –

1425-2004-000 5814-0003-002 3900-2005-000 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-002 2504-0011-000 –

1425-2004-000 – 3900-2002-007 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-001 2504-0011-000 –

1425-2004-000 – 3900-2002-006 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-024 2504-0011-000 –

1425-2004-000 5814-0003-002 3900-2005-000 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-005 2504-0011-000 –

1425-2004-000 – 3900-2002-007 1210-2000-000 1402-0336-001 1425-0009-015 1802-0087-004 2504-0011-000 –

1425-0010-004 5814-0003-000 3900-2014-002 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-006 2504-0013-001 –

1425-0010-004 5814-0003-000 3900-2014-001 1210-0090-000 1402-0339-002 1425-0009-006 1802-0087-031 2504-0013-001 –

1425-0010-004 5814-0003-002 3900-0347-005 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-008 2504-0013-001 –

1425-0010-004 5814-0003-001 3900-2014-003 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-007 2504-0013-001 –

1425-0010-004 5814-0003-000 3900-2014-002 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-031 2504-0013-001 –

1425-0010-004 5814-0003-001 3900-2014-003 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-010 2504-0013-001

1425-0010-004 5814-0003-002 3900-0347-005 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-011 2504-0013-001 –

1425-0010-004 5814-0003-000 3900-2014-001 1210-0090-000 1402-0339-002 1425-0009-016 1802-0087-036 2504-0013-001 –

1425-0014-000 5814-0003-000 3900-0361-000 1210-0090-001 1402-0339-003 1425-0009-017 1802-0087-012 2504-0012-001 –

1425-0014-000 5814-0003-002 3900-0361-001 1210-0090-001 1402-0339-003 1425-0009-017 1802-0087-013 2504-0012-001 –

1425-0014-000 5814-0003-000 3900-0361-002 1210-0090-001 1402-0339-003 1425-0009-017 1802-0087-031 2504-0012-001 –

1425-0013-000 5814-0003-000 3900-0362-000 1210-0096-000 1402-0339-003 1425-0009-017 1802-0087-014 2504-0012-001 1432-0002-003

1425-0013-000 5814-0003-002 3900-0362-001 1210-0096-000 1402-0339-003 1425-0009-017 1802-0087-015 2504-0012-001 1432-0002-003

1425-0013-000 5814-0003-000 3900-0362-002 1210-0096-000 1402-0339-003 1425-0009-017 1802-0087-026 2504-0012-001 1432-0002-003

1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-016 2504-0014-001 1432-0002-001

1425-0011-003 5814-0003-002 3900-0363-001 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-017 2504-0014-001 1432-0002-003

1425-0011-003 5814-0003-000 3900-0364-000 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-018 2504-0014-001 1432-0002-001

1425-0011-003 5814-0003-002 3900-0363-000 1210-0098-000 1402-0340-002 1425-0012-007 1802-0087-019 2504-0014-001 1432-0002-003