Page 1

Page 2

ENGLISH

Illustrations on pages 8, 9, 28, 29, 30

NOTICE: The Manufacturer and/or its Local Official Distributors assume no responsibility for product malfunction or for physical injury or property damage

resulting in whole or in part from criminal or negligent use of the product, improper or careless handling, unauthorized modifications, use of defective, improper, hand-loaded, reloaded or remanufactured ammunition, customer

abuse or neglect of the product, or other influences beyond manufacturer’s direct and immediate control.

WARNING: ALL FIREARMS HAVE LETHAL POTENTIAL. READ THE BASIC

SAFETY RULES CAREFULLY AND UNDERSTAND THEM FULLY BEFORE

ATTEMPTING TO USE THIS FIREARM.

CONTENTS

Page

BASIC SAFETY RULES 4

In addition to the Basic Safety Rules, there are other Safety Rules pertaining to the

loading, unloading, disassembly, assembly and use of this firearm located throughout

this manual.

WARNING: READ THE ENTIRE MANUAL CAREFULLY BEFORE USING

THIS FIREARM. MAKE SURE THAT ANY PERSON USING OR HAVING

ACCESS TO THIS FIREARM READS AND UNDERSTANDS ALL OF THIS

MANUAL PRIOR TO USE OR ACCESS.

NOTICE: As the interchangeable barrel of this shotgun has a serial number

different from that stamped on the receiver, it may be necessary, when referring to the gun, to specify also the serial number of the barrel/s.

NOMENCLATURE 8

DESCRIPTION 10

TECHNICAL FEATURES AND DATA 12

OPERATION 12

DISASSEMBLY 16

ROUTINE MAINTENANCE 17

REASSEMBLY 18

SPECIAL MAINTENANCE 21

MAGAZINE CAPACITY 22

MOBILCHOKE®TUBES 23

STOCK DROP AND CAST MODIFICATION 24

RECOIL PAD 25

2

3

REVERSIBLE SAFETY BUTTON 26

Page 3

-

To reduce the risk of accidents

involving children, unload your firearm, lock it and store the ammunition in a

Please note that devices intended to prevent accidents

- for example, cable locks, chamber plugs, etc, - may not prevent use or misuse of

your firearm by a determined person. Steel gun safes may be more appropriate to

reduce the likelihood of intentional misuse of a firearm by an unauthorized child or

Never rely solely on a safety device to prevent an accident. It is imperative that you

-

scribed in these safety rules and elsewhere in the product manual. To further famil

-

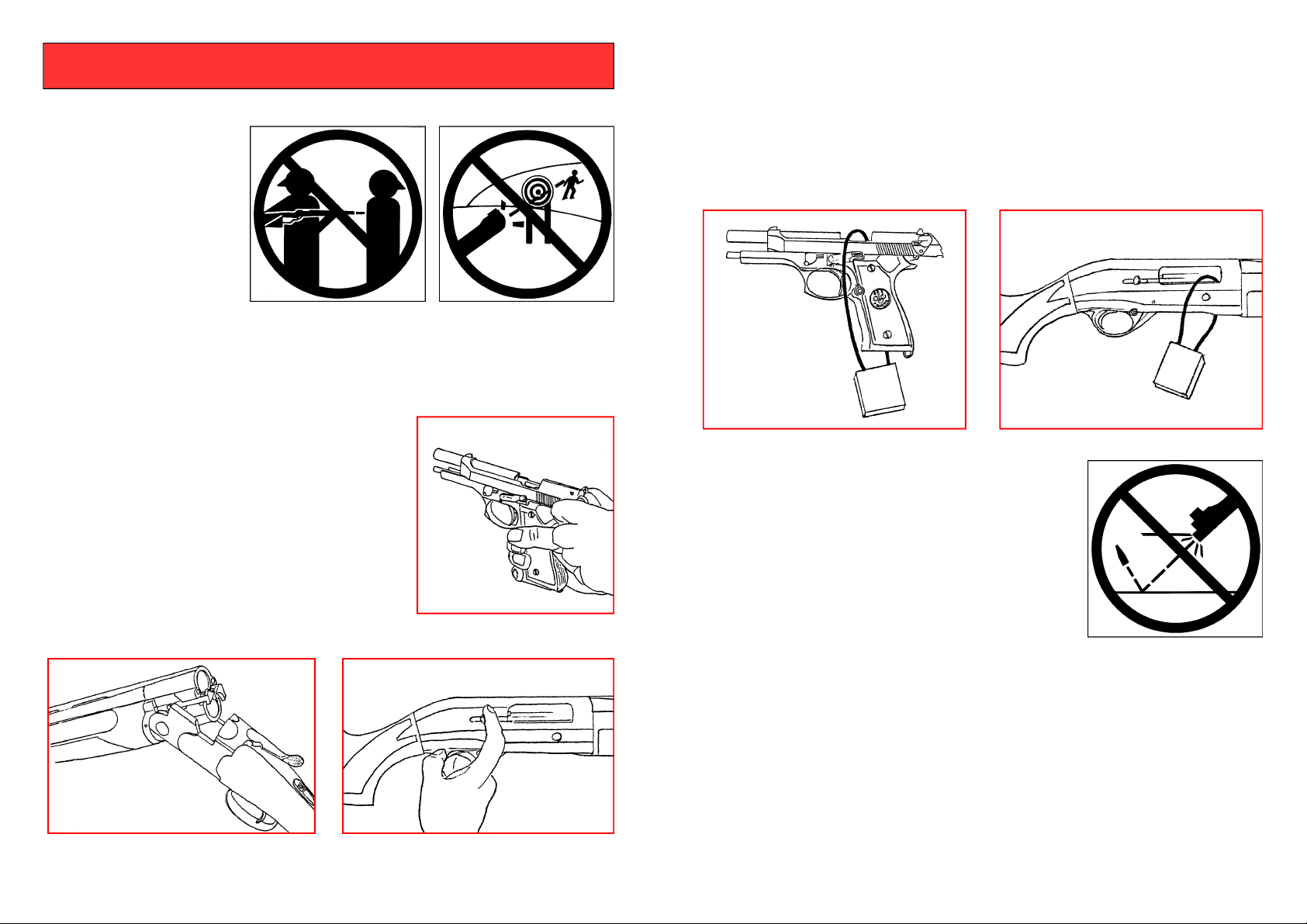

BASIC SAFETY RULES

1. NEVER POINT A FIREARM AT SOMETHING THAT IS NOT SAFE TO SHOOT.

1. Never let the muzzle of a

firearm point at any part of

your body or at another

person. This is especially

important when loading or

unloading the firearm.

When you are shooting at

a target, know what is behind it. Some bullets can

travel over a mile. If you

miss your target or if the

bullet penetrates the target, it is your responsibility

to ensure that the shot does not cause unintended injury or damage.

2. ALWAYS TREAT A FIREARM AS IF IT WERE

LOADED.

2. Never assume that a firearm is unloaded. The on-

ly certain way to ensure that a firearm is empty

is to open the chamber and visually examine

the inside to see if a round is present.

Removing the magazine will not guarantee that

a pistol is unloaded or cannot fire. Shotguns

and rifles can be checked by cycling or removing

all rounds and by then opening the chamber so

that a visual inspection of the chamber for any remaining rounds can be made.

3. STORE YOUR FIREARM SO THAT CHILDREN CANNOT GAIN ACCESS TO

IT.

3. It is your responsibility to insure that children under the age of 18 or other unautho

rized persons do not gain access to your firearm.

separate locked location.

person.

4. NEVER SHOOT AT WATER OR AT A HARD

SURFACE.

4. Shooting at the surface of water or at a rock or oth-

er hard surface increases the chance of ricochets or

fragmentation of the bullet or shot, which can result

in the projectile striking an unintended or peripheral

target.

4

5. KNOW THE SAFETY FEATURES OF THE FIREARM YOU ARE USING, BUT

REMEMBER: SAFETY DEVICES ARE NOT A SUBSTITUTE FOR SAFE HANDLING PROCEDURES.

5.

know and use the safety features of the particular firearm you are handling, but ac

cidents can best be prevented by following the safe handling procedures de-

iarize yourself with the proper use of this or other firearms, take a Firearms Safety

Course taught by an expert in firearms use and safety procedures.

5

Page 4

ammunition may result in exposure to lead and other substances known to cause

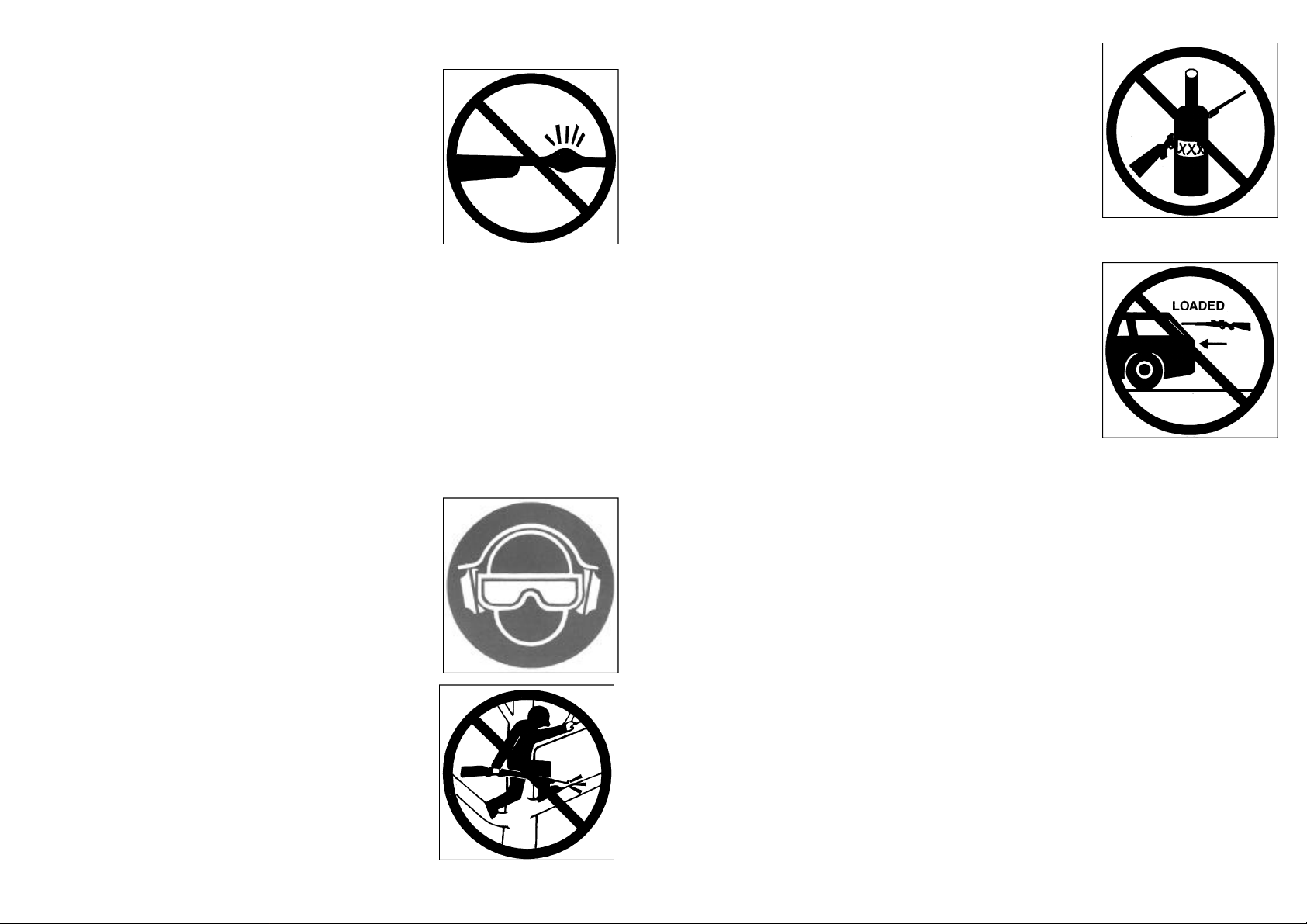

6. PROPERLY MAINTAIN YOUR FIREARM.

6. Store and carry your firearm so that dirt or lint does not

accumulate in the working parts. Clean and oil your

firearm, following the instructions provided in this manual, after each use to prevent corrosion, damage to

the barrel or accumulation of impurities which can prevent use of the gun in an emergency. Always check

the barrel prior to loading to ensure that it is clean and

free from obstructions. Firing against an obstruction

can rupture the barrel and injure yourself or others

nearby. In case you hear an unusual noise when

shooting, stop firing immediately, ingage the manual

safety and unload the firearm. Make sure the chamber

is free from any obstruction or possible bullet blocked

inside the barrel due to defective or improper ammunition.

7. USE PROPER AMMUNITION.

7. Only use factory-loaded, new ammunition manufactured to industry specifications:

CIP (Europe and elsewhere), SAAMI (U.S.A.). Be certain that each round you use

is in the proper caliber or gauge and type for the particular firearm. The caliber or

gauge of the firearm is clearly marked on the barrels of shotguns and on the slide

or barrel of pistols. The use of reloaded or remanufactured ammunition can increase the likelihood of excessive cartridge pressures, casehead ruptures or other

defects in the ammunition which can cause damage to your firearm and injury to

yourself or others nearby.

10. AVOID ALCOHOLIC BEVERAGES OR JUDGMENT OR REFLEX IMPAIRING MEDICATION

WHEN SHOOTING.

10. Do not drink and shoot. If you take medication that

can impair motor reactions or judgment, do not handle a firearm while you are under the influence of the

medication.

11. NEVER TRANSPORT A LOADED FIREARM.

11. Unload a firearm before putting it in a vehicle.

Hunters and target shooters should load their

firearm only at their destination. If you carry a

firearm for self-protection, leaving the chamber unloaded can reduce the chance of accidental discharge.

8. ALWAYS WEAR PROTECTIVE GLASSES AND EARPLUGS WHEN SHOOTING.

8. The chance that gas, gunpowder or metal fragments

will blow back and injure a shooter who is firing a gun

is rare, but the injury that can be sustained in such circumstances is severe, including the possible loss of

eyesight. A shooter must always wear impact resistant

shooting glasses when firing any firearm. Earplugs

help reduce the chance of hearing damage from

shooting.

9. NEVER CLIMB A TREE, FENCE OR OBSTRUCTION WITH A LOADED FIREARM.

9. Open and empty the chamber of your firearm before

climbing or descending a tree or before climbing a

fence or jumping over a ditch or obstruction. Never

pull or push a loaded firearm toward yourself or another person.

6

12. LEAD WARNING.

11. Discharging firearms in poorly ventilated areas, cleaning firearms, or handling

birth defects, reproductive harm, and other serious physical injury. Have adequate ventilation at all times. Wash hands thoroughly after exposure.

7

Page 5

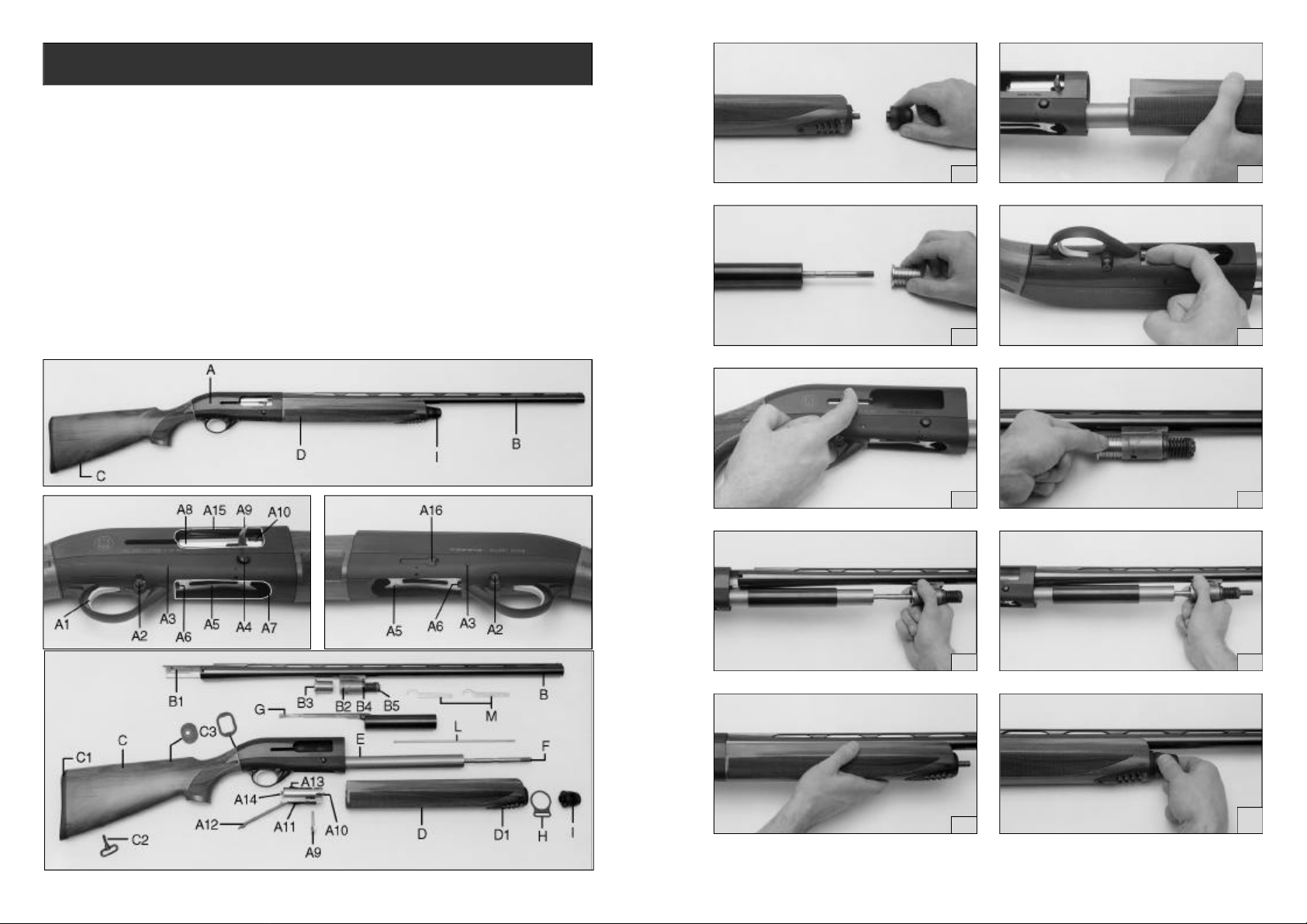

NOMENCLATURE

A Receiver

A1 Trigger

A2 Reversible safety button

A3 Trigger plate retaining pin

A4 Breech bolt release-button

A5 Carrier

A6 Carrier stop push-button

A7 Loading gate

A8 Breech bolt

A9 Cocking handle

A10 Extractor

A11 Breech bolt slide

A12 Connecting rod

A13 Locking block

A14 Firing pin

A15 Ejection port

A16 Cut-off

B Barrel

B1 Barrel tang

B2 Gas cylinder

B3 Piston

B4 Exhaust valve assembly

B5 Valve assembly locking nut and

counter-nut

C Stock

C1 Interchangeable butt plate

C2 Stock swivel

C3 Drop/cast spacers

D Fore-end

D1 Fore-end flange with exhaust port

E Magazine tube

F Magazine tube cap with shaft

G Operating rod with sleeve

H Front swivel

I Fore-end cap

L 1-round magazine capacity reduc-

er plug

M Valve hook wrenches

1 2

3 4

5 6

7 8

9

10

9

8

Page 6

of the stock metal plate allows one to adjust the stock drop and cast by simply modi

-

cessories: 1-round magazine capacity reducer plug, spare recoil pad, stock drop and

-

versions, a set

-

DESCRIPTION

The AL391 Urika semi-automatic shotgun, 12 and 20 gauge, comes with the following features:

STREAMLINED RECEIVER DESIGN

The skilfully rounded shape of the receiver promotes instinctive and quick target acquisition. The matted anti-glare black-finish of the upper and lower parts of the receiver highlight the bright finish of the sides to confer to the Beretta AL391 Urika a new

appearance and distinctive character.

GAS OPERATION SYSTEM WITH EXHAUST VALVE

STOCK

The stock is designed to accept either a plastic butt-plate or a rubber recoil pad with

out any adjustment. By assembling rubber recoil pads of different thicknesses, one

can modify the length of pull.

STOCK DROP AND CAST SPACERS

The design of the fiber-glass reinforced technopolymer receiver - stock spacer and

fying their assembly position. Different stock drop and cast dimensions can be ob-

tained using the extra set of spacers supplied.

The unique gas operation system, with gas cylinder and self cleaning piston, is provided with a self-cleaning exhaust valve which automatically expels the excess gas of

the most powerful cartridges: The result is that the shotgun, without any adjustment ,

fires everything from the light 24 gr. (7/8 oz.) loads to the powerful 57 gr. (2 oz.) 3”

Magnum 12 ga. shotshells.

The exhaust valve assembly remains attached to the gas cylinder, thus allowing easy

and quick disassembly and reassembly of the shotgun.

RECOIL DAMPER

The elastic recoil damper reduces stress from the impact of the breech bolt on the receiver and absorbs part of the vibrations normally transmitted to the shooter.

TRIGGER PLATE

The high strength fiber-glass reinforced technopolymer trigger plate offers many advantages: Self-cleaning property, high absorption of vibrations and more comfort to

the touch in cold weather conditions. The large opening of the trigger guard allows

the use of gloves.

CUT-OFF DEVICE

The cut-off control is positioned on the left side of the receiver: It can be engaged

when the breech bolt is positioned in the closed position with the use of one hand. If

the cut-off is accidentally left engaged, automatic reloading after the first shot will disengage it.

ACCESSORIES

The AL391 Urika is supplied with a modern design case and a complement of accast spacers, grip cap (wood stock field models only), stock swivels (field models on

ly), 25 ml. Beretta Gun Oil, valve hook wrenches and, for Mobilchoke

of 5 choke tubes with special spanner.

NOTICE: The AL391 Urika barrels are not interchangeable with those of former models (AL 390, A 390 ST, A 304 etc.)

®

REVERSIBLE SAFETY BUTTON

The cross-bolt safety button can be assembled for standard right-hand use or reversed for left-hand use.

10

11

Page 7

forward rim of the ejection port. This could damage both the handle and receiver.

Check the barrel. The bore and chamber must be clean and free from obstructions.

-

TECHNICAL FEATURES AND DATA

Gauge

Barrel chamber

Operation

Locking system

Receiver

Barrel

Rib

Front sight

Safety

Magazine

Stock, fore-end

Length of pull

Weight (approx.) *

(*)

Weights are approximate, dependent on wood density and barrel length.

NOTICE: The numbers noted below refer to the photographs on pages 9, 78,

79, 80.

12, 20

2 3/4” and 3”

semi-automatic, gas operation with exhaust

valve mounted on the barrel

elevated locking block

light alloy with recoil damper

steel, chromium-plated bore and chamber

ventilated

metal bead; special front sight for competition

models

cross bolt, reversible for left-handed shooters

3 rounds (plugged to 2)

selected walnut, checkered or high strength

fiber-glass reinforced technopolymer.

Adjustable drop. Cast-off or cast-on

362÷376 mm (14.25”-14.80”) (field)

365÷380 mm (14.37”-14.96”) (competition)

From 3.000 Kg. (6.6 lbs.) to 3.300 kg. (7.3 lbs.)

(12 ga. field versions)

From 2.700 Kg. (6.0 lbs.) to 3.000 Kg. (6.6 lbs)

(20 ga.)

From 3.300 Kg. (7.3 lbs.) to 3.500 Kg. (7.7 lbs.)

(12 ga. competition versions)

OPERATION

ASSEMBLING THE BARREL

The Beretta AL391 Urika semi-automatic shotgun is factory packed with the barrel

separate from the stock / receiver / fore-end assembly.

Assemble the barrel to the stock / receiver / fore-end assembly as follows:

CAUTION: If, for any reason, the breech bolt is open and the fore-end is separated from stock / receiver assembly, avoid pressing the breech bolt release button and be careful to keep your fingers away from the ejection port.

Should the breech bolt release button be pressed in this condition, the breech

bolt would slam forward and would stop only when the cocking handle hits the

l

l

Unscrew (counterclockwise) the fore-end cap from the stock / receiver / fore-end

assembly. (Fig. 1)

l

Pull the fore-end off the magazine tube. (Fig. 2)

l

Remove the piston. (Fig. 3)

l

Check that the carrier stop push button is completely depressed. If not, depress it

completely. (Fig. 4)

l

Pull the cocking handle backward to bring the breech bolt in the OPEN position.

(Fig. 5)

CAUTION: Should the breech bolt release button be pressed in this condition,

the breech bolt would slam forward and would stop only when the cocking

handle hits the forward rim of the ejection port. This could damage both the

handle and receiver.

l

Insert the piston into the gas cylinder. (Fig. 6)

l

Partially slide the barrel tang into the receiver, taking care that the piston does not

drop out of the gas cylinder and that the magazine tube cap shaft enters the piston

hole as well as that of the gas cylinder and the valve assembly. (Fig. 7)

l

Slide the barrel tang home into the receiver. (Fig. 8)

l

Slide the fore-end into place over the gas cylinder, valve assembly and magazine

tube. Check that the fore-end is perfectly centered on the receiver face. The foreend is correctly assembled when there is no space left between the parts. (Fig. 9)

l

Place the front swivel ring (if desired and supplied) on the fore-end flange and com

pletely tighten the fore-end cap. (Fig. 10)

l

Close the breech bolt by depressing the breech bolt release button, keeping your

fingers away from the ejection port. (Fig. 11)

WARNING: All assembly, disassembly and maintenance procedures should

be carried out with the firearm unloaded (magazine tube empty, receiver empty

and cartridge chamber empty). Check that the firearm is unloaded by looking

through the ejection port, the loading gate and the chamber.

WARNING: During the assembly, disassembly and maintenance procedures,

never point a firearm at someone or at hard and flat surfaces. Treat the firearm

as if it were loaded. (See points 1, 2 and 4 of the BASIC SAFETY RULES).

12

CAUTION: While depressing the breech bolt release button to close the

breech bolt, make sure that the cut-off is not inadvertently engaged. Should

this occur, the breech bolt would be kept OPEN by the cut-off lever. In this

case, always keeping your fingers away from the ejection port, close the

breech bolt by operating the cut-off. (Fig. 12)

l

Keeping the breech bolt retracted approximately 2 cm (1 inch), depress the trigger

to lower the hammer. (Fig. 13)

13

Page 8

LOADING THE FIREARM

WARNING: Before loading the firearm, practice the following loading proce-

dures without the use of ammunition. Never handle a loaded firearm until you

are fully familiar with the loading procedures. Before loading the shotgun,

make sure that the safety is engaged. Always point the firearm in a safe direction. (See points 1, 2 and 4 of the BASIC SAFETY RULES).

WARNING: Always keep your fingers away from the trigger and keep the trigger free from any contact when you do not intend to fire.

l

To fire, disengage the safety and pull the trigger.

l

When the last round has been fired, the breech bolt remains open, thus signalling

that the magazine is empty. (Fig. 19)

l

Engage the safety and, if required, reload the firearm as indicated.

USE OF THE CUT-OFF DEVICE

The cut-off device allows one to extract a live round from the cartridge chamber and

lock the breech bolt open for safety or to replace the round in the chamber, without

feeding a new round from the magazine.

l

Retract the breech bolt by means of the cocking handle until it hooks into the OPEN

position. (Fig. 14)

l

Engage the safety by pushing the safety button until the red ring disappears.

(Fig. 15)

WARNING: When the safety button shows the red ring, the firearm is in the

FIRE position.

NOTICE: The safety can be engaged only when the hammer is cocked.

l

Insert the first round into the cartridge chamber through the ejection port. (Fig. 16)

l

Depress the breech bolt release button to lock the breech bolt, keeping fingers

away from the ejection port. (Fig. 17)

WARNING: The firearm is now loaded and ready to fire. Always keep your fingers away from the trigger and keep the trigger free from any contact when

you do not intend to fire. Never point the firearm at something that is not safe

to shoot. (See points 1, 2 and 4 of the BASIC SAFETY RULES).

NOTICE: The manufacturer assumes no responsibility for any injury or property damage resulting from improper or careless handling, intentional or accidental discharge of the firearm.

WARNING: The firearm is now loaded with a cartridge in the chamber and the

safety is engaged. Never point a firearm at something that is not safe to shoot.

(See points 1, 2 and 4 of the BASIC SAFETY RULES).

l

Make sure that the safety is engaged.

l

Engage the cut-off by depressing the cut-off lever (round side). (Fig. 20)

l

Retract the breech bolt by means of the cocking handle to extract the live round

from the cartridge chamber and eject it through the ejection port. At the end of its

travel, the breech bolt is hooked into the OPEN position by the carrier which is

locked by the cut-off device. Feeding from magazine is blocked. (Fig. 21)

l

Under safety conditions, insert the extracted cartridge or another cartridge into the

cartridge chamber.

l

Keeping fingers away from the ejection port, depress the cut-off lever to close the

breech bolt. (Fig. 12)

WARNING: The firearm is loaded and ready to fire again. Make sure that the

safety is fully engaged. Never point a firearm at something that is not safe to

shoot. (See points 1, 2 and 4 of the BASIC SAFETY RULES).

l

To fire, disengage the safety and pull the trigger.

NOTICE: If the firearm is to function properly, it is recommended that the cutoff be used as described above. In particular, it must be remembered that the

breech bolt, when held OPEN by the cut-off, can be closed only by operating

the cut-off lever.

CAUTION: Should the breech bolt remain open, check that the cut-off is not

inadvertently engaged. If it is, always keeping your fingers away from the ejection port, close the breech bolt by operating the cut-off button. (Fig. 12)

l

Insert through the loading gate the other rounds by placing each round on the carrier and pressing it down and forward into the magazine tube until it engages the stop

tooth. (Fig. 18)

14

UNLOADING THE FIREARM

WARNING: The firearm is loaded and ready to fire. Always keep your fingers

away from the trigger and keep the trigger free from any contact when you do

not intend to fire. Never point a firearm at someone or at hard and flat surfaces. (See points 1, 2 and 4 of the BASIC SAFETY RULES).

15

Page 9

Push out the trigger plate retaining pin by pressing it with a drift punch or other simi

-

At the end of the hunting or shooting day, perform the Routine Maintenance as

l

Pointing the firearm in a safe direction, check that safety is engaged (red ring covered).

l

Engage the cut-off and retract the breech bolt to extract and eject the chambered

live round. (Fig. 20-21)

l

Keeping fingers away from the ejection port, depress the cut-off lever to close the

breech bolt. (Fig. 12)

l

Pressing down the carrier and at the same time pushing against the cartridge in the

magazine, depress the breech bolt release button to ease exit of the shells from the

magazine tube. (Fig. 22)

l

Check to ensure the magazine tube and receiver are empty. Disengage the safety.

Be careful where you point the firearm, even though it might not be loaded.

l

Keeping the breech bolt retracted approximately 2 cm (1 inch), to allow a visual

check of the cartridge chamber to ensure it is empty, depress the trigger to lower

the hammer. (Fig. 13)

DISASSEMBLY

breech bolt assembly from the receiver. (Fig. 25)

l

The breech bolt assembly, no longer held by the operating rod, will divide into:

(Fig. 26)

l

- breech bolt with firing pin, locking block, extractor, springs and pins;

TRIGGER PLATE

l

Engage the safety (the hammer is cocked).

l

Depress the carrier stop push-button. (Fig. 4)

l

lar object. (Fig. 27)

l

Keeping the breech bolt release button pressed, extract the trigger plate by pulling

on the trigger guard with a forward and downward movement. (Fig. 28)

CAUTION: Further disassembly of the firearm is not recommended, unless

carried out by a competent gunsmith.

WARNING: Check the firearm is unloaded (cartridge chamber empty, receiver

empty, magazine tube empty). Check that the firearm is unloaded by looking

through the ejection port, the loading gate and the chamber. If the shotgun is

not unloaded, unload it as described in the chapter “Unloading the firearm”.

Lower the hammer on the unloaded gun by pulling the trigger.

WARNING: Never point a firearm at someone or at hard and flat surfaces.

Treat the firearm as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

BARREL

l

Retract the breech bolt until it hooks into the OPEN position. (Fig. 14)

l

Unscrew (counterclockwise) the fore-end cap from the firearm and remove the front

swivel, if mounted. (Fig. 10)

l

With one hand hold down the barrel and with the other hand slide the fore-end off

the magazine tube. (Fig. 9)

l

Grasping the barrel and holding the piston inside the gas cylinder with the right

thumb to prevent dropping it, slide the barrel assembly forward off the stock / receiver assembly. (Fig. 7)

l

Slide the piston off the gas cylinder. (Fig. 6)

BREECH BOLT

l

Holding the cocking handle with the index or middle finger of the left hand, depress

the breech bolt release button and allow the breech bolt to slide slowly forward until

it stops. (Fig. 23)

l

Extract the cocking handle from the breech bolt slide. (Fig. 24)

l

Holding the stock / receiver assembly on a table with the loading gate facing upward, slide the operating rod sleeve forward off the magazine tube to extract the

16

NOTICE: Wholesalers, dealers or gunsmiths (unless they are a Repair Station

authorized by the Manufacturer and/or by its Local Official Distributors) are not

authorized to make any Warranty repair or adjustment on behalf of the

Manufacturer.

ROUTINE MAINTENANCE

When combustion residues, grease or dirt particles have accumulated in the action,

clean and lubricate the firearm.

Cleaning and lubrication of the shotgun after use is the best guarantee for protection

of parts against corrosion deriving from combustion residues and from use of the

firearm in humid or saline environments.

indicated.

WARNING: Check that the firearm is unloaded (cartridge chamber empty, re-

ceiver empty, magazine tube empty). Check that the firearm is unloaded by

looking through the ejection port, the loading gate and the chamber. If the

shotgun is not unloaded, unload it as described in the chapter “Unloading the

firearm”. Lower the hammer on the unloaded gun by pulling the trigger.

WARNING: Never point a firearm at someone or at hard and flat surfaces.

Treat the firearm as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

WARNING: Excess oil and grease obstructing the bore even partially are very

dangerous when firing and may cause damages to the shotgun and serious

injury to the shooter and bystanders. Never spray or apply oil to the shotshells.

Use lubricants properly: you are responsible for the proper care and maintenance of your firearm.

17

Page 10

Every 3000-5000 rounds (according to the type of ammunition used) and in any

BARREL

TRIGGER PLATE

l

After use, thoroughly clean the barrel bore by passing a swab through it to remove

combustion residues. If necessary, use a cleaning rod with bronze brush and/or a

patch soaked in a bore cleaning solvent.

l

Thoroughly clean the barrel tang locking shoulder.

l

Pull a clean soft patch through the barrel bore.

l

Lightly lubricate the barrel bore by pulling through it a soft clean patch treated with

Beretta gun oil.

CAUTION: Do not apply excess oil: accumulation of oil attracts dirt which can

plug the barrel and interfere with the functioning and reliability of the gun.

GAS CYLINDER, PISTON, MAGAZINE TUBE CAP SHAFT, EXHAUST VALVE

ASSEMBLY

CAUTION: Magnum cartridges and particularly Super Magnum (3”) shotshells

produce a high amount of combustion gases. The particular composition of

some Super Magnum shotshells’ powder can generate a strong deposit of

combustion residues. The parts of the shotgun which, coming into contact with

the gases, are more affected by the combustion residues are the gas cylinder

(inside) and the piston with its bushing.

l

Check that the piston slides freely inside the gas cylinder.

l

Carefully clean the inner side of the gas cylinder with a bronze brush sprayed with

Beretta gun oil.

l

When all combustion residues are removed, clean the inside of the gas cylinder

with a soft cloth.

l

Carefully clean the piston and check that the piston bushing can move freely in its

housing.

l

If necessary, also clean the exhaust valve and the magazine tube cap shaft.

CAUTION: Do not oil these parts.

l

Maintain as described for the breech bolt assembly.

RECEIVER

l

Maintain as described for the breech bolt assembly. Lightly oil the slide rails of the

breech bolt inside the receiver.

MAGAZINE TUBE

l

Clean the outside of the magazine tube with a soft cloth sprayed with Beretta gun

oil.

l

Carefully dry with a soft cloth and lightly oil the parts.

case at the end of the hunting or shooting season, before storing the gun, in

addition to the Routine Maintenance, perform the Special Maintenance as described later in this manual.

REASSEMBLY

WARNING: Check that the firearm is unloaded (cartridge chamber empty, re-

ceiver empty, magazine tube empty). Check that the firearm is unloaded by

looking through the ejection port, the loading gate and the chamber. If the

shotgun is not unloaded, unload it as described in the chapter “Unloading the

firearm”. Lower the hammer on the unloaded gun by pulling the trigger.

WARNING: Never point a firearm at someone or at hard and flat surfaces.

Treat the firearm as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

Every 500-1000 rounds (according to the type of ammunition used), complete

the Routine Maintenance with the following extra operations.

FORE-END FLANGE

l

Carefully clean the fore-end flange exhaust valve port with a soft brush sprayed with

Beretta gun oil. Carefully dry the flange with a soft cloth.

BREECH BOLT ASSEMBLY

l

Thoroughly clean the parts with a small brush and Beretta gun oil.

l

Carefully dry with a soft cloth and lightly oil the parts with Beretta gun oil.

18

TRIGGER PLATE

l

Operate in the reverse order to what is described in the chapter “Disassembly”

making sure that the hammer is cocked, the safety engaged and the carrier stop

push-button depressed. (Fig. 28)

l

Insert the trigger plate retaining pin, ensuring that the trigger plate hole is centered

on the receiver hole.

BREECH BOLT

l

Reassemble the breech bolt slide with connecting rod to the breech bolt. (Fig. 36)

19

Page 11

Unscrew the valve assembly counter-nut using the supplied hook wrench, operating

Every 3000-5000 rounds (according to the type of ammunition used) and in any

l

Insert the operating rod into the breech bolt slide slot. (Fig. 37)

l

Depress the carrier stop push-button. (Fig. 4)

l

Holding the stock/receiver assembly on a table with the ejection port facing upward,

slide the operating rod sleeve on the magazine tube (the breech bolt rests on the

operating rod) and partially insert the breech bolt inside the receiver. (Fig. 25)

l

Holding the stock/receiver vertically, slide the operating rod sleeve downward, compressing the recoil spring until the breech bolt hooks into the OPEN position. (Fig.

38)

NOTICE: To carry out the described operation with ease, the head of the

breech bolt connecting rod must rest in the recoil spring guide housing. This

will easily occur when the connecting rod is perfectly coaxial to the breech bolt

and centered in the cocking handle slideway of the receiver.

l

Insert the cocking handle into the breech bolt slide and push it until it clicks home.

(Fig. 24)

SPECIAL MAINTENANCE

case at the end of the hunting season, before storing the shotgun, in addition

to the Routine Maintenance, also perform the following Special Maintenance

operations.

WARNING: Check the firearm is unloaded (cartridge chamber empty, receiver

empty, magazine tube empty). Check that the firearm is unloaded by looking

through the ejection port, the loading gate and the chamber. If the shotgun is

not unloaded, unload it as described in the chapter “Unloading the firearm”.

Lower the hammer on the unloaded gun by pulling the trigger.

WARNING: Never point a firearm at someone or at hard and flat surfaces.

Treat the firearm as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

BARREL

l

Check the barrel. The bore and cartridge chamber must be clean and free from obstructions.

l

Insert the piston into the gas cylinder. (Fig. 6)

l

Check that the breech bolt is in the OPEN position.

l

Partially slide the barrel tang into the receiver, taking care that the piston does not

drop out of the gas cylinder and that the magazine tube cap shaft enters the piston

hole as well as that of the gas cylinder and the valve assembly. (Fig. 7)

l

Slide the barrel tang home into the receiver. (Fig. 8)

l

Slide the fore-end into place over the gas cylinder, valve assembly and magazine

tube. Check that the fore-end is perfectly centered on the receiver face. The foreend is correctly assembled when there is no space left between the parts. (Fig. 9)

l

Place the front swivel ring (if desired and supplied) on the fore-end flange and completely tighten the fore-end cap. (Fig. 10)

l

Close the breech bolt by depressing the breech bolt release button, keeping your

fingers away from the ejection port. (Fig. 11)

CAUTION: While depressing the breech bolt release button to close the

breech bolt, make sure that the cut-off is not inadvertently engaged. Should

this occur, the breech bolt would be kept OPEN by the cut-off lever. In this

case, always keeping your fingers away from the ejection port, close the

breech bolt by operating the cut-off. (Fig. 12)

l

Keeping the breech bolt retracted approximately 2 cm (1 inch), depress the trigger

to lower the hammer. (Fig. 13)

WARNING: Do not store firearms in places which are or could be accessible

by children or other persons whose unfamiliarity with firearms might lead to

unsafe use. Always store your firearms securely and unloaded, separate from

ammunition. (See point 3 of the BASIC SAFETY RULES).

20

EXHAUST VALVE ASSEMBLY

CAUTION: Use only the supplied hook wrenches to screw and unscrew the

valve assembly locking nut and counter-nut. These spanners are designed

and have the right dimensions to produce the correct driving torque when a

force of medium intensity is applied. Never attempt to use different wrenches

which could produce an excessive driving torque. Do not apply excessive

force when using the supplied spanners.

CAUTION: Before starting the disassembly of the exhaust valve assembly,

carefully observe the position of the components parts. This will be of great

help during the reassembly operations.

DISASSEMBLY AND CLEANING

l

Remove the barrel from the shotgun.

l

counterclockwise. (Fig. 29)

l

Unscrew the valve assembly nut using the supplied wrench. (Fig. 30)

l

Slide from the valve shaft the spring, the valve and the valve centering ring.

(Fig. 31)

l

Slide from the gas cylinder the valve shaft. (Fig. 32)

l

Thoroughly clean the parts with Beretta gun oil. If necessary, use a bronze brush.

CAUTION: Be careful not to damage the threaded surfaces with excessive

rubbing.

l

Carefully dry with a soft cloth.

l

Lightly oil the parts with Beretta gun oil.

21

Page 12

CAUTION: Do not apply excess oil: accumulation of oil attracts dirt which can

plug the barrel and interfere with the functioning and reliability of the gun.

MOBILCHOKE®TUBES

REASSEMBLY

l

Insert the valve shaft into the gas cylinder, letting the shaft lugs enter the cylinder

recesses. (Fig. 33)

l

Place the valve centering ring, the valve and the valve spring around the valve shaft

.

l

Make sure that the valve is assembled with the outside recess turned to contain the

first coil of the spring. (Fig. 34)

l

Manually screw the valve nut on the valve shaft until tight.

l

Using the supplied hook wrench, tighten the valve nut against the valve centering

ring.

l

Manually screw the valve counter-nut on the valve shaft until tight against the valve

nut.

l

Keeping the valve nut tight using one of the two hook wrenches, tighten the

counter-nut against the nut with the other wrench. (Fig. 35)

MAGAZINE CAPACITY

The magazine tube capacity of the AL391 Urika (which has a three-round capacity)

has been limited to two rounds by the application of a plug in order to comply with the

sporting gun laws in force in many countries.

This plug, which is factory mounted, reduces the capacity of the AL391 Urika to no

more than three rounds (two in the magazine, one in the chamber).

In some areas, shooting is allowed only with shotguns having a capacity of no more

than two rounds.

To use the AL391 Urika in these areas, it will be necessary to limit the magazine capacity to only one round.

It is possible to increase the magazine capacity from two to three rounds in the countries where it is allowed.

NOTICE: These operations must be carried out by a competent gunsmith.

NOTICE: Beretta Mobilchoke®SP (Steel-Proof) screw-in chokes tubes have

been specially designed to take the punishment of non-toxic steel shot.

For best results with steel shot, Beretta recommends a modified choke. Full

choke constriction when using steel shot does not increase pattern density

and often distorts normal pattern density associated with lead.

Remember that standard old type Beretta Mobilchoke®tubes were not designed for steel shot. Before shooting steel shot cartridges check that the

Beretta Mobilchoke®tubes are marked SP.

CHANGING AND CLEANING THE CHOKES

WARNING: Check that the firearm is unloaded (cartridge chamber empty, re-

ceiver empty, magazine tube empty). Check that the firearm is unloaded by

looking through the ejection port, the loading gate and the chamber. If the

shotgun is not unloaded, unload it as described in the chapter “Unloading the

firearm”. Lower the hammer on the unloaded gun by pulling the trigger.

WARNING: Never look into the muzzle or change tubes on a loaded gun

even with safety engaged.

WARNING: Never point a firearm at someone or at hard and flat surfaces.

Treat the firearm as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

l

Unscrew (counterclockwise) the choke using the supplied spanner. (Fig. 39)

l

Carefully clean the choke housing. If necessary, use a patch sprayed with Beretta

gun oil.

l

Carefully dry the choke housing using a soft patch.

l

Insert the desired choke into the choke housing, checking that it is perfectly clean

inside and outside. (Fig. 40)

l

Manually screw on (clockwise) the choke. Tighten it with the multiple spanner.

NOTICE: Wholesalers, dealers or gunsmiths (unless they are a Repair Station

authorized by the Manufacturer and/or by its Local Official Distributors) are not

authorized to make any Warranty repair or adjustment on behalf of the

Manufacturer.

22

WARNING: During the hunting or shooting day, under safe conditions

(firearms unloaded with cartridge chamber empty, receiver empty, magazine

empty and breech bolt in OPEN position) check whether the choke has

worked loose. Should this happen, the choke must be tightened again using

the supplied spanner.

WARNING: Remember that you should never use a Mobilchoke®barrel with-

out a Mobilchoke®tube inserted. Shooting without the choke tube is dangerous and can damage the barrel’s internal screw thread irreparably.

23

Page 13

-

STOCK DROP AND CAST MODIFICATION

The Beretta AL391 Urika semi-automatic shotgun is factory set with a heel drop of

55 or 60 mm. (2.16” or 2.36”) (field, sporting, skeet models), of 40 mm. (1.57”) (trap

models) and cast-off (right-handed shooters).

The components which determine the drop and the cast are:

¿ Receiver-stock spacer made of technopolymer, fiber-glass reinforced.

¡ Stock metal plate.

Both the spacer ¿ and the plate ¡ are designed to secure two different drops with

cast-off or with cast-on (for left handed shooters) depending on how they are assembled.

Other measures of stock drop can be obtained using the supplied extra set of spacers.

CHANGING THE STOCK DROP AND CAST SPACERS

NOTICE: The “DX” mark on the spacer and on the plate means “cast-off”, the

“SX” mark means “cast-on”. The stock drop measures are in millimetres. The

stock drop and cast of the spacer ¿ must always correspond to those of the

metal plate ¡.

NOTICE: Stock drop and cast modification must be carried out by a competent gunsmith.

NECESSARY TOOLS

l

Screwdriver.

l

Hexagonal tube spanner (13 mm).

l

Torque wrench (suggested).

l

Remove the recoil pad using the screwdriver.

l

Disassemble the stock using the spanner and take off the spacers.

l

Put the spacer ¿ around the stock

bolt tube. Make sure that the

spacer shows on the top the drop

and cast wanted (“C-60-DX” in the

drawing).

l

Put the rear plate ¡ and the washer in

the back hole of the stock until the plate

reaches its own seat in the stock. Make sure

that the plate shows on the top the same drop

and cast of the spacer on the top (“C-60-DX” in

the drawing).

l

Use the screwdriver to center the plate and the

washer.

l

Assemble the stock, making sure to locate the stock bolt

tube through the rear plate ¡ and the washer. Also make sure

that the front spacer ¿ is centered between the stock and the receiver. (During this operation keep the shotgun vertical with the

barrel down).

l

Using the spanner, screw on and tighten the stock retaining nut with a

torque of about 1,6/1,8 kgm (11.6/13.0 Ftlb) (Kg meter). A torque wrench is useful

for this purpose.

l

Screw on the recoil pad.

WARNING: The improper observance of this procedure could cause damage

to the shotgun and/or injury to the bystanders.

WARNING: Check that the firearm is unloaded (cartridge chamber empty, receiver empty, magazine tube empty). Check that the firearm is unloaded by

looking through the ejection port, the loading gate and the chamber. If the

shotgun is not unloaded, unload it as described in the chapter “Unloading the

firearm”. Lower the hammer on the unloaded gun by pulling the trigger.

RECOIL PAD

The standard plastic butt-plate or rubber recoil pad can be replaced with a rubber re

coil pad of different thickness without any adjustment. By assembling rubber recoil

pads of different thickness it is possible to modify the length of pull.

NOTICE: This operation must be carried out by a competent gunsmith.

WARNING: Never point a firearm at someone or at hard and flat surfaces.

Treat the firearm as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

24

25

Page 14

REVERSIBLE SAFETY BUTTON

WARNING: Check that the firearm is unloaded (cartridge chamber empty, re-

ceiver empty, magazine tube empty). Check that the firearm is unloaded by

looking through the ejection port, the loading gate and the chamber. If the

shotgun is not unloaded, unload it as described in the chapter “Unloading the

firearm”. Lower the hammer on the unloaded gun by pulling the trigger.

WARNING: Never point a firearm at someone or at hard and flat surfaces.

Treat the firearm as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

The safety button is factory assembled to be engaged by pushing it from the left to

the right side of the receiver and disengaged in the opposite direction with the index

finger of the right hand (right-handed shooters).

By reversing the safety button, the safety is engaged by pushing from the right to the

left side of the receiver and is disengaged in the opposite way by using the index finger of the left hand (left-handed shooters).

To invert the safety button:

Cock the hammer. Keeping the safety plunger depressed with a drift punch, push the

safety out of its housing (from the right to the left side of the firearm).

CAUTION: The safety plunger spring, when mounted, is in a compressed condition. Take care not to lose the plunger and its spring.

NOTE:

Reverse the safety and insert it into its housing from the left to the right side of the

firearm and click it into position, keeping the safety plunger depressed.

NOTICE: This operation must be carried out by a competent gunsmith.

26

27

Page 15

11 12

21

22

13

15 16

17

14

18

23

25

27

24

26

28

28

19 20

29

30

29

Page 16

31

Printed in Italy

Batan - Gardone V.T.

32

30

33

35

37

39

34

36

38

40

Le illustrazioni e descrizioni di questo opuscolo si intendono fornite a titolo indicativo. La Casa si riserva pertanto il

diritto di apportare ai suoi modelli, in qualsiasi momento e senza preavviso, quelle modifiche che ritenesse utili per

migliorarli o per qualsiasi esigenza di carattere costruttivo e commerciale.

The illustrations and descriptions given in this brochure are intended as a general guide only, and must not be taken

as binding. The Company, therefore, reserves the right to make, at any moment and without notice, any changes it

thinks necessary to improve its models or to meet any requirements of manufacturing or commercial nature.

Les illustrations et les descriptions contenues dans ce prospectus ne sont données qu'à titre indicatif. La Maison se

réserve le droit de modifier, à tout moment et sans préavis, ses modèles pour les améliorer ou pour n'importe quelle

exigence de caractère constructif et commercial.

Beretta Pubblicità - cod. 61160

2/99 (5)

Page 17

Loading...

Loading...