Page 1

IT

IT

Italiano

EN

FR

ES

DE

RU

SV

GR

English

Français

Español

Deutsch

Pусский

Svenska

Ελληνικά

2

Page 2

ALWAYS KEEP THIS MANUAL WITH YOUR FIREARM. INCLUDE IT WITH

THE FIREARM WHEN IT CHANGES OWNERSHIP.

WARNING: FIREARMS CAN BE DANGEROUS AND CAN POTENTIALLY

CAUSE SERIOUS INJURY, DAMAGE TO PROPERTY OR DEATH, IF HANDLED

IMPROPERLY. THE FOLLOWING SAFETY RULES ARE AN IMPORTANT

REMINDER THAT FIREARM SAFETY IS YOUR RESPONSIBILITY.

!

WARNING: Always ensure that the safety is fully engaged until ready to fi re.

NOTICE: The Manufacturer and/or its Local Offi cial Distributors assume no

liability for product malfunction or for physical injury or property damage resulting

in whole or in part from criminal or negligent use of the product, improper or

careless handling, unauthorised modifi cations, use of defective, improper, hand-

loaded, reloaded or remanufactured ammunition, customer misuse or neglect

of the product, or other factors beyond manufacturer's direct and immediate

control.

In addition to the Basic Safety Rules, there are other Safety Rules pertaining to

the loading, unloading, disassembly, assembly and use of this fi rearm, located

throughout this manual.

WARNING: READ THE ENTIRE MANUAL CAREFULLY BEFORE USING THIS

FIREARM. MAKE SURE THAT ANY PERSON USING OR HAVING ACCESS

TO THIS FIREARM READS AND UNDERSTANDS THIS ENTIRE MANUAL

PRIOR TO USE OR ACCESS.

NOTICE: As the interchangeable barrel of this shotgun has a serial number

different from that stamped on the receiver, it may be necessary, when referring

to the gun, to specify also the serial number of the barrel/s.

WE RECOMMEND THE USE OF ORIGINAL BERETTA SPARE PARTS

AND ACCESSORIES. THE USE OF OTHER MANUFACTURER'S SPARE

PARTS AND ACCESSORIES COULD CAUSE MALFUNCTIONS AND/

OR BREAKAGES THAT WILL NOT BE COVERED BY THE BERETTA

WARRANTY.

!

!

EN

!

!

3

Page 3

EN

BASIC SAFETY RULES

CAUTION: READ THIS MANUAL CAREFULLY BEFORE USING THE

SHOTGUN.

CAUTION: FIREARMS CAN BE DANGEROUS AND CAN POTENTIALLY

CAUSE SERIOUS INJURY, DAMAGE TO PROPERTY OR DEATH, IF HANDLED

IMPROPERLY. THE FOLLOWING SAFETY RULES ARE AN IMPORTANT

REMINDER THAT FIREARM SAFETY IS YOUR RESPONSIBILITY.

1. NEVER POINT A FIREARM AT SOMETHING THAT IS NOT SAFE TO

SHOOT.

Never let the muzzle of a fi rearm point at any part of your body or at another

person. This is especially important when loading or unloading the fi rearm.

When you are shooting at a target, know what is behind it. Some bullets

can travel over a mile. If you miss your target or if the bullet penetrates

the target, it is your responsibility to ensure that the shot does not cause

unintended injury or damage.

2. ALWAYS TREAT A FIREARM AS IF IT WERE LOADED.

Never assume that a fi rearm is unloaded. The only

certain way to ensure there are no cartridges in

a fi rearm is to open the chamber and visually

and physically examine the inside to see if a

round is present. Removing or unloading the

magazine will not guarantee that a fi rearm is

unloaded or cannot fi re. Shotguns and rifl es can

be checked by cycling or removing all rounds and

by then opening and inspecting the chamber so that a visual inspection of

the chamber for any remaining rounds can be made.

4

Page 4

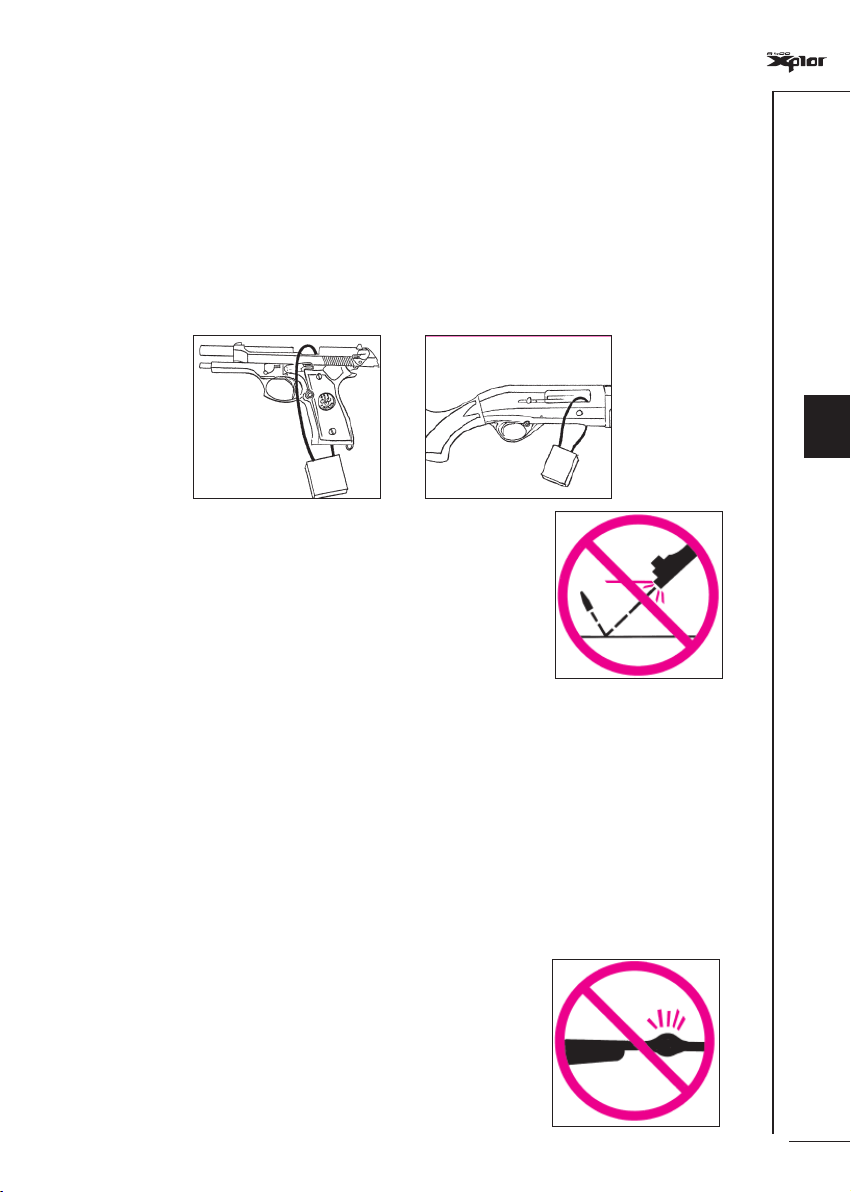

3. STORE YOUR FIREARM SO THAT CHILDREN CANNOT GAIN ACCESS

TO IT.

It is your responsibility to ensure that children under the age of 18 or other

unauthorised persons do not gain access to your fi rearm. To reduce the

risk of accidents involving children, unload your fi rearm, lock it and

store the ammunition in a separate locked location. Please note that

devices intended to prevent accidents - for example, cable locks, chamber

plugs, etc., - may not prevent use or misuse of your fi rearm by a determined

person. Firearm storage in a steel gun safe may be more appropriate

to reduce the likelihood of intentional misuse of a fi rearm by a child or

unauthorised person.

4. NEVER SHOOT AT WATER OR AT A HARD SURFACE.

Shooting at the surface of water or at a rock or other

hard surface increases the chance of ricochets or

fragmentation of the bullet or shot, which can result

in the projectile striking an unintended or peripheral

target.

EN

5. KNOW THE SAFETY FEATURES OF THE FIREARM YOU ARE USING,

BUT REMEMBER: SAFETY DEVICES ARE NOT A SUBSTITUTE FOR

SAFE HANDLING PROCEDURES.

Never rely solely on a safety device to prevent an accident. It is imperative

that you know and use the safety features of the particular fi rearm you

are handling, but accidents can best be prevented by following the safe

handling procedures described in these safety rules and elsewhere in the

product manual. To further familiarise yourself with the proper use of this

or other fi rearms, take a Firearms Safety Course taught by an expert in

fi rearms use and safety procedures.

6. PROPERLY MAINTAIN YOUR FIREARM.

Store and carry your fi rearm so that dirt or lint

does not accumulate in the working parts. Clean

and oil your fi rearm, following the instructions

provided in this manual, after each use to prevent

corrosion, damage to the barrel or accumulation of

impurities which can prevent use of the fi rearm in an

emergency. Always check the bore and chamber(s)

prior to loading to ensure that they are clean and

free from obstructions. Firing with an obstruction

5

Page 5

EN

in the barrel or chamber can rupture the barrel and injure you or others

nearby. In the event you hear an unusual noise when shooting, stop fi ring

immediately, engage the manual safety and unload the fi rearm. Make sure

the chamber and barrel are free from any obstruction, like a bullet blocked

inside the barrel due to defective or improper ammunition.

7. USE PROPER AMMUNITION.

Only use factory-loaded, new ammunition manufactured to industry

specifi cations: CIP (Europe and elsewhere), SAAMI® (U.S.A.). Be certain

that each round you use is in the proper calibre or gauge and type for the

particular fi rearm. The calibre or gauge of the fi rearm is clearly marked

on the barrels of shotguns and on the slide or barrel of pistols. The use

of reloaded or remanufactured ammunition can increase the likelihood of

excessive cartridge pressures, case-head ruptures or other defects in the

ammunition that can cause damage to your fi rearm and injury to yourself

or others nearby.

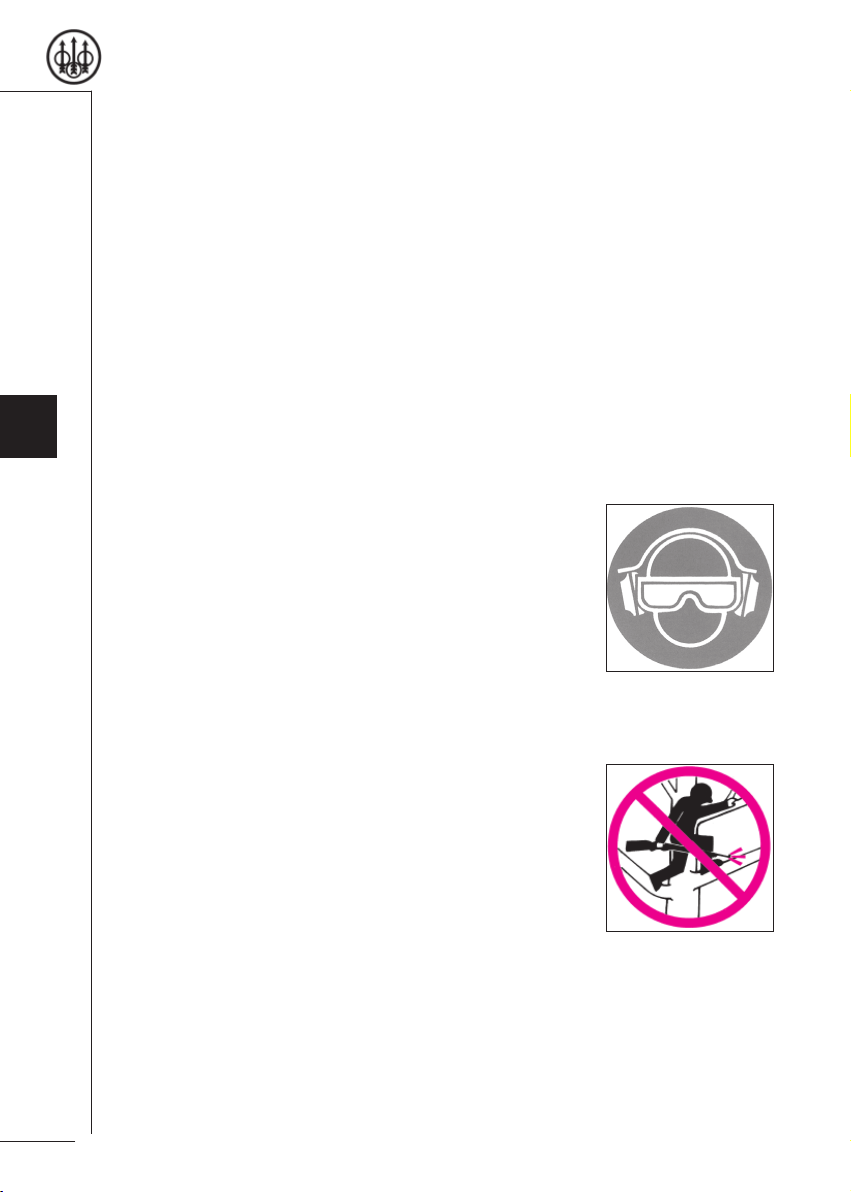

8. ALWAYS WEAR PROTECTIVE GLASSES AND EARPLUGS WHEN

SHOOTING.

The chance that gas, gunpowder or metal fragments

will blow back and injure a shooter who is fi ring a gun

is rare, but the injury that can be sustained in such

circumstances can be severe, including the possible

loss of eyesight. A shooter must always wear impact

resistant shooting glasses when fi ring any fi rearm.

Noise-reducing earplugs or headphones will reduce

the risk of damage to hearing caused by prolonged

shooting activity.

9. NEVER CLIMB A TREE, FENCE OR OBSTRUCTION WITH A LOADED

FIREARM.

Open and empty the chamber(s) of your fi rearm

and engage the manual safety before climbing or

descending a tree or before climbing a fence or

jumping over a ditch or other obstruction. Never

pull or push a loaded fi rearm toward yourself or

another person. Always unload a fi rearm, visually

and physically check to see that the magazine,

loading mechanism and chamber are unloaded, and

action is open before handing it to another person.

Never take a fi rearm from another person unless it is unloaded, visually and

physically checked to confi rm it is unloaded, and the action is open.

6

Page 6

10. AVOID ALCOHOLIC BEVERAGES OR JUDGEMENT/REFLEX IMPAIRING MEDICATION WHEN

SHOOTING.

Do not drink and shoot. If you take medication that

can impair motor reactions or judgement, do not

handle a fi rearm while you are under the infl uence

of the medication.

11. NEVER TRANSPORT A LOADED FIREARM.

Unload a fi rearm before putting it in a vehicle (chamber empty, magazine

empty). Hunters and target shooters should load their fi rearm only at their

destination, and only when they are ready to shoot. If you carry a fi rearm

for self-protection, leaving the chamber unloaded can reduce the chance of

an unintentional discharge.

12. LEAD WARNING.

Discharging fi rearms in poorly ventilated areas, cleaning fi rearms, or

handling ammunition may result in exposure to lead and other substances

known to cause birth defects, reproductive harm, and other serious physical

injury. Have adequate ventilation at all times. Wash hands thoroughly after

exposure.

CAUTION: It is YOUR responsibility to know and abide by Federal, State and

Local laws governing the sale, transportation and use of fi rearms in your area.

WARNING: This fi rearm has the capability of taking your life or the life of

someone else! Always be extremely careful with your fi rearm. An accident is

almost always the result of not following basic fi rearm safety rules.

Especially for U.S. consumers:

For information about Firearm Safety Courses in your area, please visit the

National Rifl e Association’s web site at www.nra.org.

EN

!

!

7

Page 7

EN

NOMENCLATURE

A Receiver

A1 Trigger

A2 Safety button

A3 Trigger guard

A4 Trigger guard retaining pin

A5 Breech bolt release button

A6 Carrier

A7 Carrier stop push button

A8 Loading gate

A9 Ejection port/cartridge chamber

A10 Cut-off

B Breech bolt assembly

B1 Cocking handle

B2 Two lugs locking head

B3 Operating rods with sleeve

C Barrel

C1 Barrel breech

C2 Indexing lugs

C3 Locking shoulders

C4 Gas cylinder

C5 Piston with elastic seal

C6 Exhaust valve assembly

C7 Optimachoke

C8 Choke tube spanner

C9 Front sight

C10 Top rib

C11 Muzzle

D Stock

D1 Recoil pad

D2 Kick Off

E Fore-end

E1 Fore-end fl ange with exhaust port

F Magazine tube

G Front swivel

H Fore-end cap

device

®

HP choke tube

8

Page 8

Contents

BASIC SAFETY RULES 4

NOMENCLATURE 8

DESCRIPTION 10

DATA AND TECHNICAL CHARACTERISTICS 15

OBSTRUCTION / CHOKE TUBES CONDITION CHECK 16

ASSEMBLY OF PACKAGED FIREARM 16

LOAD CHECK 19

AMMUNITION 20

HOW TO LOAD THE FIREARM 21

HOW TO USE THE CUT-OFF DEVICE 23

HOW TO UNLOAD THE SHOTGUN 24

DISASSEMBLY 25

®

BERETTA OPTIMACHOKE

ROUTINE MAINTENANCE 29

SPECIAL MAINTENANCE 31

REASSEMBLY 31

STOCK DROP AND CAST MODIFICATION 33

STORAGE 35

HP CHOKE TUBES 26

EN

9

Page 9

EN

DESCRIPTION

In 1960, one of the world's fi rst semi-automatic gas operated fi eld shotgun was

created: the Beretta mod. 60. Since then, building on the experience and skills

acquired in designing and constructing this reliable operating system, Beretta is

pleased to present its new A400 Xplor series.

Developed from the versatile Beretta gas operated, self-cleaning system, the

advanced design of the new A400 Xplor uses an exclusive exhaust valve that

allows the shotgun to “fi re” a broad range of ammunition. In combination with the

rotating head of the breech bolt, the new system further reduces the already low

recoil felt, directing the recoil force directly in line with the shoulder of the shooter.

This minimises recoil of the fi rearm on fi ring and lends additional stability to the

rifl e in fi ring subsequent rounds.

In the new semi-automatic A400 Xplor, Beretta has thought of every detail in

the design phase, with the utmost attention to comfort, design and maintenance

requirements. The new parts design, the minimal number of components,

the new materials and new anti-recoil devices make the A400 Xplor the new

standard for future generations of semi-automatic shotgun.

DESIGNED FOR PERFORMANCE AND COMFORT

Every detail, from the greatest to the very smallest, has been the object of

careful study and assessment in order to attain two key objectives: visual appeal

and superior performance. The ellipse motif and the Beretta logo, interpreted

artistically on the back of the fore-end, is uniformly yet discreetly discernible on

the main parts, giving the shotgun a futuristic, state of the art design.

10

The receiver: The ergonomically rounded back of the light alloy receiver fi ts

smoothly into the stock, enabling rapid and instinctive target acquisition.

Constructed using a special aluminium alloy, the A400 Xplor has undergone

a colored anodic oxidation process that protects the fi rearm from rusting and

scratching.

The cocking handle has been resized to minimise effort in the manual breech

bolt opening phase.

The trigger guard, in heavy duty polymer, has an innovative new texture. Its

new semi-square shape makes fi nger positioning easier. The rounded shape

and absence of sharp corners have been designed for more rapid, more secure

trigger grip. The use of a technopolymer ensures that the colour will remain in the

parts traditionally subject to rubbing while at the same time enhancing sensitivity

of touch in cold climates. The opening of the trigger guard is bigger so the trigger

is accessible even to a gloved hand.

The cut-off and breech bolt release button have been resized, with contours

designed for fast, safe and reliable operation, with maximum noise reduction

during fi ring.

Page 10

The trigger mecchanism has been redesigned. The new stainless steel carrier

withstands rust and wear and offers more sturdiness in the execution of its vital

function.

The safety button, also newly designed, now offers a wider surface for easier

operation. For accidental engaging or disengaging, the safety is protected and

topped by a protruding edge that also enhances its appearance.

The trigger is chrome-plated for ultimate rust protection. Its silver colour sets it

apart from the other parts of the shotgun.

The fore-end has long, slender contours that add to the harmony of the A400

Xplor’s overall design. Combined with the design of the gas fl ange, the front

section of the fi rearm is absolutely unique. The new checkering, created using

sophisticated laser technology, wraps around and provides a more secure grip

even in bad weather conditions, while the surface remains pleasant to the touch.

The artistic interpretation of the Beretta logo can be seen at the back. The length

of the fore-end has been revisited to make hand positioning easier, thereby

improving the handling and swinging of the shotgun. The cap has a new polymer

structure that makes it very lightweight, weather and rust-resistant.

The stock has also been totally reconceived to provide superior comfort and a

secure grip to ensure the highest performance during fi ring. Made of fi ne walnut

carefully selected for its colour characteristics, design and resistant fi nish, its

grip contour is designed to optimally accommodate the hand of the user with

a top ambidextrous fi nger rest, a characteristic only found in the fi nest hunting

guns. The underside of the grip is fl ush with the stock, creating an unparalleled

effect of continuity and harmony. The grip is optimised thanks to the doublesided “diamond-cut” laser checkering, chosen for its appearance and for its

exclusive slip-proof qualities.

EN

To ensure reduced recoil felt, the ultra-light recoil pad offers an ideal support

surface made of technopolymer foam, for enhanced recoil absorption.

REDUCED NUMBER OF COMPONENTS

The Beretta semi-automatic A400 Xplor is characterised by a particularly small

number of assemblies. The shotgun is composed of fi ve main assembly groups

which can be fi eld stripped by the user, for quick and easy disassembly. A fi rearm

that can be easily taken apart is also easier to clean. Easy cleaning encourages

to perform more careful maintenance on the fi rearm ensuring long-term reliability.

11

Page 11

EN

ROTATING BOLT HEAD LOCK

The Beretta semi-automatic A400 Xplor has a breech bolt with a rotating head

with two lugs that operate the lock of the barrel breech. The long breech has two

indexing lugs and a large support surface that make it possible to eliminate the

movement of the barrel when fi ring, thereby increasing precision. The breech

bolt body is connected with the two operating rods and therefore is guided and

activated symmetrically, with components sliding more smoothly as a result, for

easier disassembly and reassembly of the breech bolt unit.

GAS-OPERATED SYSTEM WITH EXHAUST VALVE

The exclusive gas-operated system, patented by Beretta, with

a self-cleaning cylinder and piston, has a self-cleaning exhaust

valve, so that excess pressure caused by the most powerful

cartridges can be decreased automatically: as a result, the shotgun

without any adjustment or intervention can shoot cartridges from

70 mm (2

version can fi re from 70 mm (2

Supermagnum 89 mm (3 1/2 in) /64 g (2 1/4 oz) loads.

Beretta recommends: To immediately obtain superior fi rearm performance and

optimum cartridges versatility from your A400 Xplor, fi re some medium power

cartridges fi rst (32g/1

The semi-automatic gas-operated A400 Xplor has also been optimised to ensure

lower gas dispersal. As a result, the system has a self-cleaning feature that

further minimises maintenance and signifi cantly reduces the stress to which the

operating parts are subjected to at higher charges, thereby ensuring the greatest

possible service life of the fi rearm.

The new piston has been designed to constantly clean out gunpowder residue

in the cylinder, increasing the effi ciency of the fi rearm and reducing the need for

maintenance. The elastic piston seal has a rough fi nish to optimise cleaning.

3

/4 in) /24 g (7/8 oz), to 76 mm (3 in) /57 g (2 oz). The “UNICO”

1

/8 oz).

3

/4 in) /24 g (7/8 oz) cartridges to the powerful

12

SHOTGUN ASSEMBLY WARNING: In order to prevent damage to the elastic

!

piston seal, fi rst insert the piston into the chamber cylinder and then insert the

magazine tube cap shaft through the piston hole.

The valve unit is connected to the barrel, making assembly and disassembly of

the barrel itself easier.

SUPER RESISTANT RECEIVER

Completely and precisely machined from a solid block of special light alloy

aluminium, it has moveable parts in steel, polymers, high quality light alloys,

assembled with particular care, checked and polished to ensure exceptional

operation. All metal parts are protected by special fi nishes against wear, and tear

and rusting. The length of the receiver is shorter in the semi-automatic versions

of the A400 Xplor series, to minimise bulkiness of the fi rearm and obtain easy

Page 12

handling in the narrow spaces, even when using long barrels.

The safety button can be reversed for left-handed shooters.

OPTIMA-BORE® HP BARREL/OPTIMACHOKE® HP

TUBES

In alloy steel, made with the exclusive cold hammering process to ensure

perfect concentricity, the barrel of the new Beretta semi-automatic A400 Xplor

is exceptionally robust and lightweight at the same time. Designed for use with

steel shot cartridges, it has a new Optima-Bore® HP (High Performance) internal

profi le with a lengthened forcing cone for enhanced pattern distribution and

reduced felt recoil. The bore is chrome plated to ensure the longest life and

resistance to rust, wear and tear and to increase the shot velocity, while it is deep

blued on the exterior.

The new Beretta Optimachoke® HP (High Performance) internal choke tubes are

designed to reduce shot deformation and to enhance shot pattern distribution

and concentration. Made in high performance nickel plated steel, the Beretta

Optimachoke® HP choke tubes ensure the highest protection against rust and

resistance to use of steel shot.

The attention that Beretta pays systematically to reduce the recoil reached new

heights with the A400 Xplor.

The A400 Xplor is the only semi-automatic shotgun in the world to be equipped

(depending on the specifi c model or by request) with three anti-recoil devices.

The combination of the three devices results in an unprecedented shooting

experience.

EN

KICK OFF DEVICE RECOIL ABSORPTION

The Beretta Kick Off system (supplied with the Kick Off version of the A400 Xplor)

has been created to further attenuate the recoil sensation of the fi rearm on fi ring.

Thanks to the Kick Off device, the recoil force gradually disperses through two

hydraulic (oil) dampers inserted on the inside of the stock with evident comfort

for the shooter. At the same time, vibrations and movement reporting of the

barrel are signifi cantly reduced on shooting. Longevity, reliability and handling of

the fi rearm are guaranteed.

PATENTED KICK OFF3 DEVICE FOR RECOIL

ABSORPTION

KICK OFF3 is the very latest innovation in the effective and noticeable reduction

of recoil, developed by the Kick Off design team at Beretta. The KICK OFF3 is

located inside the stock bolt tube and works during the fi nal backward travel

phase of the breech bolt during the operating cycle, for impact attenuation and

shock reduction.

13

Page 13

EN

BERETTA’S INNOVATIVE MICROCORE RECOIL PAD

The most exciting new feature of the A400 Xplor is the special Beretta Microcore

recoil pad, providing unparalleled recoil energy absorption capacity. Thanks to

the open-cell technopolymer foam, in response to pressure during fi ring, the

recoil pad immediately begins to gently relax without expanding or warping. The

material was specially formulated by Beretta after years of careful testing and

observation on shooting fi elds around the world.

The stock is designed to accept interchangeable recoil pads without the need

for adjustment. By using different sized pads, the length of pull can be varied.

CUT-OFF

The cut-off is positioned on the left side of the receiver: it can be activated using

one hand with the breech bolt locked. If the cut-off is accidentally engaged it will

disengage automatically in the feeding phase after fi ring.

DROP AND CAST SPACERS

Between the stock and the receiver is a technopolymer spacer and inside the

stock is a stainless steel plate that can be used to change the drop and cast of

the stock by simply modifying the assembly confi guration. A set of additional

spacers is also provided to further change the drop by replacing the spacer pair.

MAGAZINE CAPACITY

The magazine has a two-round capacity*, in line with current hunting regulations

in many countries, made possible by the insertion of a reducer. This reducer

restricts fi rearm use to no more than three rounds (two in the magazine, and one

in the cartridge chamber). This device is fi tted by Beretta during manufacture

and assembly of the A400 Xplor. In certain specifi c areas, hunting is only

authorised with fi rearms of not more than two rounds. To use the A400 Xplor in

these regions, the magazine capacity must be limited to a single shot with the

provided reducer plug (operation to be performed by a competent gunsmith).

14

* see “Ammunition”.

ACCESSORIES

The Beretta A400 Xplor shotgun comes in a case that contains the fi rearm and a

complete range of accessories for personalising and cleaning the fi rearm.

WARNING: There are many special Beretta parts and accessories to personalise

your fi rearm. To request this extensive line of parts and accessories, please

contact your local Beretta dealer.

Page 14

DATA AND TECHNICAL

CHARACTERISTICS

Gauge 12

Cartridge chamber 70 mm (2

depending on the version

Operation Semi-automatic, with exhaust valve

Locking system Rotating head breech bolt

Receiver Light alloy

Barrel Alloy steel, fully chromed bore

Rib Ventilated

Front sight Metal bead

Safety Button-operated, on trigger guard

Magazine* Limited to two rounds

Stock Walnut, with ambidextrous fi nger rest. Beretta

Microcore Recoil pad. Adjustable drop. Cast-on,

cast-off. Available with Kick off and Kick off³. Kick

off³ is standard on the “UNICO” version.

3

/4”, 3”) and 89 mm (23/

”

, 3”, 31/2),

4

EN

15

Page 15

EN

OBSTRUCTION /

CHOKE TUBES CONDITION CHECK

Check the barrel to ensure there are no obstructions in the chamber and bore.

This is extremely important because serious injury can result to the user or to

nearby persons if a cartridge is fi red in an obstructed barrel or chamber.

Check the inside of the barrel prior to completely assembling the fi rearm and

before use; if the fi rearm is already assembled the following procedure should

be followed:

• Follow the instructions in the “Disassembly” section and remove the barrel

from the shotgun.

• After removing the barrel, look right through the barrel from the rear and make

sure there are no obstructions, even minor ones.

• If an obstruction in the barrel is detected, a competent gunsmith must remove

the obstruction. Inspect again the shotgun before it can be fi red.

• Remount the barrel, following the instructions set out in the “Reassembly”

section.

CHECKING THE CONDITION OF THE CHOKE TUBES

• Always check the appearance and cleaning of the choke tubes before using

the shotgun.

• Check correct tightness in the barrel with the spanner provided.

• Never use choke tubes that show signs of defects, warping or incrustation.

• Make sure that the choke tube inserted is appropriate for the intended use and

shot type to be used (steel or lead). See “Ammunition” chapter.

16

ASSEMBLY OF PACKAGED FIREARM

CAUTION: THIS FIREARM HAS THE CAPABILITY OF TAKING YOUR LIFE

OR THE LIFE OF SOMEONE ELSE! ALWAYS BE VERY CAREFUL WHEN

HANDLING YOUR FIREARM. AN ACCIDENT IS NEARLY ALWAYS THE

RESULT OF FAILURE TO COMPLY WITH SAFETY RULES, OR INCORRECT

USE.

WARNING: Beretta assumes no liability for any injury or damage to property

!

resulting from improper or careless handling, or intentional or accidental fi ring

of the shotgun.

WARNING: All assembly, disassembly and maintenance procedures should be

carried out with the fi rearm unloaded (cartridge chamber, receiver and magazine

!

empty). Inspect the fi rearm by looking through the ejection port, the loading gate

and the chamber.

Page 16

WARNING: During assembly, disassembly and maintenance procedures, never

point a fi rearm at someone or at hard or fl at surfaces. Always treat the fi rearm as

if it were loaded (See points 1, 2 and 4 of the BASIC SAFETY RULES).

The Beretta semi-automatic A400 Xplor comes with barrel and stock-receiverfore-end assembly packaged separately.

Mount the barrel onto the stock-receiver-fore-end assembly as described

below:

NOTICE: It is advisable to carry out the assembly operations over a table to

catch components should they drop.

CAUTION: In the unlikely event that the breech bolt assembly is in the unlocked

(OPEN) position, do not press the release button and keep your fi nger away

from the ejection port.

When the release button is pressed, the breech bolt is pushed forward by the

recoil spring, until it is stopped at the ejection port by the cocking handle, with the

likelihood of damage to both parts.

• Check the barrel. The barrel and cartridge chamber must be clean and free

from obstructions (see “Checking for obstructions”).

• Check that the choke tube is inserted in the barrel and tightened correctly,

clean and in good condition (see “Checking the condition of the choke tubes”).

• Unscrew the front cap of the fore-end in an anticlockwise direction (Fig. 1).

• Pull the fore-end right out (Fig. 2).

• Check that the piston is positioned inside the gas cylinder of the barrel (Fig.

3). If the piston is mounted on the magazine tube, remove it (Fig. 4) and insert

it into the cylinder of the barrel, making sure to tighten the elastic seal with the

fi ngers to facilitate insertion of the piston into the cylinder (Fig. 5).

!

!

!

EN

CAUTION: In order to prevent damage to the elastic piston seal, fi rst insert the

piston into the chamber cylinder and then insert the magazine tube cap shaft

through the piston hole.

• Check that the carrier stop push button is pressed all the way down. Otherwise,

push it down (Fig. 6).

• Use the cocking handle to retract the breech bolt until it snaps into the unlocked

position (Fig. 7).

CAUTION: When the release button is pressed, the breech bolt is pushed

forward by the recoil spring, until it is stopped at the ejection port by the cocking

handle, with the likelihood of damage to both parts.

• Insert the barrel into the receiver, ensuring that the magazine tube cap shaft

enters the piston hole as well as the gas cylinder hole with the valve assembly

(Fig. 10,11,12).

• Push it all the way into the receiver until it stops.

!

!

17

Page 17

EN

• Slide the fore-end into place over the gas cylinder / the valve assembly and

magazine tube (Fig. 13). checking for the correct centering on the receiver

face. The fore-end is in the correct position when it is fully against the receiver

(Fig. 14).

• Tighten the front cap of the fore-end all the way (Fig. 15).

• Keep your fi ngers away from the ejection port, press the breech bolt release

button and gently guide the breech bolt to lock (Fig. 16).

CAUTION: When pressing the release button to close the breech bolt, be sure to

not accidentally engage the cut-off lever. If this occurs, the breech bolt will be kept

!

open by the cut-off lever. In this case, close the breech bolt while disengaging the

cut-off lever. Keep the fi ngers away from the ejection port (Fig. 17).

• Keeping the breech bolt retracted 2 cm, pull the trigger to decock the hammer

(Fig. 18).

WARNING: The safety can only be engaged with the hammer cocked. The

hammer is cocked by pulling back the breech bolt. When the safety button shows

!

the red ring, the SAFETY IS DISENGAGED, so the fi rearm is ready for use.

When the red ring is not visible on the safety button, the SAFETY IS ENGAGED.

WARNING: Store your fi rearm so that children or other persons not familiar

with fi rearms cannot gain access to it. To reduce the risk of accidents involving

!

children, unload your fi rearm and lock it away. Store the ammunition in a separate

locked location. (See point 3 of the BASIC SAFETY RULES.)

18

Page 18

LOAD CHECK

At various points in this manual, you will be requested to inspect the ejection

port, the loading gate, and the cartridge chamber of your Beretta semi-automatic

A400 Xplor to ensure that it is unloaded. This should become second nature to

you, as should the following precautions:

• Never assume that the gun is unloaded.

• Never point or push the gun toward yourself or another person.

• Always inspect the ejection port, the loading gate and the cartridge chamber to

make sure they are empty. The cartridge chamber is the portion of the barrel

into which the cartridge is inserted (Fig. 19).

• Pull back the breech bolt to lock it into the open position and engage the safety

before handing the shotgun to another person.

• Never take from or give the shotgun to another person unless the breech bolt

has been opened and the ejection port, loading gate and cartridge chamber

have been inspected to ensure they are completely empty.

Inspect the ejection port, the loading gate and cartridge chamber as indicated

below:

CAUTION: Keep your fi nger off the trigger and keep the barrel pointed in a safe

direction.

• Check that the carrier stop push button is pressed all the way down. Otherwise,

push it down (Fig. 6).

• Use the cocking handle to to retract the breech bolt until it snaps into the open

position (Fig. 7).

• Engage the manual safety by pressing the safety button to hide the red ring

(Fig. 8).

• Inspect the fi rearm by looking through the ejection port, the feeding gate and

the cartridge chamber. They must be empty. Check that there are no cartridges

in the magazine tube. If there are, unload the fi rearm as indicated in “How to

unload the fi rearm”.

• Press the breech bolt release button and gently guide it to the locked position

(Fig. 16).

• Disengage the safety (Fig. 9) (red ring visible) and hold the breech bolt back 2

cm, pull the trigger, to decock the hammer (Fig. 18).

EN

!

CAUTION: When the safety button shows the red ring, the SAFETY IS

DISENGAGED, so the fi rearm is ready for use. When the red ring is not visible

on the safety button, the SAFETY IS ENGAGED.

!

19

Page 19

EN

AMMUNITION

WARNING: Beretta assumes no liability for physical injury or property damage

resulting from the use of defective, improper, hand-loaded, reloaded or

!

remanufactured ammunition. Serious damage or injury, even death, may be

caused from the use of ammunition that is not suitable, loaded with force, or

loaded with obstructions in the barrel.

The Beretta A400 Xplor semi-automatic shotgun has different cartridge

chambers, depending on the version. The shotgun does not require

adjustments or interventions to shoot from 70 mm (2 3/4 in) /24 g (7/8 oz), to

76 mm (3 in) /57 g (2 oz) cartridges.

The “UNICO” version without any adjustments or interventions can shoot from

70 mm (2 3/4 in) /24 g (7/8 oz) to the powerful Supermagnum 89 mm (3 in.) /64 g

(2 1/4 oz) loads.

Beretta recommends: To immediately obtain superior fi rearm performance and

optimum cartdridge versatility from your A400 Xplor, fi re some medium power

cartridges fi rst (32g / 1 1/8 oz).

20

CAUTION: The Beretta semi-automatic A400 Xplor has an Optima-Bore

barrel and Optimachoke® HP choke tubes that make it possible to fi re High

!

Performance steel shot ammunition. Follow the instructions for use of choke

tubes appropriate for the use of steel shot, as set out in the “Steel shot” section.

You will fi nd the markings for the gauge and chamber length for your shotgun on

the side of the barrel (Fig. 20). Every A400 Xplor has been tested with special

proof test ammunition at 1320 bar with high performance steel shot. These tests

guarantee the ability to shoot either ordinary or HP steel shot (usually higher

than 3.5 mm of diameter) which cause higher pressure in the barrel.

CAUTION: Never use cartridges that do not correspond to the indicators on the

barrel.

!

CAUTION: Only use cartridges with a length equal to or less than the chamber

length indicated on the barrel.

!

CAUTION: To avoid using improper ammunition, always check the characteristics

stamped on the cartridge box and on the cartridge. Be sure to use the right

!

cartridge gauge and length for your fi rearm.

STEEL SHOT

All Beretta barrels, as well as the “SP” (Steel Proof) Beretta choke tubes,

are designed for use with factory steel shot cartridges loaded to international

standard specifi cations. When steel shot cartridges are fi red, the best results

are obtained by using open chokes (C0000/CL, 0000/IC, 000/M). Full choke

constrictions (0/F, 00/M) when using steel shot, do not increase pattern density

®

HP

Page 20

and will distort normal pattern density, accelerating wear and tear. The use of

reloaded or remanufactured ammunition can increase the likelihood of excessive

pressure, case rupture or other defects in the ammunition.

MAGAZINE CAPACITY

The magazine of the A400 Xplor has a capacity limited to 2 shots, in line with the

current hunting regulations in many countries, due to the insertion of a reducer.

This reducer restricts fi rearm use to no more than three rounds (two in the

magazine, and one in the cartridge chamber).

This device is fi tted by Beretta during manufacture and assembly of the A400

Xplor.

WARNING: Wholesalers, dealers or gunsmiths are not authorised to carry out

any Warranty repair or adjustment on behalf of the Manufacturer (unless they

are a Repair Point authorised by the Manufacturer and/or by its Local Offi cial

Distributors).

HOW TO LOAD THE FIREARM

WARNING: Before loading the fi rearm, it is a good idea to practice the following

handling procedures without the use of ammunition. Never handle a loaded

fi rearm until you are fully familiar with the loading procedures. Always inspect the

ejection port, the loading gate and the cartridge chamber to make sure they are

empty. Check that there are no cartridges in the magazine tube. Before loading

the fi rearm, ensure that the safety is engaged. Always keep the fi rearm pointed

in a safe direction. (See points 1, 2 and 4 of the BASIC SAFETY RULES.)

!

EN

!

WARNING: Always check the barrel before loading the fi rearm to make sure that

it is clean and free of possible obstructions (see: “Checking for obstructions”).

WARNING: Check the conditions and correct tightness of the choke tubes in the

barrel. Never use the shotgun without the choke tube inserted (see. “Checking

the condition of the choke tubes”).

WARNING: The shooter and all bystanders must always wear protective eyewear and ear protection during shooting. Residue from gunpowder, lubricant or

metal fragments may be projected backwards and cause injury. Noise-reducing

earplugs or earmuffs will reduce the risk of damage to hearing caused by

prolonged shooting activity.

CAUTION: Always keep your fi nger off the trigger and avoid contact of other

objects with the trigger if you don't intend to fi re.

!

!

!

!

21

Page 21

EN

• Check that the carrier stop push button is pressed all the way down. Otherwise,

push it down (Fig. 6).

• Use the cocking handle to retract the breech bolt until it snaps into the open

position (Fig. 7).

• Engage the manual safety by pressing the safety button to hide the red ring

(Fig. 8).

CAUTION: The safety can only beengaged with the hammer in the cocked

position. The hammer is cocked by pulling back the breech bolt. When the safety

!

button shows the red ring, the SAFETY IS DISENGAGED, so the fi rearm is

ready for use. When the red ring is not visible on the safety button, the SAFETY

IS ENGAGED.

WARNING: The manual safety is merely a mechanical device and is in no way a

substitute for the Basic Safety Rules of fi rearm handling (Fig. 21).

!

• Introduce the fi rst cartridge into the cartridge chamber through the ejection

port (Fig. 22).

• Keeping your hands away from the ejection port, press the release button and

guide the breech bolt to lock.

WARNING: The fi rearm is now loaded and ready to fi re after the manual safety

is disengaged. Always keep your fi nger off the trigger and avoid contact with

!

the trigger by other objects if you don't intend to fi re. Never point a fi rearm at

something that is not safe to shoot. (See points 1, 2 and 4 of the BASIC SAFETY

RULES).

22

WARNING: Beretta assumes no liability for any injury or property damage

!

resulting from improper or careless handling or intentional or accidental fi ring of

the shotgun.

CAUTION: If the breech bolt remains in the open position, check that the cut-off

is not inadvertently engaged. Keep your hands away from the ejection port and

!

disengage the cut-off (Fig. 17).

• Move the carrier to insert the cartridges into the magazine through the loading

gate to hook onto the cartridge retaining tooth (Fig. 23).

• To fi re, disengage the safety (Fig. 9) (red ring visible) and pull the trigger.

• After fi ring the fi rst round, release the trigger to set up the shotgun for the next

round.

• The shotgun will fi re the cartridge in the chamber fi rst, and then it will

automatically introduce the cartridge from the magazine tube into the chamber.

WARNING: After pulling the trigger, if the shotgun doesn't fi re, engage the

!

safety, wait at least one minute and unload the shotgun as described in the

corresponding section.

Never attempt to reuse or fi re ammunition that did not fi re the fi rst time. Dispose

Page 22

of unfi red or damaged ammunition properly, in accordance with the ammunition

manufacturer’s recommendations.

WARNING: If another cartridge is fi red into an obstructed barrel, damage and

very serious injury may occur.

If you do not plan to fi re a second shot, engage the safety (red ring not visible)

keeping the fi rearm pointed in a safe direction and the fi ngers away from the

trigger. If you have fi nished fi ring, unload the shotgun as indicated in: “How to

unload the shotgun”.

• When the last round has been fi red, the breech bolt remains open, showing

that the magazine is empty (Fig. 24).

• Engage the safety (Fig. 8) (red ring not visible) and if necessary, reload the

shotgun according to the instructions given previously.

WARNING: Always unload the fi rearm immediately after fi ring is completed.

Never store a loaded fi rearm. To store the shotgun, see: “Storage”.

HOW TO USE THE CUT-OFF DEVICE

The cut-off device enables a live round to be extracted from the cartridge

chamber and for the breech bolt to be locked open as a safety measure or for

the round to be replaced in the chamber without feeding a new round from the

magazine.

WARNING: Firearm loaded with cartridge in the chamber and safety engaged.

Never point a fi rearm at something that is not safe to shoot. (See points 1, 2 and

4 of the BASIC SAFETY RULES.)

• Ensure that the safety is engaged (Fig. 8). The red ring of the safety is not

visible.

• Engage the cut-off device pressing the lever on the left side of the receiver

(round part) (Fig. 25).

• Pull the breech bolt back to the end stop using the handle. In this phase, the

live cartridge is extracted from the cartridge chamber and ejected through the

ejection port (Fig. 26), the breech bolt stops on the carrier locked by the cut-off

device. Feeding from the magazine is blocked.

• Once safety conditions are restored, insert the extracted loaded cartridge (Fig.

21) or other desired cartridge type into the chamber.

• Keeping the fi ngers away from the ejection port, disengage the cut-off to

release the breech bolt so that it locks (Fig. 17).

!

EN

!

!

WARNING: The fi rearm is loaded and ready to fi re after the manual safety is

disengaged. Check that the safety is correctly engaged. Never point a fi rearm at

something that is not safe to shoot. (See points 1, 2 and 4 of the BASIC SAFETY

RULES).

• To fi re, disengage the safety (Fig. 9) (red ring visible) and pull the trigger.

!

23

Page 23

EN

CAUTION: For correct functioning of the shotgun, the cut-off is to be used as

described. In particular, it should be remembered that the breech bolt, held open

!

by the cut-off device, must be closed, operating solely on the cut-off device itself.

HOW TO UNLOAD THE SHOTGUN

WARNING: The fi rearm is loaded and ready to fi re. Always keep your fi nger off

the trigger and avoid contact with the trigger by other objects if you don't intend

!

to fi re. Never point the fi rearm at someone or at hard, fl at surfaces. (See points

1, 2 and 4 of the BASIC SAFETY RULES.)

• Keeping the fi rearm pointed in a safe direction, check that the safety is

engaged (Fig. 8) (red ring not visible).

• Engage the cut-off (Fig. 25), pull back the breech bolt to extract and expel the

live cartridge from the chamber (Fig. 26).

• Keeping the fi ngers away from the ejection port, disengage the cut-off to

release the breech bolt so that it locks (Fig. 17).

• Raise the carrier, push the cartridge lightly into the magazine tube and at the

same time press down the release button, guiding the cartridges out of the

magazine tube.

• After checking the magazine tube and the receiver are empty, keeping the

shotgun pointed in a safe direction, disengage the safety (Fig. 9) (red ring

visible).

• Keeping the breech bolt pulled back 2 cm, pull the trigger, thereby decocking

the hammer (Fig. 18).

24

Page 24

FIELD STRIPPING

WARNING: Always check that the shotgun is unloaded (empty cartridge chamber,

empty receiver, empty magazine). Inspect the fi rearm by looking through the

ejection port, the loading gate and the chamber. If it is not empty, unload it as

instructed in the relevant section. Check that the hammer is decocked.

WARNING: Never point the fi rearm at someone or at hard, fl at surfaces. Always

treat the shotgun as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES.)

NOTICE: It is advisable to carry out the disassembly operations over a table to

catch components should they drop.

!

!

!

BARREL

• Check that the carrier stop push button is pressed all the way down. If it is not,

push it all the way down (Fig. 6).

• Pull the breech bolt all the way back so that it remains open (Fig. 7).

• Unscrew the front cap of fore-end in an anticlockwise direction (Fig. 27).

• Holding the shotgun by the barrel, pull the fore-end straight out toward the

muzzle (Fig. 28).

• Pull the barrel out of the stock-receiver assembly while holding the piston

inside the gas cylinder (Fig. 29).

NOTICE: NEVER STRIP the spring of the valve or the valve retaining nut. The

valve device is self-cleaning and requires no maintenance. If necessary, contact

a competent gunsmith.

BREECH BOLT ASSEMBLY

(Breech bolt, operating rods with sleeve, recoil spring, and piston stop.)

WARNING: The breech bolt assembly need only to be disassembled in order to

clean its components.

• Keeping the index or middle fi nger of the left hand on the cocking handle,

press the release button and allow the breech bolt to move forward slowly until

it stops (Fig. 31).

• Press the head of the breech bolt until the groove on its neck corresponds to

the edge of the bolt body (Fig. 32).

• Keeping the head depressed in this position, extract the cocking handle from

the breech bolt, pulling forcefully (Fig. 33).

• Over a fl at surface, with the ejection port pointed upwards, pull forward on the

breech bolt assembly, the operating rods with sleeve, the recoil spring, and the

spring holder, to force the breech bolt out from the receiver (Fig. 34 and 35).

EN

!

!

25

Page 25

TRIGGER PLATE

NOTICE: The trigger plate only needs to be disassembled in order to clean the

trigger mechanism.

!

• Engage the safety (the hammer is cocked) (Fig. 8).

• Press the carrier stop push button, if it has not already been pressed (Fig. 6).

• Remove the trigger guard retaining pin by pressing with a pin punch or an awl

(Fig. 36).

• Keeping the release button pushed all the way down, remove the trigger plate

from the receiver using the trigger guard as a lever, fi rst in the direction of the

barrel and then outward (Fig. 37).

EN

BERETTA OPTIMACHOKE® HP TUBES

Beretta Optimachoke® HP (High Performance) tubes are built in high resistance

steel to ensure a long life and rust protection and are designed to withstand the

use of steel shot. They can also shoot High Performance steel ammunitions.

NOTICE: The Optima-Bore

Optimachoke® HP tubes. Other types of interchangeable Beretta choke tubes

are not appropriate for use with Optima-Bore® HP barrels and these will alter the

shot pattern distribution.

!

®

HP barrel of the A400 Xplor can only mount

26

Page 26

Beretta Optimachoke® HP tubes

Beretta markings American

Designation

0 (*) F (Full) SP (Steel Proof)

00 (**)

000 (***) M (Modifi ed) SP (Steel Proof) III

0000 (****)

C0000 (C****) CL (Cylinder) SP (Steel Proof) IIIII

(1)

Not recommended for steel shot.

Optimachoke® is a registered trademark of Fabbrica d’Armi Pietro Beretta S.p.A.

IM (Improved

Modifi ed)

IC (Improved

Cylinder)

Compatibility of

choke tubes with

steel shot

SP (Steel Proof)

SP (Steel Proof) IIII

Notches

on the

(1)

(1)

rim

I

II

CHECKING THE CONDITION OF THE CHOKE TUBES

• Always check the appearance and cleaning of the choke tubes before using

the shotgun.

• Check correct tightness in the barrel with the spanner provided.

• Never use choke tubes that show signs of defects, warping or incrustation.

• Make sure that the choke tube inserted is appropriate for the intended use and

shot type to be used (steel or lead). See “Ammunition” chapter.

EN

REMOVAL OF CHOKE TUBE

WARNING: Always check that the shotgun is unloaded (empty cartridge

chamber, empty receiver, empty magazine). Inspect the fi rearm by looking

through the ejection port, the loading gate and the chamber. If it is not empty,

unload it as instructed in the relevant section.

WARNING: Never look directly through the barrel from the muzzle and do not

replace the choke with the shotgun loaded even with the safety engaged.

CAUTION: The safety can only be inserted with the hammer cocked. The hammer

is cocked by pulling back the breech bolt. When the safety button shows the red

ring, the SAFETY IS DISENGAGED, so the fi rearm is ready for use. When the

red ring is not visible on the safety button, the SAFETY IS ENGAGED.

• Unscrew the choke tube, in an anticlockwise direction, with the spanner

provided (Fig. 38).

• Remove the choke tube from the muzzle of the barrel (Fig. 39).

!

!

!

27

Page 27

CLEANING OF CHOKE TUBES AND ITS HOUSING

WARNING: Always check that the shotgun is unloaded (empty cartridge chamber,

empty receiver, empty magazine). Inspect the fi rearm by looking through the

!

ejection port, the loading gate and the chamber. If it is not empty, unload it as

instructed in the relevant section. Check that the hammer is decocked.

WARNING: Never look directly through the barrel from the muzzle and do not

replace the choke with the shotgun loaded even with the safety engaged.

!

• Clean the choke housing thoroughly using, if necessary, a brush swab soaked

with Beretta Gun Oil. Dry with a soft cloth.

• Check that the choke is perfectly clean inside and outside.

• Apply a thin fi lm of Beretta Gun Oil on the barrel thread and choke tube.

EN

INSERTION OF CHOKE TUBES

CAUTION: Always check that the shotgun is unloaded (empty cartridge chamber,

empty receiver, empty magazine). Inspect the fi rearm by looking through the

!

ejection port, the loading gate and the chamber. If it is not empty, unload it as

instructed in the relevant section. Check that the hammer is decocked.

CAUTION: Never look directly through the barrel from the muzzle and do not

replace the choke with the shotgun loaded even with the safety engaged.

!

CAUTION: Check that the choke tube is in pristine condition (not damaged) prior

to installing it.

!

• Make sure that the barrel thread and choke tube are perfectly clean and lightly

oiled.

• Install the desired choke tube.

• Manually screw the choke tube clockwise into the barrel. Use the Beretta

spanner provided to tighten the choke tube until it is fully lowered into its seat

in the barrel. Forcefully tighten it manually.

• Remove the spanner from the barrel.

CAUTION: Periodically check that the choke tube is tightened correctly,

ensuring that the shotgun is unloaded (empty cartridge chamber, empty receiver

!

and empty magazine) and breech bolt in the open position. If necessary, fi rmly

tighten the choke tube with the Beretta spanner. Correct tightening of the choke

tube will avoid the occurrence of shotgun damage or injury.

28

CAUTION: The choke must be kept correctly tightened in the barrel at all times,

even during storage and cleaning. Cleaning the barrel without the choke tube

!

installed may lead to dirt becoming lodged in the barrel thread and preventing

the choke tube from screwing in properly, or to the formation of rust or obstruction

in the barrel.

Page 28

WARNING: Never shoot the choke barrel without inserting a choke tube.

Shooting without a choke tube in the barrel is very dangerous, as residues of

lead or debris may become lodged in the thread creating an obstruction within

the barrel. Also, not using a choke tube will damage the threading of the barrel

irreparably and result in irregular shot spread.

Do not alter or modify an existing fi xed choke Beretta barrel for the use of

interchangeable choke tubes. The barrel wall thickness would be too thin to

safely contain the pressure levels generated by shooting.

ROUTINE MAINTENANCE

Clean and lubricate your shotgun any time combustion residue, grease or dirt is

deposited in any of the mechanisms. Cleaning and lubrication of the fi rearm after

each use is the best way of ensuring that the components are protected against

combustion corrosion or rusting from use in humid or salty environments.

At the end of a shooting day, carry out the Routine Maintenance as indicated

below.

WARNING: Always check that the shotgun is unloaded (empty cartridge chamber,

empty receiver, empty magazine). Inspect the fi rearm by looking through the

ejection port, the loading gate and the chamber. If it is not empty, unload it as

instructed in the relevant section. Check that the hammer is decocked.

WARNING: Never point the fi rearm at someone or at hard, fl at surfaces. Always

treat the shotgun as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

!

EN

!

!

NOTICE: For Routine Maintenance, simply disassemble it following the

procedures described in the relevant section.

BARREL

• Carefully clean the inside of the barrel with a soft cloth (fl annel) to remove any

combustion residue. If necessary, use a bronze brush or a cloth soaked with

Beretta Gun Oil.

• Thoroughly clean the locking shoulders on the barrel breech.

• Pull a soft, clean, dry cloth through the barrel.

• Lightly lubricate the barrel with a soft clean cloth soaked with Beretta Gun Oil.

• Check the barrel. The barrel and cartridge chamber must be clean and free

from obstructions.

CAUTION: Excess oil or grease obstructing the barrel, even partially, is very

dangerous when fi ring and may cause damage to the shotgun and serious injury

to the shooter and to bystanders. Never spray or apply oil to the cartridges. Use

lubricants properly. You are responsible for the proper care and maintenance of

your fi rearm.

!

!

29

Page 29

EN

GAS CYLINDER, PISTON, MAGAZINE TUBE

CAUTION: Use of Magnum and Super Magnum cartridges results in high

combustion gas emissions.

!

The particular composition of the powders of some Super Magnum ammunition

can leave consistent deposits of combustion residue. The parts of the shotgun

where this problem is most likely to arise are the gas cylinder, the piston and

elastic piston seal and the magazine tube.

• Spray the piston, elastic piston seal and magazine tube and clean with Beretta

Gun Oil.

• Ensure that the piston glides freely on the magazine tube.

• To clean the walls of the gas cylinder, spray the walls with Beretta Gun Oil and

clean thoroughly with a bronze brush.

• After removing any combustion residue, clean the inside of the gas cylinder

with a clean cloth.

NOTICE: The components specifi ed above must not be lubricated.

!

EXHAUST VALVE ASSEMBLY

NOTICE: NEVER DISASSEMBLE the exhaust valve assembly. If necessary,

contact a competent gunsmith.

!

30

Page 30

SPECIAL MAINTENANCE

Depending on the conditions of use of the fi rearm, and at the end of

the hunting season, Beretta recommends you carry out the following

extraordinary maintenance operations in order to keep the shotgun in

perfect working order.

BREECH BOLT ASSEMBLY

(Breech bolt, operating rods with sleeve, recoil spring, and piston stop).

• Spray the parts and clean with Beretta Gun Oil.

• Thoroughly dry with a soft cloth and lightly lubricate.

TRIGGER PLATE

• Thoroughly clean the parts with a soft cloth.

• Lightly lubricate all the metal components and the trigger plate retaining pin.

RECEIVER

• Proceed as indicated for the breech bolt. Clean thoroughly with a soft cloth

and lubricate the internal breech bolt guides.

CAUTION: Do not attempt to carry out repairs to any fi rearm without proper

knowledge or training. Do not alter parts or use substitute parts not manufactured

by Beretta. Any alterations or adjustments that may be necessary to the operating

mechanism should be performed by the Manufacturer or by its Local Authorised

Distributor.

REASSEMBLY

WARNING: Always check that the shotgun is unloaded (empty cartridge

chamber, empty receiver, empty magazine). Inspect the fi rearm by looking

through the ejection port, the loading gate and the chamber. If it is not empty,

unload it as instructed in the relevant section.

WARNING: Never point the fi rearm at someone or at hard, fl at surfaces. Always

treat the shotgun as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

EN

!

!

!

31

Page 31

EN

TRIGGER PLATE (Fig. 39)

• Work in reverse order to assembly, taking care to ensure that the hammer

is cocked, the safety is engaged and the carrier stop push button is pressed

down.

• Keeping the release button pressed well down, make the rear part of the trigger

plate adhere precisely to the receiver and push fi rmly towards the stock, as far

as it will go.

• Rotate the trigger plate until it is inserted in its housing in the receiver.

• Insert the trigger guard retaining pin only when the hole of the trigger guard is

centred on the receiver.

BREECH BOLT ASSEMBLY (Fig. 35)

(Breech bolt, operating rods with sleeve, recoil spring, and piston stop).

• Working on a fl at surface with the ejection port turned up, mount the breech

bolt assembly, operating rods with sleeve, recoil spring and piston stop on the

magazine tube (Fig. 34).

• Push the operating rods with sleeve all the way in to insert the breech bolt into

the receiver.

• Press the head of the breech bolt until the groove on its neck corresponds to

the edge of the bolt body (Fig. 32).

• Keeping the head pressed down in this position, insert the cocking handle on

the breech bolt. Fasten it into position by hitting it fi rmly (Fig. 33).

32

BARREL

• Check the barrel. The barrel and cartridge chamber must be clean and free

from obstructions.

• Insert the piston into the gas cylinder of the barrel, tightening the elastic seal

with the fi ngers to make it easier to install the piston in the cylinder (Fig. 5).

• Check that the carrier stop push button is pressed all the way down. If it is not,

push it all the way down (Fig. 6).

• Pull the breech bolt all the way back so that it remains open (Fig. 7).

CAUTION: When the release button is pressed, the breech bolt is pushed

forward by the recoil spring, until it is stopped at the ejection port by the cocking

!

handle, with the likelihood of damage to both parts.

• Insert the barrel into the receiver, ensuring that the magazine tube enters the

piston hole as well as that of the gas cylinder and the valve assembly (Fig.

10,11,12).

• Push it all the way into the receiver until it stops.

Page 32

• Slide the fore-end into place over the gas cylinder / the valve assembly and

magazine tube (Fig. 13). checking for the correct centering on the receiver

face. The fore-end is in the correct position when it is fully against the receiver

(Fig. 14).

• Screw the fore-end cap on tightly (Fig. 15).

• Keep your fi ngers away from the ejection port, press the breech bolt release

button and gently guide the breech bolt to lock (Fig. 16).

CAUTION: When pressing the release button to close the breech bolt, be sure

to not accidentally engage the cut-off lever. If this occurs, the breech bolt will be

kept open by the cut-off lever. In this case, lock the breech bolt while disengaging

the cut-off lever. Keep the fi ngers away from the ejection port (Fig. 17).

• Keeping the breech bolt pulled back 2 cm, pull the trigger, thereby decocking

the hammer (Fig. 18).

WARNING: Store your fi rearm so that children or other persons not familiar

with fi rearms cannot gain access to it. To reduce the risk of accidents involving

children, unload your fi rearm and lock it away. Store the ammunition in a separate

locked location. (See point 3 of the BASIC SAFETY RULES).

NOTICE: If the fi rearm will not be used for a long time, keep it lubricated and

disassembled (see the chapters “Maintenance” and “Storage”).

STOCK DROP AND CAST MODIFICATION

WARNING: Always check that the shotgun is unloaded (empty cartridge

chamber, empty receiver, empty magazine). Inspect the fi rearm by looking

through the ejection port, the loading gate and the chamber. If it is not empty,

unload it as instructed in the relevant section.

WARNING: Never point the fi rearm at someone or at hard, fl at surfaces. Always

treat the shotgun as if it were loaded. (See points 1, 2 and 4 of the BASIC

SAFETY RULES).

The Beretta semi-automatic A400 Xplor has a pre-set factory stock cast-off

setting (for right-handed shooters) with 55 or 60 mm drop.

The components which govern the drop and the cast are (see Fig. 40):

the drop-cast front spacer, made of reinforced technopolymer fi breglass.

the stock steel plate.

!

EN

!

!

!

!

Both the front spacer and the plate are designed to secure two different

drops, each with a cast-off or a cast-on (for left-handed shooters) depending on

how they are assembled. A set of additional spacers is also provided to further

change the drop by replacing the spacer pair.

33

Page 33

EN

REPLACING THE STOCK DROP AND CAST SPACERS

NOTICE: The right-hand cast is designated by the initials DX. The left-hand cast

is designated by the initials SX. The drop and cast of the front spacer and

!

plate must always be synchronised.

WARNING: Stock drop and cast modifi cation must be carried out by a competent

gunsmith. Failure to comply with these instructions can lead to damage to

!

property or injury to persons

REQUIRED TOOLS

1 Philips and 1 fl at-head screwdriver.

1 Torque wrench T15

1 Hexagonal spanner, 6 mm.

1 Tube spanner, 13 mm.

1 Torque wrench (previously mentioned) with a 13-mm pipe extension.

FIELD STRIPPING

• Use the Phillips screwdriver to remove the two screws sunk into the stock.

• Remove the Beretta Microcore recoil pad from the stock or Kick Off (Only for

Kick Off versions).

• (Only for Kick Off versions) Remove the Kick Off recoil absorption device by

unscrewing the special screws using a Torx T15 screwdriver.

• Use the 13-mm tube spanner to completely unscrew the retaining nut of the

stock and remove the nut, spring washer and plate .

• Separate the stock from the receiver and remove the plate .

34

Page 34

REASSEMBLY

• Centre the front spacer on the stock bolt tube. Make sure that the indicator

showing the desired drop and cast (“C-60-DX” in the diagram) is visible on the

spacer.

• Reposition the stock. Place the rear plate inside the stock. Make sure that

the same marking is visible on the plates.

• Use the 13-mm tube spanner to insert the retaining nut of the stock and spring

washer and tighten down with tightening torque 1.6 - 1.8 Kgm (Kilogrammeters). The use of a proper dynamometric spanner is recommended.

• (Only for Kick Off versions) Insert the Kick Off recoil absorption device into the

stock and tighten with the special screws using a Torx T15 screwdriver.

• (Only for the Kick Off versions) Mount the Beretta Microcore recoil pad into the

Kick Off holes (Only for the Kick Off versions) or onto the stock. Tighten the

screws using the Phillips screwdriver.

STORAGE

WARNING: To reduce the risk of accidents involving children or unauthorised

persons, keep your fi rearm locked away and store the ammunition in a separate

locked location!

NOTICE: Store the fi rearm disassembled (barrel/fore-end and receiver/stock)

in the supplied case. Before storage, always check the condition of the shotgun

and its case. Ensure that they are perfectly dry.

Moisture and water drops can damage the shotgun.

EN

!

!

NOTICE: Do not store the shotgun in a leather or fabric case. These materials

attract moisture, even though they may appear to be perfectly dry.

!

35

Page 35

IT

IT

EN

FR

ES

NOTES

DE

RU

SV

GR

36

Page 36

NOTES

IT

IT

EN

FR

ES

37

DE

RU

SV

GR

Page 37

IT

IT

EN

FR

ES

NOTES

DE

RU

SV

GR

38

Page 38

NOTES

IT

IT

EN

FR

ES

39

DE

RU

SV

GR

Loading...

Loading...