BENSHAW RB3-1-S-040A-11C, RB3-1-S-052A-12C, RB3-1-S-065A-12C, RB3-1-S-077A-13C, RB3-1-S-096A-13C User Manual

...

TM

RediStart

Solid State Starter

Control

RB3, RC3, RX3E Models

User Manual

890034-02-00

December 2006

Motor Starter Card Set: BIPC-400100-01-03

Software Version 1: 810023-02-01

Software Version 2: 810024-01-01

Gate Driver Card: 300047-01 Rev. 13

2006 Benshaw Inc.

©

Benshaw retains the right to change specifications and illustrations in text without prior notification. The contents of this document may

not be copied without the explicit permission of Benshaw.

Important Reader Notice

Congratulations on the purchase of your new Benshaw RediStart MX3Solid State Starter. This manual contains the information to install and

program the MX

This manual may not cover all of the applications for the RediStart MX

concerning installation, programming, operation, or maintenance specific to the RediStart MX

The content of this manual will not modify any prior agreement, commitment or relationship between the customer and Benshaw. The sales

contract contains the entire obligation of Benshaw. The warranty enclosed within the contract between the parties is the only warranty that

Benshaw will recognize and any statements contained herein do not create new warranties or modify the existing warranty in any way.

Any electrical or mechanical modifications to Benshaw products without prior written consent of Benshaw will void all warranties and may also

void cUL listing or other safety certifications, unauthorized modifications may also result in product damage operation malfunctions or personal

injury.

Incorrect handling of the starter may result with an unexpected fault or damage to the starter. For best results on operating the RediStart MX

starter, carefully read this manual and all warning labels attached to the starter before installation and operation. Keep this manual on hand for

reference.

Do not attempt to install, operate, maintain or inspect the starter until you have thoroughly read this manual and related documents carefully

and can use the equipment correctly.

Do not use the starter until you have a full knowledge of the equipment, safety procedures and instructions.

This instruction manual classifies safety instruction levels under "WARNING" and "CAUTION".

3

Solid State Starter.

Electrical Hazard that could result in injury or death.

3

. Also, it may not provide information on every possible contingency

3

Series Starters.

3

Caution that could result in damage to the starter.

Highlight marking an important point in the documentation.

Please follow the instructions of both safety levels as they are important to personal safety.

High Voltage

Motor control equipment and electronic controllers are connected to hazardous line voltages. When servicing starters and electronic

controllers, there may be exposed components with housings or protrusions at or above line potential. Extreme care should be taken

to protect against shock.

Stand on an insulating pad and make it a habit to use only one hand when checking components. Always work with another person

in case an emergency occurs. Disconnect power before checking controllers or performing maintenance. Be sure equipment is

properly grounded. Wear safety glasses whenever working on electronic controllers or rotating machinery.

TRADEMARK NOTICE

Benshaw and are registered trademarks of Benshaw Incorporated.

UL is a trademark of Underwriters Laboratories, Incorporated.

Electric Shock Prevention

While power is on or soft starter is running, do not open the front cover. You may get an electrical shock.

•

This soft starter contains high voltage which can cause electric shock resulting in personal injury or loss of life.

•

Be sure all AC power is removed from the soft starter before servicing.

•

Do not connect or disconnect the wires to or from soft starter when power is applied.

•

Make sure ground connection is in place.

•

Always install the soft starter before wiring. Otherwise, you may get an electrical shock or be injured.

•

Operate the switches with dry hands to prevent an electrical shock.

•

Risk of Electric Shock - More than one disconnect switch may be required to de-energize the equipment before servicing.

•

Injury Prevention

Service only by qualified personnel.

•

Make sure power-up restart is off to prevent any unexpected operation of the motor.

•

Make certain proper shield installation is in place.

•

Apply only the voltage that is specified in this manual to the terminals to prevent damage.

•

Transportation and Installation

Use proper lifting gear when carrying products, to prevent injury.

•

Make certain that the installation position and materials can withstand the weight of the soft starter. Refer to the installation information in this

•

manual for correct installation.

If parts are missing, or soft starter is damaged, do not operate the RediStart MX3.

•

Do not stand or rest heavy objects on the soft starter, as damage to the soft starter may result.

•

Do not subject the soft starter to impact or dropping.

•

Make certain to prevent screws, wire fragments, conductive bodies, oil or other flammable substances from entering the soft starter.

•

SAFETY PRECAUTIONS

Safety Precautions

Trial Run

•

Check all parameters, and ensure that the application will not be damaged by a sudden start-up.

Emergency Stop

•

To prevent the machine and equipment from hazardous conditions if the soft starter fails, provide a safety backup such as an emergency brake.

Disposing of the RediStart MX

•

Never dispose of electrical components via incineration. Contact your state environmental agency for details on disposal of electrical components

and packaging in your area.

3

i

TABLE OF CONTENTS

Table of Contents

1 INTRODUCTION ............................................ 2

2 TECHNICAL SPECIFICATIONS ................................... 8

2.1 General Information ........................................... 8

2.2 Electrical Ratings ............................................. 8

2.2.1 Terminal Points and Functions........................................8

2.2.2 Measurements and Accuracies........................................10

2.2.3 List of Motor Protection Features ......................................10

2.2.4 Solid State Motor Overload..........................................11

2.2.5 CT Ratios ....................................................12

2.2.6 Optional RTD Module Specifications ....................................13

2.2.7 Zero Sequence Ground Fault CT.......................................14

2.3 Starter Power Ratings .......................................... 14

2.3.1 Standard Duty (350% for 30 sec) Ratings ..................................15

2.3.2 Heavy Duty (500% current for 30 sec) Ratings ...............................16

2.3.3 Severe Duty (600% current for 30 sec) Ratings ...............................17

2.3.4 Inside Delta Connected Standard Duty (350% for 30 sec) Ratings ....................18

2.3.5 RB3 Power Stack Ratings and Protection Requirements .........................19

2.3.6 Power Stack Input Ratings with Protection Requirements for Separate Bypass ............20

2.3.7 Power Stack Input Ratings with Protection Requirements for RC No Bypass .............21

2.3.8 RB3 Starter Control Power Requirements .................................22

2.3.9 RC3 Starter Control Power Requirements .................................22

2.4 Dimensions ................................................ 23

2.4.1 RB3 Chassis with Integral Bypass ......................................23

2.4.2 RC3 Chassis with no Bypass .........................................24

2.5 Environmental Conditions........................................ 25

2.6 Altitude Derating ............................................. 26

2.7 Real Time Clock.............................................. 26

2.8 Approvals ................................................. 26

2.9 Certificate of Compliance ........................................ 26

3 INSTALLATION ............................................. 28

3.1 Before You Start.............................................. 28

3.1.1 Installation Precautions ............................................28

3.1.2 Safety Precautions ...............................................28

3.2 Installation Considerations ....................................... 29

3.2.1 Site Preparation ................................................29

3.2.2 EMC Installation Guidelines .........................................29

3.2.3 Use of Power Factor Capacitors .......................................29

3.2.4 Use of Electro-Mechanical Brakes ......................................29

3.2.5 Reversing Contactor..............................................29

3.3 Mounting Considerations ........................................ 30

3.3.1 Bypassed Starters ...............................................30

3.3.2 Non-Bypassed Starters ............................................30

3.4 Wiring Considerations .......................................... 31

3.4.1 Wiring Practices ................................................31

3.4.2 Considerations for Control and Power Wiring...............................31

3.4.3 Considerations for Signal Wiring ......................................31

3.4.4 Meggering a Motor ..............................................31

3.4.5 High Pot Testing ................................................31

3.5 Power and Control drawings for Bypassed and Non Bypassed Power Stacks ...........32

ii

TABLE OF CONTENTS

3.6 Power Wiring ............................................... 35

3.6.1 Recommended Incoming Line Protection .................................35

3.6.2 Recommended Wire Gauges.......................................35

3.6.3 Power Wire Connections ...........................................35

3.6.4 Motor Lead Length ..............................................35

3.6.5 Compression Lugs...............................................36

3.6.6 Torque Requirements for Power Wiring Terminations ..........................37

3.7 Current Transformers .......................................... 38

3.7.1 CT Mounting ..................................................38

3.7.2 CT Polarity ...................................................38

3.7.3 Zero Sequence Ground Fault Current Transformer ............................39

3.8 Control Card Layout ........................................... 41

3.9 I/O Card Layout ............................................. 42

3.10 Terminal Block Layout ......................................... 43

3.11 Control Wiring.............................................. 44

3.11.1 Control Power ................................................44

3.11.2 Output Relays.................................................44

3.11.3 Digital Input .................................................45

3.11.4 Analog Input .................................................46

3.11.5 Analog Output ................................................46

3.11.6 SW1 DIP Switch ...............................................47

3.11.7 Motor PTC ..................................................47

3.11.8 RTD Module Connector ...........................................47

3.12 Remote LCD Keypad/Display ..................................... 48

3.12.1 Remote Display................................................48

3.12.2 Installing Display...............................................48

3.12.3 Display Cutout ................................................49

3.13 RTD Module Installation ........................................ 50

3.13.1 Location ....................................................50

3.13.2 Modbus Address ...............................................50

3.13.3 Power Connections..............................................50

3.13.4 RS-485 Communication ...........................................51

3.13.5 RTD Connections...............................................51

3.13.6 RTD Temperature vs. Resistance ......................................52

4 KEYPAD OPERATION ......................................... 54

4.1 Introduction ................................................ 54

4.2 Description of the LEDs on the Keypad ................................ 54

4.3 Description of the Keys on the Remote LCD Keypad ......................... 55

4.4 Alphanumeric Display .......................................... 56

4.4.1 Power Up Screen................................................56

4.4.2 Operate Screen .................................................56

4.4.3 Parameter Group Screens...........................................57

4.4.4 Meter Pages ..................................................58

4.4.5 Fault Log Screen ................................................59

4.4.6 Fault Screen...................................................59

4.4.7 Event Recorder.................................................59

4.4.8 Lockout Screen .................................................60

4.4.9 Alarm Screen ..................................................61

4.5 Procedure for Setting Data ........................................ 61

4.6 Jump Code ................................................ 62

4.7 Restoring Factory Parameter Settings ................................. 62

4.8 Resetting a Fault ............................................. 62

iii

TABLE OF CONTENTS

4.9 Emergency Overload Reset ....................................... 62

4.10 LED Display ............................................... 62

5 PARAMETER GROUPS ......................................... 64

5.1 Introduction ................................................ 64

5.2 LCD Display Parameters ......................................... 64

5.2.1 Quick Start Group ...............................................64

5.2.2 Control Function Group ...........................................65

5.2.3 Protection Group ...............................................66

5.2.4 I/O Group ...................................................67

5.2.5 RTD Group ...................................................68

5.2.6 Function Group ................................................69

5.2.7 Fault Log Group (FL1 - FL9) .........................................70

5.2.8 Event Log Group (E01 - E99) .........................................70

6 PARAMETER DESCRIPTION ..................................... 72

6.1 Parameter Descriptions ......................................... 72

7 THEORY OF OPERATION ....................................... 138

7.1 Solid State Motor Overload Protection ................................. 138

7.1.1 Overview ....................................................138

7.1.2 Setting Up The MX

7.1.3 Motor Overload Operation ..........................................140

7.1.4 Current Imbalance / Negative Sequence Current Compensation ....................140

7.1.5 Harmonic Compensation ...........................................141

7.1.6 Hot / Cold Motor Overload Compensation ................................141

7.1.7 RTD Overload Biasing ............................................143

7.1.8 Overload Auto Lockout ...........................................144

7.1.9 Separate Starting and Running Motor Overload Settings ........................144

7.1.10 Motor Cooling While Stopped .......................................145

7.1.11 Motor Cooling While Running .......................................146

7.1.12 Emergency Motor Overload Reset .....................................146

7.2 Motor Service Factor ........................................... 147

7.3 Acceleration Control ........................................... 148

7.3.1 Current Ramp Settings, Ramps and Times .................................148

7.3.2 Programming A Kick Current ........................................149

7.3.3 TruTorque Acceleration Control Settings and Times ...........................149

7.3.4 Power Control Acceleration Settings and Times..............................151

7.3.5 Open Loop Voltage Ramps and Times ...................................152

7.3.6 Tachometer Ramp Selection .........................................153

7.3.7 Dual Acceleration Ramp Control ......................................154

7.3.8 Acceleration Ramp Selection .........................................155

7.3.9 Changing Ramp Profiles ...........................................156

7.4 Deceleration Control ........................................... 157

7.4.1 Voltage Control Deceleration ........................................157

7.4.2 TruTorque Deceleration ...........................................158

7.5 Braking Controls ............................................. 159

7.5.1 DC Injection Braking, Standard Duty ....................................160

7.5.2 DC Injection Braking, Heavy Duty .....................................160

7.5.3 Braking Output Relay .............................................160

7.5.4 Stand Alone Overload Relay for emergency ATL (Across The Line) Operation ............160

7.5.5 DC Injection Brake Wiring Example.....................................161

7.5.6 DC Brake Timing ...............................................162

7.5.7 DC Injection Brake Enable and Disable Digital Inputs ..........................162

7.5.8 Use of Optional Hall Effect Current Sensor ................................163

7.5.9 DC Injection Braking Parameters ......................................164

3

Motor Overload ....................................138

iv

TABLE OF CONTENTS

7.6 Slow Speed Cyclo Converter ...................................... 164

7.6.1 Operation ....................................................164

7.6.2 Slow Speed Cyclo Converter Parameters ..................................165

7.7 Inside Delta Connected Starter ..................................... 166

7.7.1 Line Connected Soft Starter .........................................166

7.7.2 Inside Delta Connected Starter........................................167

7.8 Wye Delta Starter ............................................. 168

7.9 Across The Line (Full Voltage Starter) ................................. 171

7.10 Single Phase Soft Starter ........................................ 172

7.11 Phase Control .............................................. 173

7.11.1 Phase Controller: ...............................................174

7.11.2 Master/Slave Starter Configuration:....................................174

7.12 Current Follower ............................................ 175

7.13 Start/Stop Control with a Hand/Off/Auto Selector Switch .................... 176

7.14 Simplified I/O Schematics ....................................... 177

7.15 Remote Modbus Communications .................................. 178

7.15.1 Supported Commands............................................178

7.15.2 Modbus Register Addresses ........................................178

7.15.3 Cable Specifications .............................................178

7.15.4 Terminating Resistors ............................................178

7.15.5 Grounding...................................................178

7.15.6 Shielding ...................................................178

7.15.7 Wiring .....................................................179

8 TROUBLESHOOTING & MAINTENANCE .............................182

8.1 Safety Precautions ............................................ 182

8.2 Preventative Maintenance ........................................ 182

8.2.1 General Information..............................................182

8.2.2 Preventative Maintenance ..........................................182

8.3 General Troubleshooting Charts .................................... 183

8.3.1 Motor does not start, no output to motor ..................................183

8.3.2 During starting, motor rotates but does not reach full speed ......................184

8.3.3 Starter not accelerating as desired .....................................184

8.3.4 Starter not decelerating as desired......................................185

8.3.5 Motor stops unexpectedly while running .................................185

8.3.6 Metering incorrect ...............................................186

8.3.7 Other Situations ................................................187

8.4 Fault Code Table ............................................. 188

8.5 SCR Testing ................................................ 195

8.5.1 Resistance....................................................195

8.5.2 Voltage .....................................................195

8.5.3 Integral Bypass (RB3) .............................................195

8.6 Built In Self Test Functions ....................................... 195

8.6.1 Standard BIST Tests ............................................195

8.6.2

Powered BIST Tests ............................................197

8.7 SCR Replacement ............................................. 198

8.7.1 Typical Stack Assembly............................................198

8.7.2 SCR Removal..................................................198

8.7.3 SCR Installation ................................................198

8.7.4 SCR Clamp ...................................................199

8.7.5 Tightening Clamp ...............................................199

8.7.6 Testing SCR...................................................199

v

TABLE OF CONTENTS

APPENDIX A EVENT CODES ...................................... 202

APPENDIX B ALARM CODES...................................... 203

APPENDIX C FAULT CODES ...................................... 205

APPENDIX D SPARE PARTS ...................................... 207

APPENDIX E EU DECLARATION OF CONFORMITY ....................... 208

APPENDIX F MODBUS REGISTER MAP ............................... 209

APPENDIX G PARAMETER TABLES ................................. 222

vi

1 Introduction

1

1 - INTRODUCTION

Using this Manual

Layout This manual is divided into 9 sections. Each section contains topics related to the section. The sections are as

Symbols There are 2 symbols used in this manual to highlight important information. The symbols appear as the

follows:

•

•

•

•

•

•

•

•

•

following:

Introduction

Technical Information

Installation

Keypad Operation

Parameters

Parameter Descriptions

Theory of Operation

Troubleshooting & Maintenance

Appendices

Electrical Hazard warns of situations in which a high voltage can cause physical injury, death and/or

damage equipment.

Caution warns of situations in which physical injury and/damage to equipment may occur by means other

than electrical.

Highlight mark an important point in the documentation.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Only qualified personnel familiar with low voltage equipment are to perform work described in this set of instructions.

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E.

Turn off all power before working on or inside equipment.

Use a properly rated voltage sensing device to confirm that the power is off.

Before performing visual inspections, tests, or maintenance on the equipment, disconnect all sources of electric power.

Assume that circuits are live until they have been completely de-energized, tested, and tagged. Pay particular attention to

the design of the power system. Consider all sources of power, including the possibility of backfeeding.

Replace all devices, doors, and covers before turning on power to this equipment.

Failure to follow these instructions will result in death or serious injury.

2

General Information Benshaw offers its customers the following:

Start-up services

•

On-site training services

•

Technical support

•

Detailed documentation

•

Replacement parts

•

z NOTE: Information about products and services is available by contacting Benshaw, refer to page 4.

1 - INTRODUCTION

Benshaw Services

Start-Up Services Benshaw technical field support personnel are available to customers with the initial start-up of the RediStart

On-Site Training Services Benshaw technical field support personnel are available to conduct on-site training on RediStart MX

Technical Support Benshaw technical support personnel are available (at no charge) to answer customer questions and provide

Documentation Benshaw provides all customers with:

On-Line Documentation

Replacement Parts Spare and replacement parts can be purchased from Benshaw Technical Support.

Software Number This manual pertains to the software version number 1) 810023-02-01.

Hardware Number This manual pertains to the card hardware assembly version number BIPC-400100-01-03.

3

MX

. Information about start-up services and fees are available by contacting Benshaw.

3

operations and troubleshooting.

technical support over the telephone. For more information about contacting technical support personnel, refer

to page 4.

Operations manual.

•

Wiring diagram.

•

All drawings are produced in AutoCAD© format. The drawings are available on standard CD / DVD or via

e-mail by contacting Benshaw.

3

All RediStart MX

documentation is available on-line at http://www.benshaw.com.

2) 810024-01-01.

Publication History See page 229.

Warranty Benshaw provides a 1 year standard warranty with its starters. An extension to the 3 year warranty is provided

when a Benshaw or Benshaw authorized service technician completes the installation and initial start up. The

warranty data sheet must also be signed and returned. The cost of this service is not included in the price of

the Benshaw soft starter and will be quoted specifically to each customers needs. All recommended

maintenance procedures must be followed throughout the warranty period to ensure validity. This

information is also available by going online to register at www.benshaw.com.

3

1 - INTRODUCTION

Contacting Benshaw

Contacting Benshaw Information about Benshaw products and services is available by contacting Benshaw at one of the following

offices:

Benshaw Inc. Corporate Headquarters

1659 E. Sutter Road

Glenshaw, PA 15116

Phone: (412) 487-8235

Tech Support: (800) 203-2416

Fax: (412) 487-4201

Benshaw Canada Controls Inc.

550 Bright Street East

Listowel, Ontario N4W 3W3

Phone: (519) 291-5112

Tech Support: (877) 236-7429 (BEN-SHAW)

Fax: (519) 291-2595

Benshaw West

14715 North 78th Way, Suite 600

Scottsdale, AZ 85260

Phone: (480) 905-0601

Fax: (480) 905-0757

Benshaw High Point

EPC Division

645 McWay Drive

High Point, NC 27263

Phone: (336) 434-4445

Fax: (336) 434-9682

Benshaw Mobile

CSD Division

5821 Rangeline Road, Suite 202

Theodor, AL 36582

Phone: (251) 443-5911

Fax: (251) 443-5966

Benshaw Pueblo

Trane Division

1 Jetway Court

Pueblo, CO 81001

Phone: (719) 948-1405

Fax: (719) 948-1445

Technical support for the RediStart MX

service department at one of the above telephone numbers. A service technician is available Monday through

Friday from 8:00 a.m. to 5:00 p.m. EST.

z NOTE: An on-call technician is available after normal business hours and on weekends by calling

Benshaw and following the recorded instructions.

To help assure prompt and accurate service, please have the following information available when contacting

Benshaw:

•

Name of Company

•

Telephone number where the caller can be contacted

•

Fax number of caller

•

Benshaw product name

•

Benshaw model number

•

Benshaw serial number

•

Name of product distributor

•

Approximate date of purchase

•

Voltage of motor attached to Benshaw product

•

FLA of motor attached to Benshaw product

•

A brief description of the application

3

Series is available at no charge by contacting Benshaw’s customer

4

Figure 1: RediStart MX3Series Model Numbers

RB3-1-S-052A-12C

1 - INTRODUCTION

Interpreting Model Numbers

C = Open Chassis

Frame Size

Amp Rating, (0 - 999A)

Fault Level

S = Standard

H = High

Type of Bypass

0 = None (only available with RC)

1 = Integrated

2 = Separate, Definite Purpose (Only with 1000V Starter)

3 = Separate, ATL IEC AC3 Rated

4 = Separate, ATL NEMA Rated (AC4)

Type of Control

2=MX

3=MX

2

3

Family of RediStart Starter

B = Bypass

C = Continuous

5

1 - INTRODUCTION

General Overview of a Reduced Voltage Starter

General Overview The RediStart MX3motor starter is a microprocessor-controlled starter for single or three-phase motors. The

Features The enhanced engineering features of the starter include:

starter can be custom designed for specific applications. A few of the features are:

Solid state design.

•

Reduced voltage starting and soft stopping.

•

Closed-loop motor current control, power (kW) control, torque control.

•

Programmable motor protection.

•

Programmable operating parameters.

•

Programmable metering.

•

Communications

•

Each starter can operate within applied line voltage and frequency values of 100VAC to 600VAC (optional

1000VAC) and 23 to 72Hz.

The starter can be programmed for any motor FLA and all of the common motor service factors. It enables

operators to control both motor acceleration and deceleration. The RediStart MX

and its load from damage that could be caused by incorrect phase order wiring.

The starter continually monitors the amount of current being delivered to the motor. This protects the motor

from overheating or drawing excess current.

Multiple frame sizes

•

Universal voltage operation

•

Universal frequency operation

•

Programmable motor overload multiplier

•

Controlled acceleration and deceleration

•

Phase rotation protection

•

Regulated current control

•

3

can also protect the motor

• Electronic motor thermal overload protection

•

Electronic over/under current protection

•

Single phase protection

•

Line-to-line current imbalance protection

•

Stalled motor protection

•

Programmable metering

•

Passcode protected

•

Programmable Relays

•

Analog output with digital offset and span adjustment

•

Analog input with digital offset and span adjustment

•

Voltage and Current Accuracy of 3%

•

Slow speed (Cyclo Conversion) 1.0 – 40.0% forward and reverse

•

Motor winding heater (Anti-Condensation)

•

Anti-windmilling brake

•

PTC Thermistor

•

99 Event Recorder

•

9 Fault Log

•

Real Time Clock

•

Zero Sequence Ground Fault

•

Backspin Timer

•

Starts per Hour

•

Time between Starts

•

PORT (Power Outage Ride Through)

•

16 RTDs with O/L Biasing

•

D.C. Injection Braking (Light or Heavy duty)

6

2 Technical Specifications

7

2 - TECHNICAL SPECIFICATIONS

Technical Specifications

2.1 General Information

The physical specifications of the starter vary depending upon its configuration. The applicable motor current determines the

configuration and its specific application requirements.

Specifications are subject to change without notice.

This document covers the control electronics and several power sections:

MX3control card set

•

RB Power Stacks with Bypass, Integral and Separate

•

RC Power Stacks, Continuous operation, NO bypass

•

Electrical Ratings

2.2 Electrical Ratings

2.2.1 Terminal Points and Functions

Table 1: Terminals

Function

Control Power TB1 G, ground

Relay 1 (R1) TB2 NO1:Normally Open Contact

Relay 2 (R2) TB2 NO2: Normally Open Contact

Relay 3 (R3) TB2 NO3: Normally Open Contact

Relay 4 (R4) J3 R4A: Normally Open Contact

Relay 5 (R5) J3 R5A: Normally Open Contact

Relay 6 (R6) J3 R6A: Normally Open Contact

Terminal

Block

Terminal Number Description

N, 120VAC neutral

N, 120VAC neutral

L, 120VAC line

L, 120VAC line

RC1:Common

NC1: Normally Closed Contact

RC2: Common Contact

NC2: Normally Closed Contact

RC3: Common Contact

NC3: Normally Closed Contact

R4B: Normally Open Contact

R5B: Normally Open Contact

R6B: Normally Open Contact

96 – 144 VAC input, 50/60 Hz

45VA required for control card

Relay Output, SPDT form C

NO Contact (resistive) NC Contact(resistive)

5A at 250VAC 3A at 250VAC

5A at 125VAC 3A at 125VAC

5A at 30VDC 3A at 30VDC

1250VA 750VA

Relay Output, SPDT form C

NO Contact (resistive) NC Contact(resistive)

5A at 250VAC 3A at 250VAC

5A at 125VAC 3A at 125VAC

5A at 30VDC 3A at 30VDC

1250VA 750VA

10A at 250VAC

10A at 125VAC

10A at 30VDC

2500VA

Relay Output, SPST-NO form A

Resistive:

5A at 250VAC

5A at 125VAC

5A at 30VDC

1250VA

Relay Output, SPST-NO form A

Resistive:

5A at 250VAC

5A at 125VAC

5A at 30VDC

1250VA

Relay Output, SPST-NO form A

Resistive:

5A at 250VAC

5A at 125VAC

5A at 30VDC

1250VA

8

2 - TECHNICAL SPECIFICATIONS

Table 1: Terminals

Function

Digital Inputs TB3 1: Start

Digital Inputs J6 1: DI4

Serial Comm TB4 1: B+

Analog I/O TB5 1: Ain Power

PTC Thermistor Input J7 1: Motor PTC

Zero Sequence Ground

Fault

Display RJ45 Door Mounted Display Connector

Terminal

Block

J15 1: CT input

Terminal Number Description

120VAC digital input

2: DI1

3: DI2

4: DI3

5: Common

2: DI5

3: DI6

4: DI7

5: DI8

6: Common

2: A3: COM

2: Ain +

3: Ain 4: Common

5: Aout

6: Common

7: Shield

2: Motor PTC

2: CT input

2500V optical isolation

4mA current draw

Off: 0-35VAC

On: 60-120VAC

120VAC digital input

2500V optical isolation

4mA current draw

Off: 0-35VAC

On: 60-120VAC

Modbus RTU serial communication port.

RS-485 interface

19.2k baud maximum

2500V Isolation

Input:

Voltage or Current

Voltage: 0-10VDC, 67KW impedance

Current: 0-20mA, 500W impedance

Output:

Voltage or Current

Voltage: 0-10VDC, 120mA maximum

Current: 0-20mA, 500W load maximum

Positive Temperature Coefficient Thermistor

- Trip resistance 3.5K, ± 300 Ohms.

- Reset resistance 1.65K, ± 150 Ohms.

- Open terminal voltage is 15V.

- PTC voltage at 4Kohms = 8.55V. (>7.5V)

- Response time adjustable between 1 and 5

seconds.

- Maximum cold resistance of PTC chain = 1500

Ohms.

Zero Sequence Ground Fault

CT Type: 50:0.025 (2000:1 ratio)

Measurement range: 0.1A - 25.0 Amps Accuracy : +/- 3%

Burden at 25Amps : 0.0089VA.

SCR J6 to J11 1: Gate

Phase C.T. J12 1: CT1+

Wire Gauge

The terminals can support 1- 14 AWG wire or 2-16 AWG wires or smaller.

Torque Rating

The terminals on the control cards have a torque rating of 5.0-inch lb. or 0.56Nm. This MUST be

followed or damage will occur to the terminals.

z NOTE: Refer to Control Card Layouts starting on page 41.

2: Cathode

SCR gate Connections

Phase CT Connector

2: CT1

3: CT2+

4: CT2

5: CT3+

6: CT3

9

2 - TECHNICAL SPECIFICATIONS

2.2.2 Measurements and Accuracies

Table 2: Measurements and Accuracies

Internal Measurements

CT Inputs

Line Voltage Inputs

Metering

Current

Voltage

Watts

Volts-Amps

Watt-Hours

Line Frequency

Ground Fault

Zero Seq GF

Run Time

Analog Input

Analog Output

Conversion: True RMS, Sampling @ 1.562kHz

Range: 1-6400A

Conversion: True RMS, Sampling @ 1.562kHz

Range: 100VAC to 1000VAC, 23 to 72 Hz

0 – 40,000 Amps ± 3%

0 – 1250 Volts ± 3%

0 – 9,999 MW ± 5%

0 – 9,999 MVA ± 5%

0 – 10,000 MWh ± 5%

PF

-0.01 to +0.01 (Lag & Lead) ± 5%

23–72Hz±0.1Hz

5 – 100% FLA ± 5% (Machine Protection)

0.1 – 25.0 Amps ± 3%

± 3 seconds per 24 hour period

Accuracy ± 3% of full scale (10 bit)

Accuracy ±2% of full scale (12 bit)

z NOTE: Percent accuracy is percent of full scale of the given ranges, Current = Motor

FLA, Voltage = 1000V, Watts/Volts-Amps/Watt-Hours = Motor & Voltage range

2.2.3 List of Motor Protection Features

•

ANSI 14 – Speed Switch and Tachometer Trip

•

ANSI 19 – Reduced Voltage Start

•

ANSI 27 / 59 – Adjustable over/under voltage protection (Off or 1 to 40%, time 0.1 to 90.0 sec. in 0.1 sec.

•

ANSI 37 – Undercurrent detection (Off or 5 to 100% and time 0.1 to 90.0 sec. in 0.1 sec. intervals)

•

ANSI 38 – Bearing RTD

•

ANSI 46 – Current imbalance detection (Off or 5 to 40%)

•

ANSI 47 – Phase rotation (selectable ABC, CBA, Insensitive, or Single Phase)

•

ANSI 48 – Adjustable up-to-speed / stall timer (1 to 900 sec. in 1 sec. intervals)

•

ANSI 49 – Stator RTD

•

ANSI 50 – Instantaneous electronic overcurrent trip

•

ANSI 51 – Electronic motor overload (Off, class 1 to 40, separate starting and running curves available)

•

ANSI 51 – Overcurrent detection (Off or 50 to 800% and time 0.1 to 90.0 sec. in 0.1 sec. intervals)

•

ANSI 51G – Residual Ground fault detection (Off or 5 to 100% of motor FLA)

•

ANSI 66 – Starts/Hour & Time Between Starts

•

ANSI 74 – Alarm relay output available

•

ANSI 81 – Over / Under Frequency

•

ANSI 86 – Overload lockout

•

Single Phase Protection

•

Shorted SCR detection

•

Mechanical Jam

intervals, independent over and under voltage levels)

Other RTD

Open RTD Alarm

Zero Sequence Ground Fault Detection (Off, 0.1 - 25Amps)

Restart Block (Backspin Timer)

10

2 - TECHNICAL SPECIFICATIONS

1

10

100

1000

10000

100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

Current % (FLA)

Seconds to Trip

Class 5

Class 10

Class 15

Class 20

Class 25

Class 30

Class 35

Class 40

2.2.4 Solid State Motor Overload

3

The MX

control has an advanced I2t electronic motor overload (OL) protection function. For optimal motor protection the MX3control

has forty standard NEMA style overload curves available for use. Separate overloads can be programmed, one for acceleration and

another for normal running operation. The overloads can be individual, the same or completely disabled if necessary. The MX

overload function also implements a NEMA based current imbalance overload compensation, RTD Biasing, user adjustable hot and cold

motor compensation and user adjustable exponential motor cooling.

Figure 2: Commonly Used Overload Curves

3

motor

The motor overload will NOT trip when the current is less than motor Full Load Amps (FLA) * Service Factor (SF).

The motor overload "pick up" point current is at motor Full Load Amps (FLA) * Service Factor (SF).

The motor overload trip time will be reduced when there is a current imbalance present.

z NOTE: Refer to Theory of Operation, Chapter 7 in section 7.1 for more motor overload details and a larger graph.

Refer to http://www.benshaw.com/olcurves.html for an automated overload calculator.

11

2 - TECHNICAL SPECIFICATIONS

2.2.5 CT Ratios

Table 3: CT Ratios

CT Ratio

72:1

(4 wraps 288:1)

96:1

(3 wraps 288:1)

144:1

(2 wraps 288:1)

288:1 15 64

864:1 45 190

2640:1 135 590

3900:1 200 870

5760:1 295 1285

8000:1 410 1800

14400:1

(CT-CT combination)

28800:1

(CT-CT combination)

For the following CT Ratios, consult factory.

50:5 11 45

150:5 33 135

250:5 55 225

800:5 176 720

2000:5 440 1800

5000:5 1100 4500

Minimum FLA

(A rms)

4

521

832

740 3200

1475 6400

Maximum FLA

(A rms)

16

12

2.2.6 Optional RTD Module Specifications

The starter has the option of operating with up to two Benshaw SPR-100P remote RTD modules.

Table 4: Remote RTD Module Specifications

2 - TECHNICAL SPECIFICATIONS

Model Number

RTD Type

TCR (a)

Maximum Lead Resistance

Recommended Lead Resistance

Shorted Lead Detection

Open Lead Detection

RTD Sensing Current

RTD Sensing Voltage

Range

Resolution

Accuracy

Sampling Rate

Number of RTDs

Input Voltage

Communication Type

®

Modbus

Addresses

Operating Environment

Terminal Strips

Dimensions

Listing

SPR-100P

100W Platinum, 3 lead

0.00385 W/W/°C

(DIN 43760)

25W per lead

Less than 16W per lead

<60W

> 260W

10 mA DC

10V DC maximum

0to200°C (32 to 392 °F)

1 °C (1.8 °F)

±1.0% full scale (±2 °Cor±3.6 °F)

1 RTD per second

8

24 Volts DC ± 20%, 2.5W

Modbus RTU, RS-485, 19.2Kbps

16 to 23

-40 to 60 °C (-40 to 140 °F), up to 95% R.H.,

non-condensing

Accepts one or two stranded copper wires of the same

size from 12 to 30 AWG

5½"Wx3½"Hx2¼"D

cUL

13

2 - TECHNICAL SPECIFICATIONS

2.2.7 Zero Sequence Ground Fault CT

The Benshaw BICT 2000/1-6 CT has the following excitation curve.

Figure 3: BICT2000/1-6 Excitation Curve

Starter Power Ratings

2.3 Starter Power Ratings

Each RB3 model starter is rated for three different starting duties. For example, a starter can operate a:

300HP motor for a standard duty start (350% for 30 seconds)

Or

200HP for a heavy duty start (500% for 30 seconds)

Or

150HP motor for a class 30 start (600% for 30 seconds)

Or

450HP motor when connected to the inside delta of a motor for a class 10 start (350% for 30 seconds)

14

2.3.1 Standard Duty (350% for 30 sec) Ratings

Table 5: Standard Duty Horsepower Ratings

Standard Duty (350% current for 30 seconds, 115% Continuous)

2 - TECHNICAL SPECIFICATIONS

MODEL NUMBER

RB3-1-S-027A-11C 27 7.5 10 15 20 25

RB3-1-S-040A-11C 40 10 15 25 30 40

RB3-1-S-052A-12C 52 15 20 30 40 50

RB3-1-S-065A-12C 65 20 25 40 50 60

RB3-1-S-077A-13C 77 25 30 40 60 75

RB3-1-S-096A-13C 96 30 40 50 75 100

RB3-1-S-125A-14C 125 40 50 75 100 125

RB3-1-S-156A-14C 156 50 60 75 125 150

RB3-1-S-180A-14C 180 60 75 100 150 200

RB3-1-S-180A-15C 180 60 75 100 150 200

RB3-1-S-240A-15C 240 75 100 150 200 250

RB3-1-S-302A-15C 302 100 125 150 250 300

RB3-1-S-361A-16C 361 125 150 200 300 400

RB3-1-S-414A-17C 414 150 150 250 350 400

RB3-1-S-477A-17C 477 150 200 300 400 500

RB3-1-S-515A-17C 515 200 200 300 450 500

RB3-1-S-590A-18C 590 200 250 350 500 600

RB3-1-S-720A-19C 720 250 300 400 600 700

RB3-1-S-838A-20C 838 300 350 500 700 800

NOMINAL

AMPS

200-208V 230-240V 380-400V 440-480V 575-600V

HORSEPOWER RATING

z NOTE: Do not exceed Class 10 overload setting.

15

2 - TECHNICAL SPECIFICATIONS

2.3.2 Heavy Duty (500% current for 30 sec) Ratings

Table 6: Heavy Duty Horsepower Ratings

Heavy Duty (500% current for 30 seconds, 125% Continuous)

MODEL NUMBER

RB3-1-S-027A-11C 24 7.5 10 15 20 25

RB3-1-S-040A-11C 40 10 15 25 30 40

RB3-1-S-052A-12C 54 15 20 30 40 50

RB3-1-S-065A-12C 54 15 20 30 40 50

RB3-1-S-077A-13C 54 15 20 30 40 50

RB3-1-S-096A-13C 96 30 40 50 75 100

RB3-1-S-125A-14C 125 40 50 75 100 125

RB3-1-S-156A-14C 125 40 50 75 100 125

RB3-1-S-180A-14C 125 40 50 75 100 125

RB3-1-S-180A-15C 180 60 75 100 150 200

RB3-1-S-240A-15C 215 60 75 125 150 200

RB3-1-S-302A-15C 215 60 75 125 150 200

RB3-1-S-361A-16C 252 75 100 150 200 250

RB3-1-S-414A-17C 372 125 150 200 300 400

RB3-1-S-477A-17C 372 125 150 200 300 400

RB3-1-S-515A-17C 372 125 150 200 300 400

RB3-1-S-590A-18C 551 200 200 300 450 500

RB3-1-S-720A-19C 623 200 250 350 500 600

RB3-1-S-838A-20C 623 200 250 350 500 600

NOMINAL

AMPS

200-208V 230-240V 380-400V 440-480V 575-600V

HORSEPOWER RATING

z NOTE: Do not exceed Class 20 overload setting.

16

2.3.3 Severe Duty (600% current for 30 sec) Ratings

Table 7: Severe Duty Horsepower Ratings

Severe Duty (600% current for 30 seconds 125% Continuous)

2 - TECHNICAL SPECIFICATIONS

MODEL NUMBER

RB3-1-S-027A-11C 24 5 7.5 10 15 20

RB3-1-S-040A-11C 40 10 10 20 30 40

RB3-1-S-052A-12C 45 10 15 25 30 40

RB3-1-S-065A-12C 45 10 15 25 30 40

RB3-1-S-077A-13C 45 10 15 25 30 40

RB3-1-S-096A-13C 77 25 30 40 60 75

RB3-1-S-125A-14C 105 30 40 60 75 100

RB3-1-S-156A-14C 105 30 40 60 75 100

RB3-1-S-180A-14C 105 30 40 60 75 100

RB3-1-S-180A-15C 180 50 60 100 125 150

RB3-1-S-240A-15C 180 50 60 100 125 150

RB3-1-S-302A-15C 180 50 60 100 125 150

RB3-1-S-361A-16C 210 60 75 125 150 200

RB3-1-S-414A-17C 310 100 125 150 250 300

RB3-1-S-477A-17C 310 100 125 150 250 300

RB3-1-S-515A-17C 310 100 125 150 250 300

RB3-1-S-590A-18C 515 150 200 300 450 500

RB3-1-S-720A-19C 515 150 200 300 450 500

RB3-1-S-838A-20C 515 150 200 300 450 500

NOMINAL

AMPS

200-208V 230-240V 380-400V 440-480V 575-600V

HORSEPOWER RATING

z NOTE: Do not exceed Class 30 overload setting.

17

2 - TECHNICAL SPECIFICATIONS

2.3.4 Inside Delta Connected Standard Duty (350% for 30 sec) Ratings

Table 8: Inside Delta Standard Duty Horsepower Ratings

INSIDE DELTA Std Duty (350% start for 30 seconds 115% Continuous)

MODEL NUMBER

RB3-1-S-125A-14C 180 60 75 100 150 200

RB3-1-S-156A-14C 240 75 100 150 200 250

RB3-1-S-180A-14C 279 75 100 150 200 250

RB3-1-S-180A-15C 279 75 100 150 200 250

RB3-1-S-240A-15C 361 125 150 200 300 400

RB3-1-S-302A-15C 414 150 150 250 350 400

RB3-1-S-361A-16C 515 200 150 250 450 400

RB3-1-S-414A-17C 590 200 250 350 500 600

RB3-1-S-477A-17C 720 250 300 400 600 700

RB3-1-S-515A-17C 800 250 300 500 600 700

RB3-1-S-590A-18C 838 300 350 500 700 800

RB3-1-S-720A-19C 1116 300 350 700 900 800

RB3-1-S-838A-20C 1300 400 500 800 1000 1200

z NOTE: Do not exceed Class 10 overload setting.

NOMINAL

AMPS

200-208V 220-240V 380-415V 440-480V 575-600V

HORSEPOWER RATING

18

2.3.5 RB3 Power Stack Ratings and Protection Requirements

(W)

Bypassed

Loss, After

Running Watt

Circuit

Maximum

Rating (A)

Breaker Trip

Fuse Size

Maximum

Current (A)

Class

J/T/RK1/RK5 45/70* 60/100* 49

J/T/RK1/RK5 70/100* 100/150* 49.8

J/T/RK1/RK5 90/125* 125/200* 51

J/T/RK1/RK5 110/175* 150/250* 53.7

J/T/RK1/RK5 125/200* 175/300* 56

J/T/RK1/RK5 150/250* 225/350* 59

J/T/RK1/RK5 200/300* 300/450* 62

J/T/RK1/RK5 250/400* 350/600* 66

Allowable Fuse

3

3

3

3

3

3

4

J/T/RK1/RK5 300/450* 450/700* 71

4

4

2 - TECHNICAL SPECIFICATIONS

L 900/1300* 1300/2000* 140

L 1000/1600* 1400/2000* 165

L 1200/1800* 1800/2500* 205

L/T 700/1100* 1000/1600* 103

L/T 800/1200* 1200/1800* 120

J/T/RK1/RK5 300/450* 450/700* 71

J/T/RK1/RK5 400/600* 600/900* 75

J/T/RK1/RK5/L 500/800* 700/1100* 82

4

4

J/T/RK1/RK5/L 600/900* 900/1300* 92

4

4

4

4

4

4

L 1400/2000* 2000/3000* 245

4

4

Connection Type

Unit

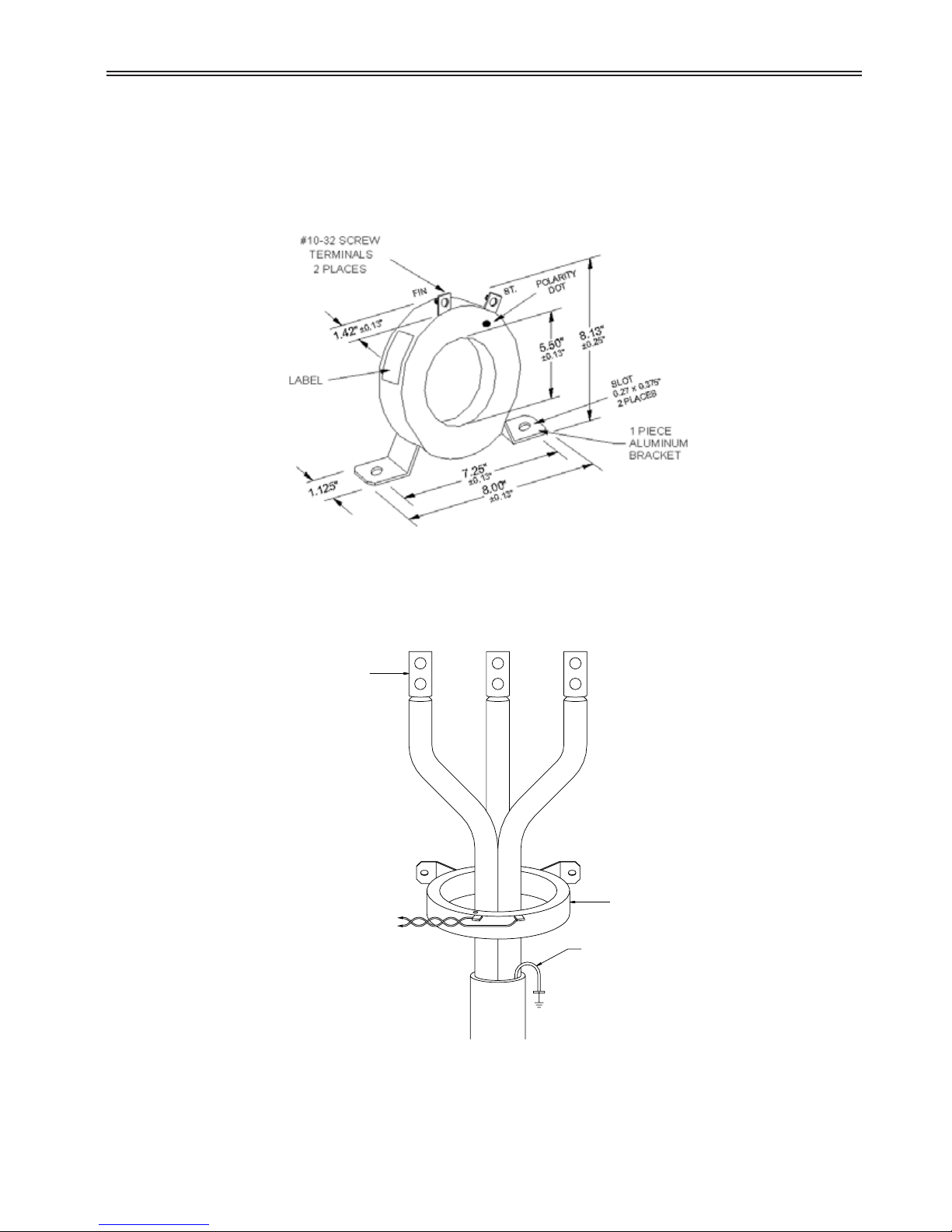

Withstand

Unit

Withstand

115%

Current (A)

Nominal

Current (A)

115%

Current

Line Load

5

High. Fault

Rating (KA)

5

Std. Fault

Rating (KA)

Inside Delta

Inside Delta

(A)

Rating

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

1

1

2

2

3

3

4

4

4

4

4

4

4

4

4

4

4

Bus Tab

4

4

(A)

Current

Nominal

Model Number

RB_1_027A11C 27 31 - 48 5 5 Power Block

RB_1_040A11C 40 46 - 71 5 5 Power Block

RB_1_052A12C 52 60 - 93 10 10 Power Block

RB_1_065A12C 65 75 - 116 10 10 Power Block

RB_1_590A18C 590 679 915 1052 42 65 Bus Tab

RB_1_477A17C 477 549 739 850 42 65 Bus Tab

RB_1_077A13C 77 89 - 137 10 10 Bus Tab

RB_1_096A13C 96 110 - 171 10 10 Bus Tab

RB_1_125A14C 125 144 194 223 18 30 Bus Tab

RB_1_156A14C 156 179 242 278 18 30 Bus Tab

RB_1_180A14C 180 207 279 321 18 30 Bus Tab

RB_1_180A15C 180 207 279 321 30 65 Bus Tab

RB_1_240A15C 240 276 372 428 30 65 Bus Tab

RB_1_302A15C 302 347 468 538 30 65 Bus Tab

RB_1_361A16C 361 415 560 643 30 65 Bus Tab

RB_1_515A17C 515 592 798 918 42 65 Bus Tab

RB_1_720A18C 720 828 1116 1283 42 65 Bus Tab

RB_1_414A17C 414 476 642 738 42 65 Bus Tab

RB_1_838A19C 838 964 1299 1494 42 65 Bus Tab

* Rating for Inside Delta Application

1 Power Block wire size #12-#4awg

2 Power Block wire size #10-#1awg

3BusTabwith1hole¼"diameter

4 Bus Tab with NEMA 2 hole pattern ½" diameter ¾" apart as defined by NEMA Standard CC1

5 For higher kAIC ratings, consult factory

19

2 - TECHNICAL SPECIFICATIONS

2.3.6 Power Stack Input Ratings with Protection Requirements for Separate Bypass

(W)

After

Running

Watt Loss,

Maximum

Maximum

Allowable Fuse

Bypassed

Circuit Breaker

Trip Rating (A)

Fuse Size

Current (A)

Class

L/T 700/1100* 1000/1600* 103

J/T/RK1/RK5 45/70* 60/100* 49

J/T/RK1/RK5 70/100* 100/150* 49.8

J/T/RK1/RK5 90/125* 125/200* 51

J/T/RK1/RK5 110/175* 150/250* 53.7

J/T/RK1/RK5 125/200* 175/300* 56

J/T/RK1/RK5 150/250* 225/350* 59

J/T/RK1/RK5 200/300* 300/450* 62

J/T/RK1/RK5 250/400* 350/600* 66

J/T/RK1/RK5 300/450* 450/700* 71

J/T/RK1/RK5 300/450* 450/700* 71

J/T/RK1/RK5 400/600* 600/900* 75

J/T/RK1/RK5/L 500/800* 700/1100* 82

3

3

3

3

3

3

4

4

4

4

4

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

Bus Tab

1

1

2

2

3

3

4

4

4

Bus Tab

4

4

J/T/RK1/RK5/L 600/900* 900/1300* 92

4

4

4

Bus Tab

Bus Tab

Bus Tab

4

4

4

4

4

L/T 800/1200* 1200/1800* 120

Bus Tab

L 900/1300* 1300/2000* 140

L 1000/1600* 1400/2000* 165

L 1200/1800* 1800/2500* 205

L 1400/2000* 2000/3000* 245

4

4

4

4

Bus Tab

Bus Tab

Bus Tab

Bus Tab

4

4

4

4

Connection Type

NEMA (AC4)

AC3 Unit

115%

Nominal

115%

Nominal

Line Load

5

(KA)

Fault Rating

Unit Withstand

5

(KA)

Withstand

Fault Rating

Inside Delta

Current (A)

Current (A)

Inside Delta

(A)

Rating

Current

(A)

Current

Bus Tab

Factory

Consult

Model Number

RB_2_027A11C 27 31 - - 5 5 Power Block

RB_2_040A11C 40 46 - - 5 10 Power Block

RB_2_052A12C 52 60 - - 5 10 Power Block

20

RB_2_065A12C 65 75 - - 10 10 Power Block

RB_2_361A16C 361 415 560 643 30 30 Bus Tab

RB_2_077A13C 77 89 - - 10 10 Bus Tab

RB_2_096A13C 96 110 - - 10 10 Bus Tab

RB_2_125A14C 125 144 194 223 10 10 Bus Tab

RB_2_156A14C 156 179 242 278 10 18 Bus Tab

RB_2_180A14C 180 207 279 321 10 18 Bus Tab

RB_2_180A15C 180 207 279 321 10 18 Bus Tab

RB_2_240A15C 240 276 372 428 18 18 Bus Tab

RB_2_302A15C 302 347 468 538 18 30 Bus Tab

RB_2_414A17C 414 476 642 738 30 30 Bus Tab

RB_2_590A18C 590 679 915 1052 30 30 Bus Tab

RB_2_477A17C 477 549 739 850 30 30 Bus Tab

RB_2_515A17C 515 592 798 918 30 30 Bus Tab

RB_2_720A18C 720 828 1116 1283 30 30 Bus Tab

RB_2_838A19C 838 964 1299 1494 Consult Factory

* Rating for Inside Delta Application

1 Power Block wire size #12-#4awg

2 Power Block wire size #10-#1awg

3BusTabwith1hole¼"diameter

4 Bus Tab with NEMA 2 hole pattern ½" diameter ¾" apart as defined by NEMA Standard CC1

5 For higher kAIC ratings, consult factory

2 - TECHNICAL SPECIFICATIONS

2.3.7 Power Stack Input Ratings with Protection Requirements for RC No Bypass

(W)

After

Running

Watt Loss,

Protected Rating

Bypassed

Short

Circuit

Trip Plug

Rating

65kA 950

400A

600A

65kA 1240

400A

600A

85kA 1520

800A

1200a

85kA 1845

800A

800A

1200A

85kA 2145

1200A

1200 –

85kA 2445

1600A

1200 –

85kA 3045

1600A

Current Limiting Circuit Breaker

Rating

Current Limiting Circuit Breaker Protected

Connection Type

Unit

Withstand

Catalog

Short

Maximum Fuse

Allowable Fuse

Fault

Rating

Number

Rating

Circuit

Current (A)

Class

Line Load

4

(kA)

CED63B 60A 42kA 110

50kA

100kA

40

60

J/600V AC T/RK1

1

Power Block

1

Power Block

CED63B 60A 42Ka 145

50kA

100kA

60

100

J/600V AC T/RK1

1

Power Block

1

CED63B 100A 42kA 175

50kA

100kA

60

100

J/600V AC T/RK1

1

Power Block

2

1

2

J/600V AC T/RK1 225 100kA CED63B 100A 42kA 210

Power Block

1

1

J/600V AC T/RK1 225 100kA CED63B 125A 42kA 240

Power Block

1

1

J/600V AC T/RK1 225 100kA CFD63B 225A 42kA 285

Power Block

1

1

J/600V AC T/RK1 225 100kA CFD63B 225A 42kA 360

Power Block

CJD63B

CLD63b

CJD63B

CLD63b

CND63b

CND63B

CND63b

CND63B

CND63b

CND63B

HPD63F160

50kA

100kA

100kA

1600

2000

1600

HPD63F160

50kA

2000

125%

Current

(A)

Current

Nominal

Model Number

RC_ 0 _027A11C 27 33.75 42

RC_ 0 _040A11C 40 50 42 Power Block

RC_ 0 _052A12C 52 65 42 Power Block

RC_ 0 _065A12C 65 81 42 Power Block

RC_ 0 _077A13C 77 96 42 Power Block

RC_ 0 _096A13C 96 120 42 Power Block

RC_ 0 _124A33C 124 155 42 Power Block

RC_ 0 _125A14C 125 155 42 Bus Tab Bus Tab J/600V AC T/RK1 350 100kA CFD63B 225A 42kA 360

RC_ 0 _156A14C 156 195 42 Bus Tab Bus Tab J/600V AC T/RK1 400 100kA CFD63B 225A 65kA 435

RC_ 0 _180A15C 180 2225 42 Bus Tab Bus Tab J/600V AC T/RK1 400 100kA CFD63B 250A 65kA 495

RC_ 0 _240A15C 240 300 42 Bus Tab Bus Tab J/600V AC T/RK1 600 100kA CFD63B 400A 65kA 645

RC_ 0 _302A15C 302 377 42 Bus Tab Bus Tab J/600V AC T/RK1 800 100kA CFD63B 400A 65kA 800

RC_ 0 _361A16C 361 421 42 Bus Tab Bus Tab J/600V AC T/RK1 800 100kA

RC_ 0 _477A17C 477 596 42 Bus Tab Bus Tab J/600V AC T/RK1 800 100kA

RC_ 0 _590A18C 590 737 42 Bus Tab Bus Tab L 1400 100kA

RC_ 0 _720A18C 720 900 42 Bus Tab Bus Tab L 1600 100kA

RC_ 0 _840A19C 840 1050 85 Bus Tab Bus Tab L 1600 100kA

RC_ 0 _960A19C 960 1200 85 Bus Tab Bus Tab L

1PowerBlockwiresize#6awgmax

2PowerBlockwiresize#2awgmax

3 Power Block wire size #2/0 max

RC_ 0_1200KA19C 1200 1440 85 Bus Tab Bus Tab L

4 For higher kAIC ratings, consult factory

21

2 - TECHNICAL SPECIFICATIONS

2.3.8 RB3 Starter Control Power Requirements

Table 9: RB3 Starter CPT VA Requirements

Power

Model Number

RB3-1-S-027A-11C 74 75 RB3-1-S-240A-15C 243 250

RB3-1-S-040A-11C 74 75 RB3-1-S-302A-15C 243 250

RB3-1-S-052A-12C 111 125 RB3-1-S-361A-16C 243 250

RB3-1-S-065A-12C 111 125 RB3-1-S-414A-17C 441 450

RB3-1-S-077A-13C 111 125 RB3-1-S-477A-17C 441 450

RB3-1-S-096A-13C 111 125 RB3-1-S-515A-17C 441 450

RB3-1-S-125A-14C 131 150 RB3-1-S-590A-18C 441 450

RB3-1-S-156A-14C 243 250 RB3-1-S-720A-19C 441 450

RB3-1-S-180A-14C 243 250 RB3-1-S-838A-20C 243 250

2.3.9 RC3 Starter Control Power Requirements

Model Number

RC3-1-S-027A-31C 45 75 RC3-1-S-240A-35C 123 150

RC3-1-S-040A-31C 45 75 RC3-1-S-302A-35C 123 150

RC3-1-S-052A-31C 45 75 RC3-1-S-361A-35C 201 250

RC3-1-S-065A-32C 45 75 RC3-1-S-414A-35C 150 200

RC3-1-S-077A-32C 45 75 RC3-1-S-477A-35C 225 350

RC3-1-S-096A-33C 45 75 RC3-1-S-590A-35C 225 350

RC3-1-S-124A-33C 45 75 RC3-1-S-720A-36C 225 350

RC3-1-S-125A-34C 123 150 RC3-1-S-840A-19C 225 350

RC3-1-S-156A-34C 123 150 RC3-1-S-960A-20C 225 350

RC3-1-S-180A-34C 123 150 RC3-1-S-1200A-37C 285 350

Required

(VA)

Table 10: RC3 Starter CPT VA Requirements

Power

Required

(VA)

Recommended

Min. TX size

Recommended

Min. TX size

Model Number

Model Number

Power

Required

(VA)

Power

Required

(VA)

Recommended

Min. TX size

Recommended

Min. TX size

22

2.4 Dimensions

2.4.1 RB3 Chassis with Integral Bypass

Figure 4: RB3 - 96A, 830A

2 - TECHNICAL SPECIFICATIONS

Mechanical Drawings

Figure 5: RB3 125 - 361A

Model

RB3 27-65A

RB3 77-96A

RB3 838A

Model

RB3 125A

RB3 156-180A

RB3 180-302A

RB3 361A

ABCDEF

14 10 12.5 8.43 0.84 0.31

15 10 13.5 8.43 0.84 0.31

27.75 26.6 23.5 8.7 N/A 0.31

ABCDEF

19.5 12.27 13.25 4 0.5 0.31

21.25 12.27 15.25 4 0.5 0.31

22.75 12.27 16.75 4 0.5 0.31

23.87 13.09 18.63 4.31 0.5 0.31

23

2 - TECHNICAL SPECIFICATIONS

Figure 6: RB3 414 - 838A

2.4.2 RC3 Chassis with no Bypass

Figure 7: RC3 0 - 124A

Model

RB3 414-590A

RB3 720A 30.04 18.5 28 6 N/A 0.31

RB3 838A 27.75 26.6 23.5 8.7 N/A 0.31

ABCDEF

28.29 18.5 26.25 6 N/A 0.31

24

Model

RC3 27-52A

RC3 65-77A

RC3 96-124A

ABC D E

14 9.875 3.375 4.69 8-32 TAP

18 10 4.375 4.75 ¼-20 TAP

27 10 5.313 4.75 ¼-20 TAP

Figure 8: RC3 156 - 590A

2 - TECHNICAL SPECIFICATIONS

2.5 Environmental Conditions

Operating Temperatures

Table 11: Environmental Ratings

Storage Temperatures

Model

RC3 156-180A

RC3 240A

RC3 302-361A

RC3 477A

RC3 590A

ABCD E

18 15 17 13.5 0.3

24 15 23 13.5 0.5

28 17.25 27 15.75 0.5

28 20 27 18.5 0.5

35 20 34 18.5 0.5

Environmental Conditions

-10°C to +40°C (14°F to 104°F)enclosed

-10°C to +50°C (14°F to 122°F)open

-20°C to +70°C (-4°F to 155°F)

Maximum Vibration 5.9m/s2(19.2ft/s2) [0.6G]

Humidity

Altitude

Cooling

0% to 95% non condensing

1000m (3300ft) without derating

RC (Natural convection)

RB (Bypassed)

25

2 - TECHNICAL SPECIFICATIONS

Altitude Derating

2.6 Altitude Derating

Benshaw's starters are capable of operating at altitudes up to 3,300 feet (1000 meters) without requiring altitude derating. Table 12

provides the derating percentage to be considered when using a starter above 3,300 feet (1000 meters).

Table 12: Altitude Derating

Real Time Clock

2.7 Real Time Clock

The MX3comes with a real time clock. The user can enter the actual time and the starter will use this time when it logs faults in the fault

recorder as well as events in the event recorder. This can help with troubleshooting. The system clock does not recognize daylight

savings time.

Accuracy: +- 1 minute per month

Range: 1/1/1972 to 1/1/2107 with automatic leap year compensation.

Approvals

3300 Feet

4300 Feet

5300 Feet

6300 Feet

7300 Feet

8300 Feet

9300 Feet

Altitude

1006 meters 0.0%

1311 meters 3.0%

1615 meters 6.0%

1920 meters 9.0%

2225 meters 12.0%

2530 meters 15.0%

2835 meters 18.0%

Percent Derating (Amps)

2.8 Approvals

MX3Control Card set is UL, cUL Recognized

Certificate of Compliance

2.9 Certificate of Compliance

CE Mark, See Appendix E on page 208.

26

3 Installation

27

3 - INSTALLATION

Before You Start

3.1 Before You Start

3.1.1 Installation Precautions

Inspection

Before storing or installing the RediStart MX

Remove the starter from its package and inspect exterior for shipping damage. If damage is apparent, notify the shipping agent and

•

your sales representative.

Open the enclosure and inspect the starter for any apparent damage or foreign objects. Ensure that all of the mounting hardware and

•

terminal connection hardware is properly seated, securely fastened, and undamaged.

Ensure all connections and wires are secured.

•

Read the technical data label affixed to the starter and ensure that the correct horsepower and input voltage for the application has

•

been purchased.

The numbering system for a chassis is shown below.

General Information

Installation of some models may require halting production during installation. If applicable, ensure that the starter is installed when

production can be halted long enough to accommodate the installation. Before installing the starter, ensure:

The wiring diagram (supplied separately with the starter) is correct for the required application.

•

The starter is the correct current rating and voltage rating for the motor being started.

•

All of the installation safety precautions are followed.

•

The correct power source is available.

•

The starter control method has been selected.

•

The connection cables have been obtained (lugs) and associated mounting hardware.

•

The necessary installation tools and supplies are procured.

•

The installation site meets all environmental specifications for the starter NEMA/CEMA rating.

•

The motor being started has been installed and is ready to be started.

•

Any power factor correction capacitors (PFCC) are installed on the power source side of the starter and not on the motor side.

•

Failure to remove power factor correction or surge capacitors from the load side of the starter will result in serious damage to the starter

that will not be covered by the starter warranty. The capacitors must be connected to the line side of the starter. The up-to-speed (UTS)

contact can be used to energize the capacitors after the motor has reached full speed.

3

Series Starter, thoroughly inspect the device for possible shipping damage. Upon receipt:

3.1.2 Safety Precautions

To ensure the safety of the individuals installing the starter, and the safe operation of the starter, observe the following guidelines:

•

Ensure that the installation site meets all of the required environmental conditions (Refer to Site Preparation, page 29).

•

LOCK OUT ALL SOURCES OF POWER.

•

Install circuit disconnecting devices (i.e., circuit breaker, fused disconnect or non-fused disconnect) if they were not previously

installed by the factory as part of the package.

•

Install short circuit protection (i.e., circuit breaker or fuses) if not previously installed by the factory as part of the package.

•

Consult Power Ratings for the fault rating on pages 19-21.

•

Follow all NEC (National Electrical Code) and/or C.S.A. (Canadian Standards Association) standards or Local Codes as applicable.

•

Remove any foreign objects from the interior of the enclosure, especially wire strands that may be left over from installation wiring.

•

Ensure that a qualified electrician installs wiring.

•

Ensure that the individuals installing the starter are wearing ALL protective eyewear and clothing.

•

Ensure the starter is protected from debris, metal shavings and any other foreign objects.

The opening of the branch circuit protective device may be an indication that a fault current has been interrupted. To reduce the risk of

electrical shock, current carrying parts and other components of the starter should be inspected and replaced if damaged.

28

3.2 Installation Considerations

3.2.1 Site Preparation

General Information

Before the starter can be installed, the installation site must be prepared. The customer is responsible for:

Providing the correct power source

•

Providing the correct power protection

•

Selecting the control mechanism

•

Obtaining the connection cables, lugs and all other hardware

•

Ensuring the installation site meets all environmental specifications for the enclosure NEMA rating

•

Installing and connecting the motor

•

Power Cables

The power cables for the starter must have the correct NEC/CSA current rating for the unit being installed. Depending upon the model,

the power cables can range from a single #14 AWG conductor to four 750 MCM cables. (Consult local and national codes for selecting

wire size).

Site Requirements

The installation site must adhere to the applicable starter NEMA/CEMA rating. For optimal performance, the installation site must meet

the appropriate environmental and altitude requirements.

3.2.2 EMC Installation Guidelines

General In order to help our customers comply with European electromagnetic compatibility standards, Benshaw Inc. has

developed the following guidelines.

3 - INSTALLATION

Installation Considerations

Attention This product has been designed for Class A equipment. Use of the product in domestic environments may cause radio

Enclosure Install the product in a grounded metal enclosure.

Grounding Connect a grounding conductor to the screw or terminal provided as standard on each controller. Refer to layout/power

Wiring Refer to Wiring Practices on page 31.

Filtering To comply with Conducted Emission Limits (CE requirement), a high voltage (1000V or greater) 0.1 uF capacitor

3.2.3 Use of Power Factor Capacitors

Power factor correction capacitors and surge capacitors CAN NOT be connected between the starter and the motor. These devices can

damage the SCRs during ramping. These devices appear like a short circuit to the SCR when it turns on, which causes a di/dt level

greater than the SCR can handle. If used, power factor correction capacitors or surge capacitors must be connected ahead of the starter

and sequenced into the power circuit after the start is completed. A programmable relay can be configured as an up-to-speed (UTS) relay

and then used to pull-in a contactor to connect the capacitors after the motor has reached full speed.

z NOTE: If the motor manufacturer supplies surge capacitors they must be removed before starting.

3.2.4 Use of Electro-Mechanical Brakes

If an electro-mechanical brake is used with the starter, it must be powered from the line side of the starter to ensure full voltage is applied

to the brake during a start so it will properly release. A programmable relay can be configured as a run relay and then used to pull-in a

contactor to power the brake whenever the starter is providing power to the motor.

3.2.5 Reversing Contactor

If the application requires a reversing contactor, it should be connected on the output side (load) of the soft starter. The contactor must

be closed before starting the soft starter. The soft starter must be off before switching the direction of the reversing contactor. The

reversing contactor must never be switched while the soft starter is operating.

interference, in which case the installer may need to use additional mitigation methods.

wiring schematic for grounding provision location.

should be connected from each input line to ground at the point where the line enters the cabinet.

29

3 - INSTALLATION

Mounting Considerations

3.3 Mounting Considerations

3.3.1 Bypassed Starters

Provisions should be made to ensure that the average temperature inside the enclosure never rises above 50°C. If the temperature inside

the enclosure is too high, the starter can be damaged or the operational life can be reduced.

3.3.2 Non-Bypassed Starters

Provisions should be made to ensure that the temperature inside the enclosure never rises above 50°C. If the temperature inside the

enclosure is too high, the starter can be damaged or the operational life can be reduced. As a general rule of thumb, the following

ventilation guidelines can be followed.

Current Range Bottom of Enclosure Top of Enclosure

< 200 amps Fans or grills depending on enclosure size

200 to 300 amps 2 x 4” grills (12 sq. in.) 2 x 4” grills (12 sq.in.)

301 to 400 amps 1 x 4” fan (115 cfm) 2 x 4” grills (12 sq.in.)

401 to 600 amps 2 x 4” fan (230 cfm) 2 x 6” grills (28 sq.in.)

601 to 700 amps 2 x 6” fan (470 cfm) 2 x 6” grills (28 sq.in.)

> 700 amps Consult factory Consult Factory

Table 13: Ventilation Requirements

The starter produces 4 watts of heat per amp of current and 26 square inches of enclosure surface is required per watt of heat generation.

Contact Benshaw and ask for the enclosure sizing technical note for more information concerning starters in sealed enclosures. Benshaw

supplies starters under 124 amps non-bypassed, with the heat sink protruding from the back of the enclosure. This allows a small

enclosure size while still maintaining the cooling capability of the starter.

30

3.4 Wiring Considerations

3.4.1 Wiring Practices

When making power and control signal connections, the following should be observed:

Never connect input AC power to the motor output terminals T1/U, T2/V, or T3/W.

•

Power wiring to the motor must have the maximum possible separation from all other wiring. Do not run control wiring in the same

•

conduit; this separation reduces the possibility of coupling electrical noise between circuits. Minimum spacing between metallic

conduits containing different wire groups should be three inches (8cm).

Minimum spacing between different wiring groups in the same tray should be six inches.

•

Wire runs outside an enclosure should be run in metallic conduit or have shielding/armor with equivalent attenuation.

•

Whenever power and control wiring cross it should be at a 90 degrees angle.

•

Different wire groups should be run in separate conduits.

•

With a reversing application, the starter must be installed in front of the reversing contactors.

•

z NOTE: Local electrical codes must be adhered to for all wiring practices.

3.4.2 Considerations for Control and Power Wiring

Control wiring refers to wires connected to the control terminal strip that normally carry 24V to 115V and Power wiring refers to wires

connected to the line and load terminals that normally carries 200VAC - 600VAC respectively. Select power wiring as follows:

Use only UL or CSA recognized wire.

•

Wire voltage rating must be a minimum of 300V for 230VAC systems and 600V (Class 1 wire) for 460VAC and 600VAC systems.

•

Grounding must be in accordance with NEC, CEC or local codes. If multiple starters are installed near each other, each must be

•

connected to ground. Take care to not form a ground loop. The grounds should be connected in a STAR configuration.

Wire must be made of copper and rated 60/75°C for units 124 Amps and below. Larger amp units may use copper or aluminum wire.

•

Refer to NEC table 310-16 or local codes for proper wire selection.

3 - INSTALLATION

Wiring Considerations

3.4.3 Considerations for Signal Wiring

Signal wiring refers to the wires connected to the control terminal strip that are low voltage signals, below 15V.

• Shielded wire is recommended to prevent electrical noise interference from causing improper operation or nuisance tripping.

•

Signal wire rating should carry as high of a voltage rating as possible, normally at least 300V.

•

Routing of signal wire is important to keep as far away from control and power wiring as possible.

3.4.4 Meggering a Motor

If the motor needs to be meggered, remove the motor leads from the starter before conducting the test. Failure to comply may damage the

SCRs and WILL damage the control board, which WILL NOT be replaced under warranty.

3.4.5 High Pot Testing

If the starter needs to be high pot tested, perform a DC high pot test. The maximum high point voltage must not exceed 2.0 times rated

RMS voltage + 1000VAC (High pot to 75% of Factory). Failure to comply WILL damage the control board, which WILL NOT be

replaced under warranty. An example to find the high point voltage is (2.0 * rated RMS voltage + 1000) * 0.75.

31

3 - INSTALLATION

Power and Control Drawings for Bypassed and Non Bypassed Power Stacks

3.5 Power and Control drawings for Bypassed and Non Bypassed Power Stacks

Figure 9: Power Schematic for RB3 Low HP

32

BIPC-400100-01

MX3 CARD ASSEMBLY

CONSISTS OF BIPC-300055-03 (TOP)

& BIPC-300034-02 (BOTTOM)

stop

reset

START

enter

menu

Starters

Figure 10: Power Schematic for RB3 High HP

3 - INSTALLATION

BIPC-400100-01

MX3 CARD ASSEMBLY

CONSISTS OF BIPC-300055-03 (TOP)

& BIPC-300034-02 (BOTTOM)

reset

stop

START

enter

menu

Starters

33

3 - INSTALLATION

Figure 11: Power Schematic for RC3

34

BIPC-400100-01

MX3 CARD ASSEMBLY

CONSISTS OF BIPC-300055-03 (TOP)

& BIPC-300034-02 (BOTTOM)

reset

stop

START

enter

menu

Starters