BENSH

Use Guid

e

®

890048-01-00

9,I

c.

M2L 3000 Series VFD

2

which can cause personal injury or death

Important Reader Notice

Congratulations on the purchase of your new Benshaw M2L 3000 Medium Voltage Variable Frequency Drive, hereafter referred in this document as the “M2L 3000” or the “drive”.

This User Guide may not cover all of the applications for the M2L 3000, nor can it provide information on every possible contingency concerning installation, programming, operation, or maintenance specific to M2L 3000 VFD systems.

The content of this manual will not modify any prior agreement, commitment or relationship between the customer and Benshaw. The sales contract contains the entire obligation of Benshaw. The warranty enclosed within the contract between the

parties is the only warranty that Benshaw will recognize, and any statements contained herein do not create new warranties or

modify the existing warranty in any way.

Any electrical or mechanical modifications to Benshaw products without prior written consent of Benshaw will void all warranties, and may also void any safety certifications; unauthorized modifications may also result in product damage, operation malfunctions, or personal injury.

Incorrect handling of the drive may result in an unexpected fault or equipment damage. For best results when operating the

M2L 3000 drive, carefully read this manual and all warning labels attached to the system before installation and operation.

Keep this manual on hand for reference.

Do not attempt to install, operate, maintain or inspect the drive until you have thoroughly read this manual and related documents carefully, and can use the equipment correctly.

Do not use the drive until you have a full knowledge of the equipment, safety procedures and instructions.

Symbols

This User Guide classifies safety, protection, and general information levels as Warning,

Caution, and Note.

WARNING: Warns of a physical safety condition or Electrical Hazard

CAUTION: Warns of situations in which equipment damage may occur

NOTE: Indicates a specific piece of information applicable to the use or operation of the drive.

3

M2L 3000 Series VFD

WARNINGS HAZARDS OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH.

Failure to follow the instructions below may result in serious injury or death.

DANGER. This equipment does not provide isolation. Separate isolating

means required. Isolation devices can take several forms with the most

simple being an appropriately sized disconnect switch and contactor pair

utilizing the Inverter ‘Shunt Trip’ controls, or an appropriately sized and

protected vacuum circuit breaker also capable of remote operation from

the inverter ‘Shunt Trip’ controls. See page 32 for more information.

WARNING: At any time the system is energized with Medium Voltage

power, apply appropriate personal protective equipment (PPE) and follow

safe electrical work practices when operating or working near the system.

See NFPA 70E.

Cabinet Fault Limit: <10kA @ 10 Cycles

Min Arc Boundary: 40 Inches

Recommended Min. PPE: #1 at > 40 inches

WARNING: Branch circuit protection is required for the equipment. See

page 32 for more information.

WARNING: Only qualified personnel familiar with the use and hazards of

medium voltage equipment are to perform work described in this set of

instructions.

WARNING: Before performing visual inspections, tests, or maintenance

on the equipment, disconnect all sources of electric power. Assume that

circuits are live until completely de-energized, tested, and tagged.

Pay particular attention to the design of the power system. Consider all

sources of power, including the possibility of backfeeding.

Use a properly rated voltage sensing device to confirm that the power is

fully removed.

WARNING: Always perform applicable lock-out/tag-out procedures (either general or site-specific) before performing any maintenance or troubleshooting on the system.

WARNING: To avoid potentially lethal levels of both AC and DC voltages,

do not remove the cover to access the MV Input/Output section of the Inverter while the Inverter is energized.

WARNING: Equipment may be supplied from multiple power sources.

Refer to drawings for more information.

4

wire

CAUTIONS

WARNING: Potentially hazardous voltages will remain in the cells until

the capacitors are able to de-energize. Wait at least 30 minutes after

main power is removed for the stored voltages to dissipate if removing

the Inverter Cell or Input/Output section covers. Do not rely solely on the

voltage values displayed on the HMI Meter Values screen to determine if

it is safe to remove the covers on the Inverter Cell and Input/Output sections.

WARNING: The Control section contains 240V control power when active. The Control section does not contain medium voltage levels supplied from the mains, and can be carefully accessed by qualified personnel while medium voltage from the AC mains is applied to the system.

WARNING: Replace all devices, doors, and covers before applying

power to this equipment.

WARNING: Do not attempt to lift and position either the Converter or Inverter with a crane without the proper equipment or experience performing this type of operation. Benshaw can arrange the services of professional firms who routinely rig and lift heavy equipment.

CAUTION: Special care must be taken with covers that have a ground

attached to the inside that ties them to ground potential. It is important that the connection integrity of this wire be maintained to avoid

compromising the immunity of the Inverter to Electromagnetic Interference (EMI) and safety.

CAUTION: Always be aware of electrostatic discharge (ESD) when working near or touching components inside the drive. Handling of components sensitive to ESD should be done by qualified personnel only, familiar with ESD mitigation techniques.

CAUTION: Parameter settings and adjustments should be performed by

those familiar with VFD and motor operation characteristics. It is not recommended for users unfamiliar with these concepts.

5

M2L 3000 Series VFD

6

Table of Contents

IMPORTANT READER NOTICE ....................................................................................................................................................................... 3

Symbols ............................................................................................................................................................................................. 3

1 - Introduction .............................................................................................................................................................................. 11

DOCUMENTATION ................................................................................................................................................................................... 11

ON-LINE DOCUMENTATION....................................................................................................................................................................... 11

REPLACEMENT PARTS ............................................................................................................................................................................... 11

PUBLICATION HISTORY ............................................................................................................................................................................. 11

WARRANTY ............................................................................................................................................................................................ 11

CONTACTING BENSHAW ........................................................................................................................................................................... 11

SYSTEM DESIGN FEATURES ........................................................................................................................................................................ 12

PART NUMBER DEFINITIONS ...................................................................................................................................................................... 14

2 - Specifications ............................................................................................................................................................................ 17

GENERAL SPECIFICATIONS ......................................................................................................................................................................... 17

CONVERTER INPUT: ................................................................................................................................................................................. 17

ENVIRONMENTAL .................................................................................................................................................................................... 17

CONDITIONS ........................................................................................................................................................................................... 17

COOLING SYSTEM .................................................................................................................................................................................... 18

CONSTRUCTION ...................................................................................................................................................................................... 18

LIFTING PROVISIONS ................................................................................................................................................................................ 18

MINIMUM CLEARANCE ............................................................................................................................................................................. 18

ELECTRICAL RATINGS – 300A UNIT ............................................................................................................................................................ 19

ELECTRICAL RATINGS – 260A UNIT ............................................................................................................................................................. 20

COMMON ELECTRICAL RATINGS – 260A AND 300A UNITS ............................................................................................................................. 21

3 – Installation ............................................................................................................................................................................... 25

EMC INSTALLATION GUIDELINES ................................................................................................................................................................ 25

WIRING CONSIDERATIONS ........................................................................................................................................................................ 26

WIRING SCHEMATICS ............................................................................................................................................................................... 27

POWER WIRING ...................................................................................................................................................................................... 30

Input Line Requirements ................................................................................................................................................................. 30

Recommended Wire Gauges .......................................................................................................................................................... 30

Power Wire Connections ................................................................................................................................................................. 30

Compression Lugs ........................................................................................................................................................................... 30

Motor Lead Length ......................................................................................................................................................................... 31

Input Line Requirements ................................................................................................................................................................. 31

DC Lead Length Between Converter and Inverter ........................................................................................................................... 31

4 - Theory of Operation ................................................................................................................................................................. 33

M2L 3000 OVERVIEW ............................................................................................................................................................................ 33

CONVERTER............................................................................................................................................................................................ 34

INVERTER ............................................................................................................................................................................................... 36

IGBT Cell .......................................................................................................................................................................................... 36

5 - Operation ................................................................................................................................................................................. 41

INTRODUCTION ....................................................................................................................................................................................... 41

HMI OVERVIEW ..................................................................................................................................................................................... 42

STATUS INDICATORS................................................................................................................................................................................. 43

GETTING THE DRIVE READY ....................................................................................................................................................................... 45

OPERATING THE DRIVE ............................................................................................................................................................................. 46

7

M2L 3000 Series VFD

SELECTABLE VIEW OPTIONS ....................................................................................................................................................................... 47

6 - Parameter List .......................................................................................................................................................................... 57

DRIVE GROUP PARAMETER LIST ................................................................................................................................................................ 57

FUNCTION GROUP PARAMETER LIST ........................................................................................................................................................ 58

AFN (ADVANCED FUNCTION) GROUP PARAMETER LIST .................................................................................................................................. 61

I/O (INPUT/OUTPUT) GROUP PARAMETER LIST ............................................................................................................................................ 62

7 - Parameter Descriptions ............................................................................................................................................................ 73

DRIVE GROUP PARAMETERS ...................................................................................................................................................................... 73

FUNCTION GROUP PARAMETERS ................................................................................................................................................................ 77

AFN (ADVANCED FUNCTION) GROUP PARAMETERS ...................................................................................................................................... 83

I/O (INPUT/OUTPUT) GROUP PARAMETERS ................................................................................................................................................. 85

Digital Input Options ....................................................................................................................................................................... 85

Digital Output Options .................................................................................................................................................................... 87

Analog Input Options ...................................................................................................................................................................... 88

Low/High Parameters Process and Input Value ............................................................................................................................. 89

INVERTER ANALOG OUTPUT FUNCTIONS (I/O-72 THROUGH I/O-79) ............................................................................................................... 90

Analog Output Options ................................................................................................................................................................... 90

ANALOG OUTPUT PARAMETERS (I/O-80 THROUGH I/O-223) ........................................................................................................................ 92

Analog Output Type ........................................................................................................................................................................ 92

Process and Output Value Low/High .............................................................................................................................................. 92

CCI I/O PARAMETERS .............................................................................................................................................................................. 92

8 – Fault Conditions ....................................................................................................................................................................... 93

TABLE KEY ............................................................................................................................................................................................. 93

9 – Spare Parts ............................................................................................................................................................................. 125

SPARE PARTS LIST .................................................................................................................................................................................. 125

References ................................................................................................................................................................................... 127

Appendix A: Profibus-DP Modbus ................................................................................................................................................ 129

PROFIBUS-DP CONNECTION .................................................................................................................................................................... 129

PROFIBUS-DP INPUT DATA ..................................................................................................................................................................... 129

PROFIBUS-DP OUTPUT DATA .................................................................................................................................................................. 131

Glossary ....................................................................................................................................................................................... 133

COMPONENTS ...................................................................................................................................................................................... 133

18-Pulse Transformer ................................................................................................................................................................... 133

2-Position DC Landing Pad ............................................................................................................................................................ 133

3-Position AC Landing Pad ............................................................................................................................................................ 133

Card Cage ..................................................................................................................................................................................... 133

Computer Card .............................................................................................................................................................................. 133

Control Power Transformer .......................................................................................................................................................... 133

Converter ...................................................................................................................................................................................... 133

DC Bus Bar .................................................................................................................................................................................... 134

Disconnect Switch ......................................................................................................................................................................... 134

Dual Diode Module ....................................................................................................................................................................... 134

Ethernet Switch ............................................................................................................................................................................. 134

FOB ............................................................................................................................................................................................... 134

HMI ............................................................................................................................................................................................... 134

IGBT .............................................................................................................................................................................................. 134

8

Inner Air Filter ............................................................................................................................................................................... 134

Inverter ......................................................................................................................................................................................... 134

Inverter IO ..................................................................................................................................................................................... 134

Isolating CT ................................................................................................................................................................................... 135

Loop Power Supply Reactor .......................................................................................................................................................... 135

Loop Power Supply Transformer ................................................................................................................................................... 135

Main Contactor ............................................................................................................................................................................. 135

Main Contactor Relay ................................................................................................................................................................... 135

Modular Fan Assembly ................................................................................................................................................................. 135

Outer Air Filter .............................................................................................................................................................................. 135

Pole Filter ...................................................................................................................................................................................... 135

Power Cell ..................................................................................................................................................................................... 135

Power Cell Back Panel ................................................................................................................................................................... 136

Power FOB .................................................................................................................................................................................... 136

Precharge Board ........................................................................................................................................................................... 136

Precharge Board Cover ................................................................................................................................................................. 136

Precharge Resistor ........................................................................................................................................................................ 136

Rectifier Module ........................................................................................................................................................................... 136

SD Card ......................................................................................................................................................................................... 136

Shunt Trip Relay ............................................................................................................................................................................ 136

Snubber Assembly ......................................................................................................................................................................... 136

Surge Arrestor ............................................................................................................................................................................... 136

Thermal Switch Isolation Receiver Board ..................................................................................................................................... 137

Thermal Switch Isolation Transmitter Board ................................................................................................................................ 137

CONCEPTS............................................................................................................................................................................................ 137

Arm ............................................................................................................................................................................................... 137

ATL ................................................................................................................................................................................................ 137

Control Power ............................................................................................................................................................................... 137

Front End ...................................................................................................................................................................................... 137

Ground Fault ................................................................................................................................................................................. 137

Look Ahead ................................................................................................................................................................................... 138

Loop Power Supply........................................................................................................................................................................ 138

Low Voltage .................................................................................................................................................................................. 138

Medium Voltage ........................................................................................................................................................................... 138

Precharge ...................................................................................................................................................................................... 138

VFD ............................................................................................................................................................................................... 138

Revision History ........................................................................................................................................................................... 140

9

M2L 3000 Series VFD

10

1 - Introduction

A brief description of the application

1 - Introduction

Benshaw personnel are available to answer all inquiries including information regarding start-up services and on-site training. Refer to the following pages for contact information.

Documentation

On-Line Documentation

Replacement Parts

Publication History

Warranty

Contacting Benshaw

Benshaw can provide all customers with:

User Guides

Drawings / Wiring Diagrams

Drawings are available on CD / DVD or via e-mail by contacting Benshaw Customer

Service.

All MVVFD documentation is available on-line at www.benshaw.com.

Spare and replacement parts can be purchased from Benshaw Technical Support.

Refer to the inside back cover.

Benshaw provides a standard 5 Year factory warranty on the M2L 3000 MVVFD System.

Information about all Benshaw products and services is available on the internet at

www.benshaw.com, or by contacting Benshaw at one of the following offices:

Benshaw Corporate Headquarters Benshaw Canada

615 Alpha Drive

Pittsburgh, PA 15238

Phone: 412-968-0100

Tech Support: 1-800-203-2416

Fax: 412-968-5415

Technical support is available by contacting Benshaw Customer Service at any of the

above telephone numbers. A service technician is available Monday through Friday from

8:00 a.m. to 5:00 p.m. EST.

NOTE: An on-call technician is available after normal business hours and on weekends. Call Benshaw and follow the recorded instructions.

550 Bright Street East

Listowel, Ontario N4W 3W3

Phone: 519-291-5112

Tech Support: 1-877-291-5112

Fax: (519) 291-2595

To help assure prompt and accurate service, please have the following information

available when contacting Benshaw:

Name of Company

Telephone number where the caller can be contacted

Fax number of caller

Benshaw product name

Benshaw model number

Benshaw serial number

Name of product distributor

Approximate date of purchase

11

M2L 3000 Series VFD

System Design Features

Compact Modular Design

Simplistic component arrangement with minimal total part count compared to

competitive offerings

Unique modular power inverter

o Voltage requirements met by configuring standard IGBT cells

o Self-healing film capacitors that do not need reforming, superior to

common electrolytics

o Field maintenance and repair using pre-assembled, pre-tested power

cells

o Internal communication through high-speed fiber optics using Ethernet

protocol for high noise immunity and high bandwidth

Installation Flexibility

Robust Control Architecture

Arc Flash Resistant Design

Patented topology that enables extended separation of converter and inverter

sections

Uses a standard input transformer in the converter that can accommodate a

wide range of input voltages (480 - 13.8 kV)

Interconnection using standard high-voltage cable

Reduced heat load and space requirements in environmentally-conditioned

equipment rooms with a remotely located converter

Customer sourcing of the transformer (per Benshaw’s specification)

Operation directly from customer DC bus (per Benshaw’s specification)

Remote or direct mounted HMI and optional controls

Modern Control Platform

Distributed control with intelligent power cells

Ultra-fast dual core processor for high-speed processing and expansion capa-

bility

Industry-standard card cage

o Front access for easy removal and replacement

o Low Voltage Differential Signaling backplane - EMI resistant

Industry standard field buses and communication protocols

Profibus DP, Modbus TCP/IP, http, Ethernet IP, DeviceNet, via built in compo-

nents or industrial gateways

Benshaw Connect for monitoring, parameter setting, and review of event logs

at the drive or over the internet via optional modem

Arc flash footprint inherently lower

o Utilizes distributed energy storage

o No centralized bulk storage capacitors

o Optical arc flash detection in each power cell

o Offending cell is immediately reported to the control system

Fault currents greatly reduced compared to other VFDs

o Converter will not feed energy into faults

Increased user safety work envelope

o Remote control via HMI, industrial gateway, digital and analog I/o, or

Benshaw Connect PC tool

12

User Interface

1 - Introduction

Intuitive, user-friendly touch screen

No need to remember multi-use key assignments used on other low-end user

interfaces

Benshaw Connect Tool Suite

o Application allows for seamless connectivity between a PC and the drive

o Easy to use configuration and diagnostic tool

o Windows-based tool for use on Windows XP, Windows 7 and Windows 10

Energy Efficiency

Energy Savings

Unique modular inverter design has improved efficiency over Cascaded H-

Bridge and Neutral Point Clamped (NPC) inverter designs.

Uses the latest in efficient IGBT designs for minimum losses and maximum

performance.

Inverter efficiency >99% over a wide speed range and wide load range

Modular inverter design allowing the input converter to operate more effi-

ciently than other inverter designs reducing losses

No efficiency reducing output transformers or output filters are required

Input power supply power factor of ≥0.95 minimizes losses in the power sup-

ply and input wiring

Shaft power of motor driven equipment (fans, pumps, blower) is proportional

to the cube of the rotational speed

By design, VFDs improve efficiency at low speeds

Considerable energy savings can be achieved by outfitting motors with VFDs,

as the speed can be adjusted to match the required load

13

M2L 3000 Series VFD

UL Applicable Base Part Numbers:

Part Number Definitions

14

1 - Introduction

NOTE: Only the 260A and 300A models are presently available as UL listed models.

15

M2L 3000 Series VFD

16

2 - Specifications

General Specifications

Inverter Output –

Variable Torque:

2 - Specifications

Rated Output Power Up to 9 MW

Output Voltage 0 – 7200 Volts

Converter Input:

Environmental

Output Frequency (Min/Max) 0.1 – 300 Hz

Rated Output Currents Available 130A, 260A, 300A, 440A, 550A, 660A, 770A

Required Auxiliary Supply 230 VAC (-0%/+10%), 60 Hz

Rated Supply Voltage 480 – 13.8 kV

Rated System Frequency 50 – 66 Hz

Input Distortion Meets IEEE 519 when using 18-pulse or

greater rectifier system

Voltage Variations Steady State: +/- 10%

Transient State: +10%, -30% for 30 Line Cycles

Frequency Variations Steady State: 95 - 105%

Transient State: +/-5% / sec

Ambient Temperature Min. 0o C (no frost), Max. 40o C

Conditions

Humidity 95%, no condensation

Air Quality No corrosive gasses or semi-conductive dust

Pollution IEC 61010-1 and UL 840 Degree 2

IEC 60664-3 (Optional)

Seismic IBC-2006 (3G on stiff soil)

Altitude 1,000 meters

4,000 meters derated operation

17

M2L 3000 Series VFD

Cooling System

Construction

Power Connection Type

Auxiliary Cable Entry Bottom or Top

Lifting Provisions

Minimum Clearance

Cooling Method

Inverter/Converter

Fans Designed for N-1

Redundancy

Fans Designed for N-1 Redundancy

Heat Loss at Full Load (max)

Inverter

Converter

Power Connection Entry Bottom or Top

Inverter

Converter

Integral channel slots in bottom cabinet frames

(Front x Back x Sides x Above) 36 x 0 x 0 x 36 inches

Forced Air

<1% Full Load kW

<2% Full Load kW

Cables

Cables

18

2 - Specifications

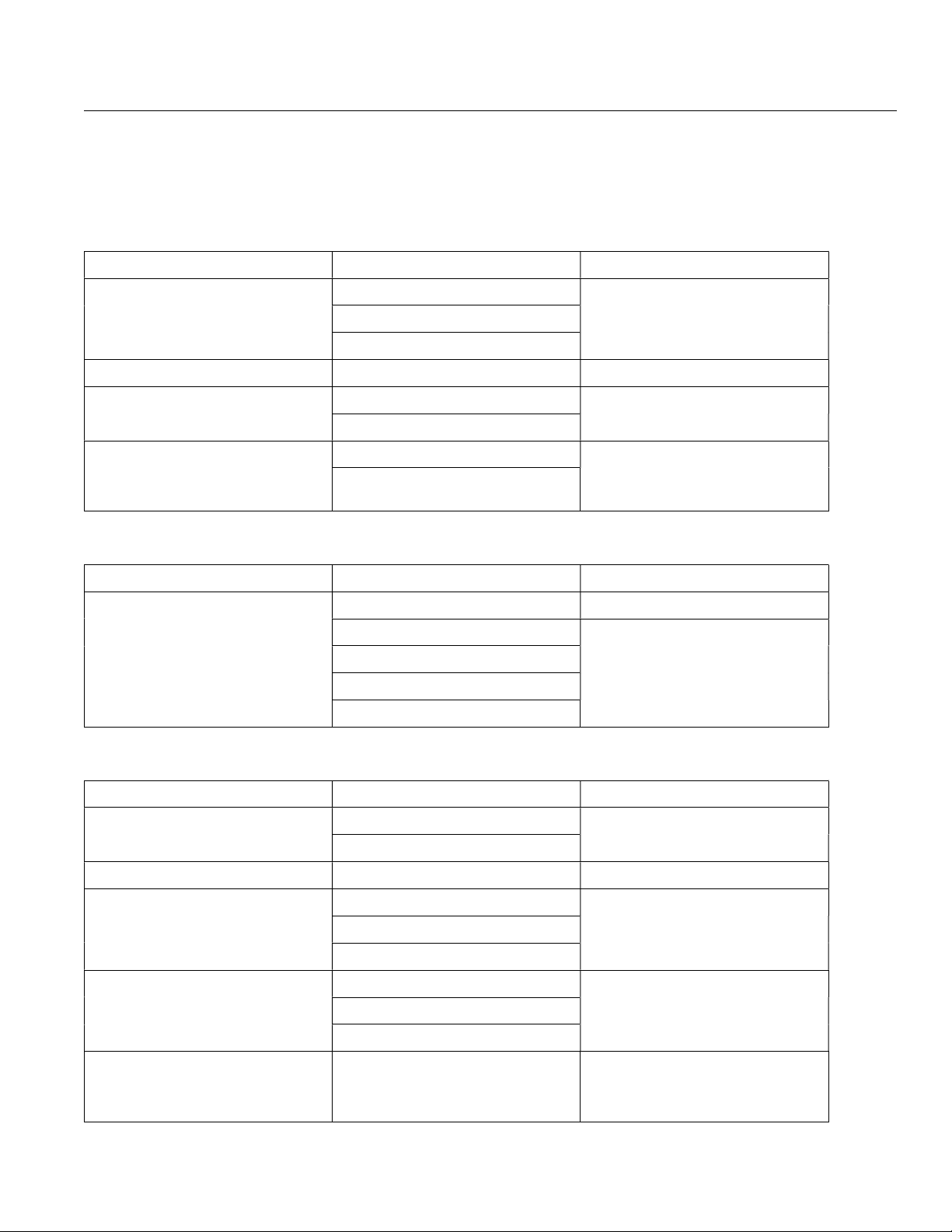

Electrical Ratings – 300A Unit

Terminal Points and Functions

Table 1: Converter Power Wiring Terminals

Function Terminal Description

AC Line Power Input H1 (L1/R) 3 Phase AC Line Power to Con-

H2 (L2/S)

H3 (L3/T)

Chassis Ground CG Ground Input

DC Power Output DC (+) DC Power to Inverter

DC (-)

AC Control Power Input FU10 (L) Single Phase AC Control Power

FU11 (N)

Table 2: Converter Control Wiring Terminals

verter (Transformer Terminals)

4160VAC 260A 50/60Hz.

6300VDC 292A

from Inverter (for Fans)

230VAC 20A 50/60Hz.

Function Terminal Description

Control Wiring to / from Converter TB1-6 (relay common) 115VAC from Inverter

TB1-6TW (relay NC contact) 3A 125VAC

TB1-6TF (relay NC contact)

TB1-6CW (relay NC contact)

TB1-6CF (relay NC contact)

Table 3: Inverter Power Wiring Terminals

Function Terminal Description

DC Bus Power Input DC (+) DC Bus Power from Converter

DC (-)

Ground CG Chassis Ground

AC Motor Power Output T1 3 Phase AC Power to Motor

T2

T3

AC Control Power Input TB1-4 (L) Single Phase AC Control Power to

TB1-5 (N)

TB1-GND

6300VDC 292A

0 to 4160VAC 300A

0 to 60Hz. PWM

Inverter

230VAC 40A 50/60Hz.

AC Control Power Output TB2-4D

TB2-5D

Single Phase AC Control Power to

Converter (for Fans)

230VAC 20A 50/60Hz.

19

M2L 3000 Series VFD

Electrical Ratings – 260A unit

Terminal Points and Functions

Table 4: Converter Power Wiring Terminals

Function Terminal Description

AC Line Power Input H1 (L1/R) 3 Phase AC Line Power to Con-

H2 (L2/S)

H3 (L3/T)

Chassis Ground CG Ground Input

DC Power Output DC (+) DC Power to Inverter

DC (-)

AC Control Power Input FU10 (L) Single Phase AC Control Power

FU11 (N)

Table 5: Converter Control Wiring Terminals

verter (Transformer Terminals)

4160VAC 230A 50/60Hz.

6300VDC 259A

from Inverter (for Fans)

230VAC 20A 50/60Hz.

Function Terminal Description

Control Wiring to / from Converter TB1-6 (relay common) 115VAC from Inverter

TB1-6TW (relay NC contact) 3A 125VAC

TB1-6TF (relay NC contact)

TB1-6CW (relay NC contact)

TB1-6CF (relay NC contact)

Table 6: Inverter Power Wiring Terminals

Function Terminal Description

DC Bus Power Input DC (+) DC Bus Power from Converter

DC (-)

Ground CG Chassis Ground

AC Motor Power Output T1 3 Phase AC Power to Motor

T2

T3

AC Control Power Input TB1-4 (L) Single Phase AC Control Power to

TB1-5 (N)

TB1-GND

6300VDC 259A

0 to 4160VAC 260A

0 to 60Hz. PWM

Inverter

230VAC 40A 50/60Hz.

AC Control Power Output TB2-4D

TB2-5D

20

Single Phase AC Control Power to

Converter (for Fans)

230VAC 20A 50/60Hz.

Common Electrical Ratings – 260A and 300A Units

Table 7: Inverter Control Wiring Terminals

Function Terminal Description

Control Wiring to / from Inverter TB5-6 115VAC to Converter

TB6-6TW 120VAC Digital Inputs

TB6-6TF

TB6-6CW

TB6-6CF

2500V optical isolation

2.3mA current draw

Off: 0-40VAC, On: 79-120VAC

2 - Specifications

Control Wiring to Shunt Trip Circuit

Breaker from Inverter

Table 8: Inverter Signal Wiring Terminals (To Customer)

Function Terminal Description

Signal Wiring from Inverter TB7-60 (AO1) 4 – 20mA Analog Outputs

Table 9: Inverter Control Wiring Terminals (From Customer)

Function Terminal Description

TB6-100 (relay NC contact) Resistive: 10A

TB6-101 (relay common)

TB6-102 (relay NO contact)

TB7-61 (AO1 COM)

TB7-62 (AO3)

TB7-63 (AO3 COM)

TB7-64 (AO2)

TB7-65 (AO2 COM)

TB7-66 (AO4)

TB7-67 (AO4 COM)

Inductive: 7A

20mA / 5VDC minimum

500V optical isolation

600 ohm load maximum

Control Wiring to Inverter TB7-68 (DI4) 120VAC Digital Inputs

TB7-69 (DI5)

TB7-70 (DI7)

TB7-71 (DI6)

TB7-80 (DI11)

TB7-81 (DI10)

TB7-82 (DI12)

2500V optical isolation

2.3mA draw

Off: 0-40VAC, On: 79-120VAC

21

M2L 3000 Series VFD

Table 10: Inverter Signal Wiring Terminals (From Customer)

Function Terminal Description

Signal Wiring to Inverter TB7-72 (AI1) 4 – 20mA Analog Inputs

TB7-73 (AI1 COM)

TB7-74 (AI3)

TB7-75 (AI3 COM)

TB7-76 (AI2)

TB7-77 (AI2 COM)

TB7-78 (AI4)

TB7-79 (AI4 COM)

Table 11: Inverter Control Wiring Terminals (To Customer)

Function Terminal Description

Control Wiring from Inverter TB7-83 (DO2) 230VAC Relay Outputs

500V optical isolation

<100 ohm input resistance

TB7-84 (L2)

TB7-85 (DO3)

TB7-86 (L1)

TB7-87 (DO4)

TB7-88 (L2)

TB7-89 (DO5)

TB7-90 (L1)

TB7-91 (DO6)

TB7-92 (L2)

2500V optical isolation

2A maximum

10mA / 5VDC minimum

22

2 - Specifications

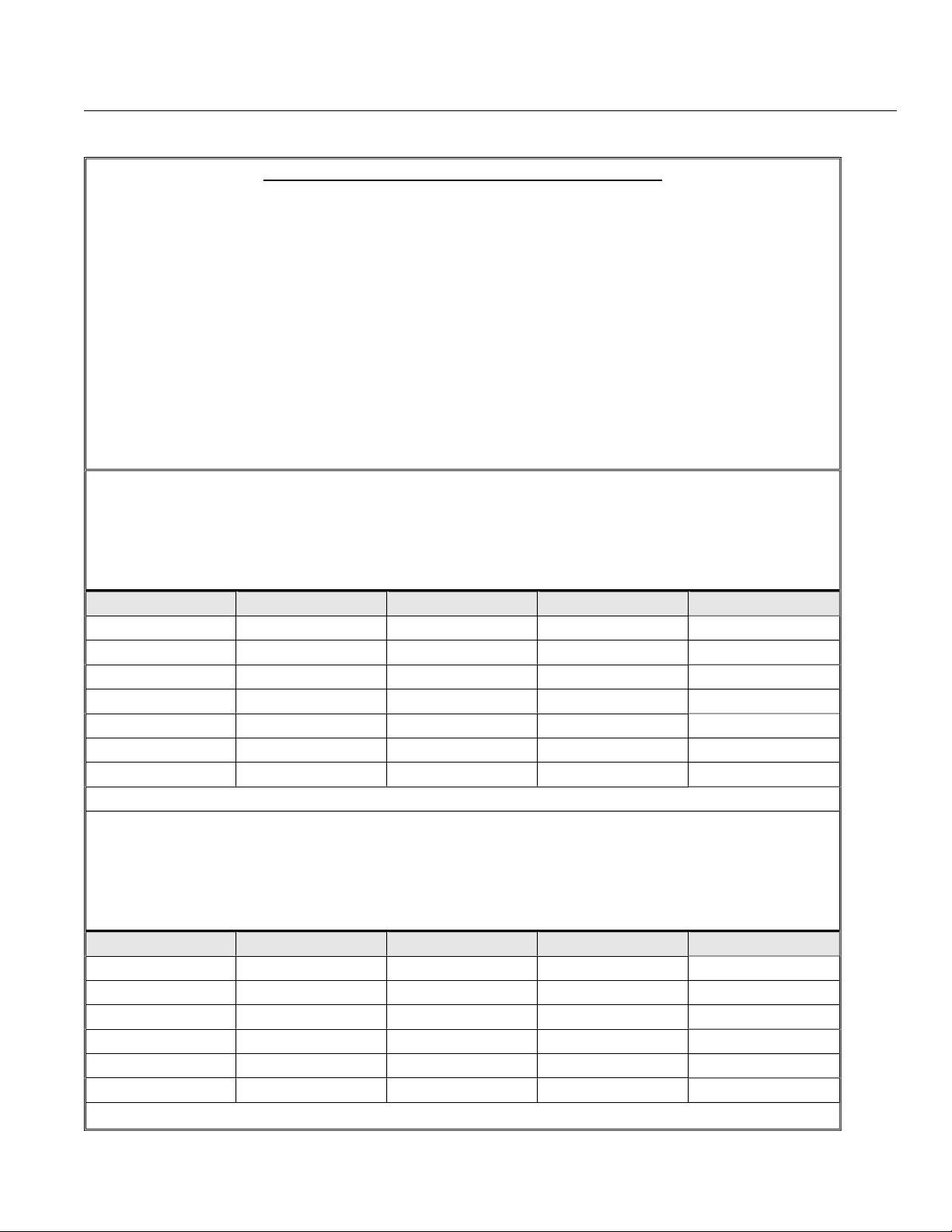

Table 12: UL Ratings Label / Nameplate 300A

MEDIUM VOLTAGE CONVERSION EQUIPMENT XXXX PA

UL MODEL NO: XCSUAC6CO + M2LU6CGE10

DESCRIPTION: CONVERTER + INVERTER

HP: 2250

NOM. INPUT: 4160 VAC, 260 A, 3Ø, 60 Hz

MAX. INPUT: 4576 VAC, 285 A.

OUTPUT: 0 – 4160 VAC, 300 A, 3Ø, 0 – 60 Hz

SHORT CIRCUIT WITHSTAND RATING: 50 KA @ 4160 V

RESISTENCIA A CORTOCIRCUITOS: 50 KA @ 4160 V

INDICE DE RESISTANCE AUX COURTS-CIRCUITS: 50 KA @ 4160 V

BIL RATING: 45 KV ALTITUDE CLASS 2000m

DILECTRIC RATING: 16975 VDC

BENSHAW ITEM NO.: XCSUAC6CO (Enclosure 1 of 2)

SERIAL NO.:

INPUT: 4160 VAC, 260A, 3Ø, 60 Hz

TRANSITION OUTPUT: 6200 VDC, 300 ADC

CONTROL VOLTAGE: 230 VAC, 20 A, 1Ø, 60 Hz (FROM Enclosure 2 of 2)

FUSE # MFR MODEL AMPS VOLTS

FU1,FU2.FU3 MERSEN A150X 300 1500

FU4,FU5,FU6 MERSEN A150X 300 1500

FU7,FU8,FU9 MERSEN A150X 300 1500

*FU10,FU11 MERSEN ATDR 20 600

FU12A,FU12B MERSEN CC1500CP 20 1500

FU13A,FU13B MERSEN CC1500CP 20 1500

FU14A,FU14B MERSEN CC1500CP 20 1500

*WARNING: FUSES MAY BE ENERGIZED / LAB-100435-01

BENSHAW ITEM NO.: M2LU6CGE10 (Enclosure 2 of 2)

SERIAL NO.:

TRANSITION INPUT: 6200 VDC, 300 ADC

OUTPUT: 0 – 4160 VAC, 300 A, 30, 0 – 60 Hz

INPUT CONTROL VOLTAGE: 230 VAC, 40 A, 10, 60 Hz

FUSE # MFR MODEL AMPS VOLTS

*FU1,FU2 MERSEN AJT 40 600

*FU3,FU4 MERSEN ATQR 10 600

*FU5,FU6 MERSEN ATQR 3 600

*FU7,FU8 MERSEN ATQR 10 600

*FU9,FU10 MERSEN ATQR 20 600

*FU11,FU12 MERSEN ATQR 15 600

*WARNING: FUSES MAY BE ENERGIZED / LAB-100436-01

23

M2L 3000 Series VFD

Table 13: UL Ratings Label / Nameplate 260A

MEDIUM VOLTAGE CONVERSION EQUIPMENT XXXX PA

UL MODEL NO: XCSUAC6CN + M2LU6CFE10

DESCRIPTION: CONVERTER + INVERTER

HP: 2000

NOM. INPUT: 4160 VAC, 230 A, 3Ø, 60 Hz

MAX. INPUT: 4576 VAC, 253 A.

OUTPUT: 0 – 4160 VAC, 300 A, 3Ø, 0 – 60 Hz

SHORT CIRCUIT WITHSTAND RATING: 50 KA @ 4160 V

RESISTENCIA A CORTOCIRCUITOS: 50 KA @ 4160 V

INDICE DE RESISTANCE AUX COURTS-CIRCUITS: 50 KA @ 4160 V

BIL RATING: 45 KV ALTITUDE CLASS 2000m

DILECTRIC RATING: 16975 VDC

BENSHAW ITEM NO.: XCSUAC6CN (Enclosure 1 of 2)

SERIAL NO.:

INPUT: 4160 VAC, 230A, 3Ø, 60 Hz

TRANSITION OUTPUT: 6200 VDC, 300 ADC

CONTROL VOLTAGE: 230 VAC, 20 A, 1Ø, 60 Hz (FROM Enclosure 2 of 2)

FUSE # MFR MODEL AMPS VOLTS

FU1,FU2.FU3 MERSEN A150X 300 1500

FU4,FU5,FU6 MERSEN A150X 300 1500

FU7,FU8,FU9 MERSEN A150X 300 1500

*FU10,FU11 MERSEN ATDR 20 600

FU12A,FU12B MERSEN CC1500CP 20 1500

FU13A,FU13B MERSEN CC1500CP 20 1500

FU14A,FU14B MERSEN CC1500CP 20 1500

*WARNING: FUSES MAY BE ENERGIZED / LAB-100442-01

BENSHAW ITEM NO.: M2LU6CFE10 (Enclosure 2 of 2)

SERIAL NO.:

TRANSITION INPUT: 6200 VDC, 259 ADC

OUTPUT: 0 – 4160 VAC, 260 A, 3Ø, 0 – 60 Hz

INPUT CONTROL VOLTAGE: 230 VAC, 40 A, 1Ø, 60 Hz

FUSE # MFR MODEL AMPS VOLTS

*FU1,FU2 MERSEN AJT 40 600

*FU3,FU4 MERSEN ATQR 10 600

*FU5,FU6 MERSEN ATQR 3 600

*FU7,FU8 MERSEN ATQR 10 600

*FU9,FU10 MERSEN ATQR 20 600

*FU11,FU12 MERSEN ATQR 15 600

*WARNING: FUSES MAY BE ENERGIZED / LAB-100443-01

24

3 - Installation

3 – Installation

EMC Installation Guidelines

General

In order to help our customers comply with European electromagnetic compatibility standards, Benshaw

Inc. has developed the following guidelines.

Attention

This product has been designed for Class A equipment. Use of the product in domestic environments may cause

radio interference, in which case the installer may need to use additional mitigation methods.

Enclosure

Install the product in a grounded metal enclosure.

Grounding

Connect a grounding conductor to the screw or terminal provided as standard on each controller. Refer to lay

out/power wiring schematic for grounding provision location.

Wiring

Refer to Wiring Practices on page 26.

25

M2L 3000 Series VFD

Wiring Considerations

Wiring Practices

When making power and control signal electrical connections, the following should be observed:

Never connect input AC power to the motor output terminals T1/U, T2/V, or T3/W.

Power wiring from the power source and to the motor must have the maximum possible physical separation-

from all other wiring. Do not run control wiring or signal wiring in the same conduit; this separation reduces

the possibility of coupling electrical noise between circuits. Minimum spacing between metallic conduits containing different wire groups should be three inches (8cm).

Minimum spacing between different wiring groups in the same wire tray should be six inches (15 cm)

Wire runs outside an enclosure should be run in metallic conduit or have shielding/armor with equivalent atten-

uation.

Whenever power and control or signal wiring cross, it should be at a 90 degree angle.

Different wire groups should be run in separate conduits.

NOTE: Local electrical codes must be adhered to for all wiring practices.

Considerations for Control and Power Wiring

Control wiring refers to wires connected to control terminal strips that normally carry 24V to 115V. AC Power wiring

refers to wires connected to the line and load terminals that normally carries 4160VAC. Power wiring for cabinet

fans carries 240VAC. DC Power wiring refers to wires connected to terminals that normally carry 6400VDC. Select

power wiring as follows:

Use only UL or CSA recognized wire.

Grounding must be in accordance with NEC, CEC, or local codes. If multiple Drives are installed, then each

Drive must be individually connected to ground. Take care not to form a ground loop. The grounds should be

connected in a STAR configuration.

Considerations for Signal Wiring

Signal wiring refers to the wires connected to control terminal strips that are low voltage signals, below 15V.

Shielded wire is recommended to prevent electrical noise interference from causing improper operation or nui-

sance tripping.

Signal wire rating should carry as high of a voltage rating as possible, normally at least 300V.

It is important to keep the routing of signal wiring as far away from control and power wiring as possible.

Meggering a Motor

If the motor needs to be meggered, remove the motor leads from the Drive before conducting the test. Failure to

comply may damage the IGBTs and WILL damage the control circuitry, which WILL NOT be replaced under warranty.

High Pot (High Potential) Testing

If the Drive needs to be high pot tested, perform a DC high pot test. The maximum high pot voltage must not exceed 8520VDC. Failure to comply WILL damage the control circuitry, which WILL NOT be replaced under warranty.

Note: For Inverter High Pot Test, both control cables connected to the sides of the Pre-Charge Board need to

be temporarily disconnected.

26

Wiring Schematics

3 - Installation

Figure 1: MV Drive System Layout

27

M2L 3000 Series VFD

Figure 2: Converter Power and Control Circuit Portions

28

Figure 3: Inverter Power and Control Circuit Portions

3 - Installation

29

M2L 3000 Series VFD

1/0 BLU-1/0S20

500 MCM

BLU-050S2

2/0 BLU-2/0S4

600 MCM

BLU-060S1

3/0 BLU-3/0S1

650 MCM

BLU-065S5

4/0 BLU-4/0S1

750 MCM

BLU-075S

250 MCM

BLU-025S 800 MCM

BLU-080S 300 MCM

BLU-030S 1000 MCM

BLU-100S

350 MCM

BLU-035S 1500 MCM

BLU-150S 400 MCM

BLU-040S4

2000 MCM

BLU-200S

1/0 BLU-1/0D20 500 MCM

BLU-050D2

2/0 BLU-2/0D4 600 MCM

BLU-060D1

3/0 BLU-3/0D1 650 MCM

BLU-065D5

4/0 BLU-4/0D1 750 MCM

BLU-075D 250 MCM

BLU-025D 800 MCM

BLU-080D

300 MCM

BLU-030D 1000 MCM

BLU-100D

350 MCM

BLU-035D 1500 MCM

BLU-150D

400 MCM

BLU-040D4

2000 MCM

BLU-200D 450 MCM BLU-045D1

Power Wiring

Input Line Requirements

The input line source needs to be an adequate source to start the motor, generally 2 times the rating of the motor

FLA. (This may not apply in some cases such as being connected to a generator).

Recommended Wire Gauges

The wire gauge selection is based on the FLA of the motor. Refer to NEC table 310, 60 or CEC Part 1, Table 2 or

local code requirements for selecting the correct wire sizing. Ensure appropriate wire derating for temperature is

applied. In some areas local codes may take precedence over the NEC or CEC. Refer to your local requirements.

Power Wire Connections

Attach the motor cables:

• Use the T1, T2 and T3 terminals. Use lugs/crimps or terminals (lugs and crimps are to be provided by the

customer).

Attach the power source cables:

• Use the L1, L2 and L3 terminals. Use lugs/crimps or terminals (lugs and crimps are to be provided by the

customer).

Compression Lugs

The following is a list of the recommended crimp-on wire connectors manufactured by Penn-Union Corp. for copper

wire.

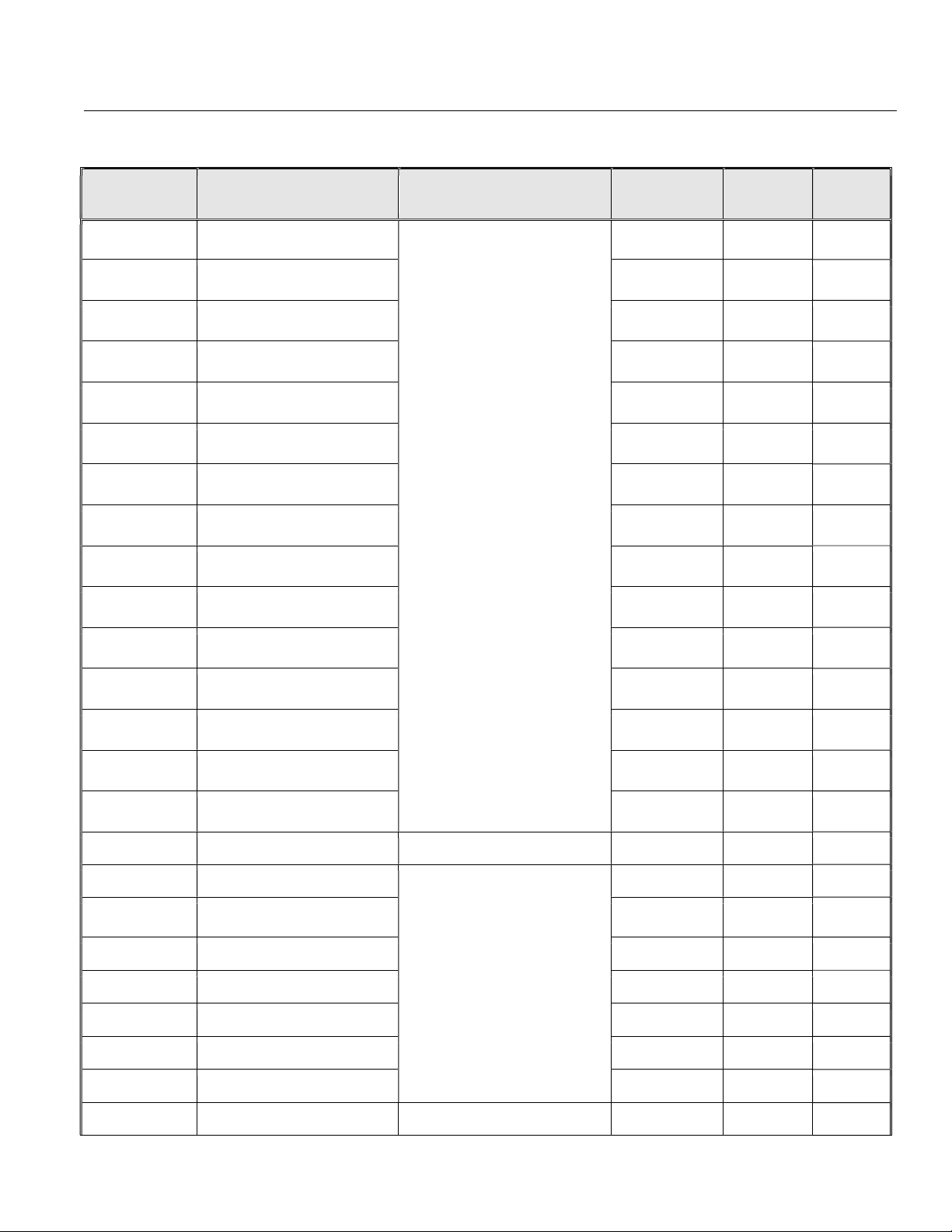

Table 14: Single Hole Compression Lugs

Wire Size Part # Wire Size Part #

450 MCM BLU-045S1

Table 15: Two Hole Compression Lugs

Wire Size Part # Wire Size Part #

30

3 - Installation

inch (1.2mm) or less

0.047 inch (1.2mm)

value of slot width or length not corresponding to those specified above, the largest torque value associated with the

Motor Lead Length

The standard drive can operate a motor with a maximum of 600 feet of properly sized cable between the “T” leads

of the drive and those of the motor. For wire runs greater than 600 feet contact Benshaw Inc. for application assis

tance.

Input Line Requirements

The standard drive can operate with a maximum of 300 feet of properly sized cable between the converter and the

inverter.

For wire runs greater than 300 feet, contact Benshaw for application assistance.

DC Lead Length Between Converter and Inverter

The converter and inverter can be located separate from each other. However, the maximum separation distance is

limited by the voltage drop of the wiring. The wire gauge must be chosen to minimize voltage drop. The wiring should comply with all local electrical codes, as stated on previous page. Consult Benshaw for more information.

Torque Requirements for Power Wiring Terminations

Table 16: Slotted Screws and Hex Bolts

Wire size installed in

conductor

AWG or kcmil (mm²)

18 - 10 (0.82 - 5.3) 20 (2.3) 35 (4.0) 80 (9.0) 75 (8.5)

8 (8.4) 25 (2.8) 40 (4.5) 80 (9.0) 75 (8.5)

6 - 4 (13.3 - 21.2) 35 (4.0) 45 (5.1) 165 (18.6) 110 (12.4)

3 (26.7) 35 (4.0) 50 (5.6) 275 (31.1) 150 (16.9)

2 (33.6) 40 (4.5) 50 (5.6) 275 (31.1) 150 (16.9)

1 (42.4) -- -- 50 (5.6) 275 (31.1) 150 (16.9)

1/0 - 2/0 (53.5 -64.4) -- -- 50 (5.6) 385 (43.5) 180 (20.3)

3/0 - 4/0 (85.0 - 107.2) -- -- 50 (5.6) 500 (56.5) 250 (28.2)

250 - 350 (127-177) -- -- 50 (5.6) 650 (73.4) 325 (36.7)

400 (203) -- -- 50 (5.6) 825 (93.2) 375 (42.4)

500 (253) -- -- 50 (5.6) 825 (93.2) 375 (42.4)

600 - 750 (304-380) -- -- 50 (5.6) 1000 (113.0) 375 (42.4)

800 - 1000 (406-508) -- -- 50 (5.6) 1100 (124.3) 500 (56.5)

1250 - 2000 (635-1010) -- -- -- -- 1100 (124.3) 600 (67.8)

Slotted head NO.10 and larger Hexagonal head-external drive socket wrench

Slot width 0.047

and slot length ¼

inch (6.4mm) or less

Slot width over

or slot length ¼

inch (6.4mm) or

Tightening torque, pound-inches (N-m)

Split-bolt connectors Other connectors

greater

NOTE: For a

conductor size shall be marked. Slot width is the nominal design value. Slot length is measured at the bottom of the slot.

31

M2L 3000 Series VFD

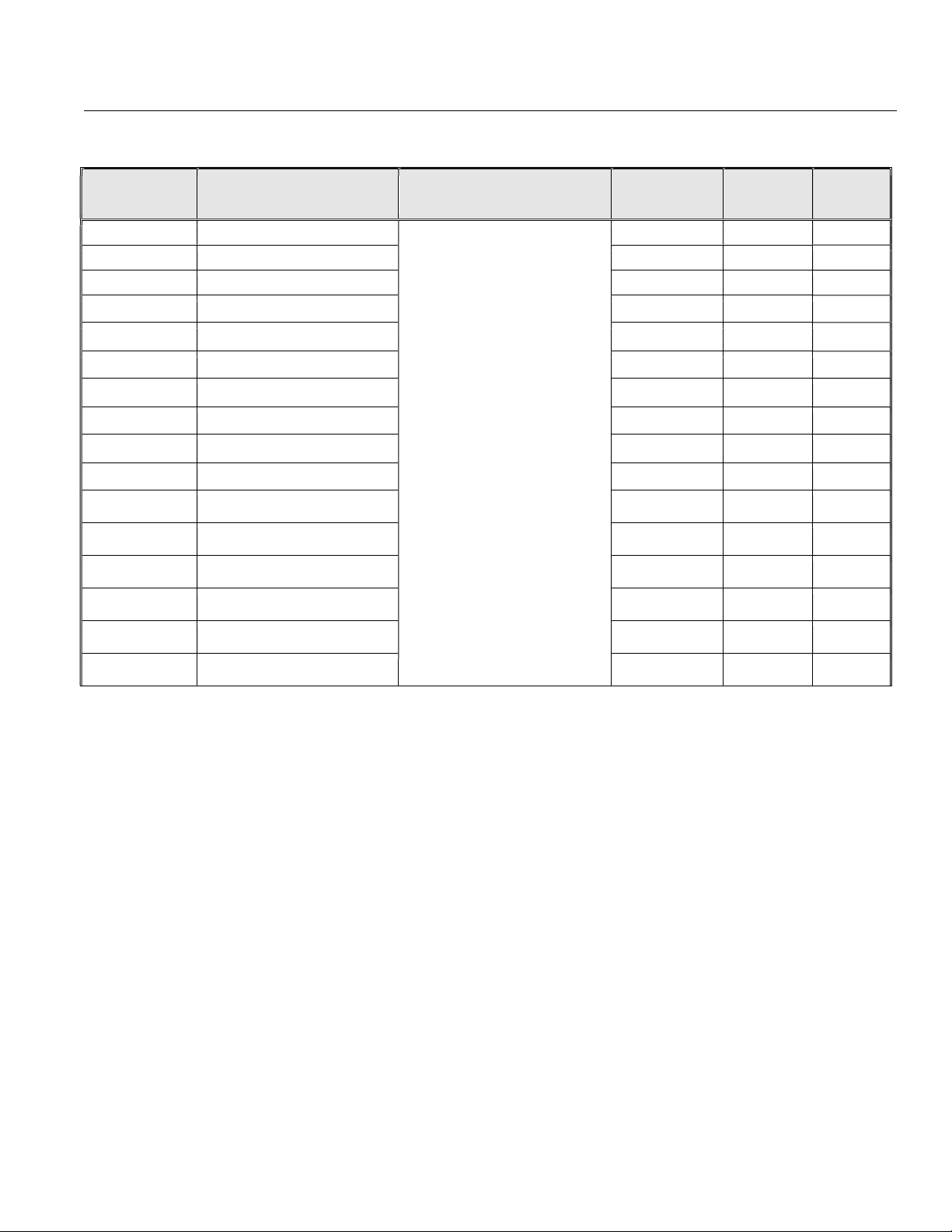

Socket size across flats Tightening torque

Inches (mm) Pound-inches (N-m)

1/8 (3.2) 45 (5.1)

5/32 (4) 100 (11.3)

3/16 (4.8) 120 (13.6)

7/32 (5.6) 150 (16.9)

1/4 (6.4) 200 (22.6)

5/16 (7.9) 275 (31.1)

3/8 (9.5) 275 (42.4)

1/2 (12.7) 500 (56.5)

9/16 (14.3) 600 (67.8

NOTE: For screws with multiple tightening means, the largest torque value associated with the conductor size shall be marked. Slot length shall be measured at the

bottom of the slot..

DANGER. This equipment does not provide isolation. Separate isolating means required. Isolation devices can

take several forms with the most simple being an appropriately sized disconnect switch and contactor pair utilizing the Inverter ‘Shunt Trip’ controls, or an appropriately sized and protected vacuum circuit breaker also capable of remote operation from the inverter ‘Shunt Trip’ controls.

WARNING: Primary power source overcurrent protection is required. For disconnect switch and contactor pairs,

the components must be sized to accommodate the following fuse size ratings per chart below: (this also includes the table requirement of the list)

Table 17: Tightening Torque for Hex Screws

4160 Volt 260 Amp VFD; 300E 5500V fuse Mersen A055F2DORO-300E or equiv.

4160 Volt 300 Amp VFD; 350E 5500V fuse Mersen A055F2DORO-350E or equiv.

This unit provides electronic motor overload protection, refer to pages 77-79 for setup and operational details.

Grounding of the Inverter System: Install ground connections for the inverter system (transformer rectifier

converter and inverter) and the motor by following the correct specifications to ensure safe and accurate operation. Using the inverter and the motor without the specified grounding connections may result in electric shock

and damage to the equipment. This shall include all input, output, and DC shielded power cable connection

grounds as applicable per installation.

32

4 – Theory of Operation

4 - Theory of Operation

The Benshaw M2L 3000 family of medium voltage variable frequency motor drives features a unique power circuit, and a

state-of-the-art control platform, to provide the utmost in performance and application flexibility.

The M2L 3000 product family is forced-air cooled, and spans a power range from 300 hp to 6,200 hp, operating at industry

standard medium voltages up to 7200 VAC output. The drives can be used to control induction and wound field synchronous motors.

This section provides an overview of the drive architecture, along with descriptions of major system components.

M2L 3000 Overview

The M2L 3000 variable frequency drive consists of two major system elements, shown in Figure 4; A Converter (Input

Power Stage) and an Inverter (Output Power Stage). The purpose of the Converter is to convert incoming voltage from the

AC mains into DC. The DC is passed to the Inverter using standard high-voltage shielded cable, where it is converted into

variable voltage, variable frequency 3-phase AC, then applied to the motor.

AC

AC

Mains

Input

Power

Stage

DC

Inverter

Stage

Output

Motor

Figure 4: Benshaw M2L 3000 Block Digrams

Most modern MV VFDs employ dual energy conversions (i.e. AC-to-DC and AC-to-DC), but are constrained to have these

constituent elements located in close physical proximity to each other, to avoid electrical complications that would compromise the operation of the drive, and adversely affect reliability. The M2L 3000 is not constrained in this manner. The Inverter

can be located adjacent to, or remotely from, the Converter without causing any adverse affects on the operation of the

drive. This feature imparts great application flexibility to users who may have space constraints, or choose to locate the heat

producing Converter away from environmentally conditioned equipment rooms or spaces.

33

M2L 3000 Series VFD

Converter

The Converter, or Input Stage, consists of a medium voltage transformer and full-bridge rectifiers that convert the incoming AC mains

voltage to a fixed source of DC. Individual 3-phase bridge rectifiers

are connected in series, as shown in Figure 5, to produce the required DC voltage for the inverter.

The Converter does not contain any capacitors for energy storage.

Energy storage in the drive is distributed among identical power

modules in the drive’s Inverter. The distributed capacitive energy

storage greatly reduces arc flash potential and substantially improves reliability.

The transformer is a standard rectifier grade transformer consisting

of a single 3-phase primary winding, with three (3) secondary windings, appropriately phase shifted to yield an 18-pulse current waveform in the primary for low harmonic distortion. The total harmonic

distortion (THD) of the primary current is typically ~2.3% for a 1000

hp, 4160 VAC drive operating at full power, which easily complies

with IEEE 519 distortion requirements.

Typically, the primary voltage of the transformer is identical to the AC

operating voltage of the motor; however, the M2L 3000 can accommodate voltages that differ from the motor voltage. For example, a

customer application may require that a 4160 VAC induction motor

be operated from a 2300 VAC or 13.8k VAC source. In this case, the

primary winding would be specified to be 2300 VAC or 13.8 kVAC.

The secondary winding voltages have been selected to generate the

DC voltage needed to synthesize AC waveforms for 4160 VAC at its

output terminals.

Two typical size Converter enclosures (small and large frame) are

shown in Figure 6, with all electrical components contained within the

enclosures. The enclosure design allows for top or bottom entry of all

cable connections between the AC mains and the Inverter.

The Converter is forced-air cooled. Cooling air is drawn through filters on the front of the enclosure by multiple blowers mounted on the

top. The Converter is designed to function with “N-1 Redundancy”

(for example only 2 of 3, or 4 of 5 blowers operating), providing redundant protection and high operating availability. Filter elements are

provided in series on the front of the enclosure, to block the ingress

of dirt and dust particulates. The filter assembly mounts over a protective screen, welded to the enclosure, that prevents inadvertent

contact with the resident high voltages when the filter media is removed for cleaning or replacement.

The enclosure also contains internal baffles that route air flow

through critical areas of the transformer, and across the rectifier assemblies. Thermal sensors are located in the input air stream to the

blowers, to detect over temperature conditions. The standard Converter enclosure is rated for NEMA 1 applications. Enclosures with

other environmental ratings are available.

Figure 5: M2L 3000 Converter

Figure 6: 300 Amp Converter

34

4 – Theory of Operation

X9X7X8

X3X1X2X4X5X6+20

-20

+5%

-5%

+5%

-5%

X7X9X8

Converter Details

The standard transformer consists of a single 3-phase primary winding, with three 3phase secondary windings that are phase displaced to produce an 18-pulse current

waveform in the primary winding. The primary winding includes taps to adjust for slight

variations in the incoming line voltage, to accommodate nominal, low, or high line conditions. Variations of ±5% can be accommodated by jumpering the incoming AC cables

to the to +5% tap for high line conditions and the -5% tap for low line conditions.

Three secondary windings are physically shifted on the transformer core to yield voltages that are phase displaced by ±20 electrical degrees with respect to the primary

winding. Figure 4 shows the schematic diagram of a typical transformer.

Each secondary winding is connected to a dedicated 6-pulse, full-wave bridge rectifier

that converts AC to DC, as shown schematically in Figure 7.

The DC terminals of all three (3) rectifier bridges are connected in series, such that the

appropriate output voltage is generated at the output of the VFD.

H3

H2

H1

H3

H2

o

X4

X6

o

X5

0

H1

Figure 7: Main Transformer

Figure 8: 6-Pulse Bridge Rectifier

12, 24 and 36 pulse converters are optionally avalilable

-5%

+5%

X3

X2

o

X1

35

M2L 3000 Series VFD

Inverter

The role of the Inverter is to convert DC voltage produced by the Converter to variable voltage, variable frequency AC, to be

applied to the motor terminals. The Inverter utilizes a topology known as Modular Multi-Level Converter (M2LC), which offers

many benefits.

M2LC topology allows the Converter to be located remotely from the Inverter, for the ultimate in application flexibility. The

Inverter is a modular design enabling rapid drive repair by simple removal and replacement of a faulty module or “cell”. Replacing a cell can be done in a matter of minutes, minimizing downtime and process interruption.

IGBT Cell

The standard building block in the M2L 3000 Converter is the “cell”. A variety of cell

sizes are available, having different current ratings to configure drives at different

power levels.

A cell consists of Insulated Gate Bipolar Transistors (IGBTs), capacitors, associated

control, communication and gating circuitry, heatsinks, and sensors; all housed in a

metal enclosure. A depiction of the cell is shown below in Figure 9.

Figure 9: IGBT Cell

Each cell contains IGBT switching devices and film capacitors. These film capacitors

offer significant improvements over conventional electrolytic capacitor technologies.

This technology is more stable, and safer, than conventional capacitors that can explode from the buildup of high pressures within the capacitor if a failure should occur.

Embedded cell circuitry provides intelligence for control and communication. Communication with the central control system of the drive occurs over optical fiber, using an

Ethernet protocol that greatly improves speed and noise immunity. Each cell is designed to sense voltage and current, eliminating the need to place external voltage and

current sensors on the motor leads.

The elimination of external sensors removes single points of failure, improving drive reliability.

36

4 – Theory of Operation

CBA

AC Outputs

Inverter Packaging

A typical 4160VAC inverter contains eighteen (18) cells, arranged 6 cells per phase as

shown in Figure 7. The cells are connected in series within each phase, and the

phases are connected in parallel across the internal DC bus. DC voltage is divided

evenly among the cells in each phase.

The cells in each phase work together to create the AC output waveform. Pulse width

modulation (PWM) control is used to convert DC voltage into a low distortion AC waveform, which is applied to the motor terminals labeled A, B and C in Figure 10. Each output phase provides an equivalent waveform for optimal harmonic characteristics. As

such, output filters are not required. Additionally, the Inverter has been designed to

work with standard, non-inverter grade motors commonly found in use today.

+ DC

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

Cell

- DC

Figure 10: 18 Cell Inverter

The front view of a typical small frame 1500 hp Inverter is shown below in Figure 11.

Other specialized configurations of the Inverter can be utilized for higher horsepower

and/or voltage applications. The typical enclosure is partitioned into 3 sections: Cell, Input/Output and Control. The enclosure contains internal structural members that provide strength, rigidity and voltage isolation, with bolt-on metal covers for each section

attached to the structural members.

Control Section

Cell Section

Input/Output Section

Figure 11: Typical 1500 hp Inverter Front View

37

M2L 3000 Series VFD

WARNING: Do not remove the Cell or Input/Output Section covers to access the Inverter while the Inverter is energized. Potentially lethal levels

of both AC and DC voltages will be exposed which may result in serious

injury or death.

WARNING: Potentially hazardous voltages will remain in the cells until

the internal capacitors are able to de-energize. Wait at least 30 minutes

after main power is removed for the stored voltages to dissipate if removing the Inverter Cell or Input/Output section covers. Do not rely solely on

the voltage values displayed on the HMI to determine if it is safe to remove the covers on the Inverter Cell and Input/Output sections.

WARNING: The Control section contains 240V control power when active. The Control section does not contain medium voltage levels supplied from the mains, and can be carefully accessed by qualified personnel while medium voltage from the AC mains is applied to the system.

CAUTION: Special care must be taken with the cover over the Control

section and all access panels. A ground wire is attached to the inside of

that cover that ties it to ground potential. It is important that the connection integrity of this wire be maintained to avoid compromising the immunity of the Inverter to Electromagnetic Interference (EMI.).

38

4 – Theory of Operation

IGBT Cell (18)

AC Midpoint (3)

Cooling Blowers

welded to the enclosure, that prevents inadvertent contact with the resident high volt-

Hub Controller

Card Rack

I/O Rack

Converter

Connections

Motor

Connections

Figure 12: Typical 1500 hp Inverter – Front View with Covers Removed

Figure 12 represents a typical small frame, 1500 hp, 18 Cell Inverter with the front covers removed. IGBT cells can be seen as 3 vertical columns in the right side of the enclosure. The leftmost vertical column, located closest to the center of the enclosure, is

Phase A followed by Phases B and C. The AC midpoint of each phase is located behind

the grey panels covering the AC terminals and inductive filters.

Internal cabling routes the AC outputs from the phases to the Input/Output section of the

Inverter, in the area located in the lower left of the enclosure. Also shown in this section

are components associated with the pre-charge function and current loop power for the

IGBT cells.

The Input/Output section of the enclosure is the area where power connections are

made to the Inverter. AC output cables from the motor are attached to landing pads on

the right side of the Input/Output section, while high voltage cables that interconnect the

Converter and Inverter are attached to landing pads on the left side. The enclosure allows for top or bottom entry of both AC and DC cables.

The Inverter is forced-air cooled. Air is drawn through filters on the front of the enclosure

by blowers mounted on the top. The Inverter is designed to function with only 3 of the 4

blowers operating at any given time, providing redundancy and high operating availability. Two filter elements are provided in series on the front of the enclosure to block the

ingress of dirt and dust particles. The filter assembly mounts over a protective screen,

ages when the filter media is removed for cleaning or replacement.

The compartmental nature of the Inverter’s internal design provides baffling to route air

flow through critical areas of the enclosure. The standard Inverter enclosure is rated for

NEMA 1 applications.

For testing and checkout purposes, the Inverter is designed with a power supply system

that enables control power to be applied without medium voltage main power being applied.

.

39

M2L 3000 Series VFD

40

5 - Operation

5 - Operation

This section provides basic operation instructions for the M2L 3000 HMI (Human-Machine Interface) controller.

WARNING: Only qualified personnel familiar with the use and hazards of

medium voltage equipment are to perform work described in this set of

instructions.

Introduction The HMI is an interactive controller and display which provides the ability to both monitor and

control operation of the drive.

Custom parameters are accessible to modify the characteristics of drive performance. Refer to

Section 5 - Parameter List, for the complete list of user accessible parameters in tabular format,

and to Section 6 - Parameter Descriptions, for explanations of how each parameter is used. Initial

setup of basic parameters may be required for your site application, and should be configured

during drive commissioning. Many parameters can also be adjusted while the drive is running, as

noted in the parameter tables in Section 5 of this manual.

CAUTION: Parameter settings and adjustments should be performed by those

familiar with VFD and motor operation characteristics. It is not recommended

for users unfamiliar with these concepts.

41

M2L 3000 Series VFD

HMI Overview

The HMI display can be divided into three primary areas:

Selectable View Most of the HMI screen is dedicated to the active view, selectable at run time. The default view

shows Speed Setpoint, Output Frequency, and general status indicators, intended to be visible at

a distance.

Navigation Menu This menu is visible at all times, at a fixed position at the bottom of the screen. The navigation

buttons can be used to switch between different views.

Drive Controls Located to the right of the Navigation Menu, the Drive controls also remain visible regardless of

the active View.

This area will contain Start/Stop buttons when the drive is configured for HMI control, and

Running/Stopped status indicators for other control modes. If the default view is not selected, this

area will also display the output frequency while the Drive is running.

42

Status Indicators

5 - Operation

The general status indicators shown on the Main HMI view give an overview of the Drive status.

Blinking indicators on this screen are designed to draw attention so that error conditions can be

quickly resolved.

Ready This indicator will turn green when the Drive is ready to run. If the Drive is configured for HMI

control, the Start button will also turn green.

Fault The M2L 3000 is designed to detect and report various fault conditions. When a fault occurs, the

status indicator on the right and the Main button on the Navigation Menu will blink red. The name

of the latched fault will appear across the top of the screen. Refer to Section 7 - Fault Conditions,

for a complete list of Faults, descriptions and solutions.

Once the underlying cause of a fault is resolved, the fault can be cleared by pressing the Reset

button to the left of the fault name. A fault reset can also be performed by a configured digital

input, or by a plant PLC writing to the control register.

Lockout Lockout conditions will prevent the Drive from running. When any lockout occurs, the status

indicator on the right and the Lockouts Warnings Limits button will blink orange. Unlike faults,

lockouts do not latch; the lockout will clear as soon as the underlying condition is resolved, without

a manual reset.

Any lockout condition that occurs while the Drive is running will trigger a fault with the same name.

This fault is latched, so that the lockout cannot be cleared before it is seen by the operator.

Warning Warning conditions are less serious than faults or lockouts, and will not prevent the drive from

running. Some warnings, such as Cell Board Temperature, indicate that a meter is approaching

the trip point, and a fault or lockout is likely to occur. When a warning occurs, the indicator on the

right will display solid yellow. If no lockout is active, the Lockouts Warnings Limits menu button will

also turn yellow.

Limit Limits are triggered when following normal operation would cause the Drive to fault. The Drive will

temporarily ignore some parameter settings, such as Acceleration Ramp Time, in order to run

without faulting. When a limit occurs, the indicator on the right will display solid yellow. If no

lockout is active, the Lockouts Warnings Limits menu button will also turn yellow.

43

M2L 3000 Series VFD

Select Lockouts Warnings Limits from the navigation menu to view the specific lockout,

warning, and limit conditions. For each status indicator on the Main view, multiple conditions

could be present.

NOTE: Lockout, Warning, and Limit conditions are not latched indefinitely,