Recycle Disassemble Instruction

(Dismantled Information)

Requirements according to ANNEX VII of DIRECTIVE 2012/19/EU

on waste electrical and electronic equipment (WEEE)

Materials and components with hazardous content

LCDs may contain hazardous substances like Pb and BFRs which are covered by

exemptions under the RoHS directive. However, the majority is present in the printed

circuit boards assembly. In order to reduce emissions as much as possible, a complete

disposal of the old appliance is required. This treatment may only be performed in

authorized handling plants.

Product Name: Interactive flat panel

Model No.: RE7501

Disassembly Tools

Tool

picture

Philips Screwdriver for M3

screw

nosed pliers

Diagonal Cutting Pliers

Slotted screwdriver

Six Point Sockets

Philips Screwdriver for M2.5

screw

knife

Disassembly process

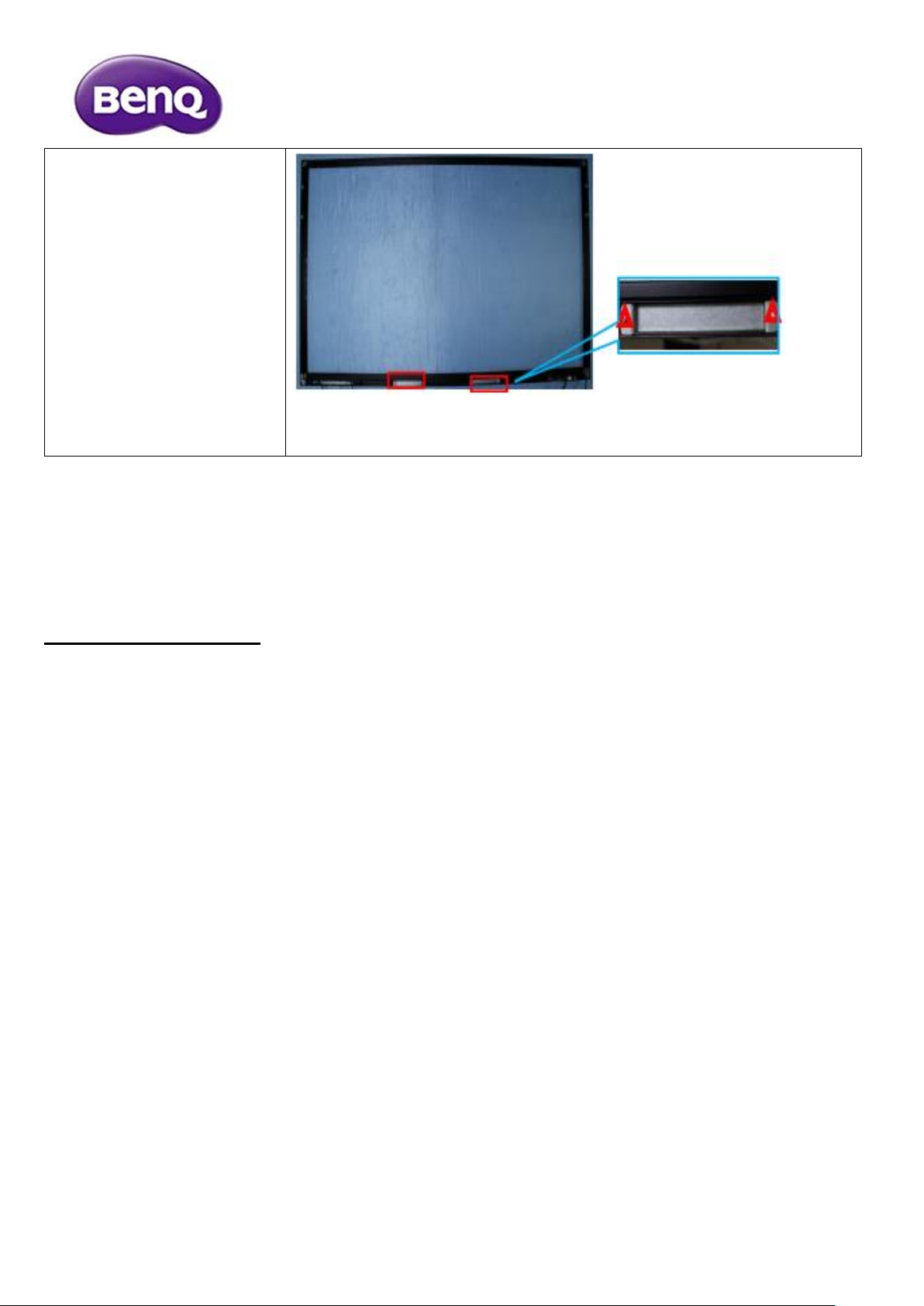

Remove 13 screws that

M4 ×6mm flat

head nickel plated

mechanical screw

1.Remove 6 screws that

M3 ×11mm flat head

nickel plated mechanical

screw.

2.Remove 1 screw that

M3 ×6mm countersunk

head nickel-plated

mechanical screw

Remove 16 screws that

M3 ×6mm meson head

nickel-plated mechanical

screw.

1.Remove 12 screws

that M4 ×6mm flat

head nickel-plated

mechanical screw

2.Remove the rear cover

1.Pull the horn line

2.Remove 8 screws that

M3×6mm P head with

spring pad with flat pad

coated with blue zinc

mechanical screw.

3.Remove the horns

1.Remove 6 screws

that M4 ×6mm flat

head nickel-plated

mechanical screw

2.Remove 1 screws

that Ф 4 x 5 mm round

head toothed pads

blue zinc plating

machine screws

3.Remove the Switch

bracket and IO baffle

1.Remove 6 screws that

M3 ×6mm meson

head nickel-plated

mechanical screw

2.Remove 2 screws that

M4 ×6mm flat head

nickel-plated mechanical

screw

3.Remove the back shell

1.Remove The main

board

2.Remove OPS adapter

plate

3.Remove The power

supply board

1.Remove 4 screws that

M3×4mm meson head

nickel-plated mechanical

screw

2.Remove 2 screws that

M3×6mm P head with

spring pad with flat pad

coated with blue zinc

mechanical screw

3.Remove OPS guide

bracket and WIFI board

fixed bracket

1.Remove 4 screws that

M3×6mm P head with

spring pad with flat pad

coated with blue zinc

mechanical screw.

2.Remove 1 screw that

Φ 3 * 3.0 * 4 mm

resistance to fall outside

the hexagon blue zinc

plated screws.

3.Remove the OPS

mounting bracket

1.Remove 4 screws that

Φ 3 x 6 countersunk

head black zinc plating

machine screws

2.Remove IO side baffle

1.Remove 8 screws that

M3×6mm P head with

spring pad with flat pad

coated with blue zinc

mechanical screw

2.Remove The Cable tie

fixed seats

1.Remove 3 screws that

M3×6mm P head with

spring pad with flat pad

coated with blue zinc

mechanical screw

2.Remove Rear cover

support frames

1.Remove 16 screws

that M3×6mm P head

with spring pad with flat

pad coated with blue

zinc mechanical screw.

2.Remove Screen fixing

brackets.

3.Tear off the masking

mylar.

1.Remove 2 screws that

M3×6mm P head

with spring pad with flat

pad coated with blue

zinc mechanical screw.

2.Remove 1 screw that

M4 ×5mm round head

with tooth pad plain tail

plated with blue zinc

mechanical screw.

3.Remove Front plate

support

1.Remove 2 screws that

M3×6mm P head

with spring pad with flat

pad coated with blue

zinc mechanical screw.

2.Remove Press the key

plate support

1.Remove 48 screws

that M3×6mm P head

with spring pad with flat

pad coated with blue

zinc mechanical screw.

2.Remove 6 screws that

M4 ×6mm round

head flat tail with spring

pad plated with blue zinc

mechanical screw.

3.Tear off 10 lightblocking mylar tablets

1.Remove 32 screws

that M3 ×3.3mm

countersunk head plated

with blue zincmechanical

screw.

2.Remove glass

preforms

1. Tear the foam pad off

the glass.

2.Tear off the EVA pad

(

100 ×10 ×1.5mm

)

attached to the frame

1. Remove 4 screws that

M3×6mm P head with

spring pad with flat pad

coated with blue zinc

mechanical screw.

2.Remove holders for

fixed stylus pen

Disassembly Time

Total time: about 35 minutes

Loading...

Loading...