Page 1

1

Applicable Country & Regions: Europe

Service Manual for BenQ:

LCD E24-5500

(D-SUB + HDMI + Audio + USB +

S-Video+ YPbPr + SPDIF +

SCART + Common Interface +

Black Chassis Colors)

P/N: 9H.V1875.TBE

Product Service Manual – Level 1~2

Version: 1st

Date:12-20-2010

Notice:

For RO to input specific “Legal Requirement” in specific NS regarding to responsibility and

liability statements.

Please check BenQ’s eSupport web site, http://esupport.benq.com

, to ensure that you have the

most recent version of this manual.

First Edition (Dec. 2010)

©

Copyright BenQ Corporation 2010. All Right Reserved.

Page 2

2

Content Index

Abbreviations & Acronyms ........................................................................................................................................ 3

1. About this Manual ................................................................................................................................................... 5

1.1 Important ............................................................................................................................................................ 5

1.2 Trademark .......................................................................................................................................................... 5

2. Introduction ............................................................................................................................................................. 6

2.1 RoHS (2002/95/EC) Requirements – Applied to all countries require RoHS. .................................................... 6

2.2 Safety Warning and Notice ................................................................................................................................. 6

2.3 Compliance Statement ....................................................................................................................................... 7

3. General Description ................................................................................................................................................ 8

4. Related service information ................................................................................................................................... 8

5. Product Overview ................................................................................................................................................... 9

5.1 Monitor Specifications ........................................................................................................................................ 9

5.2 Packing ............................................................................................................................................................. 11

5.3 Customer Acceptance ...................................................................................................................................... 13

Level 1 Cosmetic / Appearance / Alignment Service ............................................................................................ 15

Visual Inspection & Cleaning .................................................................................................................................. 15

Software/Firmware Upgrade Process .................................................................................................................... 25

Adjustment / Alignment Procedure ......................................................................................................................... 29

Level 2 Circuit Board and Standard Parts Replacement ...................................................................................... 40

Product Exploded View .......................................................................................................................................... 40

Six Angles’ View ..................................................................................................................................................... 42

Product Disassembly .............................................................................................................................................. 43

Assembly SOP ....................................................................................................................................................... 47

Block Diagram ........................................................................................................................................................ 51

Schematic Diagram ................................................................................................................................................ 53

Troubleshooting ...................................................................................................................................................... 71

PCB LAYOUT ............................................................................................................................................................. 77

Appendix 1 – Screw List / Torque ........................................................................................................................... 87

Appendix 2 –CODE LIST: IR ..................................................................................................................................... 88

Page 3

3

Abbreviations & Acronyms

A

ADC Analog to Digital Converter

AFC Automatic Frequency Control: control signal used to tune to the correct frequency

B

BenQ BenQ Corporation

BTSC Broadcast Television System Committee

C

CPU Central Process Unit

CVBS Composite Video Blanking and Synchronization

D

DLP Digital Light Processing / Texas Instruments®

DMD Digital Micro mirror Device

DRAM Dynamic RAM

DVI Digital Visual Interface

DVI-D Digital Visual Interface-digital

DVI-I Digital Visual Interface-Integrated

E

EEPROM Electrically Erasable and Programmable Read Only Memory

F

FLASH FLASH memory

G

G-TXT Green Teletext

H

HDMI High Definition Multimedia Interface, digital audio and video interface

HP Head Phone

I

IR Infra-red

I2C Integrated IC bus

L

LED Light Emitting Diode

LVDS Low Voltage Differential Signal, data transmission system for high

M

MOSFET Metal Oxide Semiconductor Field Effect Transistor

Page 4

4

N

NC Not Connected

NVM Non Volatile Memory: IC containing TV related data (for example, options)

O

OSD On Screen Display

P

PC Personal Computer

PCB Printed Circuit Board (or PWB)

R

RC Remote Control transmitter

RGB

Red, Green and Blue. The primary color signals for TV. By mixing levels of R, G

and B, all colors (Y/C) are

ROM Read Only Memory

S

SDA Data signal on I2C bus

SDRAM Synchronous DRAM

SW Sub Woofer / Software

T

THD Total Harmonic Distortion

V

VGA Video Graphics Array

Y

YPbPr

Component video (Y= Luminance, Pb / Pr= Color difference signals B-Y and R-Y,

other amplitudes w.r.t. to YUV)

Y/C

Video related signals: Y consists of luminance signal, blanking level and sync; C

consists of color signal.

Page 5

5

1. About this Manual

The purpose of Service Manual is to provide a guide line to engineers to repair different models. The appearance

and capability is introduced in this Service Manual. It is better for repair engineer to have a rough idea of this model

through reading the Service Manual. Please do pay attention to the item part of the disassembly when repair the

machine and also do the protection of panel any time. When repairing the circuit board, please follow the

requirement of RoHS and refer to the circuit diagram and repairing process that attached in the Service Manual.

The method of firmware updated, the way of using the menu and some information that may be used when

repairing are also attached in the Service Manual that provide repair engineer various choice.

1.1 Important

Only trained service personnel who are familiar with this BenQ Product shall perform service or

maintenance to it. Before performing any maintenance or service, the engineer MUST read the “Important

Safety Information”.

1.2 Trademark

Page 6

6

2. Introduction

This section contains general service information, please read through carefully. It should be stored for easy

access place.

2.1 RoHS (2002/95/EC) Requirements – Applied to all countries require RoHS.

The RoHS (Restriction of Hazardous Substance in Electrical and Electronic Equipment Directive) is a legal

requirement by EU (European Union) for the global electronics industry which sold in EU and some counties also

require this requirement. Any electrical and electronics products launched in the market after June 2006 should

meet this RoHS requirements. Products launched in the market before June 2006 are not required to compliant

with RoHS parts. If the original parts are not RoHS complaints, the replacement parts can be non ROHS

complaints, but if the original parts are RoHS compliant, the replacement parts MUST be RoHS complaints.

If the product service or maintenance require replacing any parts, please confirming the RoHS requirement before

replace them.

2.2 Safety Warning and Notice

Installation

1. Do not use your monitor under any of the following environmental conditions:

Extremely high or low temperature, or in direct sunlight

Dusty places

Highly humid, exposed to rain, or close to water

Exposed to vibrations or impacts in places such as cars, buses, trains, and other rail vehicles

Near heating appliances such as radiators, heaters, fuel stoves, and other heat-generating items (including

audio amplifiers)

An enclosed place (such as a closet or bookcase) without appropriate ventilation

An uneven or sloping surface

Exposed to chemical substances or smoke

2. Do not block vents and openings by clothes or curtains.

3. Carry the monitor carefully.

4. Do not place the monitor face down on the floor or a desk surface directly. Otherwise, scratches on the panel

surface may occur.

5. Do not place heavy loads on the monitor to avoid possible personal injury or damage to the monitor.

6. Ensure that children do not hang or climb onto the monitor.

7. Keep all packing bags out of reach of children.

Page 7

7

Operation

1. To protect your eyesight, please refer to the user manual to set the optimal screen resolution and the viewing

distance.

2. To reduce eye fatigue, take a break on a regular basis while using the monitor.

Avoid taking either one of the following actions for a long time. Otherwise, burn marks may occur.

Use the monitor in the aspect ratio of 2.35:1, 4:3, or 16:9.

Place a still image (such as an OSD menu, fixed text or image) on the screen.

3. To avoid possible damage to the monitor, do not touch the monitor panel by hand, pen, or any other sharp

objects.

4. Excessively frequent plug and unplug of video connectors (D-sub / HDMI) may cause damage to the monitor.

5. This monitor is designed mainly for personal use. If you want to use the monitor in a public place or a harsh

environment, contact your nearest BenQ service center for assistance.

6. To avoid possible electric shock, do not dissemble or repair the monitor.

7. If a bad smell or an abnormal sound appears to come from the monitor, contact your nearest BenQ service

center for assistance immediately.

Cleaning

1. Ensure that the power is unplugged before cleaning your monitor

2. Use a monitor cleaner and a soft cloth to clean your monitor.

3. Do not use solvents such as alcohol to clean your monitor.

Power

1. To avoid possible damage to the monitor, do not use it in a region where power supply is unstable.

2. Ensure that the power cord is connected to a grounded power outlet before turning on the monitor.

3. Use only the power cord provided by BenQ.

4. Never use a power cord that appears to be damaged or frayed.

5. To avoid possible danger, observe the total electric load when using the monitor with a (multi-outlet) extension

cord.

6. Always turn off the monitor before unplugging the power cord.

2.3 Compliance Statement

Caution: This Optical Storage Product contains a Laser device. Refer to the product specifications and your local

Laser Safety Compliance Requirements.

Page 8

8

3. General Description

This new LCD (Liquid Crystal Display) monitor BenQ E24-5500 offers numerous features and functions, for

example:

LED

Minimal space requirements thanks to slim casing

Optimum ergonomic characteristics (totally distortion-free, excellent picture definition and color purity right into

the corners)

Contrast ratio 3000:1 (Panel) / 20 million:1 (DCR), brightness 250nits

MAX. resolution (1920 x 1080)

Automatic scanning of horizontal frequencies from 30 to 83 kHz and refresh rates (vertical frequencies) from 56

to 76 Hz (absolutely flicker-free)

Digital screen controller with microprocessor for storing 15 different display modes

Freely adjustable color alignment for matching the screen colors to the colors of various input and output devices

Convenient operation via integrated OSD (On-Screen-Display) menu

VESA-DDC compatibility

Plug & play capability

Power management for reducing power consumption when the computer is not in use

This operating manual contains important information you require to start up and run your LCD monitor.

This specification defines the requirements for the 24″ MICROPROCESSOR based Multi-mode supported high

resolution color LCD monitor. This monitor can be directly connected to general 15-pin VGA connector and 19-pin

HDMI connector, also supports VESA DPMS power management and plug & play function.

Additional information

Due to the nature of liquid crystal display (LCD) technology, the picture resolution is always fixed. For the best

display performance, please set the display resolution to 1920 x 1080 pixels with an aspect ratio of 2.35:1, 4:3, or

16:9. This is called “Native Resolution” or maximal resolution - that is, the clearest picture. Lower resolutions are

displayed on a full screen through an interpolation circuit. Image blurring across pixel boundaries can occur with the

interpolated resolution depending upon the image type and its initial resolution.

4. Related service information

This Service Manual contains general information. There are 2 levels of service:

Level 1: Cosmetic / Appearance / Alignment Service

Level 2: Circuit Board or Standard Parts Replacement

Service Web Site

eSupport URL: http://esupport.benq.com

Page 9

9

5. Product Overview

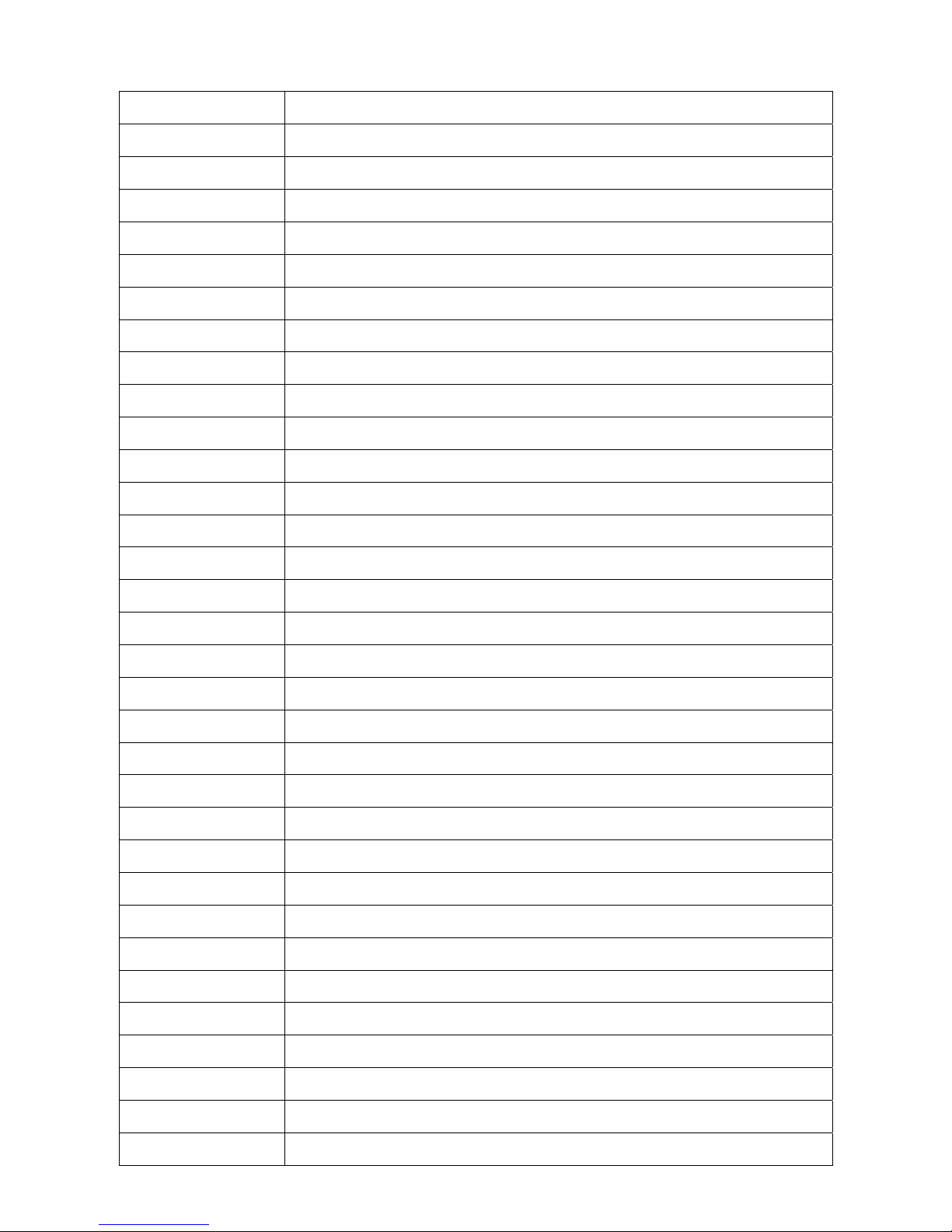

5.1 Monitor Specifications

Display

Backlight type LED

Size 24″

Resolution 1920 x 1080

Brightness (cd/m2) (typical) 250nits

Contrast ratio 3000:1

Dynamic Contrast Ratio 20M:1

Response time 25ms

Color depth/colors 8bits

Viewing angle (up/down/ left/right) 178/178/178/178 degrees

TV tuner system

Analog PAL/SECAM

Digital DVB-T/C

Video

Senseye

• Noise reduction • Flesh tone • ACE •

Dynamic backlight

Aspect ratio

• Normal (4:3) • Zoom1 • Zoom2 (2.35:1) •

Wide (16:9) • Panorama

MPEG Noise Reduction Yes

24P True Cinema (no frequency doubling) Yes

Audio

Sound mode

• Standard

• Music

• Cinema

• Speech

• User

Speaker output 5W x 2

Surround system SRS Trusurround HD

Steady Sound Yes

Features

USB multimedia playback

• JPEG

• MP3 • MPEG-1,2,4 • H.264

HDMI CEC Yes

Teletext 1000 pages

Intelligent Shut Down Yes

Time-Shift Yes

Sleep Timer Yes

Clock Yes

Parental Yes

MHEG-5 Yes

Stand tilt/swivel Tilt only (-7 ~ 17 degrees)

Page 10

10

Input terminals

RF tuner 1

HDMI 2

Composite 1

Component 1

S-Video 1

SCART 1

D-sub (VGA) 1

Common Interface 1

USB 1

PC Audio In 1

Output terminals

Video out No

SPDIF out 1

Headphone jack 1

Power

Power input 100 ~ 240 V

Power consumption <60W

Standby mode <0.5W

Dimensions

Dimensions with stand (W x H x D mm) 587.3mm (W) x 424.7mm (H) x184.9mm (D)

Dimensions without stand (W x H x D mm) 587.3mm (W) x 369.9mm (H) x 45.8mm (D)

Weight with stand (Kg) 6kg

Weight without stand (Kg) 4.3kg

Page 11

11

5.2 Packing

When packing the monitor into the carton, please follow the pictures as below.

1. Using the EPE bag to pack the monitor without base

2. Using the EPS to pack the monitor

Page 12

12

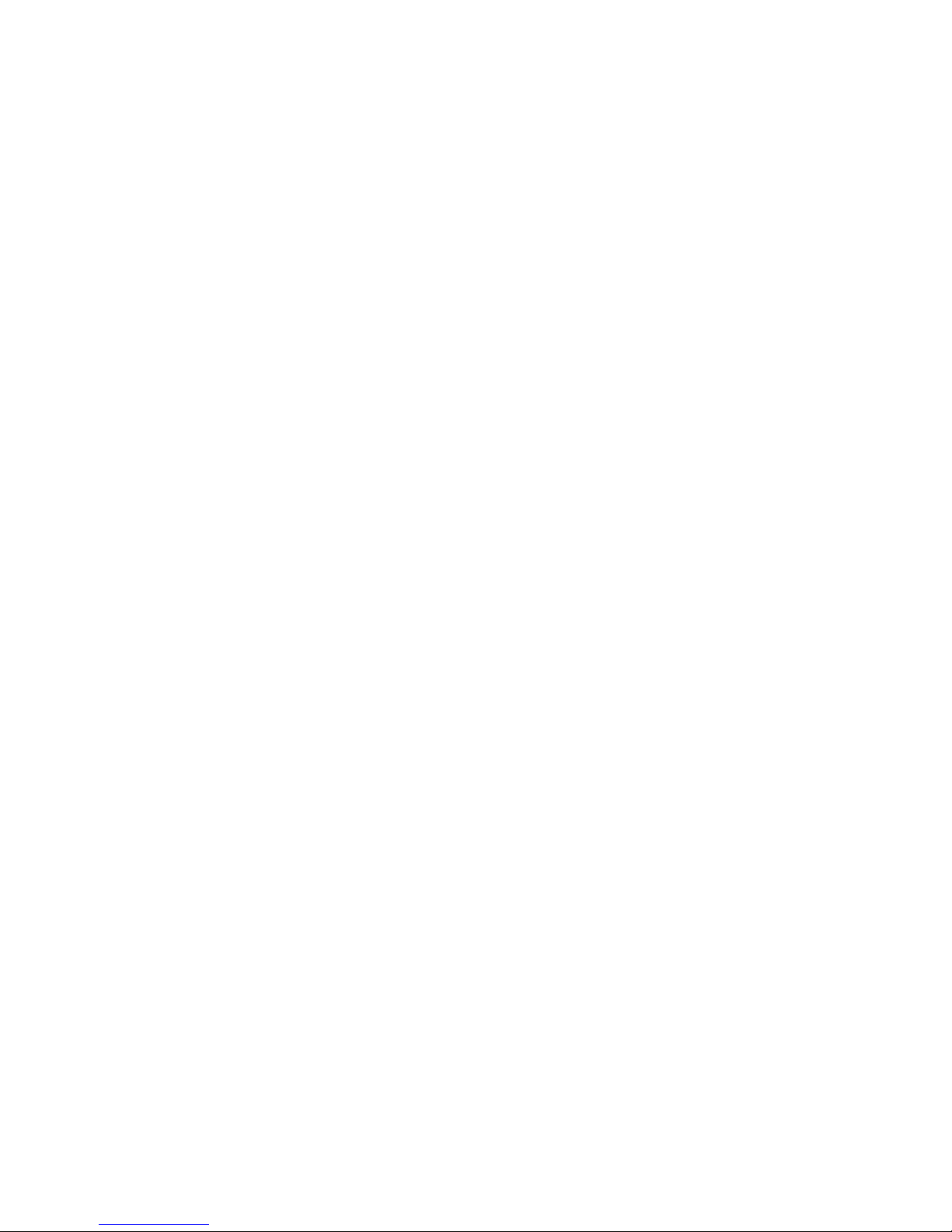

3. Putting the power cord, remote control, screws, battery, and user manual in the position as the picture shows

below.

User manual The remote control and screws

The battery

The power cord

Page 13

13

5.3 Customer Acceptance

E24-5500 (AUO Panel) LCD TV Customer Acceptance Criteria

1.0 SCOPE

This document establishes the general workmanship standards and functional Acceptance criteria for LCD TV

model SV4231 Produced by AUO Inc.

2.0 PURPOSE

The purpose of this publication is to define a procedure for inspection of the LCD TV by means of a customer

acceptance test, the method of evaluation of defects and rules for specifying acceptance levels.

3.0 APPLICATION

The "Customer Acceptance Criteria" is applicable to the inspection of the LCD TV, completely packed and ready for

dispatch to customers. Unless otherwise specified, the customer acceptance inspection should be conducted at

manufacturer's site.

4.0 DEFINITION

The "Customer Acceptance Criteria" is the document defining the process of examining, testing or otherwise

comparing the product with a given set of specified technical, esthetic and workmanship requirements leading to an

evaluation of the "degree of fitness for use", including possible personal injury or property damage for the user of the

product.

5.0 CLASSIFICATION OF DEFECTS

The defects are grouped into the following classes:

5.1 Critical defect

A critical defect is a defect that judgment and experience indicate is likely to result in hazardous or unsafe conditions

for individuals using, maintaining or depending upon the product.

5.2 Major defect

A major defect is a defect, other than critical that is likely to result in failure, or to reduce materially the usability of the

product for its intended purpose.

5.3 Minor defect

A minor defect is a defect that is not likely to reduce materially the usability of the product for its intended purpose, or

is a departure from established standards having little bearing on the effective use of operation of the product.

Note: If BenQ defect undefined failure, and it judged that is reduce the merchandise ability, BenQ CM Inform this

defect. After that parties make communication and decide how to solve.

6.0 CLASSIFICATION OF DEFECTIVES

A defective is a product, which contains one or more defects. The defective will be classified into following classes:

6.1 Major defective

A major defective contains one or more defects and may also contain minor defects but contains no critical defect.

6.2 Minor defective

A minor defective contains one or more minor defects but contains no critical and major defects.

7.0 EXPRESSION OF DEFECTIVES

Number of defects

Percent of defects = ------------------------------------------------ X 100%

Number of products inspected

8.0 INSPECTION STANDARD

Unless otherwise specified, the inspection standard will be defined by MIL- STD-105E (ISO-2859), SINGLE

Page 14

14

SAMPLING PLAN. Level Ⅱ is in use all the time, inspection levels are normal, reduce and tighten.

8.1 Acceptance Quality Level

8.1.1 When a critical defect is found, this must be reported immediately upon detection, the lot or batch shall be

rejected and further shipments shall be held up pending instructions from the responsible person in relevant

organization.

8.1.2

Major Defective: 0.65 AQL

Minor Defective: 1.5 AQL

9.0 GENERAL RULES

The inspection must be carried out by trained inspectors having good knowledge of the meaning of “fitness for use".

The inspection must be based upon the documents concerning the completely assembled and packed product when

more defects appear with the same cause only the most serious defect must be taken into account. Defects found in

accessories packed with the product as connecting cables, plugs, adapters and the like, and being inspected as a

part of the complete product, must be included in the evaluation.

The evaluation must be within the limits of the product specification and, for not specified characteristics, be related

to the design model, limit samples or judgment of a jury of experts. Faults must be demonstrable.

10.0 TEST CONDITIONS

Unless otherwise prescribed, the test conditions are as follows:

. Cold set (switch off for at least 2 hours)

. Nominal mains voltage

. Environmental illumination variable from 500 to 800 Lux (300-500 Lux in Normal I Area)

. Temperature: 24±2℃

. Warm up time: 30minutes minimum.

. Visual inspection shall be down with the distance from eyes to the sample 45 cm.

. Display mode: Primary mode SXGA 60Hz

11.0 TEST EQUIPMENTS

11.1 BenQ PCs with BenQ display adapter or other specific display adapter, which is agreed upon by both parties

11.2 Test program by AUO

11.3 Power saving test tool

11.4 Minolta color analyzer (CA-210)

11.5 Pattern Generator: Chroma

11.6 Fluke or TV signal

11.7 DVD player

11.8 Speaker

Page 15

15

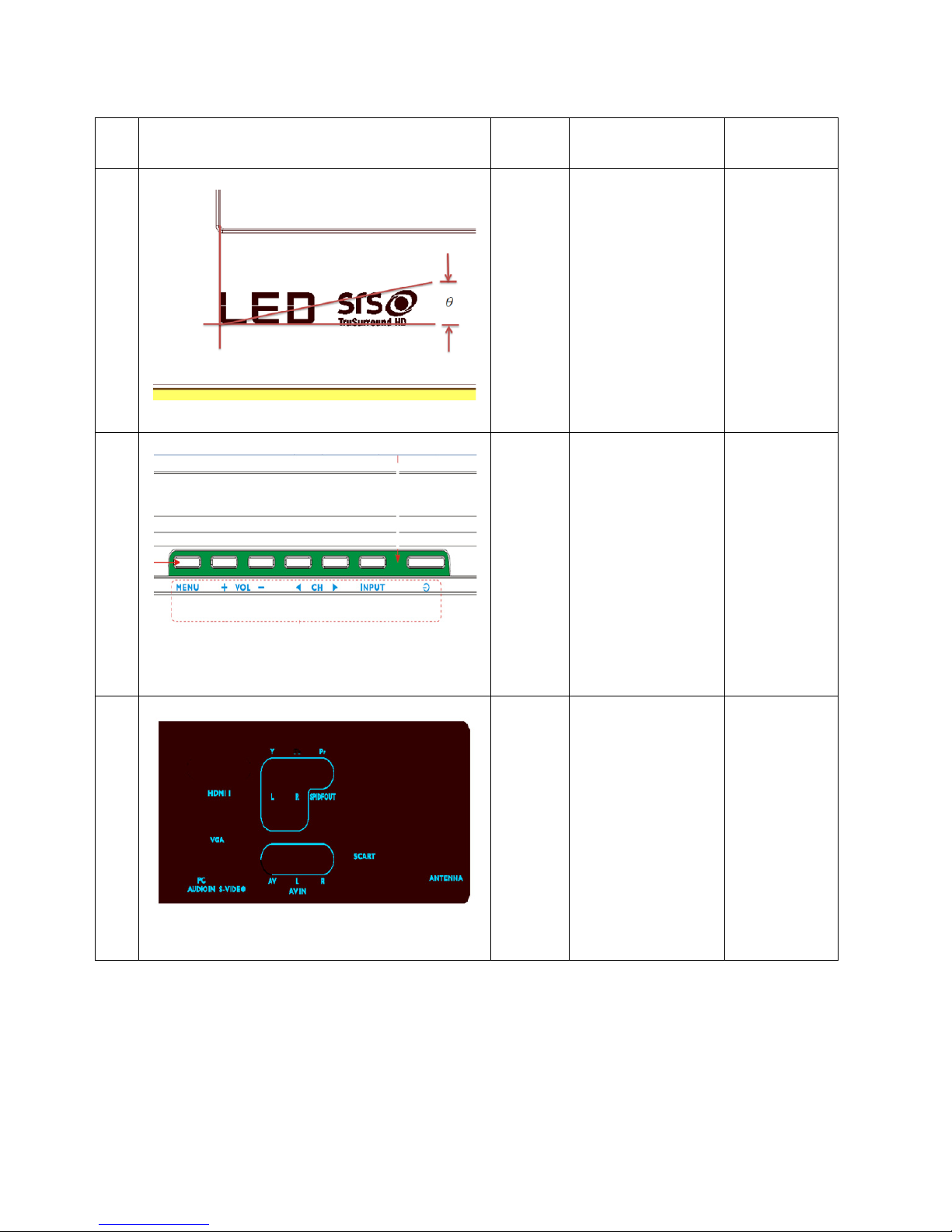

Level 1 Cosmetic / Appearance / Alignment Service

Visual Inspection & Cleaning

Item Description

ID

SPEC

Remark

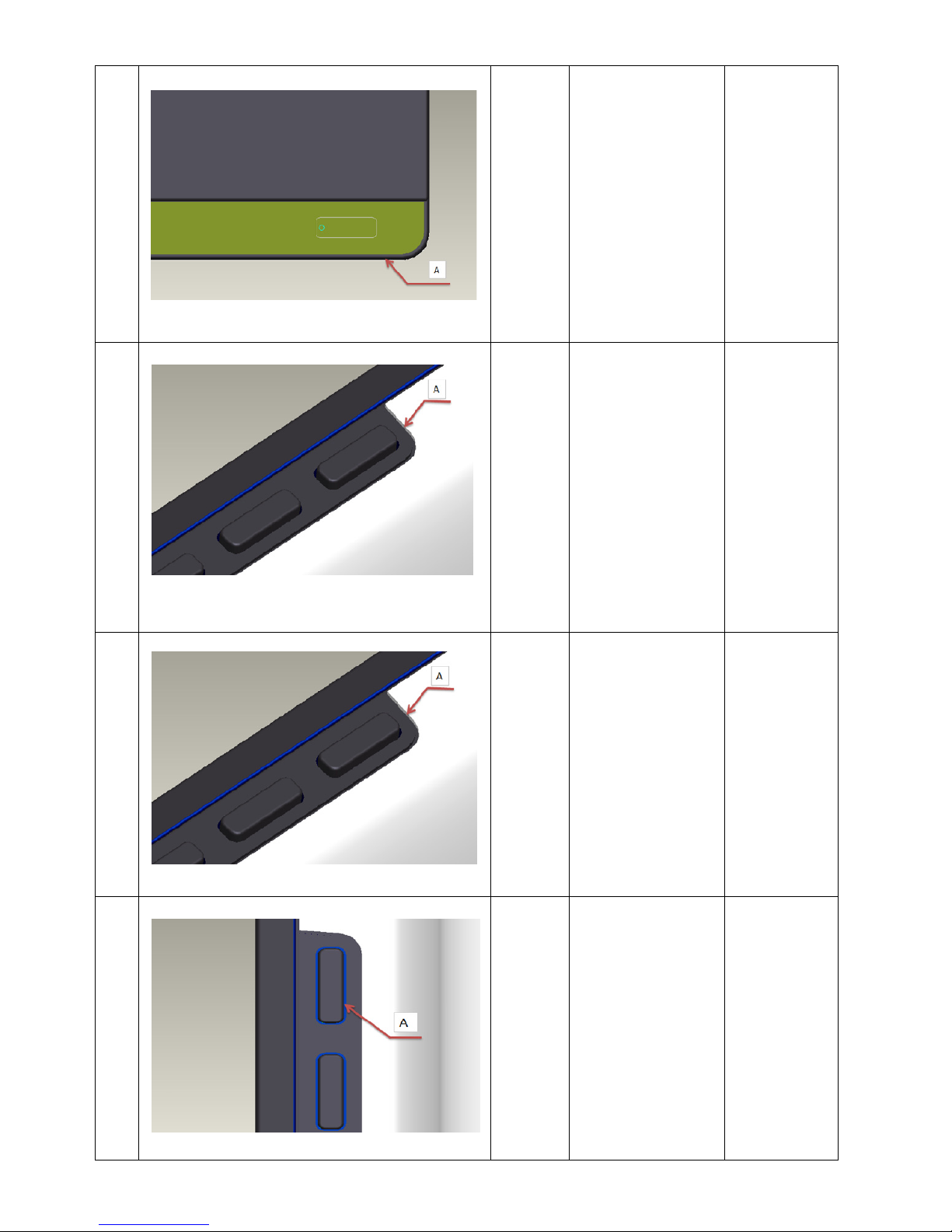

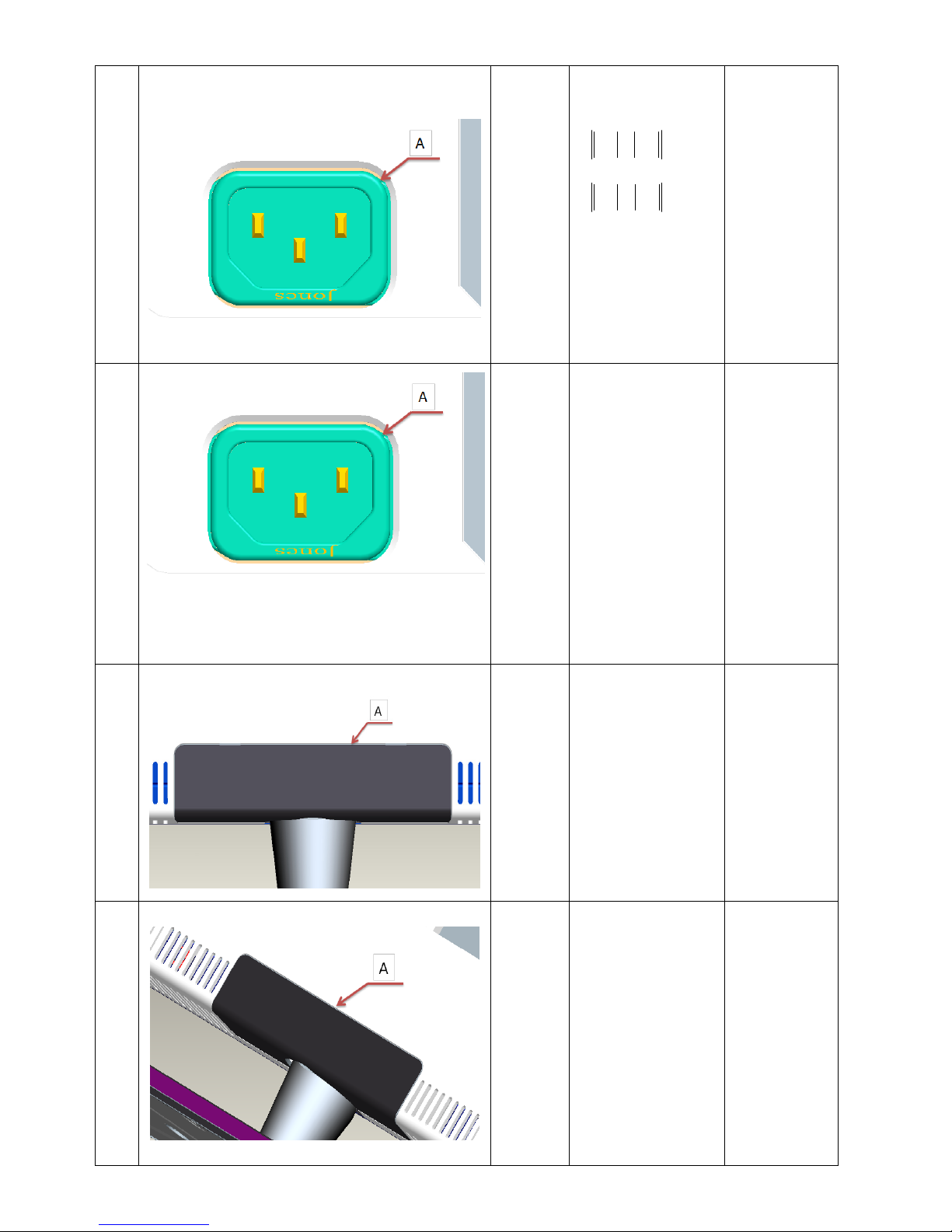

1

Bezel printing

Offset < =0.2mm

Tilt(θ) <= 0.2mm

Offset include

X/Y axis

2

Bezel printing

Offset < =0.2mm

Tilt(θ) <= 0.2mm

Offset include

X/Y axis

3

Component Mylar printing

Offset < =0.2mm

Tilt(θ) <= 0.2mm

Offset include

X/Y axis

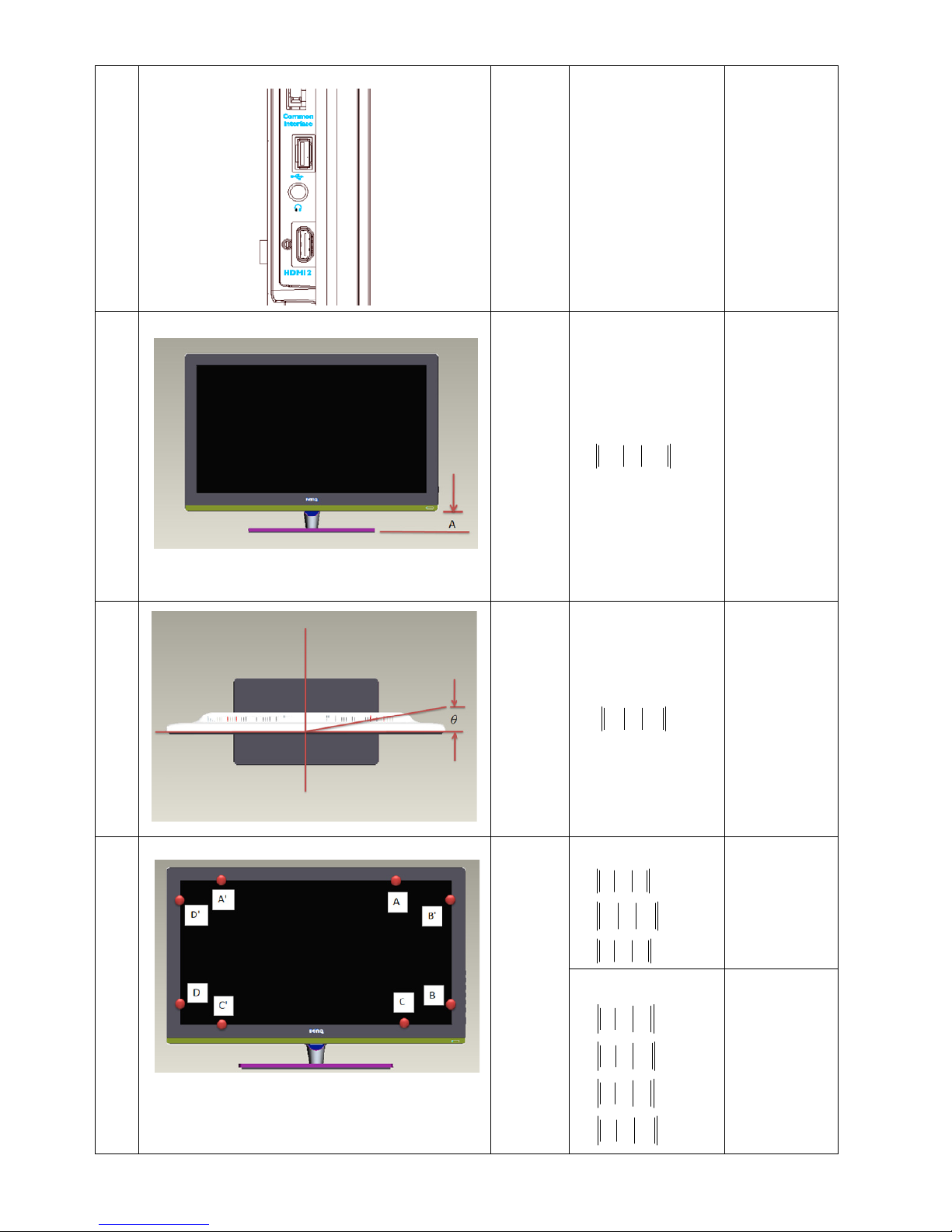

Page 16

16

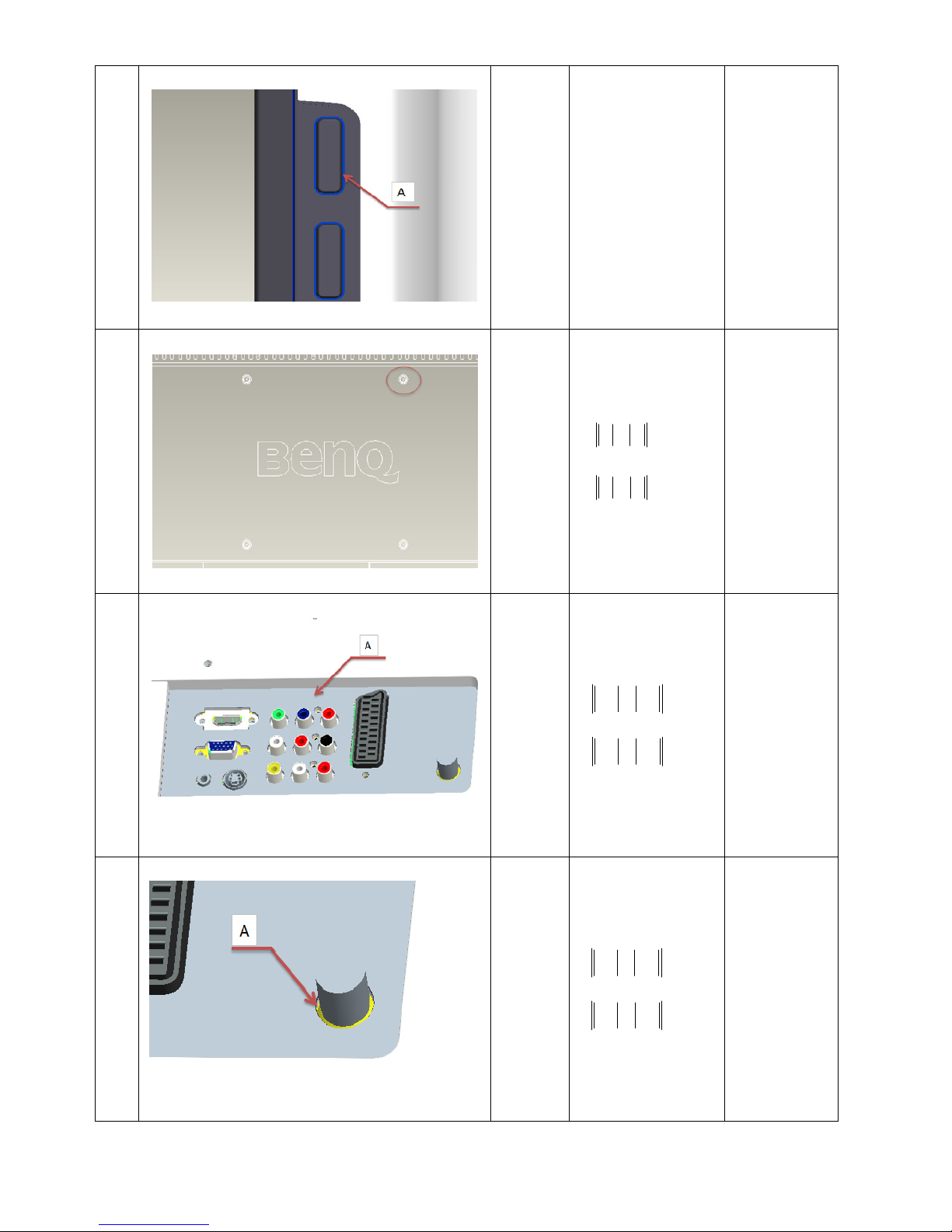

4

Rear cover printing

Offset < =0.2mm

Tilt(θ) <= 0.2mm

Offset include

X/Y axis

5

The height difference with left and right side

5 ARAL

6

machines Twist specifications

3 RL

7

Black side specifications

Shift Tolerance

2.1

2.1

2.1

''

DB

CA

CA

Tilt

0.1

0.1

0.1

0.1

'

'

'

'

DD

BB

CC

AA

Page 17

17

8

The gap of the Bezel and Panel

0.1

A

The Gap of the

panel and

bezel must be

symmetrical.

the difference

<= 0.5mm

9

The gap of the Bezel and rear cover

specification A = 0.5

3.0

1.0

AA

10

The STEP of the Bezel and rear cover

5.0

3.0

AA

11

The gap of the Bezel and decorations

ID SPEC Gap = 0.2 mm

2.0

2.0

AA

Page 18

18

12

The STEP of the Bezel and decorations

ID SPEC = 0.0

3.0

1.0

AA

The compages

accords to

bezel template

as a

benchmark.

13

The gap of the Bezel OSD and rear cover

ID SPEC =0.5 mm

2.0

15.0

AA

14

The step of the Bezel OSD and rear

cover

2.0

2.0

AA

The compages

accords to

bezel template

as a

benchmark.

After

compages the

rear cover is

under the

bezel.

15

The gap of the OSD BTN and bezel

ID SPEC =0.3 mm

15.0

15.0

AA

Page 19

19

16

The STEP of the OSD BTN and bezel

ID SPEC = 1.2 mm

2.0

2.0

AA

The height of

the key-press

and bezel

must be evenly

when

assembled the

key-press.

17

The gap of the Rear cover VESA Hole

position

4.0 RL

4.0 BT

18

The gap of the Mylar and rear cover

compages

3.0

RL

AA

3.0

BT

AA

19

The gap of the tuner connector and rear

cover

7.0

RL

AA

7.0

BT

AA

Cable can't

Insert no

bottom

Page 20

20

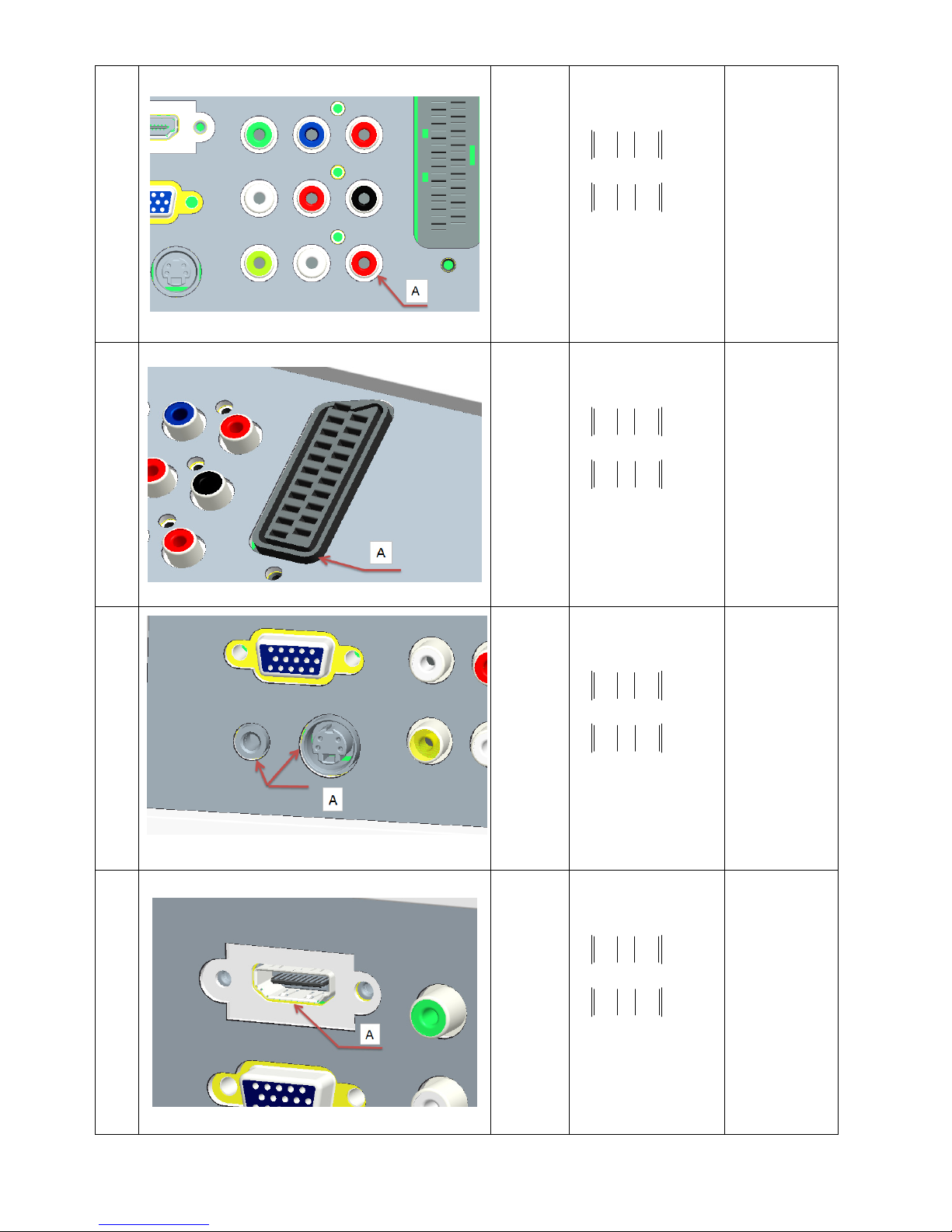

20

The gap of the component connector and

rear cover

7.0

RL

AA

7.0

BT

AA

Cable can't

Insert no

bottom

21

The gap of the Scart Connector and rear

cover

7.0

RL

AA

7.0

BT

AA

Cable can't

Insert no

bottom

22

The gap specification of the S-Video /

Audio in and rear cover

7.0

RL

AA

7.0

BT

AA

Cable can't

Insert no

bottom

23

The gap specification of the HDMI and

rear cover

7.0

RL

AA

7.0

BT

AA

Cable can't

Insert no

bottom

Page 21

21

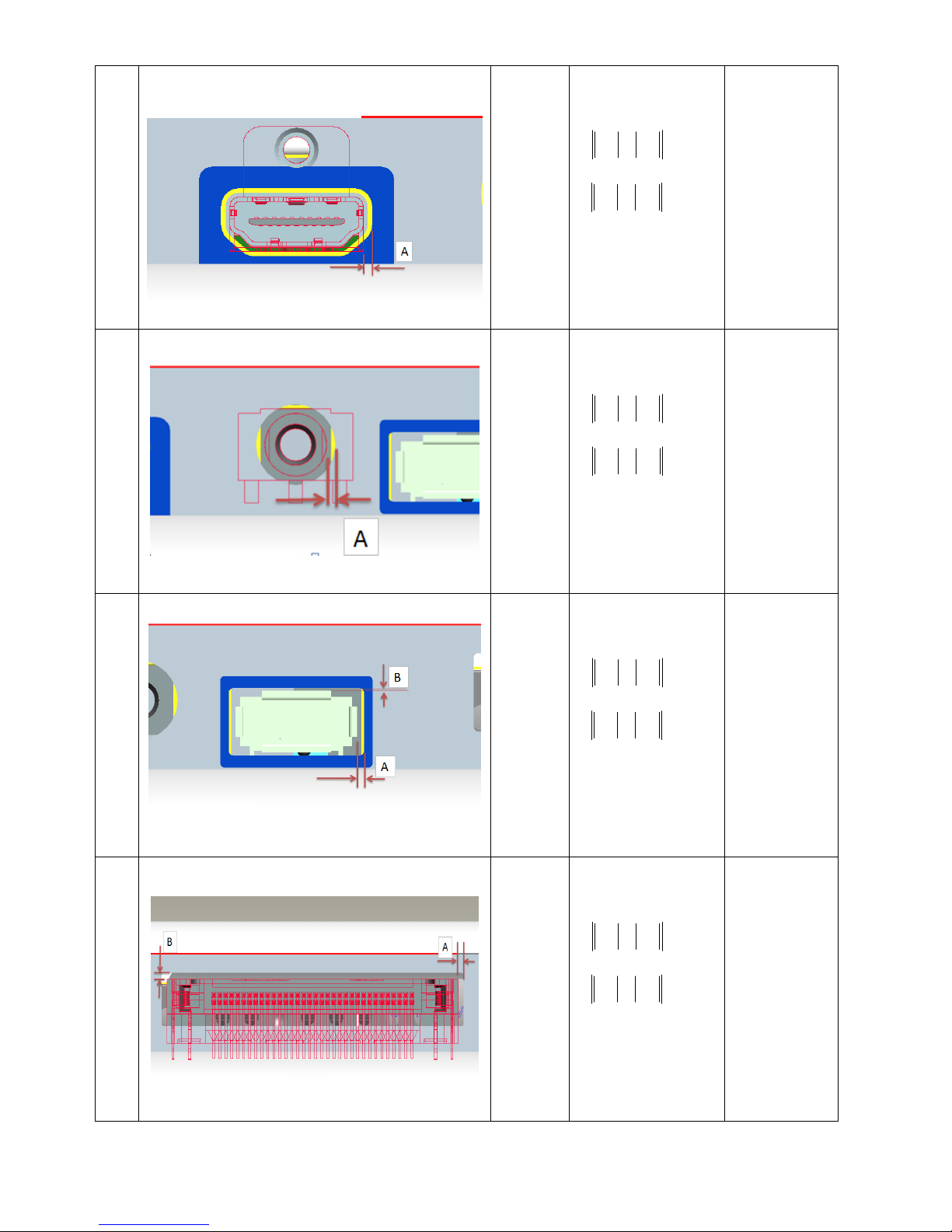

24

The gap of the Side HDMI and rear

cover

0.1

RL

AA

4.0

BT

AA

25

The gap of the Side Headphone and rea

r

cover

0.1

RL

AA

0.1

BT

AA

26

0.1

RL

AA

4.0

BT

BB

27

0.1

RL

AA

4.0

BT

BB

Page 22

22

28

The gap of the AC-Socket and rear cover

compages

ID SPEC = 0.5 mm

6.0

RL

AA

6.0

BT

AA

29

The STEP of the AC-Socket and rear cover

compages

ID SPEC

=

E24

=

1.2mm

2.1

2.0

AA

Do not see the

internal bracket

30

The gap of the Hinge Cover and rea

r

cover

Gap Spec A = 0.15 mm

15.0

15.0

AA

31

The Step of the Hinge Cover and rear

cover

Below the template<

0.3

Page 23

23

32

The gap of the aluminum plaque and

stand

Gap Spec A = 0.2 mm

2.0

2.0

AA

33

The STEP of the aluminum plaque and

stand

ID SPEC = 0.5 mm

15.0

15.0

AA

34

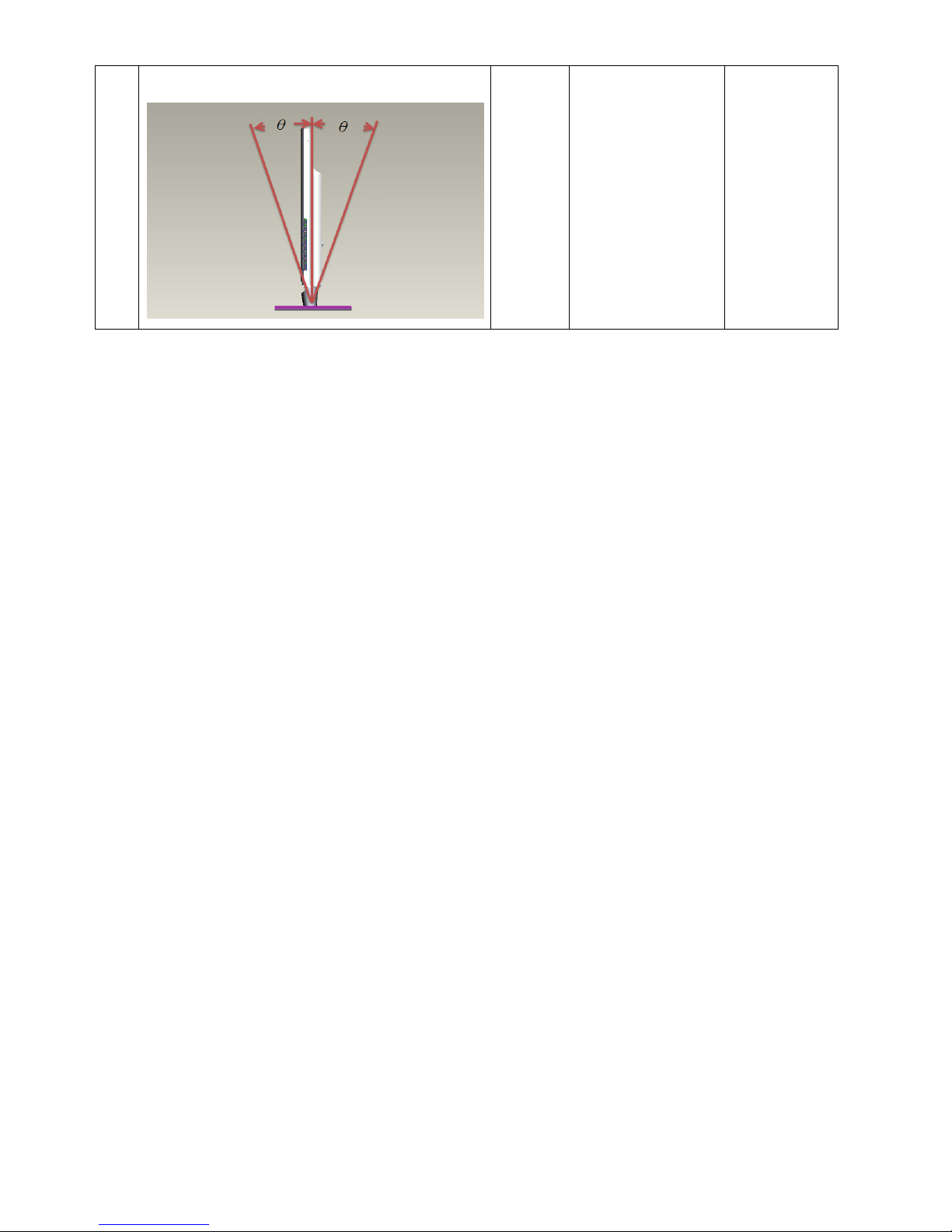

Backward force M

3.05.1

Forward force N

3.05.1

35

Machine stress shaking seconds. Time = T

)(6 SECT

Page 24

24

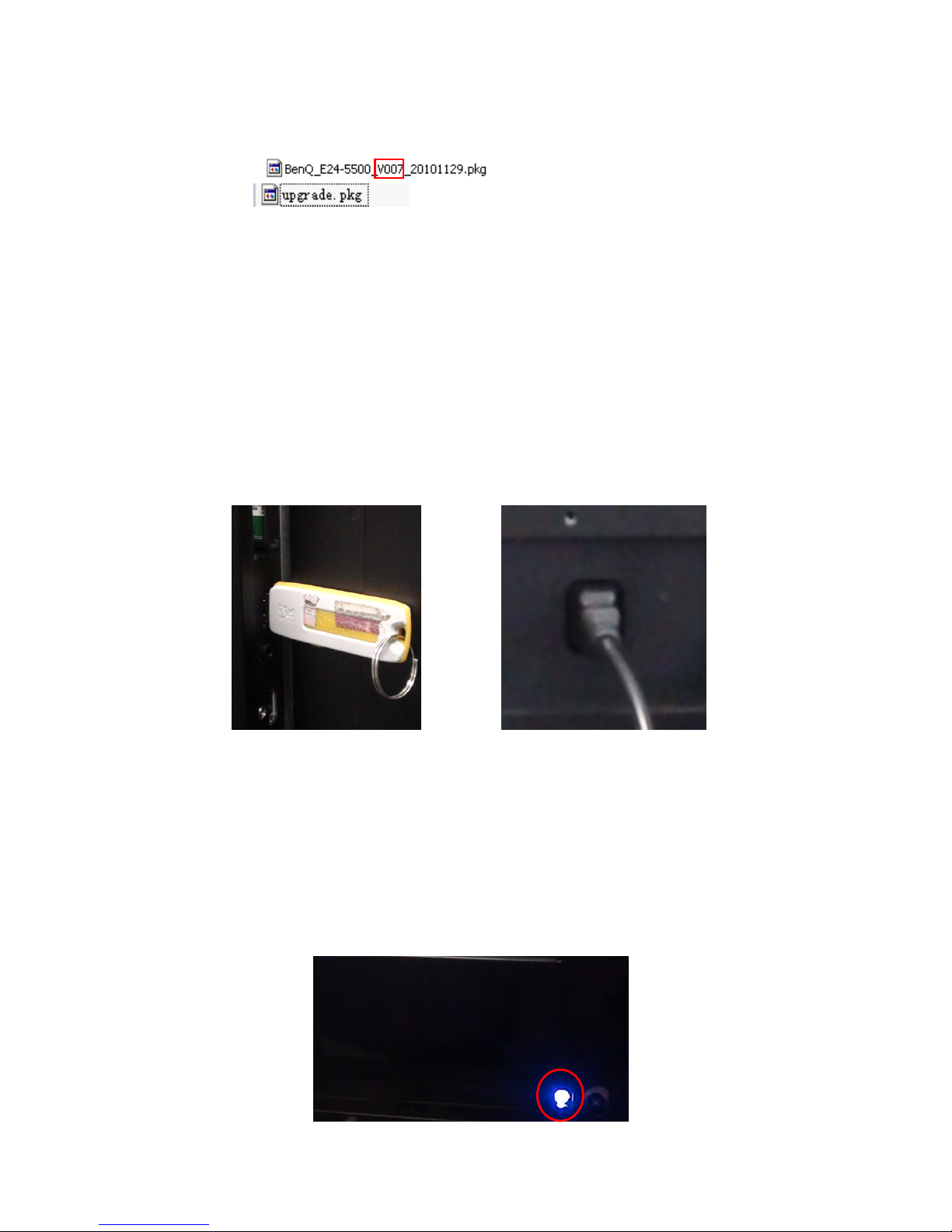

36

degrees of pitch and lean back

00

00

5.15.15:l

5.15.5:p

eanback

itch

Page 25

25

Software/Firmware Upgrade Process

Step 1: Ready for F/W Upgrade

1.1 Change the software file name to ” upgrade.pkg” ,eg:

Before change:

After change:

1.2 Prepare a USB memory (The file system of USB memory must be FAT16 or FAT 32).

1.3 Copy the file (upgrade.pkg) from your computer to the U-disk root path, and remove it from computer’s

USB port!

Note: 1). Note the version of this F/W is V007 before you change the software file name.

2). The software file name must be changed, or TV can’t detect the F/W.

Step 2: F/W Upgrade (There are two methods to upgrade, I will introduce them separately.)

Method 1:

2.1 Plug the USB memory on the USB port on the side I/O port of TV as figure 2.1.

2.2 AC on (Power plug as Figure 2.2)

Figure 2.1 Figure2.2

2.3. After TV monitor AC on, the logo LED color starts to flash as figure2.3, which indicates the TV is upgrading,

forbid to unplug power or U-disk from TV.

Figure 2.3

Page 26

26

2.4. When the monitor screen becomes lights, the upgrade is completed. Unplug the U-disk from TV monitor and

press “power” on remote control or right side power button of TV monitor to restart it as figure2.4.

Figure2.4

Step 3: Check the F/W version and reset to default.

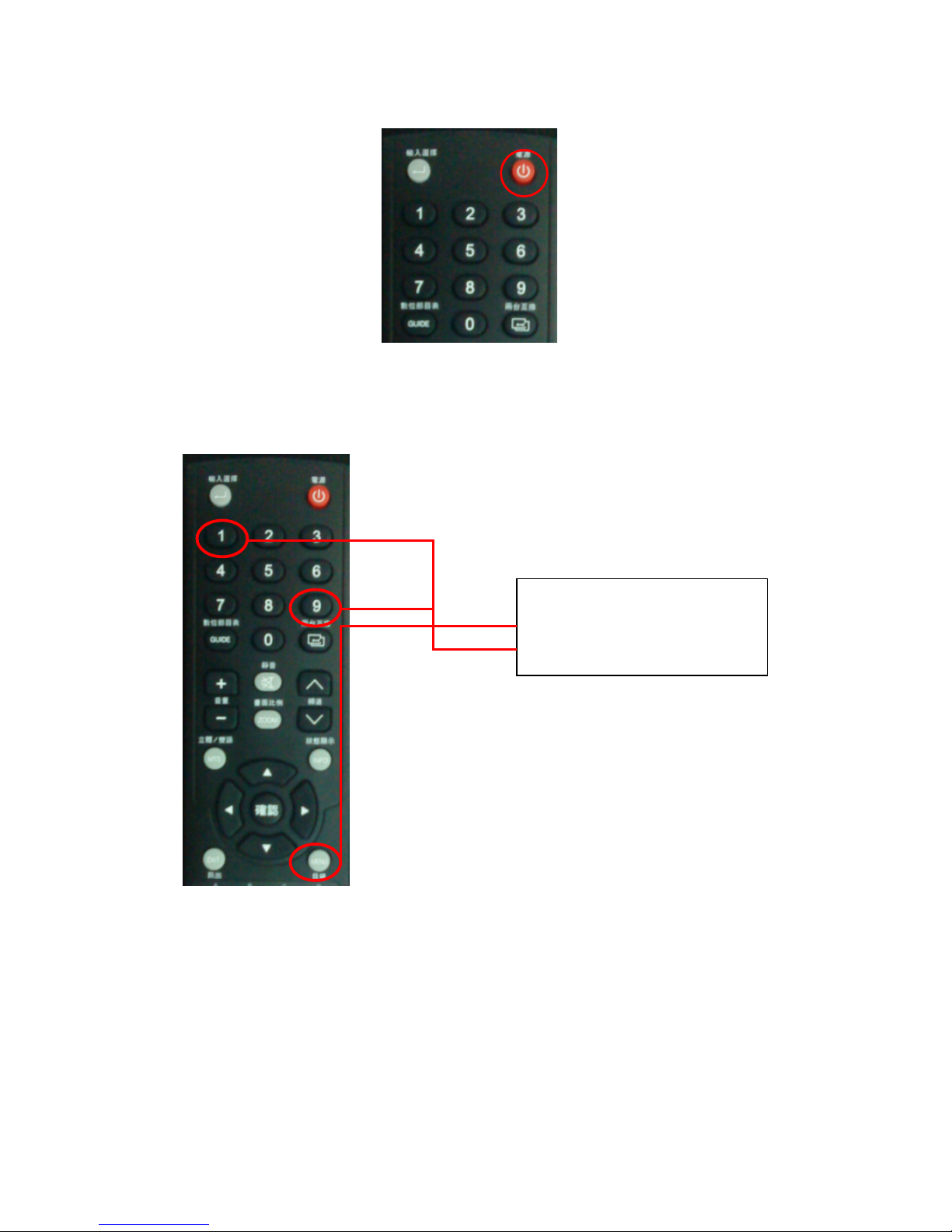

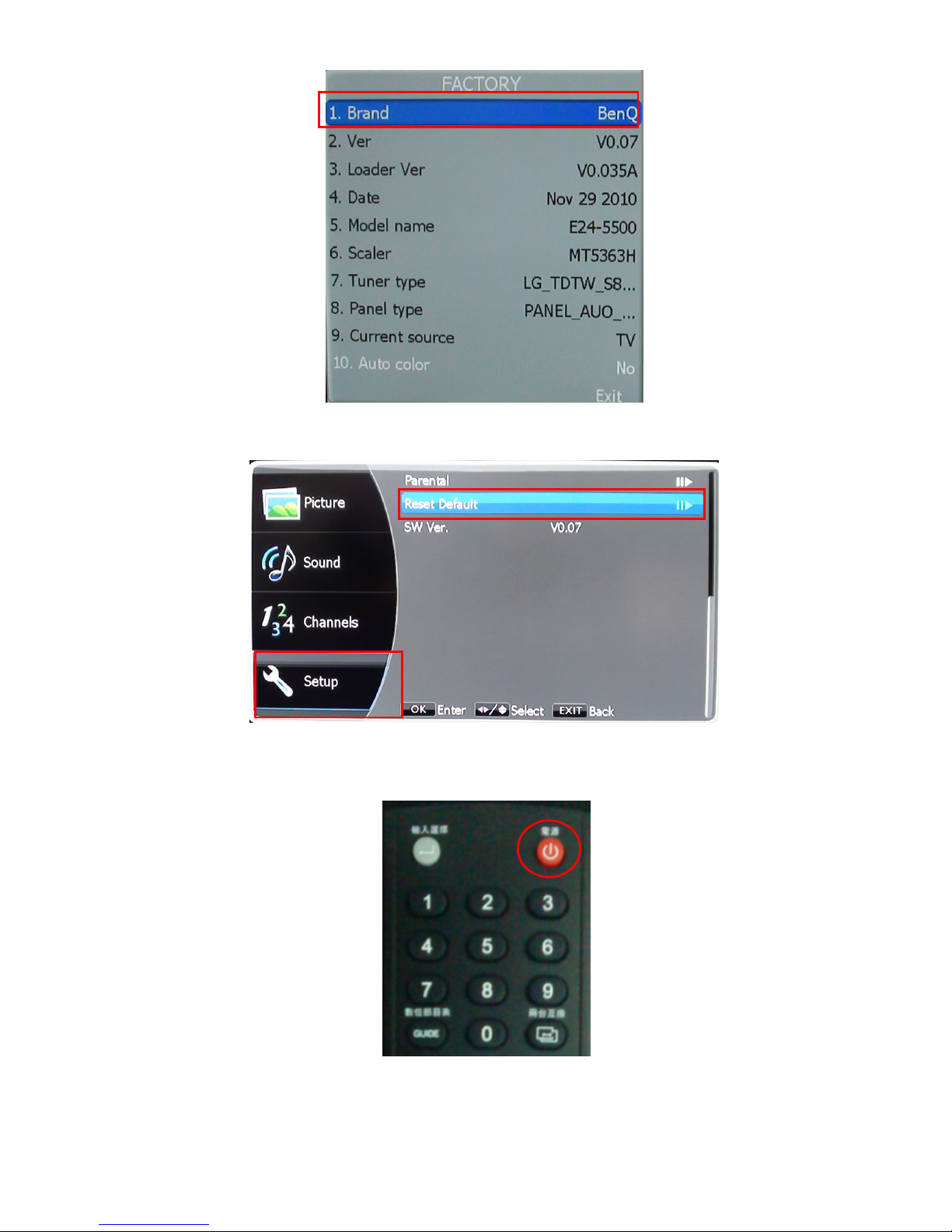

3.1 Unplug the U-disk. And press “menu+1999” to enter factory model to check whether the TV present FW

Version is the same as the upgrade FW version. Do as the figure3.1.

Figure 3.1

3.2. Check the F/W version on the second item of the factory mode info as figure3.2.

Do the following steps rapidly:

1. Press “MENU”;

2. Press”1”+”9” +”9” +”9”;

Page 27

27

Figure 3.2

3.2 If the FW version is correct, then do factory reset in user menu as figure3.6, else skip to step2 to redo upgrade.

Method 2:

Step1. AC on and turn on TV by remote control or right side “power” button of TV monitor as figure2.1.1.

Figure2.1.1

Step2. Plug U-disk with “upgrade.pkg” file to TV monitor, and it will detect the U-disk as figure2.2.1.

Page 28

28

Figure2.2.1

2.1 Select “YES” and press “ok” to automatic upgrade as figure2.2.2.

Fig2.2.2

2.2 After the progress is 100%, unplug U-disk from TV and enter factory model to check whether the FW version is

correct and do factory in user menu. As to the other details, please refer to the method 1.

Page 29

29

Adjustment / Alignment Procedure

The Control Panel

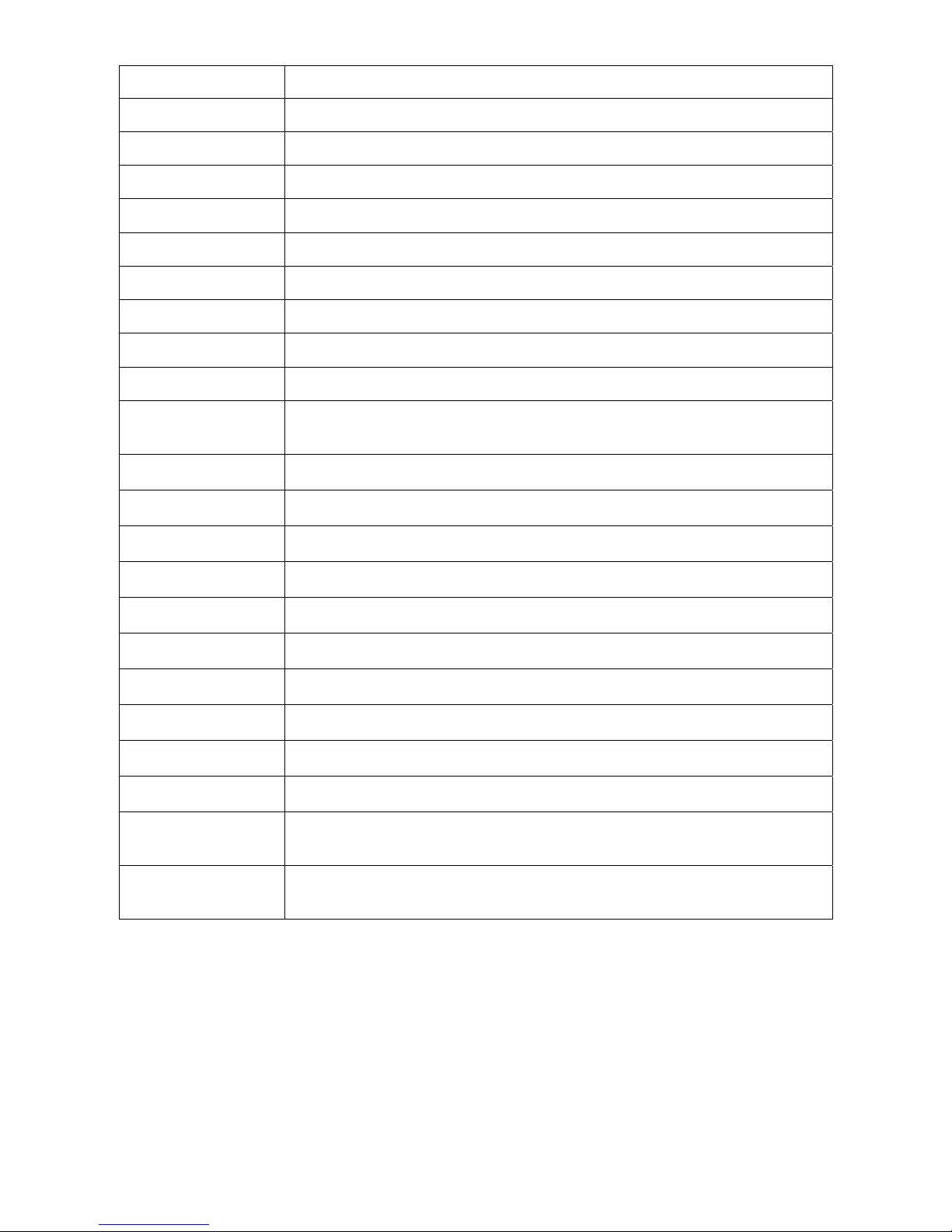

No. Name Remote Control Description

1 MENU button

Enters or exits the OSD menu.

2

VOL (Volume)

+/- button

• +: Volume up / Navigates to the right

(OSD)

• -: Volume down / Navigates to the left

(OSD)

3

CH (Channel)

▲/▼button

• ▲: Channel up / Moves up (OSD)

• ▼: Channel down / Moves down

(OSD)

4 INPUT button

• Selects an input source.

• In the OSD menu, executes

selections or to enter a submenu you

have selected.

5

Power

Turns on/off the TV.

Page 30

30

Adjusting aspect ratio

The TV can resize and reshape an image to suit your requirements. The visual result depends upon the setting your

have chosen, and the original aspect ratio of the input image. Press Zoom on the remote control to cycle through

different aspect ratios.

Auto Normal 4:3 Wide

Video source

(HD) 4:3

X

Video source

(HD) 16:9

X

Video source

(SD) 4:3

X

Video source

(SD) 16:9

X

Computer

source 4:3

X X

X

Computer

source 16:9

X X

X

Page 31

31

Zoom 1 Zoom 2 Panorama Full Screen

Video source

(HD) 4:3

X X X X

Video source

(HD) 16:9

X X X X

Video source

(SD) 4:3

X

Video source

(SD) 16:9

X

Computer

source 4:3

X X X

Computer

Source 16:9

X X X

• “X” means that the related aspect ratio is not available.

• Available aspect ratio options are dependent on the type of input signal being selected. When the TV is

connected to a computer (via D-Sub or HDMI), only 16:9 and 4:3 are available for selection.

• If the input video signal is in letter box format, select “Zoom” to obtain a wider viewable area.

• To avoid possible “image retention” or “screen burn-in” on the LCD screen of your TV, it is recommended that

you change the aspect ratio from time to time and prevent the TV from displaying a static image for a

prolonged period of time.

• The available menu items are dependent on the input source being selected. Unavailable items will be

grayed out or not displayed.

Page 32

32

Navigating the OSD menu

To enter the On-Screen Display (OSD) menu, press MENU on the remote control or MENU on the TV. Next, follow

the navigation guides shown on the screen bottom.

For example, you can:

1. Press ▲ or ▼on the remote control or CH ▲/▼on the TV to move among 4 different main menus: Picture, Sound,

Channels, and Setup.

2. Press OK on the remote control to enter the submenu of a selected (as highlighted on the screen) menu.

3. Press ▲ or ▼ on the remote control to select an item in the submenu.

4. Press ◄, ◄, ▲ or ▼ on the remote control to adjust settings.

5. Press EXIT on the remote control to return to the previous menu or close the OSD menu (pressing MENU on the

TV closes the OSD menu directly).

See the following section for more information on OSD.

Available menu items may vary depending on the selected input source.

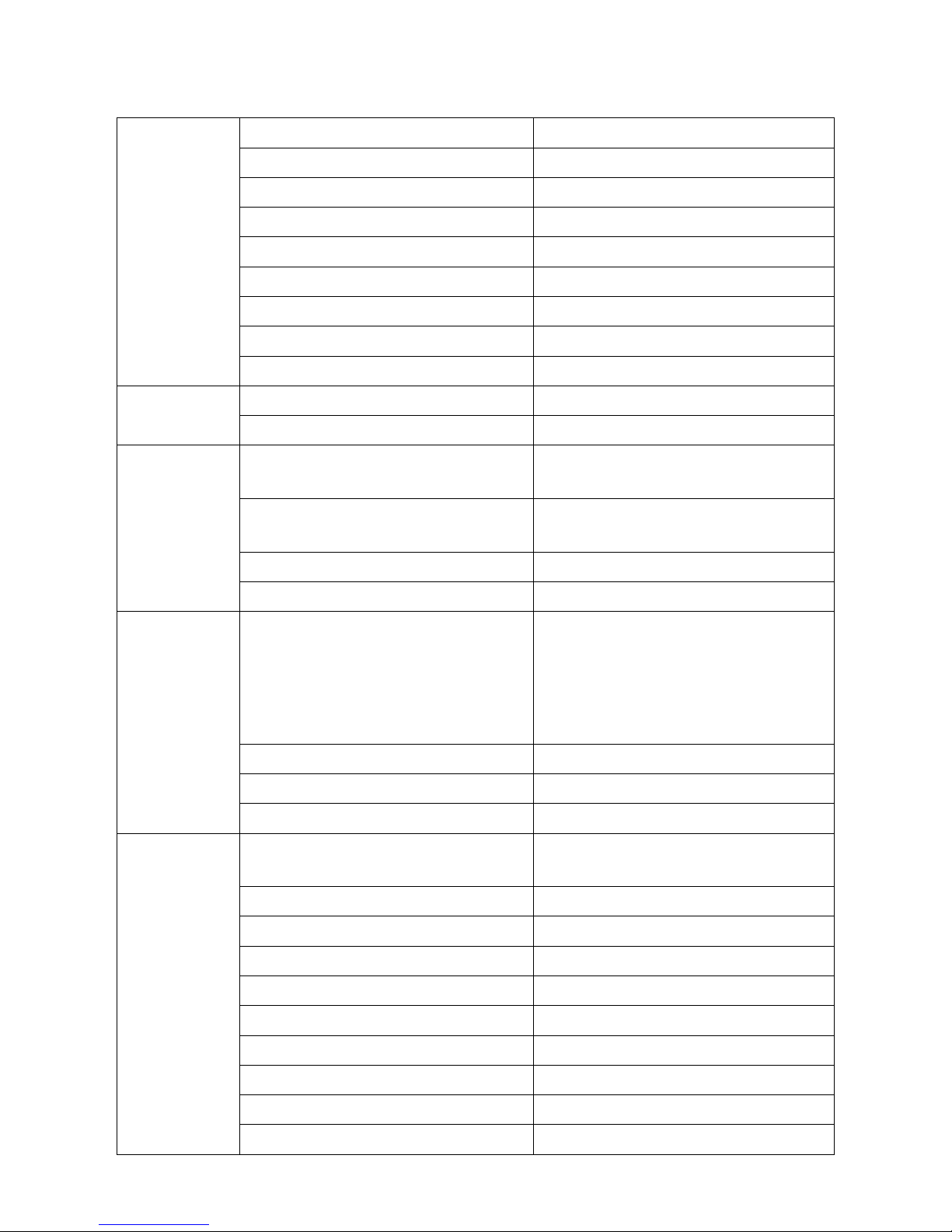

Picture menu

Item Function

Picture Mode

• Vivid: Suitable for viewing in brighter environments. Color, contrast, and brightness of

the image are increased to suit the brighter lighting condition.

• Standard: Suitable for viewing in environments with normal lighting condition. This most

closely represents the broadcast standard quality. No alteration to color, contract or

brightness has been made.

• Cinema: Suitable for viewing movies in darker environments.

Colors have been adjusted to more accurately represent natural skin tones.

• Eco: Saves electricity with low power consumption by providing minimum brightness.

• User: Your own customized picture mode.

Brightness Adjusts the balance between light and dark shades.

Contrast Adjusts the degree of difference between lightness and darkness.

Backlight Adjusts backlight intensity.

Colour Adjusts image color intensity.

Page 33

33

Tint Adjusts color balance.

Sharpness

Adjusts image sharpness level.

When viewing text-rich contents from the VGA or DVI input, you may need to set the

sharpness level to 0 for a suitable display result.

Colour Temperature

Adjusts the color temperature of the black and white part of the image. You can choose

from Normal, Cool, Warm, or User.

Senseye Setting

Adjusts settings in Noise Reduction, Flesh Tone, ACE (Auto Contrast Enhancement),

and Dynamic Backlight.

Picture menu (if connected to a computer via VGA)

Item Function

Brightness Same as above

Contrast Same as above

Colour Temperature Same as above

Auto Configuration Adjusts all related settings automatically by the TV itself.

Position

Adjusts the horizontal and vertical positions of the image in order to center it on the

screen.

Phase Adjusts the display phase to correct shimmering or distortion of the image.

Clock Adjusts the display clock frequency to correct shimmering or distortion of the image.

Sound menu

Item Function

Sound Mode Selects a sound effect.

Equalizer Adjusts sound signals in various frequency ranges.

Treble Adjusts the high tones in sound.

Bass Adjusts the low tones in sound.

Balance

Adjusts the distribution of sounds between the left and the right audio channels of the

built-in speakers, headphone, or SPDIF audio output.

Page 34

34

SRS Surround

Turns on/off the SRS TruSurround HD sound effect, which creates an immersive,

feature-rich surround sound experience from two speakers, complete with rich bass, high

frequency detail and clear dialog.

TV Speaker Turns on/off the built-in speakers.

Digital Audio Out Toggles among Dolby Digital, PCM, and Off.

SPDIF Delay Adjusts the delay time of SPDIF output.

Lip-Sync Sets the delay time of audio output to adjust lip synchronization.

Steady Sound

When Steady Sound is on, it suppresses the possible volume fluctuation between

programming and commercials.

Type

Toggles among Normal, Hard of Hearing (for hearing impaired), and Audio Description

(for visually impaired).

Audio Description Adjusts the volume of Audio Description.

Channels menu

Item Function

Tuner Mode Toggles between two signal sources: Antenna and Cable.

Country Selects the area where this TV is installed.

1st Audio Selects the main audio channel.

2nd Audio Selects the auxiliary audio channel.

Channels

• Channel Scan: Press OK to start automatic channel scanning. All detected channels

will be automatically stored on the TV.

• Update Scan: Scan all channels again to refresh the current stored channel list.

• Signal RF Scan: Used for scanning modulated radio frequency signals.

• Analog Manual Scan: Scans analog TV channels manually.

• Favorites Network Select: Chooses the network you want to watch if more than one

TV network uses the same signal frequency.

• Channel Skip: Omits a selected (already scanned) TV channel.

• Channel Sort: Decides the order of how all scanned channels are displayed.

Page 35

35

• Channel Edit: Customizes the number and name of a channel.

• Decoder: Decides what channels to use if these channels are from a set-top box

connected to the TV via SCART.

• Analog CH Fine Tune: Manually adjusts the frequency used by a channel.

• Clean Channel List: Removes all scanned channels.

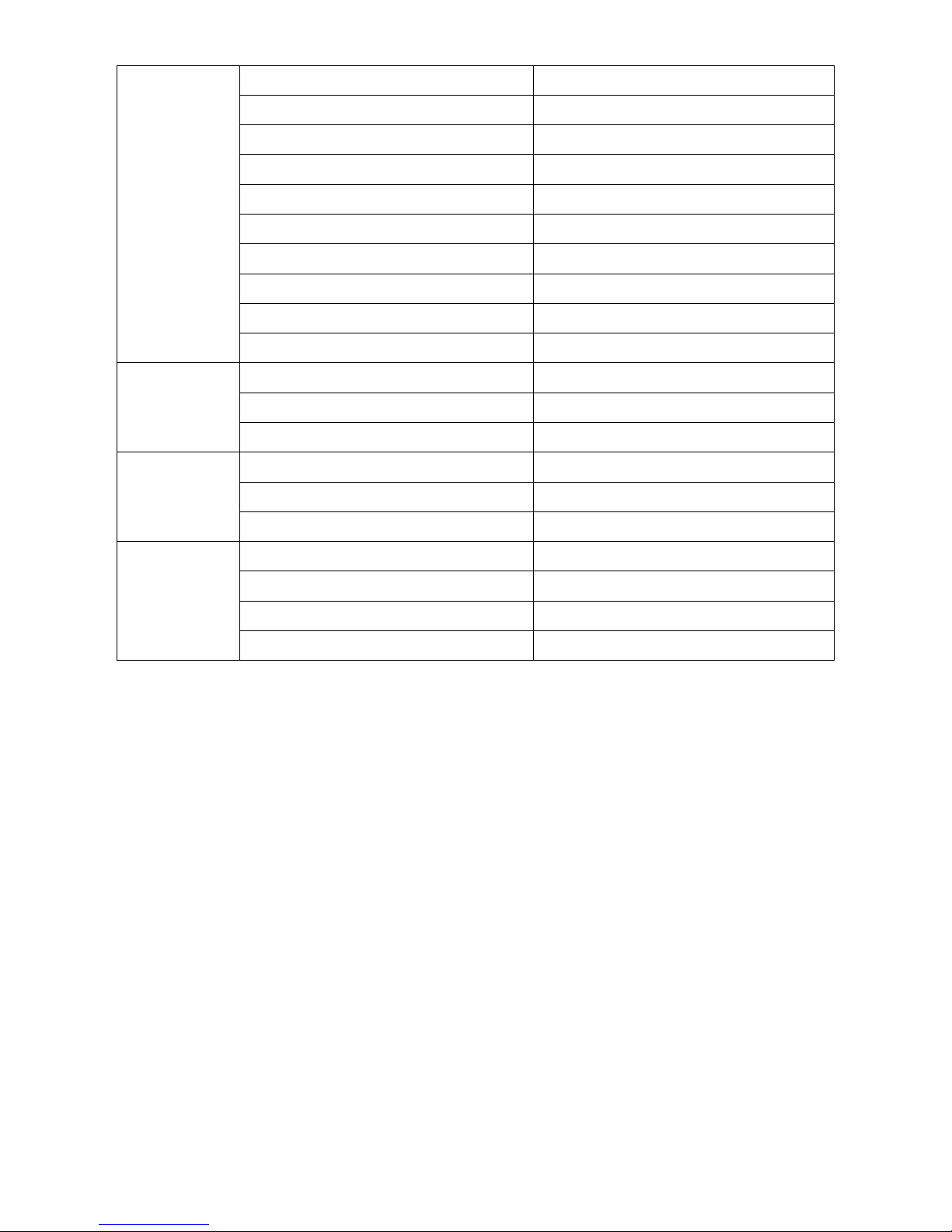

Setup menu

Item Function

Menu Language Selects the language for the OSD menu.

Picture Format

Toggles among different aspect ratios: Auto, Normal, Zoom1, Zoom2, Wide, and

Panorama.

• Zoom 1 sets the TV screen image to 14:9 (the screen image is also cut off by 3% from

the top and the bottom respectively).

• Zoom 2 sets the TV screen image to 16:9 (the screen image is also cut off by 13% from

the top and the bottom respectively and by 3% from the left and the right respectively).

• When a computer is connected, only two picture formats (Full Screen and 4:3) are

available.

Time Sets the local date and time depending on your time zone.

Sleep Timer

Sets the timer for the TV to automatically enter the standby mode.

To quit the standby mode, press the Power key on the remote control.

SCART Toggles among different signals when SCART is in use.

Subtitle Sets what text translations are displayed.

Teletext Language Selects the language for Teletext.

Common Interface Displays the status and information when Common Interface is in use.

Auto (CEC) Turns on/off automatic CEC (Consumer Electronics Control) when HDMI is in use.

OAD

Turns on/off OAD (Over Air Download). When OAD is on, updated service or firmware

upgrade can be done.

HDMI Mode Toggles among different HDMI timing modes: Auto, Graphic, and Video.

Page 36

36

HDMI Scan Info

Sets underscan or overscan info to avoid possible black border on the screen when

HDMI is use.

Shop

• On: sets to the Shop mode.

• Off: sets to the Home mode (less power consumption).

E-sticker Displays BenQ TV features.

Demo

When the Shop mode is on, turning on the Demo mode displays a second screen

showing color enhancement effects.

Parental

Helps concerned parents control the access (such as limited time and channels) to the

TV.

Reset Default

Restore all settings to their default values.

The TV channel memory will not be cleared. That is, you do not need to scan and

store the TV channels again after reset.

Software Version Displays the current TV firmware version information.

Available OSD options may vary depending on the model you purchase and may be changed for further

improvement without prior notice.

Time-shift

Time-shift is a convenient tool for you to record the current program shown on TV if you need to be away from the

TV for a while:

1. While you are watching a digital TV channel, plug a USB device into the USB port of the TV.

2. Press

on the remote control to start Time-shift recording. If this is the first time you use the USB device,

the TV will perform the following tasks (please follow the on-screen instructions):

• Detects whether the available empty space is more than 1GB and the USB transmission speed is at least 5. 0

MB/sec.

• Formats the USB device at your choice. If you choose not to format the USB device, all current data on the USB

device will not be removed.

3. If all the above conditions are met, the TV will then start time-shift recording automatically.

4. Once you are back, press

to start time-shift playback. You can press ◄or► on the remote control to fast

rewind/forward at the speed (2X, 4X, 8X, 16X, or 32X). (Press

to resume playback.). Also, you can press

/ to move forward/backward playback a little.

5. To exit time-shift playback, press

. Note that all recorded videos will be automatically removed from the USB

device.

• The USB device must be in the FAT32 file system. Plus, transmission speed of the USB device must be at

least 5.0 MB/sec and the available empty space should be at least 1 GB.

• Once the USB device is full during time-shift recording, time-shift recording will stop automatically.

Viewing images/videos or listening to the music

If you have images, videos, or music stored in a USB device, you can view/ listen to them on the TV:

Page 37

37

1. Turn on the TV, and then plug a USB device into the USB port of the TV.

2. Repeated press Input on the remote control until USB is selected. A folder view of the USB device will then

display on the screen.

3. Press

on the remote control to select a media type: Photo, Music, or Video.

4. Press

and to select other options (such as effects) as needed.

5. Press ◄, ►, ▲ or ▼on the remote control to move to a file you wish to start and press

on the remote

control. All files will automatically be played backed in a sequence.

The USB external storage device must be in the FAT32 file system.

Hotel Mode (Menu + 100108)

Note: When there is any change from OSD settings, the system need to be DC rebooted

Function Option

Power key lock Default

Maximum volume Default

Volume fixed Default

Volume fixed level 30

Remote control enable Yes

Keypad control enable Yes

MENU key enable Yes

Input mode start Default

Input mod fixed Default

Hotel mode off

Reset

Exit

Copy Settings To SUB Press

Copy Settings To TV Press

Factory Mode (Menu + 1999)

Brand BENQ

Main-MCU Ver V0.01

Ver V0.11

Loader Ver V0.029A

Date Dec 31 2010

Model name E24-5500

Scaler MT5363H

Tuner type LG_TDTW_S8…

Panel type PANEL_AUO…

Current source VGA

Auto color NO

ADC R Gain 83

Page 38

38

ADC G Gain 82

ADC B Gain 79

ADC R Offset 113

ADC G Offset 109

ADC B Offset 100

Color temp Cool

Scaler R Gain 77

Scaler G Gain 107

Scaler B Gain 128

Scaler R Offset 125

Scaler G Offset 125

Scaler B Offset 125

Burn in No

EEPROM Init. Press

Back LIT time 131Hr

BlackLight Max 0

BlackLight Max 196

Language English

Preset Press

OAD Enable Yes

VGA Switch EDID

BAUD RATE 115200

VGA UART DISABLE

EFUSE ENABLE

Rotate Screen DISABLE

Up Sync SPK 0

Up Sync HP 0

Up Sync SPDIF 0

ORT mode LAST_STATUS

Gamma ENABLE

DFM MODE No

Exit

Page 39

39

Supported HDMI video timing

Timing Resolution

Horizontal Freq.

(kHz)

Vertical Freq.

(Hz)

Pixel Freq.

(MHz)

Note

480i 720 x 480 (1440 x 480) 15.735 60i 27 HDMI & DVI

576i 720 x 576 (1440 x 576) 15.625 50i 27 HDMI & DVI

480p 720 x 480 31.47 60p 27 HDMI & DVI

576p 720 x 576 31.25 50p 27 HDMI & DVI

720p60 1280 x 720 45.00 60p 74.25 HDMI & DVI

720p50 1280 x 720 37.50 50p 74.25 HDMI & DVI

1080i60 1920 x 1080 33.75 60i 74.25 HDMI & DVI

1080i50 1920 x 1080 28.13 50i 74.25 HDMI & DVI

1080p60 1920 x 1080 67.5 60p 148.5 HDMI & DVI

1080p50 1920 x 1080 56.25 50p 148.5 HDMI & DVI

1080p24 1920 x 1080 27 24 74.25 HDMI

1080p25 1920 x 1080 28.125 25 74.25 HDMI

1080p30 1920 x 1080 33.75 30 74.25 HDMI

Supported computer (D-sub/VGA) input signal resolutions

Resolution Horizontal Freq. (kHz) Vertical Freq. (Hz) Pixel Freq. (MHz) Note

640 x 480 60 31.5 25.7 VESA

640 x 480 72 37.86 31.50 VESA

640 x 480 75 37.5 31.5 VESA

720 x 400 70 31.469 28.322 VESA

800 x 600 60 37.9 40.00 VESA

800 x 600 72 48.08 50.00 VESA

800 x 600 75 46.9 49.50 VESA

1024 x 768 60 48.4 65.00 VESA

1024 x 768 70 56.48 75.00 VESA

1280 x 720 60 44.77 74.50

1280 x 800 60 49.70 83.5

1280 x 1024 60 64.0 108.00 VESA

1366 x 768 60 47.712 85.5 VESA

1440 x 900 60 55.935 106.5 VESA

1680 x 1050 60 65.29 146.25 VESA

1920 x 1080 60 67.5 148.5

• Resolutions outside of these tables are not recognized and will not be displayed.

• When you connect the TV to a computer, you should adjust the resolution in the display properties of the

computer to closely match the native resolution of the TV. For example, 1920×1080@60Hz.

Page 40

40

Level 2 Circuit Board and Standard Parts Replacement

Product Exploded View

Note: The parts information listed below are for reference only, and are subject to change without notice. Please

go to http://cs.tpv.com.cn/hello1.asp

for the latest information.

Item Description Qty Unit

1 DECO L24WTV-TBENQ4 1 PCS

2 LOGO BENQ 1 PCS

3 BEZEL L24WTV-TBENQ4 1 PCS

4 SPEAKER 1 PCS

6 PANEL 1 PCS

7 IR BOARD 1 PCS

9 KEY 1 PCS

10 KEY BOARD 1 PCS

12 MAIN BOARD 1 PCS

13 POWER BOARD 1 PCS

15 MAIN_FRAME 1 PCS

16 INSULATING SHEET 1 PCS

17 REAR COVER 1 PCS

18 BKT-VESA 1 PCS

19 IR LABEL 1 PCS

20 COVER-HINGE 1 PCS

Page 41

41

21 HINGE 1 PCS

23 DECO L26WTV-TBENQ4 1 PCS

24 STAND L26WTV-TBENQ4 1 PCS

26 BASE L26WTV-TBENQ4 1 PCS

27 PLATE_BASE 1 PCS

32 FOOT PAD 1 PCS

33 SHEET 1 PCS

SCREW

Item Part No. Description Qty Unit

5 0Q1G1040 6120 SPEAKER & BEZEL 4 PCS

8 0D1G1030 8120 IR BOARD & BEZEL 1 PCS

11 0D1G1030 8120 MAIN BOARD & MAINFRAME 4 PCS

14 0M1G1740 6120 POWER BOARD & MAINFRAME 1 PCS

22 0M1G1740 10225 CR3 HINGE & REAR COVER 4 PCS

25 0Q1G 130 6120 STAND & HINGE 1 PCS

28 0Q1G 130 6120 PLATE_BASE & BASE 8 PCS

29 0M1G1140 12125 STAND & BASE 3 PCS

30 0M1G 930 6 47 CR3 HDMI & MAINFRAME 1 PCS

31 0M1G 930 8120 HINGE BKT & BEZEL 2 PCS

34 0M1G 130 6 47 CR3 HDMI & REAR COVER 2 PCS

35 0Q1G 930 8 47 CR3 MAIN BOARD & REAR COVER 3 PCS

ART.

Part No. Description Qty Unit

Q44GK044101 EPS 1 PCS

Q44GK044201 EPS 1 PCS

Q44G6000 491A CARTON 1 PCS

Page 42

42

Six Angles’ View

Page 43

43

Product Disassembly

1) Remove the base

Place the monitor face down on a smooth surface. Be careful to avoid scratch and injury during the process of

uninstall. And then remove the base.

2) Remove the stand

Remove the hinge cover and the screws in red to remove the stand.

Pls use a little force when remove

the hinge cover by hand.

Note: If you can’t remove it, you can

use flathead screwdriver (push

down along the direction of arrow),

but you must be careful.

Page 44

44

3) Remove the rear cover

Remove the rear cover as follow:

Note: The BEZEL CLIP is easy to break.

Page 45

45

4) Remove the key board, IR board and speakers from the bezel; remove the main frame from the panel.

5) Remove the boards from the main frame.

Note: The KEY CLIP is easy to break.

Page 46

46

6) The panel

7) The Bezel.

Page 47

47

Assembly SOP

1) Stick the non-woven fabric on the mainframe.

2) Assemble the main board, power board and FFC wire.

Page 48

48

3) Stick the non-woven fabric and Mylar on the panel.

Note: Non-woven Fabric needs to stick from the front of panel metallic edging which couldn’t be

exceeded; And Non-woven Fabric need to be smoothed up and stuck in prison.

4) Assemble the bezel and the panel.

Note: Put the wire on the panel. Don’t pin it.

Non-Woven

Fabric

Page 49

49

5) Assemble the mainframe on the panel. Insert the pin and tidy the wire.

6) Assemble the rear cover.

Stick the non-woven fabric on the rear cover.

Lock the rear cover.

Page 50

50

7) Assemble the hinge.

8) Assemble the base.

9) Assemble the hinge-cover.

Page 51

51

Block Diagram

Main Board

Page 52

52

Power Board

Converter Board

EMI filter

Start Resistor

(R905,R908,R909)

PWM Control

(IC901)

Transformer

AC input

5V

Bridge

Rectifier

and Filter

Feedback

Circuit

Rectifier

diodes

Power Switch

(Q901)

Photo coupler

(IC902)

16V

D801

LED

(CN804)

PWM Control

MP3389EF

(U801)

16V

DIM

ON/OFF

L801

Page 53

53

Schematic Diagram

Main Board

715G3988M0D001005K

FB702 120R/3000mA

1 2

R735

24K1/16W

PWR_5V_13,8, 11,13

PWR_16V_1

R710

NC

DV33SB

C4209

100N 50V

R4303

NC

R708

10K+-5%1/16W

U751

IC G903T63UF 0.6A/3.3V SOT-223

3 2

1

4

VIN VOUT

GND

4

SMD

2.3A

INVERTER_ON_OFF14

C701

NC

POWER_DETECT

+

C702

470uF 16V

﹁

0603

MPS

C765

10U 16V

C767

10U 16V

C720

10N 50V

+5V_SW3,4,6,9,11, 12,13,14

INVERTER_ON_OFF

FB4203120R/3000mA

1 2

Q705

NC

3

1

2

C4210

NC

C704

10N 50V

+16V

R711

56K 1/16W

FB4204 120R/3000mA

1 2

R4306

100K1/16W

MCU_5V_POWER_ON15

C712

1UF16V

C719

10U 16V

PWR_5V15

Q704

AO4411

123

4

876

5

SSS

G

DDD

D

STAND_BY

C732

1uF 25V

PWR_5V_1

FB705

220R/2000mA

12

C735

100N 16V

R731

0R05 1/10W

R729

56K 1/16W

R721

10.2K 1/10W

DV333,4,5,6,8,9,10 ,12,13,14

R4308

NC

R705

22K1/16W

C705

100N 50V

R4309

NC

DV115

R724

22K1/16W

POWER_DETECT9

R725

NC

R713

NC

PWR_5V_1

Q706

LMBT3904LT1G

3

1

2

R4304

4.7K1/16W

Q1157

NC

123

4

876

5

SSS

G

DDD

D

C718

1500P50V

OPWRSB8

C716

NC/180P 50V

PWR_5V_1

R733

10K 1/10W

PWR_5V_1

FB701120R/3000mA

1 2

DV33SB8,12, 13,15

Q702

LMBT3904LT1G

3

1

2

BRIGHT_ADJ14

D701

NC/SS3P4

1 2

PWR_5V_1

POWER_ON

C708

100N 16V

CN701

CONN

1

2

3

4

5

6

7

8

9

10

R720

4K12 +-1% 1/10W

PWR_5V

PWR_16V

C707

100N 16V

PWR_5V

R718

3.3K 1/16W

OPWRSB

+16V13

R730

10K 1/10W

POWER_ON8,15

PWR_16V_13,13

C4211

NC

PWR_5V_1

U701

MP9403EN-LF-Z

1

2

3

4 5

6

7

8

9

BS

IN

SW

GND FB

COMP

EN

SS

Therm al Pad

Q1158

NC

3

1

2

PWR_16V_1

DV11

R4310

NC

1

Custom

114Thursday, December 16, 2010

715G3988M0B0010050

01. POWER-1

G3988-M0B-001-0050-2-101216

OEM MOD EL Size

Rev

Date

Sheet

of

TPV MODE L

PCB NAME

称爹

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

PWR_5V

C4212

NC

+5V_SW

C717

100N 16V

R736

100K1/16W

STAND_BY9

BRIGHT_ADJ

R728

4.7K1/16W

R4305

10K+-5%1/16W

R4311

NC

PWR_16V_1

C709

1UF16V

SMD/0402

R714

4.7K1/16W

L701

15uH

C715

100N 16V

PWR_5V_1

+

C4208

330uF 35V

+

C713

470uF 16V

confirm function_Jason

+16V

Q707

AO4411

123

4

876

5

SSS

G

DDD

D

C731

1uF 25V

R4312

NC

DV11

GMT

0.6A

SOT223

MCU_5V_POWER_ON

R4307

NC

Page 54

54

PWR_5V_1

+

C714

100uF25V

R751

10K+-5%1/16W

1

Custom

214Friday , Novem ber 05, 2010

715G3988M0B0010050

02. POWER-2

G3988-M0B-001-0050-2-101105

OEM MOD EL Size

Rev

Date

Sheet

of

TPV MOD EL

PCB NAME

称爹

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

PANEL_VCC14

FB4215 N C/120R/3000m A

1 2

C436

1UF16V

0603

C724

1UF16V

PANEL_PWR

C764

10U 16V

C758

10U 16V

D703

NC

DV18_DDR7

D702

NC

+5V_SW2,4,6,9, 11,12,13,14

U753

3 2

1

VIN VOUT

GND/AD J

Q750

AO4411

123

4

876

5

SSS

G

DDD

D

+

C721

470uF 16V

PWR_16V_12,13

D705

RGP15D

R756

120R 1% 1/10W

AV33

+5V_TUN ER

R719

56R 1/10W 1%

C761

1UF16V

+

C753

100UF 16V

C759

100N 16V

C754

100N 50V

FB4213 120R/3000mA

1 2

PANEL_PWR

DV18_DDR

C4214

100N 16V

C763

1UF16V

DV33

R758

NC

R757

1R 1%

4.95

R753

4.7K1/16W

DV33SB2, 8,12,13,15

+

C752

100UF 16V

R750

22K1/16W

1104

PANEL_VCC

R755

56K 1/16W

D704

RGP15D

PANEL_VCC_ON/ OFF

FB4214 120R/3000mA

1 2

Q751

LMBT3904LT1G

3

1

2

FB752

220R/2000mA

1 2

U702

G1084T43Uf

23

1

VOUTVIN

ADJ

R717

120R 1% 1/10W

U75 4

SC4215HSETRT

1

2

3

4

8

7

6

5

9

NC

EN

VIN

NC

GND

FB

VO

NC

TH1

C711

10U 16V

C4213

100N 16V

AV12

AV336,12,14

FB4216 N C/120R/3000m A

1 2

U750

G1117-33T43UF

123

ADJ(GND)

VOUT(TAB)

VIN

FB751

NC/220R /2000mA

1 2

+

C755

100uF 16V

R761

5K1 1/10W 1%

PANEL_VCC_ON/ OFF6

U752

G1117-33T43UF

123

ADJ(GND )

VOUT(TAB)

VIN

PANEL_PWR

R760

43K 1/10W 1%

R759

2.4K 1/10W

AV124,5,6, 7,12,14

C722

10U 16V

+5V_SW

PWR_5V_12,8,11,13

+

C762

100UF 16V

1104

PWR_16V_1

DV334,5,6, 8,9,10,12,13, 14

1%

R765

10K+-5%1/16W

伦猾

6.3x5.5 SMD

105 2000hr

+5V_TUN ER4

DV33

C757

NC/10U 16V

FB706

220R/2000mA

12

Page 55

55

CI_IND ATA1

CVBS0P

R1036

NC/4.7K1/16W

C1041

100N 16V

DV33_DVBC

GND_Tuner

CI_INDATA69

R1011

300R

C1006

30PF 50V

R1017

0R05 OHM

R1018

0R05 OHM

GND_Tuner

GND_Tuner

FAT_IN-6

CI_INSYNC9

CI_INDATA09

R1005

10K+-5%1/16W

TCK_19

DV12_VADC

FB1002

120R/3000mA

1 2

TU102

NC/TUNER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

252627

28

RF Pin In/Out

Ant Pwr

GND

NC

RF AGC

GND

VP(TUN)

VT

GND

NC

AS

SCL

SDA

NC

IF_AGC

DIF1

DIF2

WIF OUT

NC

NC

NC

NC

NC

NC

TH1

TH2

TH3

TH4

TP1000

1

CVBS0P6

TU_FAT_IN2-_T

TVAVLID

C1039

100N 16V

C1034

100N 16V

C1028

NC/10N 16V

+5V_T1

C1040

10U 16V

R1016

NC/4.7K1/16W

+5V_SW

TUNER_CLK_Demod

TUNER_DATA_Demod

MPX_N

RP1002

0OHM 1/16W

1

2

3

4

8

7

6

5

RF_AGC_NXP

C1036

100N 16V

RF_AGC_TUNER9

MPX_P6

CI_INSYNC

R1049

51R 1%

R1030

NC/100R 1/ 16W 5%

TUNER_CLK

C4235

10U 16V

TSYN C

+5V_TUNER3

+5V_TUNER

GND_Tuner

U101

Si2163

123456789

10

29

30

31

33

32

34

35

36

282726252423222120

19

11

12

13

15

16

17

14

18

37

GND

AGC_IF

AGC_RF

SCL_HOST

SDA_HOST

VDD_CORE

TS_VAL

TS_SYNC

TS_CLK

GND

ADC_IP

ADC_IN

ADC_CP

SDA_MAST

ADC_CN

SCL_MAST

RESSI_ADC

GPIO_0

VDD_VADC

VDDH_ANA

ADDR

XTAL_I

XTAL_O

VDD_VCORE

RESETB

TS_ERR/GPIO_2

TS_DATA7

GND

TS_DATA0

TS_DATA1

TS_DATA2

VDD_HVIO

TS_DATA4

TS_DATA5

TS_DATA3

TS_DATA6

GND

R1038

NC/0R05OHM1/16W

C1037

100N 16V

FB1014

120R/3000mA

1 2

GND_Tuner

M_AOLRC K5,6

GND_Tuner

TCK_1

R1001

NC/75OHM1/16W

R1006

10K+-5%1/16W

FB1005

120R/3000mA

1 2

TU_FAT_IN2-

L1003

0.33uH 10%

FB1003

120R/3000mA

1 2

C1022

33P 50V

C1013

47N16V

C1026

NC/47pF 50V

TU_F AT_IN 2+_ T

C1005

30PF 50V

X1000

16MHZ 20P

1 2

C1004

100N 16V

FAT_IN-

IF_AGC_C

GND_Tuner

TU_FAT_IN2+

TDO

TUNER_CLK_Demod

R1041 0R05 OHM

C1008

100N 16V

FAT+

C1019 33P 50V

+

C1000

330uF 10V

TDO9

R1010

0R05 OHM

TSYN C

DV33SB2,8,12, 13,15

TU_FAT_IN2+

R1033

10K+-5%1/16W

R1042 0R05 OHM

FB1013 120R /500mA

1 2

CI_INDATA39

C1049

10P 50V

R1002

4.7K1/16W

TUNER_DATA6

LNA_ON/OFF9

IF_AGC

GND_Tuner

TUNER_BYPASS_I n6

T_SC L

DV12_DVBC

RP1000

0OHM 1/16W

1

2

3

4

8

7

6

5

R1037

NC/4.7K1/16W

C1014

47N16V

T_SD A

C1038

100N 16V

R1035

100OHM1/16W

DV112,5

+5V_T1

TU_MPX_P2

GND_Tuner

TUNER_DATA

1

Custom

314Monday, Nov ember 01, 2010

715G3988M0B0010050

03. TUNER

G3988-M0B-001-0050-2-101101

OEM MOD EL Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

称爹

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

FAT_IN+_C

C1010

39pF 50V

LNA_ON/OFF

MPX_P1

C1012

47N16V

DV33_DVBC

CI_INVALID9

TU_FAT_IN2-

U103

TS5A3157DCKR

1

2

3 4

5

6

NO

GND

NC COM

V+

IN

R1025

0R05 OHM

RP1001

0OHM 1/16W

1

2

3

4

8

7

6

5

C1009

1N 50V

FAT+

TU_FAT_IN2-

FB1004

120R/3000mA

1 2

R1007

10K+-5%1/16W

C1017

220pF 50V

IF_AGCT_T

FB1008

120R/3000mA

1 2

SYSTEM_REST

CI_INVALI D

R1012

300R

AV123,5,6,7, 12,14

RF_AGC

R1028

NC/0R05OHM1/16W

IF_AGC

TUNER_BYPASS_I n

DV333,5,6,8,9,10,12, 13,14

FAT-

FB1001

120R/3000mA

1 2

C1031 100P 50V

DV33_DVBC

C1025

NC/15PF50V

FB1022

120R/3000mA

1 2

CI_IND ATA5

R1047

0R05 OHM

FB1019

120R/3000mA

1 2

R1043

0R05 OHM

FAT-

GND_Tuner

GND_Tuner

TUNER_CVBS1

C1029

NC/1N 50V

SYSTEM_REST9

C1015

47N16V

R1008

10K+-5%1/16W

R1044

0R05 OHM

L1008

NC

TUNER_CLK6

AV12

IF_AGCT

FAT_IN+_C

TUNER_CLK_Demod

R1045

0R05 OHM

Back

TUNER_CVBS1

MPX_P

FB1006

220R/2000mA

1 2

C1003

100N 16V

TVAVLID9

M_AOLRC K

+5V_TUNER

C1021

22P 50V

R1029

NC/100R 1/16W 5%

DV33

CI_IND ATA6

C1001

10U 16V

CI_INDATA79

T_SD A

C1018

33P 50V

IF_AGCT6

CI_IND ATA0

TUNER_DATA

FAT_IN+6

TCK_1

TU101

TUNER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

171819

20

ANT[+5V]

LNA ON/OFF

GND

+B(5V)

RF AGC

GND

SDA

SCL

TU AS

DIF[+]

DIF[-]

IF AGC

NC

NC

NC

NC

TH1

TH2

TH3

TH4

RF_AGCT

GND_Tuner

R1021

0R05 OHM

CI_INCLK9

TU_F AT_IN 2-_ T

FB1000

120R/3000mA

1 2

TUNER_DATA_Demod

C1011

39pF 50V

R1040

NC/0R05OHM1/16W

L1001

0.22uH 10%

C1097

10N 50V

MPX_N1

L1002

0.33uH 10%

R1023

4.7K1/16W

CI_INDATA19

TU_FAT_IN2+

C1035

100N 16V

DV12_DVBC

R1046

0R05 OHM

DV33_DVBC

R1027

NC/0R05OHM1/16W

C1007

100N 16V

C1046

NC

C4233

10N 50V

GND_Tuner

CI_INDATA29

RF_AGC_NXP

TVAVLID

DV33_DVBC

CI_IND ATA2

RP1003

0OHM 1/16W

1

2

3

4

8

7

6

5

FB1017

120R/3000mA

1 2

R1039

100OHM1/16W

FAT_IN+

CI_IND ATA3

FB1015

120R/3000mA

12

C4232

10N 50V

R1026

NC/0R05OHM1/16W

SMD/0402

TUNER_CVBS

FAT_IN-_C

FB1011

120R/3000mA

1 2

R1000

NC/75OHM1/16W

R1048

51R 1%

R1003

4.7K1/16W

C1002

10U 16V

C4236

100N 16V

FB1023

60 OHM

12

GND_Tuner

IF_AGCT_T

RF_AGC_TUNER

TCK_0

Q1001

NC/BC857C

RF_AGCT6

+5V_SW2,3,6, 9,11,12,13, 14

DV12_DVBC

C1016

220pF 50V

C4234

100N 16V

GND_TunerGND_Tuner

L1000

0.22uH 10%

GND_Tuner

MPX_N6

CI_IND ATA4

TU_FAT_IN2+_T

R1024

NC/100K1/16W

R1034

NC/0R05OHM1/16W

R1019

1K 1/16W

C1042

NC/10P 50V

AV12

TSYN C9

CI_INCLK

TUNER_CLK

T_SC L

IF_AGC_C

C1033

100N 16V

Front

FB1016

120R/3000mA

1 2

GND_Tuner

TDO

TUNER_DATA_Demod

FAT_IN-_C

DV12_VADC

CI_INDATA49

CI_INDATA59

TU_MPX_P2

C1030

NC/1N 50V

FB1012

120R/3000mA

1 2

C1027

NC/10N 16V

CI_IND ATA7

L1005

NC/0.22uH 10%

FB1009

120R/3000mA

1 2

FB1007

120R/3000mA

1 2

C1020

22P 50V

Page 56

56

R4005

4.7K1/16W

C4005

100N 16V

SMD/0402

R4006

4.7K1/16W

AV12

SMD/0402

DV11

FB4000

120R/3000mA

1 2

DV11

C4013

100N 16V

SMD/0402

R4003

4.7K1/16W

SMD/0402 SMD/0402

M_AOL RC K

C4011

100N 16V

C4014

100N 16V

AV123,4,6,7,12,14

DV33

C4001

100N 16V

R4004

4.7K1/16W

M_AOB CK

C4008

100N 16V

R4002

NC/4.7K1/16W

SMD/0402

M_AOSDATA0

Power

&

Ground

U401A

MT5363LIMG

AF29

AG32

AH33

AG30

Y3

J4

L4

W4

J6

L6

W6

C8

E8

G8

AE8

D9

F9

AF9

G10

AB13

AD13

N14

R14

W14

AC14

P15

T15

V15

AB15

U16

W16

AA16

AC16

T17

V17

Y17

AB17

R18

U18

W18

AA18

AC18

T19

V19

Y19

AB19

N20

R20

U20

W20

AA20

AC20

B21

D21

P21

T21

V21

Y21

AB21

AD21

E22

G22

R22

U22

W22

AA22

AC22

AM1

AL2

AN2

AM3

AL4

AN4

AK5

AM5

AJ6

AL6

AH7

AK7

AM7

AJ8

AL8

AG12

V13

Y13

U14

AA14

AE14

Y15

AD15

R16

AE16

AD17

AE18

AD19

AE20

N22

AE22

N24

W24

AA24

T25

V25

H23

J30

H31

V31

W32

W34

W36

AF13

AH29

AH31

P23

T23

V23

Y23

AB23

AD23

R24

U24 AC24

AE24

P25

AD25

Y25

AB25

AF15

AVDD12_TVDPLL

AVDD12_SY SPLL

AVDD12_ADC PLL

AVDD12_APLL

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCK

VCCIO33

VCCIO33

VCCIO33

VCCIO33

VCCIO33

VCCIO33

VCCIO33

VCCIO33

AVSS12_PLL

AVSS12_PLL

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS

DVSS DVSS

DVSS

DVSS

DVSS

VCCK

VCCK

VCCIO33

DV333,4,6, 8,9,10,12, 13,14

SMD/0402

C4000

100N 16V

M_OPCTRL3

SMD/0402

1

Custom

414Friday , September 10, 2010

715G3988M0B0010050

04. MT5362 BYPASS/TRAP.

G3988-M0B-001-0050-1-100901

OEM MOD EL Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

称爹

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

M_AOL RC K4,6

M_SPDIF_Out6,11

M_AOBCK6

M_OPW M1

C4004

100N 16V

SMD/0402

R4000

4.7K1/16W

C4006

100N 16V

SMD/0402

SMD/0402

DV112

C4002

100N 16V

M_OPW M19

SMD/0402

C4012

100N 16V

SMD/0402

C4015

100N 16V

SMD/0402

M_SPD IF _Ou t

DV33

SMD/0402

C4007

100N 16V

M_AOSDATA06

SMD/0402

AVDD1V25_PLL

C4010

100N 16V

DV33

C4003

100N 16V

R4001

4.7K1/16W

C4009

100N 16V

M_OPCTRL38,11,12

AVDD1V25_PLL

Page 57

57

1

Custom

514Friday , September 10, 2010

715G3988M0B0010050

05. MT5362 PERIPHERAL/USB2.0

G3988-M0B-001-0050-1-100901

OEM MOD EL Size

Rev

Date

Sheet

of

TPV MODEL

PCB NAME

称爹

T P V ( Top Victory Electronics Co . , Ltd. )

Key Component

絬 隔 瓜 絪 腹

SOY111

GP11

USB_DM

FB4058

120R/500mA

1 2

R4054

4.7K1/16W

HSYNC11,15

M_AOLRCK4,5

Y0P

COM1

RF_AGCT4

Tuner_ByPas s_Out10

AVDD3V3_ADAC0

VSYNC

CN103

CONN

3

2

1

65

4

AVDD3V3_SIF

AV1_R_In

---><---|>

Line_Out_R13

SMD/0402

SMD/0402

SCART1_R_In10

YPbPr_L_In

AVDD3V3_DIG

MPX_N

C4052

100N 16V

FB4057

120R/500mA

1 2

CVBS0N11

HP_Out_L

FAT_IN-

SMD/0402

COM010

C4064

10U 16V

R4056

0R05 1/10W

R4063

0R05 1/10W

C4059

100N 16V

SMD/0402

USB_PWR_OCP9

USB_PWR_EN9

HP_Out_R

CVBS0N

TP4155

1

PB1P11

Audio I/F

MT5363LIMG

U401F

W30

Y29

AA30

Y31

T31

U30

AB33

AD33

V35

Y33

AC32

AC34

V37

AA32

AB31

AE34

U34

Y35

AB35

U32

AE36

AA34

AD35

AF33

U36

Y37

AB37

AF35

V33

AA36

AC36

AF37

AJ30

AK29

AK31

AL30

AM33

AN36

AN34

L32

M37

K31

K33

L34

N32

P35

L36

M35

P37

AVDD33_REF_AADC

AVSS33_REF_AADC

VMID_AADC

AVDD33_AADC

AVDD33_ADAC1

AVSS33_ADAC1

AIN4_R_AAD C

AIN0_L_AADC

AL2

AVSS33_AADC

AIN1_R_AAD C

AIN0_R_AAD C

AL3

AIN4_L_AADC

AIN1_L_AADC

AVSS33_ADAC0

AR2

AIN5_R_AAD C

AIN2_R_AAD C

AL1

AR0

AIN5_L_AADC

AIN2_L_AADC

AVDD33_ADAC0

AR3

AIN6_R_AAD C

AIN3_R_AAD C

AVICM

AR1

AIN6_L_AADC

AIN3_L_AADC

AL0

AVSS33_DIG

AVSS33_SIF

AVDD33_DIG

AVDD33_SIF

AF

MPXN

MPXP

ALIN

AOLRCK

AOSDATA3

ASPDIF

AOBCK

AOSDATA4

AOSDATA1

AOSDATA0

AOMCLK

AOSDATA2

R4060

0R05 1/10W

SY0

C4051

100N 16V

USB_DP12

AV1_L_In

R4053

4.7K1/16W

M_AOSDATA0

COM0

DV333, 4,5,8,9,10,12,13,14

VGA_L_In11

VSYNC11,15

GP

D4050

BAV99

3

1

2

+

C4063

100UF 16V

Monitor_Out_L

TUNER_DATA

Y1P11

Monitor_Out_R

C4069

1uF 16V

USB_DM12

SOY1

CVBS0P4

SMD/0402

PB0P10

AVDD1V25_RGB

VGA_R_In11

PANEL_VCC_ON/OF F3

M_SPDIF_Out

SMD/0402

R4050

560R 1/10W 1%

MPX_N4

U105

G5250M1T1U

1

2

34

5

OUT

GND

OCEN

IN

C4055

100N 16V

SCART1_Out_R10

R4052 0R05 OHM

RP

AVDD3V3_SIF

PANEL_VCC_ON/OF F

YPbPr_R_In11

+5V_SW

DV33

AMP_MUTE13

VGA_R_In

AVDD3V3_ADAC0

AVDD3V3_ADAC1

TUNER_BYPASS_In4

BP11

AV33

Inverter

C4067

1UF16V

AV33

PR1P11

C4068

1uF 16V

SMD/0402

SMD/0402

AV33

IF_AGCT4

R4051 0R05 OHM

TUNER_BYPASS_In

M_AOBCK

C4054

100N 16V

+5V_SW2,3, 4,9,11,12,13,14

PB0P

VGA_L_In

SMD/0402

VIMD_AADC

SMD/0402

AV33

HP_Out_L13

RP11

AV123,4,5,7,12,14

SCART1_L_In10

PR1P

SOG11

AVDD3V3_REFP_AADC

BL_ON/OFF14

C4061

100N 16V

M_SPDIF_Out5,11

FB4060

220R/2000mA

1 2

AVDD3V3_DIG

RF_AGCT

SOY0

TUNER_CLK

Video I/F

MT5363LIMG

U401D

AR32

AN32

AR34

AU34

AP33

AT33

AP35

AT35

AR36

AU36

AM31

AT37

AP37

AG34

AH35

AH37

AG36

AR30

AN30

AM29

AP31

AT31

AR22

AU22

AP23

AT23

AR24

AU24

AP25

AT25

AM25

AR26

AU26

AP27

AT27

AN26

AR28

AU28

AP29

AT29

AU30

N34

M31

M33

N36

AVSS33_CVBS

AVDD33_CVBS

SY1

SC1

SY0

SC0

CVBS2P

CVBS3P

CVBS0N

CVBS1P

BYPASS0

CVBS0P

TUNER_BYPASS

AVDD33_DEMOD1

ADCINN_DEMOD

ADCINP_DEMOD

AVSS33_DEMOD1

AVSS33_VDAC

AVDD33_VDAC

FS_VDAC

VDAC_OUT1

VDAC_OUT2

HSYNC

VSYNC

SOG

BP

COM

GP

SOY1

RP

AVDD12_RGB

COM1

Y1P

PR1P

PB1P

AVSS12_RGB

Y0P

SOY0

PB0P

COM0

PR0P

TUNER_DATA

IF_AGC

RF_AGC

TUNER_CLK

SMD/0402

SMD/0402

AVDD3V3_CVBS

USB_PWR_EN

R4057

0R05 1/10W

SMD/0402

AVDD3V3_VDAC

HP_Out_R13

M_AOLRC K

TP41591

R4058

0R05 1/10W

SMD/0402

Y0P10

ADAC_VCM

BP

TP4050

1

VIMD_AADC

SMD/0402

SCART1_Out_L10

TUNER_DATA4

AMP_MUTE

Line_Out_L13

CVBS3P

C4050

100N 16V

CVBS0P

CVBS1P

AVDD1V25_RGB

AV1_R_In11

SCART1_Out_L

Y1P

C4060

100N 16V

C4057

100N 16V

AVDD3V3_AADC

SOG

MPX_P

SC0

AV33

COM

AV33

AVDD3V3_ADAC1

C4053

100N 16V

AVDD3V3_REFP_AADC

BL_ON/OFF

COM11

SCART1_Out_R

R4055

NC/10K1/16W

TUNER_CLK4

+5V_SW

TX_RX_ON /O FF11

Line_Out_L

R4059

0R05 1/10W

PR0P10

D4051

BAV99

3

1

2

AV333,12,14

HSYNC

YPbPr_R_In

SY011

SOY010

AVDD3V3_VDAC

AV33

SCART1_L_In

PR0P

Tuner_ByPass_Out

MPX_P4

FAT_IN+

R4062

0R05 1/10W

CVBS3P10

COM111

TX_RX_ON/ OFF

C406510U 16V

---><---|>

AV1_L_In11

PB1P

AV33

ADAC_VCM

AVDD3V3_CVBS

TP41601

USB_DP

AVDD3V3_DEMOD

R4061

0R05 1/10W

SCART1_R_In

C4062

1uF 16V

AV12

t

TH4050

NC/PTCR

1 2

AVDD3V3_AADC

SMD/0402

FAT_IN-4

YPbPr_L_In11

C4058

100N 16V

SC011

C4066

100N 16V