Benq G2220HD Service manual

Product Service Manual

Service Manual for BenQ:

G2220HD&G2220HDA

P/N: 9H.L07LN.IXX

Applicable for All Regions

Version: 001

Date:2009/12/18

Notice:

- For RO to input specific “Legal Requirement” in specific NS regarding to responsibility and liability statements.

- Please check BenQ’s eSupport web site, http://esupport.benq.com

, to ensure that you have the most recent

version of this manual.

First Edition (July, 2008)

© Copyright BenQ Corporation 2008. All Right Reserved.

1

Content Index

1. About This Manual............................................................................................................... 3

1.1 Trademark ...................................................................................................................... 3

2. Precautions & Safety Notices.............................................................................................. 4

2.1 Safety Precaution ...........................................................................................................4

2.2 Product Safety Notice..................................................................................................... 4

2.3 Service Notes ................................................................................................................. 4

3. Product Overview................................................................................................................ 5

3.1 Power Supply ................................................................................................................. 5

3.2 Signal Interface............................................................................................................... 5

3.3 Scan Range.................................................................................................................... 5

3.4 Support Timings.............................................................................................................. 6

3.5 Operational & Function Specification.............................................................................. 7

3.6 LCD Characteristics...................................................................................................... 10

3.7 User Controls................................................................................................................ 10

3.8 Mechanical Characteristics........................................................................................... 10

3.9 Pallet & Shipment ......................................................................................................... 11

4 Level 1 Cosmetic / Appearance / Alignment Service .......................................................... 12

4.1 Software / Firmware Upgrade Process......................................................................... 12

4.2 Alignment Procedure (for function adjustment)............................................................. 13

5. Level 2 Disassembly/Assembly/Circuit Board/Standard Parts Replacement..................... 18

5.1 Exploded Diagram ........................................................................................................ 18

5.2 Assembly Block ............................................................................................................ 19

5.3 Disassembly Block ....................................................................................................... 23

5.4 Block diagram...............................................................................................................27

5.5 Lay out.......................................................................................................................... 35

5.6 Circuit operation theory ................................................................................................ 38

5.7 Trouble Shooting Guide................................................................................................ 41

6. Dimmession drawing…………………………………………………………………….....…….47

2

1. About This Manual

This manual contains information about maintenance and service of BenQ products. Use this manual to

perform diagnostics tests, troubleshoot problems, and align the BenQ product.

1.1 Trademark

The following terms are trademarks of BenQ Corporation:

Importance

Only trained service personnel who are familiar with this BenQ Product shall perform service or maintenance

to it. Before performing any maintenance or service, the engineer MUST read the “Safety Note”

3

2. Precautions & Safety Notices

2.1 Safety Precaution

This monitor is manufactured and tested on a ground principle that a user’s safety comes first. However,

improper used or installation may cause damage to the monitor as well as to the user.

WARNINGS:

z This monitor should be operated only at the correct power sources indicated on the label on the rear of the

monitor. If you’re unsure of the power supply in you residence, consult your local dealer or Power

Company.

z Do not try to repair the monitor by yourself, as it contains no user-serviceable parts. This monitor should

only be repaired by a qualified technician.

z Do not remove the monitor cabinet. There is high-voltage parts inside that may cause electric shock to

human bodies.

z Stop using the monitor if the cabinet is damaged. Have it checked by a service technician.

z Put your monitor only in a lean, cool, dry environment. If it gets wet, unplug the power cable immediately

and consult your closed dealer.

z Always unplug the monitor before cleaning it. Clean the cabinet with a clean, dry cloth. Apply

non-ammonia based cleaner onto the cloth, not directly onto the class screen.

z Do not place heavy objects on the monitor or power cord.

2.2 Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety visual inspections and the

protection afforded by them cannot necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Before replacing any of these components read the parts list in this manual

carefully. The use of substitute replacement parts, which do not have the same safety characteristics as

specified in the parts list, may create shock, fire, or other hazards.

2.3 Service Notes

z When replacing parts or circuit boards, clamp the lead wires around terminals before soldering.

z Keep wires away from high voltage, high temperature components and sharp edges.

z Keep wires in their original position so as to reduce interference.

z Adjustment of this product please refers to the user’ manual.

4

3. Product Overview

3.1 Power Supply

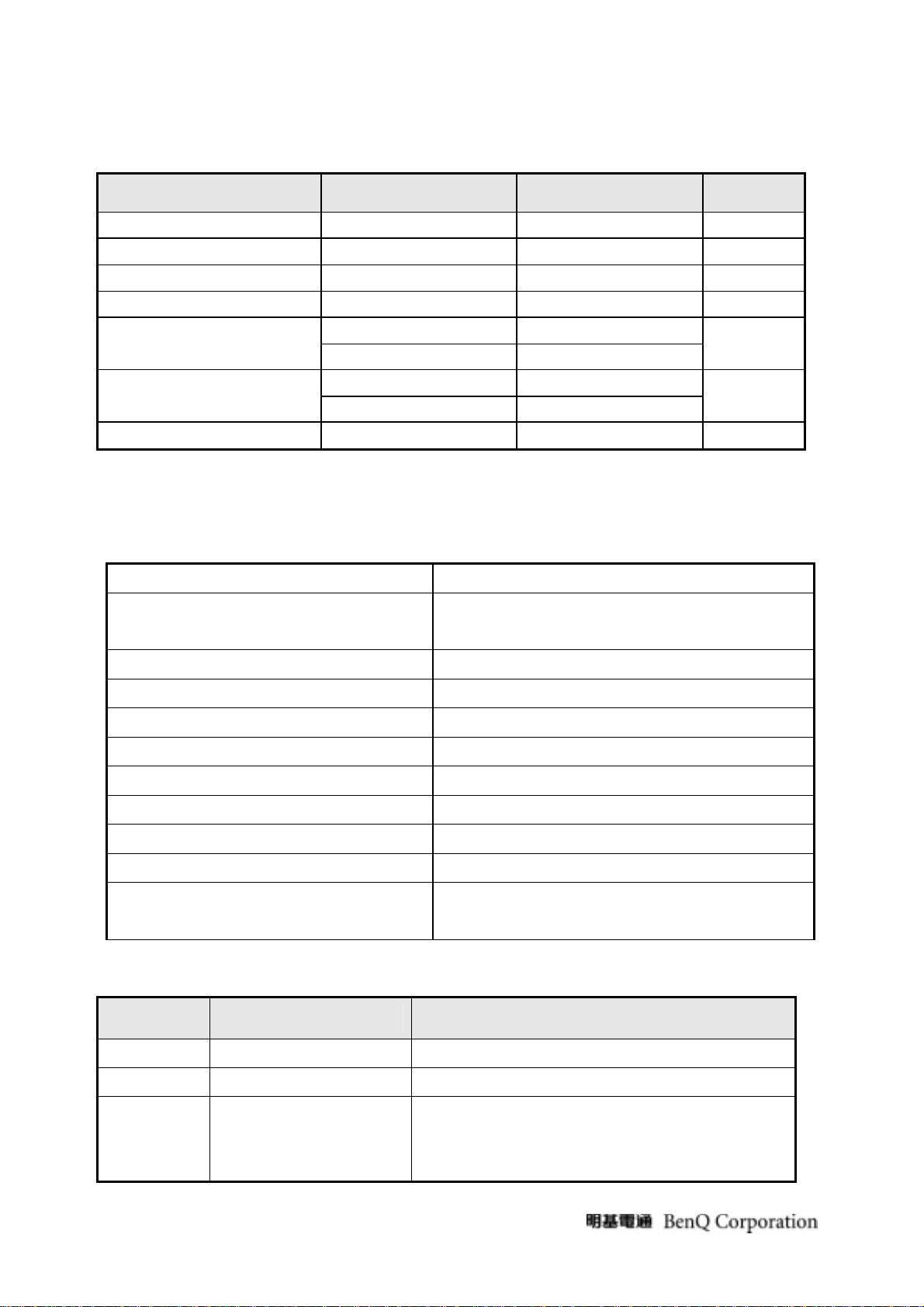

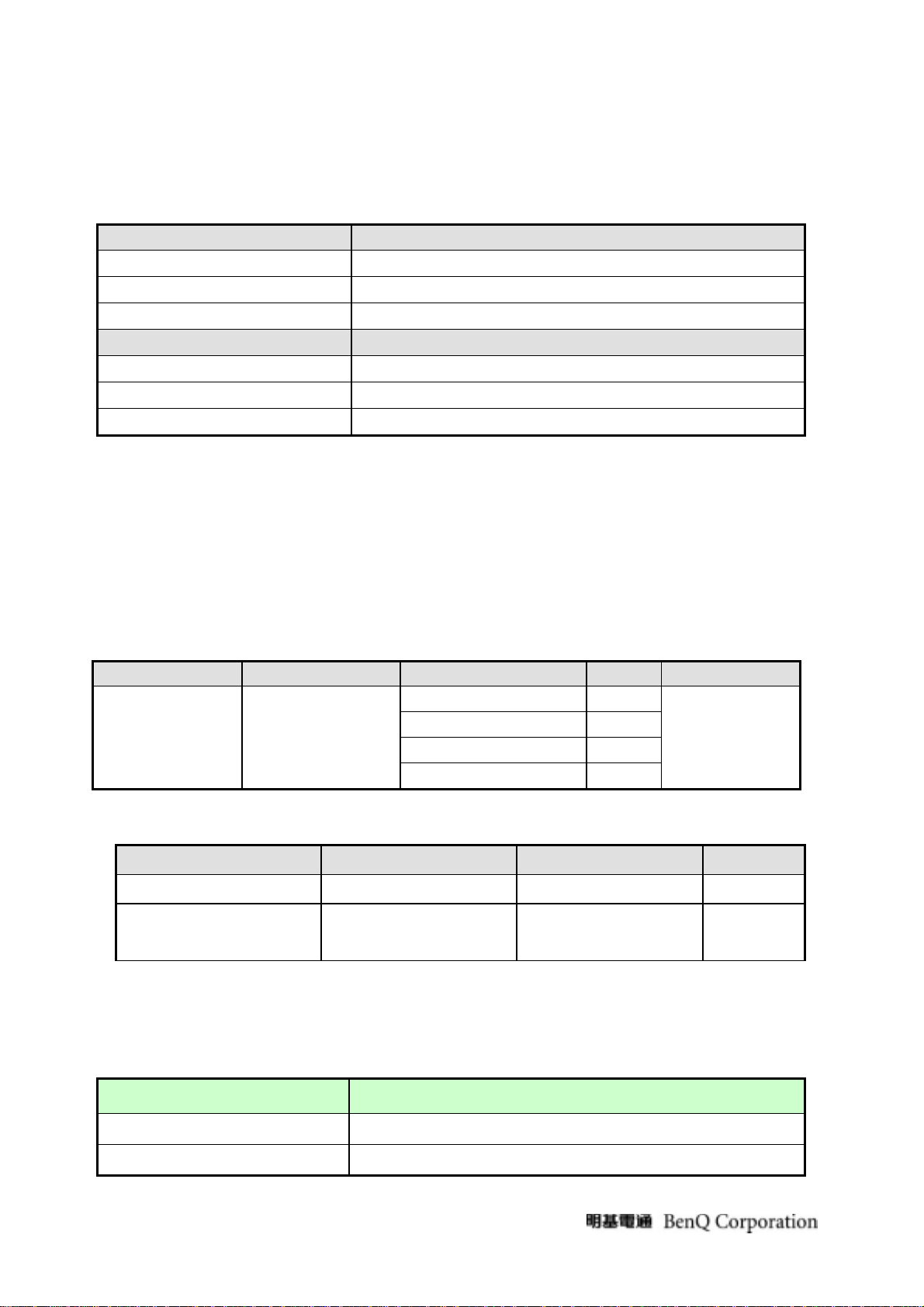

Items Condition Spec Note

AC Input Voltage range Universal input full range 90~264Vac

AC Input Voltage rating Universal input full range 100~240Vac

AC input frequency range 90~264Vac 47~63Hz

AC input frequency rating 100~240Vac 50~60Hz

100Vac 1.5A(max) AC Input Current

240Vac 0.8A(max)

Inrush Current

AC-DC power Efficiency

Note2. Before each test, the buck capacitors need to be discharged.

Before each test, it must be 10 minutes at least after the latest test.

Hot star not component be damaged.

3.2 Signal Interface

100Vac,cold star,25°C 40A (max)

240Vac,cold star,25°C 60A(max)

DC output full loading ≥75%

See Note2

Input Connector Analog : D-sub 15

Video Cable Strain Relief

Video Cable Connector DB-15 Pin out Compliant DDC 2B

Video Signals Video RGB (Analog)

Video Impedance 75 Ohms (Analog)

Maximum PC Video Signal 950 mV with no damage to monitor

Maximum Mac Video Signal 1250 mV with no damage to monitor

Sync Signals TTL

DDC 1/2B Compliant with Revision 1.3s

Sync Compatibility Separate Sync / Composite Sync / Sync on Green

Video Compatibility

Equal to twice the weight of the monitor for five

minutes

Shall be compatible with all PC type computers,

Macintosh computers, and after market video cards

3.3 Scan Range

Item Condition Specification

Horizontal

Vertical Sync polarity: (+) or (-) 50Hz~76Hz

Out of Range

Sync polarity: (+) or (-)

Sync don’t in the range:

Horizontal: 24kz~83KHz or

Vertical : 50Hz~76Hz

24kz~83KHz

Message “Out of Range!” on screen

5

Cable not

No VGA cable or DVI cable Message ‘’No cable connected !’’ on screen

connect

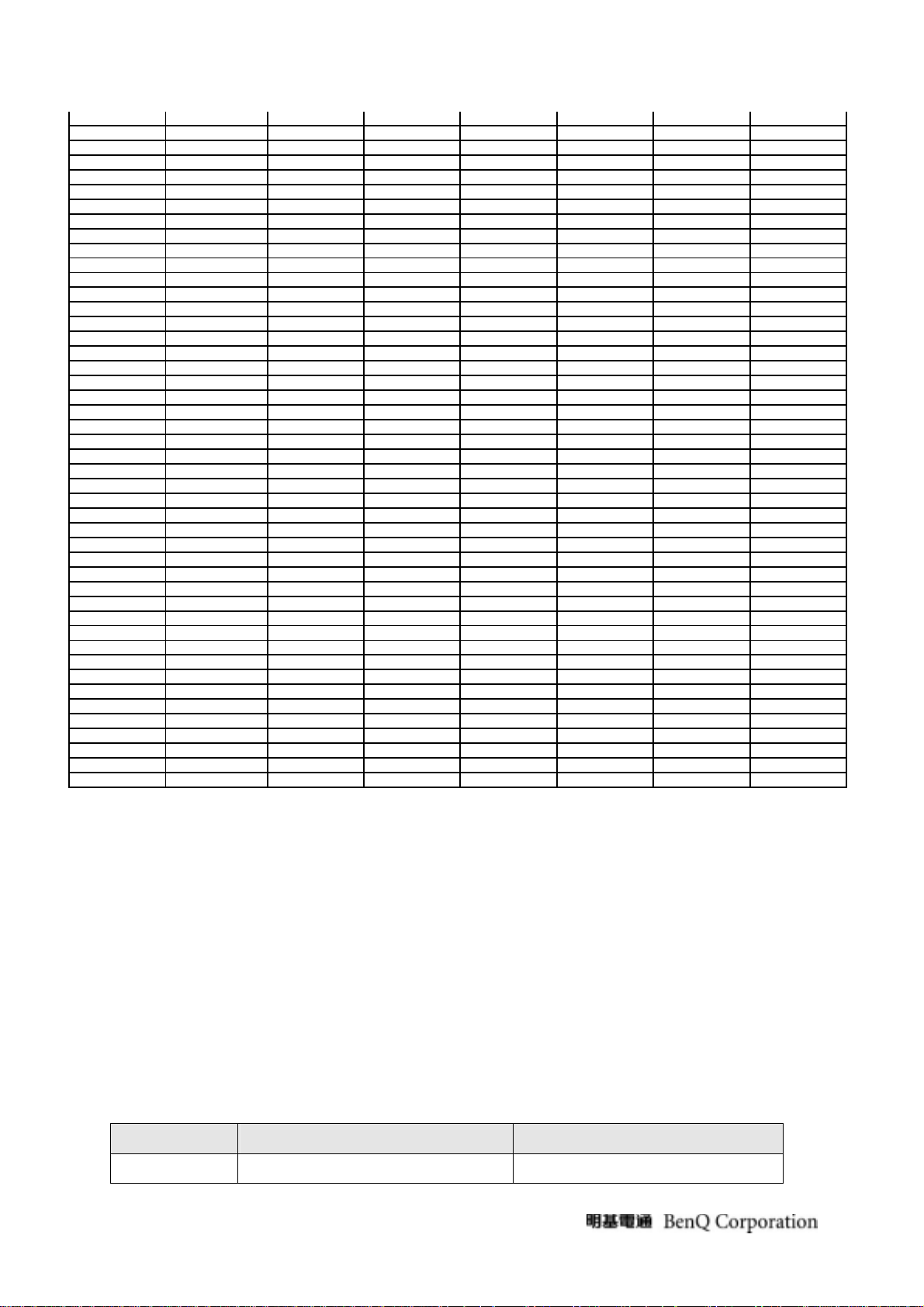

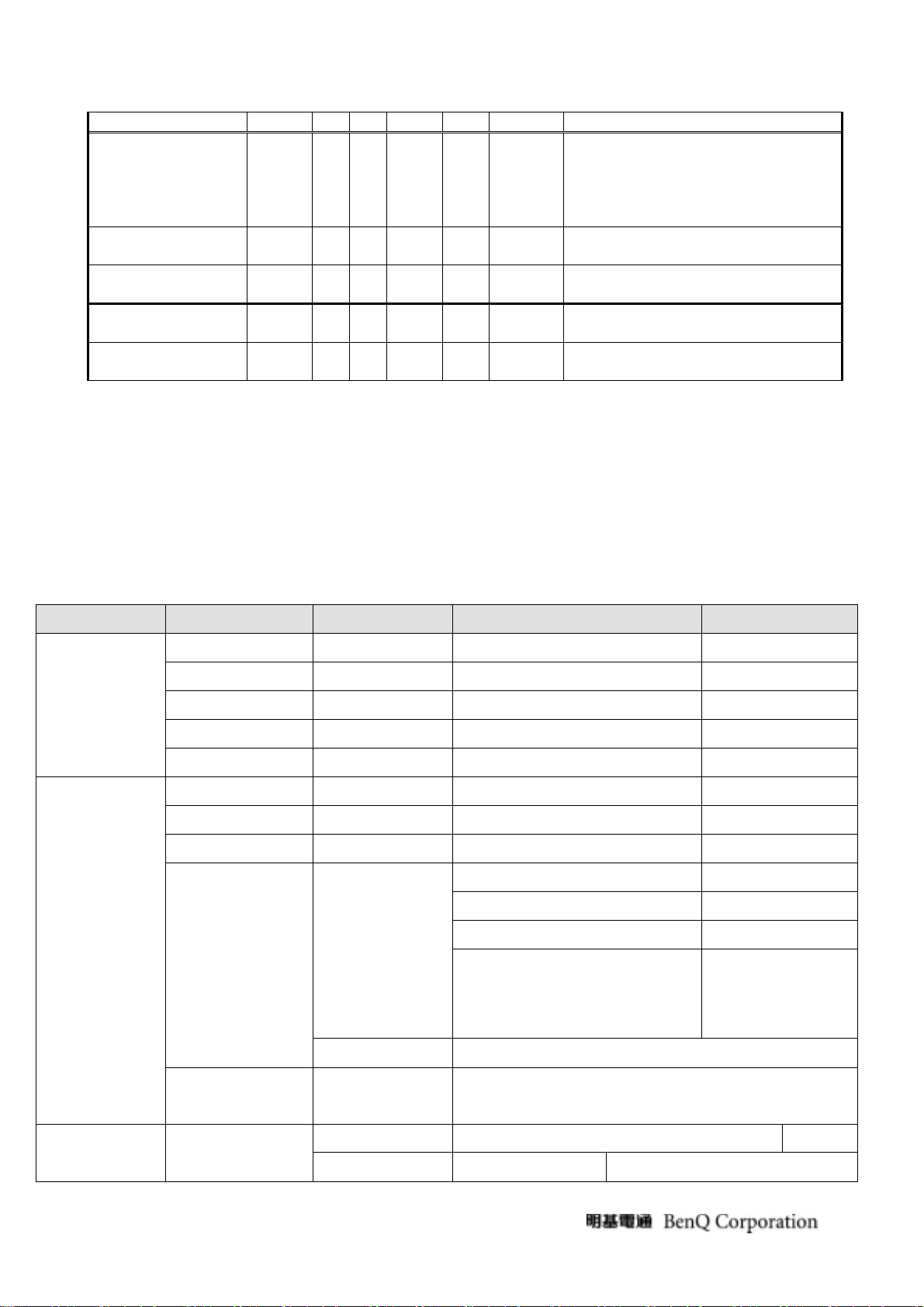

3.4 Support Timings

BenQ customer preset Timings are as below:

P: Preset Mode

NP: Non Preset Mode

FS: Fail Save Mode (shows “Out of Range”, but still can see picture)

O: Out of Range (only show “Out of Range”, without picture)

No.

1 640x350 31.47 + 70.09 - 25.18 Preset

2 640x350 37.86 + 85.08 - 31.50 Fail Safe Mode

3 640x400 31.47 - 70.09 + 25.18 Non Preset

4 640x400 37.86 - 85.08 + 31.5 Fail Safe Mode

5 640x480 35.00 - 66.67 - 30.24 Non Preset

6 640x480 31.47 - 59.94 - 25.17 Preset

7 640x480 37.86 - 72.81 - 31.50 Non Preset

8 640x480 37.50 - 75.00 - 31.50 Preset

9 640x480 43.27 - 85.01 - 36.00 Fail Safe Mode

10 640x500 31.00 - 57.76 - 25.25 Non Preset

11 720x400 31.47 - 70.08 + 28.32 Preset

12 720x400 37.93 - 85.04 + 35.5 Fail Safe Mode

13 832x624 49.71 - 74.53 - 57.27 Preset

14 800x600 35.16 + 56.25 + 36.00 Non Preset

15 800x600 37.88 + 60.32 + 40.00 Preset

16 800x600 48.08 + 72.19 + 50.00 Non Preset

17 800x600 46.88 + 75.00 + 49.50 Preset

18 800x600 53.67 + 85.06 + 56.25 Fail Safe Mode

19 848x480 31.02 + 60.00 + 33.75 Non Preset

20 848x480 29.83 - 59.66 + 31.50 Non Preset

21 848x480 35.00 - 70.00 + 37.52 Non Preset

22 848x480 36.07 - 72.00 + 39.25 Non Preset

23 848x480 37.68 - 74.77 + 41.00 Non Preset

24 720x576 35.910 - 59.950 + 32.71 Non Preset

25 1024x768-I 35.52 + 43.48 + 44.9 Fail Safe Mode

26 1024x768 48.36 - 60.00 - 65.00 Preset

27 1024x768 56.48 - 70.07 - 75.00 Non Preset

28 1024x768 57.67 - 72.00 + 78.43 Non Preset

29 1024x768 60.24 - 74.93 - 80.00 Preset

30 1024x768 60.02 + 75.03 + 78.75 Preset

31 1024x768 68.68 + 85.00 + 94.50 Fail Safe Mode

32 1152x720 44.86 - 60 + 66.75 Preset

33 1152x864 63.85 + 70.01 + 94.50 Non Preset

34 1152x864 67.50 + 75.00 + 108.00 Non Preset

35 1152x864 77.09 - 85.00 + 119.651 Fail Safe Mode

36 1152x870 68.68 - 75.06 - 100.00 Preset

37 1152x900 61.80 - 65.95 - 92.94 Preset

38 1152x900 71.73 - 76.07 - 105.59 Non Preset

39 1280x720 45.00 - 59.94 + 74.25 Preset

40 1280x720 44.77 - 59.86 + 74.50 Preset

41 1280x720 56.46 - 74.78 + 95.75 Preset

42 1280x768-R 47.40 + 60.00 - 68.25 Preset

43 1280x768 47.78 - 59.87 + 79.50 Preset

44 1280x768 60.29 - 74.89 + 102.25 Non Preset

45 1280x768 68.63 - 84.84 + 117.50 Fail Safe Mode

46 1280x800 49.31 + 59.91 + 71 Non Preset

47 1280x800 49.702 - 59.81 + 83.50 Preset

48 1280x800 58.3 - 70 + 88.25 Non Preset

49 1280x800 60.048 - 72 + 102.8 Non Preset

50 1280x800 62.795 - 74.934 + 106.6 Preset

51 1280x800 71.55 - 84.88 + 122.5 Fail Safe Mode

52 1280x960 60.00 + 60.00 + 108.00 Preset

53 1280x960 85.94 + 85.00 + 148.50 Fail Safe Mode

54 1280x1024 63.98 + 60.02 + 108.00 Preset

55 1280x1024 74.88 + 69.85 + 126.99 Non Preset

56 1280x1024 74.40 - 70.00 - 124.90 Non Preset

57 1280x1024 77.90 + 72.00 + 134.60 Non Preset

Pixel

Format

Horz Freq (kHz) Horz Polarity Vert Freq (Hz) Vert Polarity Pixel Clk (MHz) Mode

6

58 1280x1024 79.98 + 75.02 + 135.00 Preset

59 1280x1024 81.18 - 76.16 - 135.09 Non Preset

60 1280x1024 91.15 + 85.02 + 157.50 Fail Safe Mode

61 1360x768 47.71 + 60.01 + 85.50 Preset

62 1366x768 47.71 + 59.79 + 85.50 Preset

63 1400x1050-R 64.74 + 59.95 - 101.00 Non Preset

64 1400x1050 65.32 - 59.98 + 121.75 Non Preset

65 1400x1050 82.28 - 74.87 + 156.00 Non Preset

66 1400x1050 93.88 - 84.96 + 179.50 Fail Safe Mode

67 1440x900-R 55.496 + 59.901 - 88.75 Preset

68 1440x900 55.935 - 59.887 + 106.5 Preset

69 1440x900 70.6 - 75 + 136.75 Preset

70 1600x1000-R 61.648 + 59.910 - 108.5 Preset

71 1600x1000 62.14 - 59.87 + 132.25 Non Preset

72 1600x1000 78.356 - 74.83 + 169.25 Non Preset

73 1600x1200-R 74.01 + 59.92 - 130.25 Non Preset

74 1600x1200 75.00 + 60.00 + 162.00 Preset

75 1600x1200 81.25 + 65.00 + 175.50 Non Preset

76 1600x1200 87.50 + 70.00 + 189.00 Non Preset

77 1600x1200 93.75 + 75.00 + 202.50 Non Preset

78 1600x1200 106.25 + 85.00 + 229.50 Out of Range

79 1680x1050-R 64.67 + 59.88 - 119.00 Non Preset

80 1680x1050 65.29 - 59.95 + 146.25 Preset

81 1680x1050 82.306 - 75 + 187 Preset

82 1600x1280 79.5 - 59.9 + 171.75 Non Preset

83 1792X1344 83.57 - 59.9 + 203.25 Fail Safe Mode

84 1792X1344 105.290 - 75.00 + 257.75 Out of Range

85 1856X1392 86.485 - 59.934 + 217.25 Out of Range

86 1856X1392 109 - 74.918 + 277.5 Out of Range

87 1800x1440 89.4 - 59.9 + 218.25 Out of Range

88 1920x1080-R 66.587 + 59.934 - 138.5 Preset

89 1920x1080 67.158 - 59.963 + 173 Preset

90 1920x1080 67.5 + 60 + 148.5 Preset

91 1920X1200-R5 61.418 + 49.974 - 127.750 Fail Safe Mode

92 1920X1200-R 74.04 + 59.95 - 154.00 Fail Safe Mode

93 1920X1200 74.56 - 59.89 + 193.25 Fail Safe Mode

94 1920X1200 94.04 - 74.93 + 245.25 Out of Range

95 1920X1440-R 88.822 + 59.9 - 184.75 Fail Safe Mode

96 1920X1440 89.532 - 59.968 + 233.500 Out of Range

97 1920X1440 112.50 - 74.9 + 298 Out of Range

98 2048x1152-R 70.992 + 59.9 - 156.75 Out of Range

99 2048x1152 71.584 - 59.9 + 197 Out of Range

100 2048x1536-R 94.7 + 59.9 - 209.25 Out of Range

101 2048x1536 95.4 - 59.9 + 267.25 Out of Range

102 2560x1600-R 98.713 + 59.972 - 268.5 Out of Range

103 2560x1600 99.4 - 59.9 + 348.5 Out of Range

Remark :

default mode : 1920x1080P 60Hz

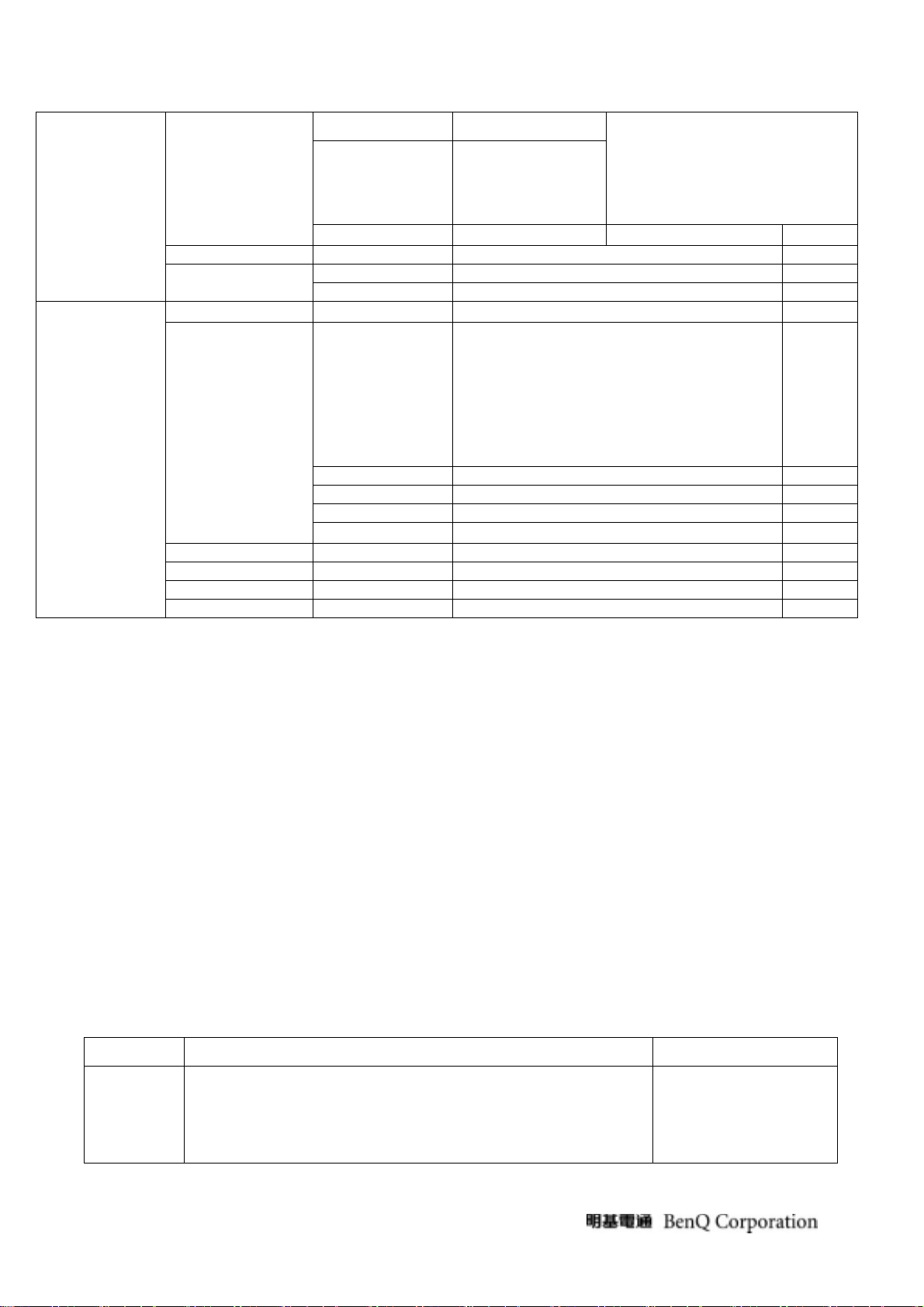

3.5 Operational & Function Specification

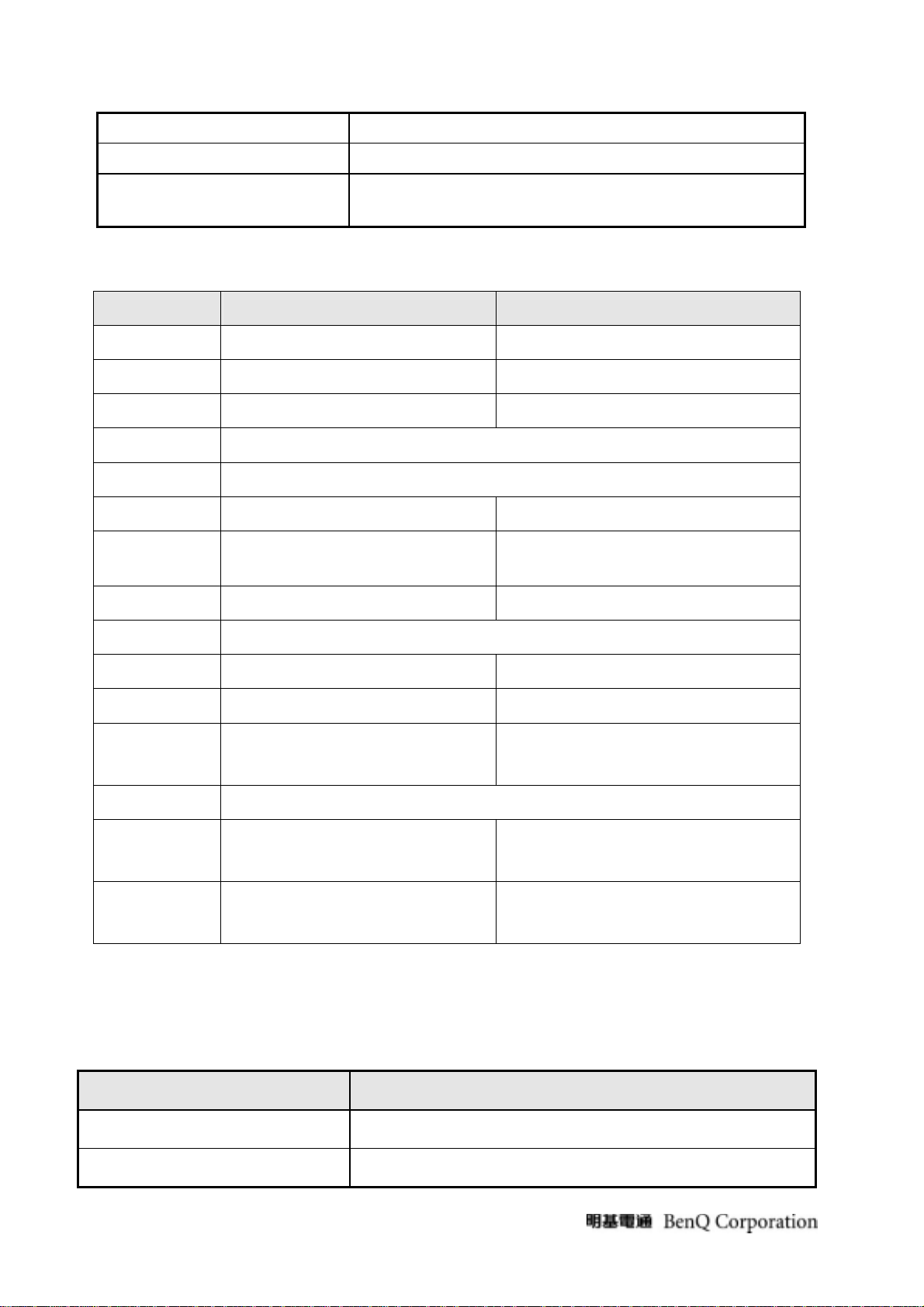

3.5.1 Video Performance

* All Spec. of monitor need to warm up at lease 1hr

Supplier AUO CMO

Model name AUO M215HW01 V0: M216H1-L01

7

Display Area 476.64(H)x268.11(V) 477.504(H)x268.596(V)

Pixel Pitch 0.248(H)x0.248(V) 0. 248(H)x0.248(V)

Display Colors 16.7M(6 Bit+Hi-FRC)

Number of Pixel 1,920(H) X 1,080(V),

Brightness Min: 240cd/m2; Typical: 300cd/m2 Min: 250cd/m2; Typical: 300cd/m2

Contrast Ratio

Min: 600:1

Typical: 1000:1

Min: 700:1

Typical: 1000:1

Viewing Angle Hor: 170°, Ver: 160° (Typical, CR=10) Hor: 170°, Ver: 160° (Typical, CR>10)

Display Mode Normally White

Frame rate 50~75Hz 50~75Hz

Response Time Typical: 5ms; Max: 8ms Typical: 5ms; Max: 8ms

Surface

Treatment

Anti-glare, 3H Hard coating (3H), AG(Haze25%)

Lamp 4 CCFL

Outline

Dimension

Brightness

uniformity

495.6 (W) X 292.2 (H) X 16.35 (D)

(typ.)

499.5 (W) X 292.6 (H) X 17 (D) (typ.)

Min: 75%; Typical: 80% / 9 points. Min: 75% / 9 points.

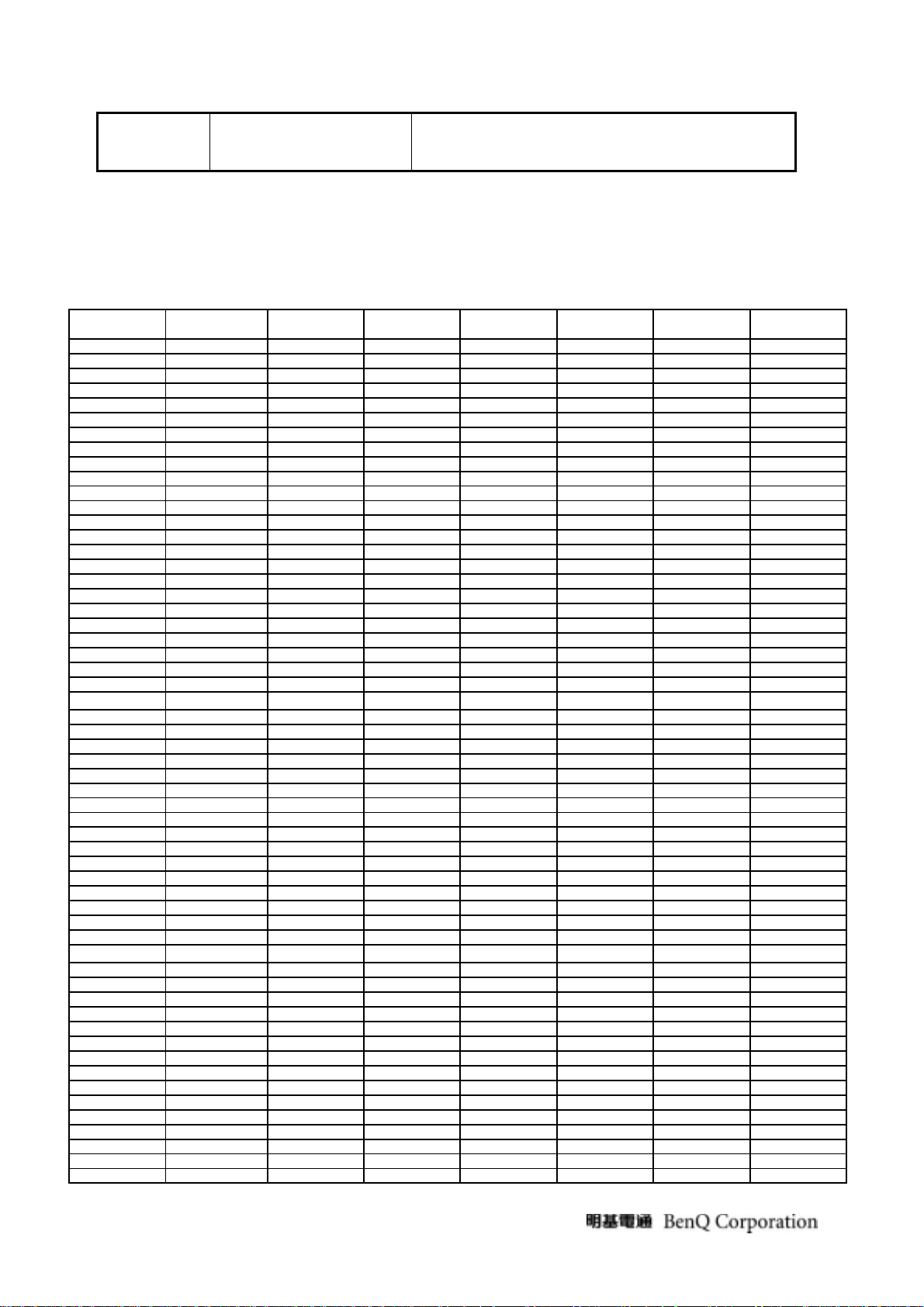

3.5.2 Brightness Adjustable Range

The test to verify specifications in this section shall be performed under the following standard

conditions unless otherwise noted.

Temperature : 25 ± 5°C

Test pattern : white

Video Resolution : 1920 x 1080@60HZ

Video input level : 700 mV ± 2%

Warm-up time : 30 minutes

Item Condition SPEC

Brightness=0%

Contrast = 0%

Brightness=100%

Luminance Range

Contrast = 100%

Brightness=90%

Contrast = 50%

NA

AUO ≥ 240 cd/m

CMO ≥ 250 cd/m2

NA

2

8

3.5.3 Environment

Operating Specification

Temperature range

0°C to 50°C

Relative humidity 5% to 90%

Altitude 0 to 10000 feet

Storage

Temperature range

-20°C to 60°C

Relative humidity 5% to 90%

Altitude 0 to 30000 feet

3.5.4

Speaker : 1.5W 12Ω X 2

Input impedance : ≥ 10K ohm

Frequency response range : 500Hz – 20 kHz

Signal to noise ratio : ≥ 75 dB ±3

Output power : 1.0 W + 1.0 W (Typical) @5%THD (Input sine wave signal: 1 KHz/0.7Vrms)

3.5.5 Electrostatic discharge Requirements

Item Condition Spec Remark

Electrostatic

InnoLux SPEC

Discharge

3.5.6 Reliability

Items Condition Spec Note

MTBF 95% Confidence

CCFL Life time Luminance becomes 50%

Note1. Display an all white field at mid Brightness and Contrast settings.

Contact discharge : 4KV ●

Contact discharge : 8KV

Air discharge : 8KV ●

Air discharge : 15KV

≧ 60,000 Hours

≧ 40,000 Hours at 7.5mA

(min)

D-sub cable pin

need test 4KV and

DVI cable test 4KV

Note1

3.5.7 Audio performance

Items Specification

Speaker

Input impedance

1.5W 12Ω X 2

≥ 10K ohm

9

Frequency response range 500Hz – 20kHz

Signal to noise ratio

Output power

≥ 70 dB±3

1.0 W + 1.0 W (Typical) @5%THD (Input sine wave

signal:1KHz/0.7Vrms)

3.6 LCD Characteristics

3.6.1 The physical definition &technology summary of LCD panel

Supplier AUO CMO

Model name AUO M215HW01 V0: M216H1-L01

Display Area 476.64(H)x268.11(V) 477.504(H)x268.596(V)

Pixel Pitch 0.248(H)x0.248(V) 0. 248(H)x0.248(V)

Display Colors 16.7M(6 Bit+Hi-FRC)

Number of Pixel 1,920(H) X 1,080(V),

Brightness Min: 240cd/m2; Typical: 300cd/m2 Min: 250cd/m2; Typical: 300cd/m2

Contrast Ratio

Min: 600:1

Typical: 1000:1

Min: 700:1

Typical: 1000:1

Viewing Angle Hor: 170°, Ver: 160° (Typical, CR=10) Hor: 170°, Ver: 160° (Typical, CR>10)

Display Mode Normally White

Frame rate 50~75Hz 50~75Hz

Response Time Typical: 5ms; Max: 8ms Typical: 5ms; Max: 8ms

Surface

Anti-glare, 3H Hard coating(3H),AG(Haze25%)

Treatment

Lamp 4 CCFL

Outline

495.6 (W) X 292.2 (H) X 16.35 (D)

499.5 (W) X 292.6 (H) X 17 (D) (typ.)

Dimension

(typ.)

Brightness

Min: 75%; Typical: 80% / 9 points. Min: 75% / 9 points.

uniformity

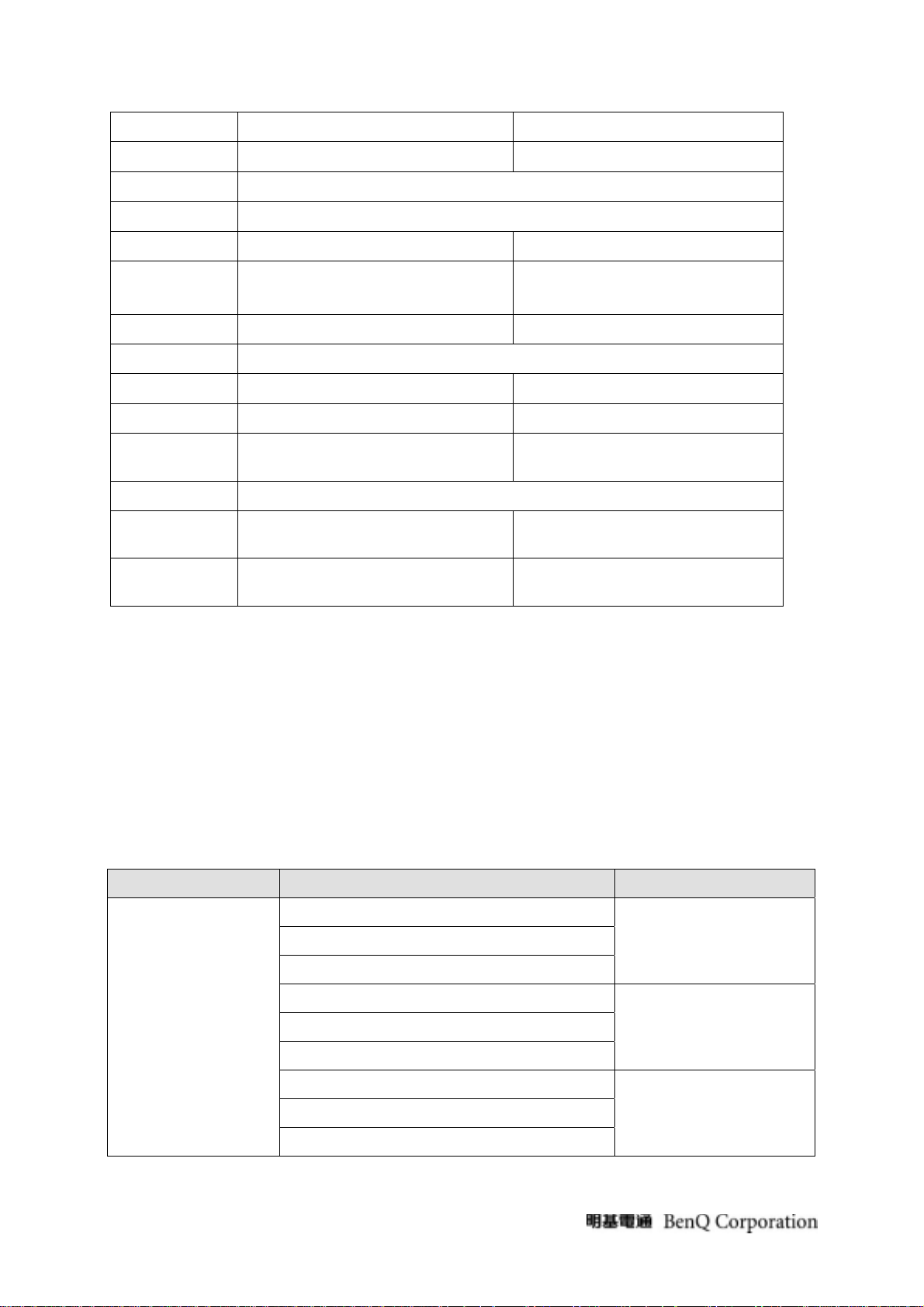

3.7 User Controls

User’s hardware control definition:

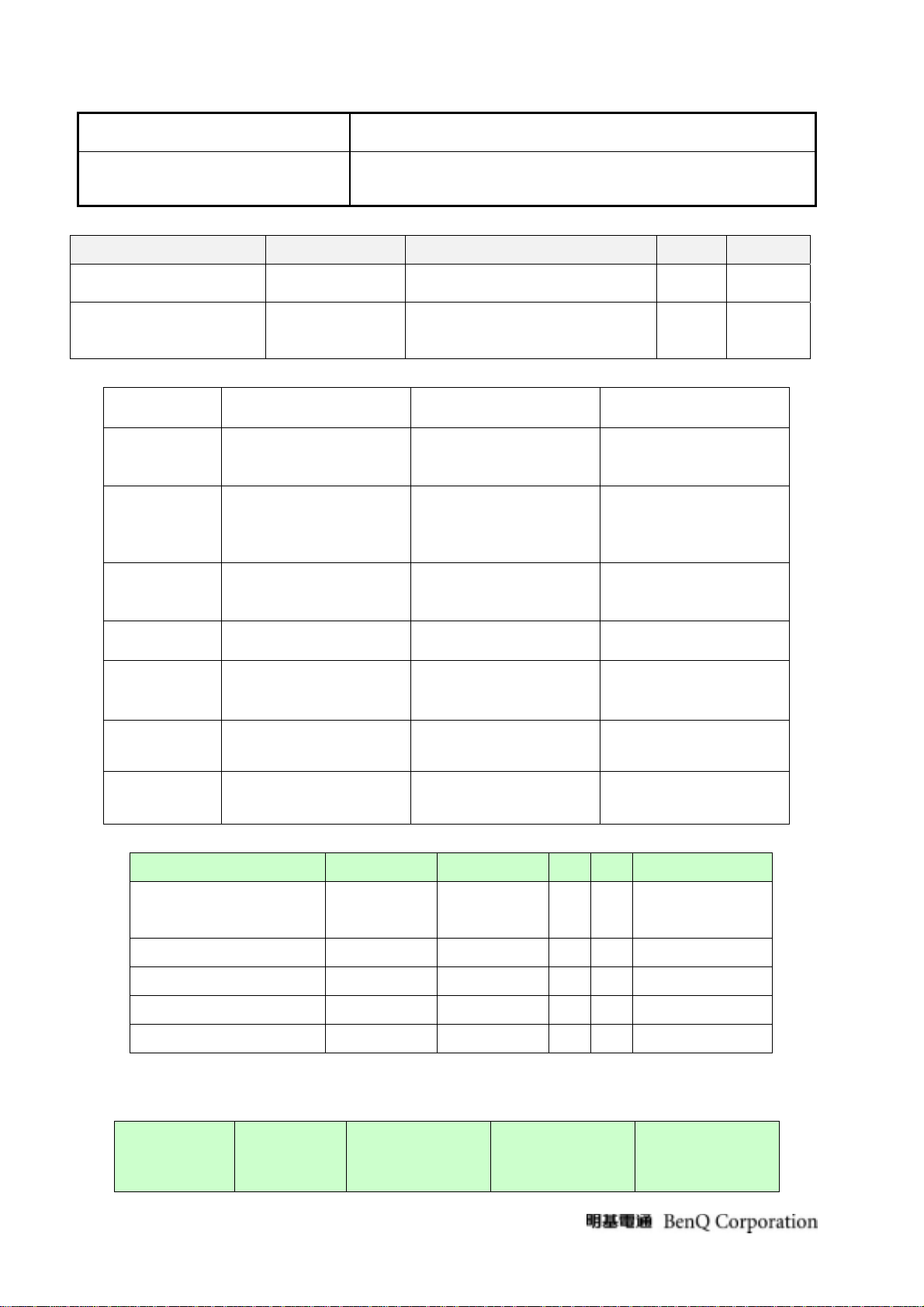

3.8 Mechanical Characteristics

3.8.1Dimension

Dimension (Monitor with Stand) Spec

Width

Height

509.6mm

392.9mm

10

Depth

175mm

4.3±0.5 Kg ( Net )

Monitor Weight

6.1±0.5Kg( Gross / with packing)

3.8.2 Weight

Item condition Spec OK Remark

Monitor (Net)

Monitor with

4.3±0.5 Kg ( Net )

6.1±0.5Kg( Gross / with packing)

packing(Gross)

3.8.3 Plastic

Item TEXTURE No. COLOR No. Material

Front Bezel

Back cover

Arm rear

Arm front

Base

Function key

Led lens

3.8.4 Carton

Carton:Item condition Spec OK NA Remark

HIGH GLOSSY(光澤度

95)POLISHING 6000 &

MT11000 & MT11006

HIGH GLOSSY(光澤度

95)POLISHING 6000 &

POLISHING 2000 &

MT11020&MT11006

HIGH GLOSSY(光澤度

95)POLISHING 6000 &

T11006 & MT11000

HIGH GLOSSY(光澤度

95)POLISHING 6000

HIGH GLOSSY(光澤度

95)POLISHING 6000 &

MT11000 & 放電花

HIGH GLOSSY(光澤度

95)POLISHING 6000

HIGH GLOSSY(光澤度

95)POLISHING 6000

BCS-7015A(Black)

BCS-7015A(Black)

BCS-7015A(Black)

BCS-7015A(Black)

BCS-7015A(Black)

ABS+PMMA

ABS

ABS+PMMA

ABS+PMMA

ABS+PMMA

BCS-7015A(Black) ABS+PMMA

Clear PC

Color

Material C Flute

Compression strength 200 KGF

Burst strength 16 KGF/cm2

Stacked quantity 4 Layers

3.9Pallet & Shipment

3.9.1 Container Specification

Stowing Type Containter Quantity of

Produces (sets)

(Every container)

11

A Flute For JP

√

JP:250 KGF

√

JP:19.4 KGF/cm2

√

4 Layers

√

Quantity of

Produces (sets)

(Every Pallet)

按照客戶提供的

色板來做

Quantity of

Pallet (sets)

(Every container)

20’SEA

784 Pallet A: 88

Pallet B:72

Pallet A:4

Pallet B:6

40’SEA 1656 Pallet A:88

Pallet B:72

With Pallet

Without Pallet

3.9.2 Specification

Product:

Net Weight (Kg) Gross Weight(Kg)

4.8±0.3 Kg ( Net) 6.1±0.5Kg --- 509.6*175*392.9mm

20’AIR 528 Pallet A:60

Pallet B:48

40’AIR 1116 Pallet A:60

Pallet B:48

40’ N/A N/A N/A

Dimension w/o Base

LxWxH (mm)

Pallet A:9

Pallet B:12

Pallet A:4

Pallet B:6

Pallet A:9

Pallet B:12

Dimension w/ Base

LxWxH (mm)

Package:

Items Spec

Packaging Refer to ME PACKING SPEC

Ink The ink shall not rub off after a suitable drying time

Shipping Carton Type

Shipping Carton Handholds

Length 570m

Height 458m

Width 125

Gross Weight 6.1kg+/-0.5

Units per Pallet

4 Level 1 Cosmetic / Appearance / Alignment Service

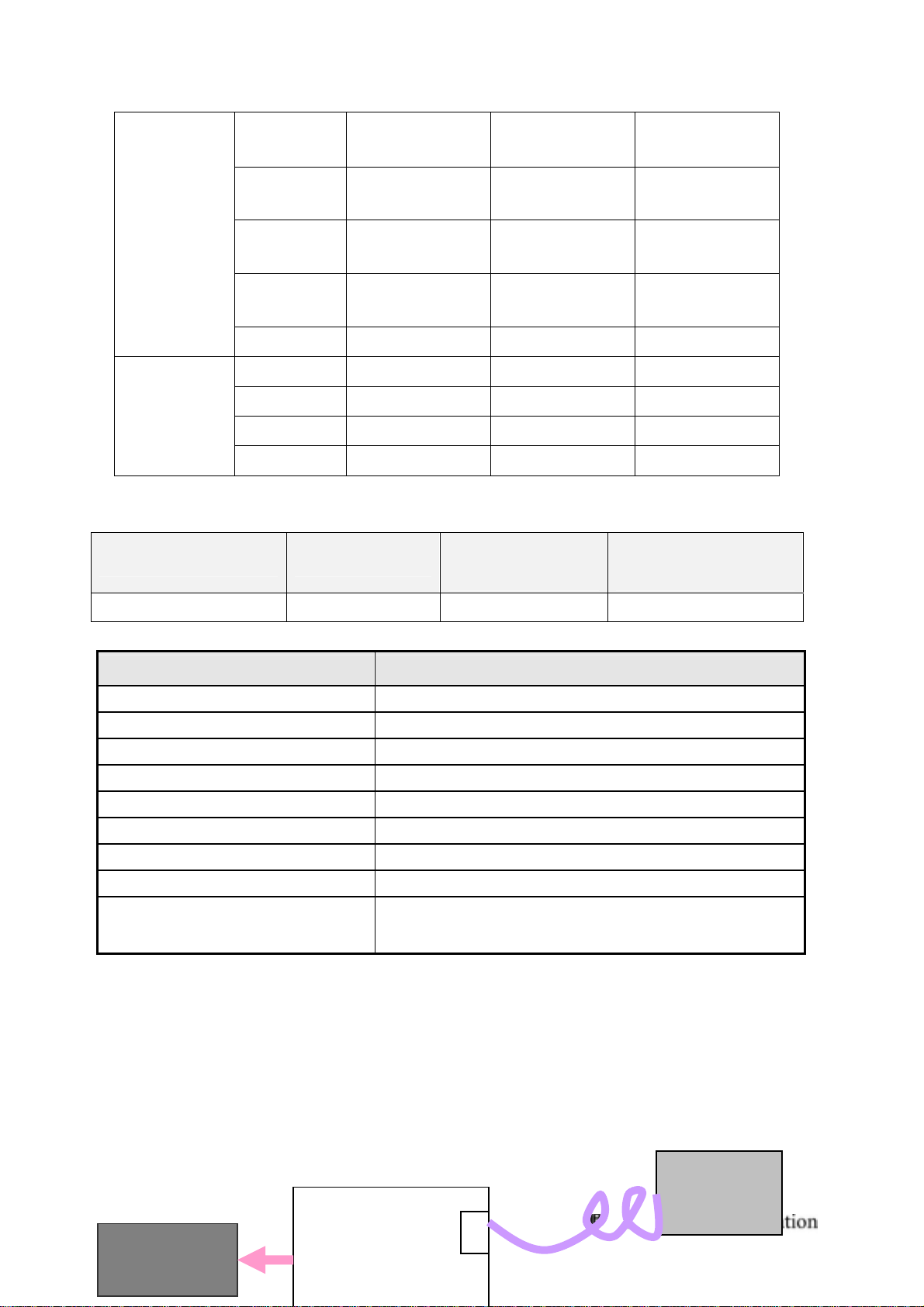

4.1 Software / Firmware Upgrade Process

Upload firmware to Flash ROM via VGA Cable

One Piece Construction

Yes

88 sets / pallet A

72 sets / pallet B

1. Connect ISP board between monitor and PC as below configuration.

Insert to Parallel

Port on PC

ISP Board

D-SUB

12

LCD Monitor

D-Sub

Parallel

Port

2. Select the Flash ROM type which is used in this monitor, then select the ISP button, and then choose

corresponding firmware, and load them to Flash ROM.

4.2 Alignment Procedure (for function adjustment)

4.2.1 Preparation:

1. Setup input timing VESA to 1920*1080@60Hz,32-Grays pattern.

2. Setup units and keep it warm up for at least 30 minutes.

4.2.2 Timing adjustment

1. Enter to factory mode setting area (by pressing "ENTER"+ "MENU" + "POWER" at the same time during

power off).

2. Check the settings to following values:

contrast =50;

brightness=90;

3. Then turn off the monitor power.

4.2.3 Function key Definitions

4.2.3.1 Control buttons on the rear side of monitor

CONTROL KEY KEYS FUNCTION

A. When OSD displays, press [MENU] to return to previous level menu

[MENU]

B. When OSD isn’t shown on screen, press [MENU] to enter OSD interface

C. Press [MENU] to enter Service Page When OSD isn’t shown on screen in Service

Page Mode

A. When OSD displays, press [Enter] to perform function of menu icon that is highlight

[Enter]

or enter next level menu

B. When OSD isn’t shown on screen, press[Enter] to change input source

A. When “MENU OSD” displays, press these keys to change the contents of an

[◄], [►]

adjustment item, or change an adjustment value

B. When “MENU OSD” un-displays, press [►] to show Brightness/contrast Menu

press [◄] to Show Picture Mode Menu.

[POWER] Power on or power off the monitor

[Auto] press [Auto] to perform auto-adjustment

4.2.3.2 Hot Key Operation

FUNCTION HOT KEY OPERATION DESCRIPTION

13

MENU

FACTORY MODE

Picture Mode

Auto Adjustment

Service Page

Input Source

Note: Picture Mode Standard <( Movie <( Dynamics <( Photo <( sRGB <( Standard

Auto Power on/off function in service mode:

Default is “off”, Monitor will remember the last status before AC off. And monitor would always be off while AC

off->on in “off” mode.

4.2.3.3 OSD Control

The On-Screen Display (OSD) shall be an easy to use icon based menu through keypad OSD

buttons or remote control unit. The unit shall leave the factory with all OSD controls set to their

default values.

First level Second level Third level Fourth level Default

●

● ●

□ □

●

●

Enter Auto POWER

●

●

●

Press[MENU], [Enter]& [POWER] at

the same time, when Monitor is Power

On OSD menu will be shown with “F”

on the left top. Select “F” for entering

factory mode.

To Show & Change Picture Mode

Menu

press [Auto] to process, Auto

Adjustment

Press [MENU] + [POWER] to Enter

Service Page Mode when power off

Press [Enter] to change Input Source

when OSD isn’t Display.

DISPLAY

PICTURE

Auto Adjustment - - -

H. Position (0~100) - 50

V. Position (0~100) - 50

Pixel Clock (0~100) - 50

Phase (0~63) - -

Brightness (0~100) - 90

Contrast (0~100) - 50

Sharpness (1~5) - 3

Normal Normal

Bluish -

Reddish -

User Mode

(0,1,2,3,4,5)

100

Color

Dynamic Contrast

*Color

temperature

¾ Red (0~100)

¾ Green (0~100)

¾ Blue (0~100)

Reset Color (YES/NO)

*Dynamic

Contrast

**Picture Mode

ADVANCED

Standard StandardPICTURE

Movie

Sharpness 不可调节 1.任一项模式下 Senseye Demo 设

14

Dynamics

y

Sharpness 不可调节

为 ON 另外两个模式下的 Senseye

Demo 自动变为 ON

Senseye Demo (ON/OFF) OFF

Display Mode

Input(DVI Model)

OSD Settings

SYSTEM

DDC/CI (ON/OFF) - ON

Information - -

Reset All (YES/NO) -

4.2.3.4. Factory Mode Introduction

Photo

Sharpness 不可调节

2. Senseye Demo 处于 ON 时,做

Auto 自动变为 OFF

sRGB

Sharpness 不可调节

Full full

Aspect

D-sub/DVI D-sub

17 languages

English/日本語/简体中文/繁體中文

Language

/Français/Deutsch/Italiano/Español/Polski/

English

Česky/Magyar/(SiCG/BiH/CRO)/Română/Ned

erlands/Русский/Svenska /Português

H. Position (0~100) 50

V. Position (0~100) 50

Display Time (5, 10, 15, 20, 25, 30) 15

OSD Lock

(ON/OFF)(按 Menu 鍵 15s 即可解除鎖定)

OFF

Press[MENU], [Enter]& [POWER] at the same time, when Monitor is Power On OSD menu will be shown with

“F” on the left top. Select “F” for entering factory mode.

AUTO Level: Automatically calibrate chip ADC parameter by using chip internal DAC.

GAIN: ADC gain value

OFFSET: ADC offset value

C1-Blue: Set color temperature 9300K

C2-Red: Set color temperature 5800K

C3-Normal: Set color temperature 6500K

C5-User: Set user preferred color temperature

Lang type: 17

Reset BL Hr: the time of backlight

Reset Total Hr: the total time when connect power

Return: Escape from Factory menu.

4.2.3.5After repair, to ensure the quality you should do the following test and adjustment

Item Content Equipment

Tes t OS D

function

1.Signal is set as 1920×1080@60Hz under General-1

2.Checking whether each single function key and compound function ke

can be worked.

Chroma

Signal Generator

15

Loading...

Loading...