Page 1

®

Bendix® MV-2™ Control Module

RED

COVER (1)

SD-03-3412

2

3

9

4

7

8

6

1

YELLOW

5

FIGURE 1 FIGURE 2

DESCRIPTION

The Bendix® MV-2™ control module is an integrated control

assembly designed for control panel mounting in a

truck-tractor. The bodies for the module, as well as “spool”

inserts, are molded of a nonmetallic, noncorrosive material.

The assembly consists of two push-pull valves and a dual

circuit supply valve which triggers at a preset pressure

differential. The valve “spool” inserts, as well as the dual

circuit supply valve spool and shuttle, may be removed from

the valve bodies without disconnecting the air lines.

The MV-2™ module includes a spring loaded dual circuit

supply valve which selects, as the air source for both control

valves, the No. 1 reservoir at all times unless the pressure in

the No. 1 reservoir falls not more than 30 P .S.I. below that of

the No. 2 reservoir, when the dual circuit supply valve will

shuttle and establish the No. 2 reservoir as the supply . An

auxiliary air delivery port is also available which receives its

supply from the dual circuit supply valve. All air connections

are at the bottom of the valve, as shown on Figure 3, including

the auxiliary air delivery port.

The MV-2™ module provides all the functions of a standard

three valve combination plus supply reservoir source

selection:

1. Tractor protection control

2. Trailer service air supply

3. System park

4. Trailer park only

5. Trailer charge with tractor spring brakes applied (tractor

park only)

TP-3

TRACTOR

PROTECTION

VALVE

6. Supply reservoir selection

™

EXHAUST

DELIVERY - TRAILER

SB-3

RESERVOIR #1

DELIVERY - TRACTOR

RESERVOIR #2

RESERVOIR #1

SUPPLY

AUXILIARY AIR

DELIVERY

SUPPLY

RESERVOIR #2

PORT DESIGNATIONS

MV-2™ CONTROL

MODULE

FIGURE 3

1

Page 2

The trailer air supply valve (red button) (see Figure 1) delivers

air to the trailer supply line and also will trip (Pop out)

automatically and shut off the trailer supply if pressure

decreases to 40 ±5 P.S.I.

NOTE: Reservoir No. 1 must be the reservoir that supplies

the rear tractor axle(s).

Reservoir No. 2 must be the reservoir that supplies

the front axle.

The parking brake valve (yellow button) controls the spring

brakes on the tractor and when exhausted, simultaneously

causes the trailer supply valve to trip and exhaust, thus

applying both tractor and trailer parking brakes as required

by Federal Regulations. The trailer brakes may be

independently released by pushing only the trailer air supply

valve (red button) in.

OPERATION

Initial Charge

With the system completely discharged, both buttons are

out (Figure 4). When system pressure reaches 65 P.S.I.,

the red button (trailer supply) may be pushed in (Figure 5)

and should stay in, charging the trailer system and releasing

the trailer brakes. The yellow button may now be pushed in

which will supply air to the tractor spring brakes, releasing

them.

Normal Operating Position (Figure 7)

Automatic Application

With both buttons in, in the normal run configuration, if the

supply pressure to the push-pull valves is reduced to

40 ±5 P.S.I., the red button (trailer supply valve) must pop

out, applying the emergency or parking brakes on the trailer .

If the red button is held in manually and the pressure

decreases to 30 ±5 P.S.I., a tripper piston within the trailer

control spool will move upward, exhausting the trailer supply,

effecting the required non-override feature. The yellow (parking

brake) button will pop out at approx. 20-30 P.S.I.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the MV -2

module should be inspected every 6 months or 1500

operating hours, whichever comes first, for proper operation.

Should the MV-2™ module not meet the elements of the

operational tests noted in this document, further investigation

and service of the valve may be required.

SYSTEM PARK

™

With both buttons pushed in, air is now being supplied to

the trailer and to the tractor spring brakes; all brakes are

released.

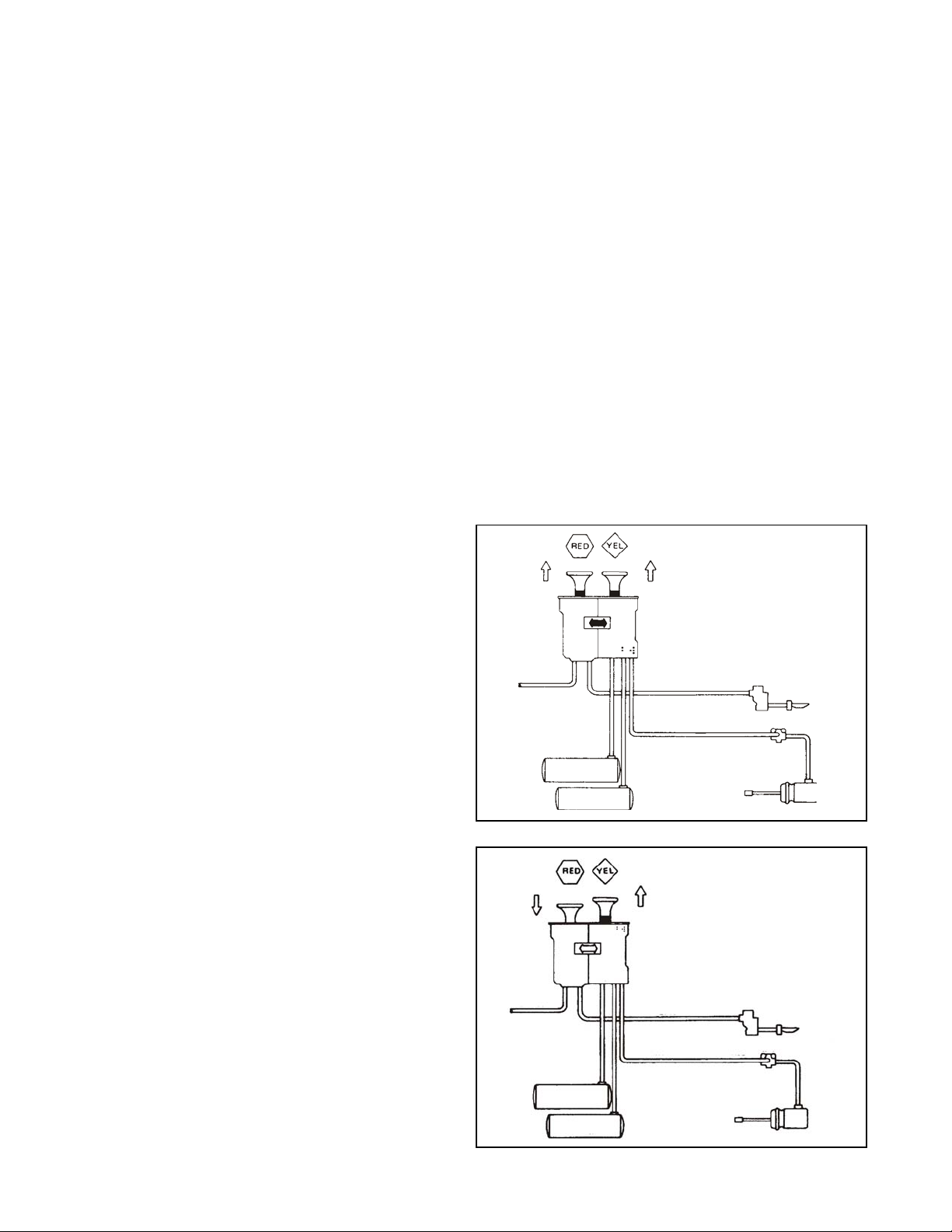

Actuation of Trailer Park or Emergency Brakes

(Figure 6)

To actuate the trailer brakes only, the red button is pulled

out, exhausting the trailer supply line. The trailer brakes are

now applied either by air emergency or spring brakes,

depending on the type of trailer system. This mode would

be used to uncouple from the trailer and during bobtail

operation.

System Park (Figure 4)

With both buttons in for normal run modes, the parking

brakes on both tractor and trailer may be actuated by pulling

the yellow (parking brake) button out, which exhausts the

air from the tractor spring brakes and simultaneously causes

the red (trailer supply) button to pop out, applying the trailer

brakes. This complies with Federal Regulations that one

control must apply all the parking brakes on the vehicle.

Trailer Charge (Figure 5)

If both valves are out, parking the combination vehicle, and it

is desired to recharge the trailer (leaving the tractor spring

brakes applied,) the red button may be pushed in

repressurizing the trailer supply line. This mode might also

be used to park a combination vehicle with air actuated

emergency brakes on the trailer to provide demonstrated

parking capability with tractor spring brakes only .

CONTROL

FIGURE 4

MV-2

CONTROL

MODULE

EXHAUST

FIGURE 5

MV-2

MODULE

EXHAUST

™

™

SERVICE

RESERVOIR #1

SERVICE

RESERVOIR #2

SERVICE

RESERVOIR #1

SERVICE

RESERVOIR #2

SUPPLY TO TRAILER

TRACTOR SPRING BRAKE CONTROL

CHARGE TRAILER WITH

TRACTOR PARKED

TRACTOR

PROTECTION

SUPPLY TO TRAILER

TRACTOR SPRING BRAKE CONTROL

TP-3

TRACTOR

PROTECTION

VALVE

TP-3™

VALVE

™

QRV

SB-3

QRV

SB-3

2

Page 3

PARK TRAILER WITH

TRACTOR RELEASED

OR BOBTAIL TRACTOR

™

MV-2

CONTROL

MODULE

EXHAUST

SERVICE

RESERVOIR #1

SERVICE

RESERVOIR #2

SUPPLY TO TRAILER

TRACTOR SPRING BRAKE CONTROL

TP-3

TRACTOR

PROTECTION

VALVE

™

QRV

SB-3

FIGURE 6

NORMAL OPERATING

POSITION

™

MV-2

CONTROL

MODULE

EXHAUST

SERVICE

RESERVOIR #1

SERVICE

RESERVOIR #2

SUPPLY TO TRAILER

TRACTOR SPRING BRAKE CONTROL

™

TP-3

TRACTOR

PROTECTION

VALVE

QRV

SB-3

FIGURE 7

OPERATING & LEAKAGE TEST

1. Charge the air brake system to 65 P.S.I. and check for

leakage between body seals, body and cover plates.

No leakage permitted.

2. With supply pressure still at 65 P .S.I., push the red button

in. The button must stay in. Leakage at the exhaust

port must not exceed a 1" bubble in 5 seconds.

3. Develop a leak in the line delivering air to the trailer supply

circuit. The red button must pop at 40 ± 5 P.S.I. and

maintain the supply pressure. Leakage at the exhaust

port must not exceed a 1" bubble in 5 seconds.

4. Hold the red button in and again develop a leak in the

supply circuit. Air must start to escape from the exhaust

port when the trailer supply line pressure reaches

30 ±5 P.S.I.

5. Release the red button and rebuild the supply pressure

to at least 40 P .S.I. Push in the yellow button; the yellow

button must remain in. Leakage at the exhaust port should

not exceed a 1" bubble in 5 seconds.

6. Develop a leak in the tractor spring brake delivery circuit.

The yellow button must pop at 25 ±5 P .S.I. and maint ain

supply pressure. Leakage at the exhaust port should

not exceed a 1" bubble in 5 seconds.

7. Charge the system to 120 P .S.I. and push both buttons

in. Pull the red button out. The yellow button must remain

in.

8. Push the red button in and pull the yellow button out.

The red button must pop out almost instantaneously .

9. Install a gauge to monitor tractor spring brake delivery

pressure. Apply 120 P.S.I. to both reservoirs (No. 1 &

No. 2). Push in the yellow button. Delivery pressure

should equal the pressure in reservoir No. 1. Reduce

the pressure in No. 1 reservoir. Delivery pressure and

No. 1 reservoir pressure should descend together to

105-90 P .S.I. at which point the dual circuit supply valve

shuttle should switch to No. 2 reservoir and delivery

pressure should increase to No. 2 reservoir pressure.

After the No. 1 reservoir pressure is reduced to zero,

there should not be audible leakage at the No. 1 reservoir

opening. Close the leak which had been created in the

No. 1 reservoir.

10. Leaving the yellow button in, recharge the No. 2 reservoir

to 120 P.S.I. The delivery pressure should also read

120 P.S.I. Recharge the No. 1 reservoir to 100 P.S.I.

Slowly vent the No. 2 reservoir. As the No. 2 reservoir

pressure and the delivery line pressure descend,

pressure should stabilize at approx. 100 P.S.I.

11. Close all vents or leakage points and charge both

reservoirs to 120 P.S.I. Position the red button out and

the yellow button in. Develop a leak in the spring brake

delivery line and hold the yellow button in. No. 1 reservoir

pressure must reduce to zero and No. 2 reservoir

pressure to 20 - 30 P.S.I. The dual circuit supply valve

shuttle should cycle several times during this leakdown

period.

REMOVING AND REPLACING SPOOL ASSEMBLIES

Block the wheels or otherwise secure the vehicle and drain

all reservoirs. It should be unnecessary to remove the MV-2

module from the vehicle. Remove any panel, plate or whatever

is necessary to expose the valve cover plates. It is

recommended that the valve be serviced by replacing the

complete spool assemblies. The dual circuit supply valve

feature may be serviced by replacing four (4) o-rings and

one (1) spring, available in a maintenance kit.

DISASSEMBL Y - Spools (Figure 2)

1. Remove the cover plate screws. (Four in each cover)

and cover (1).

2. Carefully pull the spool assemblies out of their respective

body bores by pulling on the buttons.

3. Remove the roll pins (2) which retain the buttons on the

spool stems and remove buttons and cover plates.

™

3

Page 4

DISASSEMBL Y - Dual Circuit Supply V alve

1. The dual circuit supply valve is located in the tractor

control body. (The one from which the spool with the

yellow button has been removed.) Grasp the web in the

top of the valve spool (3) (Figure 2) with narrow nose

pliers, twist and pull valve spool out. The shuttle (4) should

also come out with the spool. Remove the shuttle return

spring (5) and o-rings (6), (7), (8) and (9).

CLEANING & INSPECTION

The non metallic components which comprise most of the

parts of the MV-2™ module should not be immersed in

any solvent type cleaner. Old lubricant should be wiped

off parts to be reused and the bores of the body wiped out

with a clean dry cloth.

ASSEMBLY - Dual Circuit Supply Valve (Figure 2)

Lubricate o-rings, bore and sliding surfaces with silicone

lubricant Bendix 291126 BW -650-M Dow Corning 55-M.

1. Place the shuttle return spring (5) in the dual circuit

supply valve bore in the body .

2. Install o-rings (6) & (7) on the shuttle (4) and (8) & (9) on

the valve spool (3).

3. Insert the small end of the shuttle in the spool and insert

the assembly into the valve bore, flush with top of body .

The dual circuit supply valve spool is retained in the body

by the same cover plate which also retains the tractor

control (yellow button) spool.

ASSEMBL Y - SPOOLS

If old spools are being used, the o-rings and all sliding

surfaces should be lubricated with Bendix BW-650-M Silicone

Lubricant (291 126). If new service replacement spools are

being installed, they will be pre-lubricated.

1. Place cover plates over each plunger stem. The cover

plates are identical and are installed convex side up.

2. Place the red button on the longer spool (for trailer air

supply), matching the groove in the button with the tongue

in the cover plate (where applicable), and secure the

button with the button roll pin. Place the yellow button

on the shorter spool (for tractor air supply), matching

button and cover (where applicable) and securing with

button roll pin as before. If new service spools are used,

a new roll pin will be found in each spool package.

3. Insert the shorter spool assembly (yellow button) in the

tractor supply bore (housing with the dual supply valve).

If the entire valve assembly has been removed, position

the assembly so that the tractor control body housing is

at 3 o’clock. With the open bore (trailer supply) at 9

o’clock, rotate the button until wording on top-center is

horizontally readable. The stepped side of the cover plate

should be covering the dual supply valve. Secure the

plate with the four flat head Phillips screws; torque to 25

inch pounds. Insert the longer spool assembly (red

button) in the remaining bore. The stepped sides of the

cover plates should key with each other when the

remaining four flat head screws are torqued to 25 inch

pounds.

BW1584 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.

4

SERVICE TEST

Repeat the “Operating and Leakage T est”.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation,

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

EXTREME CAUTION should

™

Loading...

Loading...