Page 1

Bendix® LP-2™ & LP-3™ Low Pressure Indicators

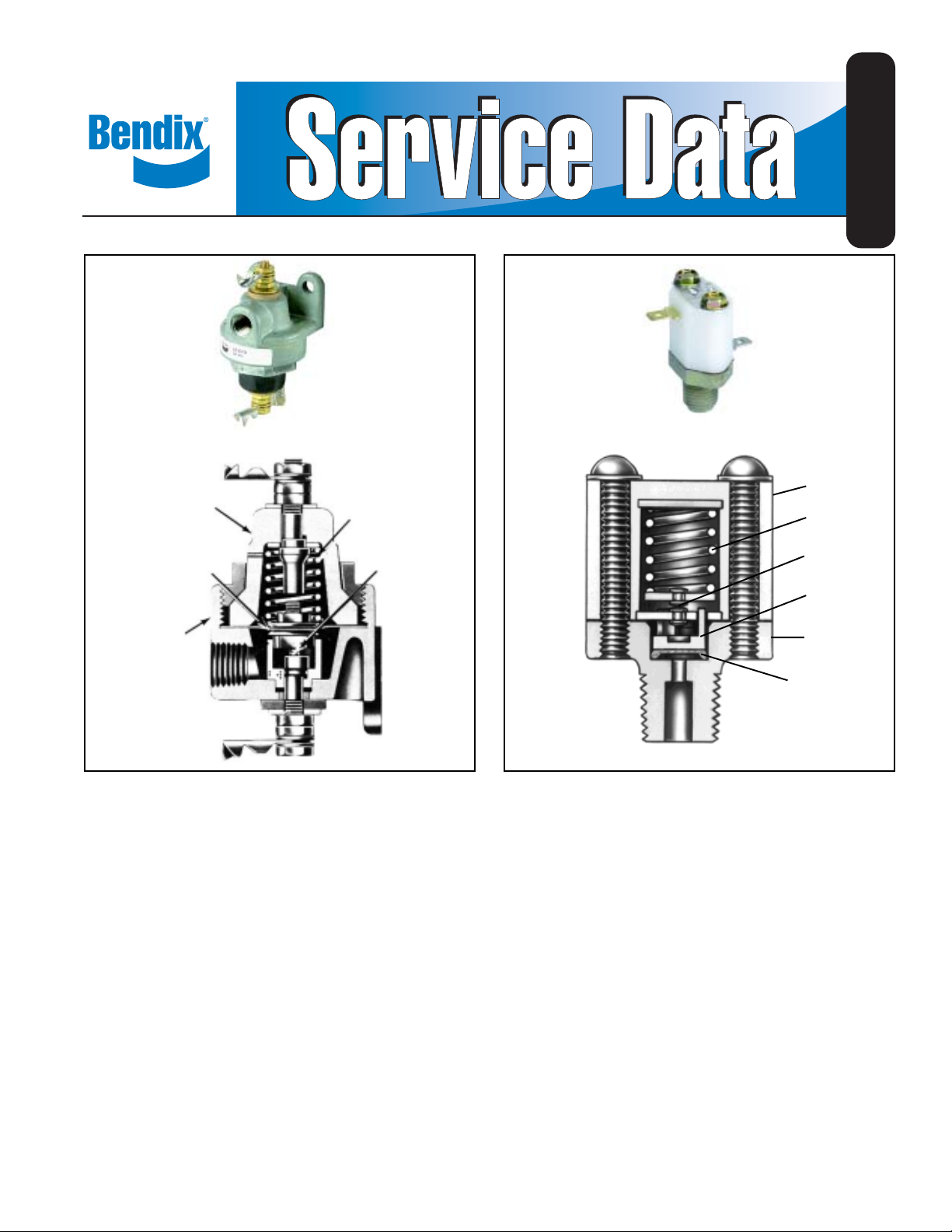

COVER

SPRING

SD-06-1600

COVER

SPRING

DIAPHRAGM

BODY

FIGURE 1 - LP-2™ LOW PRESSURE INDICAT O R FIGURE 2 - LP-3™ LOW PRESSURE INDICAT O R

DESCRIPTION

The low pressure indicator is a safety device designed to

give an automatic warning to the driver whenever air pressure

in the air brake system is below the safe minimum for normal

vehicle operation. It is usually used to operate an electrical

buzzer or warning light, or both, which are audible or visible

to the driver.

Two styles of low pressure indicators are currently

manufactured.

CONTACT

POINTS

O-RING

DIAPHRAGM

The LP-3™ low pressure indicator is the newer style,

consisting of a die cast body, nylon cover and employs a

spring loaded o-ring diaphragm and piston. The LP-3

indicator is available with either one terminal or two. The

single terminal unit utilizes a metallic gasket between body

and case to ground the lower contract strip. The two terminal

unit utilizes a phenolic insulating gasket to isolate both

terminals from the vehicle frame.

The electrical contacts provided in both the LP-2™ and LP-3

indicators remain closed by spring force until the air brake

system pressure below the diaphragm is above the setting

The LP-2™ low pressure indicator, which is the older style

and consists of a die cast body with a spring loaded

diaphragm clamped between the body and the Bakelite

cover.

(force) of the low pressure indicator spring. The setting of

the indicator and piece number is marked on a label on the

valve body. If a label is not present, then the vehicle manual

should be consulted for the proper setting. The nominal

setting of the indicator is 60 psi; however , pressure settings

may vary depending upon the vehicle.

CONTACT

POINTS

PISTON

BODY

™

™

1

Page 2

OPERATION

To describe the operation, we shall assume that the low

pressure indicator is set for 60 psi. When air pressure at the

supply port and under the diaphragm is above 60 psi, the

electrical contacts remain open because the force exerted

by air pressure underneath the diaphragm overcomes the

force exerted by the spring above the diaphragm.

When air pressure below the diaphragm drops below 60 psi,

the spring exerts a force which is greater than the force

exerted by the air pressure below the diaphragm. This causes

™

the diaphragm (and the piston in the LP-3

indicator) to

move and allow the electrical contacts to close. This

completes or closes the electrical circuit to the warning

device, warning the driver of low air pressure in the system.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

5. Disconnect the air line and mounting bolts or unscrew

the Indicator from the fitting and remove.

INSTALLING

1. Install in a convenient location for servicing.

2. Connect to a reservoir pressure line at a high point in the

system for adequate drainage.

™

3. If installing an LP-2

indicator, use a supply line of 1/4

O.D. minimum.

4. Connect the Indicator terminals in series with the ignition

switch and the warning device.

DISASSEMBLY

NOTE: It is generally recommended that the low pressure

indicator, if faulty, be replaced with a new unit;

however, service p arts are available; and if repairs

are necessary , the following will apply:

LP-2™ indicator. Unscrew the cover ret ainer from the body .

Remove cover and remove spring and diaphragm assembly .

No two vehicles operate under identical conditions; as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the low

pressure indicator should be inspected every 6 months or

1500 operating hours, whichever comes first, for proper

operation. Should the low pressure indicator not meet the

elements of the operational tests noted in this document,

further investigation and service of the valve may be required.

TESTING FOR SERVICEABILITY

OPERA TING TEST

1. If possible, determine the setting of the low pressure

indicator by referring to the label on the valve or the vehicle

manual.

2. Operation of the low pressure indicator may be checked

with ignition switch “on” by reducing the system pressure

and observing that low pressure warning occurs when

system pressure drops below the setting of the low

pressure indicator. The contacts will be closed when

the warning device operates. If the setting of the indicator

is unknown, the contacts should close between

approximately 70 psi and 50 psi.

LEAKAGE TEST

1. With air pressure present at the supply port, coat the

indicator with soap solution. No leakage permitted.

REMOVING

1. Block the wheels. Otherwise, secure the vehicle with

other than service brakes.

2. The ignition switch should be in the “off” position.

3. Drain the air from the system.

4. Disconnect the electrical connections at the low pressure

indicator.

LP-3™ indicator. Remove cover screws, lockwashers.

Remove cover, contact disc, spring, and shim(s). (Note:

Shims may or may not be present.) Remove contact plate,

gasket, piston, and o-ring diaphragm.

CLEANING AND INSPECTION

1. Clean all metal parts in mineral spirits and dry them

completely.

2. Inspect all parts for excessive wear or deterioration.

Check the valve spring for cracks or corrosion.

3. Inspect contact points. If contact points are not severely

pitted, they can be dressed with a fine file.

Replace all parts that were discarded and any parts not

found to be serviceable during inspection, using only genuine

Bendix replacement parts.

ASSEMBLY

NOTE: When using pipe thread sealant during assembly

and installation, take particular care to prevent the

sealant from entering the valve itself. Apply the

sealant beginning with the second thread back from

the end.

LP-2™ INDICA TOR

1. Place and position the diaphragm assembly in the body.

Position the spring so that it rests on the upper

diaphragm follower.

2. Place cover over the diaphragm and screw cover retainer

to the body and tighten securely. (Torque to 110-130

inch pounds.)

2

Page 3

LP-3™ INDICA TOR

1. Lubricate bore of body and both sides of the o-ring

diaphragm with silicone lubricant BW-650-M (Bendix

piece no. 291 126).

2. Install o-ring diaphragm in body . (Note: o-ring portion of

diaphragm should face supply port.)

3. Install piston in body. Flat side of piston should face

o-ring diaphragm.

4. Install gasket. (Always use a phenolic gasket in a two

terminal switch and a metallic gasket in the single

terminal.)

5. Position contact plate over fingers of piston. Contact

plate should rest on face of gasket.

6. If shim(s) are used, place shim(s) in cover.

7. Place spring in cover.

8. Place contact point so that it rests on spring.

9. Install cover on body, using machine screws, making

certain that the contact plate is in position over fingers

of piston, and arm of contact plate is positioned so that

it will fit in groove of cover.

10. Tighten screws securely . (T orque to 20-30 inch pounds).

TEST OF REBUIL T LOW PRESSURE INDICA TOR

After rebuilding, perform the leakage and operating tests as

outlined in section “T esting for Serviceability .”

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

®

3

Page 4

4

BW1447 © 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 7/2006 Printed in U.S.A.

Loading...

Loading...