Page 1

Bendix™ VORAD® Collision Warning System

Troubleshooting Guide

Bendix™ VORAD® Collision Warning System

BW2849 (Formerly VOTS0030)

December 2011

EVT-300

Page 2

Fault Isolation Procedures

General Warnings

Before starting a vehicle:

1. Sit in the driver’s seat.

2. Place the vehicle in neutral.

3. Set the parking brake.

4. Disengage the clutch.

Before working on the vehicle or leaving the cab with the engine

running:

1. Place the vehicle in neutral.

2. Set the parking brake.

3. Block the wheels.

Do not operate the vehicle if the alternator lamp is lit or if the

gauges indicate low voltage.

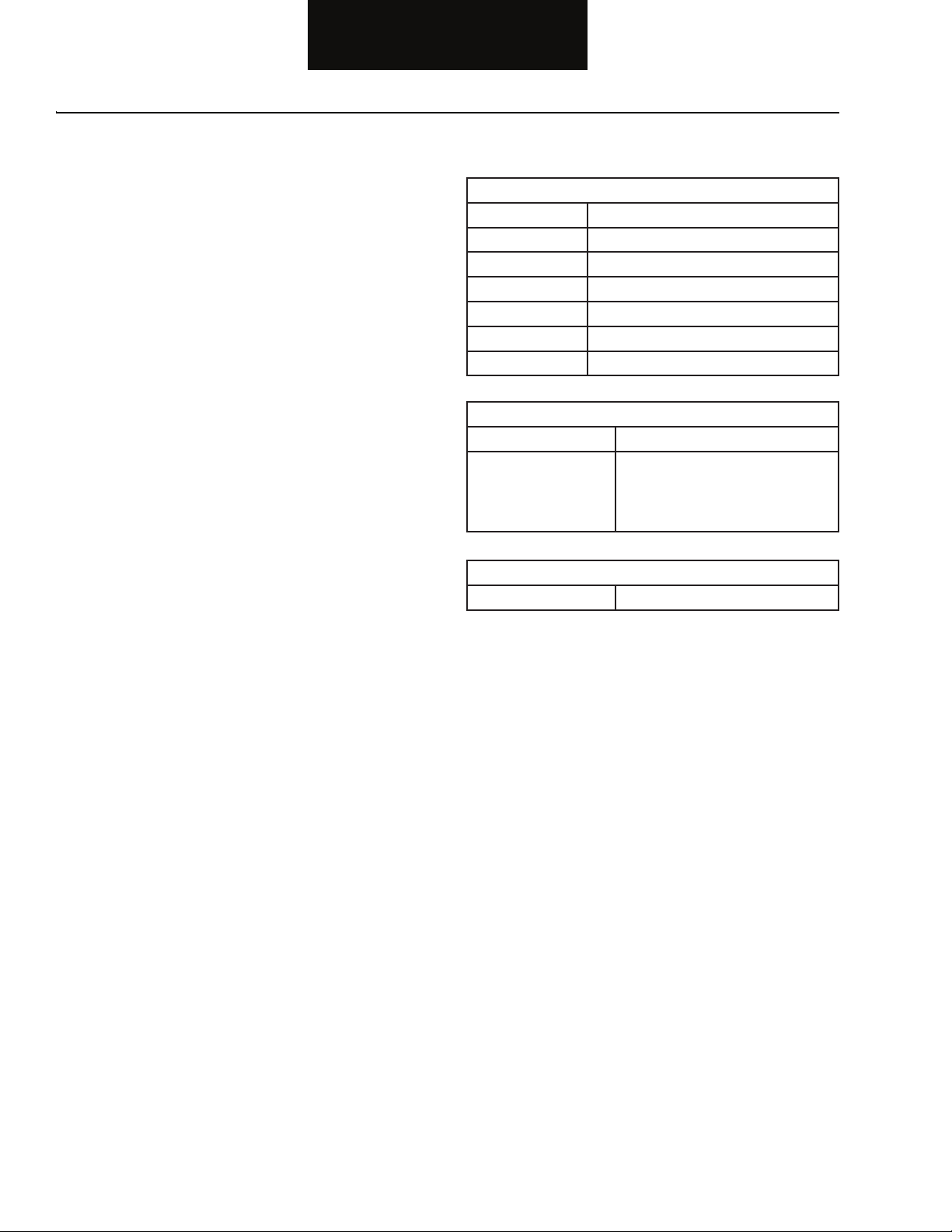

Suggested Tools

NEXIQ Technologies 1-800-639-6774 www.NEXIQ.com

Part No. Description

104004 Pro-Link GRAPHIQ

208040 Multi-Protocol Cartridge (MPC)

804001 MPC Eaton System Software

501003A Data Cable

405048 6- and 9-Pin Deutsch Diagnostic Adapter

125032 USB Link™ Vehicle Link Adapter

Bendix 1-800-AIR-BRAKE www.bendix.com

Part No. Description

ServiceRanger 2.8 PC-based Diagnostics

For EVT-300 specifi c ServiceRanger

questions call Bendix at

1-800-AIR-BRAKE

Standard Commercial Product

Volt/OHM Meter (VOM)

™

Related Publications

For more information call 1-800-AIR-BRAKE in the U.S., Canada,

and Mexico.

Page 3

Table of Contents

Section 1: Introduction

Diagnostic Procedure ........................................................ 1-1

Fault Code Retrieval and Clearing ..................................... 1-2

Fault Code Isolation Procedure Index................................ 1-3

Driving Techniques ............................................................ 1-4

Symptom-Driven Index ...................................................... 1-7

Section 2: Fault Isolation Procedures

Pretests

Electrical Pretest ............................................................... 2-1

Power-Up Sequence Test .................................................. 2-5

Component and System Codes

Component Code: 11, 12 (SID 254, FMI 4,12)

Central Processing Unit (CPU) ................................ 2-19

Component Code: 13, 34 (SID 9, FMI 2, 4, 5, 12)

Driver Display Unit ................................................... 2-21

Component Code: 14, 35 (SID 1, 2, FMI 2, 12, 14)

Antenna Assembly .................................................. 2-29

Component Code: 15 (SID 10, FMI 2)

Right Side Sensor ................................................... 2-37

Component Code: 16 (SID 11, FMI 2)

Left Side Sensor ...................................................... 2-43

Component Code: 21 (SID 7, FMI 2)

Right Turn Signal ..................................................... 2-49

Component Code: 22 (SID 8, FMI 2)

Left Turn Signal ....................................................... 2-53

Component Code: 23 (SID 3, FMI 2)

Brake Input Error ..................................................... 2-57

Component Code: 24 (SID 6, FMI 2)

Speed Input Error .................................................... 2-63

Component Code: 25, 32 (SID 231, FMI 2, 12,14)

J-1939 Signal and Cruise Signal ............................. 2-67

Component Code: 31 (SID 250, FMI 2)

J-1587 Data Link ..................................................... 2-75

Component Code: 33 (SID 248, FMI 12)

VBUS ...................................................................... 2-81

Section 3: Symptom Isolation Procedures

Symptom Tests

Antenna Not Detecting Targets .......................................... 3-1

Antenna Target Detection Test .......................................... 3-2

Side Sensor Not Detecting Targets ................................... 3-3

Side Sensor Detection Test ............................................... 3-4

Driver Card Not Reading ................................................. 3-11

Driver Detection Test ....................................................... 3-12

Appendix

VORAD® Wiring Diagram ..................................................A-1

Fault Code Tree ................................................................. A-3

Table of Contents

Table of Contents

Page 4

Fault Isolation Procedures

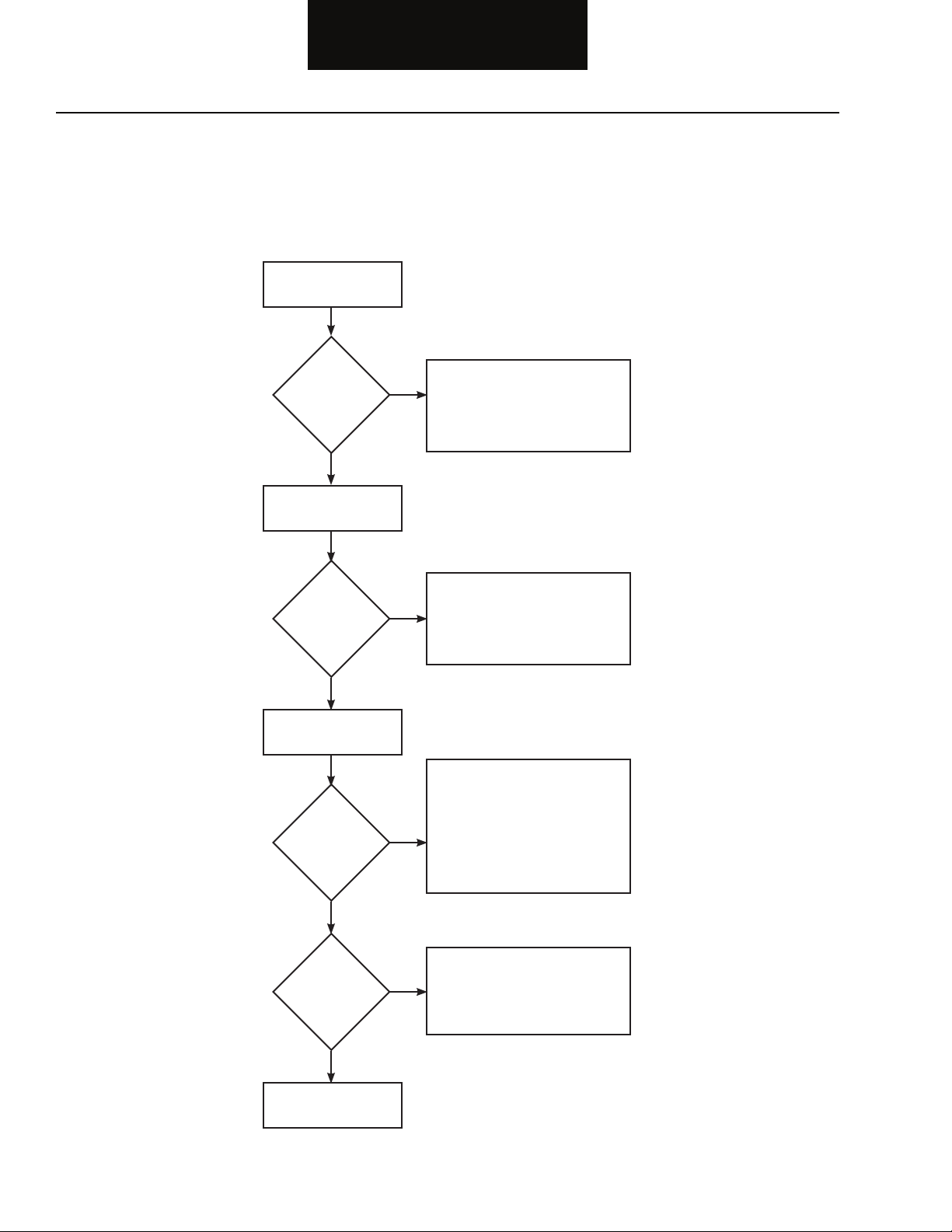

Diagnostic Procedure

Follow the fl owchart below for all Bendix™ VORAD® system failures. Perform tests and procedures as directed by the fl owchart.

Key On

Is the

Driver Display

Unit lamp lit?

(For Freightliner IDI,

skip this step.)

YES

NO

Perform Electrical Pretest

•

(page 2-1)

Perform Power-up Sequence Test

•

(page 2-5)

Retrieve Active Codes

(page 1-3)

Active

Codes?

NO

Retrieve Active Codes

(page 1-3)

Inactive

Codes?

NO

YES

YES

Perform Electrical Pretest

•

(page 2-1)

Refer to the Fault Code Isolation

•

Procedure Index to select a fault

code isolation procedure (page 1-4)

Perform Electrical Pretest (page 2-1)

•

Record and clear codes (page 1-3)

Perform Driving Techniques to

•

reproduce the inactive fault code

(page 1-5)

Refer to the Fault Code Isolation

Procedure Index to select a fault

code isolation procedure (page 1-4)

1-1

Symptom?

NO

Test Complete.

YES

Perform Electrical Pretest

•

(page 2-1)

Refer to the Symptom-Driven

•

Index to select a symptom isolation

procedure (page 1-8)

Page 5

Fault Code Retrieval and Clearing

Fault Isolation Procedures

RETRIEVING FAULT CODES

Note: Retrieve Bendix™ VORAD® system fault codes by enabling

the VORAD system’s self-diagnostic mode.

You can also use a PC-based Service Tool, such as ServiceRanger

2.8, or a Pro-Link tool, to retrieve VORAD system fault codes.

1. Put the vehicle in neutral.

2. Set the parking brake.

3. To activate Failure Display Mode, press in and hold

the Driver Display Unit “VOLUME” knob while turning the

key on.

Note: For software versions 013 and higher, hold “VOLUME” knob

in for 8 seconds.

4. Wait until the Driver Display Unit’s red “FAIL” indicator

light begins fl ashing two-digit fault codes and release

the volume knob. If no fault codes are found, the Driver

Display Unit will fl ash a code 41. At the conclusion of

fl ashing the fault codes, the system will fl ash a code 41.

5. TO READ ACTIVE FAULT CODES: Position the Driver

Display Unit “RANGE” knob to the left of center and only

active codes will be sent to the “FAIL” indicator light.

CLEARING FAULT CODES

1. Inactive fault codes must be cleared using a PC-based

Service Tool, such as ServiceRanger 2.8, or a Pro-Link

tool.

2. Active fault codes change to inactive fault codes when

the fault has been corrected. Clear inactive fault codes.

3. Turn key off and allow system to power down.

Service Procedure

4. Start vehicle and verify no fault codes reoccur.

6. TO READ INACTIVE FAULT CODES: Position the Driver

Display Unit “RANGE” knob to the right of center and

only inactive codes will be sent to the “FAIL” indicator

light.

7. Observe the sequence of fl ashes on the indicator lamp

and record the codes. A one to two second pause

separates each stored code, and at the conclusion of

fl ashing the fault codes, the system will fl ash a code 41.

The sequence automatically repeats after all codes have

been fl ashed.

1-2

Page 6

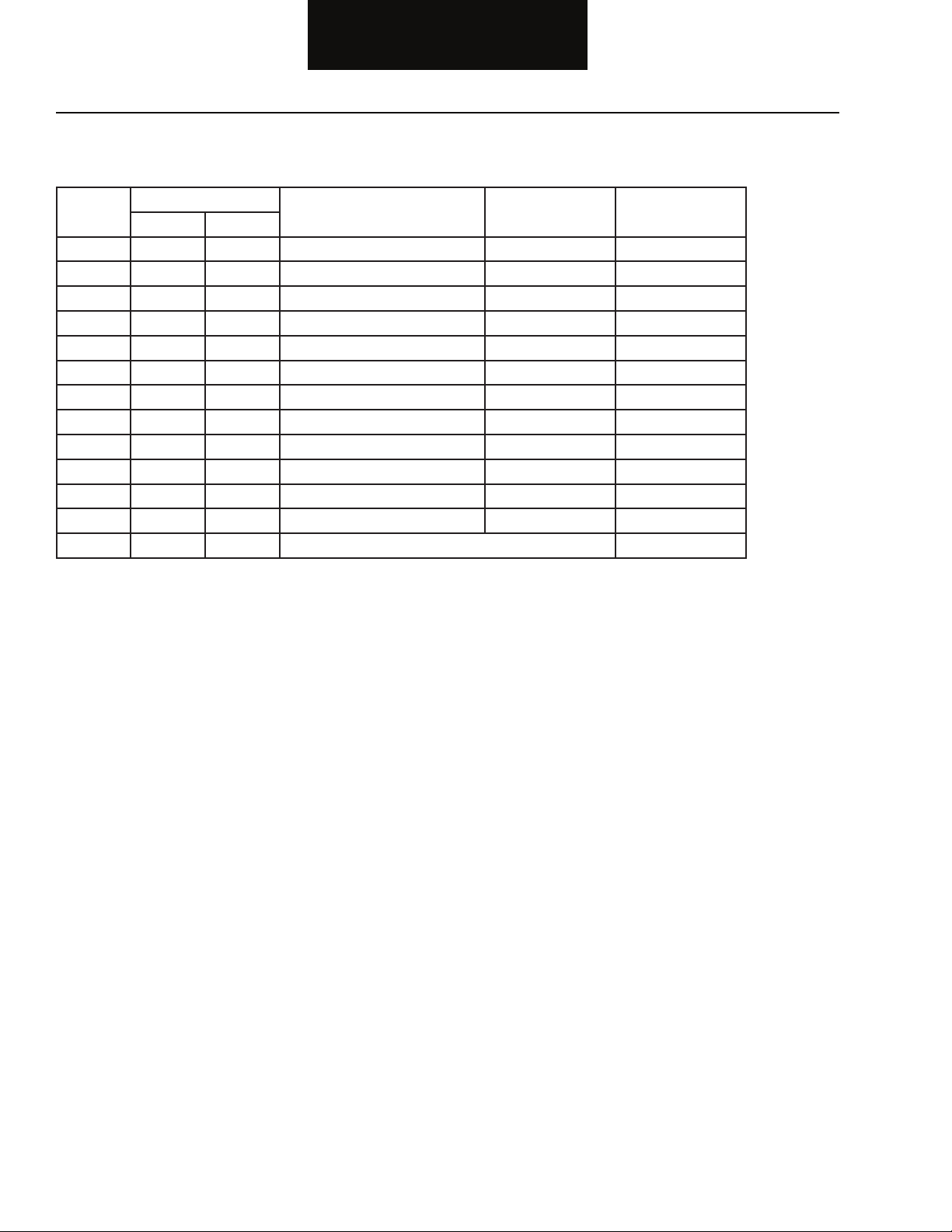

Fault Isolation Procedures

Fault Code Isolation Procedure Index

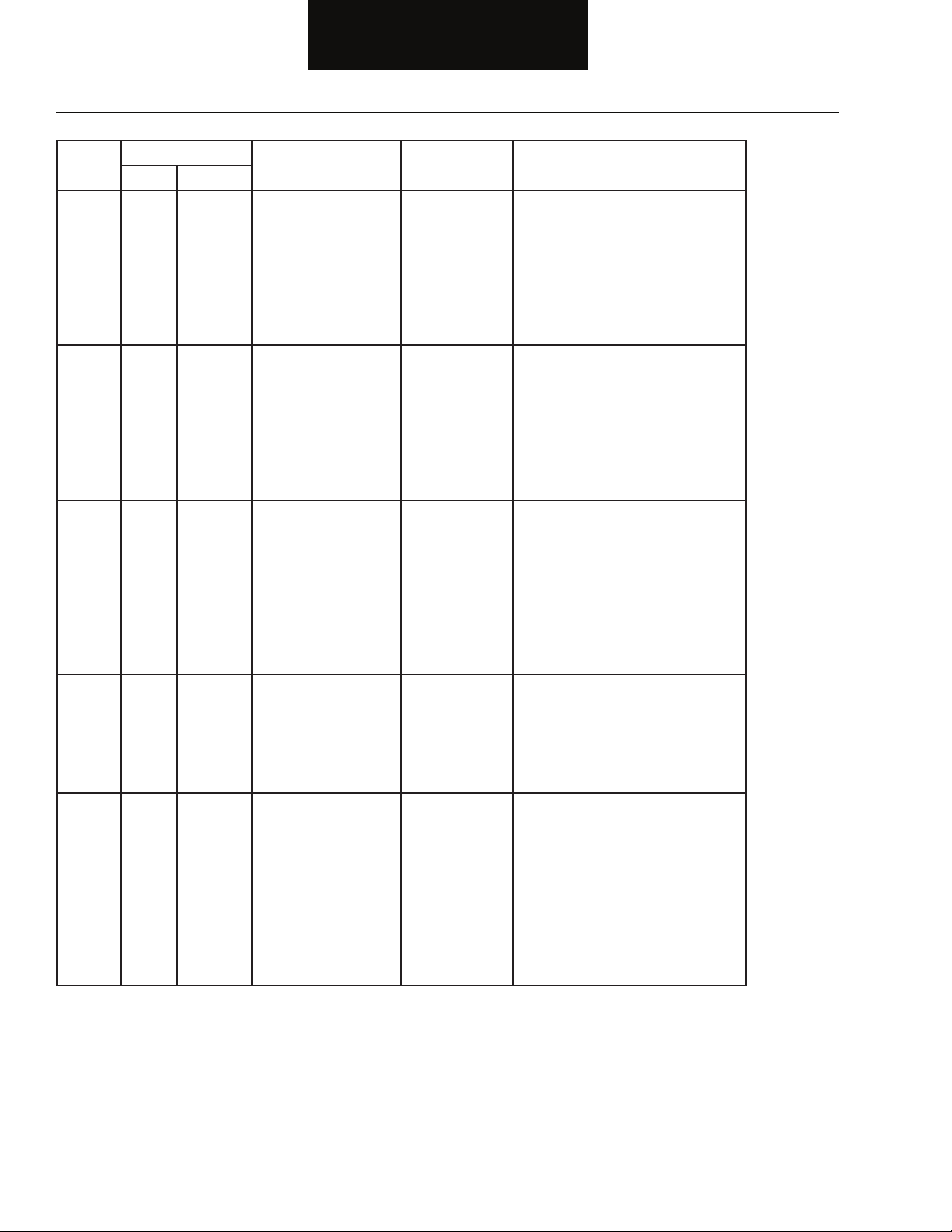

Fault

Codes

11, 12 254 4,12 Central Processing Unit Component 2 - 19

13, 34 9 2,4,5,12 Driver Display Unit Component 2 - 21

14, 35 1,2 2,12,14 Antenna Assembly Component 2 - 29

15 10 2 Right Side Sensor Component 2 - 37

16 11 2 Left Side Sensor Component 2 - 43

21 7 2 Right Turn Signal Component 2 - 49

22 8 2 Left Turn Signal Component 2 - 53

23 3 2 Brake Input Signal Component 2 - 57

24 6 2 Speed Input Signal Component 2 - 63

25, 32 231 2,12,14 J-1939 Data Link Signal System 2 - 67

31 250 2 J-1587 Data Link Signal System 2 - 75

33 248 12 VBUS Component 2 - 81

41 No Fault or End of Fault Codes

Hand-Held Codes

Description Type of Code Page NumberSID FMI

1-3

Page 7

Driving Techniques

Fault Isolation Procedures

Fault

Codes

11, 12 254 4,12 Central Processing Unit Component Key on. If the fault is present, the

13, 34 9 2,4,5,12 Driver Display Unit

14, 35 1,2 2,12,14 Antenna Component Key on. If the fault is present, the

15 10 2 Right Side Sensor Component Key on. If the fault is present, the

16 11 2 Left Side Sensor Component Key on. If the fault is present, the

Hand-Held Codes

Description Type of Code Driving TechniqueSID FMI

(Not applicable for

Freightliner IDI.)

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat and vibration.

Component Key on. If the fault is present, the

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat and vibration.

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat and vibration.

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat and vibration.

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat and vibration.

Service Procedure

1-4

Page 8

Fault Isolation Procedures

Fault

Codes

21 7 2 Right Turn Signal System Key on. If the fault is present, the

22 8 2 Left Turn Signal System Key on. If the fault is present, the

23 3 2 Brake Input Signal System Key on. Apply service brake for

24 6 2 Speed Input Signal System Select a forward gear and drive at a

25, 32 231 2,12,14 J-1939 Data Link Signal System Key on. If the fault is present, the

Hand-Held Codes

Description Type of Code Driving TechniqueSID FMI

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat and vibration.

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat and vibration.

a minimum of 8 seconds. If the

fault is present, the system should

automatically detect the problem and

set the code. If the fault is not present at

key on, operate the vehicle and attempt

to duplicate the driving conditions

that triggered the fault code. Possible

triggers include heat and vibration.

steady speed no slower than 10 MPH.

It may be necessary to operate the

vehicle for a prolonged period of time

if the cause of failure is related to heat

and vibration.

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat, vibration, and varying levels of

throttle demand. It may take up to 75

seconds to set this fault.

1-5

Page 9

Fault Isolation Procedures

Fault

Codes

31 250 2 J-1587 Data Link Signal System Key on. If the fault is present, the

33 248 12 VBUS Component Key on. If the fault is present, the

41 No Fault or End of Fault

Hand-Held Codes

Description Type of Code Driving TechniqueSID FMI

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat, vibration, and varying levels of

throttle demand. It may take up to 75

seconds to set this fault.

system should automatically detect the

problem and set the code. If the fault

is not present at key on, operate the

vehicle and attempt to duplicate the

driving conditions that triggered the

fault code. Possible triggers include

heat, vibration, and varying levels of

throttle demand. It may take up to 75

seconds to set this fault.

Codes

Service Procedure

1-6

Page 10

Fault Isolation Procedures

Symptom-Driving Index

Symptom Isolation Procedure Page Number

Antenna Not Detecting Targets Antenna Not Detecting Targets 3 - 1

Side Sensor Not Detecting Targets Side Sensor Not Detecting Targets 3 - 3

Driver Card Not Reading Driver Card Not Reading 3 - 11

1-7

Page 11

Fault Isolation Procedures

Service Procedure

This page left blank intentionally.

1-8

Page 12

Electrical Pretest

Harness

Fault Isolation Procedures

Overview

The pretest does not relate to any specifi c fault code, but must

be completed before performing Fault Code Isolation Table

procedures. The pretest verifi es the basic electrical inputs before

testing individual circuits.

Detection

There is no detection process specifi cally for the basic electrical

supply. However, failures of this type are generally detected by the

Bendix™ VORAD® system or the driver as some other type of fault

code or symptom.

Fallback

There is no fallback for the electrical pretest, however, it may affect

other systems.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

Possible Causes

This pretest can be used for any of the following:

• Corroded Power Contacts

• Blown Fuse

• Wiring Harness

• Low Batteries

2-1

Page 13

Fault Isolation Procedures

VOLT

V ACOM

Electrical Pretest

Step A Procedure Condition Action

1. Key off.

2. Inspect starter/battery

connections for integrity.

3. Measure voltage across

battery.

If voltage is 11 to 13 volts

on a 12 volt system or 22 to

26 on a 24 volt system

If voltage is outside of

range

Go to Step B.

Repair or replace batteries and

charging system as required.

Repeat this step.

Electrical Pretest

2-2

Page 14

Fault Isolation Procedures

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Electrical Pretest, continued

Step B Procedure Condition Action

1. Key off.

2. Disconnect negative (-) battery

cable.

3. Disconnect 32-way connector

from Central Processing Unit.

4. Measure resistance

between 32-way

connector pin C-2 and

ground.

If resistance is 0 to .5 ohms

If resistance is outside of

range

Go to Step C.

Repair ground path for Bendix™

VORAD® system. Go to Step A.

2-3

Page 15

Fault Isolation Procedures

VOLT

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Electrical Pretest, continued

Step C Procedure Condition Action

1. Key off.

2. Connect negative (-) battery

cable.

3. Key on.

4. Measure voltage

between 32-way

connector pin C-1 and

C-2.

If voltage is within .6 volts

of battery voltage

If voltage is outside of

range

Test complete.

Repair power path for Bendix™

VORAD® system. Fuse may be blown.

Reconnect all connectors. Go to

Step A.

Electrical Pretest

2-4

Page 16

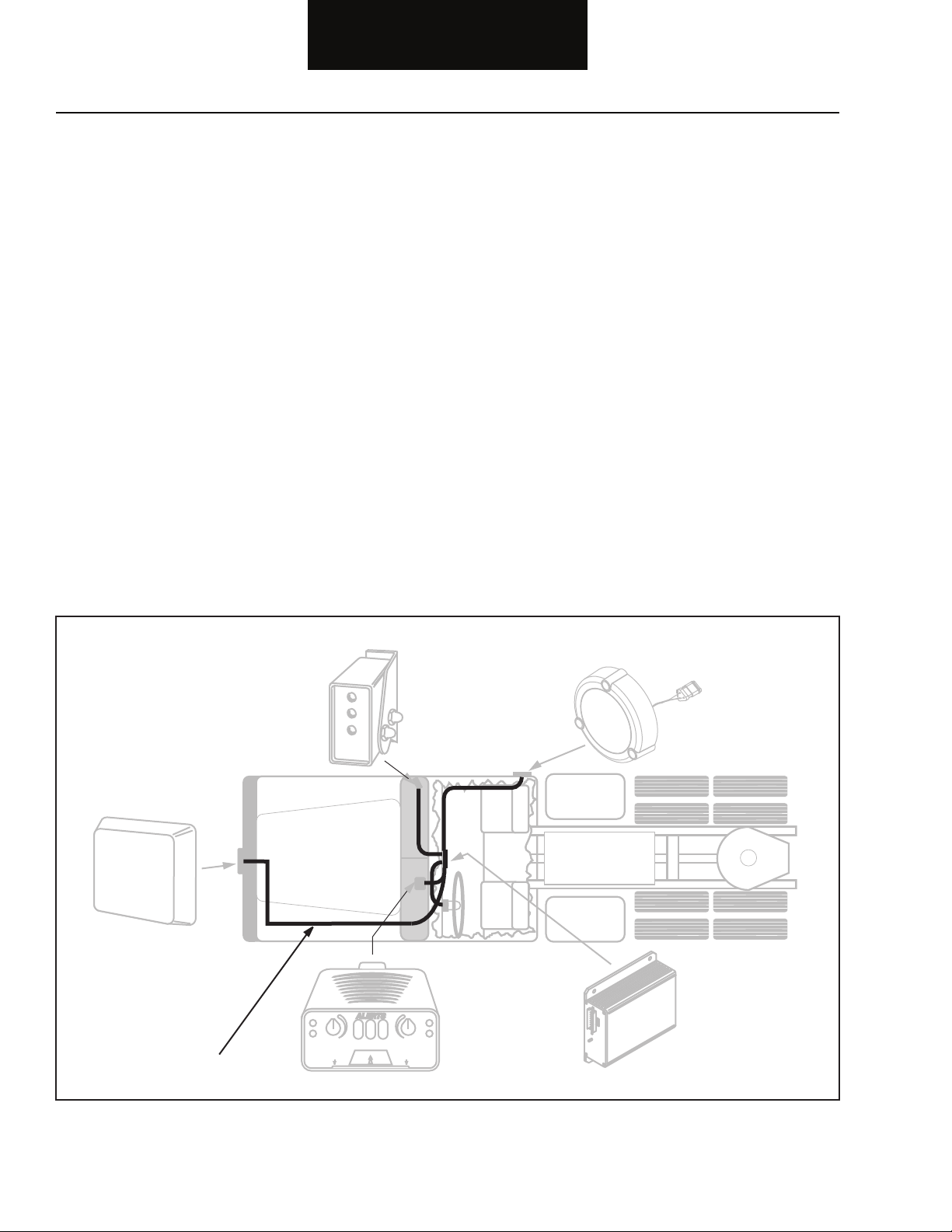

Power-Up Sequence Test

Harness

Driver

Display Unit

Central

Processing Unit

Fault Isolation Procedures

Overview

A failure during the power-up self-check indicates a failure of the

Central Processing Unit.

Detection

The power-up self-check is performed automatically each time the

key is turned on. Turn the key on and watch the Driver Display Unit.

If lights on the Driver Display Unit remain on after 15 seconds, or

never come on, the self-check has failed. NOTE: Not applicable for

Freightliner IDI (Integrated Dash Interface).

Fallback

If self-check fails, the product can not perform any operations.

Required Tools

• Digital Volt/Ohm Meter

Possible Causes

• Central Processing Unit

• Driver Display Unit

• Vehicle Harness

2-5

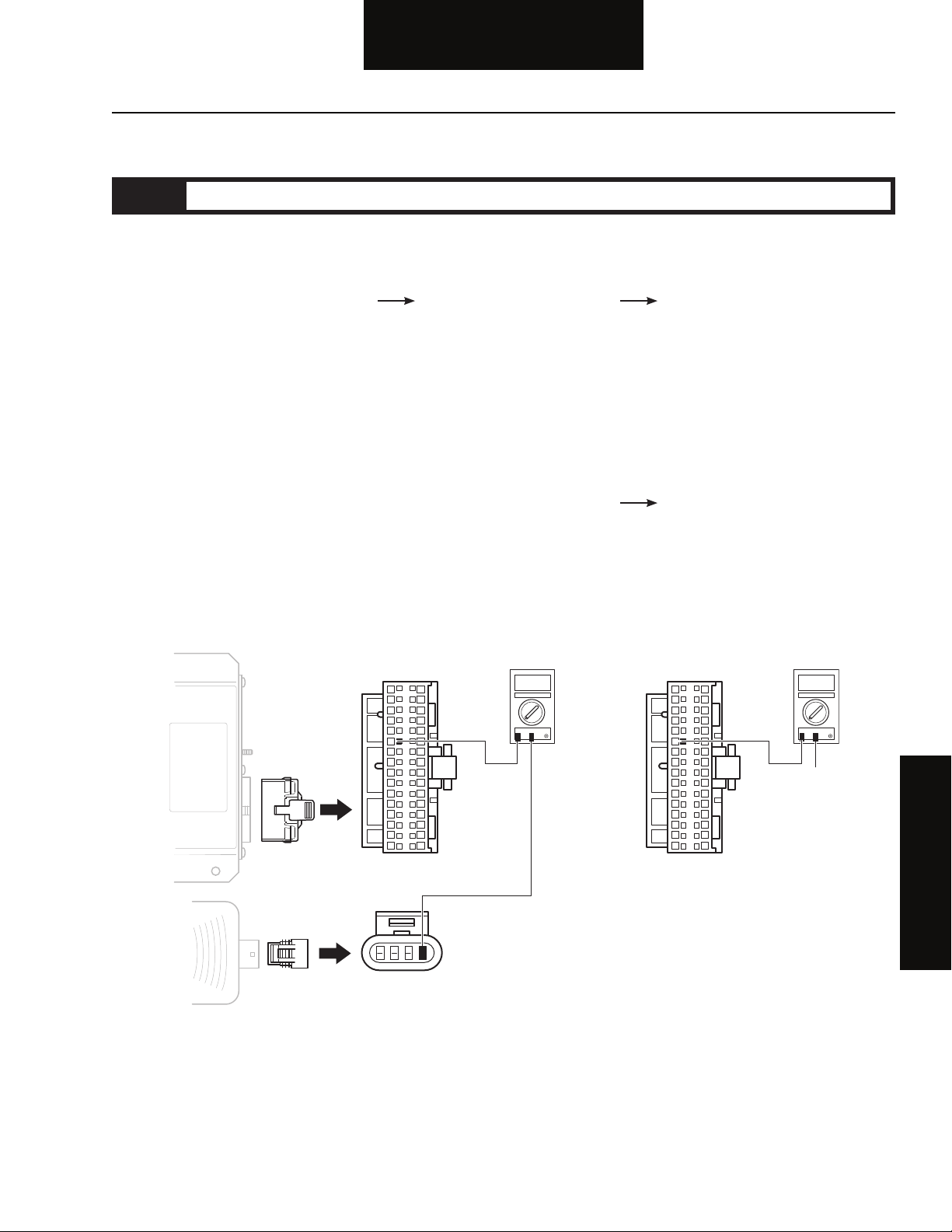

Page 17

Fault Isolation Procedures

VOLT

V ACOM

D C B A

Power-Up Sequence Test

Step A Procedure Condition Action

1. Before performing this test, the

Electrical Pretest must pass.

2. Key on.

3. Observe the Driver

Display Unit.

If lights turn on the go off

after approximately 15

Test complete.

seconds

Note: Not applicable for

Freightliner IDI

If lights fail to turn on

If lights turn on and stay on

Go to Step B.

Go to Step C.

Step B Procedure Condition Action

1. Key on.

2. Disconnect the 4-way connector

from the Driver Display Unit.

Note: Not applicable for

Freightliner IDI.

3. Measure voltage

between pins C and D

on the Driver Display

Unit 4-way connector.

If voltage is between 7.0

and 7.5 volts

Go to Step C.

Power-Up Sequence Test

If voltage is outside of

range

Go to Step G.

2-6

Page 18

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

OHMS

V ACOM

OHMS

GROUND

V ACOM

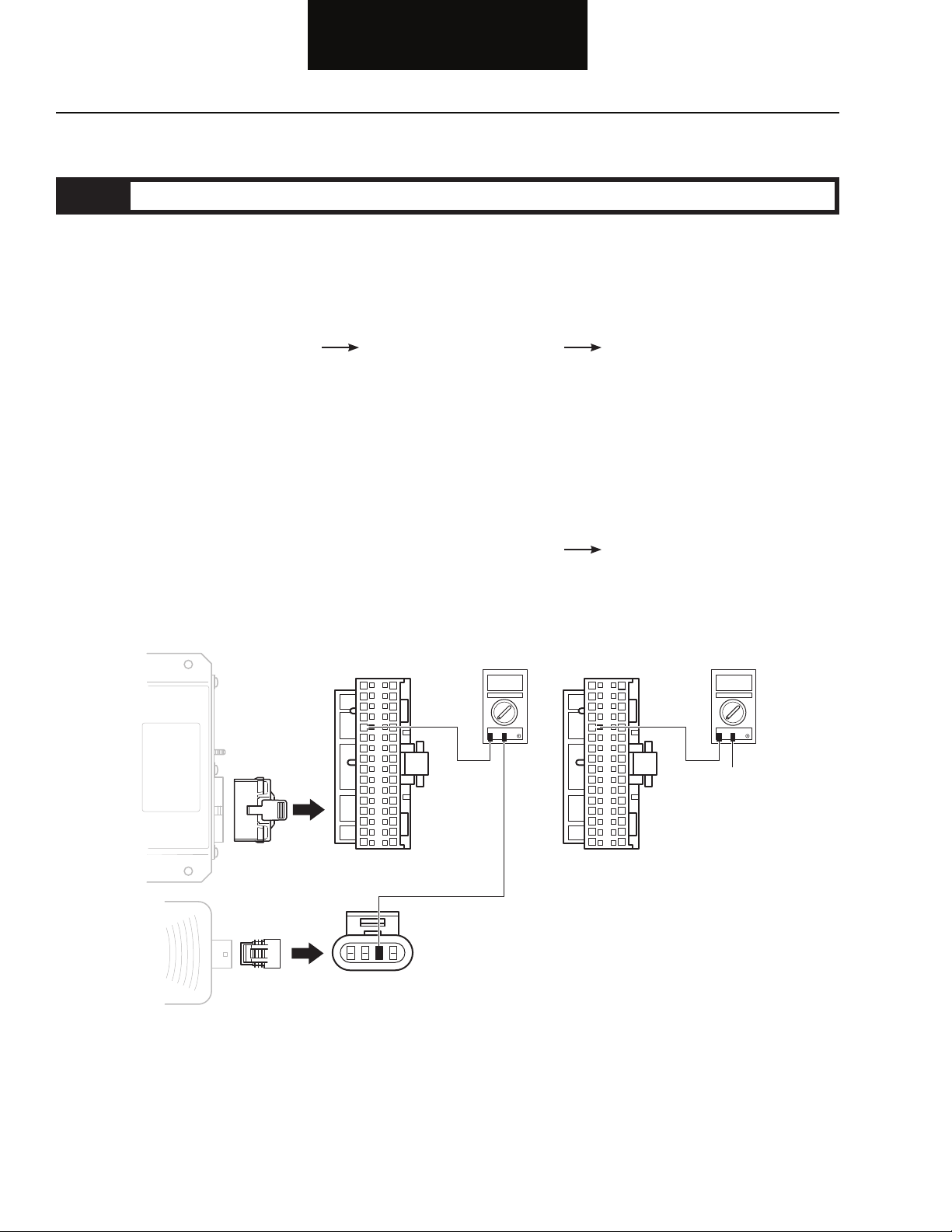

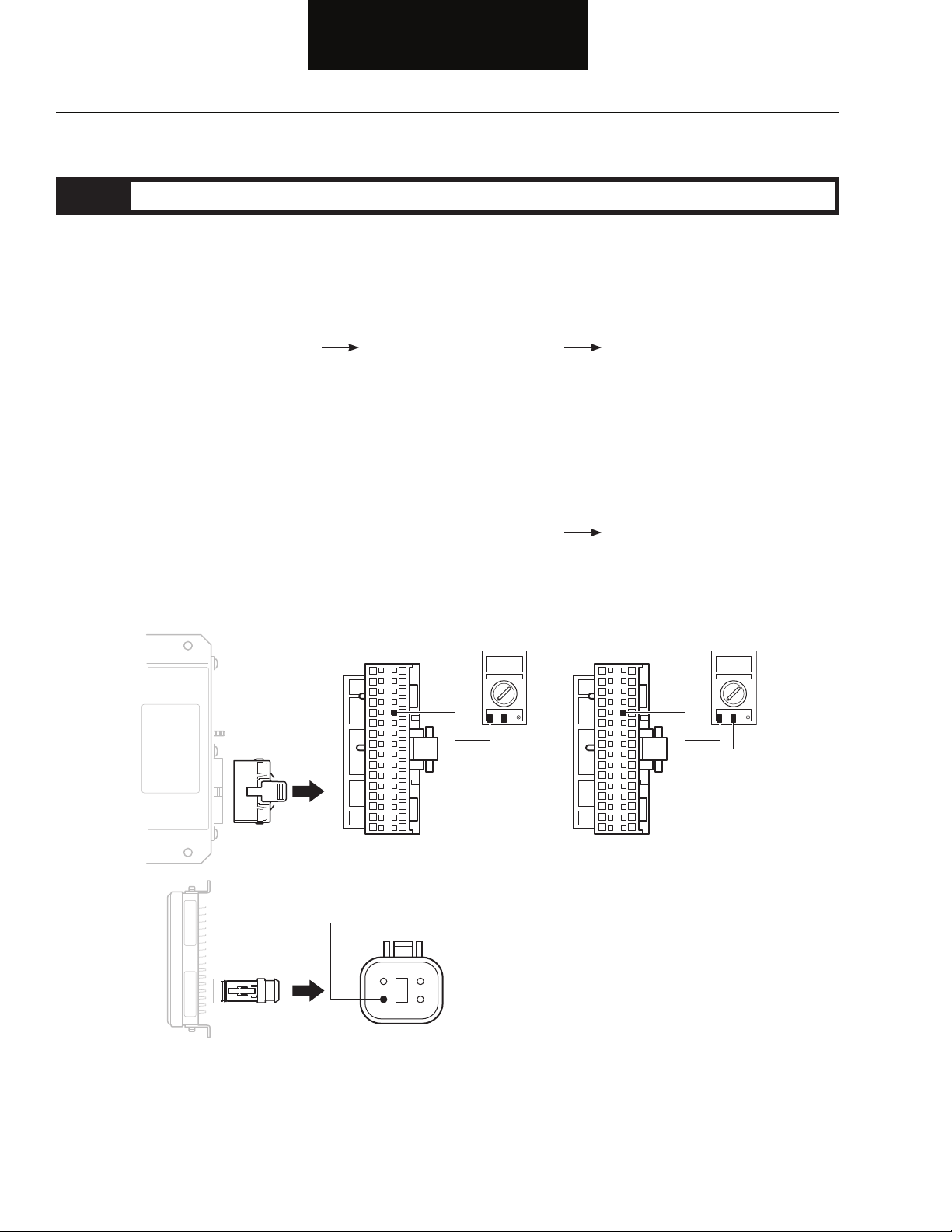

Power-Up Sequence Test, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin D3

and Driver Display

4-way connector

pin D.

• Central Processing

Unit 32-way

connector pin D3

and ground.

If resistance between D3 and

pin D is 0 to .3 ohms and if

resistance between pin D3

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step D.

Repair OEM wiring harness between

Driver Display Unit and Central

Processing Unit. Go to Step V.

2-7

Page 19

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

OHMS

V ACOM

OHMS

GROUND

V ACOM

Power-Up Sequence Test, continued

Step D Procedure Condition Action

1. Key off.

2. Measure resistance between:

• Central Processing

Unit 32-way

connector pin D4

and Driver Display

4-way connector

pin C.

• Central Processing

Unit 32-way

connector pin D4

and ground.

If resistance between pin D4

and pin C is 0 to .3 ohms and

if resistance between pin D4

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step E.

Repair OEM wiring harness between

Driver Display Unit and Central

Processing Unit. Go to Step V.

Power-Up Sequence Test

2-8

Page 20

Fault Isolation Procedures

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

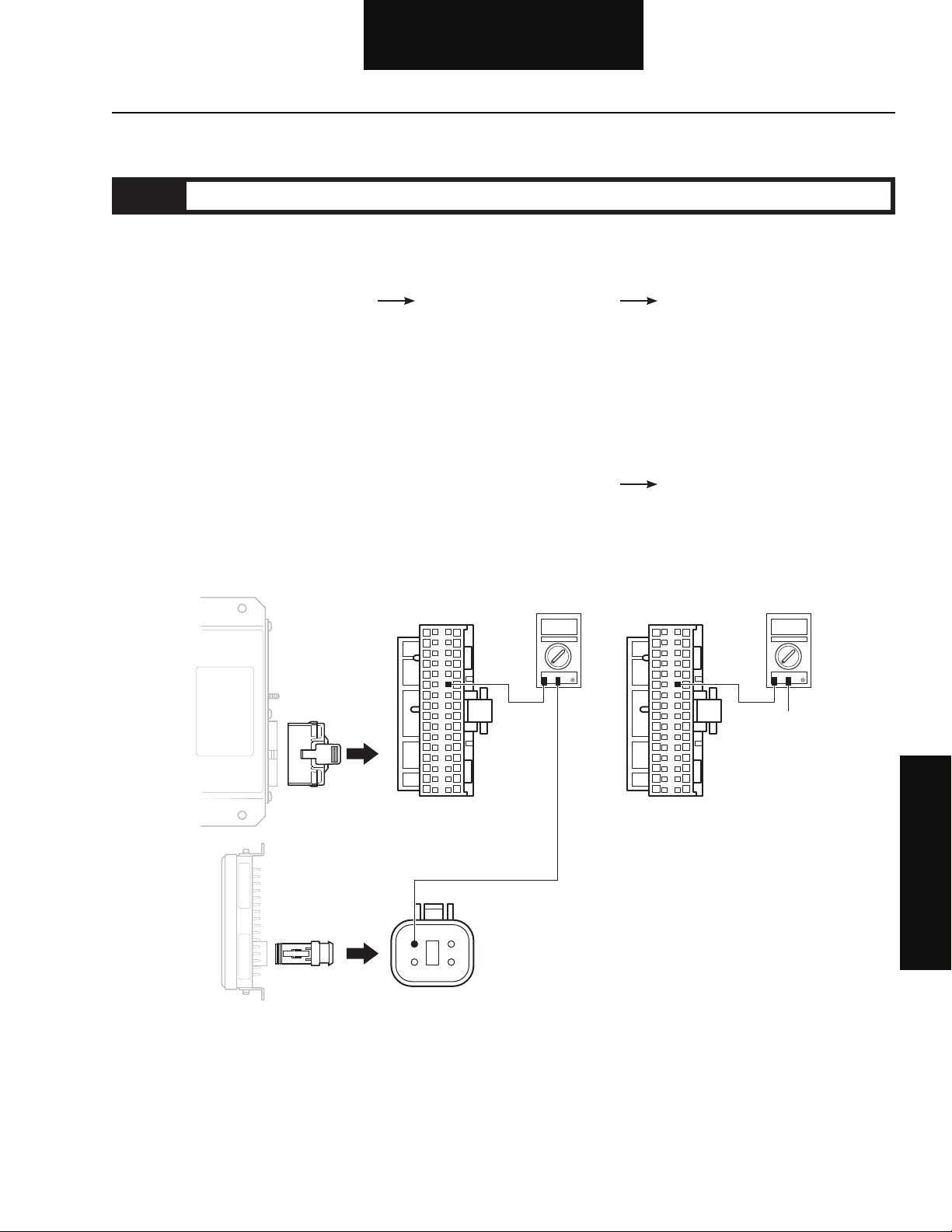

Power-Up Sequence Test, continued

Step E Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin D5

and Driver Display

4-way connector

pin B.

• Central Processing

Unit 32-way

connector pin D5

and ground.

If resistance between pin D5

and pin B is 0 to .3 ohms and if

resistance between pin D5

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step F.

Repair OEM wiring harness between

Driver Display Unit and Central

Processing Unit. Go to Step V.

2-9

Page 21

Fault Isolation Procedures

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

Power-Up Sequence Test, continued

Step F Procedure Condition Action

1. Key off.

2. Measure resistance between:

• Central Processing

Unit 32-way

connector pin D6

and Driver Display

4-way connector

pin A.

• Central Processing

Unit 32-way

connector pin D6

and ground.

If resistance between pin D6

and pin A is 0 to .3 ohms and

if resistance between pin D6

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step G.

Repair OEM wiring harness between

Driver Display Unit and Central

Processing Unit. Go to Step V.

Power-Up Sequence Test

2-10

Page 22

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

2 3

4

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Power-Up Sequence Test, continued

Step G Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector and Front

Antenna 4-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C3

and Antenna

4-way connector

pin 4.

• Central Processing

Unit 32-way

connector pin C3

and ground.

If resistance between pin C3 and

pin 4 is 0 to .3 ohms and if

resistance between pin C3

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step H.

Repair OEM wiring harness between

Antenna and Central Processing Unit.

Go to Step V.

2-11

Page 23

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

2

3

4

Power-Up Sequence Test, continued

Step H Procedure Condition Action

1. Key off.

2. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C4

and Antenna

4-way connector

pin 3.

• Central Processing

Unit 32-way

connector and pin C4

and ground.

If resistance between pin C4

and pin 3 is 0 to .3 ohms and

if resistance between pin C4

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step I.

Repair OEM wiring harness between

Antenna and Central Processing Unit.

Go to Step V.

Power-Up Sequence Test

2-12

Page 24

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

2 3

4

Power-Up Sequence Test, continued

Step I Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C5

and Antenna 4-way

connector pin 2.

• Central Processing

Unit 32-way

connector pin

C5 and ground.

If resistance between pin C5 and

pin 2 is 0 to .3 ohms and if

resistance between pin C5

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step J.

Repair OEM wiring harness between

Antenna and the Central Processing

Unit. Go to Step V.

2-13

Page 25

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

GROUND

V ACOM

OHMS

V ACOM

1

2 3

4

Power-Up Sequence Test, continued

Step J Procedure Condition Action

1. Key off.

2. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C6

and Antenna 4-way

connector pin 1.

• Central Processing

Unit 32-way

connector and pin C6

and ground.

If resistance between pin C6

and pin 1 is 0 to .3 ohms and

if resistance between pin C6

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step K.

Repair OEM wiring harness between

Antenna and Central Processing Unit.

Go to Step V.

Power-Up Sequence Test

2-14

Page 26

Fault Isolation Procedures

Power-Up Sequence Test, continued

Step K Procedure Condition Action

1. Key off.

2. Reconnect Central Processing Unit

32-way connector.

3. Connect spare Front Antenna

to 4-way connector.

4. Key on.

5. Check error codes. If no error codes

If error codes

Replace Antenna.

Go to Step V.

Replace Central Processing Unit.

Go to Step L.

2-15

Page 27

Fault Isolation Procedures

Power-Up Sequence Test, continued

Step L Procedure Condition Action

1. Key off.

2. Connect spare Driver

Display to 4-way

connector.

3. Key on.

4. Check error codes. If no error codes

If error codes

Replace Driver Display Unit.

Go to Step V.

Go to Step A.

Find error in testing.

Power-Up Sequence Test

2-16

Page 28

Fault Isolation Procedures

Power-Up Sequence Test, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on page 2.

5. Use Driving Techniques to attempt

to set a code. See “Driving

Techniques” on page 4.

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 2.

Note: If problem still exists there

may be a software

compatibility problem.

Contact your Bendix

representative.

If no codes

If code appears

Test complete.

See “Fault Code Isolation

Procedure Index” on page 3.

2-17

Page 29

Power-Up Sequence Test, continued

Fault Isolation Procedures

This page left blank intentionally.

Power-Up Sequence Test

2-18

Page 30

Component Code: 11, 12

Central

Processing Unit

(SID 254, FMI 4, 12)

Central Processing Unit (CPU)

Fault Isolation Procedures

Overview

This fault indicates an internal failure of the Central Processing

Unit.

Detection

The Central Processing Unit checks the program memory every

time the key is turned on. If the Central Processing Unit is able to

detect a failure within its own memory, it sets these fault codes.

Fallback

This fault causes a failure of the Bendix™ VORAD® system.

Required Tools

• Basic Hand Tools

• Troubleshooting Guide

Possible Causes

• Central Processing Unit

2-19

Page 31

Fault Isolation Procedures

Code 11, 12 (SID 254, FMI 4, 12), Central Processing Unit (CPU)

Step A Procedure Condition Action

1. Key off.

2. Retrieve codes. If code 11 is active

If code 11 is inactive

Replace Central Processing Unit.

Test complete.

(SID 254, FMI 4, 12)

Code 11, 12

2-20

Page 32

Component Code: 13, 34

Harness

Driver

Display Unit

Central

Processing Unit

(SID 9, FMI 2, 4, 5, 12)

Driver Display Unit

Fault Isolation Procedures

Overview

This fault code indicates an electrical failure of the Driver Display

Unit.

Detection

Starting at key on and throughout the operation, the Central

Processing Unit constantly monitors the communication with the

Driver Display Unit. If a communication fault occurs for more than

fi ve seconds, fault code 13 is set.

Fallback

This fault causes a failure of the Bendix™ VORAD® system.

Required Tools

• Basic Hand Tools

• Troubleshooting Guide

• Digital Volt/Ohm Meter

• Data Link Tester

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• OEM Harness

• Driver Display Unit

• Central Processing Unit

2-21

Page 33

Fault Isolation Procedures

VOLT

V ACOM

D C B A

Code 13, 34 (SID 9, FMI 2, 4, 5, 12) Driver Display Unit

Step A Procedure Condition Action

1. Key off.

(SID 9, FMI 2, 4, 5, 12)

Code 13, 34

2. Using a PC-based or

If FMI 2, 4, or 5 exist

Go to Step B.

Hand-held Diagnostic

Tool check for FMI

(Failure Mode Identifi ers)

codes.

Note: If a diagnostic tool is not

available, go to Step B.

If FMI 12 exists

Replace Driver Display Unit.

Go to Step V.

Step B Procedure Condition Action

1. Key off.

2. Unplug the Driver Display

Unit 4-way connector.

3. Key on.

4. Measure voltage between

Driver Display Unit 4-way

connector pin D and pin C.

If voltage is 7.0 to 7.5 volts

If voltage is outside of range

Go to Step E.

Go to Step C.

2-22

Page 34

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

OHMS

V ACOM

OHMS

GROUND

V ACOM

Code 13, 34 (SID 9, FMI 2, 4, 5, 12) Driver Display Unit, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin D3

and Driver Display

4-way connector

pin D.

• Central Processing

Unit 32-way

connector pin D3

and ground.

If resistance between D3 and

D is 0 to .3 ohms and if

resistance between pin D3

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step D.

Repair OEM wiring harness

between Driver Display Unit

and Central Processing Unit.

Go to Step V.

2-23

Page 35

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

OHMS

V ACOM

OHMS

GROUND

V ACOM

Code 13, 34 (SID 9, FMI 2, 4, 5, 12) Driver Display Unit, continued

Step D Procedure Condition Action

1. Key off.

2. Measure resistance between:

• Central Processing

Unit 32-way

connector pin D4

and Driver Display

4-way connector

pin C.

• Central Processing

Unit 32-way

connector pin D4

and ground.

If resistance between pin D4

and pin C is 0 to .3 ohms and

if resistance between pin D4

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Replace Central Processing

Unit. Go to Step V.

Repair OEM wiring harness

between Driver Display Unit

and Central Processing Unit.

Go to Step V.

(SID 9, FMI 2, 4, 5,12)

Code 13, 34

2-24

Page 36

Fault Isolation Procedures

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

Code 13, 34 (SID 9, FMI 2, 4, 5, 12) Driver Display Unit, continued

Step E Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin D5

and Driver Display

4-way connector

pin B.

• Central Processing

Unit 32-way

connector pin D5

and ground.

If resistance between pin D5

and pin B is 0 to .3 ohms and

if resistance between pin D5

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step F.

Repair OEM wiring harness

between Driver Display Unit

and Central Processing Unit.

Go to Step V.

2-25

Page 37

Fault Isolation Procedures

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

D C B A

Code 13, 34 (SID 9, FMI 2, 4, 5, 12) Driver Display Unit, continued

Step F Procedure Condition Action

1. Key off.

2. Measure resistance between:

(SID 9, FMI 2, 4, 5, 12)

Code 13, 34

• Central Processing

Unit 32-way

connector pin D6

and Driver Display

4-way connector

pin A.

• Central Processing

Unit pin D6 and

ground.

If resistance between pin D6

and pin A is 0 to .3 ohms and

if resistance between pin D6

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step G.

Repair OEM wiring harness

between Driver Display Unit

and Central Processing Unit.

Go to Step V.

2-26

Page 38

Fault Isolation Procedures

Code 13, 34 (SID 9, FMI 2, 4, 5, 12) Driver Display Unit, continued

Step G Procedure Condition Action

1. Key off.

2. Reconnect Central Processing

Unit 32-way connector.

3. Connect spare Driver

Display to 4-way

connector.

4. Key on.

5. Check error codes. If no error codes

If error codes

Replace Driver Display Unit.

Go to Step V.

Replace Central Processing

Unit. Go to Step V.

2-27

Page 39

Fault Isolation Procedures

Code 13, 34 (SID 9, FMI 2, 4, 5, 12) Driver Display Unit, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on

page 1 - 2.

5. Use Driving Techniques to attempt

to reset the code. See “Driving

Techniques” on page 1 - 4.

(SID 9, FMI 2, 4, 5, 12)

Code 13, 34

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 1 - 2.

If no codes

If code 13 or 34 appears

If code other than 13 or 34

appears

Test complete.

Return to Step A to fi nd error

in testing.

See “Fault Code Isolation

Procedure Index” on

page 1 - 3.

2-28

Page 40

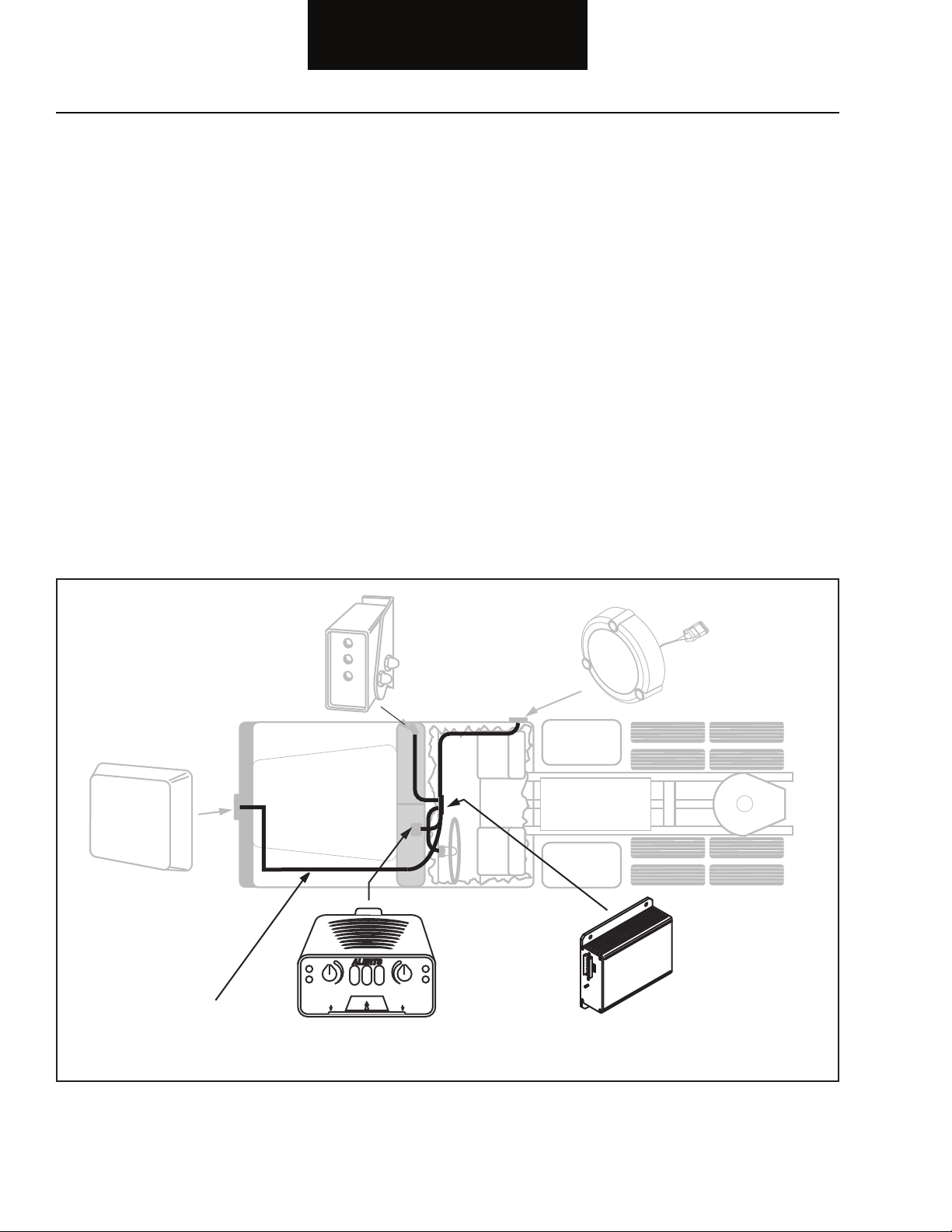

Component Code: 14, 35

Harness

Antenna

Central

Processing Unit

(SID 1, 2, FMI 2, 12, 14)

Antenna Assembly

Fault Isolation Procedures

Overview

This fault code indicates the Antenna and Central Processing Unit

are unable to communicate.

Detection

Starting at key on and throughout the operation, the Central

Processing Unit constantly monitors the communication with the

Antenna. If a communication fault occurs for more than 5 seconds,

fault code 14 is set.

Fallback

This fault causes a failure of the Bendix™ VORAD® system.

Required Tools

• Basic Hand Tools

• Troubleshooting Guide

• Digital Volt/Ohm Meter

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• Antenna Assembly

• OEM Harness

• Central Processing Unit

• Central Processing Unit / Antenna Software

Incompatibility

2-29

Page 41

Fault Isolation Procedures

VOLT

V ACOM

1

2 3

4

Code 14, 35 (SID 1, 2, FMI 2, 12, 14) Antenna

Step A Procedure Condition Action

1. Key off.

2. Using a PC-based or

If FMI 2 exists

Go to Step B.

Hand-held Diagnostic

Tool check for FMI

(Failure Mode Identifi er)

codes.

Note: If a diagnostic tool is not

If FMI 12 exists

Go to Step B.

available, go to Step B.

If FMI 14 exists

There may be a software

compatibility problem.

Contact your Bendix

representative.

Step B Procedure Condition Action

1. Key off.

2. Unplug the Antenna 4-way

connector.

3. Key on.

4. Measure voltage between

Antenna 4-way connector

pin 3 and pin 4.

If voltage is 7.0 to 7.5 volts

Go to Step E.

(SID 1, 2, FMI 2, 12, 14)

Code 14, 35

If voltage is outside of range

Go to Step C.

2-30

Page 42

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

2 3

4

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 14, 35 (SID 1, 2, FMI 2, 12, 14) Antenna, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C3

and Antenna 4-way

connector pin 4.

• Central Processing

Unit 32-way

connector pin C3

and ground.

If resistance between C3 and

pin 4 is 0 to .3 ohms and if

resistance between pin C3

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step D.

Repair OEM wiring harness

between Antenna and Central

Processing Unit. Go to Step V.

2-31

Page 43

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

2

3

4

Code 14, 35 (SID 1, 2, FMI 2, 12, 14) Antenna, continued

Step D Procedure Condition Action

1. Key off.

2. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C4

and Antenna 4-way

connector pin 3.

• Central Processing

Unit 32-way

connector pin C4

and ground.

If resistance between pin C4

and pin 3 is 0 to .3 ohms and

if resistance between pin C4

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Replace Central Processing

Unit. Go to Step V.

(SID 1, 2, FMI 2, 12, 14)

Code 14, 35

Repair OEM wiring harness

between Antenna and Central

Processing Unit. Go to Step V.

2-32

Page 44

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

2 3

4

Code 14, 35 (SID 1, 2, FMI 2, 12, 14) Antenna, continued

Step E Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C5

and Antenna 4-way

connector pin 2.

• Central Processing

Unit 32-way

connector and pin C5

and ground.

If resistance between pin C5

and pin 2 is 0 to .3 ohms and

if resistance between pin C5

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step F.

Repair OEM wiring harness

between Antenna and the Central

Processing Unit. Go to Step V.

2-33

Page 45

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

GROUND

V ACOM

OHMS

V ACOM

1

2 3

4

Code 14, 35 (SID 1, 2, FMI 2, 12, 14) Antenna, continued

Step F Procedure Condition Action

1. Key off.

2. Measure resistance between:

• Central Processing

Unit 32-way

connector pin C6

and Antenna 4-way

connector pin 1.

• Central Processing

Unit 32-way

connector pin C6

and ground.

If resistance between pin C6

and pin 1 is 0 to .3 ohms and

if resistance between pin C6

and ground is more than 10K

ohms or open circuit [OL]

If any of the above conditions

are not met

Go to Step G.

(SID 1, 2, FMI 2, 12, 14)

Code 14, 35

Repair OEM wiring harness

between Antenna and Central

Processing Unit. Go to Step V.

2-34

Page 46

Fault Isolation Procedures

Code 14, 35 (SID 1, 2, FMI 2, 12, 14) Antenna, continued

Step G Procedure Condition Action

1. Key off.

2. Reconnect Central Processing

Unit 32-way connector.

3. Connect spare Antenna

to 4-way connector.

4. Key on.

5. Check error codes. If no error codes

If error codes

Replace Antenna.

Go to Step V.

Replace Central Processing

Unit. Go to Step V.

2-35

Page 47

Fault Isolation Procedures

Code 14, 35 (SID 1, 2, FMI 2, 12, 14) Antenna, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on page

1 - 2.

(SID 1, 2, FMI 2, 12, 14)

5. Use Driving Techniques to attempt

to reset the code. See “Driving

Techniques” on page 1 - 4.

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 1 - 2.

Note: If problem still exists there

may be a software

compatibility problem.

Contact your Bendix

representative.

If no codes

If code 14 appears

If code other than 14 appears

Code 14, 35

Test complete.

Return to Step A to fi nd error

in testing.

See “Fault Code Isolation

Procedure Index” on page 1 - 3.

2-36

Page 48

Component Code: 15

Harness

Right

Side Sensor

Central

Processing Unit

(SID 10, FMI 2)

Right Side Sensor

Fault Isolation Procedures

Overview

This fault code indicates an electrical failure of the Right Side

Sensor.

Detection

Starting at key on and throughout the operation, the Central

Processing Unit constantly monitors the feedback from the Right

Side Sensor.

Fallback

This fault will not allow the Bendix™ VORAD® system to detect

objects on the right side of the vehicle.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• Wiring Harness

• Right Side Sensor

• Central Processing Unit

• System Confi guration

2-37

Page 49

Fault Isolation Procedures

VOLT

V ACOM

VOLT

V ACOM

B A

C

B A

C

Code 15 (SID 10, FMI 2) Right Side Sensor

Step A Procedure Condition Action

1. Key off.

2. Is vehicle equipped with a

Right Side Sensor?

If the vehicle has a Right Side

Sensor

If the vehicle does not have a

Right Side Sensor

Go to Step B.

The Central Processing Unit

has been programmed for a

Right Side Sensor. With a

PC-based or Hand-held

Diagnostic Tool, place the

Right Side Sensor option in

“NO” position. Go to Step V.

Step B Procedure Condition Action

1. Key off.

2. Disconnect 3-way stub connector at

the Right Side Sensor.

3. Key on.

4. Measure voltage between:

• Pins A and B.

• Pins A and C.

If voltage between pins A

and B is 1.8 to 2.5 volts and

(SID 10, FMI 2)

Code 15

If voltage between pins A

and C is 7.0 to 7.5 volts

If voltage is outside of range

Replace Right Side Sensor.

Go to Step V.

Go to Step C.

2-38

Page 50

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

B A

C

Code 15 (SID 10, FMI 2) Right Side Sensor, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• 32-way pin C12

and 3-way pin C.

• 32-way pin C12

and ground.

If resistance between C12

and pin C is 0 to 0.3 ohms

and if resistance between

pin C12 and ground is more

than 10K ohms or open

circuit [OL]

If resistance is outside

of range

Go to Step D.

Repair OEM wiring harness

between Right Side Sensor and

Central Processing Unit.

Go to Step V.

2-39

Page 51

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

AB

C

Code 15 (SID 10, FMI 2) Right Side Sensor, continued

Step D Procedure Condition Action

1. Key off.

2. Disconnect Central Processing Unit

32-way connector.

3. Measure resistance between:

• 32-way pin C13 and

3-way pin B.

• 32-way pin C13

and ground.

If resistance between pin C13

and pin B is 0 to 0.3 ohms and

if resistance between pin C13

and ground is more than 10K

ohms or open circuit [OL]

If resistance is outside

of range

Go to Step E.

Repair OEM wiring harness

between Right Side Sensor and

Central Processing Unit.

Go to Step V.

(SID 10, FMI 2)

Code 15

2-40

Page 52

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

OHMS

GROUND

V ACOM

AB

C

Code 15 (SID 10, FMI 2) Right Side Sensor, continued

Step E Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• 32-way pin C14

and 3-way pin A.

• 32-way pin C14

and ground.

If resistance between C14

and pin A is 0 to 0.3 ohms

and if resistance between

pin C14 and ground is more

than 10K ohms or open

circuit [OL]

If resistance is outside

of range

Replace Central processing Unit.

Go to Step V.

Repair OEM wiring harness

between Right Side Sensor and

Central Processing Unit.

Go to Step V.

2-41

Page 53

Fault Isolation Procedures

Code 15 (SID 10, FMI 2) Right Side Sensor, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on

page 1 - 2.

5. Use Driving Techniques to attempt

to reset the code. See “Driving

Techniques” on page 1 - 4.

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 1 - 2.

If no codes

If code 15 appears

If code other than 15 appears

Test complete.

Return to Step A to fi nd error

in testing.

See “Fault Code Isolation

Procedure Index” on page 1 - 3.

(SID 10, FMI 2)

Code 15

2-42

Page 54

Component Code: 16

Harness

Left

Side Sensor

Central

Processing Unit

(SID 11, FMI 2)

Left Side Sensor

Fault Isolation Procedures

Overview

This fault code indicates an electrical failure of the Left Side Sensor.

Detection

Starting at key on and throughout the operation, the Central

Processing Unit constantly monitors the feedback from the Left

Side Sensor.

Fallback

This fault will not allow the Bendix™ VORAD® system to detect

objects on the left side of the vehicle.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• Wiring Harness

• Left Side Sensor

• Central Processing Unit

• System Confi guration

2-43

Page 55

Fault Isolation Procedures

VOLT

V ACOM

VOLT

V ACOM

B A

C

B A

C

Code 16 (SID 11, FMI 2) Left Side Sensor

Step A Procedure Condition Action

1. Key off.

2. Is vehicle equipped with a

Left Side Sensor?

If the vehicle has a Left Side

Sensor

If the vehicle does not have a

Left Side Sensor

Go to Step B.

The Central Processing Unit

has been programmed for a

Left Side Sensor. With a

PC-based or Hand-held

Diagnostic Tool, place the

Left Side Sensor option in

“NO” position. Go to Step V.

Step B Procedure Condition Action

1. Key off.

2. Disconnect 3-way stub connector

at the Left Side Sensor.

3. Key on.

4. Measure voltage between:

• Pins A and B.

• Pins A and C.

If voltage between pins A

and B is 1.8 to 2.5 volts and

If voltage between pins A

and C is 7 to 7.5 volts

If voltage is outside of range

Replace Left Side Sensor.

Go to Step V.

Go to Step C.

(SID 11, FMI 2)

Code 16

2-44

Page 56

Fault Isolation Procedures

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

B A

C

Code 16 (SID 11, FMI 2) Left Side Sensor, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• 32-way pin D12

and 3-way pin C.

• 32-way pin D12

and ground.

If resistance between D12

and pin C is 0 to 0.3 ohms

and if resistance between

pin D12 and ground is more

than 10K ohms or open

circuit [OL]

If resistance is out of range

Go to Step D.

Repair OEM wiring harness

between Left Side Sensor and

Central Processing Unit.

Go to Step V.

2-45

Page 57

Fault Isolation Procedures

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

B A

C

Code 16 (SID 11, FMI 2) Left Side Sensor, continued

Step D Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• 32-way pin D13 and

3-way pin B.

• 32-way pin D13

and ground.

If resistance between D13

and pin B is 0 to 0.3 ohms and

if resistance between pin D13

and ground is more than 10K

ohms or open circuit [OL]

If resistance is out of range

Go to Step E.

Repair OEM wiring harness

between Left Side Sensor and

Central Processing Unit.

Go to Step V.

(SID 11, FMI 2)

Code 16

2-46

Page 58

Fault Isolation Procedures

OHMS

V ACOM

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

B A

C

Code 16 (SID 11, FMI 2) Left Side Sensor, continued

Step E Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance between:

• 32-way pin D14

and 3-way pin A.

• 32-way pin D14

and ground.

If resistance between D14

and pin A is 0 to 0.3 ohms

and if resistance between

pin D14 and ground is more

than 10K ohms or open

circuit [OL]

If resistance is out of range

Replace Central Processing

Unit. Go to Step V.

Repair OEM wiring harness

between Left Side Sensor and

Central Processing Unit.

Go to Step V.

2-47

Page 59

Fault Isolation Procedures

Code 16 (SID 11, FMI 2) Left Side Sensor, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on

page 1 - 2.

5. Use Driving Techniques to attempt

to reset the code. See “Driving

Techniques” on page 1 - 4.

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 1 - 2.

If no codes

If code 16 appears

If code other than 16 appears

Test complete.

Return to Step A to fi nd error in

testing.

See “Fault Code Isolation Procedure

Index” on page 1 - 3.

(SID 11, FMI 2)

Code 16

2-48

Page 60

Component Code: 21

Harness

Right

Turn Signal

Central

Processing Unit

(SID 7, FMI 2)

Right Turn Signal

Fault Isolation Procedures

Overview

This fault code indicates an electrical problem in the right turn

signal input. The input from the right turn signal did not match the

current operating conditions.

Detection

Starting at key on and throughout the operation, the Central

Processing Unit constantly monitors the feedback from the right

turn signal.

Fallback

This fault will not allow the Bendix™ VORAD® system to detect

objects when the operator is making a right turn.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• Central Processing Unit

• OEM Harness

• Right Turn Signal

2-49

Page 61

Fault Isolation Procedures

C

VOLT

V ACOM

1

D

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 21 (SID 7, FMI 2) Right Turn Signal

Step A Procedure Condition Action

1. Key off.

2. Is the vehicle equipped

with a Right Side Sensor?

If equipped with a Right

Side Sensor

If not equipped with a

Right Side Sensor

Go to Step B.

The Central Processing Unit

has been programmed for a

Right Side Sensor. With a

PC-based or Hand-held

Diagnostic Tool, place the

Right Side Sensor option in

“NO” position. Go to Step V.

Step B Procedure Condition Action

1. Key off.

2. Disconnect the 32-way Central

Processing Unit connector.

3. Key on.

4. Measure voltage between

Central Processing Unit

32-way connector pin C2

and C15.

If voltage is below .5 volts

Go to Step C.

Note: Do not short pins while

performing measurement.

If voltage is outside or range

Repair OEM wiring harness as

required. Go to Step V.

(SID 7, FMI 2)

Code 21

2-50

Page 62

Fault Isolation Procedures

C

VOLT

V ACOM

1

D

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 21 (SID 7, FMI 2) Right Turn Signal, continued

Step C Procedure Condition Action

1. Key off.

2. Turn on right turn signal.

3. Measure voltage between

Central Processing Unit

32-way connector pins

C2 and C15.

If voltage fl ashes within 2

volts of battery voltage

If voltage is outside of range

Replace Central Processing

Unit. Go to Step V.

Repair OEM wiring harness

as required. Go to Step V.

2-51

Page 63

Fault Isolation Procedures

Code 21 (SID 7, FMI 2) Right Turn Signal, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on

page 1 - 2.

5. Use Driving Techniques to attempt

to reset the code. See “Driving

Techniques” on page 1 - 4.

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 1 - 2.

If no codes

If code 21 appears

If code other than 21 appears

Test complete.

Return to Step A to fi nd error

in testing.

See “Fault Code Isolation Procedure

Index” on page 1 - 3.

(SID 7, FMI 2)

2-52

Code 21

Page 64

Component Code: 22

Harness

Left

Turn Signal

Central

Processing Unit

(SID 8, FMI 2)

Left Turn Signal

Fault Isolation Procedures

Overview

This fault code indicates an electrical problem in the left turn signal

input. The input from the left turn signal did not match the current

operating conditions.

Detection

Starting at key on and throughout the operation, the Central

Processing Unit constantly monitors the feedback from the left turn

signal.

Fallback

This fault will not allow the Bendix™ VORAD® system to detect

objects when the operator is making a left turn.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• Central Processing Unit

• OEM Harness

• Left Turn Signal

2-53

Page 65

Fault Isolation Procedures

C

VOLT

V ACOM

1

D

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 22 (SID 8, FMI 2) Left Turn Signal

Step A Procedure Condition Action

1. Key off.

2. Is the vehicle equipped

with a Left Side Sensor?

Step B Procedure Condition Action

1. Key off.

2. Disconnect the 32-way Central

Processing Unit connector.

If equipped with a Left

Side Sensor

If not equipped with a

Left Side Sensor

Go to Step B.

The Central Processing Unit

has been programmed for a

Left Side Sensor. With a

PC-based or Hand-held

Diagnostic Tool, place the

Left Side Sensor option in

“NO” position. Go to Step V.

(SID 8, FMI 2)

Code 22

3. Key on.

4. Measure voltage between

Central Processing Unit

32-way connector pin D15

and C2.

Note: Do not short pins while

performing measurement.

If voltage is below .5 volts

If voltage is outside of range

Go to Step C.

Repair OEM wiring harness

as required. Go to Step V.

2-54

Page 66

Fault Isolation Procedures

C

VOLT

V ACOM

1

D

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 22 (SID 8, FMI 2) Left Turn Signal, continued

Step C Procedure Condition Action

1. Key off.

2. Turn on left turn signal.

3. Measure voltage between

Central Processing Unit

32-way connector pins

D15 and C2.

If voltage measures within 2

volts of battery voltage

If voltage is outside of range

Replace Central Processing

Unit. Go to Step V.

Repair OEM wiring harness

as required. Go to Step V.

2-55

Page 67

Fault Isolation Procedures

Code 22 (SID 8, FMI 2) Left Turn Signal, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on

page 1 - 2.

5. Use Driving Techniques to attempt

to reset the code. See “Driving

Techniques” on page 1 - 4.

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 1 - 2.

If no codes

If code 22 appears

If code other than 22 appears

Test complete.

Return to Step A to fi nd error

in testing.

See “Fault Code Isolation Procedure

Index” on page 1 - 3.

(SID 8, FMI 2)

Code 22

2-56

Page 68

Component Code: 23

Harness

Central

Processing Unit

(SID 3, FMI 2)

Brake Input Error

Fault Isolation Procedures

Overview

This fault code indicates an electrical problem in the brake input.

The signal from the bake pedal, J-1939, or J-1587 data link, did not

match the current operating conditions.

Detection

Starting at key on and throughout the operation, the Bendix™

VORAD® system Central Processing Unit constantly measures this

circuit. A failure mode of short to battery, short to ground, open

circuit, or bad data is detected.

Fallback

This fault causes a failure of the VORAD system.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• Central Processing Unit

• OEM Harness

• Engine ECU

2-57

Page 69

Fault Isolation Procedures

Code 23 (SID 3, FMI 2) Brake Input Error

Step A Procedure Condition Action

1. Key off.

2. Verify the vehicle brake

lights are working

correctly.

If the brake lights are

working correctly

If the brake lights are not

working correctly

Go to Step B.

Repair vehicle brake lights.

Go to Step V.

Step B Procedure Condition Action

1. Using a PC-based or Hand-held

Diagnostic Tool verify vehicle

brake confi guration.

If confi guration is set to Discrete

If vehicle uses J-1939 or J-1587

confi guration

Go to Step C.

Repair OEM wiring harness

J-1587 or J-1939 data link

may not be connected to the

VORAD system. Go to Step V.

(SID 3, FMI 2)

Code 23

If vehicle uses LED brake lights

Contact a Bendix representative for

proper confi guration.

Note: VORAD must use either J-1939

or J-1587 to receive brake

signal when LED tail lights are

used on a vehicle.

2-58

Page 70

Fault Isolation Procedures

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 23 (SID 3, FMI 2) Brake Input Error, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Check pin C9 on 32-way

connector.

If there is a wire in C9

If there is not a wire in C9

Go to Step D.

Go to Step E.

2-59

Page 71

Fault Isolation Procedures

VOLT

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 23 (SID 3, FMI 2) Brake Input Error, continued

Step D Procedure Condition Action

1. Key off.

2. Depress brake pedal.

3. Measure voltage between

Central Processing Unit

If voltage is within 1 volt of

battery voltage

Replace Central Processing

Unit. Go to Step V.

pins C9 and C2.

If voltage is outside of range

Repair OEM wiring harness as

necessary. Go to Step V.

Step E Procedure Condition Action

(SID 3, FMI 2)

Code 23

1. Key off.

2. Reconnect Central Processing Unit

32-way connector.

3. Connect a PC-based or Hand-held

Diagnostic Tool.

4. Key on.

5. Perform brake test to

verify correct signal is

received when brake

pedal is depressed.

If correct signal is received

If correct signal is not

received

Replace Central Processing

Unit. Go to Step V.

Repair OEM wiring harness.

J-1587 or J-1939 data link

may not be connected to the

Bendix™ VORAD® system.

Go to Step V.

2-60

Page 72

Fault Isolation Procedures

Code 23 (SID 3, FMI 2) Brake Input Error, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault Code

Retrieval and Clearing” on page

1 - 2.

5. Use Driving Techniques to attempt

to reset the code. See “Driving

Techniques” on page 1 - 4.

6. Check for Codes. See

“Fault Code Retrieval and

Clearing” on page 1 - 2.

If no codes appear

If code 23 appears

If code other than 23 appears

Test complete.

Return to Step A to fi nd error

in testing.

See “Fault Code Isolation

Procedure Index” on page 1 - 3.

2-61

Page 73

Fault Isolation Procedures

Code 23 (SID 3, FMI 2) Brake Input Error, continued

(SID 3, FMI 2)

Code 23

This page left blank intentionally.

2-62

Page 74

Component Code: 24

Harness

Central

Processing Unit

(SID 6, FMI 2)

Speed Input Error

Fault Isolation Procedures

Overview

This fault code indicates an electrical problem in the speed source.

The signal from the road speed source did not match the current

operating conditions.

Detection

Starting at key on and throughout the operation, the Central

Processing Unit constantly monitors the feedback from the road

speed source. If the feedback is out of range the fault code is set.

Fallback

This fault causes a failure of the Bendix™ VORAD® system.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

• PC-based or Hand-held Diagnostic Tool

Possible Causes

This fault code can be caused by any of the following:

• Central Processing Unit

• OEM Harness

• Speed Sensor

• J-1939 or J-1587

2-63

Page 75

Fault Isolation Procedures

V ACOM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

Code 24 (SID 6, FMI 2) Speed Input Error

Step A Procedure Condition Action

1. Using a PC-based or

Hand-held Diagnostic

Tool verify vehicle speed

confi guration.

Step B Procedure Condition Action

If confi guration is set to Discrete

If vehicle uses J-1939 or

J-1587 confi guration

Go to Step B.

Repair OEM wiring harness.

J-1587 or J-1939 data link

may not be connected to the

Bendix™ VORAD® system.

Go to Step V.

1. Key off.

2. Disconnect Central Processing

Unit 32-way connector.

3. Measure resistance

between Central

Processing Unit pins C10

and C11.

Note: If 32-way connector does not

have pins in C10 and C11,

recheck vehicle confi guration

for speed source. This test is

used for discrete installations

only.

If resistance is 2 to 4K ohms

If resistance is outside of range

(SID 6, FMI 2)

Code 24

Go to Step C.

Go to Step D.

2-64

Page 76

Fault Isolation Procedures

OHMS

GROUND

V ACOM

1

CD

2

3

4

5

6

7

8

9

10

11

12

13

14

16

15

OHMS

V ACOM

A B

Code 24 (SID 6, FMI 2) Speed Input Error, continued

Step C Procedure Condition Action

1. Measure resistance

between Central

Processing Unit 32-way

connector pin C10 and

ground.

If resistance is more than

10K ohms or open circuit

[OL]

If resistance is less than 10K

ohms

Replace Central Processing

Unit. Go to Step V.

Go to Step D.

Step D Procedure Condition Action

1. Disconnect VORAD harness from

speed source.

2-65

2. Measure resistance

between speed sensor

pins A and B.

If resistance is 2 to 4K ohms

If resistance is outside of

range

Go to Step E.

Replace speed sensor.

Go to Step V.

Page 77

Fault Isolation Procedures

GROUND

OHMS

V ACOM

A

B

Code 24 (SID 6, FMI 2) Speed Input Error, continued

Step E Procedure Condition Action

1. Measure resistance

between speed sensor A

and ground.

If resistance is more than

10K ohms or open circuit

[OL]

If resistance is less than 10K

ohms

Repair the OEM wiring harness.

Go to Step V.

Replace speed sensor.

Go to Step V.

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Key on.

4. Clear Codes. See “Fault

Code Retrieval and Clearing”

on page 1 - 2.

(SID 6, FMI 2)

Code 24

5. Use Driving Techniques to attempt

to reset the code. See “Driving