Page 1

®

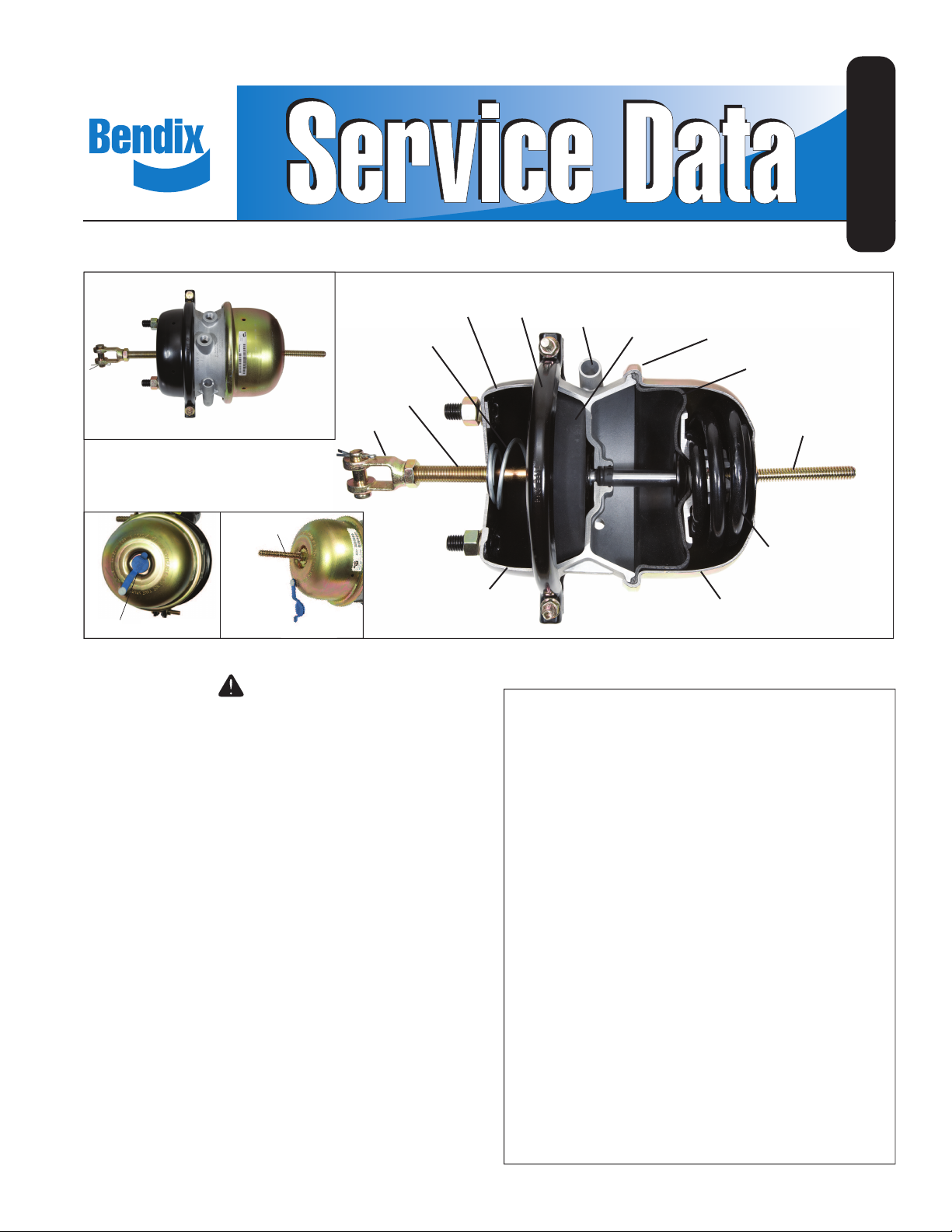

Bendix® EverSure® Spring Brake with No Touch™ Technology

SD-02-4525

NON-PRESSURE

HOUSING

SERVICE RETURN

SPRING

SERVICE

PUSH-ROD

YOKE

(Piggyback spring brake components

are not serviceable, and are shown

here for informational purposes only.)

RELEASE

TOOL

SERVICE

CHAMBER

DUST CAP INSTALLED

DUST CAP

REMOVED

WARNING

SPRING BRAKE CHAMBERS CONTAIN A LOADED

COMPRESSION SPRING. PROPERTY DAMAGE,

SERIOUS INJURY OR DEATH MAY OCCUR IF THESE

INSTRUCTIONS ARE NOT FOLLOWED COMPLETELY.

NEVER attempt to remove a spring chamber crimped

band.

Follow all industry safe maintenance practices, including

those listed on page two of these instructions.

1.0 DESCRIPTION

The Bendix® EverSure® spring brake is made up of a

conventional brake chamber and an emergency, or parking,

spring mechanism for use on vehicles equipped with cam

foundation brakes. The spring brake actuator provides:

(1) service braking, (2) parking and (3) emergency

braking. The actuator can be piped with various system

arrangements to be automatically, or manually, applied

under emergency braking conditions.

The spring brake is a diaphragm-type actuator which

converts the energy of air pressure into mechanical force.

CLAMP

BAND

T-BOLT

STORAGE

POCKET

FIGURE 1 - BENDIX® EVERSURE® SPRING BRAKE

SERVICE

DIAPHRAGM

NON-SERVICEABLE

SECTION SEALED WITH A

CRIMPED BAND

NON-SERVICEABLE

PARKING DIAPHRAGM

RELEASE

TOOL T-BOLT

NON-SERVICEABLE

NO TOUCH™ POWER

SPRING

PARKING/ EMERGENCY

BRAKE HOUSING

Index

Section Page

1.0 Description . . . . . . . . . . . . . . . . .1, 3

2.0 Safe Maintenance Practices . . . . . . . . . 2

3.0 Preventive Maintenance . . . . . . . . . . . 3

4.0 Operation and Leakage Tests. . . . . . . . . 4

5.0 Operation: General . . . . . . . . . . . . . . 4

6.0 Mechanical Release (Caging) of the

Bendix® EverSure® Spring Brake . . . . . . . 4

7.0 Clocking (Rotating) the Bendix Service

Replacement Spring Brake Chamber. . . . . 5

8.0 Mechanical Release (Caging) and Removal

of the Piggyback Spring Brake Chamber to

be Replaced . . . . . . . . . . . . . . . . . 6

9.0 Installing the Bendix® EverSure® Piggyback

Spring Brake Chamber . . . . . . . . . . . . 6

10.0 Un-Caging the Bendix® EverSure® Spring

Brake Chamber (Apply Park Brake) . . . . . 7

11.0 Removal and Installation of the Combination

Spring Brake . . . . . . . . . . . . . . . . . 7

12.0 Replacing the Service Diaphragm . . . . . . 8

1

Page 2

2.0 SAFE MAINTENANCE PRACTICES

WARNING! PLEASE READ AND

FOLLOW THESE INSTRUCTIONS TO

AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times:

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses. Where specifi cally

directed, the parking brakes may have to be

released, and/or spring brakes caged, and this

will require that the vehicle be prevented from

moving by other means for the duration of these

tests/procedures.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should

be removed. Where circumstances require

that the eng ine be in ope rati on, EXTREME

CAUTION should be used to prevent personal

injury resulting from contact wit h moving,

rotating, leaking, heated or electrically charged

components.

3. Do not attempt to install, remove, disassemble

or assemble a component until you have read

and thoroughly understand the recommended

procedures. Use only the proper tools and

observe all precautions pertaining to use of those

tools.

4. If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work

on the vehicle. If the vehicle is equipped with

a Bendix® AD-IS® air dryer system or a dryer

reservoir module, be sure to drain the purge

reservoir.

5. F o l lo wi n g t h e ve hi cl e m a n u fa ct u r e r ’ s

recommended procedures, deactivate th e

electrical system in a manner that safely removes

all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® brand replacement

parts, components and kits. R epla cement

hardware, tubing, hose, fi ttings, etc. must be

of equivalent size, type and strength as original

equipment and be designed specifi cally for such

applications and systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired.

Do not attempt repairs requiring machining or

welding unless specifi cally stated and approved

by the vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Automatic Traction Control

(ATC), the ATC function must be disabled (ATC

indicator lamp should be ON) prior to performing

any vehicle maintenance where one or more

wheels on a drive axle are lifted off the ground

and moving.

WARNING: Not all wheels and valve stems

are compatible with Bendix air disc brakes. Use only

wheels and valve stems approved by the vehicle

manufacturer to avoid the risk of valve stem shear

and other compatibility issues.

WARNING: AVOID CREATING DUST.

POSSIBLE CANCER AND LUNG DISEASE

HAZARD.

While Bendix Spicer Foundation Brake LLC (BSFB)

does not offer asbestos brake linings, the long-term

affects of some non-asbestos fi bers have not been

determined. Current Occupational Safety & Health

Administration (OSHA) regulations cover exposure

levels to some components of non-asbestos linings,

but not all. The following precautions must be used

when handling these materials.

• Avoid creating dust. Compressed air or dry

brushing must never be used for cleaning brake

assemblies or the work area.

• Bendix recommends that workers doing brake work

must take steps to minimize exposure to airborne

brake lining particles. Proper procedures to reduce

exposure include working in a well-ventilated

area, segregation of areas where brake work is

done, use of local filtered ventilation systems

or use of enclosed cells with fi ltered vacuums.

Respirators approved by the Mine Safety and Health

Administration (MSHA) or National Institute for

Occupational Safety and Health (NIOSH) should be

worn at all times during brake servicing.

• Workers must wash before eating, drinking or

smoking; shower after working, and should not

wear work clothes home. Work clothes should

be vacuumed and laundered separately without

shaking.

• OSHA regulations regarding testing, disposal

of waste and methods of reducing exposure

for asbestos are set forth in 29 Code of Federal

Regulations §1910.001. These Regulations provide

valuable information which can be utilized to reduce

exposure to airborne particles.

• Material Safety Data Sheets on this product, as

required by OSHA, are available from Bendix:

Call 1-800-247-2725 and speak to the Tech Team or

e-mail us at techteam@bendix.com

2

Page 3

The diaphragm is held between the adapter base and nonpressure plate by a two piece clamp ring.

Different size brake chambers are identifi ed by numbers,

which specify the effective area of a diaphragm. For

example, a Type 30/30 Spring Brake has 30 square inches

of effective area on each diaphragm.

The standard diaphragm material is a compound of natural

rubber with a fabric interior of nylon.

WARNING

• S pr i ng b r ake c ham b er s con t ai n a l oad ed

compression spring. Property damage, serious

injury or death may occur if instructions are not

followed completely.

• When performing any maintenance on the spring

brakes, make sure to block the wheels to prevent

vehicle rollaway.

• DO NOT SERVICE A SPRING BRAKE CHAMBER

IF IT HAS STRUCTURAL DAMAGE OF ANY KIND.

Replace the complete assembly. Dismount a

damaged spring brake by fi rst cutting the service

push rod with an acetylene torch to relieve any

force it might have.

• Do not strike any part of a spring brake chamber

for any reason. This may cause structural damage.

• Be careful not to drop a spring brake chamber at

any time. If dropped, inspect for signs of structural

damage. Replace complete assembly if damaged.

• Spring brake chambers cannot have the emergency

diaphragm replaced. Replace the whole spring

brake chamber.

• Always work from the side of the spring brake

chamber. Never work from the front or back.

3.0 PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is

performed during this period.

3.1.2 Check push-rod-to-slack-adjuster alignment from

release to full stroke position to be sure the push rod

moves out and returns properly without binding at the nonpressure plate hole or with other structures. Also, check

the angle formed by the slack adjuster arm and push rod.

It should be greater than 90 degrees when the chamber

is in the released position and approach 90 degrees at

maximum readjustment stroke.

3.1.3 Check tightness of mounting nuts. Torque on the

non-pressure plate mounting nuts should be 133-155 ft/

lbs.

3.1.4 Check cotter pins to ensure they are in place.

3.1.5 Check all hoses and lines. They should be secure

and in good condition with suffi cient length to allow for axle

movement.

3.2. EVERY 3,600 OPERATING HOURS,

100,000 MILES OR ONE (1) YEAR:

3.2.1 Carefully inspect all metal parts for cracks, distortion

or damage.

3.2.2 Perform the Leakage Test (4.2). As necessary,

install a new diaphragm or any other parts if they are worn

or deteriorated. All diaphragm sealing surfaces should be

smooth and clean. Perform the steps outlined in Section 12

(Replacing the Service Diaphragm). When the service

diaphragm, service return spring, or both, are replaced,

they should also be replaced in the corresponding chamber

on the same axle.

PARKING/

EMERGENCY

PORT

SERVICE

PORT

RELEASE

TOOL

SIDE

POCKET

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable

guide in determining the best maintenance interval for a

vehicle.

3.1 EVERY 300 OPERATING HOURS,

8,000 MILES, OR ONE (1) MONTH:

3.1.1 See Figure 2. Check push rod travel and adjust

travel at the slack adjuster if needed (only where manual

slack adjusters are used). Push rod travel should be as

short as possible without the brakes dragging (consult

the manufacturer’s installation instructions for the slack

adjuster. Excessive push rod travel reduces braking

effi ciency, shortens diaphragm life, gives slow braking

response, and wastes air.

MOUNTING NUT

SERVICE

PUSH ROD

COTTER PIN

FIGURE 2 - SPRING BRAKE EXTERNAL VIEW

YOKE

3

Page 4

MAIN SPRING

PARKING/

EMERGENCY

PORT

(MARKED “12”)

NON-PRESSURE

HOUSING

FIGURE 3 - SPRING BRAKE CUT-AWAY VIEW

DIAPHRAGM

DIAPHRAGM

PUSH ROD

4.0 OPERATION & LEAKAGE TESTS

4.1 OPERATING TEST

4.1.1 Apply the brakes and observe that all the push rods

move out promptly and without binding.

4.1.2 Release brakes and observe that all the push

rods return to the released position promptly and without

binding.

4.1.3 Check the push rod travel. The push rod travel

should be as short as possible without the brakes dragging.

Adjust travel of push rod at the slack adjuster if necessary.

4.1.4 If the orange stroke indication mark on the push rod

is visible, consult the slack adjuster service instructions

and verify the proper slack adjuster function.

4.2 LEAKAGE TEST

4.2.1 Make and hold a full brake application.

4.2.2 Using a soap solution, coat the clamping ring(s). If

leakage is detected, tighten the clamping ring only enough

to stop leakage. DO NOT OVERTIGHTEN as this can

distort sealing surface or clamping ring. Coat the area

around the push rod hole (loosen boot if applicable).

Minimal leakage is permitted (100 SCCM). If abnormal

leakage is detected, the diaphragm must be replaced.

4.2.3 Using a soap solution, check the hose fi tting for

leakage. A one-inch bubble in one minute is acceptable.

5.0 OPERATION: GENERAL

The Bendix® EverSure® Spring Brake is made up of the

service chamber and the piggyback spring brake chamber.

The Bendix EverSure Spring Brake provides ser vice

braking, parking, and emergency braking.

The spring brake can be mounted with the mounting bolts

in either a vertical or horizontal plane on standard mounting

stud centers. Two air hoses are used: the service air hose

(the connector is marked “11”); and the parking/emergency

air hose (the connector is marked “12”).

Controlled air pressure enters the service chamber through

the inlet port and acts upon the diaphragm, moving the

push plate and rod assembly forward.

When the service chamber is used to actuate cam-type

brake foundation assemblies, the yoke (which is welded

to, or threaded on, the push rod) is connected to a slack

adjuster, which in turn is connected to the brake cam shaft.

This forward motion of the push rod rotates the slack

adjuster, cam shaft and cam applying the vehicle brakes.

The greater air pressure admitted to the service chamber,

the greater the force applied by the push rod. Conversely,

the less pressure applied to the service chamber, the less

force applied by the push rod. Push rod force is determined

by multiplying the delivered air pressure by the effective

diaphragm area. For example, if 60 psi is applied to a

Type 30 service chamber, the lineal force on the end of

the push rod is approximately 1,800 lbs.

When air pressure is released from the brake chamber, the

push rod return spring – in combination with the brake shoe

return spring – returns the diaphragm, push plate and rod

assembly, slack adjuster and brake cam to their released

positions releasing the brakes.

When the driver operates the parking brake, air is

exhausted from the chamber. The main spring is allowed

to extend, which forces the push rod and the emergency

diaphragm forward. This forces the service diaphragm

and service push rod forward, which applies the brakes.

When the air pressure in the Bendix EverSure Spring Brake

chamber drops to below approximately 78 psi, the main

spring overcomes chamber pressure and forces the push

rod and emergency diaphragm forward.

6.0 MECHANICAL RELEASE (CAGING) OF

THE BENDIX® EVERSURE® SPRING BRAKE

NOTE: The Bendix® EverSure® Spring Brake Chamber

is not shipped caged. It must be caged prior to any work

being done.

6.0.1 This procedure will be made much easier if air

pressure (100-120 psi; 6.6-8.0 bar) is used to collapse

the power spring by applying air to the port marked “12”,

before turning the release bolt nut with a hand wrench or

simply by hand.

6.0.2 Remove the dust cap from the keyhole in the center

of the spring brake chamber. See Figure 1.

6.0.3 Remove the release tool assembly from the side

pocket of the spring brake chamber.

6.0.4 Insert the release tool (T-bolt) through the release

tool keyhole and into the power spring piston plate.

6.0.5 Turn the release tool one quarter turn clockwise.

4

Page 5

SERVICEABLE SECTION

NON-SERVICEABLE PIGGYBACK SECTION

SERVICE RETURN SPRING

WASHER

NUT

YOKE

PIN

FIGURE 4 - EXPLODED VIEW SHOWING SERVICEABLE AND NON-SERVICEABLE PORTIONS OF THE BRAKE

YOKE

CLAMP BAND

6.0.6 Pull on the release tool to ensure the T-section is

properly seated in the power spring piston plate.

6.0.7 Assemble the release tool washer and nut onto the

release bolt and fi nger tighten only. If caging is being done

manually, it is recommended that some type of lubrication

be applied to the release bolt threads prior to tightening to

prevent galling or stripping.

6.0.8 To manually cage the spring brake, turn the release

tool nut clockwise with a hand wrench. The maximum

releasing torque should not exceed 50 lb-ft (67.8 Nm). If

the spring has not previously been compressed by the use

of air (6.0.1, above), verify that the service side push rod

is retracting during the process and that the release bolt

is extending from inside the spring brake housing. (DO

NOT USE A HIGH SPEED AND/OR POWER DRIVEN

IMPACT WRENCH)

PRESSURE

PLATE

SERVICE

DIAPHRAGM

PARKING/

EMERGENCY

BRAKE

WARNING

Do not use an impact wrench. An impact wrench may

over torque the release tool and cause damage to the

pressure plate.

6.1 SPRING BRAKE CHAMBER REMOVAL

6.1.1 With the spring brake chamber caged and all air

pressure drained from the air brake system, disconnect

the air hoses from the spring brake chamber.

6.1.2 Remove the cotter pin from the yoke. Remove the

yoke pin.

6.1.3 While supporting the spring brake chamber in

position, remove and discard brake chamber mounting

nuts and washers (see Figure 3). Nuts and washers must

not be re-used. Remove the spring brake.

6.0.9 Rotate the release bolt nut clockwise until an

increased resistance is encountered. This should indicate

that proper caging is complete. The release bolt should be

extended all the way back, as shown in Figure 4. (DO NOT

OVER TORQUE RELEASE BOLT. OVER TORQUING

CAN CAUSE SPRING BRAKE DAMAGE.)

6.0.10 Release the air pressure from the emergency/

parking port (port “12”) after caging and prior to any

disassembly or removal from the vehicle.

IMPORTANT: To ensure the power spring is fully caged,

the extended release tool length should be fully backed

out as shown in Figure 4.

7.0 CLOCKING (ROTATING) THE

BENDIX SERVICE REPLACEMENT

SPRING BRAKE CHAMBER

NOTE: For proper installation, the service replacement

spring brake chamber may need to be clocked (rotated)

to properly position the ports or clamp band hardware.

To do so, follow the clocking procedure. Additionally,

the push rod may need to be cut to the proper length

for the application. Refer to the Bendix® ASA-5® slack

adjuster service data sheet SD-05-1269 or the Bendix®

Versajust

™

slack adjuster service data sheet SD-05-4630

as applicable, or see guidelines on proper push rod

lengths for use with these slack adjusters.

RELEASE TOOL

DUST CAP

5

Page 6

WARNING

Do not mechanically release (cage) the spring if there is

any structural damage to the brake. Caging the spring

in such a chamber may cause serious injury or death.

Replace the complete spring brake assembly.

7.0.1 If the service replacement spring brake chamber is not

caged, mechanically release (cage) the replacement spring

brake chamber by following the original manufacturer’s

instructions.

7.0.2 Apply 10 psi (1 bar) of air pressure to the service

port (“11”) of the spring brake chamber.

7.0.3 Since we will be using locking pliers to hold the

service push rod in place, be sure to protect the threads

before clamping down. The locking pliers will prevent the

push rod from retracting when they are used at the push

rod opening of the replacement spring brake chamber.

7.0.4 Release the air pressure from the service port.

7.0.5 Remove the clamp ring and hardware from the spring

brake chamber.

7.0.6 Position the adapter base inlet port by rotating it with

respect to the mounting studs, as needed.

7.0.7 Make sure that the diaphragm is properly aligned and

seated. See Figure 5. Be sure that the service diaphragm

is fully inserted into the clamp.

7.0.8 Reinstall the clamp rings and hardware. Check the

arrangement of the removed actuator and position the

hardware with respect to the mounting studs as required.

Tighten each clamp nut evenly in an alternating pattern.

Torque each clamp nut to a fi nal torque of 20-30 ft-lbs.

(28-40 Nm).

7.0.9 Inspect the clamp ring and hardware for proper

seating.

7.0.10 Apply up to around 10 psi air pressure to the

service port of the spring brake chamber. (Do not exceed

10 psi.) Remove the locking pliers from the brake chamber

push rod.

7.0.11 Perform the Leakage Test (4.2) before returning

the spring brake on the vehicle.

8.0 MECHANICAL RELEASE (CAGING) AND

REMOVAL OF THE PIGGYBACK SPRING

BRAKE CHAMBER TO BE REPLACED

NOTE: The spring brake chamber can be replaced with

the service brake chamber mounted to the vehicle, or

removed, for ease of access. To remove the assembly

from the vehicle, perform the steps outlined in Step 11.0

Removal and Installation of the Combination Spring Brake.

WARNING

Do not mechanically release (cage) the spring if there is

any structural damage to the brake. Caging the spring

in such a chamber may cause serious injury or death.

Replace the complete assembly.

8.1 Mechanic ally release the old spring brake by

following the original manufacturer’s instructions.

8.2 Ensure air pressure is removed from all air reservoirs

before removing the air hoses or working on the spring

brake.

8.3 Remove air hoses from the spring brake chamber.

Be sure to mark both hoses to ensure proper reinstallation.

8.4 Clamp a pair of locking pliers around the service

push rod touching the non-pressure housing. This cages

the service return spring.

8.5 Remove the clamp nuts and service clamp assembly

and carefully remove the old piggyback chamber.

8.6 Discard the clamp, clamp hardware and diaphragm.

9.0 INSTALLING THE BENDIX® EVERSURE®

PIGGYBACK SPRING BRAKE CHAMBER

INCORRECT CORRECT

FIGURE 5 - CORRECT DIAPHRAGM POSITION

6

FIGURE 6 - PIGGYBACK SPRING BRAKE KIT

9.1 Install new service diaphragm.

9.2 Clock chamber (See Section 7.0) as necessary.

9.3 Line up the new spring brake chamber, the service

diaphragm, and the non-pressure housing, ensuring that

they are centered.

Page 7

9.4 Assemble the service clamp assembly. Ensure

all parts are seated properly and remain centered (See

Figure 5).

9.5 Torque the clamp nuts to 20-30 ft/lbs. Remove the

locking pliers from the service push rod.

9.6 Connect the emergency air hose to the emergency/

parking port (“12”) and reconnect the service air line to

the service port (“11”). Torque fi ttings to no more than 30

ft-lbs (40 Nm).

9.7 Pressurize the service half by putting air into the

service por t. Do not exceed 120 psig. Perform the

Leakage Test (4.2).

10.0 UN-CAGING THE BENDIX® EVERSURE®

SPRING BRAKE CHAMBER

(APPLY PARK BRAKE)

10.1 Verify that the spring brake has been properly

installed on the spring brake bracket and properly attached

to the slack adjuster.

10.2 Apply air pressure (100-120 psi; 6.6-8.0 bar) to

restrain by air force the power spring.

10.3 Turn the release bolt nut counter clockwise with a

hand wrench. (DO NOT USE HIGH SPEED OR POWER

DRIVEN IMPACT WRENCH)

10.4 Connect a regulated air line to the emergency/

parking brake port (marked “12”) of the chamber (if not

connected previously).

10.5 Continue to turn the release bolt nut until the caging

tool is loose. Remove caging bolt nut and washer.

10.6 Push the release bolt tool in, turn the release bolt

a quarter-turn counter clockwise and remove it from the

pressure plate key hole.

10.7 With hands clear of moving parts, slowly release the

air pressure to the emergency/parking brake port (“12”).

Be sure to exercise caution to prevent pinching of fi ngers.

10.8 Place caging bolt in spring brake tool holder with

T-head down and seated in slot. Install washer and nut up

on exposed threads (this allows the washer to protect the

holder cavity and caging bolt from corrosive elements),

and torque the caging bolt nut to 10-15 lb-ft (14-20 Nm).

10.9 Mount the dust plug /weather seal in the keyhole

located at the rear center of the spring brake chamber.

Check around the edge of the dust plug/weather seal to

be sure it is fi rmly seated.

IMPORTANT: Always re-install the tethered dust plug/

weather seal in the spring brake caging tool key hole.

Failure to do so will result in corrosion and foreign material

ingestion through the key hole which may void the warranty.

Do not use excessive force when installing the dust plug/

weather seal. Extreme force may cause damage and make

it unusable.

Replacement dust plugs can be purchased from your local

Bendix distributor.

WARNING

Check for proper service and emergency operation

after servicing any part of the brake chamber(s). Check

the brake adjustment if the combination spring brake

was removed/installed. (Follow the vehicle manufacturer’s instructions to adjust the brakes).

11.0 REMOVAL AND INSTALLATION OF

THE COMBINATION SPRING BRAKE

11.1 SERVICE BRAKE CHAMBER

REPLACEMENT AND CLOCKING

CAUTION: Replace the brake chamber with the same type

and size as originally installed on the vehicle. Replacement

with alternate equipment (without written authorization from

Bendix and the vehicle manufacturer) could compromise

brake performance. Brake chambers can be clocked to

ensure the proper alignment of mounting studs, drain holes

and ports.

WARNING!

Do not mechanically release (cage) the spring if there

is any structural damage to the spring brake chamber.

Caging the spring in such a chamber may cause serious injury or death. Replace the complete assembly.

11.2 REPLACING THE COMBINATION

SPRING BRAKE

11.2.1 Mechanically release (cage) the old spring

brake chamber by following the original manufacturer’s

instructions (or use Section 8 for Bendix® brand spring

brakes).

11.2.2 Drain system pressure and then disconnect the

air hoses from the service brake chamber. Be sure to mark

both hoses to ensure proper re-installation.

11.2.3 Remove the cotter and yoke pins, disconnect the

yoke from the slack adjuster, remove the mounting nuts,

washer, and lock washers and remove the combination

spring brake. While removing, use care to prevent the

combination spring brake from falling.

11.2.4 Remove the brake chamber mounting hardware

from the mounting studs.

11.2.5 Remove the ser vice brake chamber from its

mounting bracket.

11.3 CLOCKING (ROTATING) THE

REPLACEMENT BRAKE CHAMBER

See Section 7 for clocking instructions.

INSTALLATION:

11.3.1 Clean and inspect the mounting bracket. Mount

the service brake chamber to the mounting bracket.

7

Page 8

11.3.2 If the service replacement is a type that provides

an extra-long threaded push rod, thread a nut onto the rod

past the point that it will need to be cut. Taking all necessary

safety precautions, cut the rod to the required length and

remove burrs. Remove the nut installed earlier to ensure

that the threads are clear.

11.3.3 Install the combination spr ing brake using

the furnished hardware. Torque the mounting nuts to

133-155 ft/lbs. (80-210 Nm) Connect the yoke to the slack

adjuster and install the yoke pin and the cotter pin.

11.3.4 Connect the air hoses to brake chamber. Torque

the fi tting to 30 ft-lbs (40 + 5 Nm). Check to be sure the air

hoses are properly supported and clamped, if necessary,

to provide proper clearance, including checking for proper

length when under full steer conditions.

11.3.5 Pressurize the service chamber by putting air into

the service port. Do not exceed 120 psig.

11.3.6 Test for leakage (see Section 4.2). Minimal

leakage is permitted (100 SCCM).

11.3.7 Uncage the main spring and return the release

tool into the release tool side pocket (see Section 10).

11.3.8 Adjust the slack adjuster per manufacturer’s

recommendations.

11.3.9 Check the function and stroke (Section 4.1).

11.3.10 Replace the dust cap in the keyhole.

WARNING

Check for proper service and emergency operation after

servicing any part of the brake chamber(s). Check the

brake adjustment if the combination spring brake was

removed/installed. (Follow the vehicle manufacturer’s

instructions to adjust the brakes).

12.0 REPLACING THE SERVICE DIAPHRAGM

See Figure 8. To replace the service diaphragm, it is not

necessary to remove the complete combination spring

brake from the vehicle (however, it can be removed for

ease of access). To remove the combination spring brake,

perform the steps outlined in Step 11.0 Removal and

Installation of the Combination Spring Brake.

When either the diaphragm, spring, or both, are replaced, they

should be replaced in the corresponding chamber on the same

axle. Use only genuine Bendix

®

brand replacement parts.

WARNING

A spring brake chamber cannot have the emergency

diaphragm replaced. Replace the whole spring brake

chamber.

12.0.1 Protect the service push rod with tape, and lock

the locking pliers on the push rod close to the non-pressure

plate. (This will hold the rod in the applied position).

12.0.2 Ensure that the spring brake chamber is caged. To

cage the spring brake chamber, perform the steps outlined

in either Step 6.0 Mechanical Release (Caging) of the

Bendix® EverSure® Spring Brake or Step 8.0 Mechanical

Release (Caging) and Removal of the Piggyback Spring

Brake Chamber to be Replaced.

12.0.3 Mark the service clamp ring and non-pressure

pla te to ensure pr o p e r alignment of par t s during

reassembly.

12.0.4 Remove the service clamp ring assembly and

the chamber. The service clamp ring is closest to the

non-pressure plate and slack adjuster. See provided

illustrations if in doubt.

12.0.5 Install new diaphragm.

12.0.6 Line up the spring brake chamber, the service

diaphragm, and the non-pressure housing, ensuring that

they are centered (see Figure 5).

12.0.7 Re-assemble the ser vice clamp assembly.

Ensure all parts are seated properly and remain centered.

12.0.8 Torque the clamp nuts to 20-30 ft/lbs. Remove

the locking pliers from the service push rod.

12.0.9 Reconnect the emergency air hose to the

emergency port (marked “12”) and reconnect the service

air line to the service port (marked “11”).

12.0.10 Pressurize the service half by putting air into the

service port. Perform the Leakage Test (Section 4.2).

12.0.11 Per form the Func t io na l Tes t and Stroke

(Section 4.1).

12.0.12 Uncage the main spring and return the release

tool into the release tool side pocket (See Section 10).

12.0.13 Replace the dust cap in the keyhole.

WARNING

Check for proper service and emergency operation after

servicing any part of the brake chamber(s). Check the

brake adjustment if the combination spring brake was

removed/installed. (Follow the vehicle manufacturer’s

instructions to adjust the brakes).

8

BW7506 © 2011 Bendix Commercial Vehicle Systems LLC. 08/11. All Rights Reserved. Printed in the United States.

Loading...

Loading...