Page 1

®

Bendix® ET- S™ & ET-S2™ Suspended Electronic Treadle

SD-15-4111

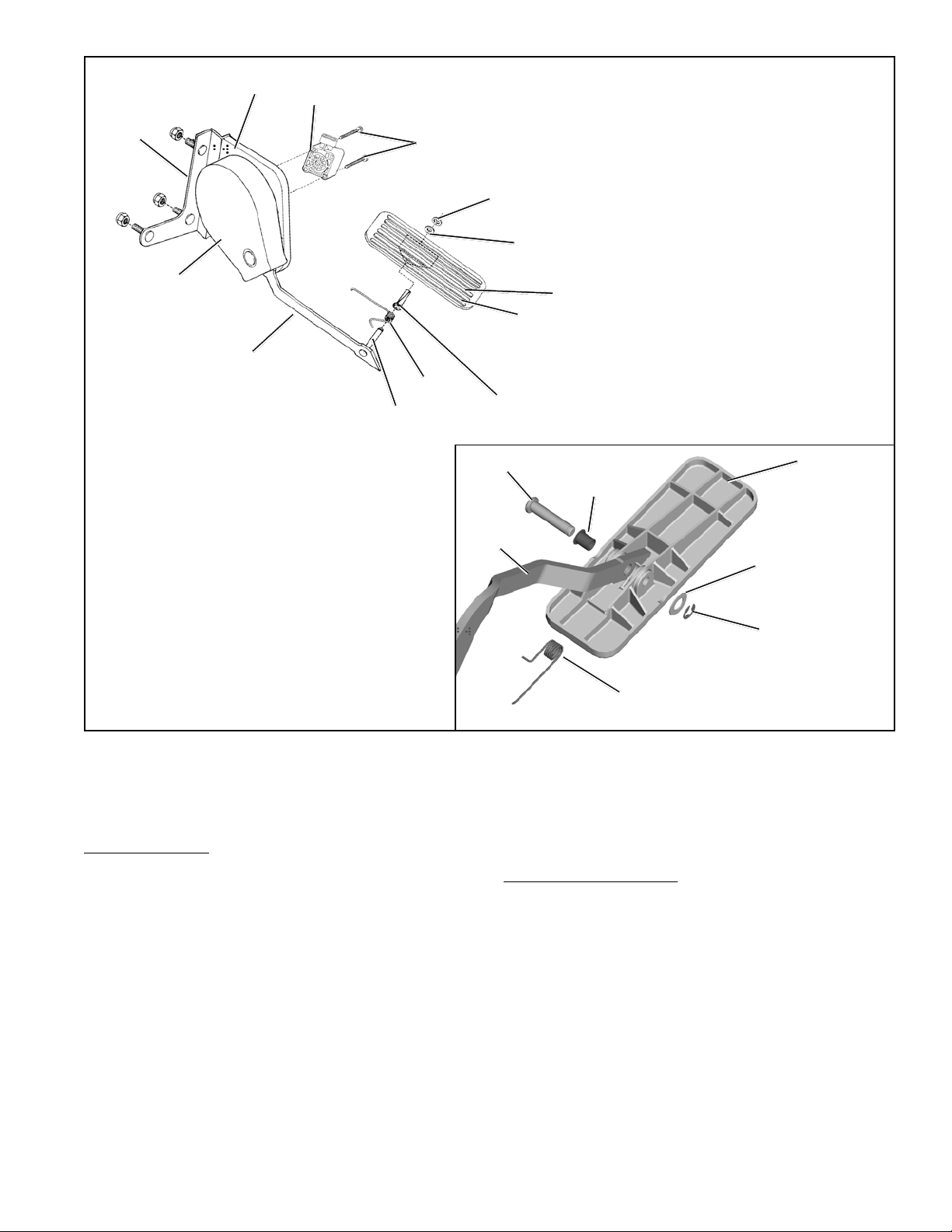

TREADLE

ACTUATOR BODY

MOUNTING

TREADLE

FIGURE 1 - ET-S

PLATE

CONNECTOR

POTENTIOMETER

ET-S™ TREADLE

™

AND ET-S2™ ELECTRONIC TREADLES

ACTUATOR BASE

MOUNTING

PLATE

DESCRIPTION

The ET-S™ and ET-S2™ treadles are engine compartment

bulkhead mounted electronic treadles. On electronically

controlled diesel engines, the electronic treadle fulfills the

same function as a conventional mechanical throttle.

However, rather than transmitting a mechanical force to the

engine governor, the electronic treadle controls engine speed

by supplying a variable electrical voltage to the engine’s

electronic controller.

The main components of the ET-S™ and ET-S2™ treadles

are: a mounting plate, suspended treadle, potentiometer

(variable resistor), actuator body and base. The selected

potentiometer, chosen for a specific engine application,

provides the electrical link to the engine control system.

OPERATION

The electronic treadles provide smooth, graduated throttle

control through the function of its potentiometer (variable

resistor). The drive shaft of the cam follower assembly

transfers any movement of the treadle to the potentiometer.

POTENTIOMETER

MOUNTING

PLATE

TREADLE PIVOT PIN

TREADLE

ET-S2™ TREADLE

DETROIT CATERPILLAR CUMMINS

DIESEL

CLOSED

THROTTLE 7 - 18% 10 - 20% 5 - 17%

IDLE (OPEN)

OPEN

THROTTLE 74 - 90% 75 - 90% 70 - 81%

(FULL)

FIGURE 2 - OUTPUT VOLTAGE, AS A PERCENTAGE OF

SUPPLY VOL TAGE

8V

CATERPILLAR

5V

™

ET-S

TREADLE

OUTPUT

VOLTAGE

○○○○○○○○○○○○○○○○○○○○○○

0V

CLOSED THROTTLE

(OPEN)

FIGURE 3 - OUTPUT VOL TAGE

CUMMINS

DETROIT

DIESEL

OPEN THROTTLE

(FULL)

MAX

RPM

ENGINE

IDLE

1

Page 2

As the potentiometer rotates, its resistance changes. This

way , the potentiometer can react to the driver’s request for

™

engine power through the ET-S

or ET-S2™ treadle by

changing resistance. The resulting change of voltage is

sensed by the electronic engine controller.

The electronic treadle receives its supply voltage from the

engine control unit. If the driver does not request engine

power, the treadle is in the idle position. This condition is

also referred to as “Closed Throttle.” In this state, the

potentiometer returns the minimum percentage of supply

voltage to the engine control unit (see Figure 2).

As the driver depresses the treadle, the electronic treadle

output voltage increases (see Figure 3). The potentiometer

allows an increased amount of its supply voltage to return to

the engine control unit, which in turn increases the engine’s

speed.

In the full, or “Open Throttle” position, the driver has

depressed the treadle to its furthest possible point. This is

the state of least potentiometer resistance. The electronic

treadle returns the maximum percentage of supply voltage

to the engine control unit (see Figure 2).

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended warranty

may be voided if intrusive maintenance is performed during

this period.

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable guide

in determining the best maintenance interval for a vehicle.

GENERAL

Important: Visually check for physical damage to the

electronic treadle such as broken or missing parts. Actuate

the pedal five times from stop to stop, noting any binding or

soft pedal response.

Important Note: DO NOT DISASSEMBLE THE ACTUA TOR

BODY. Replace the ET-S™ or ET-S2™ treadle if there is

any binding, soft pedal actuation or if the nylon washers or

retaining rings indicated in Figure 4 are cracked or have

signs of deterioration.

CAM FOLLOWER

DRIVE SHAFT

POTENTIOMETER

MOUNTING PLATE

FIGURE 4 - TOP SECTIONAL VIEW

RETAINING

RINGS

NYLON

WASHERS

Perform the inspections presented at the prescribed interval.

If the electronic treadle fails to function as described, it should

be repaired or replaced with a new or genuine Bendix remanufactured unit, available at any authorized parts outlet.

Every 3 months, or 25,000 miles, or 900 operating hours:

1. Remove any accumulated contaminants and visually

inspect the exterior of the electronic treadle assembly

for physical damage or excessive corrosion.

2. Inspect electrical connections and cable assembly for

signs of corrosion, wear, or physical damage. Replace

as necessary.

3. Inspect treadle spring, sleeve bearing, nylon washer,

rubber treadle cover (ET-S™ treadle only) and retaining

ring for cracks or deterioration. Replace as necessary .

ET-S™ & ET-S2™ TREADLE REMOVAL

1. Park the vehicle on a level surface and block the wheels.

2. Drain the air pressure from all vehicle reservoirs.

3. Disconnect the cable assembly of the potentiometer.

Lift the lock tab and pull the connectors until they

disengage.

4. Remove the electronic treadle from the vehicle, set aside

the mounting hardware for reassembly.

DISASSEMBLY

Please note that the internal mechanism of the ET-S™ and

ET-S2™ treadle are not field-serviceable and therefore

individual parts or parts kits are not available for these

components. Disassembly may lead to malfunction of the

ET-S™ or ET-S2™ treadle.

The following instructions cover the maintenance and

replacement of the potentiometer and treadle (with its

bearing, spring etc.) only. The instructions provided with

those items should be followed in lieu of the steps presented

here. There are no other field-serviceable parts.

2

Page 3

MOUNTING

PLATE

ACTUATOR

BODY

ACTUATOR

BASE 1

TREADLE

ARM

ET-S™ TREADLE

POTENTIOMETER

PIVOT PIN

2

#10 SCREWS

7

SPRING

3

RETAINING

RING

4

NYLON

WASHER

REPLACEABLE

RUBBER

COVER

™

(ET-S

TREADLE

ONLY)

6

NYLINER

BEARING

TREADLE

5

PIVOT PIN

TREADLE

ARM

FIGURE 5 - ET-S™ AND ET-S2™ TREADLE EXPLODED LINE DRAWING

All other repairs require replacement of the ET-S™ or

ET-S2™ treadle.

Refer to Figure 5 throughout the procedures.

Remove the pivot pin from the treadle assembly. Gently

release the tension on the treadle spring (7) while removing

the treadle from the treadle arm. Remove the nyliner bearing (6) from the treadle arm.

Treadle Removal:

ET-S™ Treadle

Position the treadle on its side with the potentiometer facing up. Remove the small retaining ring (3) and small nylon

washer (4) that hold the treadle on to the treadle arm and

set aside for the assembly process. After the washer is

removed, pull the treadle off, carefully releasing the pressure from the treadle spring (7). Set the spring (7), nyliner

bearing (6) and the treadle aside for the reassembly process. Inspect rubber treadle cover - replace if necessary .

ET-S2™ Treadle

Position the treadle assembly on its side with the potentiometer facing down. Remove the small retaining ring (3)

and the nylon washer (4) from the treadle pivot pin.

Potentiometer Removal:

Secure the mounting plate. Important: Do not clamp the

assembly by the treadle actuator body or base since

overclamping may cause the casting to be distorted.

Remove the two screws (2) that secure the potentiometer

(1) to the actuator base. The potentiometer (1) can then be

lifted away from the drive shaft.

CLEANING AND INSPECTION

1. Use suitable solvent to clean all metal parts (note that

mineral spirits may damage the paint finish).

2. Inspect the treadle and mounting plate for severe

corrosion, pitting, or cracks. Replace as necessary.

Superficial corrosion and/or pitting is acceptable.

6

NYLINER

BEARING

SPRING

TREADLE

4

NYLON

WASHER

3

RETAINING

RING

7

ET-S2

™

TREADLE

3

Page 4

3. Inspect the cable assembly for loose or frayed wires,

physical damage, or any contaminants on the connectors. Replace as necessary .

ASSEMBLY

1. Securely clamp the treadle mounting plate.

2. (a) For Detroit Diesel Potentiometers: Align the drive

slot, and engage the potentiometer the drive tang at the

end of the drive shaft (see Figure 4). Rotate the

DIGITAL

VOLT/

OHM

METER

POWER

SUPPLY

(9-16 VDC)

300,000 OHM RESISTOR

TEST LOAD

potentiometer clockwise until the first set of mounting

holes align. Secure using two screws: torque to 25 (±5)

in. lbs.

(b) For Caterpillar Position Sensor: Aligning the drive

slot, the position sensor engages the drive tang at the

end of the drive shaft (see Figure 4). Rotate the position

sensor clockwise until the first set of mounting holes

align. Secure using two screws : torque to 20 (±2) in.

lbs.

POTENTIOMETER

PC. NO. ON THIS SURFACE

PIN C

GROUND

PIN B

VOUT

(OUTPUT)

PIN A

Closed Throttle (open) Range: 7-18%

Open Throttle (full) Range: 74-84%

FIGURE 6 - ELECTRICAL TEST SCHEMATIC FOR THE DETROIT DIESEL CONNECTOR

Closed Throttle (open) Range: 10-20%

Open Throttle (full) Range: 75-90%

PIN A VREF

(INPUT)

2000 OHM ±5%

RESISTOR

PEDAL

POSITION

SENSOR

(PWM)

.001µF

PIN B

VOUT

(OUTPUT)

47,000 OHM ±5%

RESISTOR

VREF

(INPUT)

POTENTIOMETER

(CABLE)

POSITION SENSOR

PIN C

GROUND

Caterpillar output voltage is Pulse Width Modulated

FIGURE 7 - ELECTRICAL TEST SCHEMA TIC FOR THE CATERPILLAR CONNECTOR

4

Page 5

IDLE

VALIDATION

SWITCH

PEDAL

POSITION

SENSOR

DIODES

IVS

PIN 6

PIN 2

PIN 1

PIN 5

PIN 3

PIN 4

TEST

LOAD

470

OHM

TEST LOAD

47000 OHM

TEST

LOAD

470

OHM

.01µF

Vs

SUPPLY

VOLTAGE

V3 (LOGIC HIGH AT IDLE)

V2 (LOGIC LOW AT IDLE)

IVS GROUND

Vs

SUPPLY

VOLTAGE

V1

(OUTPUT)

APS

GROUND

Closed Throttle (open) Range: 5-17%

Open Throttle (full) Range: 70-81%

LOCK TAB

5

VS

APS GROUND

3

V1

(OUTPUT) SIG1 2

(INPUT)4

IVS GROUND

(IVS) V 2

POTENTIOMETER

SET VOLTAGE

AND PC. NO.

SHOWN

HERE

6

(IVS)

V 3

LOCK TAB

1

FIGURE 8 - ELECTRICAL TEST SCHEMATIC FOR THE CUMMINS CONNECTOR

(c) For Cummins Potentiometers:

Test 1: Where the set resistance and voltage is

shown on a label. The Cummins potentiometer on

the ET-S™ and ET-S2™ treadle has an integral idle

validation switch. It also has a set resistance value

marked on the cover, which needs to be used to properly

install the potentiometer. The drive slot in the

potentiometer should engage with the drive tang at the

end of the drive shaft. Next rotate the potentiometer

until the hole in the metal sleeve matches the mounting

holes on the actuator base. Loosely screw the

potentiometer in place but do not tighten. Connect an

ohmmeter to pins 3 (APS output) and 4 (APS ground)

as shown in Figure 8. Now the installer should read the

set resistance value marked on the label. Rotate the

potentiometer until the ohmmeter reads the same

resistance as shown on the label within ±10 Ohms. Next,

while holding the potentiometer at the set resistance

screw and lock the potentiometer in place (torque to 25

inch pounds ±5). The sleeves lock into the body of the

potentiometer for easy removal and reassembly.

Test 2: Where the potentiometer has no label, but

has engraved set voltage shown. The Cummins

potentiometer on the electronic treadle has an integral

idle validation switch. It also has a set voltage value

marked on the cover, which needs to be used to properly

install the potentiometer. The drive slot in the

potentiometer should engage with the drive tang at the

end of the drive shaft. Next rotate the potentiometer

until the hole in the metal sleeve matches the mounting

holes on the actuator base. Loosely screw the

potentiometer in place but do not tighten. Construct the

test circuit following the circuit diagram shown in Figure

8. T o make the test circuit connect the test load resistor

(47,000 Ohms) and a capacitor (.01 MicroFarads) across

pins 3 and 4 of the potentiometer. Then connect a

voltmeter to the lead ends of the test circuit. Next connect

a 5 volt power supply to the potentiometer at pin 4 (APS

ground) and pin 5 (supply voltage). Caution: Sensor

may be damaged if supply exceeds 5 volts. Now the

installer should read the set voltage value marked on

the potentiometer. Rotate the potentiometer until the

voltmeter reads the same voltage as shown on the

potentiometer within ±.02 volts. Next screw and lock

the potentiometer in place (torque to 25 inch pounds

±5). The sleeves lock into the body of the potentiometer

for easy removal and reassembly .

T est 3: Perform the following Operational Te st before

installing the electronic treadle:

OPERA TIONAL TEST

[Note for Cummins potentiometers only: The optimum

output & switch points should be achieved when the idle

voltage equals the set voltage or set resistance written on

the potentiometer. Use the test circuit shown in Figure 8.]

a. Check that the electronic treadle mounting plate is

securely attached to a smooth, flat surface in such a

way that does not twist the unit.

5

Page 6

b. Connect the potentiometer or position sensor to the volt

meter and power supply as shown in Figures 6, 7 or 8,

depending on the model. Note: The power supply needs

to be 5 VDC. Do not exceed this voltage.

c. Verify that the closed throttle (idle) output voltage, as a

percentage of supply voltage, is within the limits listed

in Figure 2. For example, with a supply voltage of 5

volts, for the Caterpillar potentiometer in its closed throttle

position, read between 0.5 to 1.0 volts (10%-20% of

supplied voltage).

d. Depress the treadle to its full throttle position. The output

voltage, as a percentage of supply voltage, should be

within the limits listed in Figure 2. For example, with a

supply voltage of 5 volts, for the Caterpillar position

sensor in its open throttle position, read between 3.75

to 4.5 volts (75-90% of supplied voltage).

e. Make five full applications and record idle position voltage

each time. Verify that idle position volt ages recorded do

not vary by more than .4% (For example, for a 5 volt

supply , if there is any variation, the difference between

the high and low readings should not exceed .02 volts).

If the electronic treadle fails to function within its specified

ranges, it should be repaired or replaced with a new or

genuine Bendix remanufactured unit, available at any

authorized parts outlet.

Treadle Installation:

ET-S™ Treadle

1. Replace the rubber treadle cover if needed.

2. Place the spring (7) on the treadle pivot pin.

3. Install the nyliner bearing (6) into the treadle. Note: the

nyliner bearing collar is placed on the treadle arm side.

Holding the spring in position, the treadle is then installed. The nylon washer (4) and retaining ring (3) secure

the treadle into position.

4. Make sure the ET-S™ treadle has a smooth, even treadle

movement.

5. Install the ET-S™ treadle on the vehicle (see ET-S™ &

ET-S2™ T readle Installation).

ET-S2™ Treadle

1. Position the treadle assembly on its side with the potentiometer facing up.

2. Insert the nyliner bearing (6) into the treadle arm with the

collar up (toward potentiometer side). The nyliner bearing (6) will protrude through the treadle arm providing a

guide for the treadle spring (7).

3. Place the treadle spring (7) on the protruding portion of the

nyliner bearing with the tangs of the treadle spring (7) pointing toward the ET-S2™ treadle body. The short tang should

rest on the top side of the treadle arm. Align the treadle

arm and treadle spring with the recess in the underside of

the treadle.

4. Insert the pivot pin from the potentiometer side of the

ET-S2™ treadle assembly through the treadle, treadle

arm, nyliner bearing (6) and spring (7). Secure with the

nylon washer (4) and retaining ring (3).

5. Make sure the ET-S2™ treadle has smooth, even treadle

movement.

6. Install the ET -S2™ treadle on the vehicle (see ET-S™ &

ET-S2™ T readle Installation).

ET-S™ & ET-S2™ TREADLE INSTALLATION

1. Using the mounting hardware set aside, install the

assembled electronic treadle on the vehicle. Torque to

between 85 and 1 10 lb. in.

2. Reconnect the cable connector by plugging it into the

potentiometer’s integral connector and pushing until the

lock tab snaps into place.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

™

6

Page 7

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

7

Page 8

8

BW1837 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 6/2004 Printed in U.S.A.

Loading...

Loading...