Page 1

®

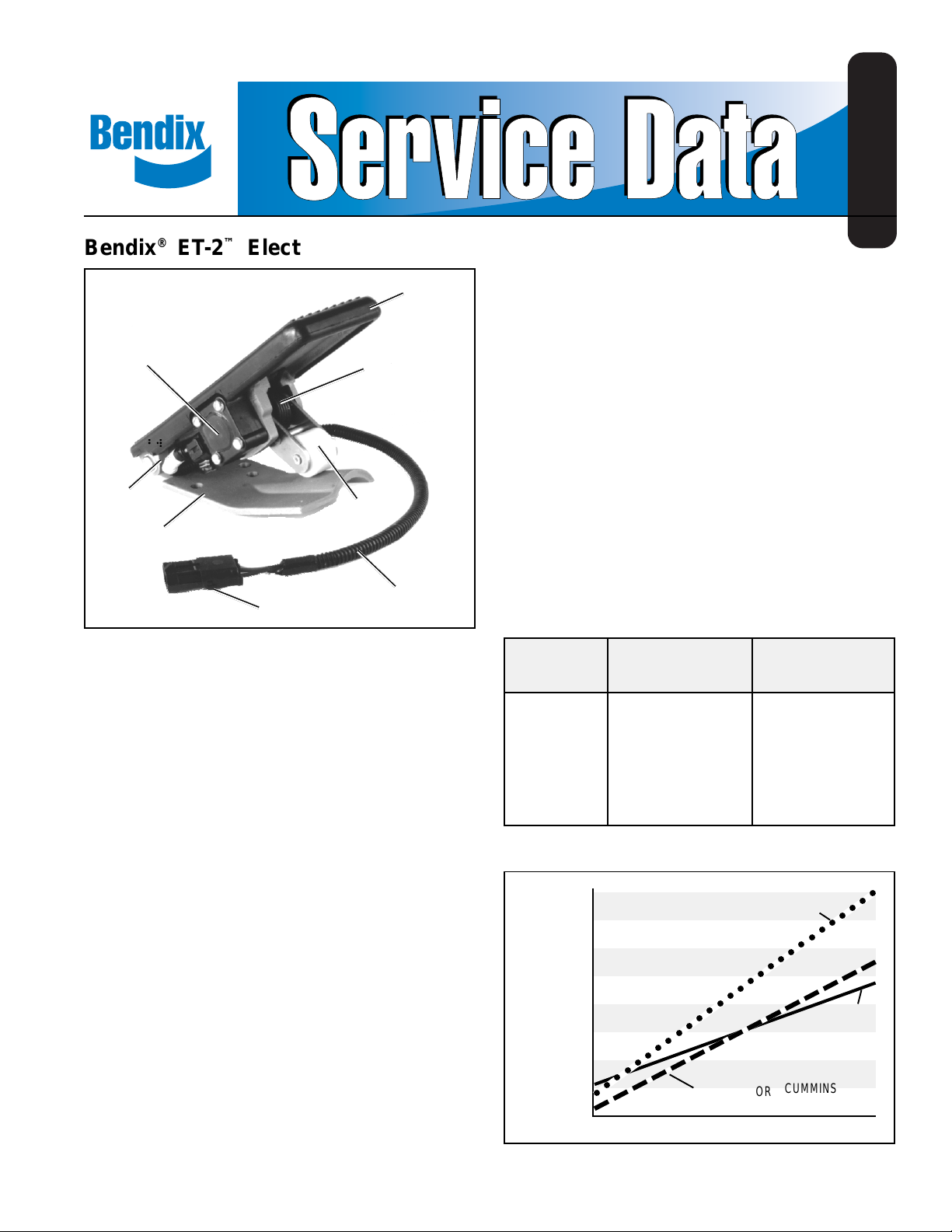

Bendix® ET-2™ Electronic Treadle

SD-15-4106

TREADLE

COVER

POTENTIOMETER

PIVOT SPRING

MOUNTING BASE

CONNECTOR

FIGURE 1 - ET-2™ ELECTRONIC TREADLE

DOUBLE RETURN

SPRING

ROLLER

CABLE ASSEMBLY

DESCRIPTION

The ET-2™ is an electronic throttle. On electronically

controlled diesel engines, the ET-2™ treadle fulfills the same

function as a conventional mechanical throttle. The ET -2

treadle controls engine speed by interacting with an

electronic fuel management controller on the engine, rather

than transmitting a mechanical force from the throttle pedal

to the engine governor.

The main components of the ET-2™ throttle are a cast

aluminum mounting base and treadle, a rubber treadle cover,

a potentiometer (variable resistor), and a roller assembly.

The potentiometer is specific to each engine application.

OPERATION

The ET-2™ treadle provides smooth, graduated throttle control

through the function of its variable resistor , or potentiometer.

The ET-2™ treadle receives its supply voltage from the engine

control unit. The lever shaft connects the roller assembly

to the potentiometer, so that any movement of the treadle

rotates the potentiometer. As the potentiometer rotates,

its resistance changes. This way, the potentiometer

communicates the throttle position to the fuel control

system by changing resistance, returning more or less of

the supplied voltage back to the electronic engine controller.

If the driver does not request engine power, the throttle is in

the idle (or “closed throttle”) position. In this state, the

potentiometer significantly reduces the amount of supply

voltage returned to the engine control unit (See Figure 2).

As the driver depresses the ET-2™ treadle, output voltage

increases (see Figure 3). The potentiometer allows an

increased amount of its supply voltage to return to the engine

control unit, which in turn increases the engine’s speed.

In the full (or “open throttle”) position, the driver has fully

depressed the ET-2™ treadle. This is the state of least

potentiometer resistance. The ET-2™ treadle returns the

maximum percentage of supply voltage to the engine control

unit (see Figure 2).

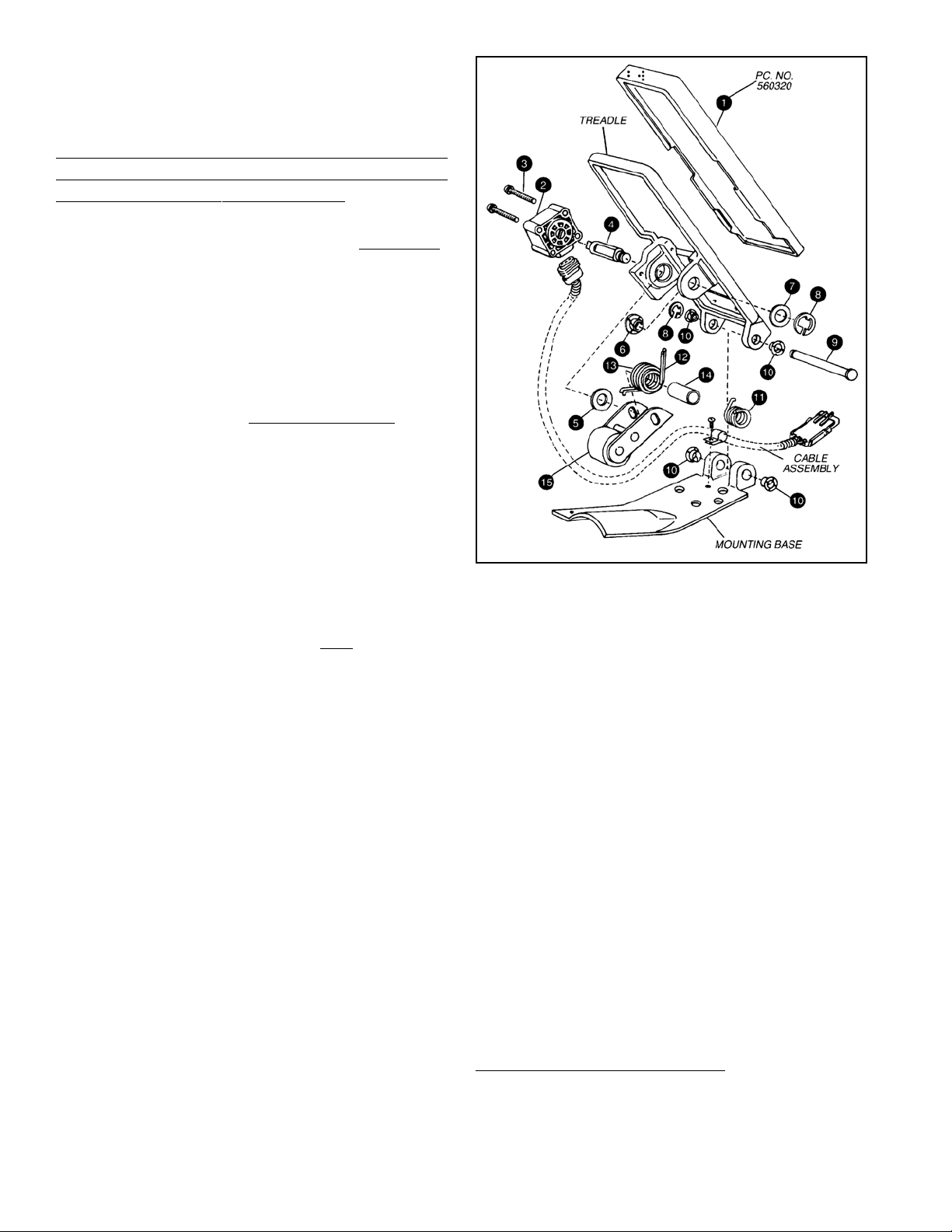

Engine Idle Throttle Full Throttle

Manufacturer (Closed) (Open)

CAT 13 - 21% 79 - 89%

™

Cummins 8 - 18% 70 - 80%

Detroit Diesel 6 - 14% 86 - 94%

Mack 10 - 20% 70 - 85%

FIGURE 2 - ET-2™ TREADLE OUTPUT VOLTAGE, AS A

PERCENTAGE OF SUPPLY VOL TAGE

8V

7

6

™

ET-2

TREADLE

OUTPUT

VOLTAGE

FIGURE 3 - ET-2

5

4

3

2

1

0V

CLOSED THROTTLE OPEN THROTTLE

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

™

TREADLE OUTPUT VOL TAGE

DETROIT

DIESEL

OR

CAT

CUMMINS

MACK

1

Page 2

Figure 3 illustrates the relationship between throttle position

and engine RPM. Potentiometer performance will vary for

each engine application, therefore potentiometers must not

be interchanged.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

FIGURE 4 - EXPLODED VIEW

PREVENTIVE MAINTENANCE

GENERAL

™

Perform the following tests and inspections at the prescribed

intervals. If the ET-2™ treadle does not function as described,

repair it or replace it with a new unit, available at any

authorized Bendix parts outlet. EVERY 3 MONTHS, 25,000

MILES, OR 900 OPERA TING HOURS:

1. Remove any accumulated contaminants and visually

inspect the exterior of the ET-2™ treadle for physical

damage or excessive corrosion.

2. Inspect electrical connections and cable assembly for

signs of corrosion, wear, or physical damage. Replace

as necessary.

3. Inspect springs (11, 12, 13) for signs of corrosion or

pitting. Replace as necessary.

4. Inspect bearings (10), washer (7), and snap rings (8)

for cracks or deterioration. Replace as necessary.

OPERATIONAL TEST

Perform these tests only if the vehicle’s throttle does not

appear to operate as expected.

Test 1: For Mack and DDC engines:

1. Unplug the cable assembly from the potentiometer’s

integral connector by lifting the lock tab and pulling

the connectors until they disengage. Inspect cable

assembly for loose terminals, frayed wires, corrosion,

2

Page 3

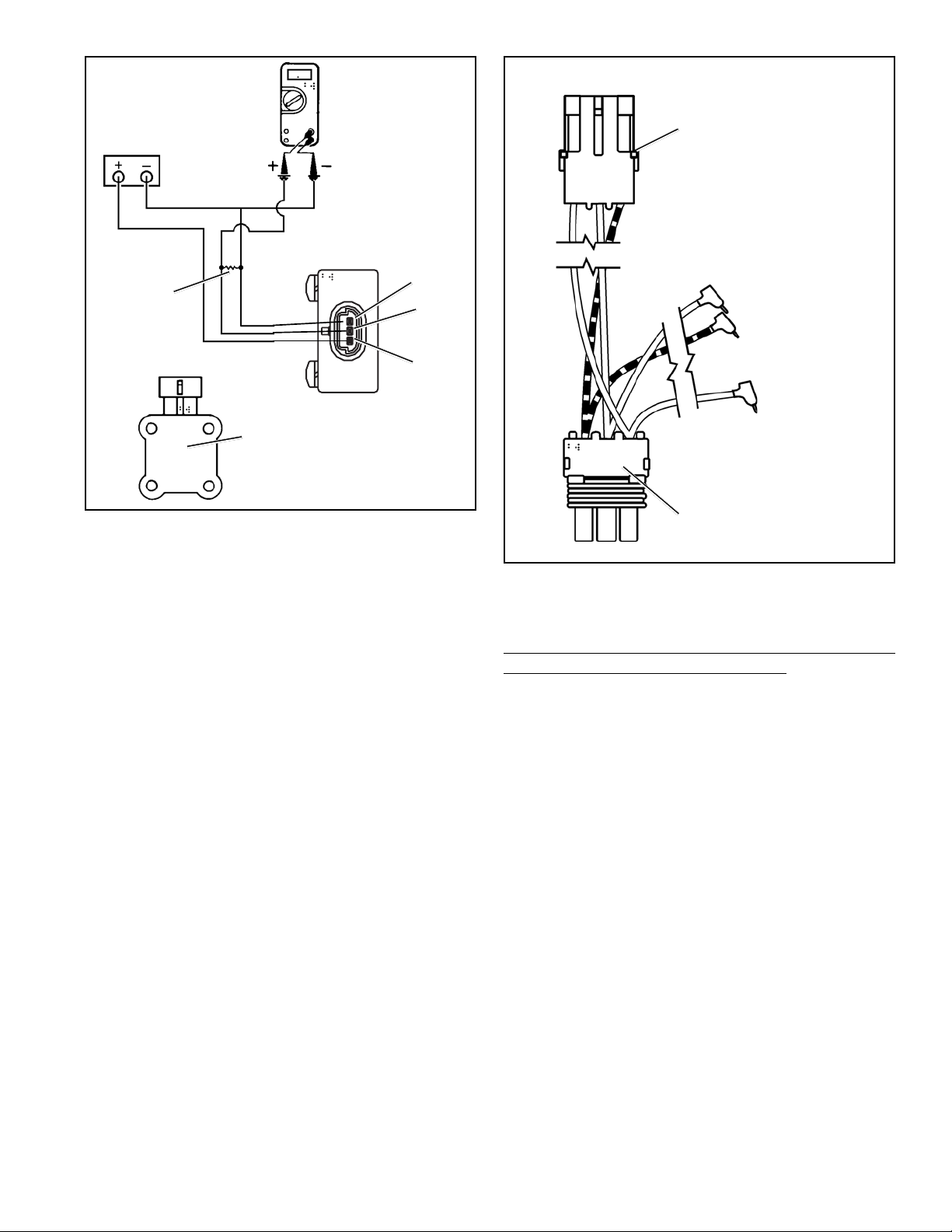

POWER

SUPPLY

(9-16 VDC)

DIGITAL

VOLT/

OHM

METER

A B C

PACKARD ELECTRIC

CONNECTOR 12010717

(CONNECTOR X)

PIN C

RESISTOR

TEST LOAD

(47,000 OHM FOR

DETROIT DIESEL,

300,000 OHM

FOR MACK)

POTENTIOMETER

POTENTIOMETER

PC. NO. ON THIS

SURFACE

FIGURE 5 - ET-2™ TREADLE ELECTRICAL TEST

SCHEMATIC FOR THE DETROIT DIESEL CONNECTOR

GROUND

PIN B

VOUT

(OUTPUT)

PIN A

VREF

(INPUT)

wear, or physical damage. Check end-to-end electrical

continuity at terminals. NOTE: Potentiometer pin

locations will remain constant (see Figure 5). However,

cable assembly connector pin out may vary from engine

to engine.

2. Remove the ET-2™ treadle from the vehicle.

3. Secure the ET-2™ treadle to a smooth, flat surface in

such a way that it does not twist the unit.

4. Connect the potentiometer to the volt meter and power

supply as shown in Figure 5. NOTE: Power supply

can be a 12 VDC vehicle battery in good condition and

with known voltage output.

5. Verify that the closed throttle (idle) output voltage, as

a percentage of supply voltage, is within the limits listed

in Figure 2.

6. Depress the treadle to its full throttle position. The

output voltage, as a percentage of supply voltage,

should be within the limits listed in Figure 2, e.g.

Testing a Detroit Diesel ET -2™ Treadle Potentiometer:

Battery = 10 VDC. Full throttle = 9 VDC. 9/10 x 100 =

90%.

7. Make several full applications and record idle position

voltage each time. Verify that idle position voltage does

not vary by more than .4% (.02 volts). If the ET-2

treadle does not operate within its specified ranges,

service the unit, or replace it with a new ET-2™ treadle,

available at your nearest Bendix parts outlet.

INPUT PIN 3

OUTPUT PIN 2

GROUND PIN 1

PACKARD ELECTRIC

CONNECTOR 12015793

C B A

FIGURE 6 - ET-2

SCHEMATIC FOR THE CUMMINS CONNECTOR

™

TREADLE ELECTRICAL TEST

(CONNECTOR Y)

Test 2: For Cummins engines (featuring a separate

potentiometer and idle validation switch):

T o test the potentiometer on the vehicle, use steps 1 through

8. Alternatively, instructions for carrying out a “bench test”

is covered in instructions 1 1 through 16.

1. First construct the “breakout” harness shown in Figure 6.

2. Insert connector X on the breakout harness into the

connector leading from the potentiometer. Then insert

connector Y on the breakout harness into the connector

leading from the dashboard wire harness.

3. Next insert pin 1 into the ground position on a voltmeter.

Then insert pin 2 into the positive position on a volt

meter.

4. Disconnect the idle validation switch cable from the

dashboard wire harness. Connect an ohmmeter to pins

A and B on the connector leading from the idle

validation switch. The positive lead should be

connected to pin A and the negative lead should be

connected to pin B.

5. Turn the vehicle’s ignition key to the “battery on”

™

position. This supplies a 5 volt input to the

potentiometer. Since the idle validation switch is no

longer connected, a fault code may be triggered on

some vehicles. This fault code will be reset at the end

of this test.

3

Page 4

6. Record the output voltage when the pedal is in the idle

position (V1). Then slowly depress the pedal. When

the ohm meter shows that the resistance has changed

from “overload” to about .003 ohms (or from .003 ohms

to “overload”), stop depressing the pedal. Record the

voltage (Vx) registered with the pedal in this position.

Then press the pedal to the full throttle position and

record the output voltage (V2).

7. Calculate the “switch point percentage” using the formula

below.

Switch point percentage = ((Vx-V1)/(V2-V1))*100

Vx = Output voltage when the switch changed

V1 = idle voltage

V2 = full throttle voltage

DIGITAL

POWER

SUPPLY

(9-16 VDC)

RESISTOR

TEST LOAD

47,000 OHM

FIGURE 7 - ET-2

SCHEMATIC FOR THE CUMMINS CONNECTOR

VOLT/

OHM

METER

POTENTIOMETER

POTENTIOMETER

PC. NO. ON THIS

SURFACE

™

TREADLE ELECTRICAL TEST

PIN C

GROUND

PIN B

VOUT

(OUTPUT)

PIN A

VREF

(INPUT)

8. The switch point percentage should be between 3% to

10%. If it is not with in this range adjust the

potentiometer by loosening the mounting screws and

turning the potentiometer within the range allowed by

the mounting holes. Repeat steps 1-7 again. If you can

not obtain the proper switch point percentage, replace

with a new ET-2™ treadle, available at your nearest

Bendix parts outlet.

9. After a successful test the vehicle may be returned to

service.

The following instructions are for a bench test for the

potentiometer used with Cummins engines.

10. Unplug the cable assembly from the potentiometer’s

integral connector by lifting the lock tab and pulling the

connectors until they disengage. Inspect cable

assembly for loose terminals, frayed wires, corrosion,

wear, or physical damage. Check end-to-end electrical

continuity at terminals. NOTE: Potentiometer pin

locations will remain constant (see Figure 5). However,

cable assembly connector pin out may vary from engine

to engine.

1 1. Remove the ET-2™ treadle from the vehicle.

12. Secure the ET-2™ treadle to a smooth, flat surface in

such a way that it does not twist the unit.

13. Connect the potentiometer to the volt meter and power

supply as shown in Figure 5. NOTE: Power supply

can be a 12 VDC vehicle battery in good condition and

with known voltage output.

14. V erify that the closed throttle (idle) output voltage, as a

percentage of supply voltage, is within the limits listed

in Figure 2.

15. Depress the treadle to its full throttle position. The

output voltage, as a percentage of supply voltage, should

be within the limits listed in Figure 2. e.g. Testing a

Detroit Diesel ET-2™ Treadle Potentiometer: Battery =

10 VDC. Full throttle = 9 VDC. 9/10 x 100 = 90%.

16. Make several full applications and record idle position

voltage each time. Verify that idle position volt age does

not vary by more than .4% (.02 volts). If the ET-2

treadle does not operate within its specified ranges,

service the unit, or replace it with a new ET-2™ treadle,

available at your nearest Bendix parts outlet.

Test 3: For Cummins engines (with integrated switch

and sensor (ISS): For use only with the Cummins Celet

Plus and later editions of the ECU. This sensor can

not be used to replace the separate potentiometer &

idle validation switch. To do this a new ET-2™ treadle

with the ISS must be purchased.

Test 1: Where the set resistance and voltage is shown

on a label. The Cummins potentiometer on the ET-2

treadle has an integral idle validation switch. It also has a

set resistance value marked on the cover , which needs to

be used to properly install the potentiometer. The drive

slot in the potentiometer should engage with the drive

tang at the end of the drive shaft. Next rotate the

potentiometer until the hole in the metal sleeve matches

the mounting holes on the actuator base. Loosely screw

the potentiometer in place but do not tighten. Connect

an ohmmeter to pins 3 (APS output) and 4 (APS ground)

as shown in Figure 8. Now the installer should read the

set resistance value marked on the label. Rotate the

™

™

4

Page 5

Closed Throttle (open) Range: 10-20%

Open Throttle (full) Range: 75-90%

PIN A VREF

(INPUT)

-8V

2000 OHM ±5%

RESISTOR

PEDAL

POSITION

SENSOR

(PWM)

.001µF

FIGURE 8 - ET-S™ TREADLE ELECTRICAL TEST SCHEMA TIC FOR THE CATERPILLAR CONNECTOR

potentiometer until the ohmmeter reads the same

resistance as shown on the label within ±10 Ohms. Next,

while holding the potentiometer at the set resistance

screw and lock the potentiometer in place (torque to 25

inch pounds ±5). The sleeves lock into the body of the

potentiometer for easy removal and reassembly.

Test 2: Where the potentiometer has no label, but

has engraved set voltage shown. The Cummins

potentiometer on the ET-2™ treadle has an integral idle

validation switch. It also has a set voltage value marked

on the cover, which needs to be used to properly install

the potentiometer. The drive slot in the potentiometer should

engage with the drive tang at the end of the drive shaft.

Next rotate the potentiometer until the hole in the metal

sleeve matches the mounting holes on the actuator base.

Loosely screw the potentiometer in place but do not

tighten. Construct the test circuit following the circuit

diagram shown in Figure 8. To make the test circuit

connect the test load resistor (47,000 Ohms) and a

capacitor (.01 Microfarads) across pins 3 and 4 of the

potentiometer. Then connect a voltmeter to the lead ends

of the test circuit. Next connect a 5 volt power supply to

the potentiometer at pin 4 (APS ground) and pin 5 (supply

voltage). Caution: Sensor may be damaged if supply

exceeds 5 volts. Now the installer should read the set

voltage value marked on the potentiometer. Rotate the

potentiometer until the voltmeter reads the same voltage

as shown on the potentiometer within ±.02 volts. Next

PIN B

VOUT

(OUTPUT)

RED

47,000 OHM ±5%

RESISTOR

PIN C

GROUND

BLACK

Caterpillar output voltage is Pulse Width Modulated

VOLTMETER (V => %)

screw and lock the potentiometer in place (torque to 25

inch pounds ±5). The sleeves lock into the body of the

potentiometer for easy removal and reassembly .

Test 4: For CA T engines:

1. Securely clamp the treadle Mounting Plate (6).

2. For Caterpillar Potentiometers: Aligning the drive slot,

the Potentiometer (1) engages the drive tang at the end

of the Cam Follower Drive Shaft (see Figure 4). Rotate

the Potentiometer clockwise until the first set of

mounting holes align. Secure using two screws (2):

torque to 20 (±2) in. lbs.

To test the Caterpillar sensor construct the test circuit

shown in Figure 7. Connect both pin B and pin C into

a voltmeter. Set the voltmeter to the settings described

in Figure 7. Record the output values in Figure 2. If

the unit does not operate within the specified ranges,

service the unit or replace it with a new ET-2™ treadle.

REMOVAL

1. Park the vehicle on a level surface and block the wheels

and/or hold the vehicle by means other than the air

brakes.

2. Drain the air pressure from all vehicle reservoirs.

3. Unplug the cable assembly at the opposite end of the

potentiometer. Disconnect by lifting the lock tab and

pulling the connectors until they disengage.

4. Remove the ET-2™ treadle from the vehicle.

(CABLE)

POTENTIOMETER

5

Page 6

DIODES

TEST

LOAD

470

PIN 6

IDLE

VALIDATION

SWITCH

PEDAL

POSITION

SENSOR

FIGURE 8 - ET-2™ TREADLE ELECTRICAL TEST SCHEMATIC FOR THE CUMMINS CONNECTOR

IVS

PIN 2

PIN 1

PIN 4

OHM

PIN 5

PIN 3

TEST LOAD

47000 OHM

TEST

LOAD

470

OHM

.01µF

Vs

SUPPLY

VOLTAGE

V3 (LOGIC HIGH AT IDLE)

V2 (LOGIC LOW AT IDLE)

IVS GROUND

Vs

SUPPLY

VOLTAGE

V1

(OUTPUT)

APS

GROUND

Closed Throttle (open) Range: 5-17%

Open Throttle (full) Range: 70-81%

LOCK TAB

5

VS

4

APS GROUND

3

V1

(OUTPUT) SIG1

(INPUT)

2

(IVS) V 2

POTENTIOMETER

SET VOLTAGE

AND PC. NO.

SHOWN

HERE

6

(IVS)

V 3

LOCK TAB

1

IVS GROUND

INSTALLATION

1. Install the assembled ET-2™ treadle on the vehicle.

2. Reconnect the cable connector by plugging it into the

potentiometer’s integral connector and pushing until

the lock tab snaps into place.

DISASSEMBLY

The following instructions present a major disassembly of

the ET-2™ treadle. They are included for reference only.

Several replacement parts and maintenance kits that do

not require full disassembly are available. The instructions

provided with those items should be followed in lieu of the

steps presented here. Refer to Figure 4 throughout the

procedures.

1. Remove the treadle cover (1).

2. Remove the pivot pin’s snap ring (8).

3. Remove the pivot pin (9) and the two nyliner bearings

(10) from the treadle’s exterior. Also remove the two

nyliner bearings (10) from the mounting base.

4. Remove the pivot spring (11).

5. Remove the screws (3) that secure the potentiometer

(2) to the treadle. Remove the potentiometer.

6. Remove the lever shaft’s snap ring (5).

7. Remove the lever shaft (4) and the washer (7). Then

remove the roller assembly (15), the inner washer (5),

and the nyliner bearing (6) from the treadle. Separate

the treadle from the mounting base.

6

8. The roller assembly consists of the lever, roller, two

springs (12 & 13), and a spring support (14). Remove

the springs and the spring support from the lever.

CLEANING & INSPECTION

1. Use mineral spirits or an equivalent solvent to clean all

metal parts. Be sure to thoroughly dry the parts.

2. Inspect the treadle and mounting base for severe

corrosion, pitting, or cracks. Replace as necessary.

Superficial corrosion and/or pitting is acceptable.

3. Inspect the cable assembly for loose or frayed wires,

physical damage, or any contaminants on the

connectors. Check end-tend electrical continuity at

terminals. Replace as necessary.

ASSEMBLY

Refer to Figure 4 throughout the assembly procedure.

1. Install the four nyliner bearings (10) on the mounting

base and treadle.

2. Place the treadle “ears” outside the mounting base

“ears” so that the holes line up.

3. Install the pivot spring (11) into the base and treadle.

The curved end of the spring fits into a small hole in the

treadle, and the straight end fits into a small hole in the

mounting base.

4. The pivot pin (9) should slide through the holes in the

“ears” of the treadle and base assembly, then through

the center of the spring. Secure the pin with its snap

ring (8). Make sure the pivot spring is straight and is

seated in its holes.

Page 7

5. The installation of the remaining components is much

easier if the inner and outer springs (12 & 13) are

compressed and caged. This can be done with a short

piece of wire, or even a paper clip. The springs should

be compressed so that their ends are approximately

one inch apart.

6. Place the spring support (14) inside the caged spring

assembly. Then insert the springs into the roller

assembly (15). The curved ends of the springs fit over

the small bar directly behind the roller.

7. In order to install the lever shaft (4), the roller assembly,

with its springs and spring support, and the washers

(5 & 7) must be aligned. This can be done by resting

™

the ET-2

treadle on its side, with the smaller ear of the

treadle facing up. Insert the washers as shown in Figure

4. Washer (5) has the larger diameter (.520"). While

holding the roller assembly in place, push the lever shaft

through the treadle ears.

8. With the ET-2

™

treadle on its side, as mentioned above,

the lever shaft should protrude from the treadle with its

snap ring groove visible. Secure the lever shaft with its

snap ring (8).

9. Turn the ET-2™ treadle upright. Place the potentiometer

(2) in the position shown in Figure 4, with its connector

facing the rear of ET-2™ treadle. Secure the

potentiometer with its screws (3). Torque to 20 inch

pounds (+/-5).

10. Install the treadle cover (1) and cable assembly as shown

in Figure 4. Clip the wire from the spring assembly so

that the straight end of the springs rest against the

underside of the treadle.

1 1. Make sure the ET-2™ treadle has smooth, even treadle

movement. Also, perform Operational Test steps 3-7

™

before installing the ET -2

12.Install the ET-2

™

treadle on the vehicle.

treadle.

7

Page 8

8

BW1650 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 6/2004 Printed in U.S.A.

Loading...

Loading...