Page 1

®

Bendix® EC-60™ ABS / ATC / ESP Controllers (Advanced)

See SD-13-4863 for Standard and Premium Controllers

See SD-13-21021 for the Bendix

®

eTrac™ Automated Air Suspension Transfer System

The driver is always responsible for the control

and safe operation of the vehicle at all times. The

Bendix® ESP® stability system does not replace the

need for a skilled, alert professional driver, reacting

appropriately and in a timely manner, and using safe

driving practices.

SD-13-4869

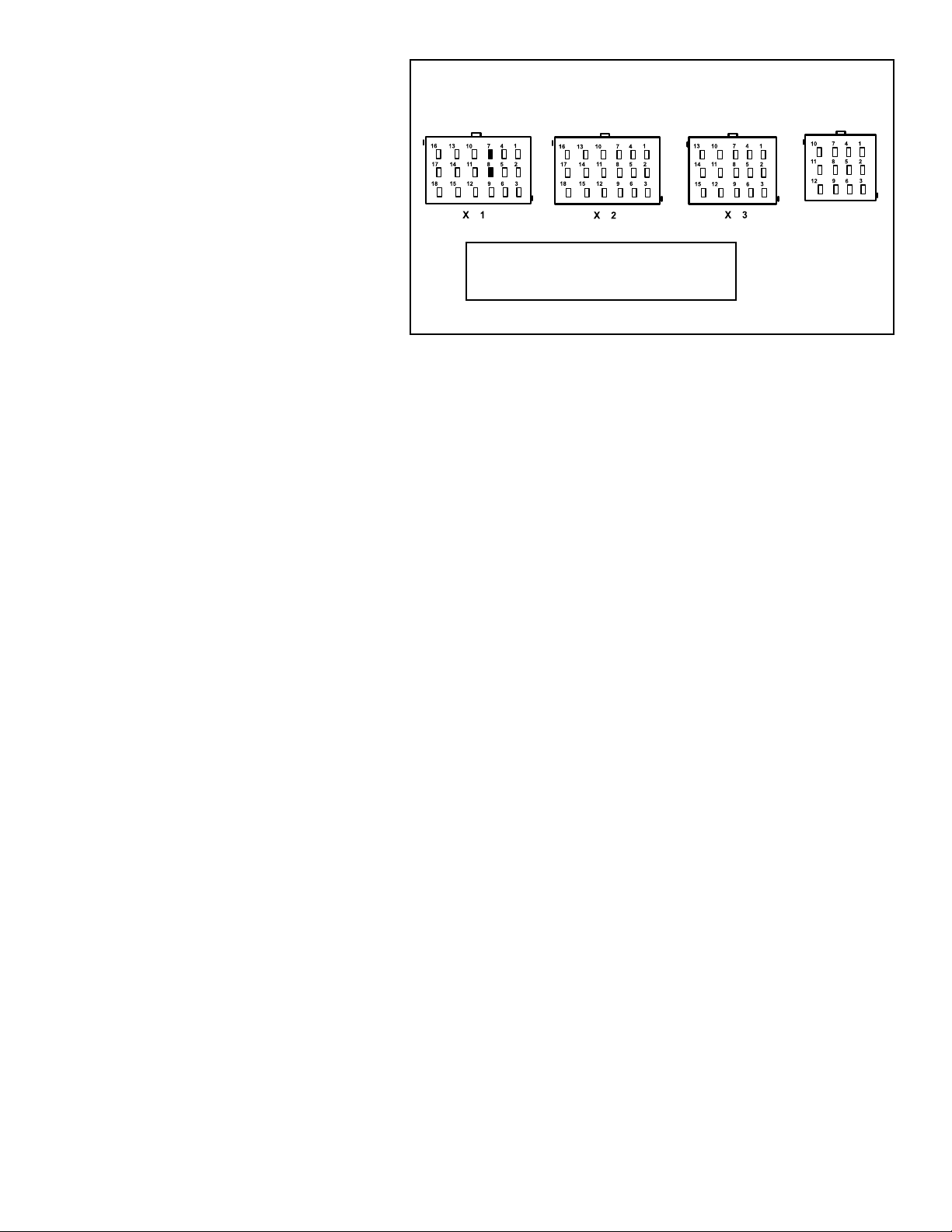

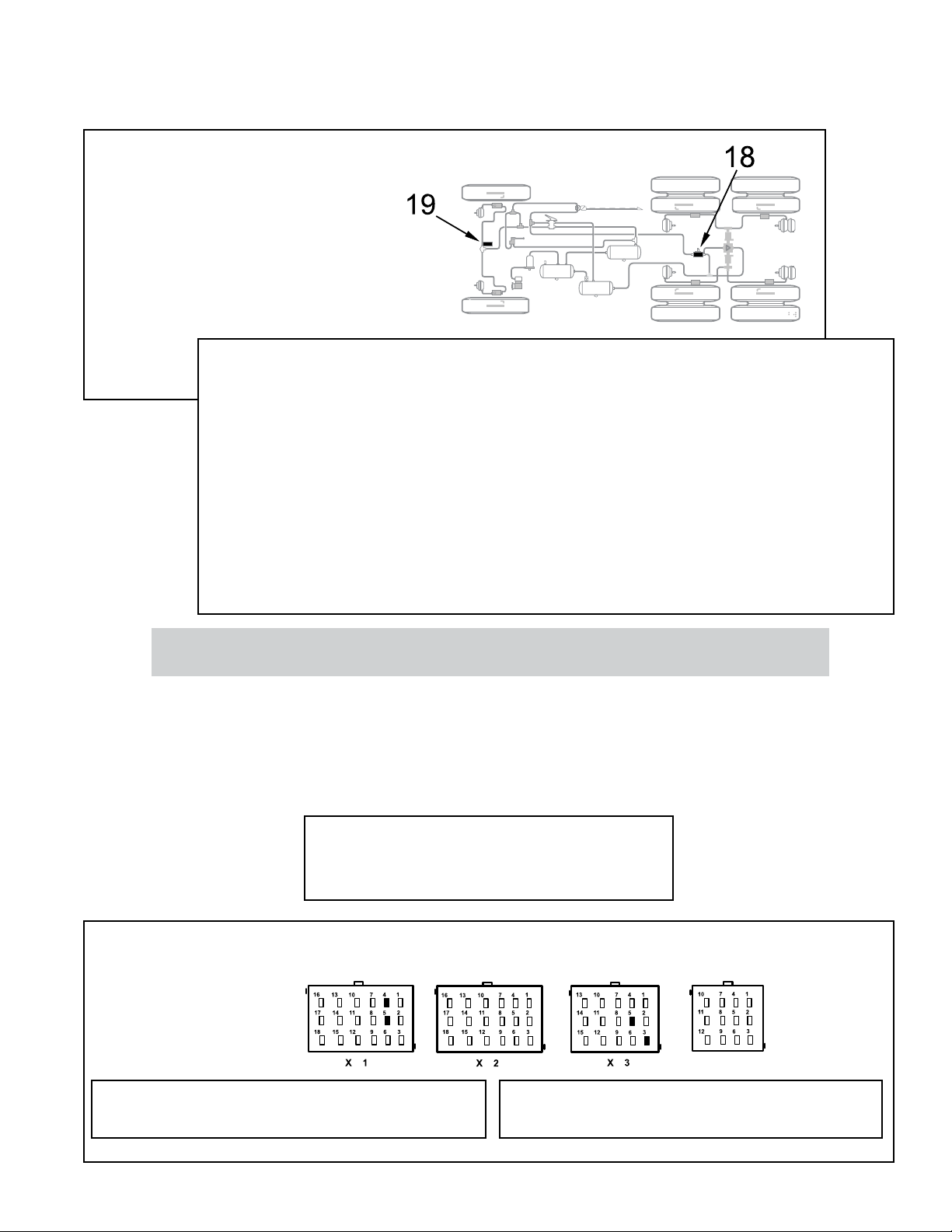

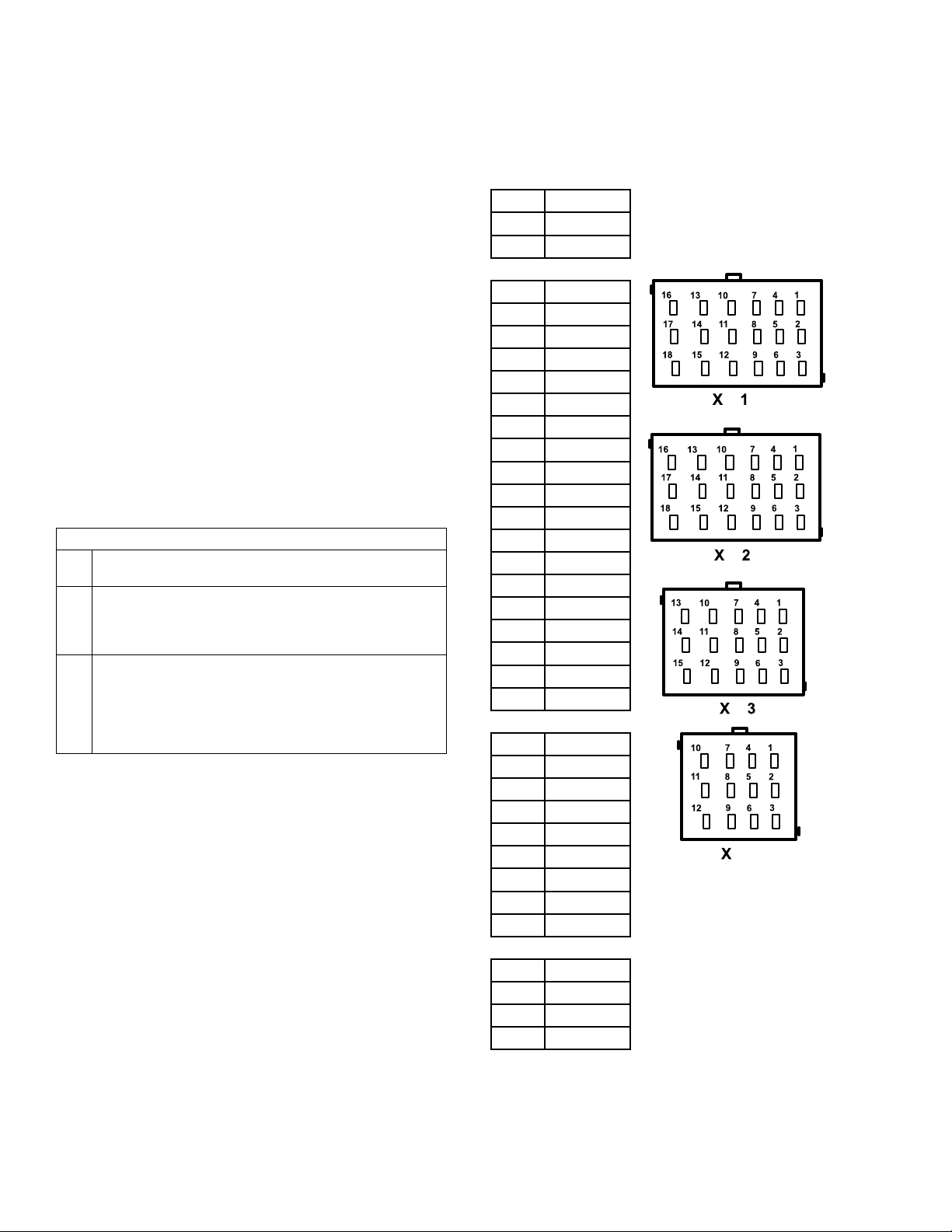

All Four Connectors Are Used.

(If only two or three connectors are in

use - see SD-13-4863)

™

FIGURE 1 - EC-60

ADVANCED CONTROLLER

INTRODUCTION

The Bendix® EC-60™ advanced controller is a member

of a family of electronic Antilock Braking System

(ABS) devices designed to help improve the braking

characteristics of air braked vehicles - including heavy- and

medium-duty buses, trucks, and tractors. ABS controllers

are also known as Electronic Control Units (ECUs).

Bendix® ABS uses wheel speed sensors, ABS pressure

modulator valves, and an ECU to control either four or six

wheels of a vehicle. The Bendix EC-60 controller monitors

individual wheel turning motion during braking and adjusts

or modulates the brake pressure at the wheel end. When

excessive wheel slip, or wheel lock-up is detected, the

Bendix EC-60 controller will activate the pressure modulator

valves to automatically reduce the brake pressure at one

or more of the wheel ends. By these actions, the ABS

system helps to maintain the vehicle's lateral stability and

steerability during heavy brake applications and during

braking on slippery surfaces.

In addition to the ABS function, advanced models of the

EC-60™ controller provide ABS-based stability features

referred to as ESP® Electronic Stability Program. The

Bendix ESP system is an ABS-based stability system that

enhances vehicle stability by both reducing engine throttle

and by applying vehicle braking based on actual vehicle

dynamics. Accordingly, the ESP system is available only on

specic approved vehicle platforms after vehicle application

and development efforts and validation testing. Only

certain limited variations of an approved vehicle platform

are permitted without further validation of the ESP system

application.

ESP stability system consists of Yaw Control (YC) and Roll

Stability Program (RSP) features.

ESP® is a registered trademark of DaimlerChrysler and is used by BCVS under license from DaimlerChrysler.

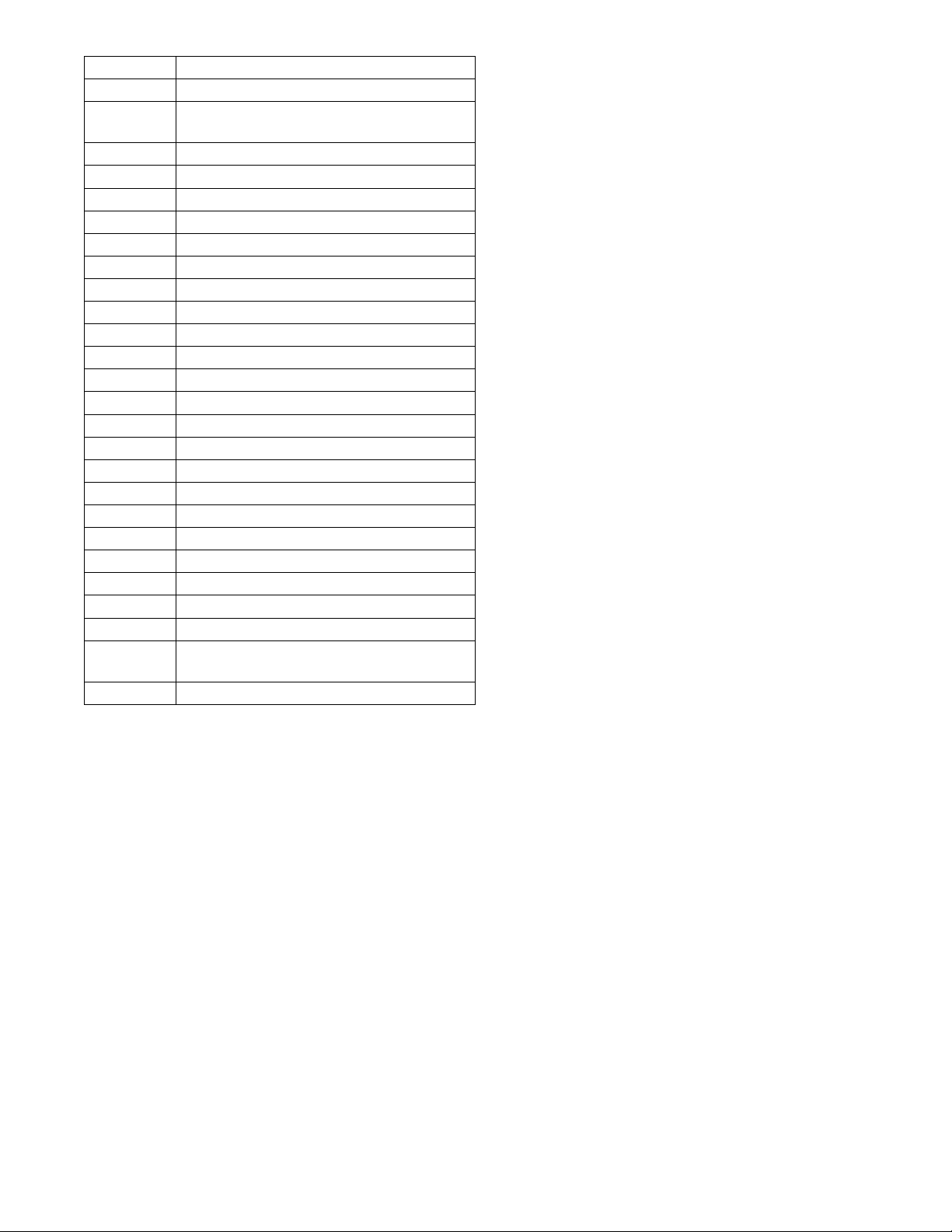

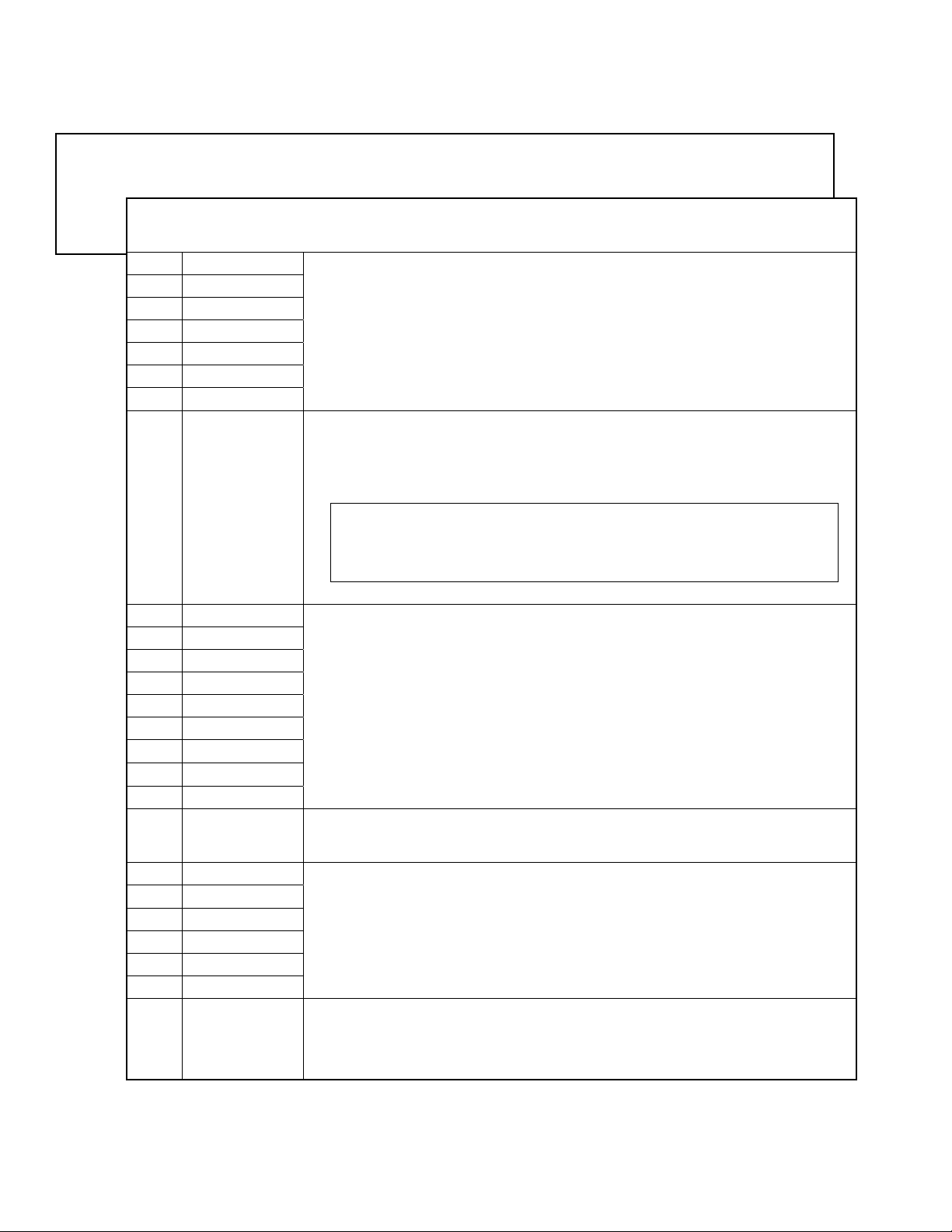

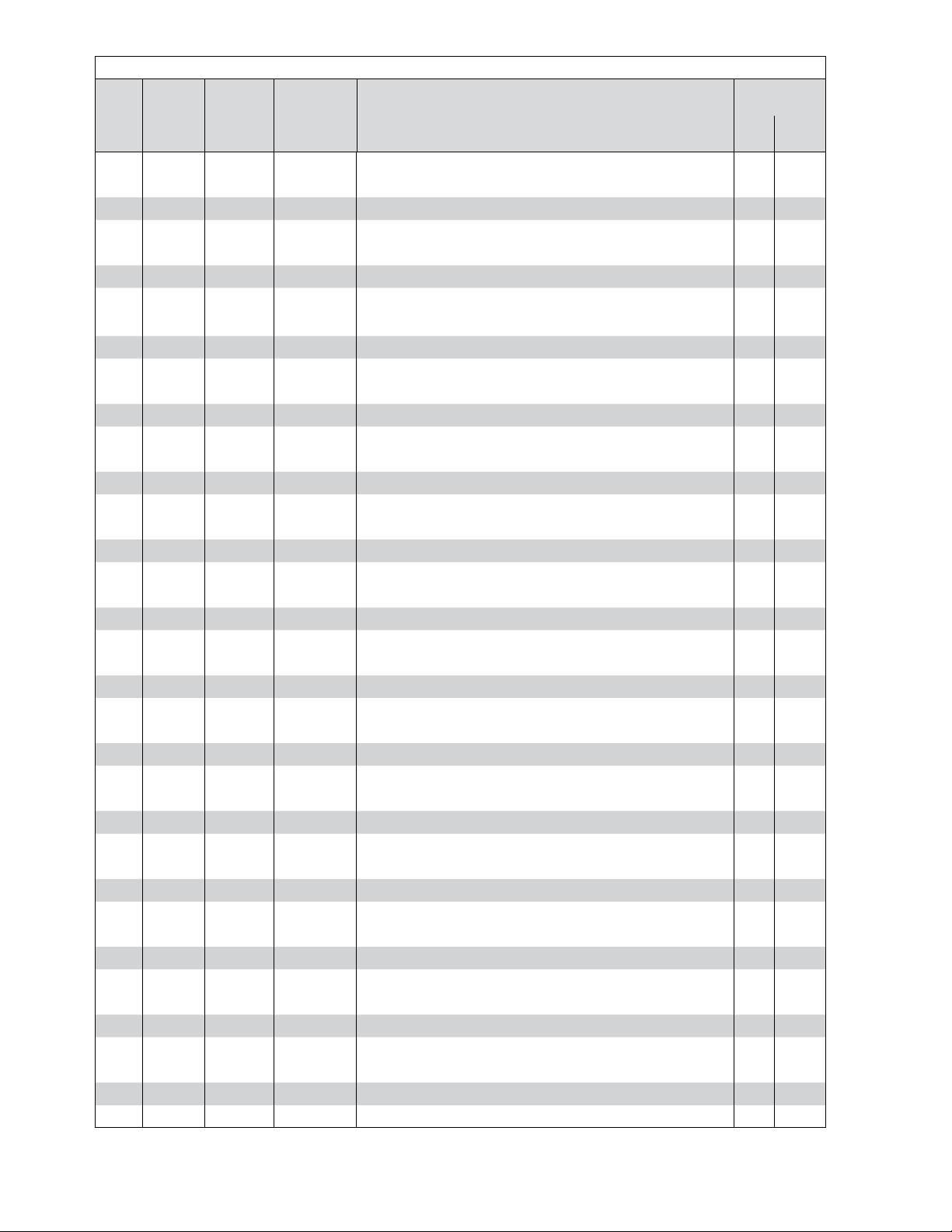

TABLE OF CONTENTS PAGE

General System Information

Introduction. . . . . . . . . . . . . . . . . . . . . . . 1

Components . . . . . . . . . . . . . . . . . . . . . 3-4

HardwareCongurations . . . . . . . . . . . . . . . 4

Bendix EC-60 Controller Inputs & Outputs . . . . . 5-7

Indicator Lamps and Power-Up Sequence . . . . . 8-9

ABS Operation . . . . . . . . . . . . . . . . . . . . . 9

ATC Operation . . . . . . . . . . . . . . . . . . 11-12

Advanced ABS With Stability . . . . . . . . . . 12-13

Important Safety Information About

The ESP Stability System . . . . . . . . . . . . 13-14

Dynamometer Test Mode . . . . . . . . . . . . . . 14

System Impact During Active Trouble Codes . . . 15

SystemReconguration . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . 17-48

Sensor Calibration . . . . . . . . . . . . . . . . 17-19

Blink Codes and Diagnostic Trouble Codes . . 21-23

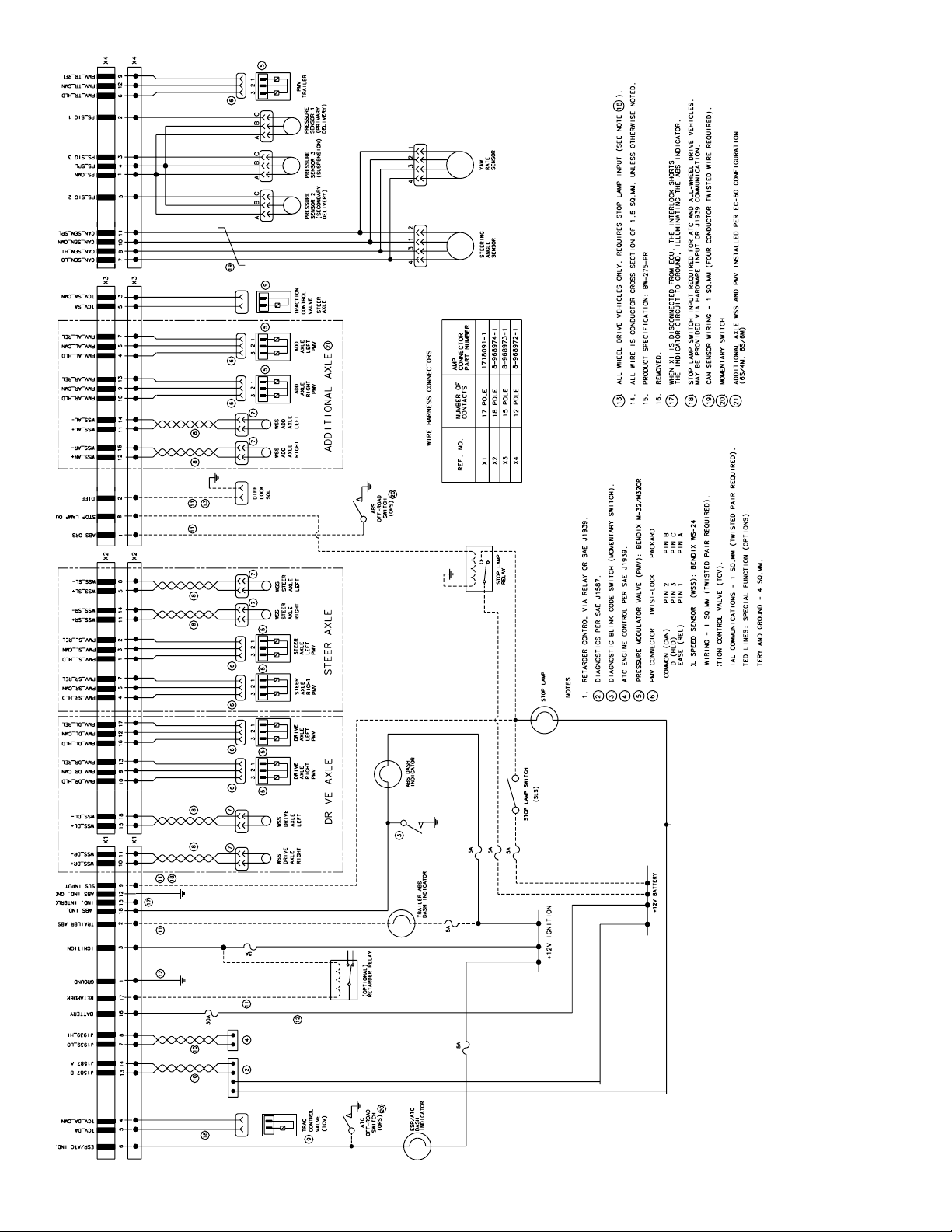

Wiring Schematic . . . . . . . . . . . . . . . . . . 48

Glossary. . . . . . . . . . . . . . . . . . . . . . . . 49

J1587 SID and FMI Codes . . . . . . . . . . . . 51-55

UDS Codes . . . . . . . . . . . . . . . . . . . . 56-60

Additional features include Automatic Traction Control

(ATC). Bendix ATC can improve vehicle traction during

acceleration, and lateral stability while accelerating through

curves. ATC utilizes Engine Torque Limiting (ETL)

where the ECU communicates with the engine’s controller

and/or Differential Braking (DB) where individual wheel

brake applications are used to improve vehicle traction.

Advanced Bendix EC-60 controllers have a drag torque

control feature which reduces driven-axle wheel slip (due

to driveline inertia) by communicating with the engine’s

controller and increasing the engine torque.

For vehicles with the Hill Start Feature optional feature,

this system interfaces between the transmission and

braking system to help the driver prevent the vehicle from

rolling downhill when moving up a steep incline from a

stationary position.

1

Page 2

CAUTION

Even with ESP-equipped vehicles, the driver remains

responsible for ensuring vehicle stability during operation.

The ESP system can only function within the limits of

physics. ESP functionality mitigates potential vehicle

stability incidents, but cannot prevent them in all cases.

Other factors such as driving too fast for road, trafc or

weather conditions, oversteering, an excessively high

vehicle Center of Gravity (CG), or poor road conditions can

cause vehicle instability that is beyond the capability of any

stability system to mitigate. In addition, the effectiveness

of ESP can be greatly reduced on vehicles towing multiple

trailer combinations.

2

CAUTION

The ESP stability system may only be used on vehicles

tested and approved by Bendix engineering. ESP

installations require on-vehicle testing and Bendix® EC-60™

parameter tuning. See "Advanced ABS with Stability

Control" on page 12 for further details.

Accordingly, the Bendix EC-60 controller is provided with

a corresponding parameter data set that is validated for

a specic vehicle platform. Therefore, specic steps are

necessary should a replacement ECU be required. See

“Obtaining a New Bendix EC-60 Advanced Controller” on

page 18 for further details.

ESP-equipped vehicles should not be driven on highbanked roads – such as those found on high-speed test or

race tracks. Test personnel must have ESP functionality

disabled prior to operating an ESP vehicle on such tracks.

Page 3

YAW CONTROL (YC)

Advanced ECU can include Yaw Control (YC) functionality,

which has the ability to apply brakes to individual wheel

ends, as well as applying the trailer brakes, to counteract

trailer “push” that, during certain maneuvers, could lead to

a loss-of-control or a jackknife incident. See "Yaw Stability"

on page 9 for further details.

Delivery

(Port 2)

Supply

(Port 1)

ROLL STABILITY PROGRAM (RSP)

The Bendix Roll Stability Program (RSP), is an all-axle

ABS solution that helps reduce vehicle speed by reducing

the engine's throttle and applying all vehicle brakes as

needed, reducing the vehicle's tendency to roll over. RSP

focuses on reducing the vehicle’s speed below the critical

roll threshold during direction-changing maneuvers such as

driving on curved highway exit ramps or obstacle avoidance

maneuvers on dry, high friction surfaces. See "Advanced

ABS with Stability Control" on page 12 for further details.

WARNING

During an RSP system intervention, the vehicle

automatically decelerates. RSP can slow the vehicle

with or without the operator applying the brake pedal,

and even when the operator is applying the throttle.

COMPONENTS

The Bendix EC-60 controller’s ABS function utilizes the

following components:

• Bendix® WS-24™ wheel speed sensors (4 or 6,

depending on configuration). Each sensor is

installed with a Bendix Sensor Clamping Sleeve

• Bendix® M-32™ or M-32QR™ Pressure Modulator

Valves (4, 5, or 6 depending on conguration)

• Dash-mounted tractor ABS Indicator Lamp

• Service brake relay valve

• Dash-mounted trailer ABS Indicator Lamp

• Optional blink code activation switch

• Optional ABS off-road switch

Sensor

90° Speed

Sensors

Clamping

Sleeve

Electrical

M-32QR

Modulator

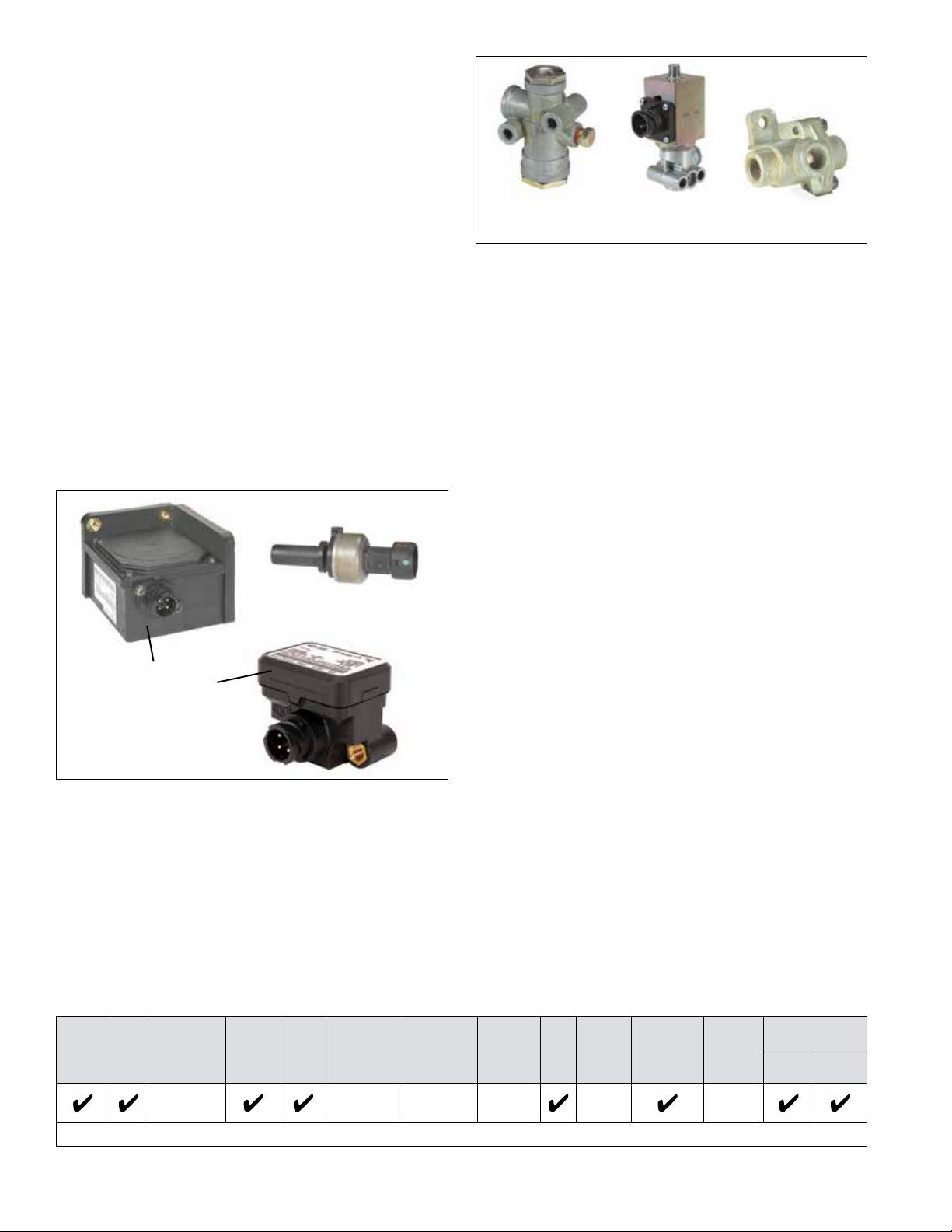

FIGURE 3 - M-32™ AND M-32QR™ MODULATORS

™

Connector

Exhaust (Port 3)

™

M-32

Modulator

The Bendix EC-60 controller ESP/RSP function utilizes the

following additional components:

• Steer Axle Traction Control Valve (may be integral

to the service brake relay valve or a stand-alone

device)

• Dash-mounted ESP status/indicator lamp (also

serves as the ATC status/indicator lamp)

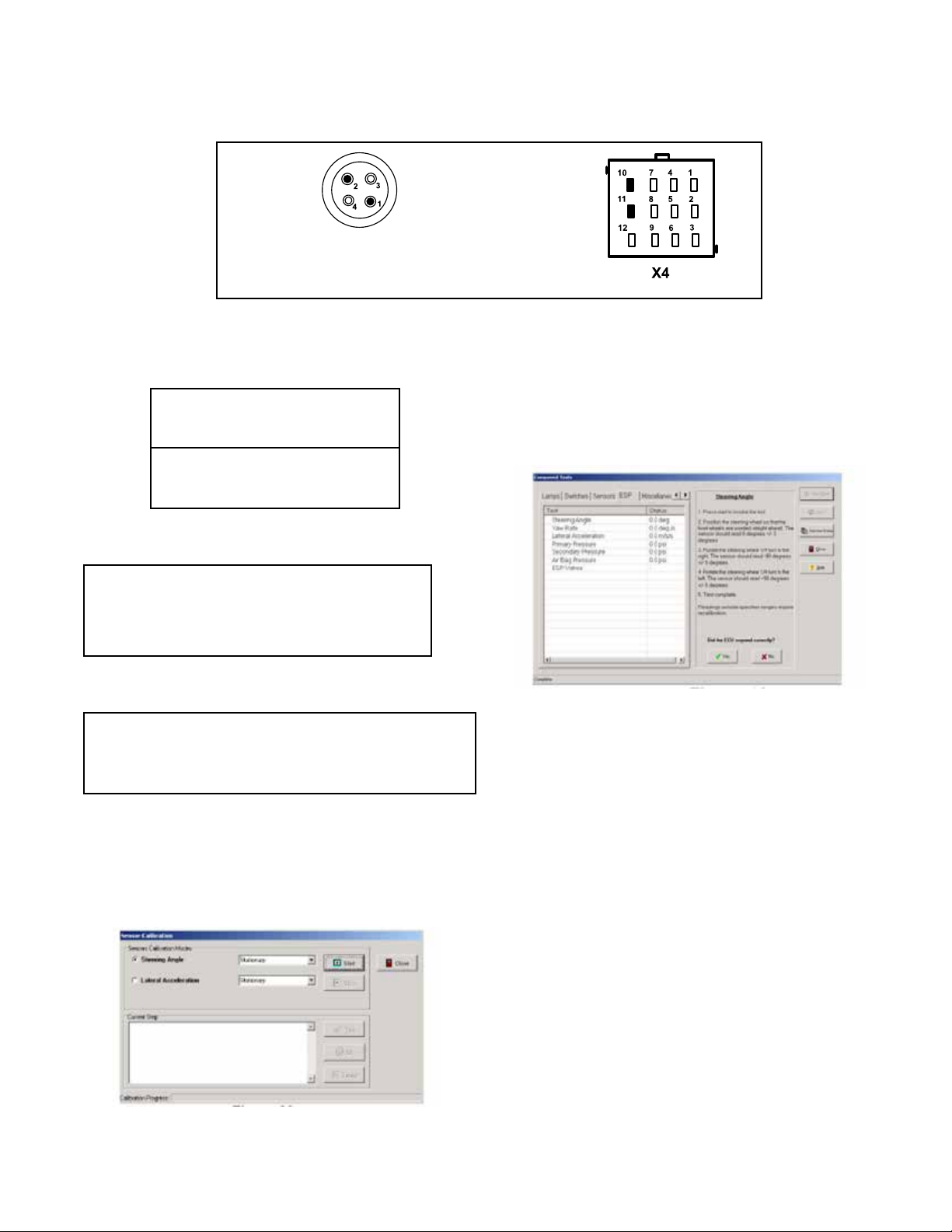

• Bendix SAS-60™ Steering Angle Sensor (mounted

to the steering column - See Figure 4)

CAUTION: When replacing a steering wheel,

take care not to damage the Steering Angle Sensor

or interfere with its operation, and the Steering Angle

Sensor must be recalibrated (see Troubleshooting

section)

• Bendix® YAS-60™ or YAS-70X™ Yaw Rate/Lateral

Acceleration Sensors (typically mounted to a crossmember near the back of the vehicle cab)

• Brake Demand Sensors (installed in the primary

and secondary delivery circuits)

• Load Sensor (typically installed in the suspension

air bag)

• An additional Modulator Valve (Bendix® M-32™ or

M-32QR™ Pressure Modulator Valve) that controls

pressure apply to trailer brakes during system

intervention

Straight Speed

Sensors

FIGURE 2 - BENDIX® WS-24™ WHEEL SPEED SENSORS

Straight

Connector

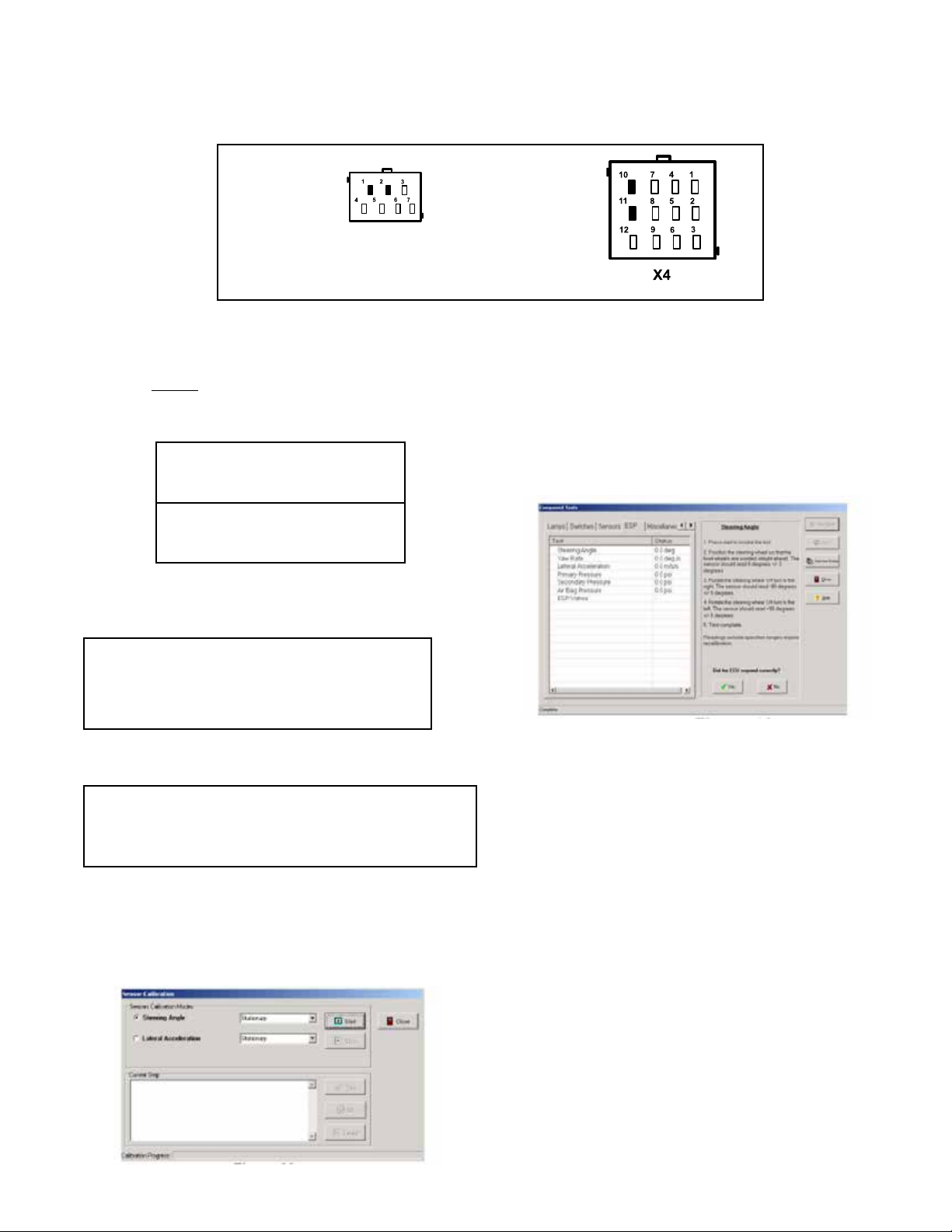

FIGURE 4 - STEERING ANGLE SENSORS

90°

Connector

3

Page 4

The Bendix® EC-60™ controller ATC function utilizes the

following additional components:

• Drive axle traction control valve (may be integral

to the service brake relay valve or a stand-alone

device)

• Dash-mounted ATC status/indicator lamp

• J1939 serial communication to engine control

module

• Stop lamp switch input (may be provided using the

ECU hardware input or J1939)

• Optional ATC mud/snow switch (sometimes referred

to as an ATC off-road switch)

The EC-60 controller Hill Start Feature utilizes the following

additional components:

• Bendix® AT-3™ Traction control valve

• Dash-mounted HSA Status/indicator lamp

• Dash-mounted enable/disable Switch

• Bendix® RV-3™ Pressure reducing valve

• Bendix® DC-4® Double check valve

Brake Demand/

Load Sensor

®

Bendix® RV-3

Pressure

Reducing Valve

FIGURE 6 - ADDITIONAL VALVES NECESSARY FOR THE

HILL START FEATURE

™

Bendix® AT-3

Traction Control

Valve

™

Bendix

Double Check

Valve

DC-4

®

BENDIX® ETRAC™ AUTOMATED AIR

SUSPENSION TRANSFER SYSTEM

The Bendix® eTrac™ automated air pressure transfer

system is used on 6 x 2 semi-tractors that feature Bendix®

premium and advanced Antilock Brake Systems (ABS).

This system complements the Bendix® Smart Automatic

Traction Control (ATC™) feature of our ABS system to

provide improved traction at low speeds (e.g. pulling away

on an inclined ramp, or in slippery conditions such as mud

or snow-covered surfaces, etc.) When active, the Bendix

eTrac system vents — or “dumps” — the air pressure of

the tag axle suspension air bags, and increases the air

pressure in the drive axle suspension air bags to a predetermined maximum. This action helps the drive axle to

gain more traction.

See SD-13-21021 for more information.

Yaw/Lateral

Accelerator Sensors

(Two examples

shown.)

FIGURE 5 - YAW AND BRAKE DEMAND/LOAD SENSORS

ABS

Off-

Road

ATC

ATC

Mud/Snow

Blink

Codes

ESP/

RSP

HSA

Bendix

eTrac

system*

Optional Optional Optional 12/24 4/5/6 4/6

ECU MOUNTING

The Bendix® EC-60™ advanced cab-mounted controller is

not protected against moisture, and must be mounted in

an environmentally protected area.

All wire harness connectors must be properly seated. The

use of secondary locks is strongly recommended.

Cab ECUs utilize connectors from the AMP MCP 2.8

product family.

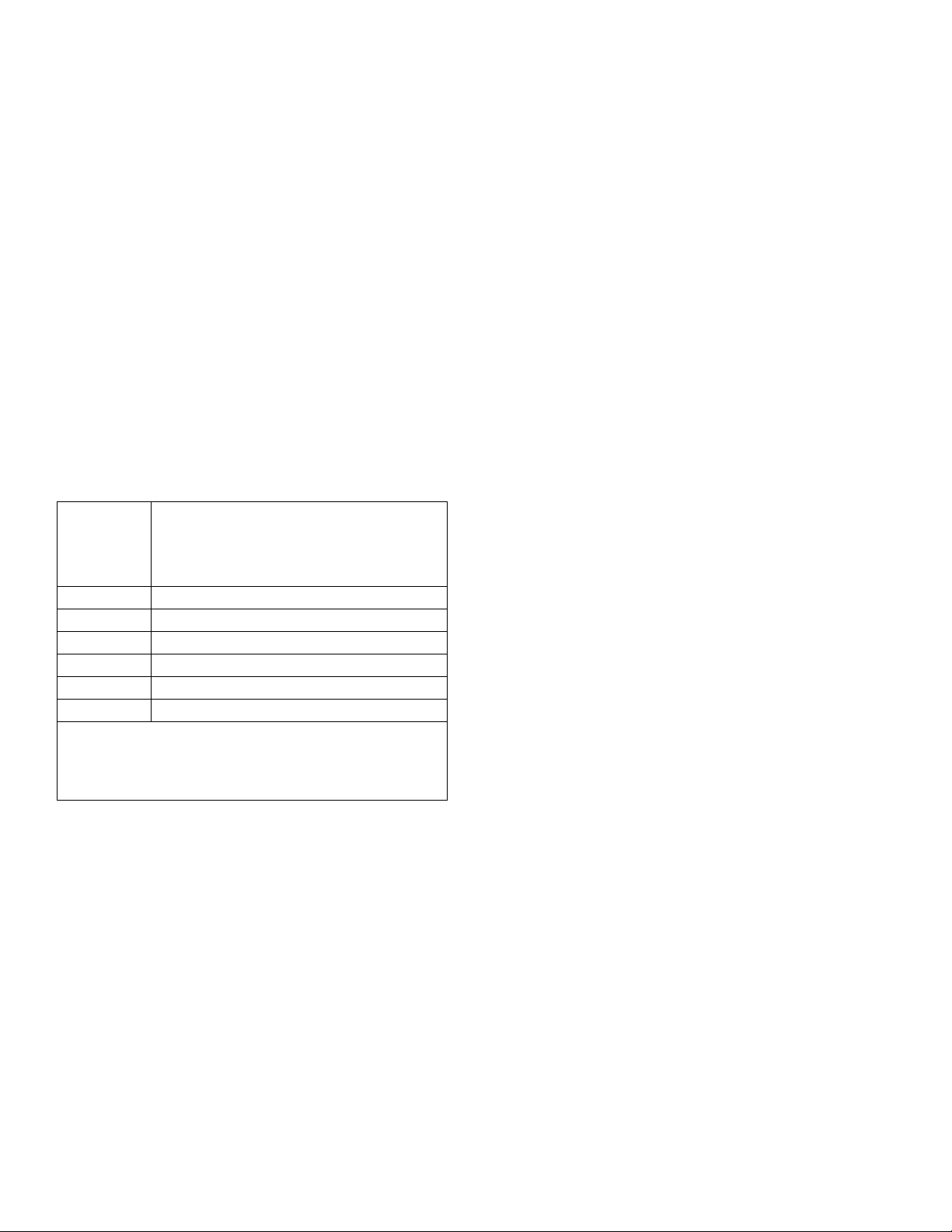

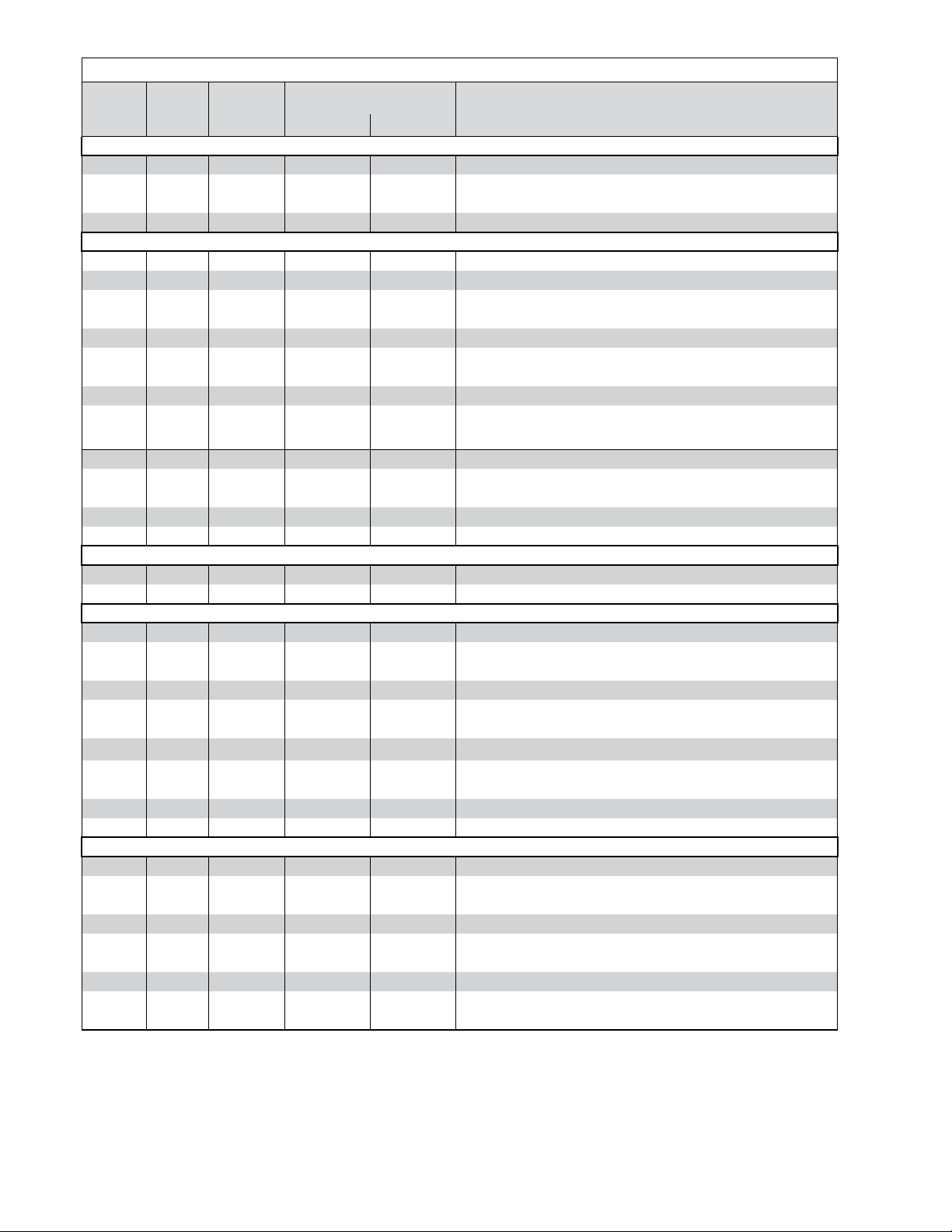

HARDWARE CONFIGURATIONS

Advanced Bendix® EC-60™ controllers support applications

up to six sensor/six modulator (6S/6M) installations with

ATC and drag torque control. They can support HSA

functions. All 12 volt models support PLC. 24 volt models

do not support PLC. See Chart 1 for more details.

®

™

Voltage

Input

PLC PMVs

Retarder

Relay

Sensors

Serial

Communication

J1587 J1939

For information about the Bendix® eTrac™ automated air suspension transfer system, see SD-13-21021

*

CHART 1 - BENDIX

4

®

EC-60™ ADVANCED CONTROLLER FEATURES

Page 5

ADVANCED BENDIX EC-60 CONTROLLERS

USE POWER LINE CARRIER (PLC)

All new towing vehicles built since March 1, 2001 have had

an in-cab trailer ABS Indicator Lamp installed.

Trailers built since March 1, 2001 transmit the status of

the trailer ABS over the power line (the blue wire of the

J560 connector) to the tractor using a Power Line Carrier

(PLC) signal. See Figures 7 and 8. Typically the signal is

broadcast by the trailer ABS ECU.

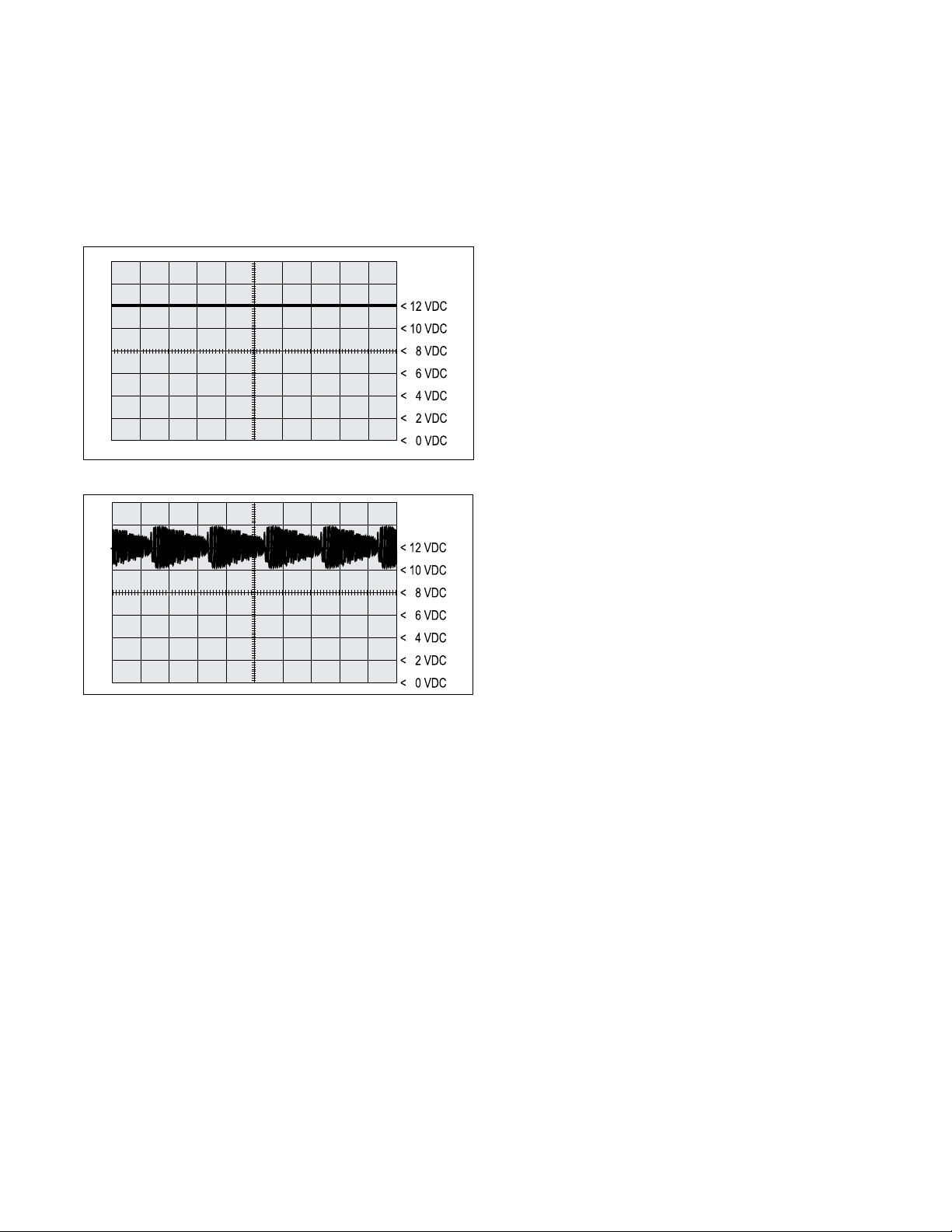

FIGURE 7 - POWER LINE WITHOUT PLC SIGNAL

FIGURE 8 - POWER LINE WITH PLC SIGNAL

The application of PLC technology for the heavy vehicle

industry in North America is known as “PLC4Trucks.”

The Advanced Bendix EC-60 controller supports PLC

communications in accordance with SAE J2497.

PLC SIGNAL

An oscilloscope can be used to measure or identify the

presence of a PLC signal on the power line. The PLC

signal is an amplitude and frequency modulated signal.

Depending on the ltering and load on the power line, the

PLC signal amplitude can range from 5.0mVp-p to 7.0

Vp-p. Suggested oscilloscope settings are AC coupling,

1 volt/div, 100 µsec/div. The signal should be measured

at the ignition power input of the Bendix EC-60 controller.

Note: An ABS trailer equipped with PLC, or a PLC

diagnostic tool, must be connected to the vehicle in order

to generate a PLC signal on the power line.

BENDIX EC-60 CONTROLLER INPUTS

Battery and Ignition Inputs

The ECU operates at a nominal supply voltage of 12 or

24 volts, depending on the ECU. The battery input is

connected through a 30 amp fuse directly to the battery.

The ignition input is applied by the ignition switch circuit

through a 5 amp fuse.

Ground Input

The Bendix EC-60 controller supports one ground input.

See page 48 for a system schematic.

ABS Indicator Lamp Ground Input

Advanced Bendix EC-60 cab ECUs require a second

ground input (X1-12) for the ABS indicator lamp. The X1

wire harness connector contains an ABS indicator lamp

interlock (X1-15), which shorts the ABS indicator lamp

circuit (X1-18) to ground if the connector is removed from

the ECU.

Bendix® WS-24™ Wheel Speed Sensors

Wheel speed data is provided to the Bendix EC-60

controller from the WS-24™ wheel speed sensor (see Figure

2). Vehicles have an exciter ring (or “tone ring”) as part of

the wheel assembly, and as the wheel turns, the teeth of

the exciter ring pass the wheel speed sensor, generating

an AC signal. The Bendix EC-60 controller receives the

AC signal, which varies in voltage and frequency as the

wheel speed changes.

Vehicle axle configurations determine the number of

WS-24™ wheel speed sensors that must be used. A vehicle

with a single rear axle requires four wheel speed sensors.

Vehicles with two rear axles can utilize six wheel speed

sensors for optimal performance.

Diagnostic Blink Code Switch

A momentary switch that grounds the ABS Indicator Lamp

output is used to place the ECU into the diagnostic blink

code mode and is typically located on the vehicle’s dash

panel.

5

Page 6

Optional ABS Off-Road Switch and Indicator

Lamp Operation

Advanced Bendix EC-60 controllers use an optional dashmounted switch for the operator to place the ECU into the

ABS off-road mode. See "Optional ABS Off-Road Mode"

on page 10 for further details. In some cases, ECUs may

also be put into the ABS off-road mode by one of the other

vehicle control modules, using a J1939 message to the

Bendix EC-60 controller.

(If you need to know if this Bendix EC-60 controller uses

a J1939 message to operate the lamp, e-mail ABS@

bendix.com, specifying the ECU part number, or call

1-800-AIR-BRAKE and speak to the Bendix TechTeam.)

WARNING: The ABS off-road mode should not be

used on normal, paved road surfaces because vehicle

stability and steerability may be adversely affected. When

the ECU is placed in the ABS off-road mode, the ABS

Indicator Lamp will ash constantly (at a rate of once per

2.5 seconds) to notify the vehicle operator that the off-road

mode is active.

Optional ATC Mud/Snow (Off-Road) Switch and

Indicator Lamp Operation (see also page 8.)

Advanced controllers use a dash-mounted switch for the

operator to place the ECU into the ATC Mud/Snow mode.

Optional Hill Start Feature Switch and Indicator

Lamp Operation (see also page 8.)

Advanced controllers use a dash-mounted switch for the

operator to place the ECU into the Hill Start Assist (HSA)

mode. HSA interfaces between the transmission and

braking system to help the driver prevent the vehicle from

rolling downhill when moving up a steep incline from a

stationary position.

WARNING: With HSA option you lose the ABS off-

road function and the retarder relay output.

When the ECU is placed in the HSA off-road mode, the

HSA Indicator Lamp will ash constantly (at a rate of once

per 2.5 seconds) to notify the vehicle operator that the HSA

mode is active. The ECU receives J1939 messages from

the transmission to engage the HSA components. When

engaged, the HSA system applies 44 psi to the rear brakes

for three (3) seconds then releases. This function is totally

controlled by the automatic transmission.

Stop Lamp Switch (SLS)

The Advanced Bendix EC-60 controller monitors the

vehicle stop lamp status. Certain vehicle functions, such

as ATC and All-Wheel Drive (AWD), use the status of the

stop lamp to determine when the driver makes a brake

application. This can be provided to the ECU via J1939

communications, or hardware input.

Brake Demand Sensors

The brake demand sensors provide the controller with an

indication of driver-applied brake pressure. One is installed

in the primary air brake circuit, and another is installed in

the secondary air brake circuit.

Load Sensor

The load sensor provides the controller with an indication

of the vehicle load. It is typically installed in one of the

suspension air bags.

Bendix® SAS-60™ Steering Angle Sensor

The Steering Angle Sensor (SAS) is used to provide driver

steering input to the controller. It reports the steering

wheel position to the controller utilizing a dedicated serial

communications link that is shared with the Yaw Rate

sensor. The controller supplies the power and ground

inputs to the Bendix SAS-60 sensor.

The Bendix SAS-60 sensor is available with two different

styles of wire harness connectors. (See Figure 4.)

Bendix® YAS-60™ or YAS-70X™ Yaw Rate/Lateral

Acceleration Sensors

Bendix yaw rate/lateral acceleration sensors are used

to provide the controller an indication of vehicle lateral

acceleration and rotation around the vertical axis. This

information is provided to the controller utilizing a dedicated

serial communications link that is shared with the Bendix

SAS-60 sensor. The controller supplies the power and

ground inputs to the yaw rate sensor.

BENDIX® EC-60™ CONTROLLER OUTPUTS

Bendix® M-32™ and M-32QR™ Pressure

Modulator Valves (PMV)

The Bendix M-32 and M-32QR pressure modulator valves

(PMV) are operated by the Bendix EC-60 controller to

modify driver applied air pressure to the service brakes

during ABS, ATC, RSP or YC activation (See page 3).

The PMV is an electropneumatic control valve and is the

last valve that air passes through on its way to the brake

chamber. The modulator hold and release solenoids are

activated to "modulate" or "control" the brake pressure

during an antilock braking event. The hold solenoid is

normally open and the release solenoid is normally closed,

such that the PMV nominally allows air to ow through.

This design allows for air delivery to brake chambers in

the event of electrical trouble.

The Advanced Bendix EC-60 controller also utilizes an

additional PMV for control of the trailer service brakes

during stability interventions.

6

Page 7

Traction Control Valve (TCV)

Advanced Bendix EC-60 controllers use two TCVs, one on

the steer axle and one on the drive axle. The TCV may be

a separate valve or integrated into the rear axle relay valve.

The controller will activate the drive axle TCV during

differential braking ATC events.

During stability interventions, the ECU will activate both

the steer axle and drive axle TCVs as required.

Stop Lamp Output

The controller provides an output to control a relay

that illuminates the vehicle stop lamps during stability

interventions. This information is also available using the

J1939 serial communications link.

ABS Indicator Lamp Control with Optional

Diagnostic Blink Code Switch

The Advanced Bendix EC-60 controller has internal circuitry

to control the ABS Indicator Lamp on the dash panel.

The ABS Lamp Illuminates:

1. During power up (e.g. when the vehicle is started) for

approximately 3 seconds and turns off after the self test

is completed, providing no Diagnostic Trouble Codes

(DTCs) are present on the ECU.

2. When full ABS operation is not available due to

presence of a DTC on the ECU.

3. If the ECU is unplugged or has no power.

4. When the ECU is placed into the ABS off-road mode

(the lamp ashes steadily at a rate of once per 2.5 sec.).

5. To display blink codes for diagnostic purposes after the

external diagnostic switch is activated.

The Bendix EC-60 controller may communicate with other

vehicle control modules to operate the ABS Indicator Lamp

using serial communications. (If you need to know if this

Bendix® EC-60™ controller uses serial communications to

operate the lamp, e-mail ABS@bendix.com, specifying the

ECU part number, or call 1-800-AIR-BRAKE and speak to

the Bendix Tech Team.)

Indicator Lamp Control Using Serial

Communications Links

As mentioned above, depending on the vehicle

manufacturer, the dash indicator lamps (ABS, ATC,

ESP and trailer ABS) may be controlled using serial

communications links. In these cases, the EC-60™

controller will send a serial communications message over

the J1939 or J1587 links indicating the required status of

the lamp(s). Another vehicle control module receives the

message and controls the indicator lamp(s).

Dynamometer Mode Indicator Lamp Operation

When the Bendix® EC-60™ controller is put into the

Dynamometer mode for testing purposes, the ATC Indicator

Lamp will be illuminated.

Retarder Relay Disable Output

The retarder relay disable output may be used to control a

retarder disable relay. When congured to use this output,

the ECU will energize the retarder disable relay and inhibit

the use of the retarder as needed.

If the ECU is congured for Hill Start Assist (HSA), the

retarder relay output pin is used to control the HSA status

lamp. The vehicle loses the retarder relay function.

SAE J1939 Serial Communications

A Controller Area Network (CAN) data link (SAE J1939) is

provided for communication. This link is used for various

functions, such as:

• To disable retarding devices during ABS operation.

• To request that the torque converter disable lock-up

during ABS operation

• To share information such as wheel speed and ECU

status with other vehicle control modules.

Advanced Bendix EC-60 controllers utilize the J1939 data

link for:

• ATC and drag torque control functions.

• Vehicle stability functions.

Trailer ABS Indicator Lamp Control

The Advanced Bendix EC-60 controller will activate a

trailer ABS Indicator Lamp (located on the dash panel) that

indicates the status of the trailer ABS unit on one, or more

trailers, or dollies that are equipped with PLC functionality.

Typically, the Bendix EC-60 controller directly controls the

trailer ABS Indicator Lamp based on the information it

receives from the trailer ABS, via PLC.

Alternatively, some vehicles require the Bendix EC-60

controller to activate the trailer ABS Indicator Lamp by

communicating with other vehicle controllers using serial

communications.

(If you need to know if this Bendix EC-60 controller uses a

serial communications message to operate the lamp, e-mail

ABS@bendix.com, specifying the ECU part number, or call

1-800-AIR-BRAKE and speak to the Bendix TechTeam.)

SAE J1708/J1587 Serial Communications

An SAE J1708 data link, implemented according to SAE

J1587 recommended practice, is available for diagnostic

purposes, as well as ECU status messages.

Interaxle Differential Lock Control

(AWD Transfer Case)

Advanced ECUs can control the interaxle differential lock

(AWD transfer case). This is recommended on AWD

vehicles, but the ECU must be specially congured to

provide this feature. E-mail ABS@bendix.com for more

details.

7

Page 8

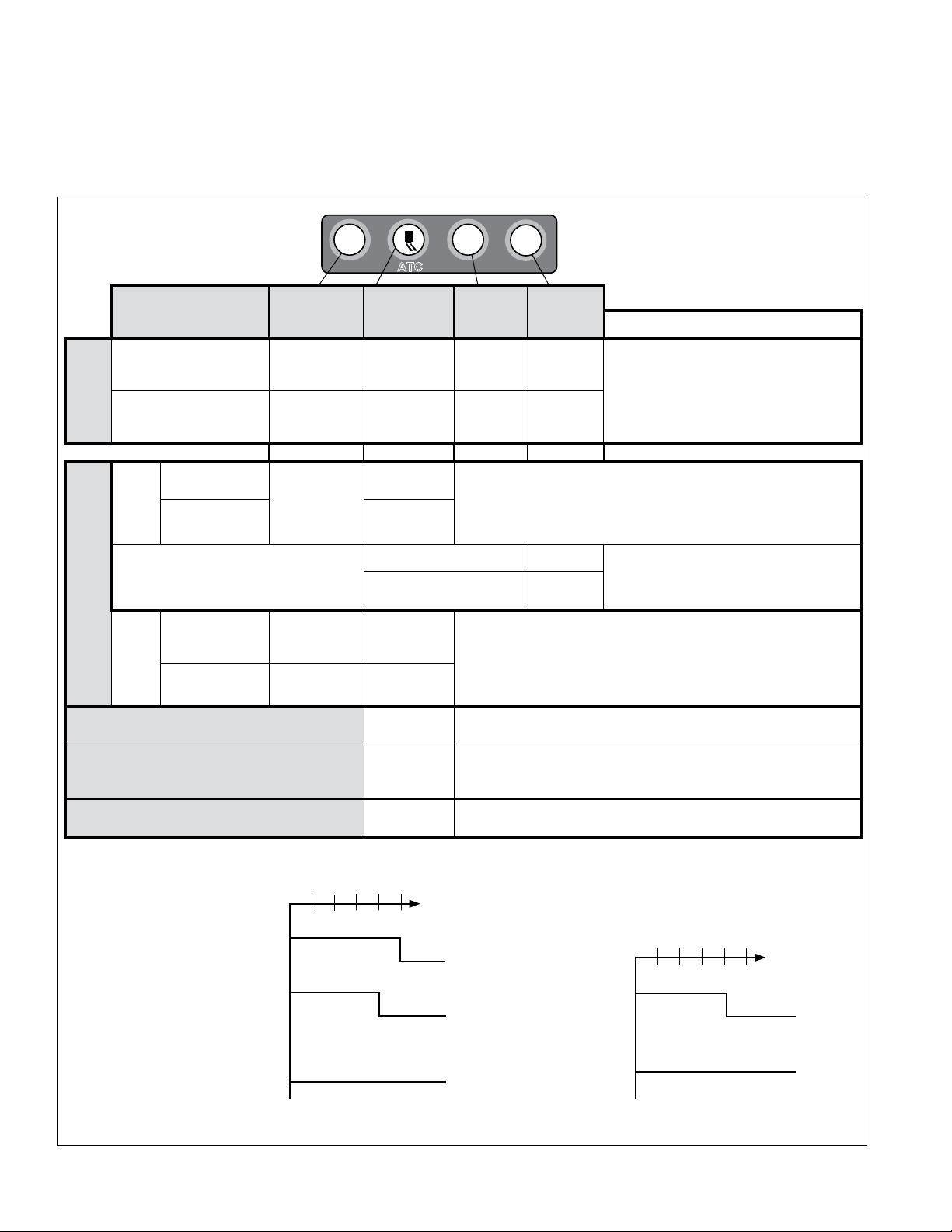

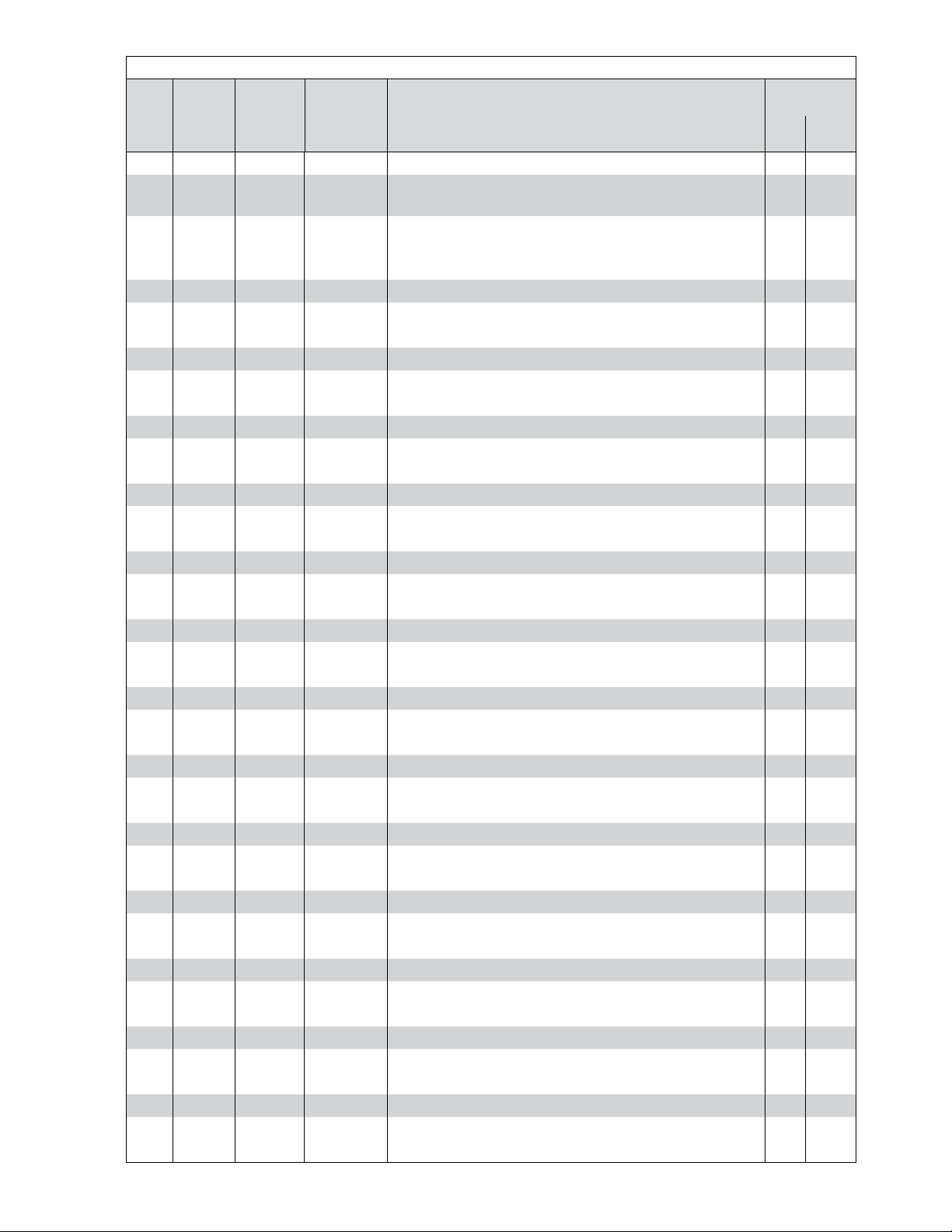

INDICATOR LAMPS AND POWER-UP

ATC

SEQUENCE

NOTICE: The vehicle operator should verify proper

operation of all installed indicator lamps (ABS, ATC/ESP,

and trailer ABS) when applying ignition power and during

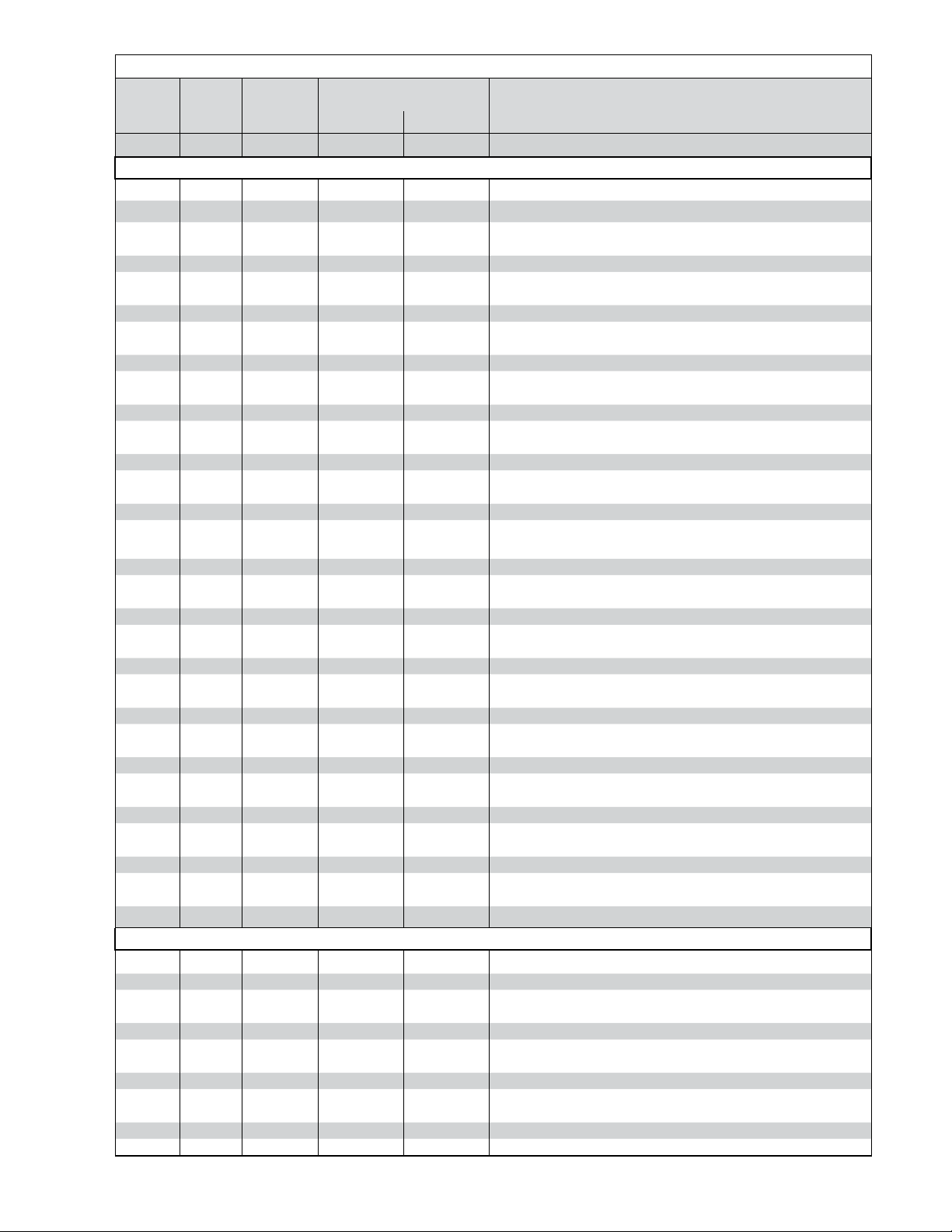

vehicle operation. See Chart 2.

Lamps that do not illuminate as expected when ignition

power is applied, or remain illuminated, indicate the need

for maintenance.

Dash Lamps

Mode

Ignition on - start up

(trailer with PLC)

3 seconds after ignition

Start Up

At Vehicle

During an Automatic Traction Control (ATC) Event

(with no Diagnostic

Trouble Codes)

ABS

Off-

Road

Mode

Vehicles with the Hill Start Feature

Deep

Special Mode Operation

Mud/

Snow/

Mode

During Dynamometer Mode

Normal

During an ATC

Event

(“Hill Start Assist”)

Normal Off

During an ATC/

ESP Event

During an ESP Event

seconds*

Lamp Off* Lamp Off* Lamp Off* Lamp Off*

Lamp ashes

slowly (every

2.5 seconds)

ABS

ABS

Lamp

On for 3

Off

TRLR

ATC/ESP

Lamp

On for 2.5

seconds*

Lamp OFF

Flashes

quickly

During HSA Event Lamp OFF

HSA Manually Disabled

Flashes

slowly (every

2.5 seconds)

Flashes

quickly

Flashes

quickly

Lamp ON

(ATC

Disabled)

Flashes

quickly

On for 3

seconds**

•

HSA

Trailer

ABS

Lamp

• Uses dash switch

• Not for rm road surfaces

• Allows more wheel lock-up (less ABS intervention)

• Mode only applies under 25 mph (Over 25 mph, the system reverts

to full ABS — including ATC/ESP — and lamp goes off.)

• Uses dash switch

• Increases allowable wheel slip during ATC interventions

• Not for rm road surfaces

• Reduces wheel slip during acceleration at low speeds

• Disables ATC monitoring functions

• When not in Dynamometer Mode, an illuminated lamp indicates an

ATC trouble code is present

System intervenes to reduce the risk of rollovers, loss-of-control, etc.

HSA

Lamp

On for 3

seconds

Flashes

slowly

Comments

*If any of the described lamp behaviors do

not occur — or if the lamp remains on during

operation — have the vehicle serviced by a

qualied mechanic as soon as possible to

restore full system functionality.

Lamp remains ON if HSA DTC is present

Power

ABS System

Application

Status Indicators

at Start-Up

Powered Vehicle ABS

Indicator Lamp

Trailer ABS

Indicator Lamp

(PLC Detected)**

Trailer ABS Indicator

Lamp**

(PLC Not Detected)

*Some vehicle manufacturers may illuminate the trailer ABS indicator lamp at power-up regardless of whether a

PLC signal is detected from the trailer or not. Consult the vehicle manufacturer’s documentation for more details.

CHART 2 - BENDIX® EC-60™ INDICATOR LAMP BEHAVIOR

8

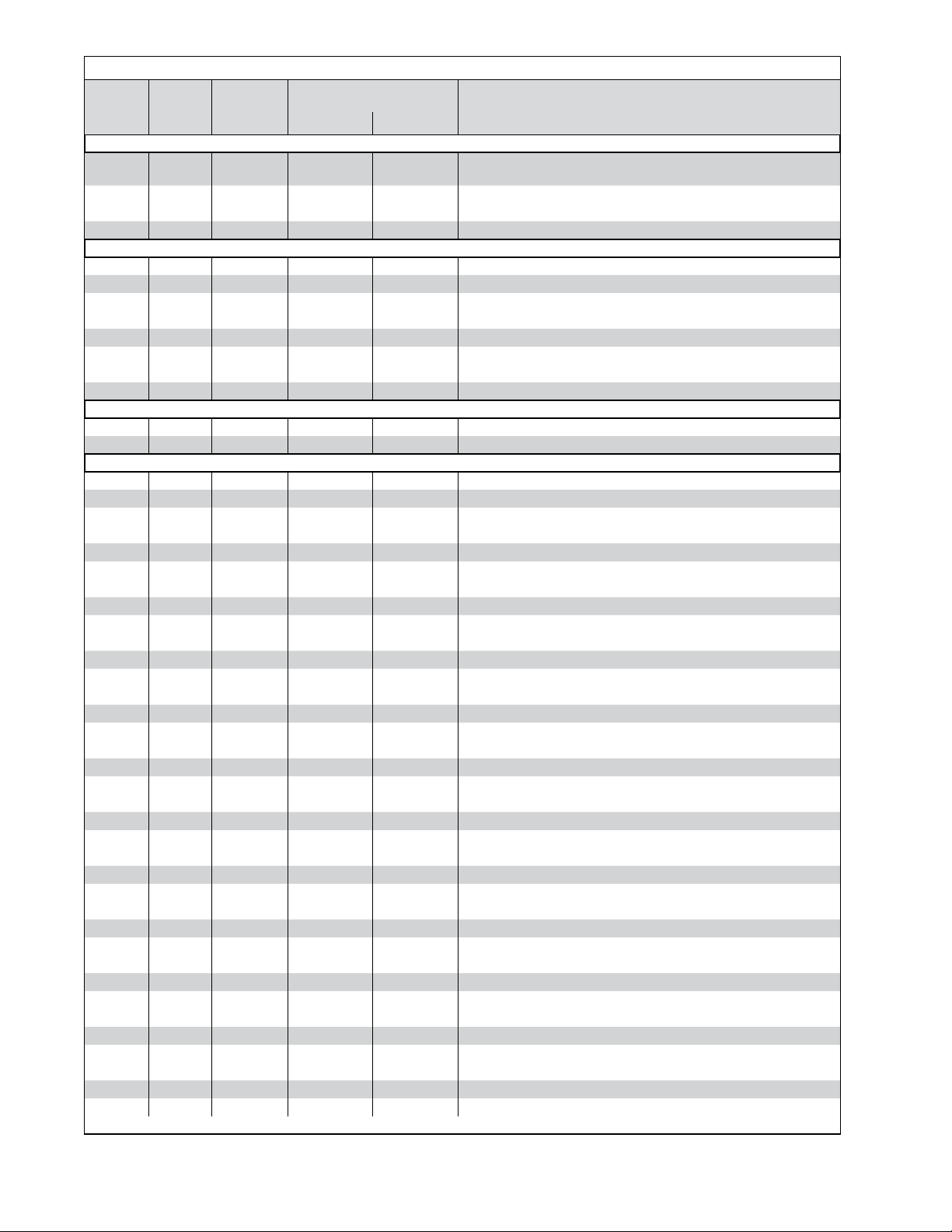

0.5 2.0 2.5 3.0 (sec.)1.5

ON

OFF

ON

OFF

ON

OFF

ATC/ESP System

Status Indicator

at Start-Up

ATC/ESP

enabled

No ESP

or ATC

0.5 2.0 2.5 3.0 (sec.)1.5

ON

OFF

ON

OFF

Power

Application

Page 9

ABS Indicator Lamp Operation (Bulb Check)

The ECU will illuminate the ABS Indicator Lamp for

approximately three seconds when ignition power is

applied, after which the lamp will extinguish if no diagnostic

trouble codes are detected.

The ECU will illuminate the ABS Indicator Lamp whenever

full ABS operation is not available due to a diagnostic

trouble code. In most cases, partial ABS is still available.

ATC/ESP Status/Indicator Lamp Operation

The ECU will illuminate the ATC/ESP lamp for approximately

2.5 seconds when ignition power is applied, after which the

lamp will extinguish, if no diagnostic trouble codes are

detected. The ECU will continuously illuminate the ATC/

ESP Indicator Lamp whenever ESP or ATC is disabled due

to a diagnostic trouble code.

During an ESP or ATC intervention, the lamp will ash

rapidly (2.5 times per second). When the ECU is placed

in the ATC Mud/Snow (off-road) mode, the lamp will ash

slowly at a rate of once every 2.5 seconds.

Trailer ABS Indicator Lamp Operation

The ECU will control the Trailer ABS Indicator Lamp

when a PLC signal (SAE J2497) from a trailer ABS ECU

is detected.

Hill Start Assist (HSA) Indicator Lamp Operation

Vehicles with HSA enabled, will illuminate the HSA Indicator

Lamp when ignition power is applied, after which the lamp

will extinguish if there are no issues with the HSA system.

ECUCongurationTest

Within two seconds of the application of ignition power, the

ECU will perform a test to detect system conguration with

regards to the number of wheel speed sensors and PMVs.

This can be audibly detected by a rapid cycling of the PMVs.

(Note: The ECU will not perform the conguration test when

wheel speed sensors show that the vehicle is in motion.)

Pressure Modulator Valve and Traction Control

Valve Chuff Test

Right Steer

Driver

Left Steer

FIGURE 9 - VEHICLE ORIENTATION (TYPICAL)

After the performance of the conguration test, the Bendix®

EC-60™ controller will perform a Bendix-patented PMV

and TCV Chuff Test. The Chuff Test is an electrical and

Right Drive

Left Drive

Right

Additional

Left

Additional

pneumatic PMV test that can assist maintenance personnel

in verifying proper PMV wiring and installation.

When ignition power is applied, each modulator solenoid

is briey energized. If the air system is fully charged and

the service brake pedal is depressed during ignition, the

modulator creates a single, sharp audible “chuff” of air

pressure. The modulators are energized in a certain

pattern, as follows: right front, left front, right rear, left rear.

This test is performed only when the vehicle is stationary

(if the vehicle moves the chuff test will not be performed).

The Bendix EC-60 controller will perform a PMV chuff test

on all installed modulators in the following order:

• Steer Axle Right PMV

• Steer Axle Left PMV

• Drive Axle Right PMV

• Drive Axle Left PMV

• Additional Axle Right PMV

• Additional Axle Left PMV

• Drive Axle TCV

The pattern will then repeat itself.

If equipped with a Bendix EC-60 advanced controller,

following the completion of the second round of PMV &

TCV chuff tests, the controller (if congured to do so) will

perform a test to cross-check the trailer PMV operation with

the vehicle stop lamps. If the trailer PMV circuit is mis-wired

(including the steer axle TCV), the PMV will exhaust a large

amount of air, or none at all.

NOTICE: If there are any active Diagnostic Trouble Codes,

the stop lamp cross-check portion of the chuff test will

not be carried out until all DTCs are fully diagnosed and

corresponding repairs are successfully conducted. The

ESP/ATC dash indicator will also be illuminated when there

are active ABS, ATC or ESP DTCs.

The ECU will not perform the PMV Chuff Test when wheel

speed sensors show that the vehicle is in motion.

ABS OPERATION

Bendix® ABS uses wheel speed sensors, ABS pressure

modulator valves, and an ECU to control either four or six

wheels of a vehicle. The Bendix EC-60 controller monitors

individual wheel turning motion during braking and adjusts

or modulates the brake pressure at the wheel end. When

excessive wheel slip, or wheel lock-up is detected, the

Bendix EC-60 controller will activate the pressure modulator

valves to automatically reduce the brake pressure at one

or more of the wheel ends. By these actions, the ABS

system helps to maintain the vehicle's lateral stability and

steerability during heavy brake applications and during

braking on slippery surfaces.

9

Page 10

Steer Axle Control

Although both wheels of the steer axle have their own wheel

speed sensor and pressure modulator valve, the Bendix

EC-60 controller blends the applied braking force between

the two steering axle brakes. This Bendix patented brake

application control, called Modied Individual Regulation

(MIR), is designed to help reduce steering wheel pull

during an ABS event on road surfaces with poor traction

(or areas of poor traction, e.g. asphalt road surfaces with

patches of ice).

Single Drive Axle Control (4x2 Vehicle)

For vehicles with a single rear drive axle (4x2), the brakes

are operated independently by the Bendix EC-60 controller,

based on the individual wheel behavior.

DualDriveAxleControl(4S/4MConguration)

For vehicles with dual drive axles (6x4) using a 4S/4M

conguration, one ABS modulator controls both right-side

rear wheels and the other modulator controls both left-side

rear wheels. Both wheels on each side receive equal

brake pressure during an ABS stop. The rear wheel speed

sensors must be installed on the axle with the lightest load.

DualRearAxleControl(6S/6MConguration)

For vehicles with dual rear axles (6x4, 6x2) using a 6S/6M

conguration, the rear wheels are controlled independently.

Therefore, brake application pressure at each wheel is

adjusted according to the individual wheel behavior on

the road surface.

6x2Vehicleswith6S/5MConguration

6x2 vehicles can utilize a 6S/5M conguration, with the

additional axle (a non-driven rear axle) having two sensors,

but only one Pressure Modulator Valve. In this case, the

PMV controls both wheels on the additional axle. The

additional axle wheels would receive equal brake pressure,

based on the wheel that is currently experiencing the most

wheel slip.

Normal Braking

During normal braking, brake pressure is delivered through

the ABS PMV and into the brake chamber. If the ECU

does not detect excessive wheel slip, it will not activate

ABS control, and normal vehicle service braking is applied.

Retarder Brake System Control

On surfaces with low traction, application of the retarder can

lead to high levels of wheel slip at the drive axle wheels,

which can adversely affect vehicle stability.

To prevent this, the Bendix® EC-60™ controller switches

off the retarder as soon as a lock-up is detected at one (or

more) of the drive axle wheels.

When the ECU is placed in the ABS off-road mode (on

vehicles equipped with this optional feature), it will switch

off the retarder only when ABS is active on a steer axle

wheel and a drive axle wheel.

Optional ABS Off-Road Mode

On some road conditions, particularly when the driving

surface is soft, the stopping distance with conventional

ABS may be longer than without ABS. This can occur

when a locked wheel on soft ground or loose gravel plows

up the road surface in front of the tire, changing the rolling

friction value. Although vehicle stopping distance with a

locked wheel (in the absence of ABS) may be shorter than

corresponding stopping distance with conventional ABS

control, vehicle steerability and stability would be reduced.

Advanced Bendix EC-60 controllers have an optional dash

switch that initiates a modied ABS control mode (know

as "off-road ABS") that more effectively accommodates

these soft road conditions to shorten stopping distance

while maintaining optimal vehicle steerability and stability.

Note: Off-road mode is not available if the vehicle is

equipped with Hill Start Assist (HSA).

WARNING: The ABS off-road mode should not

be used on normal, paved road surfaces because

vehicle stability and steerability may be reduced. The

ABSIndicatorLampwillashslowlytoindicatetothe

driver that the ABS off-road mode is engaged.

CAUTION: When ABS off-road mode is engaged,

stability functions are disabled at speeds below

approximately 25 mph. The ATC/ESP dash lamp will

illuminate to indicate to the driver that the stability

system is disabled.

The vehicle manufacturer should provide the optional ABS

off-road function only for vehicles that operate on unpaved

surfaces or that are used in off-road applications, and is

responsible for ensuring that vehicles equipped with the

ABS off-road function meet all FMVSS-121 requirements

and have adequate operator indicators and instructions.

The vehicle operator activates the off-road function with a

switch on the dash panel. A ashing ABS Indicator Lamp

indicates to the driver that the ABS off-road function is

engaged. To exit the ABS off-road mode, depress and

release the switch. A new ignition cycle will also cause

the ECU to exit the ABS off-road mode.

All-Wheel Drive (AWD) Vehicles

AWD vehicles with an engaged interaxle differential (steer

axle to rear axle)/AWD transfer case may have negative

effects on ABS performance. Optimum ABS performance

is achieved when the lockable differentials are disengaged,

allowing individual wheel control.

Advanced Bendix EC-60 controllers can be programmed

specically for this conguration to control the differential

lock/unlock solenoid in the AWD transfer case. When

programmed to do so, the ECU will disengage the locked

interaxle/AWD transfer case during an ABS event and

reengage it once the ABS event has ended.

10

Page 11

ATC OPERATION

ATC Functional Overview

Just as ABS improves vehicle stability during braking,

ATC improves vehicle stability and traction during vehicle

acceleration. The Bendix EC-60 controller ATC function

uses the same wheel speed information and modulator

control as the ABS function. The Bendix EC-60 controller

detects excessive drive wheel speed, compares the speed

to the front, non-driven wheels, and reacts to help bring the

wheel spin under control. The controller can be congured

to use engine torque limiting and/or differential braking to

control wheel spin. For optimal ATC performance, both

methods are recommended.

ATC/ESP Lamp Output/ATC Mud/Snow Switch

Input

Advanced ECUs control the ATC/ESP dash lamp as

follows.

The ATC/ESP dash lamp illuminates:

1. During power up (e.g. when the vehicle is started) for

approximately 2.5 seconds and turns off after the self

test is completed, providing no diagnostic trouble codes

are present.

2. When ESP or ATC is disabled for any reason.

3. During an ESP or ATC event (the lamp will ash rapidly

at a rate of 2.5 times per second).

4. When the ECU is placed in the ATC off-road mode

(the lamp will ash steadily at a rate of once per 2.5

seconds). This noties the vehicle operator that the

ATC Mud/Snow mode is active.

5. When the ECU is placed in the ABS off-road mode.

When in this mode, ESP will be disabled below 25 mph

and its inactive status will be indicated by a steadily

illuminated ATC/ESP lamp.

Differential Braking

Differential braking within ATC is automatically activated

when drive wheel(s) on one side of the vehicle are spinning

excessively, which typically occurs on road surfaces

with patches of ice. The traction system will then lightly

apply the brake to the drive wheel(s) that are spinning

excessively. The vehicle differential will then drive the

wheels on the other side of the vehicle.

Differential braking (as part of ATC functionality) is available

at vehicle speeds up to 25 MPH.

Disabling ATC Differential Braking

ATC differential braking is disabled under the following

conditions:

1. During power up (e.g. when the vehicle is started), until

the ECU detects a service brake application.

2. If the ECU receives a J1939 message indicating that

the vehicle is parked.

3. When the dynamometer test mode is active. The

dynamometer test mode is entered using the diagnostic

blink code switch or by using a diagnostic tool (such as

Bendix

4. In response to a serial communications request from

a diagnostic tool.

5. If ATC Differential Braking function is activated for a long

time period to avoid overheating of the brakes. It would

take approximately 3 continuous minutes of activation

for the timeout to occur. Once timed out, approixmately

2 minutes of "cool off" time would be required before

ATC Differential Braking can be used again.

6. When certain diagnostic trouble code conditions are

detected.

®

ACom® Diagnostics).

Engine Torque Limiting with Smart ATC™

Traction Control

The Bendix EC-60 controller uses Engine Torque Limiting

to control drive axle wheel slip. This is communicated to

the engine control module (using J1939), and is available

at all vehicle speeds.

Bendix® Smart ATC™ Traction Control

The Bendix EC-60 controller has an additional feature

known as Smart ATC™ traction control. Smart ATC™

traction control monitors the accelerator pedal position

(using J1939) to help provide optimum traction and vehicle

stability. By determining the driver’s throttle input and

adapting the target slip of the drive wheels to the driving

situation, the Smart ATC™ traction control allows higher

wheel slip when the accelerator pedal is applied above a

preset level.

The wheel slip allowed by Smart ATC™ is decreased when

driving through a curve for improved stability.

Disabling ATC Engine Control and Smart ATC™

Traction Control

ATC Engine Control and Smart ATC™ traction control will

be disabled under the following conditions:

1. In response to a serial communications request from

an off-board tool.

2. At power-up until the ECU detects a service brake

application.

3. If the ECU receives a J1939 message indicating that

the vehicle is parked.

4. If the dynamometer test mode is active. This may be

accomplished via an off-board tool or the diagnostic

blink code switch.

5. When certain diagnostic trouble code conditions are

detected.

11

Page 12

Optional ATC Mud/Snow (Off-Road) Mode

In some road conditions, the vehicle operator may desire

additional drive wheel slip when ATC is active. The

Advanced Bendix EC-60 controller has an optional control

mode to permit this desired performance.

The vehicle operator can activate the Mud/Snow function

with a switch on the dash panel. Alternately, a J1939

message may be used to place the vehicle in this mode.

The ATC/ESP Indicator Lamp will ash steadily at a rate

of once every 2.5 seconds to conrm that the ATC mud/

snow mode is engaged.

To exit the ATC Mud/Snow mode, depress and release the

ATC Mud/Snow switch.

ADVANCED ABS WITH STABILITY

CONTROL

Overview

ESP stability system reduces the risk of rollovers,

jackkning and other loss-of-control events. ESP features

include Roll Stability Program (RSP) and Yaw Control.

During operation, the ECU of the Bendix Advanced ABS

system constantly compares performance models to the

Drag Torque Control Functional Overview

Advanced Bendix® EC-60™ controllers have a feature

referred to as drag torque control which reduces wheel slip

on a driven axle due to driveline inertia. This condition is

addressed by increasing the engine torque to overcome

the inertia.

Drag torque control increases vehicle stability on lowtraction road surfaces during down-shifting or retarder

braking.

vehicle’s actual movement, using the wheel speed sensors

of the ABS system, as well as lateral, yaw, and steering

angle sensors. If the vehicle shows a tendency to leave

an appropriate travel path, or if critical threshold values are

approached, the system will intervene to assist the driver.

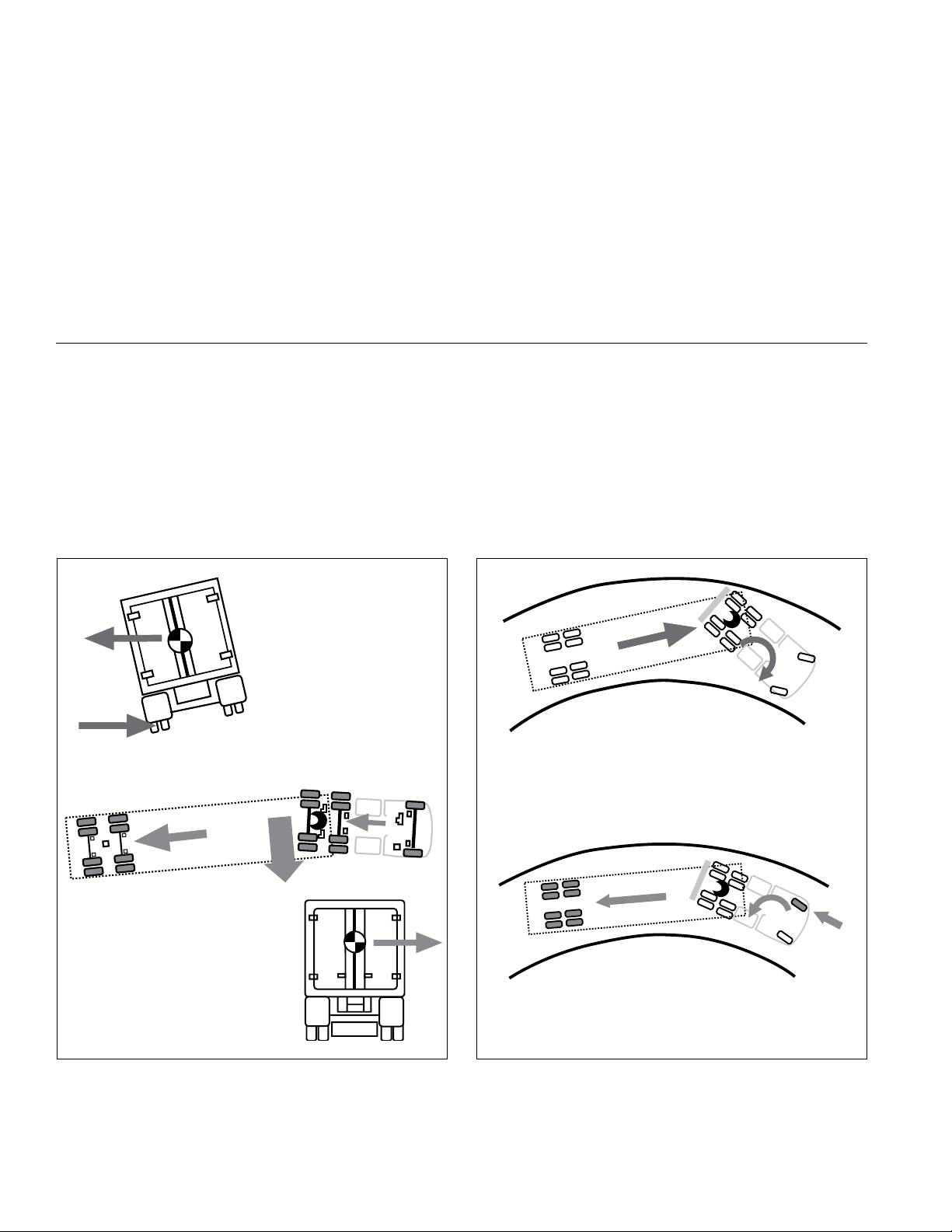

A Real World Example

Of How The RSP

System Operates:

Excessive speed for road

conditions creates forces

that exceed the threshold

at which a vehicle is likely

to rollover on a higherfriction surface.

The system automatically reduces

engine torque and applies the

service brakes (based on the

projected rollover risk) to reduce

the vehicle speed, thereby

reducing the tendency to roll over.

A Real World Example Of How Yaw Control

Operates:

Excessive speed exceeds the threshold, creating a

situation where a vehicle is likely to spin and jackknife.

®

The Bendix

and selectively applies brakes to reduce the tendency

to jackknife.

Yaw Control system reduces engine throttle

FIGURE 11 - RSP EXAMPLE

12

FIGURE 12 - YAW CONTROL EXAMPLE

Page 13

Roll Stability Program

Bendix RSP, an element of the overall ESP system,

addresses rollover conditions. In the case of a potential

roll event, the ECU will override the throttle and quickly

apply brake pressure at all wheel ends to slow the vehicle

combination. The level of braking application during an

RSP event will be proportional to roll risk. See Figure 11.

Yaw Stability

Yaw stability counteracts the tendency of a vehicle to spin

about its vertical axis. During operation, if the friction

between the road surface and the tires is not sufcient

to oppose lateral (side) forces, one or more of the tires

can slide, causing the truck/tractor to spin. These events

are referred to as either an "under-steer" situation (where

there is a lack of vehicle response to steering input due to

tire slide on the steer axle) or an "over-steer" (where the

tractor's rear end slides out due to tire slide on the rear axle)

situation. Generally, shorter wheelbase vehicles (tractors,

for instance) have less natural yaw stability, while longer

wheelbase vehicles (straight trucks, for instance) have

greater natural yaw stability. Factors that inuence yaw

stability are: wheelbase, suspension, steering geometry,

weight distribution front to rear, and vehicle track width.

Yaw Control

Yaw Control responds to a wide range of low- to highfriction surface scenarios including rollover, jackknife

and loss-of-control. It is the recommended system for all

power vehicles and especially critical for tractors pulling

trailers. In the case of vehicle slide (over-steer or understeer situations), the system will reduce the throttle and

then brake one or more of the “four corners” of the vehicle

(in addition to potentially applying the trailer brakes), thus

applying a counter-force to better align the vehicle with an

appropriate path of travel.

For example, in an over-steer situation, the system applies

the “outside” front brake; while in an under-steer condition,

the “inside” rear brake is applied. (See Figure 12)

IMPORTANT SAFETY INFORMATION

ABOUT THE BENDIX® ESP® STABILITY

SYSTEM

ESP May Reduce The Vehicle Speed

Automatically

ESP can make the vehicle decelerate automatically. ESP

can slow the vehicle with or without the operator applying

the brake, and even when the throttle is being applied.

CAUTION

To minimize unexpected deceleration and reduce the risk

of a collision the operator must:

• Avoid aggressive driving maneuvers, such as sharp

turns or abrupt lane changes at high speeds, which

might trigger the stability system.

• Always operate the vehicle safely, drive defensively,

anticipate obstacles and pay attention to road, weather

and trafc conditions. ABS, ATC and ESP stability

systems are no substitute for prudent, careful driving.

Towing Doubles Or Triples May Reduce The

Effectiveness Of Stability Systems

ESP is designed and optimized for trucks and for tractors

that tow single trailers. If a tractor equipped with ESP

is used to power multiple trailer combinations (known

as “doubles” or “triples”) the effectiveness of the ESP

system may be greatly reduced. Extremely careful

driving is always required when towing doubles or triples.

Excessive speed and aggressive maneuvers, such as

sharp turns, sudden steering inputs or abrupt lane changes

should be avoided.

Limitations Of Stability Systems

The ESP stability system’s effectiveness may be greatly

reduced if:

• The load shifts due to improper retention, accident

damage or the inherently mobile nature of some loads

(for example, hanging meat, live animals or partially

laden tankers),

• The vehicle has an unusually high or off-set center of

gravity (CG),

• One side of the vehicle drops off the pavement at an

angle that is too large to be counteracted by a reduction

in speed,

• The vehicle is used to haul double or triple trailer

combinations,

• If very rapidly winding steering inputs are inputted at

high speeds,

• There are mechanical problems with suspension

leveling of the tractor or trailer resulting in uneven loads,

• The vehicle is maneuvering on a high banked road

creating either additional side forces due to the weight

(mass) of the vehicle or a deviation between expected

& actual yaw rates,

• Gusty winds are strong enough to cause signicant

side forces on the vehicle and any towed vehicles.

To Maximize The Effectiveness Of ESP:

• Loads must be properly secured at all times.

• Drivers need to exercise extreme caution at all times,

and avoid sharp turns, sudden steering inputs or abrupt

lane changes at high speeds, particularly if:

› the vehicle hauls loads that could shift,

› the vehicle or load has a high or off-set center of

gravity (CG) when loaded, or

› the vehicle tows doubles or triples.

13

Page 14

TruckChassisModications

If the vehicle’s chassis components are altered (for example,

a wheel base extension or reduction, tag axle addition

or removal, a major body change such as conversion of

a tractor into a truck, or an axle, suspension, or steering

system component modication) the Bendix® ESP® system

must be disabled. Have a qualied mechanic replace the

Advanced EC-60 ECU with a Premium EC-60 ECU and

secure the X4 connector which will no longer be used. The

ATC/ESP indicator lamp would continue to function as an

ATC indicator lamp, and should be designated as ATC only.

WARNING:Ifamodiedvehicledoesnothave

the ESP system disabled, serious vehicle braking

and performance issues could result, including

unnecessary ESP system interventions. This can

lead to a loss-of-control of the vehicle. In addition,

remove all cab signage (e.g. visor labels, etc.) used

to show that Bendix ESP was installed and make any

necessary notations in the vehicle manual(s), so that

drivers do not misunderstand which ABS options are

installed on the vehicle.

SensorLocationModications

The location and orientation of the Steering Angle Sensor

and Yaw Rate Sensor must not be altered. When servicing,

an identical component must be used in the same

orientation (using OEM brackets & torque requirements).

During installation follow the OEM leveling guidelines.

Steering Angle Sensor Re-Calibration

Whenever maintenance or repair work is performed to the

steering mechanism, linkage, steering gear, adjustment of

the wheel track, or if the steering angle sensor is replaced,

a recalibration of the Steering Angle Sensor must be

performed.

WARNING! If the Steering Angle Sensor is not

recalibrated, the yaw control system may not function

properly, which can result in incidents leading to loss

of vehicle control. See page 19 of this document for

more details on this procedure.

DYNAMOMETER TEST MODE

CAUTION: ATC and ESP must be disabled prior

to conducting any dynamometer testing. When the

Dynamometer Test Mode is engaged, ATC brake control

and engine control along with drag torque control and ESP

are turned off. This test mode is used to avoid torque

reduction or torque increase and brake control activation

when the vehicle is operated on a dynamometer for testing

purposes.

The Dynamometer Test Mode may be activated by pressing

and releasing the diagnostic blink code switch ve times or

by using a hand-held or PC-based diagnostic tool.

During Dynamometer Test Mode the ATC lamp remains ON.

Advanced Bendix

in the Dynamometer Test Mode even if power to the ECU

is removed and re-applied. To exit the test mode, press

and release the blink code switch three times, or use a

hand-held or PC-based diagnostic tool.

®

EC-60™ Contollers will remain engaged

AUTOMATIC TIRE SIZE CALIBRATION

The ECU requires a precise rolling circumference ratio

between steer axle and drive axle tires in order for ABS,

ATC, and ESP to perform in an optimal manner. For this

reason, a continuously monitoring process takes place

in which the precise ratio is calculated. This calculated

value is stored in the ECU memory provided the following

conditions are met:

1. Rolling-circumference ratio is within the permissible

range.

2. Vehicle speed is greater than approximately 12 MPH.

3. No acceleration or deceleration is taking place.

4. There are no active speed sensor diagnostic trouble

codes.

The ECU is provided with a ratio value of 1.00 as a default

setting. If the automatic tire size alignment calculates a

different value, this is used to overwrite the original gure

in the memory. This process adapts the ABS and ATC

function to the vehicle.

14

Acceptable Tire Sizes

The speed calculation for an exciter ring with 100 teeth is

based on a default tire size of 510 revolutions per mile.

This gure is based on the actual rolling circumference of

the tires, which varies with tire size, tire wear, tire pressure,

vehicle loading, etc.

The ABS response sensitivity is reduced when the actual

rolling circumference is excessive on all wheels. For a 100

tooth exciter ring, the minimum number of tire revolutions

per mile is 426, and the maximum is 567. The ECU will

set diagnostic trouble codes if the number of revolutions

is out of this range.

Page 15

In addition, the size of the steer axle tires compared to

the drive axle tires also has to be within the ABS system

design. To avoid diagnostic trouble codes, the ratio of the

effective rolling circumference of the steer axle, divided by

the effective rolling circumference of the drive axle, must

be between 0.85 to 1.15.

ATC Modulator Diagnostic Trouble Code

ATC and ESP are disabled. ABS remains active.

J1939 Communication Diagnostic Trouble Code

ATC and ESP are disabled. ABS remains active.

CAUTION: The ESP system effectiveness relies

on the accuracy of vehicle speed. If a major change

on the tire sizes occurs such that the odometer setting

needs to be changed, the Advanced ABS controller's

setting of tire sizes must be reprogrammed to new

valuesatthesametimebyacertiedmechanic.

SYSTEM IMPACT DURING ACTIVE

TROUBLE CODES

ABS PARTIAL SHUTDOWN

Depending on which component the trouble code is

detected, the ABS, ATC, and ESP functions may be fully

or partially disabled. Even with the ABS indicator lamp

illuminated, the Bendix EC-60 controller may still provide

ABS function on wheels that are not affected. The ABS

system controller should be serviced as soon as possible.

Steer Axle ABS Modulator Diagnostic Trouble

Code

ABS on the affected wheel is disabled. ABS and ATC on

all other wheels remains active. ESP is disabled.

Drive Axle/Additional Axle ABS Modulator

Diagnostic Trouble Code

ATC is disabled. ABS on the affected wheel is disabled.

ABS on all other wheels remains active. ESP is disabled.

Steer Axle Wheel Speed Sensor Diagnostic

Trouble Code

The wheel with the diagnostic trouble code is still controlled

by using input from the remaining wheel speed sensor on

the steer axle. ABS remains active on the rear wheels.

ATC and ESP are disabled.

ECU Diagnostic Trouble Code

ABS, ATC, and ESP are disabled. The system reverts to

normal braking.

Voltage Diagnostic Trouble Code

While voltage is out of range, ABS, ATC, and ESP are

disabled. The system reverts to normal braking. When

the correct voltage level is restored, full ABS and ATC

function is available. The operating voltage range is 9.0

to 17.0 VDC for 12 volt systems, and 20 to 33.5 volts for

24 volt systems.

Steering Angle Sensor Diagnostic Trouble Code

ESP is disabled. ABS and ATC remain active.

Yaw Rate/Lateral Acceleration Sensor

Diagnostic Trouble Code

ESP is disabled. ABS and ATC remain active.

Brake Demand Pressure Sensor Diagnostic

Trouble Code

ESP is disabled. ABS and ATC remain active.

Load Sensor Diagnostic Trouble Code

ESP is disabled. ABS and ATC remain active.

Steer Axle TCV Diagnostic Trouble Code

ESP is disabled. ABS and ATC remain active.

Trailer PMV Diagnostic Trouble Code

ESP is disabled. ABS and ATC remain active.

Drive Axle/Additional Axle Wheel Speed Sensor

Diagnostic Trouble Code

ATC and ESP are disabled. In a four sensor system, ABS

on the affected wheel is disabled, but ABS on all other

wheels remains active.

In a six sensor system, ABS remains active by using input

from the remaining rear wheel speed sensor on the same

side.

15

Page 16

SYSTEM RECONFIGURATION

The Bendix® EC-60™ controller is designed to allow the

technician to change the default system settings (chosen

by the vehicle OEM) to provide additional or customized

features.

Depending on the model, the customizable features include

ABS control settings, engine module communication etc.

Many of these settings can be recongured using a hand-

held or PC-based software, such as the Bendix

Diagnostics program.

®

ACom®

ECU RECONFIGURATION

Reconguring a Bendix EC-60 controller may be carried

out by using the Blink Code Switch or by using a hand-held

or PC-based diagnostic tool.

Note: During the reconguration process, and independently

from any reconguration being carried out by the technician,

the ECU will automatically check the J1939 serial link and

communicate with other vehicle modules. In particular, if

the serial link shows that the vehicle has a retarder device

present, the ECU will congure itself to communicate with

the retarder device for improved ABS performance. For

example, if the ECU detects the presence of a retarder

disable relay during a reconguration, it will congure

itself to control the relay to disable the retarding device

as needed.

RecongurationUsingtheBlinkCodeSwitch

With ignition power removed from the Bendix EC-60

controller, depress the blink code switch. After the ignition

power is activated, depress and release the switch seven

times to initiate a reconguration event.

Diagnostic Tool

A reconguration event may be initiated using a hand-held

or PC-based diagnostic tool to communicate with the ECU

over the SAE J1587 diagnostic link.

6S/5MConguration

Advanced Bendix® EC-60™ controllers will congure for

6S/5M operation when a reconguration event is initiated

and the ECU detects that an additional axle PMV is wired

as follows:

PMV Connector ECU Connector

Hold Right Additional Axle Hold

Release Left Additional Axle Release

Common Right Additional Axle Common

16

Page 17

Troubleshooting: General

REMOVING THE BENDIX® EC-60™

CONTROLLER ASSEMBLY

1. Turn vehicle ignition off.

2. Remove as much contamination as possible prior to

disconnecting electrical connections.

3. Note the Bendix EC-60 controller assembly mounting

position on the vehicle.

4. Disconnect the electrical connectors from the Bendix

EC-60 controller.

5. Remove and retain the mounting bolts that secure the

Bendix EC-60 controller.

CAUTION

The VIN of the vehicle is stored in the ECU internal

memory, and is cross-checked by the ECU using

information obtained from other vehicle controllers.

If the VIN stored in the ECU does not match the VIN

obtained from the other vehicle controller, the ECU will

generate an ECU Internal VIN Mismatch DTC.

Accordingly, do not switch Advanced controllers from

one vehicle to another.

17

Page 18

OBTAINING A NEW BENDIX EC-60

ADVANCED CONTROLLER

Should the Advanced Bendix EC-60 controller require

replacement, certain steps must be followed:

1. Record the vehicle model, VIN, year and date of

manufacture from the vehicle.

2. Record the part number of the Bendix EC-60 Advanced

Controller.

3. Provide this information to your local OEM vehicle

service department to obtain a new ECU. The OEM

service department will install the same parameter set

in the new controller that was loaded into the original

ECU at the vehicle OEM assembly facility.

INSTALLING A NEW BENDIX® EC-60™

CONTROLLER

CAUTION When replacing the Bendix EC-60

controller, verify with the OEM service department that the

unit you are installing has the correct parameter set. Failure

to do so could result in a loss of features or degraded ESP

performance.

For further information, contact either the vehicle

manufacturer, Bendix or your local authorized Bendix

dealer.

1. Position and secure the Bendix® EC-60™ controller in

the original mounting orientation using the mounting

bolts retained during removal. Use no more torque

than is necessary to rmly secure the ECU into position.

Over-tightening the mounting hardware can cause

damage to the EC-60™ controller.

2. Reconnect the electrical connectors to the EC-60™

controller.

3. Apply power and monitor the Bendix EC-60 controller

power-up sequence to verify proper system operation.

See Troubleshooting: Wiring section beginning on page

45 for more information on wire harnesses.

WARNING: Bendix ESP stability system is validated

with specic Bendix® brand components. Always use

Bendix® brand replacement parts to prevent compromising

system performance. Bendix is not able to validate the

safe and reliable use of substitute or alternate components

that may be available from other manufacturers. Further,

suppliers of a non-Bendix® brand ABS component may

implement design changes in their component (without the

knowledge or approval of Bendix) which could negatively

affect antilock system reliability and braking performance

issues.

REMOVAL OF THE STEERING ANGLE

SENSOR

Service Checks:

1. Check all wiring and connectors. Some installations

also include an intermediate connector from the

steering angle sensor to the main vehicle wire harness.

Make sure all connections are free from visible damage.

2. Examine the sensor. Make sure the sensor, its

mounting screws, and the interface between the hub

and the steering column are not damaged.

Diagnostics:

The steering angle sensor is only operational in conjunction

with an Advanced ABS ECU. No independent diagnostics

can be performed on the sensor.

Removal:

1. Remove steering column sheathing.

2. Depending upon manufacturer, the steering angle

sensor could be located either near the steering wheel,

necessitating the removal of the steering wheel, or

near the joint to the vehicle steering mechanism,

necessitating the disconnection of this linkage.

3. Unplug sensor cable assembly from body of sensor.

Squeeze the mounting tabs and pull gently on the

connector until it disengages.

4. Unscrew all three of the mounting screws that hold the

body of the sensor to the steering column body.

5. Slide the sensor over the column to remove. Take note

if the sensor label is facing upward or downward.

Installation:

1. Obtain a new sensor. The sensor is not repairable in

the eld.

2. Slide the sensor over the column. The center hub of the

sensor must be aligned with the corresponding notch

in the column. Different column manufacturers may

implement this hub alignment in different ways. The

sensor label should be facing in the same direction as

the removed sensor.

3. Assemble to column non-moving plate with three selflocking screws.

4. Tighten screws to steering column manufacturer's

recommended torque specication.

5. Reconnect the connector. Ensure that there will be no

force applied to the sensor because the connector is

pulling on the sensor body.

6. If the wire harness leading to the sensor is being

replaced, ensure that it is adequately tie wrapped

so that the full motion of the steering column can be

achieved without pulling apart the connectors.

7. Reinstall the column sheathing. The sensor is not

protected against dirt or water intrusion, so care

must be taken not to introduce these elements during

installation.

18

Page 19

STEERING ANGLE SENSOR CALIBRATION

The steering angle sensor calibration can only be achieved

when the sensor is powered by the Advanced ABS ECU.

No stand-alone sensor calibration can be carried out. The

calibration procedure is performed using Bendix® ACom®

Diagnostic V4.0 or higher. See “Troubleshooting Diagnostic

Trouble Codes: Steering Angle Sensor (SAS-60)” for the

calibration procedure using this tool. The sensor must be

recalibrated using ACom Diagnostics after any of these

situations:

• Replacement of the steering angle sensor

• Any opening of the connector hub from the steering angle

sensor to the column

• Any maintenance or repair work on the steering linkage,

steering gear or other related mechanism

• Adjustment of the wheel alignment or wheel track

• After an accident that may have led to damage of the

steering angle sensor or assembly

WARNING: If the steering angle sensor is not

properly recalibrated as needed, the yaw control

system may not function properly, which can result

in a loss of vehicle control.

REMOVAL OF THE YAW RATE/LATERAL

ACCELERATION SENSOR

WARNING: Different generations of yaw rate/

lateral acceleration sensors are not compatible. Only

replace these sensors with exactly the same device.

Service Checks:

1. Check all wiring and connectors. Make sure all

connections are free from visible damage.

2. Examine the sensor. Make sure the sensor, its mounting

bolts, and the mounting bracket are not damaged.

3. Check the vent hole in underbody of sensor housing.

The vent hole should remain free from paint and debris

at all times.

Diagnostics:

The yaw rate sensor is only operational in conjunction with

an Advanced ABS ECU. No independent diagnostics can

be performed on the sensor.

Removal:

1. Unplug sensor cable assembly from body of sensor.

The connector must be twisted and pulled gently to

release.

2. In some mounting congurations, the sensor can be

removed independently from its mounting bracket.

Otherwise, remove entire assembly, then remove

sensor from bracket.

3. Take note of the direction in which the connector is

pointed.

Installation:

1. Obtain a new sensor. The sensor is not repairable in

the eld.

WARNING: The location of the Yaw Rate Sensor

on the vehicle, the means of fastening the unit to the

vehicle, and the sensor's orientation, MUST NOT BE

ALTERED. When servicing, an identical component

must be used in the same orientation (using

OEM brackets & torque requirements). During

installation, follow the OEM leveling guidelines.

If any of these requirements are not followed, the

advanced ABS control system may not function

properly, which can result in incidents leading to

loss of vehicle control.

2. Assembly yaw rate sensor housing to mounting bracket.

The bracket must be the same design as used on the

original vehicle conguration.

3. For Bendix® YAS-60™ Yaw Rate Sensors, the correct

fasteners are three M8 size bolts, and the xing torque

should be 20Nm (±2 Nm). For Bendix® YAS-70X™

Yaw Rate Sensors, the correct fasteners are two M10

size bolts (1.5 mm pitch angle), or OEM-supplied

hardware, and the xing torque should be 46Nm (±9

Nm). Note that the Bendix YAS-70X sensor has two

alternate designs, one with an aligning post — see the

kit instruction sheet for more information. In all cases,

the connector should be facing in the same direction

as the removed sensor. The unit must not be installed

upside-down where there is a pressure-balancing hole.

4. The sensor should be as level as possible and parallel

to the road surface when installed on the vehicle.

5. Reconnect the connector. Ensure that there will be no

force applied to the sensor because the connector is

pulling on the sensor body.

CAUTION: When removing or installing the

sensor, care must be used to prevent damage. Do not

strike or pry the sensor. Do not use an impact tool to

install the mounting hardware.

SensorLocationModications

The location and orientation of the Yaw Rate Sensor must

not be altered. When servicing, an identical component

must be used in the same orientation (using OEM brackets

& torque requirements). During installation follow the OEM

leveling guidelines.

Yaw Rate Sensor Calibration:

The yaw rate sensor calibration can only be achieved via

the Advanced ABS ECU. The sensor must be recalibrated

after any of these situations:

• Replacement of the sensor

• After an accident that may have led to damage of the

yaw rate sensor

The calibration procedure is preformed using Bendix®

ACom® Diagnostics V4.0 or higher.

See “Troubleshooting Diagnostic Trouble Codes: Yaw Rate

Sensor” for the calibration procedure.

19

Page 20

BRAKE DEMAND SENSOR CALIBRATION

Calibration must be performed under the following conditions:

• After servicing any pressure sensor related DTCs

• Replacement of any sensor

The calibration procedure is performed using Bendix ACom

Diagnostics V4.0 or newer versions.

See “Troubleshooting Diagnostic Trouble Codes: Brake

Demand Sensor/Load Sensor” for the calibration procedure.

PRESSURE SENSOR INSTALLATION

REQUIREMENTS

Service Checks:

1. Check all wiring and connectors. Make sure all

connections are free from visible damage.

2. Examine the sensor. Make sure the sensor and its

interface to the pressure location are not damaged.

Diagnostics:

The pressure sensor can be independently diagnosed

when supplied with a ve volt voltage supply to the B

location and ground to the A location. Signal output on

the C location should read approximately 0.5V if there is

no pressure applied. The signal output should increase

proportionately as pressure is applied, up to a maximum

of 4.5V at 150 psi.

Removal:

1. Unplug sensor cable assembly from body of sensor.

Pull gently on the mounting tab and connector until it

disengages.

2. Remove sensor from its pressure mounting using

approved air brake push in tting tools.

Installation:

1. Obtain a new sensor. The sensor is not repairable in

the eld.

2. Insert sensor into pressure tting using approved tools.

3. Reconnect the connector. Ensure that there will be no

force applied to the sensor because the connector is

pulling on the sensor body.

4. If the wire harness leading to the sensor is being

replaced, ensure that it is adequately tie wrapped.

Pressure Sensor Calibration:

There is no need for pressure sensor calibration as long

as the part replaced is identical to the part removed and

a component approved for use with the Bendix Advanced

ABS system. However, replacement of brake demand

sensors or clearing of demand pressure sensor related

DTCs require the following:

1. Use of ACom V4 or newer to clear the active p-sensor

fault.

2. Carrying out the demand p-sensor initialization

procedure which involves applying service brakes of

90 psi or greater for 3 sec (while stationary).

Once this procedure is carried out successfully, if there are

no other active DTCs, ATC/ESP indicator will no longer

illuminate.

20

Page 21

Troubleshooting: Blink Codes and Diagnostic Modes

ECU DIAGNOSTICS

The Bendix® EC-60™ controller contains self-testing

diagnostic circuitry that continuously checks for the normal

operation of internal components and circuitry, as well as

external ABS components and wiring.

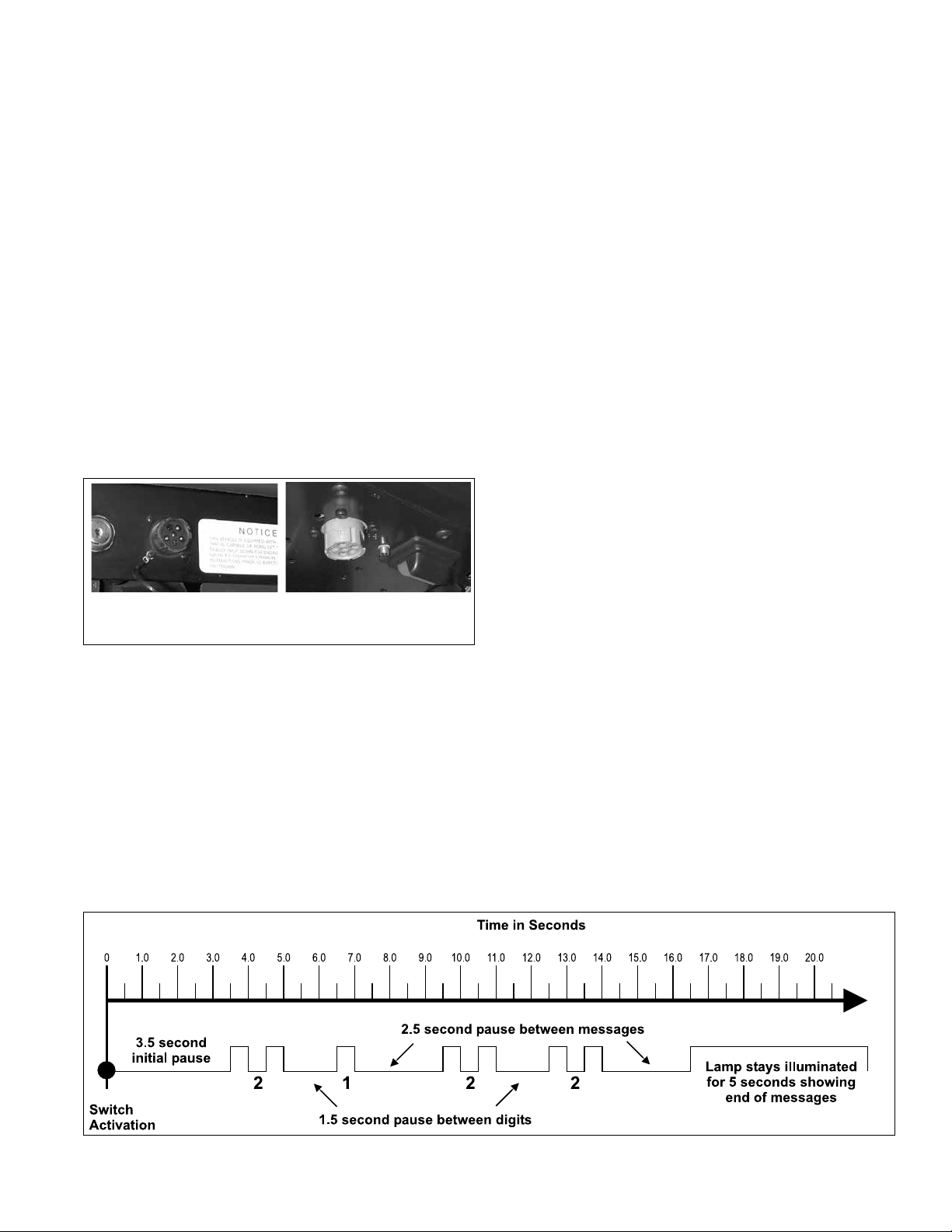

Active Diagnostic Trouble Codes

When an erroneous system condition is detected, the