Page 1

Premium wheel-end brake products

BBeennddiixx®®EEBB™™&& EESS™™AAiirr DDrruumm BBrraakkeess

SSeerrvviiccee MMaannuuaall

Page 2

General Information

Section 1: General Information

Foreword .......................................................................................................................................................................................................................4

Lining Material Warning .................................................................................................................................................................................................5

Model Coverage ............................................................................................................................................................................................................ 6

Parts Nomenclature .......................................................................................................................................................................................................8

Model ES-165-7 and EB-165-7 Interchangeability ..........................................................................................................................................12

EB

Section 2: Periodic Service

Brake Maintenance Preliminary Steps ........................................................................................................................................................................15

Brake Adjustment ........................................................................................................................................................................................................15

Brake Operation Check ............................................................................................................................................................................................... 17

Lubrication ...................................................................................................................................................................................................................17

Periodic Inspections ....................................................................................................................................................................................................18

Service Intervals ..........................................................................................................................................................................................................18

Section 3: Removal/Disassembly

Drum Removal .............................................................................................................................................................................................................19

Shoe Removal .............................................................................................................................................................................................................20

EB models (except EB-150-4L)/ES-165-5, 6, 7D, F, L/ES-150-8D, F/ES-150-6D ...........................................................................................21

ES-150-4L and EB-150-4L ...............................................................................................................................................................................23

ES-165-7M .......................................................................................................................................................................................................24

ES-165-7H ....................................................................................................................................................................................................... 26

Brake Adjuster Removal ..............................................................................................................................................................................................28

Camshaft Removal ......................................................................................................................................................................................................28

Air Chamber Bracket Removal ....................................................................................................................................................................................28

Spider Removal ...........................................................................................................................................................................................................29

Dustshield Removal .....................................................................................................................................................................................................29

Cleaning Brake Parts ...................................................................................................................................................................................................30

™

Roller and ES™ Cam Interchangeability ...................................................................................................................................................12

Section 4: Inspection

Drum Inspection ..........................................................................................................................................................................................................31

Shoe and Lining Inspection ......................................................................................................................................................................................... 32

Camshaft Radial Play Inspection .................................................................................................................................................................................34

Camshaft Inspection .................................................................................................................................................................................................... 34

Camshaft Bushing and Seal Inspection .......................................................................................................................................................................34

Spider Inspection ......................................................................................................................................................................................................... 35

Air Chamber Bracket Inspection .................................................................................................................................................................................. 35

Air Chamber Inspection ...............................................................................................................................................................................................36

Brake Adjuster Inspection ............................................................................................................................................................................................36

Section 5: Repair/Replacement

Camshaft Bushing/Grease Seal Replacement ............................................................................................................................................................37

Lining Replacement ..................................................................................................................................................................................................... 38

Section 6: Installation/Assembly

Spider Installation ........................................................................................................................................................................................................39

Dustshield Installation (Two Piece) ..............................................................................................................................................................................39

Dustshield Installation (One Piece) .............................................................................................................................................................................40

Air Chamber Bracket Installation .................................................................................................................................................................................41

Camshaft Installation ...................................................................................................................................................................................................42

Cam Head Washer Installation .................................................................................................................................................................................... 42

Brake Adjuster Installation ...........................................................................................................................................................................................43

Shoe and Lining Installation ........................................................................................................................................................................................44

Shoe Installation ..........................................................................................................................................................................................................46

ES-150-8D, F & 6D .......................................................................................................................................................................................... 46

All EB (except EB-150-4L) and ES-165-5, 6, 7D, F, L .....................................................................................................................................47

ES-165-7M .......................................................................................................................................................................................................49

ES-165-7H ....................................................................................................................................................................................................... 51

Specifi cation Chart ..................................................................................................................................................................................................57

1

Page 3

General Information

List of Illustrations and Tables

List of Illustrations

Figure 1. How to Use this Manual ................................................................................................................................................................................4

Figure 2. Bendix Brake Model Identifi cation .................................................................................................................................................................5

Figure 3. Brake Part Nomenclature, General ............................................................................................................................................................... 6

Figure 4. Brake Model Part Nomenclature ................................................................................................................................................................... 7

Figure 4. Brake Model Part Nomenclature, Continued ................................................................................................................................................. 8

Figure 5. EB™ Roller and ES™ Cam Contact Pattern .................................................................................................................................................. 12

Figure 6. Parts Identifi cation .......................................................................................................................................................................................13

Figure 6. Parts Identifi cation, Continued .................................................................................................................................................................... 14

Figure 7. Vehicle Maintenance Support ......................................................................................................................................................................15

Figure 8. Measurement, At Rest .................................................................................................................................................................................15

Figure 9. Measurement, 80 psi Applied ...................................................................................................................................................................... 16

Figure 10. Measurement, Brake Applied ....................................................................................................................................................................16

Figure 11. Brake Adjuster Adjustment ........................................................................................................................................................................16

Figure 12. Roller Retainer Removal ........................................................................................................................................................................... 21

Figure 13. Upper Cam Roller and Pin Removal ......................................................................................................................................................... 21

Figure 14. ES-165-7D, L, F Shoe Removal ................................................................................................................................................................ 22

Figure 15. Shoe Removal ........................................................................................................................................................................................... 22

Figure 16. Shoe Return Spring Removal ....................................................................................................................................................................23

Figure 17. Lower Shoe Removal ................................................................................................................................................................................23

Figure 18. Retainer Loop Removal .............................................................................................................................................................................24

Figure 19. Roller and Retainer Removal .................................................................................................................................................................... 24

Figure 20. Return Spring Removal .............................................................................................................................................................................24

Figure 21. Retaining Ring and Washer Removal ....................................................................................................................................................... 25

Figure 22. Cap Screw Removal ..................................................................................................................................................................................25

Figure 23. Anchor Pin Removal ..................................................................................................................................................................................25

Figure 24. Anchor Pin Bushing Removal ....................................................................................................................................................................25

Figure 25. Retaining Ring and Washer Removal ....................................................................................................................................................... 26

Figure 26. Cap Screw Removal ..................................................................................................................................................................................26

Figure 27. Anchor Pin Removal ..................................................................................................................................................................................26

Figure 28. Shoe Removal ........................................................................................................................................................................................... 26

Figure 29. Anchor Pin Bushing Removal ....................................................................................................................................................................27

Figure 30. Groove Pin Removal ................................................................................................................................................................................. 27

Figure 31. Brake Adjuster Removal ............................................................................................................................................................................28

Figure 32. Spider Mounting Hardware Removal ........................................................................................................................................................29

Figure 33. Dustshield Mounting Hardware Removal ..................................................................................................................................................29

Figure 34. Drum Inspection ........................................................................................................................................................................................ 31

Figure 35. Cam Roller Identifi cation ...........................................................................................................................................................................31

Figure 36. Shoe and Lining Inspection .......................................................................................................................................................................32

Figure 37. Brake and Lining Blocks ............................................................................................................................................................................ 33

Figure 38. Camshaft Radial Play Inspection ..............................................................................................................................................................34

Figure 39. Camshaft Inspection ..................................................................................................................................................................................34

Figure 40. Spider Inspection .......................................................................................................................................................................................35

Figure 41. Air Chamber Bracket Inspection ................................................................................................................................................................35

Figure 42. Air Chamber Inspection ............................................................................................................................................................................. 36

Figure 43. Brake Adjuster Inspection ..........................................................................................................................................................................36

Figure 44. Air Chamber Bracket Bushing Installation ................................................................................................................................................. 37

Figure 45. Camshaft Bushing Installation ................................................................................................................................................................... 37

Figure 46. Lining Rivet (or Bolt) Tightening Sequence ............................................................................................................................................... 38

Figure 47. Installing Spider Mounting Hardware ........................................................................................................................................................39

Figure 48. Dustshield Spacing ....................................................................................................................................................................................39

Figure 49. Designed Interference Fit ..........................................................................................................................................................................39

Figure 50. Attaching Screw Location .......................................................................................................................................................................... 40

Figure 51. Air Chamber Bracket Mounting Hardware ............................................................................................................................................... 41

Figure 52. Camshaft Installation ................................................................................................................................................................................. 42

Figure 53. Cam Head Washer Installation ..................................................................................................................................................................42

Figure 54. Shim Washer and Snap Ring Installation .................................................................................................................................................. 43

Figure 55. Brake Adjuster End Play Check ................................................................................................................................................................ 43

Figure 56. Brake Adjuster Lubrication and Adjustment ............................................................................................................................................... 43

Figure 57. Shoe Web Lubrication ...............................................................................................................................................................................45

Figure 58. Shoe Retaining Spring Installation ............................................................................................................................................................ 45

2

Page 4

General Information

List of Illustrations

Figure 59. Shoe Return Spring and Roller Installation ............................................................................................................................................... 45

Figure 60. Upper and Lower Shoe Positioning ........................................................................................................................................................... 46

Figure 61. Shoe Return Spring Installation .................................................................................................................................................................46

Figure 62. Upper and Lower Shoe Positioning ........................................................................................................................................................... 47

Figure 63. Shoe Return Spring Installation .................................................................................................................................................................47

Figure 64. Roller Retainer Installation ........................................................................................................................................................................ 48

Figure 65. Shoe Return Spring Installation .................................................................................................................................................................48

Figure 66. Retainer Installation ...................................................................................................................................................................................48

Figure 67. Anchor Pin Bushing Installation .................................................................................................................................................................49

Figure 68. Lower Shoe and Anchor Pin Installation ....................................................................................................................................................49

Figure 69. Upper Shoe and Anchor Pin Installation ....................................................................................................................................................49

Figure 70. Cap Screw Installation ...............................................................................................................................................................................49

Figure 71. Shoe Return Spring Installation .................................................................................................................................................................50

Figure 72. Roller Retainer Installation ........................................................................................................................................................................ 50

Figure 73. Roller and Retainer Installation ................................................................................................................................................................. 50

Figure 74. Retainer Installation ...................................................................................................................................................................................50

Figure 75. Groove Pin Installation .............................................................................................................................................................................. 51

Figure 76. Spider Anchor Pin Bushing Installation ..................................................................................................................................................... 51

Figure 77. Shoe Anchor Pin Bushing Installation ....................................................................................................................................................... 51

Figure 78. Lower Shoe Positioning .............................................................................................................................................................................52

Figure 79. Upper Shoe Positioning .............................................................................................................................................................................52

Figure 80. Upper Shoe Installation .............................................................................................................................................................................52

Figure 81. Lower Shoe and Anchor Pin Installation ....................................................................................................................................................52

List of Illustrations

and Tables

List of Tables

Table 1. Bendix Brake Models and Specifi cations .........................................................................................................................................................4

Table 2. Distance Range .............................................................................................................................................................................................15

Table 3. Stroke Values ................................................................................................................................................................................................. 16

Table 4. Lubrication Intervals ....................................................................................................................................................................................... 17

Table 5. Shoe Removal Procedure Index ....................................................................................................................................................................20

Table 6. Distance: Clevis Pin Hole Centerline to Air Chamber Face ...........................................................................................................................36

Table 7. Camshaft Bushing Installation Specifi cations ................................................................................................................................................37

Table 8. Shoe Installation Procedure Index .................................................................................................................................................................44

3

Page 5

General Information

Foreword/Lining Material Warning

Purpose of this Manual

This Bendix Spicer Foundation Brake LLC publication is

intended to act as a source of maintenance information

to those involved in servicing Bendix brakes.

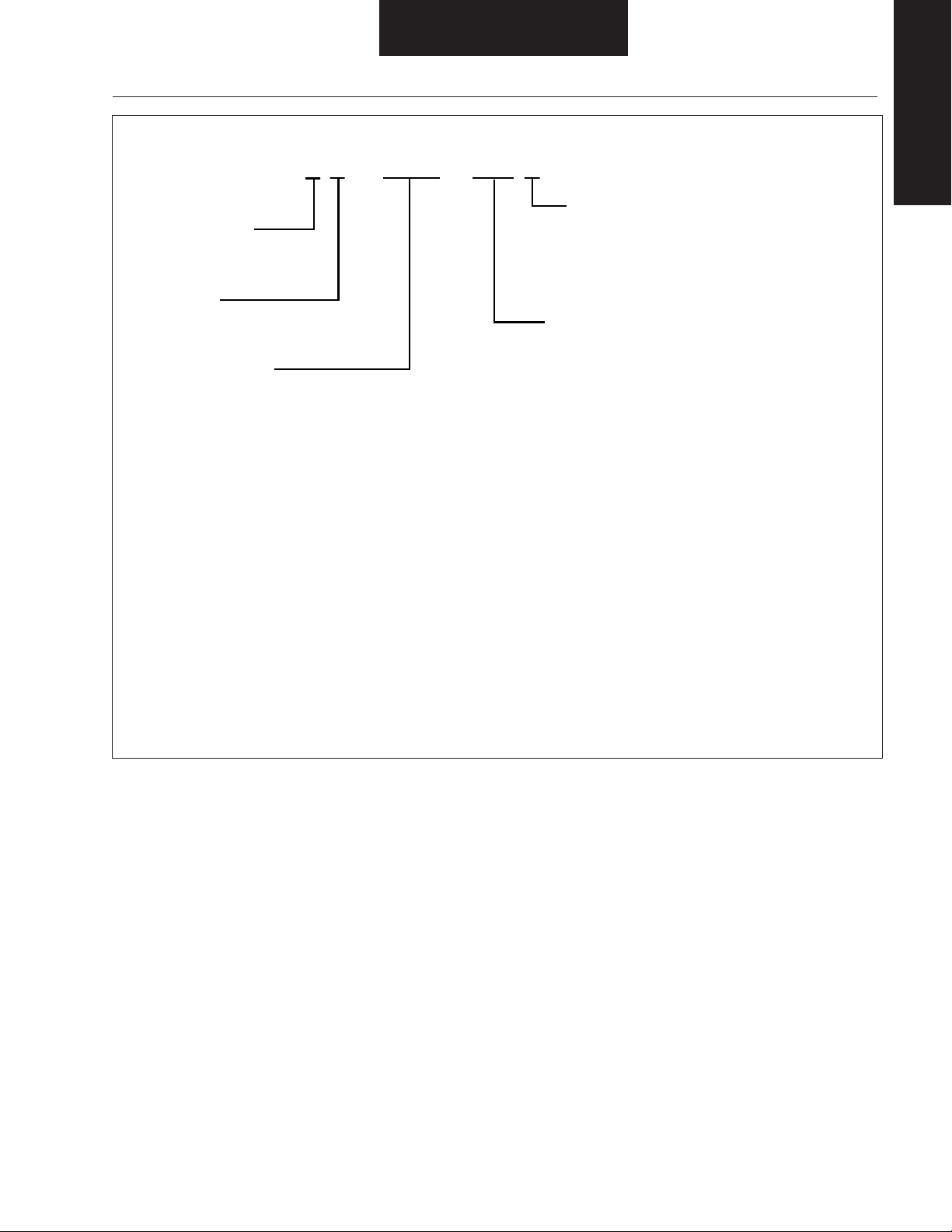

How to Use this Manual

1. Arrangement. This manual is arranged in seven sections:

General Information, Periodic Service, Removal/Disassembly,

Inspection, Repair/Replacement, Installation/Assembly and

Specifi cations. General page layout, including section and

paragraph headings, indention levels, and Figure and Table

designator information, is shown in Figure 1.

2. Table of Contents. The Table of Contents lists all section

headings and primary paragraph headings in this

publication.

3. Illustrations and Tables. Illustrations and tables are included

to help make the text of this publication clear. See the List of

Illustrations and List of Tables following the Table of

Contents.

4. Specifi cation Chart. A tabulation of all measurement

specifi cations is provided at the back of this publication.

4

Page 6

General Information

!

DANGER

AVOID CREATING DUST

POSSIBLE CANCER AND LUNG DISEASE HAZARD

Material Warning

Foreword/Lining

While Bendix Spicer Foundation Brake LLC does not offer asbestos

brake linings, the long-term effects of some non-asbestos fi bers

have not been determined. Current OSHA Regulations cover

exposure levels to some components of non-asbestos linings but not

all. The following precautions must be used when handling these

materials.

1. AVOID CREATING DUST. Compressed air or dry brushing must

never be used for cleaning brake assemblies or the work area.

2. BENDIX SPICER FOUNDATION BRAKE LLC RECOMMENDS THAT

WORKERS DOING BRAKE WORK MUST TAKE STEPS TO MINIMIZE

EXPOSURE TO AIRBORNE BRAKE LINING PARTICLES. Proper

procedures to reduce exposure include working in a well ventilated

area, segregation of areas where brake work is done, use of local

fi ltered ventilation systems or use of enclosed cells with fi ltered

vacuums. Respirators approved by the Mine Safety and Health

Administration (MSHA) or National Institute for Occupational

Safety and Health (NIOSH) should be worn at all times during

brake servicing.

3. Workers must wash before eating, drinking or smoking; shower

after working, and should not wear work clothes home. Work

clothes should be vacuumed and laundered separately without

shaking.

4. Material safety data sheets on this product, as required by

OSHA, are available from Bendix Spicer Foundation Brake LLC.

5

Page 7

General Information

Model Coverage

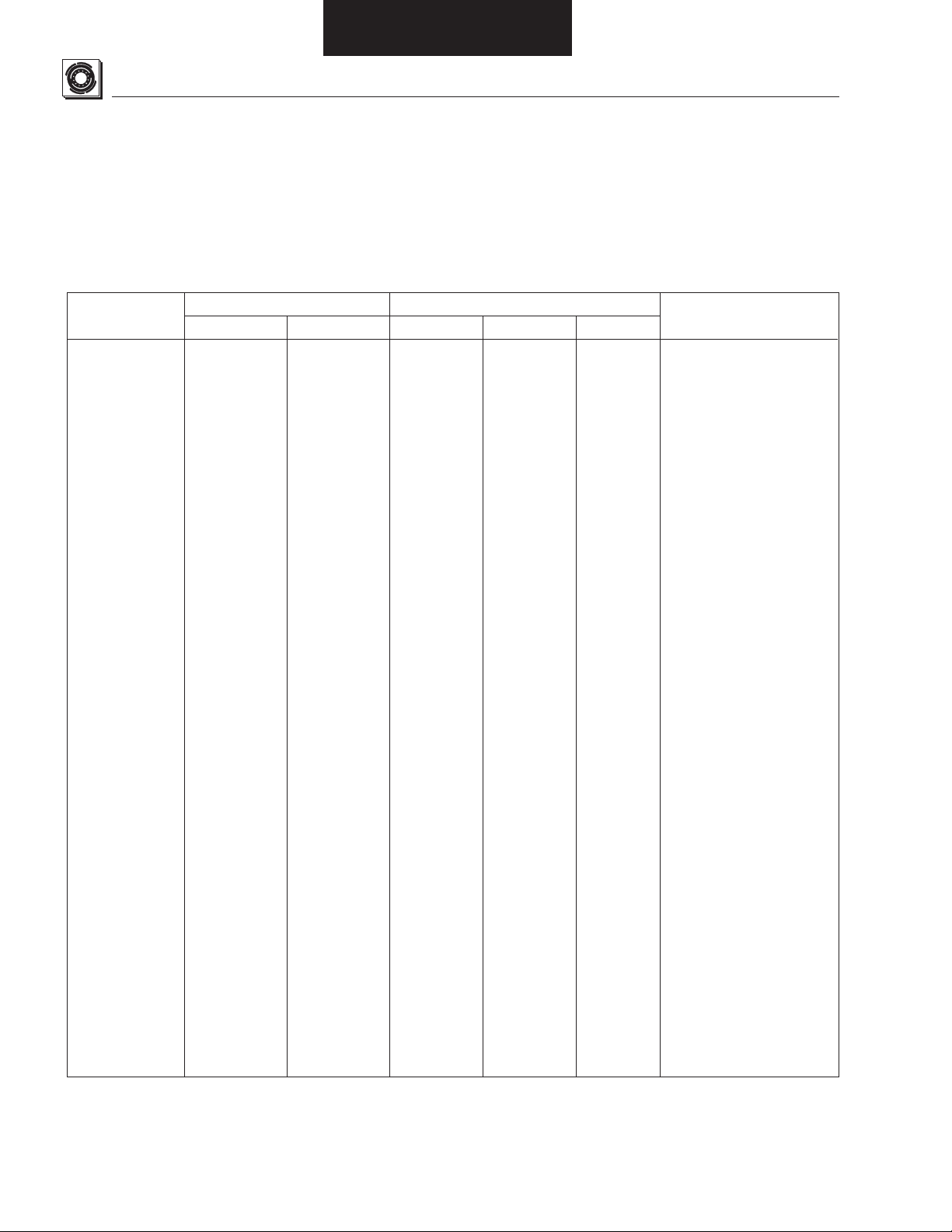

The service procedures and specifi cations in this publication

cover the Bendix brake models listed in Table 1. The basic

instructions cover all 15", 16.5", and 18" brake types and sizes,

unless specifi ed otherwise. A breakdown of Bendix brake model

identifi cation is provided in Figure 2.

Brake

Model

Size

mmin.

Shoe Spider Anchor

Confi guration

Applications

EB-150-4L 15.0 x 4 381 x 102 Fabricated Fabricated SAP Steer Axles

EB-165-5D 16.5 x 5 419 x 127 Fabricated Cast SAP Steer or Drive Axles

EB-165-5L 16.5 x 5 419 x 127 Fabricated Fabricated SAP Steer or Drive Axles

EB-165-6D 16.5 x 6 419 x 152 Fabricated Cast SAP Steer or Drive Axles

EB-165-6L 16.5 x 6 419 x 152 Fabricated Fabricated SAP Steer or Drive Axles

EB-165-7D 16.5 x 7 419 x 178 Fabricated Cast SAP Steer or Drive Axles

EB-165-7F 16.5 x 7 419 x 178 Fabricated Forged SAP Trailer Axles

EB-165-7L 16.5 x 7 419 x 178 Fabricated Fabricated SAP Steer or Drive Axles

EB-165-8D 16.5 x 8.63 419 x 219 Fabricated Cast SAP Drive Axles

EB-165-8L 16.5 x 8.63 419 x 219 Fabricated Fabricated SAP Drive Axles

EB-180-7R 18.0 x 7 457 x 178 Cast Heavy Cast SAP On/Off Hwy. Drive Axles

ES-150-4L 15.0 x 4 381 x 102 Fabricated Fabricated SAP Steer Axles

ES-150-4D 15.0 x 4 381 x 102 Fabricated Cast SAP Steer Axles

ES-150-6D 15.0 x 6 381 x 152 Fabricated Cast SAP Steer or Drive Axles

ES-150-8D 15.0 x 8.63 381 x 219 Fabricated Cast SAP Drive Axles

ES-150-8F 15.0 x 8.63 381 x 219 Fabricated Forged SAP Trailer Axles

ES-165-5D 16.5 x 5 419 x 127 Fabricated Cast SAP Steer or Drive Axles

ES-165-5L 16.5 x 5 419 x 127 Fabricated Fabricated SAP Steer or Drive Axles

ES-165-6D 16.5 x 6 419 x 152 Fabricated Cast SAP Steer or Drive Axles

ES-165-6L 16.5 x 6 419 x 152 Fabricated Fabricated SAP Steer or Drive Axles

165 XL Cast 16.5 x 6 419 x 152 Cast Cast DAP Steer Axle Transit

ES-165-7D 16.5 x 7 419 x 178 Fabricated Cast SAP Steer or Drive Axles

ES-165-7F 16.5 x 7 419 x 178 Fabricated Forged SAP Trailer Axles

ES-165-7H 16.5 x 7 419 x 178 Cast Heavy Cast DAP On/Off Hwy. Drive Axles

ES-165-7L 16.5 x 7 419 x 178 Fabricated Fabricated SAP Steer or Drive Axles

ES-165-7M 16.5 x 7 419 x 178 Fabricated Heavy Cast DAP On/Off Hwy. Drive Axles

ES-165-8L 16.5 x 8.63 419 x 219 Fabricated Fabricated SAP Drive Axles

ES-165-8D 16.5 x 8.63 419 x 219 Fabricated Cast SAP Drive Axles

ES-165-8F 16.5 x 8.63 419 x 219 Fabricated Forged SAP Trailer Axles

ES-165-8L 16.5 x 8.63 419 x 219 Fabricated Forged SAP Trailer Axles

165 XL Cast 16.5 x 10 419 x 254 Cast Cast DAP Drive Transit

Table 1. Bendix Brake Models and Specifi cations

6

Page 8

Manufacturer

Bendix Spicer

Foundation Brake

Service

B - Standard Service

S - Extended Service

Drum Diameter

122 – 12.25" (311 mm)

150 – 15" (381 mm)

165 – 16.5" (419 mm)

180 – 18" (457 mm)

Shoe Size

04 - 4" – (102 mm)

05 - 5" – (127 mm)

06 - 6" – (152 mm)

07 - 7" – (178 mm)

07 - 7.5” – (191 mm)

08 - 8.63" – (219 mm)

10 - 10" – (254 mm)

General Information

E S - 1 5 0 - 0 8 D

Configurations

A - Fab Shoe Weld On Spider Self Contained Cam Bracket SAP

B - Fab Shoe Weld On Spider Self Contained Cam Bracket DAP

D - Fabricated Shoe/Cast Spider SAP

F - Fabricated Shoe Weld On Spider SAP (Non Self Contained)

H - Cast Shoe/Heavy Cast Spider DAP

L - Fabricated Shoe/Fabricated Spider SAP

M - Fabricated Shoe/Cast Spider (DAP Closed A/P)

P - Fabricated Shoe/Weld On Spider (DAP Closed A/P)

R - Cast Shoe/Heavy Cast Spider SAP

S - Reinforced Fabricated Shoe/Heavy Cast Spider (SAP)

T - Fabricated Shoe/Weld On Spider DAP (Non Self Contained)

Configuration

Example: L = Fabricated Shoe

Fabricated Spider

Single Anchor Pin (SAP)

Shoe Size

Example: (219mm)

8 = 8.63"

Model Coverage

Figure 2. Bendix Brake Model Identifi cation

SAP - Single Anchor Pin

DAP - Double Anchor Pin

7

Page 9

Parts Nomenclature

General Information

General parts nomenclature for Bendix brake models are identifi ed

in Figure 3. Variations in shoe hold-down springs and guides are

ES-150-4L Brake

Camshaft

Retainer

Snap Ring

Brake Adjuster

Inner Washer

Camshaft

Shim

Camshaft

Bushing

Washer

Brake

Adjuster

Grease

Seal

Dustshield Screw

Shoe Assembly

*Shoe Hold-Down Spring and Guide Variation

Stabilizer Nut

Bracket

Assembly

Camshaft

Bushing

Bolt

Cam Roller

Shoe Retainer

Spring

Color - Blue

also identifi ed. Specifi c parts nomenclature for specifi c Bendix brake

models are provided in Figure 4.

Shoe Hold-Down Spring and Guide Variation

New Style

Shoe Spacer Not Required

Shoe Assembly

Camshaft

Grease

Seal

Barrel Nut

Dustshield

Assembly*

Spider

Old Style

Shoe Hold-Down Spring

Shoe Return

Spring

Color - Blue

Nut

Washer

Shoe*

Hold-Down

Spring

Shoe

Spacer

Cam Roller

Bolt*

Standard Nut

(Must be Removed for New Style Hold-Down)

Shoe Guide and Shoe

Hold-Down Spring

ES-150-4D Brake

Shoe

Return Spring

Color - Red

Cast

Spider

Cam Head

Washer

Camshaft

Figure 3. Brake Part Nomenclature, General

8

Shoe Return

Color - Grey

Shoe Assembly

Retainer

Spring

Shoe Assembly

Inspection

Hole Plug

Roller

Bracket

Stud

Roller

Lock Washer

Dustshield

Retainer

Bracket

Assembly

Nut

Camshaft

Bushing

Grease

Seal

Grease

Camshaft

Bushing

Grease

Fitting

Seal

Camshaft

Shim

Washer

Brake Adjuster

Brake Adjuster

Inner Washer

Camshaft

Retainer

Snap Ring

Page 10

General Information

Parts Nomenclature

ES-150-6D

Steer Brake

Shoe

Retainer Springs

Color - Orange

(Stamped Steel)

Camshaft

Shoe Assembly

Retainer

Shoe Return

Spring

Color - Red

Spider

Cam Head Washer

Roller

Shoe Return

Camshaft

Bushing

Spring

Roller

Grease

Seal

Retainer

Bracket

Assembly

Brake

Adjuster

Camshaft

Bushing

Camshaft

Shim

Washer

Brake Adjuster

Inner Washer

Grease

Seal

Grease Fitting

Camshaft

Retainer

Snap Ring

ES-150-8D and

ES-150-8F

Drive & Trailer

Brake

Shoe

Retainer Springs

Color - Orange

Spider

(Stamped Steel)

Cam Head Washer

Camshaft

Shoe Assembly

Shoe Assembly

Roller

Retainer

Shoe Return

Spring

Color - White

Retainer

Roller

Bracket

Assembly

Camshaft

Bushing

Grease

Seal

Camshaft

Bushing

Grease

Grease Fitting

Brake Adjuster

Seal

Camshaft

Shim

Washer

Brake Adjuster

Inner Washer

Forged Spider

Camshaft

Retainer

Snap Ring

Figure 4. Brake Model Part Nomenclature

Shoe Assembly

9

Page 11

Parts Nomenclature

General Information

Brake Model

EB-165-5D

EB-165-5L

EB-165-6D

EB-165-6F

EB-165-7D

EB-165-7F

EB-165-7L

Cam Roller and Pin for

EB-165 and EB-180 Brakes

Two-Piece Roller and Pin

Shoe Assembly

Shoe Retainer

Springs

Color - Orange

(Stamped Steel)

Camshaft

Spider

Shoe Return Spring

Dustshield

Grease Seal

Bracket Stud

Cam Roller

and pin

Shoe Assembly

Inspection

Hole Plug

Dustshield

Screw

Grease

Fitting

Camshaft

Bushing

Brake Adjuster

Camshaft

Shim Washers

Nut

Lockwasher

Note: Cast spiders are tapped

and require 4 bolts and lock-

chamber bracket assembly.

Camshaft

Retainer

Snap Ring

Brake Adjuster

Inner Washer

Grease Seal

Camshaft Bushing

Bracket Assembly

Cast Spider

washers to attach air

Brake Model

ES-165-5D

ES-165-5L

ES-165-6D

ES-165-6F

ES-165-7D

ES-165-7F

ES-165-7L

Shoe

Retainer Springs

Color - Orange

Cam Head Washer

Cast Spider

With Horse

Shoe

Return Spring

Color - Red

Spider

(Stamped Steel)

Camshaft

Collar

Cam Head

Washer

Shoe Return

Color - Grey

Shoe Assembly

Retainer

Spring

Shoe Assembly

Inspection

Hole Plug

Roller

Bracket

Stud

Roller

Lock Washer

Dustshield

Retainer

Bracket

Assembly

Nut

Camshaft

Bushing

Grease

Seal

Forged

Spider

Grease

Camshaft

Bushing

Grease

Fitting

Seal

Camshaft

Shim

Wash er

Brake Adjuster

Brake Adjuster

Inner Washer

Cast

Spider

Camshaft

Retainer

Snap Ring

Figure 4. Brake Model Part Nomenclature, Continued

10

Page 12

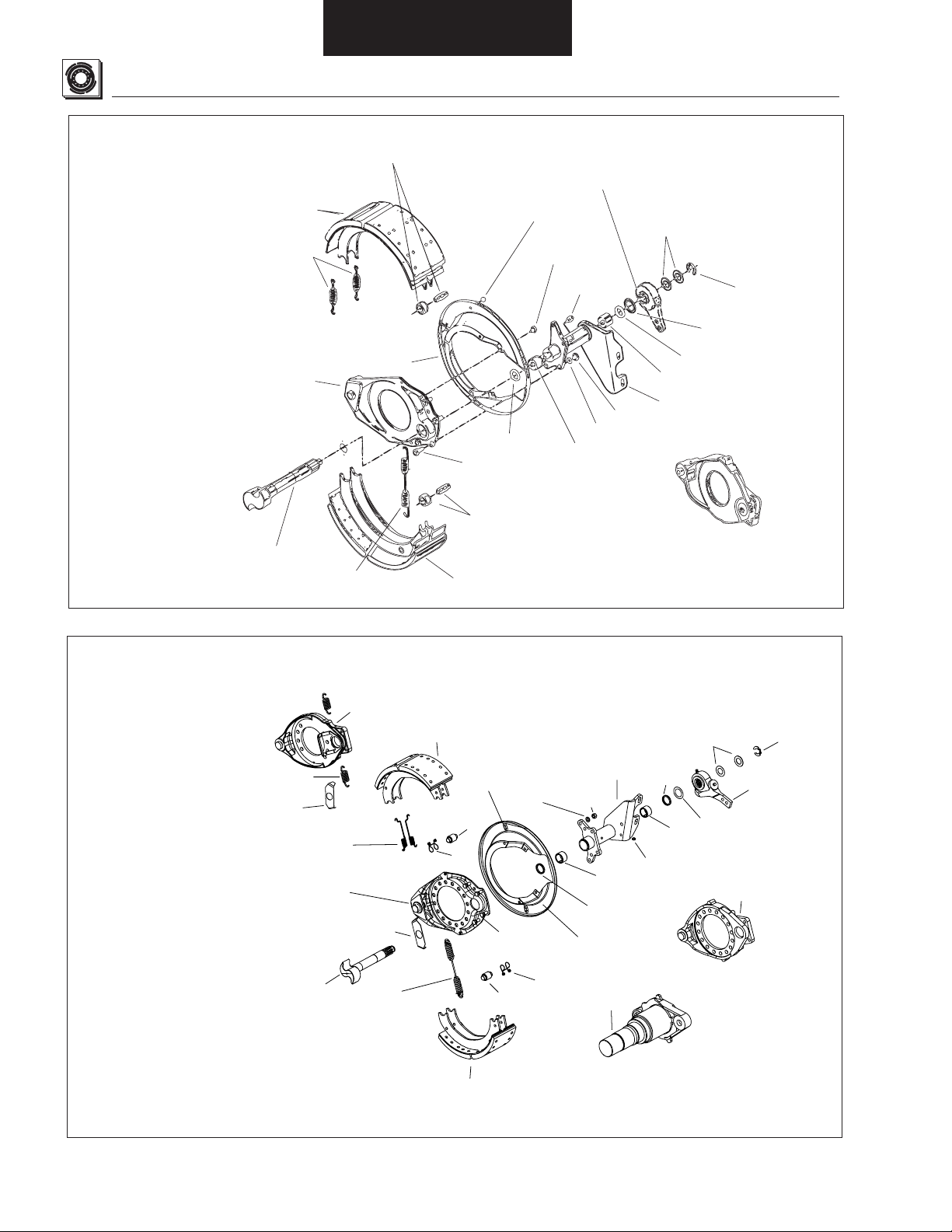

y

General Information

ES-165-7M

Heavy-Duty

Brake

ES-165-7H

Severe Duty

Brake

Cast Shoe Return Spring

Color - Orange

Fabricated Shoe Assembly

Anchor Pin

Washer

Snap Ring

Anchor Pin

Bushings

Camshaft

Snap Ring

Nut

Washer

Snap Ring

Washer

Retainer

Roller

Cast

Spider

Washer

Washer

Anchor Pin

Fabricated Shoe Assembly

Inspection

Hole Plug

Snap Ring

Dustshield

Shoe Return

Spring

Color - llow

Retainer

Roller

Brake Adjuster

Bracket

Assembly

Bracket Lock Washer

Camshaft Bushing

Grease Seal

Camshaft

Retainer

Snap Ring

Camshaft

Shim Washer

Brake Adjuster Inner Washer

Grease Seal

Camshaft Bushing

Grease Fitting

Bolt

Cast Spider H version

Roller Dowel Pin

Camshaft Roller

and Pin

Bushing

Anchor Pin

Washer

Snap Ring

NO s are tapped

and require four bolts and lockwashers

to attach air chamber bracket assembl

Bushing

.

ES-180-7R

Brake

Shoe

Retainer Springs

Color - Orange

Spider

(Stamped Steel)

Shoe Assembly

Camshaft Roller

and pin

Camshaft

Camshaft Roller

and Pin

Inspection

Hole Plug

Assembly

Lock Washer

Shoe Return

Spring

Color - Green

Bracket

Bolt

Grease

Seal

Dustshield

Camshaft

Bushing

Camshaft

Bushing

Grease

Seal

Grease

Fitting

Camshaft

Washer

Brake Adjuster

Inner Washer

Bracket Bolt

Lock Washer

Shim

Camshaft

Retainer

Snap Ring

Brake Adjuster

Shoe Assembly

11

Page 13

Parts Nomenclature

Model ES-165 and EB-165 Interchangeability

General Information

Brake parts for the Extended Service Brake (Model ES-165) are unique

and must not be intermixed with Standard Brake parts (Model EB-165)

unless otherwise instructed. These parts consist of the camshaft,

camshaft washer, return spring, cam roller and shoe/lining assembly.

Any attempt to operate the brake with other than its intended parts may

result in unsatisfactory performance.

“On-Road” Repair: If a vehicle should need “On-Road” repair and

™

ES

Brake hardware is not available, it is possible to retrofi t the brake

with Standard Brake parts in order to return the vehicle to service.

These parts consist of the Standard shoe/lining assembly, cam roller,

pin and return spring. The retaining springs and camshaft with cam

washer will work in this situation and do not need to be replaced.

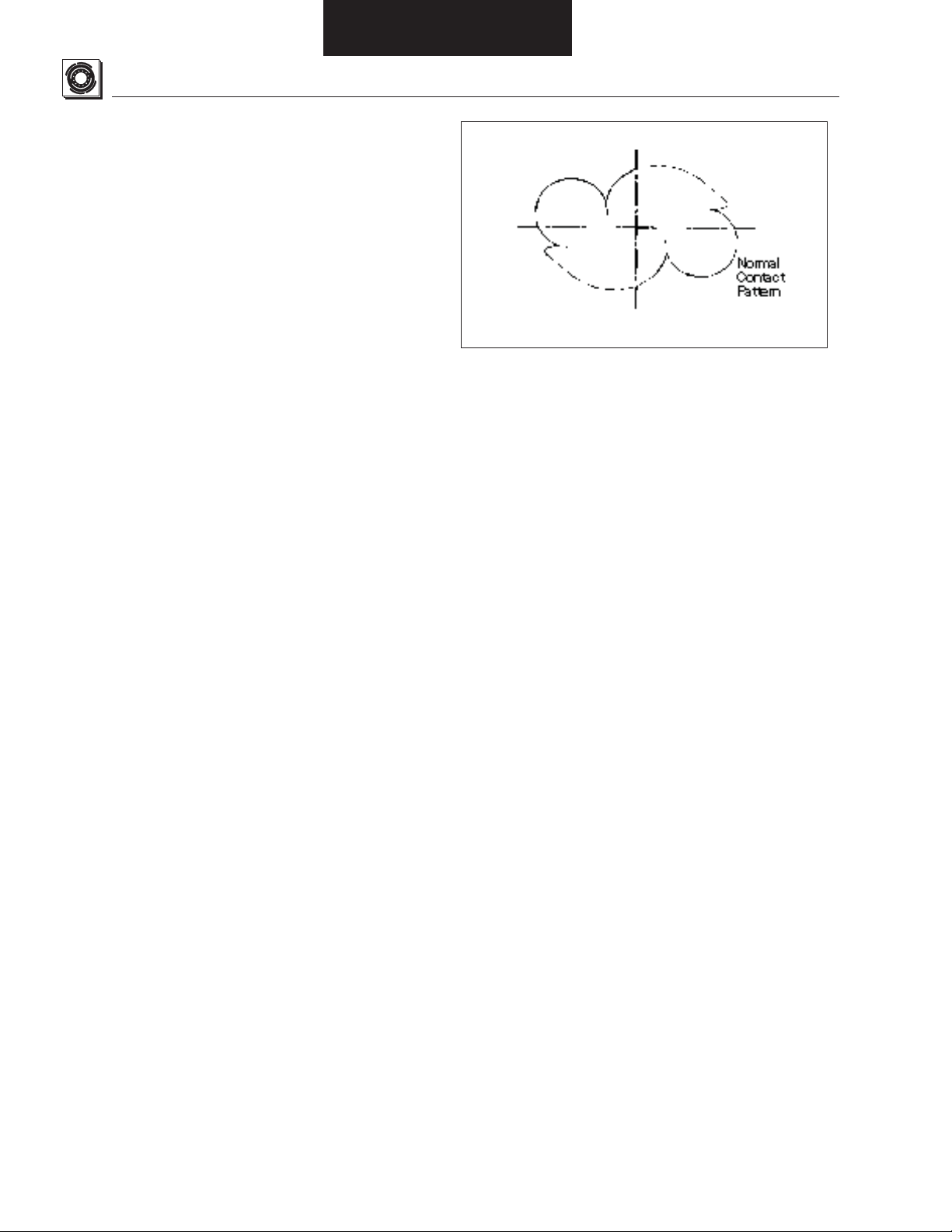

EB™ Roller and ES™ Cam Interchangeability

The EB™ Roller and the ES™ Cam are compatible and can be used

together. Figure 5 illustrates the proper fi t of an EB

™

ES

Cam. As shown, the contact pattern is at two points and the

two parts will function satisfactorily with this fi t.

NOTE: The ES

™

Roller and EB™ Cam are not compatible and should

not be used together.

™

Roller to an

EB™ Roller

Figure 5. EB

™

Roller and ES™ Cam Contact Pattern

ES

™

Cam

12

Page 14

General Information

Bendix brake model parts identifi cation for shoes, return springs,

spiders and camshafts are identifi ed in Figure 6.

Parts Nomenclature

ES-150-D,F

ES/EB 150-4L

Old

ES-165-D,L,F

New

Shoe without

Spring Attaching

Lugs

High and Low mount shoes

Figure 6. Parts Identifi cation

Shoe Return Spring

13

Page 15

Brake Spiders

General Information

Camshafts

Stamped Spider ES/EB-150-4L

Air Chamber

Brake Flange

shape for

ES/EB-150-4L

Figure 6. Parts Identifi cation, Continued

14

Page 16

Periodic Service

Parts Identifi cation

Maintenance and Adjustment

Due to the importance of a well-maintained brake system, the

inspections and maintenance listed below must be accomplished

by commercial vehicle operators at the intervals suggested.

Since driver technique and vehicle use affect the rate of brake

component wear, it may be appropriate to increase the frequency

of the following inspections to fi t individual needs based upon past

experience.

Brake Maintenance Preliminary Steps

Prior to performing any maintenance requiring removal of the tire

and wheel, the following preliminary steps must be taken to ensure

your safety. Refer to Figure 7.

Brake Adjustment - Manual Brake Adjuster

NOTE: An assistant is required to make a brake adjustment.

WARNING: Block all wheels before beginning this adjustment

!

procedure.

To determine whether Bendix Brakes require adjustment, applied

stroke is measured and compared to the maximum value for the air

chamber size in use on the vehicle.

1. Perform “Brake Maintenance Preliminary Steps” described earlier.

2. With air chamber pushrod fully retracted, measure distance from

face of air chamber to centerline of clevis pin hole. Refer to Figure 8.

If the measurement is not within ranges shown in Table 2, reposition

clevis. Remeasure the distance and repeat until within range. Record

exact measured distance as dimension “A”.

Distance: Clevis Pin Hole

Centerline to Air Chamber Face

All brakes (except 2-5/8" ± 1/16"

Mack and Trailer Axle) (66.7 ± 1.59 mm)

Figure 7. Vehicle Maintenance Support

1. Set parking brake and block wheels to prevent vehicle

movement.

2. Raise drive axle with a jack and support on suitable stands.

WARNING: Never work under a vehicle supported by a jack.

!

3. Cage spring-type brake chamber following vehicle

manufacturer’s instructions.

4-3/8" ± 1/16"

Mack brakes

(111.1 ± 1.59 mm)

Trailer Axle 6-1/2" ± 1/8"

brakes (165.1 ± 3.175 mm)

Table 2. Distance Range

Figure 8. Measurement, At Rest

15

Page 17

Maintenance and Adjustment

Periodic Service

3. Apply and hold an 80 psi brake application, and again measure

from face of air chamber to clevis pin centerline. Refer to Figure 9.

Record distance as dimension “B”.

Figure 9. Measurement, 80 psi Applied

4. Subtract dimension “A” from “B”. The difference is applied stroke.

Compare applied stroke to maximum value in Table 3. If applied

stroke equals or exceeds maximum applied stroke shown, adjust

brakes. If less than the maximum, no adjustment is required and you

may perform Brake Operation Check.

80 - 90 PSI

Air Chamber Maximum Desired

Size Applied Free

Stroke Stroke

Type 30" Long Stroke 2.5" 3/8" to 5/8"

Type 30" 2" (Without Drag)

Type 24" 1-3/4"

Type 24" (w/ 2-1/2" 2"

extended stroke)

Type 24 (w/3" extended stroke) 2.5"

Type 20" and 16" 1-3/4" 3/8" to 1/2"

Type 12" 1-3/8" 3/8" to 1/2"

Table 3. Stroke Values

NOTE: If adjustment is necessary, Bendix Brakes are adjusted to

achieve proper free stroke. The difference between free stroke and

applied stroke is merely the method used to move the brake adjuster

from rest. Applied stroke uses an 80 psi brake application; free

stroke is measured using a lever to move the brake adjuster until the

brake shoes contact the drum. If applied stroke exceeded the

maximum and adjustment is necessary, adjust the brakes as

described in steps 5 through 8 below.

16

5. Take “A” dimension exactly as before. Take “B” measurement

using a lever to move brake adjuster as shown until the shoes

contact drum. Refer to Figure 10. The result of “B” - “A” is brake

free stroke. Adjust free stroke to within range specifi ed in Table 3.

Figure 10. Measurement, Brake Applied

6. To adjust free stroke, depress locking sleeve on brake adjuster

adjustment nut and turn in direction required. Recheck free stroke

to verify it is within range. Make sure sleeve is “locked” when

adjustment is completed.

7. Verify that brakes are not dragging by spinning wheels by hand

or tapping drum lightly with a hammer and listening for a sharp

ringing sound.

8. Perform Brake Operation Check, to verify proper operation of

brakes before releasing vehicle for service.

Brake Adjustment - Automatic Slack Adjuster

NOTE: A properly working Automatic Slack Adjuster does not require

manual adjustment while in service. The manual adjuster hex is

intended for use during adjuster installation and brake overhaul.

WARNING: Automatic slack adjusters must never be repeatedly

adjusted to correct excessive in service pushrod stroke, because this

condition indicates that a problem exists with the automatic adjuster,

with the installation of the adjuster or with related foundation brake

components which manual adjustment will not correct.

1. Brake adjustment for automatic slack adjusters is the same as for

manual brake adjusters.

2. Refer to the Automatic Slack Adjuster Manufacturer's Instructions for

proper installation.

Page 18

Brake Operation Check

Periodic Service

NOTE: An assistant is required to make a thorough brake operation

check.

1. Apply brakes to 80 psi and hold. Check all air line fi ttings and air

chambers for leakage.

2. Apply and release brakes while observing operation of brake

adjusters on each axle. As brakes are applied and released, brake

adjusters should move in unison visually.

3. Investigate source and make corrections for any discrepancies

found in Steps 1 and 2.

4. Drive vehicle at low speeds in a safe area and make several brake

applications to verify safe operation and absence of pulling,

grabbing, or noise. If any of these are noted, investigate and repair

prior to releasing vehicle for service.

CAUTION: Never release a vehicle for service if any brake

!

discrepancy - no matter how minor - is evident.

Lubrication

When servicing brakes or replacing components, lubricate per guidelines listed in Lubrication Table below.

Lubricate the following components with grease specifi ed in table:

• One-piece Roller —lubricate shoe roller recess.

• Two-piece Roller—lubricate shoe roller I.D.

• Roller and anchor pin recesses of each shoe on ES & ED 150-4L models

Do Not Lubricate The Following:

Maintenance and Adjustment

• Cam head surface or related parts that contact cam head surface. For effi cient operation, the cam head surface must remain free of oil,

grease or other contaminants.

Note: When lubricating the camshaft bracket, lubricate until grease comes out at the brake adjuster end.

The seal is installed at this end with the air side in so that grease purges out.

CAUTION: Do not use moly-disulfi de loaded grease or oil because this may shorten service life.

!

Important: In no case should the lubrication interval exceed the published intervals in table below.

Component Lubrication Interval Type of Lubricant

Standard Every 50,000 miles or every 3 months Standard Chassis Grease

LMS-Low Lube Every 250,000 miles or once a year* Mobilith SHC-460 Synthetic

LMS-Lube Free None* Mobilith SHC-PM Synthetic

Table 4. Lubrication Intervals

Note: The Bendix LMS-Low Lube brake uses a special “button head” grease fi tting. This helps identify the system as an LMS Brake

Package and also indicates that system should be lubricated with a Bendix approved synthetic lubricant.

The Bendix LMS-Lube Free brake is lubricated at the factory with Mobilith SCH-PM synthetic grease and does not require lubrication at

service intervals. There is no grease fi tting on the LMS lube free components.

Brake Adjuster Lubrication: Pressure Iubricate according to manufacturer’s instructions.

17

Page 19

Periodic Service

Periodic Inspections

The component inspections discussed below are general in nature.

More detailed component inspections are normally done at overhaul.

For more specifi c guidelines, refer to the appropriate inspection

instructions in Brake Overhaul.

Service Intervals

Brake Reline

A brake reline should be done any time the lining thickness or

condition indicates the need.

Visual Inspection

A thorough visual inspection for brake wear, loose fasteners, broken

parts and/or obvious damage should be made each time the brake is

being serviced or the wheel and drum have been removed. In no case

should the visual inspection interval exceed 3 months of service.

Lining Inspection

A visual check of lining thickness and condition should be made each

time the vehicle is being serviced in the maintenance shop. In no case

should the lining thickness/condition inspection interval exceed 3

months of service.

Brake Adjustment

Brake Adjustment should be checked (and adjusted if necessary)

WEEKLY or any time applied stroke exceeds the maximums shown

in Periodic Maintenance: Brake Adjustment - Manual Brake

Adjuster.

Brake Operation Check

A complete operation check of the braking system should be made

following the instructions in Brake Operation Check, after any brake

service. In no case should the operation check interval exceed 3

months of service.

Camshaft Radial Play

Camshaft radial play should be checked with a dial indicator any

time the brake shoes have been removed from the vehicle to

assess the condition of the camshaft bushings. Refer to

Camshaft Inspection.

Camshaft Axial Play

Camshaft axial play should be checked any time the camshaft or

brake adjuster has been removed from the vehicle. Refer to the

axial play instructions in Brake Adjuster Installation, starting with

Step 6.

Brake Overhaul

A complete brake overhaul following the instructions in the

service manual should be accomplished at every third brake

reline.

Lubrication

See Periodic Service / Lubrication for detailed lube instructions

and intervals.

18

Page 20

Removal / Disassembly

A complete brake overhaul consists of:

• complete disassembly

• cleaning

• inspection

• repair and replacement of components

• assembly

• brake operation check

Detailed instructions for each of these steps are listed on the

following pages in the order in which they would normally be

encountered during a typical brake overhaul.

WARNING: The long-term effects of non-asbestos fi bers

!

have not been determined. Therefore, precautions should

be used when handling these materials.

See General Information / Lining Material Warning

Drum Removal

1. Perform “Brake Maintenance Preliminary Steps”.

2. While depressing locking sleeve, back off brake adjuster adjust-

ment nut on manual brake adjusters. Refer to Figure 11. Continue

turning until shoes are fully returned to released position and clear of

drum. On self adjusting brake adjusters, follow manufacturer’s

instructions.

NOTE: With outboard mounted drums go to step 6.

Check, Lubrication,

Inspection, Service

Figure 11. Brake Adjuster Adjustment

3. On drive axles, remove stud nuts and axle shafts. If used, remove

Iockwashers and taper dowels. If necessary, loosen dowels by holding

a brass drift in the center of the shaft head and striking it a sharp blow

with a hammer. On trailer and steer axles, remove hub cap.

WARNING: Do not strike the axle shaft fl ange with a hammer.

!

Do not use chisels or wedges to loosen shaft or dowels.

4. Remove axle spindle nut(s) and washer.

5. While rocking drum, pull outboard enough to allow removal of

outer wheel bearing.

6. Remove drum by pulling outboard while rocking from side to side.

If shoes are not clear of drum, return to Step 2 above.

CAUTION: If diffi culty is found on removal, do not force drum.

!

Excessive pulling force may damage brake components.

19

Page 21

Removal / Disassembly

Shoe Removal

Shoe Removal

Table 5 provides an index to the location of shoe removal procedures.

Locate the brake model under service and identify the page where the

appropriate shoe removal procedures are located.

Brake Model Page Number Brake Model Page Number

EB-150-4L

EB-165-5D 20 ES-150-4L 22

EB-165-5L 20 ES-150-6D 20

EB-165-6D 20 ES-150-8D 20

EB-165-6L 20 ES-150-8F 20

EB-165-7D 20 ES-165-5D 20

EB-165-7L 20 ES-165-5D 20

EB-165-7F 20 ES-165-5L 20

EB-165-8D 20 ES-165-6D 20

EB-165-8F 20 ES-165-6L 20

EB-165-8L 20 ES-165-7F 20

22 EB-180-7R 20

ES-165-7H 25

ES-165-7L 20

ES-165-7M 23

Table 5. Shoe Removal Procedure Index

20

Page 22

Removal / Disassembly

NOTE: The following procedures are divided into sections,

identifi ed by brake model numbers.

Shoe Removal

EB models (except EB-150-4L)/ES-165-5D,L /

ES-165-6D,L / ES-165-7D, F, L / ES-150-8D, F /

ES-150-4D/ES-150-6D/ES-165-8D,F,L

1. Perform steps in Removal/Disassembly: Drum Removal.

2. ES-165-5,6,7,8,D,L,F, ES-150-4D, ES-150-8D, F & 6D ONLY:

Pry roller retainer coiled loops out of both shoe web holes as

shown in Figure 12. Pivot roller retainer to swing loops clear of

shoe webs.

NOTE: EB models do not have roller retainers.

WARNING: The long term effects of non-asbestos fi bers have

!

not been determined. Therefore, precautions should be used

when handling these materials.

See General Information / Lining Material Warning

3. Using a large screwdriver or lever, lift upper shoe to stretch return

spring as shown in Figure 13.

Drum/Shoe Removal

Remove Roller and Pin, Then

Repeat for Lower Shoe.

™

For ES

Figure 13. Upper Cam Roller and Pin Removal

4. Remove upper cam roller and pin.

NOTE: ES-165-5,6,7,8D, L, F, ES-150-4D, ES-150-8D, F & 6D

ONLY: Remove roller and roller retainer as a unit.

5. Repeat Steps 2 through 4 to remove lower shoe roller and pin.

NOTE: Bendix recommends the use of a suitable brake tool when

removing rollers and return springs.

Brakes, See Note Below

Figure 12. Roller Retainer Removal

21

Page 23

Shoe Removal

Removal / Disassembly

6. Push cam end of both shoes toward cam and unhook shoe return

spring. Remove and discard spring.

NOTE: To remove return spring, position a lever or suitable tool with

notch to engage spring rod. Refer to Figure 14. Apply downward

force to stretch spring, allowing removal of upper spring hook.

Remove and discard spring.

7. Rotate both shoes around anchor pin and remove from vehicle.

Refer to Figure 15.

8. Clean and inspect remaining parts as outlined in removal/

disassembly section of this manual.

Figure 14. ES-165-7D, L, F Shoe Removal

NOTE: ES-165-5,6,7L,D/ES-150-6D steer axle brakes may use two

return springs with a horse collar or dual spring post. To remove

return springs, position a lever or suitable tool with notch to engage

spring. Return to Figure 14. Apply downward force to stretch upper

spring, allowing removal of upper spring hook. Remove and discard.

Repeat procedure for lower spring.

Figure 15. Shoe Removal

Cast Spider With

Horse Collar

22

Figure 15B. Cast Spider With Horse Collar

Page 24

Removal / Disassembly

ES-150-4L and EB-150-4L Brakes

1. Perform steps in removal/disassembly : drum removal

2. Using a large screwdriver or lever, lift upper shoe to stretch

return spring.

3. Remove upper roller.

4. Report steps 2 through 3 to remove lower roller.

5. Stretch shoe return spring and unhook it from upper shoe web.

Refer to Figure 16.

WARNING: The long term effects of non-asbestos fi bers, have

!

not been determined. Therefore, precautions should be used

when handling these materials.

See General Information / Lining Material Warning

Shoe Removal

Figure 16. Shoe Return Spring Removal

6. Rotate shoe downward and turn to allow disengagement of shoe

retaining spring from lower shoe web. Refer to Figure 17.

7. Rotate upper shoe upward and remove shoe and shoe retaining

spring.

8. Clean and inspect remaining brake parts as outlined in Removal/

Disassembly section of this manual.

Figure 17. Lower Shoe Removal

23

Page 25

Shoe Removal

Removal / Disassembly

ES-165-7M Heavy-Duty Brake

WARNING: The long term effects of non-asbestos fi bers, have

!

not been determined. Therefore, precautions should be used

when handling these materials.

See General Information / Lining Material Warning

1. Perform steps necessary for drum removal. See Removal /

Disassembly - Drum Removal.

2. Remove cap screws and dustshield, if applicable.

3. Pry roller retainer coiled loops out of both shoe web holes as

shown in Figure 18. Pivot roller retainer to swing loops clear of shoe

webs.

4. Using a lever or large screwdriver, lift upper shoe to remove

roller and retainer as a unit. Refer to Figure 19.

Figure 19. Roller and Retainer Removal

Figure 18. Retainer Loop Removal

5. Repeat Steps 3 and 4 to remove lower roller and retainer

assembly.

6. To remove return spring, position a lever or suitable tool with a

notch to engage spring rod. Refer to Figure 20. Apply downward

force to stretch spring, allowing removal of upper spring hook.

Remove and discard spring.

24

Figure 20. Return Spring Removal

Page 26

Removal / Disassembly

ES-165-7M Heavy-Duty Brake, Continued

7. Remove retaining ring and washer from drum side of both

anchor pins. Refer to Figure 21.

Figure 21. Retaining Ring and Washer Removal

8. To allow removal of anchor pins, cut lock wire and remove cap

screws from spider. Refer to Figure 22.

9. To remove upper and lower shoes, remove anchor pins with a brass

drift or a mallet. Refer to Figure 23.

Figure 23. Anchor Pin Removal

Shoe Removal

NOTE: Inspect anchor pin and bushings. If pin was seized or bushing

is grooved or worn beyond 0.031" (0.79mm), replace pin and

bushing. Always replace pins and bushings with brake reline.

10. If any noted conditions are found, drive out old anchor pin

bushings from spider. Refer to Figure 24.

Figure 22. Cap Screw Removal

Figure 24. Anchor Pin Bushing Removal

11. Clean and inspect remaining brake parts as outlined in Removal/

Disassembly section of this manual.

25

Page 27

Shoe Removal

Removal / Disassembly

ES-165-7H Severe Duty Brake

WARNING: The long term effects of non-asbestos fi bers have

not been determined. Therefore, precautions should be used

!

when handling these materials.

See General Information / Lining Material Warning

1. Perform steps necessary for drum removal, see Removal

Disassembly - Drum Removal.

2. Remove cap screws and dustshield, if applicable.

3. Remove retaining ring and washer from drum side of each anchor

pin. Refer to Figure 25.

5. Remove upper anchor pin with a brass drift or a mallet. Refer

to Figure 27.

Figure 27. Anchor Pin Removal

6. Rotate upper shoe around cam end, disengage roller end from

cam, then unhook return spring from shoe and remove upper shoe.

Refer to Figure 28. Discard return spring.

Figure 25. Retaining Ring and Washer Removal

4. To allow removal of anchor pin, cut lock wire and remove cap

screws from spider. Refer to Figure 26.

Figure 26. Cap Screw Removal

26

Figure 28. Shoe Removal

Page 28

Removal / Disassembly

7. Remove lower anchor pin to remove lower shoe.

NOTE: Inspect anchor pin and bushings. If pin was seized or

bushing is grooved or worn beyond 0.031" (0.79mm), replace pin

and bushing. Always replace pins and bushings with brake reline.

8. Drive out the old anchor pin bushings from brake shoe and

spider with a suitable driver. Refer to Figure 29.

9. Do not remove roller from the brake shoe, unless: the roller does

not roll freely, there are fl at spots on the roller, or there is more than

0.025" play between the roller and pin.

If removal of roller is necessary, use a steel punch to drive out the

groove pin, then push the pin out of the shoe. Discard roller and pin.

Refer to Figure 30.

Shoe Removal

Figure 30. Groove Pin Removal

Figure 29. Anchor Pin Bushing Removal

10. Clean and inspect remaining brake parts as outlined in Removal/

Disassembly section of this manual.

27

Page 29

Brake Adjuster Removal

Removal / Disassembly

1. Remove cotter pin and clevis pin from air chamber pushrod clevis.

2. While depressing locking sleeve, turn adjuster nut until brake

adjuster is clear of air chamber pushrod clevis. Refer to Figure 31.

NOTE: Follow manufacturer’s instructions for self adjusting brake

adjusters.

Rotate Adjuster

Until Brake

Adjuster is

Clear of Clevis

Figure 31. Brake Adjuster Removal

4. Note orientation of brake adjuster with reference to push rod

before removal to assure assembly is in proper orientation. Remove

brake adjuster with a suitable puller.

CAUTION: Do not hammer on brake adjuster to remove!

!

Damage to brake adjuster and/or camshaft splines may

result.

Camshaft Removal

1. Perform all steps for drum, shoe, and brake adjuster removal as

outlined in Removal / Disassembly section.

2. Grasp camshaft head and pull camshaft outboard to remove.

Air Chamber Bracket Removal

1. Perform all steps for drum, shoe, brake adjuster and camshaft

removal as outlined in Removal / Disassembly section.

2. Disconnect chamber air line.

3. Remove the attaching nuts (bolts on brakes with cast spider)

and pull the air chamber bracket away from the spider.

NOTE: On 16.5" diameter brakes with stamped spiders, the air

chamber bracket-to-spider studs are press fi t into the spider.

Their removal is not required to remove the air chamber bracket.

3. Remove snap ring and outer shim washer(s) from camshaft.

Bendix® ASA-5® Automatic Slack Adjuster

NOTE: On ES & EB 150-4L brake a stabilizing nut has to be

removed. The bracket-to-spider studs are pressed to fi t into the

air chamber bracket fl ange. Their removal is not required to

remove the air chamber bracket.

WARNING: To prevent personal injury, be sure to “cage”

!

spring before removing spring brake type air-chambers.

28

Page 30

Removal / Disassembly

Spider Removal

1. Perform all steps for drum and shoe removal as outlined in

Removal / Disassembly section.

2. Remove spider-to-axle attachment nuts and bolts. Refer to

Figure 32.

3. Remove spider.

Dustshield Removal

NOTE: On ES-165-7H, M Brakes, the dustshield is removed before

shoes and anchor pins are removed.

1. If applicable, remove screws and retaining clip. Remove all

screws attaching dustshield to spider (4-6 screws depending on

model). Refer to Figure 33.

2. Remove dustshield.

Camshaft/Bracket Removal

Shoe/Brake Adjuster/

Figure 32. Spider Mounting Hardware Removal

Figure 33. Dustshield Mounting Hardware Removal

T

For All 165-5,6,7,8L Models

29

Page 31

Cleaning Brake Parts

Removal / Disassembly

After removing the brake parts to be serviced, the following

cleaning procedures should be followed:

• Wire brush all parts exposed to mud, road dirt, and salt,

including spider, air chamber bracket, dustshields and exterior

of drum.

CAUTION: A layer of oxidation and dirt on the outside of a

!

brake drum acts as an insulator and may hinder normal

heat dissipation. Remove excessive deposits by wire

brushing.

• Use a vacuum cleaner to remove brake dust from drums. Wipe

interior of drums with a greaseless solvent to remove any

spilled oil.

WARNING: The long term effects of non-asbestos fi bers,

!

have not been determined. Therefore, precautions should

be used when handling these materials. Do not use

compressed air to blow from interior of drums. Brake lining

dust, when inhaled, can be injurious to health.

See General Information / Lining Material Warning

30

Page 32

Inspection

Drum Inspection

• Clean all remaining brake parts thoroughly with a suitable shop

solvent. Wipe dry with a clean, lint-free cloth.

NOTE: This information is general in nature. For specifi c brake

drum inspection guidelines, refer to the drum manufacturer’s

instructions.

1. Check for cracks, heat-checks, glazing, grooving, run-out and

out-of-round. Refer to Figure 34. Cracked drums must be

replaced. Drums which are glazed, grooved, out-of-round, etc.,

may be returned to service if they can be repaired without

exceeding manufacturer’s maximum diameter or run-out

specifi cations.

Drum Inspection

Bendix does not recommend the turning or reboring of

brake drums. The reduction of wall thickness reduces the

amount of thermal energy that can be absorbed by the

drum during braking. Also, the decrease in wall thickness

increases the amount of defl ection for the same input load.

Both of these are undesirable. If drums are refaced or

oversized, the new diameter MUST NOT exceed the

maximum diameter marked on the drum during its service

life.

Spider / Dustshield

and Cleaning

Figure 34. Drum Inspection

2. Check drum diameter. Replace drum if it exceeds maximum

diameter stamped in drum.

CAUTION: Under no circumstances should drum be used if

!

it exceeds manufacturer’s recommended maximum

diameter or run-out specifi cation.

31

Page 33

Inspection

Shoe and Lining Inspection

Inspection

1. Check shoes for bent or cracked webs, or table, broken welds,

loose rivets or elongated rivet holes. Refer to Figure 36. If any are

found, replace with Bendix OEM grade lining and shoe assemblies.

Figure 36. Shoe and Lining Inspection

2. Check anchor pin and cam roller contact areas in shoe webs for

elongation or wear. Replace shoe if diameter exceeds the following

specifi cations.

Brake Roller Anchor

Model End Pin End

All EB, All ES-165 0.836" 1.400"

ES-150-4D,

ES-150-8D, F & 6D

ES-165-7M 0.774" 1.280"

3. ES-165-7H severe duty brake only: Anchor pin bushings are

mounted in these brake shoes. Refer to Inspection-Spider

Inspection (Double Anchor Pin) for instructions.

NOTE: Two-piece roller and pin are mounted in brake shoes for 7H

model brake. Do not remove roller and roller pin unless: the roller

does not roll freely, there are fl at spots on the rollers or there is more

than 0.025" play between roller and pin. Replace roller and pin if

these conditions are found.

4. Check the linings and replace with Bendix OEM grade shoe and

lining assembly if contaminated, cracked, or worn to less than 1/4"

(6.4mm) thickness at any point (see instructions below) or 3/16"

(4.5mm) for EB/ES 150-4L brake.

NOTE: To eliminate premature Lining Replacement Bendix recommends the use of the Bendix Brake Lining Wear Gauge to accurately

measure lining thickness. This tool is available through Bendix as

BW7261.

Important: For use with air actuated cam brakes where minimum

allowable lining

thickness is 1/4 in.

(Note: Do not use for

strip linings on 15 x 4

brakes or similar

brakes.)

1. With the brake not

applied, place the tip of

the gauge between the

two lining blocks,

between the top of the shoe table and drum. Use the gauge to scrape

away any mud, rust, or other contaminants that could interfere with

proper lining measurement.

2. Remove the gauge from the brake.

3. With the vehicle’s brakes applied, try to put the gauge between the

two lining blocks and the top of the shoe table. Note “hook” of gauge

allows insertion around worn drum lip. If the tip of the gauge will not

fi t between the brake drum and the top of the shoe table, the lining is

worn below 5/16 inch

and will need to be

replaced.

4. If the tip of the gauge

fi ts between the brake

drum and the shoe

table, the lining is not

worn below 1/4 inch at

this time.

5. Because brake shoes can wear at different rates, check both shoes

on each brake and all brakes on the vehicle.

32

Page 34

Inspection

Shoe and Lining Inspection (cont’d)

Standard Production EB™ brakes use different shoe and lining

assemblies than those used for the ES models. Because of these part

differences, normal wear of either creates a unique lining wear

pattern.

™

• When the EB

ment due to normal wear, they will have a tapered shape as

shown below. The lining will be thinner at the center of shoe

than at the cam or anchor pin end.

Standard Production linings require replace-

WARNING: The long term effects of non-asbestos fi bers, have

!

not been determined. Therefore, precautions should be used

when handling these materials.

See General Information / Lining Material Warning

• When the ES™ Extended Service linings require replacement due to

normal wear, the lining thickness will be uniform all along its

length.

Lining Inspection

Drum / Shoe and

Figure 37. Brake and Lining Blocks

33

Page 35

Inspection

Inspection

Camshaft Radial Play Inspection

Camshaft radial play should be checked any time the brake shoes

have been removed from the vehicle. Refer to Figure 38.

1. Mount a suitable dial indicator with plunger referencing cam head