Page 1

®

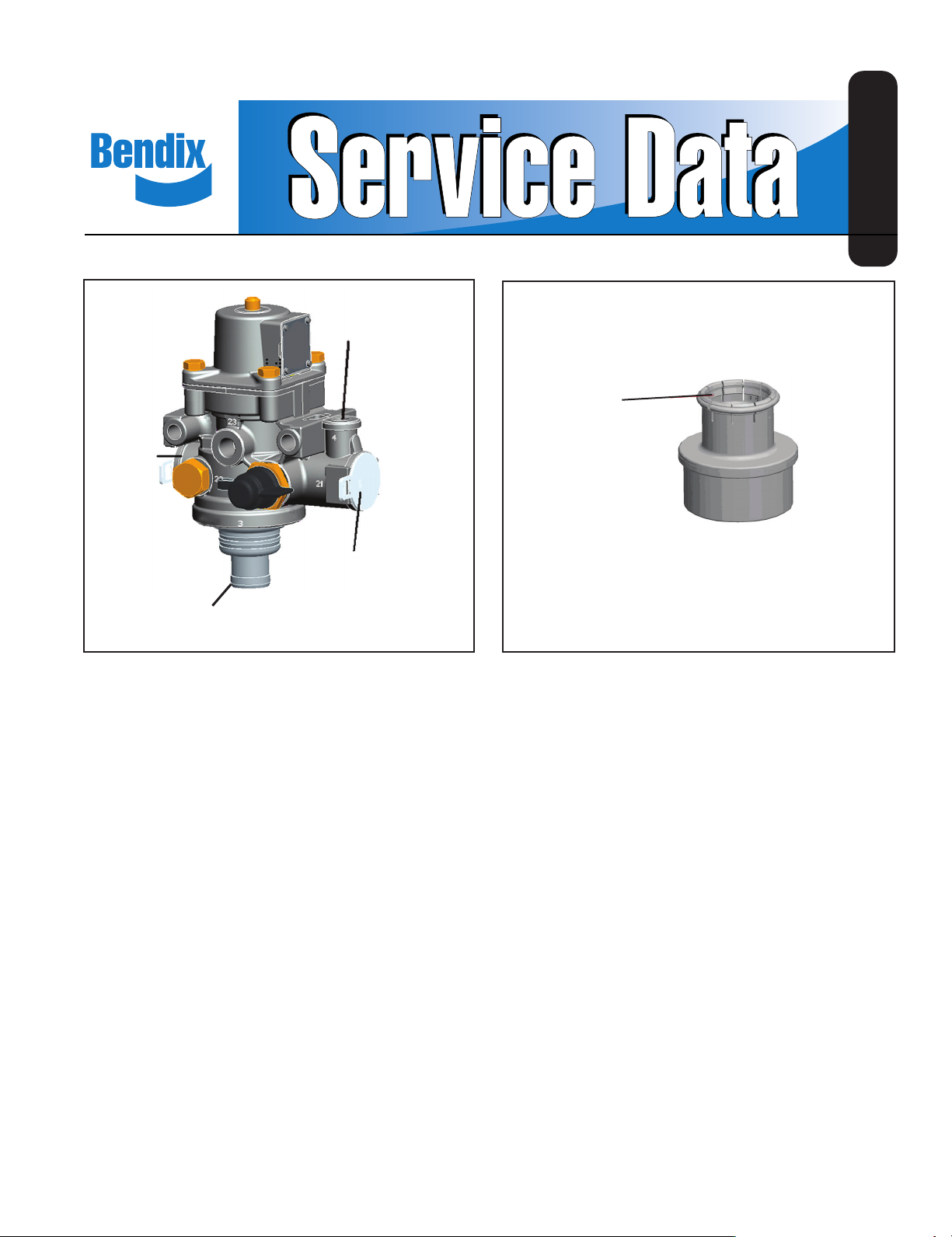

Bendix® DRO Unloader Valve

4

CONTROL

1

SUPPLY

21

DELIVERY

SD-08-203

ATTACHES

TO THE

EXHAUST OF

THE DRO VALVE

3

EXHAUST

FIGURE 1 - DRO UNLOADER VALVE

DESCRIPTION

The Bendix® DRO unloader valve allows an air dryer

with a turbo-cutoff valve to be used as a discharge line

unloaded dryer. The DRO valve allows discharge air

from the compressor to be exhausted to the atmosphere

in the unloaded mode of operation. Some compressors

are designed for discharge line unloading instead of head

unloading. When the DRO valve is placed in the discharge

line it allows both the compressor and the dryer, with turbocutoff, to function properly. The DRO valve can be used to

convert a head unloaded compressor to a discharge line

unloaded compressor.

OPERATION (SEE FIGURE 1)

The DRO unloader valve discharges air in the compressor

discharge line to the atmosphere. During the charging

operation of the compressor, air travels into the supply port

(1) of the DRO valve. When the air brake system reaches

the cut-out pressure, a pneumatic signal from the governor

is sent to the control port (4) of DRO

pneumatic signal opens the DRO valve exhaust port (3)

allowing air pressure in the compressor discharge line to

unloader valve. The

FIGURE 2 - SILENCER

exhaust to atmosphere. Any air pressure created by the

compressor during the unload operations fl ows out the

DRO unloader valve to atmosphere.

The exhaust (3) can be directed away from the valve using

a 3/4” rubber hose. The hose should be securely fastened

to the frame and should not run uphill or contain any kinks

or sharp bends.

An optional silencer, as shown in Figure 2, is available

to reduce noise level during the unloaded operation. The

silencer snaps into the bottom of the exhaust port (3).

REMOVAL

1. Disconnect the supply and delivery line fi ttings.

2. Remove the mounting hardware that secures the

DRO unloader valve to the frame rail or mounting

surface.

1

Page 2

INSTALLATION

The DRO valve can be installed in two confi gurations,

series or parallel.

Series Confi guration

The series confi guration, shown in Figure 3, allows all the

compressor discharge air to pass through the valve and

into the dryer or reservoir.

3. For series installation, install a discharge line from the

compressor to the DRO valve, as shown in Figure 3.

For parallel installation add another discharge line

into the existing compressor discharge line using a

tee fi tting. Connect the opposite end of this new line

to the DRO unloader valve as shown in Figure 4. The

valve must be at the same height or lower than the

discharge line.

TO THE

CONTROL

GOVERNOR

DRO

UNLOADER

COMPRESSOR

FIGURE 3 - SERIES CONFIGURATION

VALVE

PORT OF THE

AIR DRYER

FROM THE

RESERVOIR

TO THE SUPPLY

PORT OF THE

AIR DRYER

Parallel Confi guration

The parallel confi guration, shown in Figure 4, allows the

DRO unloader valve to be mounted using a branch circuit.

This branch circuit provides the fl exibility of installing the

unloader valve in a more convenient location. The branch

line should not run uphill or have kinks or sharp bends that

may trap condensed liquids.

TO THE SUPPLY

PORT OF THE AIR

DRYER

TO THE

GOVERNOR

CONTROL

PORT OF THE

AIR DRYER

4. For a series confi guration, the delivery line out of the

DRO should be connected to the air brake dryer or

reservoir tank.

5. For a parallel confi guration, the delivery port out of the

DRO must be plugged.

6. The supply and delivery ports are 22 mm metric

threads. The control port is 12 mm metric threads.

Consult a fi tting supplier for conversion fi ttings.

7. Make sure there is a line from the governor unloader

port to the DRO valve control port.

8. Test all connections for leaks.

9. Start the engine and allow the system to reach cutout pressure. The valve should open allowing air to

exit the exhaust port. A silencer, shown in Figure 2, is

recommended to reduce the noise level out of the DRO

valve when exhausting. Bendix provides a silencer that

snaps onto the exhaust port the DRO.

10. Fan the brakes until system cut-in is reached. The

DRO valve exhaust should shut allowing the air brake

system pressure to increase until cut-out pressure is

reached.

Note: The operating range of the DRO unloader valve is

from -40°F to 300°F. The DRO valve must be installed with

suffi cient discharge line length to prevent the air dryer inlet

temperature from exceeding 160°F.

FROM THE

PORT 21 MUST

DRO

UNLOADER

VALVE

FIGURE 4 - PARALLEL CONFIGURATION

BE PLUGGED

RESERVOIR

1. Locate a position in the discharge line of the

compressor where the DRO valve can be mounted.

The valve must be mounted at the same height or

below the compressor outlet.

2. Secure the DRO valve using 5/16” grade 5 or higher

bolts. It is not recommended to install the valve directly

on to the engine or compressor.

2

To prevent failure or freeze-ups, the control air into the

DRO valve must be free of liquid water and fl uids and the

maximum inlet pressure to the DRO valve is 174 PSI.

Page 3

GENERAL SAFETY GUIDELINES

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the

following general precautions should be

observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should

be removed. Where circumstances require

that the engine be in operation, EXTREME

CAUTION should be used to prevent personal

injury resulting from contact with moving,

rotating, leaking, heated or electrically charged

components.

3. Do not attempt to install, remove, disassemble

or assemble a component until you have read

and thoroughly understand the recommended

procedures. Use only the proper tools and

observe all precautions pertaining to use of those

tools.

4. If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work

on the vehicle. If the vehicle is equipped with

an AD-IS® air dryer system or a dryer reservoir

module, be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the

electric al syst em in a ma nner t hat sa fely r emoves

all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix

components and kits. Replacement hardware,

tubing, hose, fi ttings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifi cally for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired.

Do not attempt repairs requiring machining or

welding unless specifi cally stated and approved

by the vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Automatic Traction Control

(ATC), the ATC function must be disabled (ATC

indicator lamp should be ON) prior to performing

any vehicle maintenance where one or more

wheels on a drive axle are lifted off the ground

and moving.

®

replacement parts,

3

Page 4

4

BW2789 © 2009 Bendix Commercial Vehicle Systems LLC All rights reserved. 12/2009 Printed in U.S.A.

Loading...

Loading...