Page 1

®

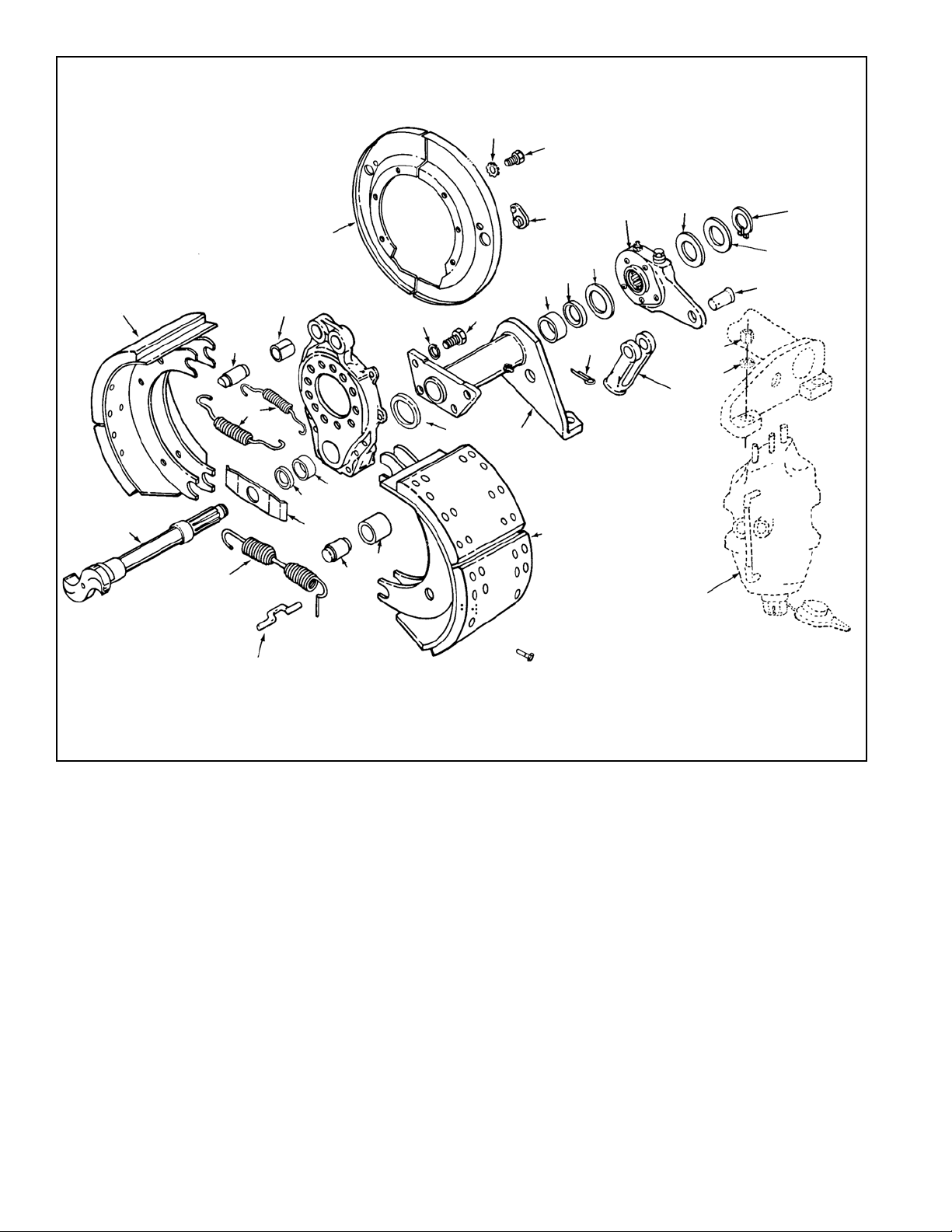

Bendix® Double Anchor Pin Cam Brake

SD-22-3260

FIGURE 1

GENERAL DESCRIPTION

The Bendix 16-1/2” x 7” double anchor pin cam brake is

designed for use on heavy duty highway vehicles. It is a

mechanically actuated, leading /trailing shoe brake with a

fixed position cam and anchors.

The brake consists of two fabricated steel shoe assemblies

individually anchored to a cast iron torque spider and

actuated by a single forged cam shaft. T wo retaining springs

secure the shoe assemblies to their respective anchor pins.

The twin webs of each shoe assembly engages the anchor

pin on one end and the cam roller on the other. A single

shoe to shoe return spring is used to maintain constant

contact between the shoe, cam roller and cam.

OPERATION

The Bendix cam brake operates in the following manner

during a braking application. The force of the push rod of

the actuator is converted from a linear force to a rotary

torque. This is accomplished by use of the slack adjuster .

This torque is transferred to the cam shaft of the foundation

brake due to the spline of the cam shaft being connected to

the gear of the slack adjuster. On the opposite end of the

cam shaft is the S-Cam which when rotated lifts the cam

rollers. This spreads the brake shoe ends apart and pivots

the shoes about the anchor pin so the brake lining comes

in contact with the rotating brake drum. The friction created

by the lining pressure against the drum generates the torque

necessary to provide a retarding force to slow down the

vehicle. The energy of the vehicle in motion is converted to

heat at the surface of the drum and lining. The heat raises

the temperature of the drum. The heat is stored in the drum

and finally dissipated to the air.

1

Page 2

26

25

13

18

20

16

22

17

24

23

8

9

30

10

12

13

11

9

8

19

15

14

4

7

6

2

28

29

5

27

1

2

3

21

FIGURE 2 - 16-1/2” DOUBLE ANCHOR PIN S-CAM BRAKE

Key No. Description Qty.

1 Snap ring 1

2 Spacer washers #reqd.

3 Yoke pin 1

4 Slack adjuster 1

5 Yoke 1

6 Cotter pin 1

7 Washer 1

8 Grease seal 2

9 Bushing 2

10 Cap screw 4

11 Lock washer 4

12 Actuator bracket and cam tube 1

13 Brake shoe assembly 2

14 Cam roller 2

15 Cam roller bushing 2

Key No. Description Qty.

16 Anchor pin 2

17 Anchor pin bushing 2

18 S-Cam shaft 1

19 Cam head washer 1

20 Shoe return spring 1

21 Spring retainer pin 2

22 Anchor spring 2

23 Dust shield 2

24 Rubber inspection plug 2

25 Cap screw 6

26 Star washer 6

27 Actuator 1

28 Nut 2

29 Washer 2

30 Sealing Ring 1

2

Page 3

PREVENTIVE MAINTENANCE

1. BRAKE ADJUSTMENT

Weekly , or whenever push rod stroke exceeds maximum

distance listed on the following chart. For complete

adjustment information, see Bendix Service Data Sheet

SD-05-1.

Full Pressure

Ser- Service Max. Max. Stroke

vice Diaphragm Stroke at which

Act- Effective With Brakes

uator Area Outside Max. Brakes Should Be

Type (Sq. In.) Diameter Stroke Adjusted Readjusted

short as

possible

without

24 24 7-7/32 2-1/4 brakes 1-3/4

30 30 8-3/32 2-1/2 dragging 2

2. BRAKE LUBRICA TION

Grease camshaft bracket with vehicle manufacturer’s

recommended chassis lube. Lube once every six months

or at each chassis lubrication.

3. BRAKE RELINE

The life of the brake lining is dependent on many factors

such as the material of the lining, type of operation the

vehicle is used for, and the driver of the vehicle. If driving

conditions require frequent braking, lining replacement

will be required more often. Reline when lining thickness

at center of shoe is 1/4”. Refer to section “Reline

Procedure”.

4. BRAKE OVERHAUL

As often as necessary to maintain adequate brake

performance. NOTE: When overhauling brake system,

provide equal service to all drive axle brakes on the

vehicle.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID PERSONAL

INJURY OR DEATH:

When working on or around brake systems and

components, the following precautions should be

observed at all times:

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

When working around or under the vehicle, stop

the engine and remove the key from the ignition.

Always keep hands away from chambers as they

may apply as system pressure drops. Always wear

safety glasses.

2. When working in the engine compartment, the

engine should be shut off and the ignition key

should be removed. Where circumstances require

that the engine be in operation, EXTREME CAUTION

should be used to prevent personal injury resulting

from contact with moving, rotating, leaking, heated

or electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to the use of those tools.

4. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

5. If the vehicle is equipped with an air over hydraulic

brake system or any auxiliary pressurized air

system, make certain to drain the air pressure from

all reservoirs before beginning

ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

6. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or pipe plug unless you are certain all

system pressure has been depleted.

7. Never exceed manufacturer’s recommended

pressure.

8. Never attempt to disassemble a component until

you have read and understand all recommended

procedures. Some components contain powerful

springs and injury can result if not properly

disassembled. Use only proper tools and observe

all precautions pertaining to use of those tools.

9. Use only genuine Bendix® replacement parts,

components and kits.

A. Use only components, devices and mounting

and attaching hardware specifically designed

for use in hydraulic brake systems.

B. All replacement hardware, tubing, hose,

fittings, etc. must be of equivalent size, type

and strength as the original equipment.

10. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

11. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

™

3

Page 4

FIGURE 3 - REMOVING CAM ROLLERS

FIGURE 4 - REMOVING SHOE RETURN SPRING

FIGURE 6 - REMOVING SLACK ADJUSTER

FIGURE5 - REMOVING SHOES

4

FIGURE 7 - REMOVING ACTUA TOR BRACKET

PREP ARATION

1. Park vehicle on a level surface and prevent movement

by means other than the brakes.

2. If equipped with spring brakes, cage the spring on all

axles to be worked on.

3. Drain air from all reservoirs.

4. Raise the axle, to be worked on until the tires clear the

ground.

5. Turn the slack adjuster adjusting screw in the opposite

direction used to adjust the brakes until the cam rollers

return to the start position on the S-cam.

6. Remove wheels and drums using the procedures specified

in the vehicle maintenance manual.

Page 5

DISASSEMBL Y (See Figure 2)

1. Insert a sturdy lever between one of the shoes and the

cam shaft housing. Pry shoe away from cam roller until

pin and roller assembly can be removed. Repeat on

opposite shoe (See Figure 3). (If cam rollers or pins show

signs of wear, galling, pitting or cracks, discard and

replace with new.)

2. Remove shoe return spring and discard. Force shoes

towards the S-cam to relieve spring tension (Figure 4).

3. Remove shoes. Lift one of the shoes off anchor pin and

lower both shoes to the floor (see Figure 5).

4. Remove the two shoe retainer springs and discard. NOTE:

If only replacing the brake shoes, no further disassembly

is required. Reverse Step s 1 thru 4. NOTE: Always install

new springs.

5. Remove the two anchor pins by sliding them out of the

bushings. If bushings are to be replaced, drive them

out of the spider using a tool of the proper diameter (a

15/16" socket will work as a driver).

6. Remove the cotter pin from the yoke of the actuator.

Remove yoke pin so the slack arm is free of the yoke.

Remove the two nuts and washers that secure the

actuator to the bracket and remove the actuator.

7. Remove snap ring and washer from splined end of cam

shaft. Remove slack adjuster from cam shaft. (A puller

may be required.) Remove spacers and the thick washer

from cam shaft (See Figure 6).

8. Remove cam shaft from actuator bracket and cam tube.

Remove large flat cam head washer from the cam shaft.

9. Mark and remove the dust shields from the spider by

removing the six cap screws using a 3/8" socket. Do

not remove unless there is apparent damage.

10.Remove the actuator bracket and cam tube from the

spider by removing the four cap screws and lockwashers

using a 3/4“ socket. Remove and discard the sealing

gasket from the end of the actuator bracket (See Figures

2 and 7).

11. Remove and discard the two cam shaft grease seals.

One at the end of the actuator bracket and one at the

cam entrance in the spider. Pry out with a large

screwdriver.

12.Remove the spider from the axle flange by removing

the twelve bolts, nuts, and lockwashers that secure it.

To facilitate assembly, note or mark the relationship of

the spider to the axle (driver or curb side) and the

orientation on the axle flange.

13. Remove and discard the two cam shaft bushings located

in the same area as the seals in Step 11. Use a drift of

adequate length to drive the bushings out. NOTE: Prior

to removal, see the “Inspection of Parts” section, Steps

1B and 3B.

CLEANING OF P ARTS

After disassembling the foundation brake, Wash the metallic

components in mineral spirits and wipe dry . Be careful not

to get any foreign material, especially grease on the brake

shoes or interior of the brake drum. Use a wire brush to

remove heavy contamination from the spider and outside

of the brake drum.

INSPECTION OF P ARTS

1. ACTUATOR BRACKET AND CAM TUBE

A. Check assembly for bent actuator bracket and broken

or cracked cam tube welds.

B. Inspect cam shaft bushing for signs of wear . Bearing

surfaces should be smooth and free of any pitting or

fractures. Insert cam shaft and measure looseness

at both ends with a dial indicator. If more than .020"

movement is noted, replace bushings and/or cam

shaft. NOTE: If it is determined that a bushing

requires replacement, both cam shaft bushings

should be replaced.

2. CAM SHAFT

A. Inspect cam shaft spline for cracks and excessive

deformation. Replace as necessary .

B. Inspect the cam shaft bearing journals for wear or

corrosion. If the shaft shows wear or roughness that

is visible or roughness that can be detected by feel,

it must be replaced.

C. Inspect cam head for cracks, and its roller surfaces

for flat spots, brinneling, or ridges. Note unusual wear

patterns which may indicate an out-of-square

condition. Replace if any of these conditions exist.

3. SPIDER

A. Inspect for cracked or broken surfaces an the spider

at the cam, anchor pins, and mounting bolt holes.

Replace any spiders with visible damage. Do not

attempt to weld or repair . Check fit of anchor pins in

torque spider. Radial clearance in excess of .010"

indicates excessive wear. Replace anchor pin

bushings and/or anchor pins.

B. Check cam shaft bushing for signs of wear. (See 1

B) Bearing surface should be smooth and free of

any pitting or fractures. NOTE: If it is determined

that the bushing requires replacement, change both

cam shaft bushings.

4. ROLLERS AND PINS

A. Inspect rollers and pins for flat spots, galling, broken

or cracked surfaces. Replace as necessary .

5. ANCHOR PIN

A. Inspect anchor pin for worn, broken or cracked

surfaces. Replace as necessary .

5

Page 6

NOTE: BOTH LIP SEALS POINT THE SAME DIRECTION LIP

.094”

6”

TOWARD SLACK ADJUSTER

FIGURE 8 - CHECKING SLACK ADJUSTER BACKLASH

6. SHOES AND LINING

A. Check shoes for bent shoe webs, cracks in shoe

table welds or webs, and elongated rivet holes.

Replace shoes if any of these conditions exist.

B. Measure the shoe span by loosely installing the

anchor pin and cam roller in the appropriate ends of

the shoe web. If the distance from center of anchor

pin to center of cam roller exceeds 11.72" replace

shoe.

C. Check linings. Replace when any of the following

conditions exist:

1. Lining thickness at thinnest point is 1/4” or less.

2. Linings are cracked or worn in an unusual or odd

pattern, i.e., lining wear tapered from side to side

across shoe table. Unusual wear patterns can

indicate damage to foundation brake parts.

3. Rivet holes are elongated in lining or shoes.

4. Lining is oil soaked.

5. Linings can be moved by hand, i.e.; loose rivets.

7. BRAKE DRUMS

A. Inspect drums for cracks, heat checking, glazing,

grooving, severe out-of-round condition or bell

mouthing (must not exceed .025 T .I.R.). Replace any

cracked drums. It is recommended that drums be

turned at reline to prevent hot spotting and achieve

quicker, more complete burnishing of the new lining.

B. Measure the drum I.D. to be sure the maximum limit

allowed (stamped on drum) has not been exceeded,

due to wear or machining.

8. MANUAL SLACK ADJUSTER

A. Check for cracks in the body and arm of the slack

adjuster.

B. Check for spline wear. The amount of backlash in

the slack adjuster to camshaft should be no more

than .094" measured 6" from centerline of the cam

shaft (See Figure 8).

C. Check ability to rotate the adjusting nut at least one

complete revolution in each direction. Force required

to rotate the adjusting nut should not exceed 15 ft.

lbs. NOTE: If any of the above conditions are found,

replace the slack adjuster. Do not attempt to repair .

LIP SEAL

CAM END

SLACK ADJUSTER END

ACTUATOR BRACKET

AND CAM TUBE

SPIDER

FIGURE 9 - SEAL INST ALLA TION

LIP SEAL

9. AUTOMA TIC SLACK ADJUSTERS

A. Consult manufacturer’s service information. (For

information on Bendix Automatic Slack Adjusters,

see Service Data Sheet SD-05-1200, formerly

SD-05-2).

10. ACTUATORS

A. Check for cracked housing, loose mounting studs.

B. Check for damage to the push rod, and push rod

boot (if so equipped).

C. Check for broken push rod return spring.

D. Check for excessive wear on yoke, yoke pin, and

slack adjuster yoke pin hole or bushing. There should

be no more than .031 combined free play in these

components.

CAUTION: If the vehicle is equipped with spring brakes,

refer to manufacturer’s instructions. High spring load, if

not handled properly , may result in serious injury or death

may result.

ASSEMBLY (SEE FIGURE 2)

1. Install the spider onto the axle flange using the twelve

bolts, lockwashers and nuts. Be sure spider is properly

oriented, as noted during disassembly . Tighten mounting

bolts to vehicle manufacturer’s specifications.

2. If anchor pin bushings or cam shaft bushings were

removed, replace with new bushings before installing

torque spider on axle. Drive into place using an

Owatonna 630-7 piloted driver or similar tool taking care

not to damage or distort the I.D. of the bushings. NOTE:

One of the cam shaft bushings is installed in the actuator

bracket and cam tube.

3. Install new cam shaft grease seals in the end of the cam

tube and actuator bracket and the cam shaft opening in

the spider. Use an Owatonna 630-7 piloted driver or similar

tool to install grease seals.

6

Page 7

CAUTION: The lip of the grease seals must be installed

correctly to prevent possible damage. The lip of the

seal that is installed in the spider must enter the opening

first. The lip of the seal that is installed in the opposite

end of the cam tube must enter last. (See Figure 9).

4. Install a new actuator bracket seal ring between the

spider and cam tube of the bracket. Install the actuator

bracket and cam tube onto the spider using four cap

screws and lockwashers. T orque to 70-80 ft. lbs. Secure

the actuator to the bracket using the two nuts and

washers. T orque to vehicle manufacturer’s specification.

5. If removed, reinstall the dust shields. Tighten the six

cap screws and lockwashers to 90-1 10 in. lbs. torque.

6. Place the cam head flat washer over the splined end of

the cam shaft and slide it to the opposite end, next to

the head of the cam. Install washer so that the bent

ends face away from the head. Coat cam shaft journals

with light film of chassis lube. Do not coat “S”-cam head.

7. Install the cam shaft with cam head flat washer into the

cam tube. Be careful not to damage the grease seals.

8. Install the thick cam shaft flat washer, the slack adjuster ,

spacers, washer, and a new snap ring in that sequence

onto the splined end of the cam shaft. Adjust end play of

the cam shaft to between .005" and .045" by using the

appropriate number of spacer washers. Make sure the

snap ring is seated into the groove at the end of the

splined camshaft.

9. Install the two anchor pins into the anchor pin bushings.

Center the anchor pins in the bushings so they protrude

equally from each end of the bushings.

10.Install new brake shoe retaining springs. Engage hook

ends of the two springs into each of the holes of the two

brake shoes.

1 1. Place the top shoe onto the spider by engaging the open

slots on the end with the retaining springs onto the anchor

pin. Place opposite end of the shoe against the S-cam.

Swing the opposite shoe with springs attached back

until slots in the shoe engage the other anchor pin, then

swing shoe towards the S-cam. Spring tension will hold

the shoes in this position. NOTE: When placing slots of

the shoes onto the anchor pins, be sure to match the

flat surfaces of the mating parts.

12.Place the short hook of the brake shoe return spring

onto the top return spring pin. Be sure spring is installed

so that the long hook on the other end of the spring is

facing the web of the brake shoe. Hold shoes against

the S-cam and push the long hook of the brake shoe

return spring over the opposite return spring pin until it

snaps in place.

13.Insert a sturdy bar between the end of one of the brake

shoes and the spider housing at the S-cam end of the

shoe. Pry down until the brake shoe roller and pin can

be installed between the S-cam and the slots in the end

of the brake shoe. Repeat the same procedure on the

other shoe.

14. Adjust the slack adjuster until the yoke pin can be

installed through the proper hole in the arm. Install a

new cotter pin to retain. Make sure the cam rollers are

in the lowest position on the cam.

15. Lubricate the cam shaft bushings by filling the cam shaft

tube with chassis lube through the zerk fitting provided.

Fill until grease is forced out in the area of the slack

adjuster. Grease should not appear at the cam head

end. If it does, the seal has not been properly installed,

or the old seals should be replaced.

16.Reinstall brake drums and wheels. T orque and adjust to

manufacturer’s specifications.

17.Spin the wheel slowly and adjust the slack adjuster until

wheel will no longer turn. Back off slack adjuster just

enough for wheel to spin freely . Be sure to adjust brakes

equally on each axle.

18.Apply and release brakes and observe slack adjusters.

Both slacks on each axle should respond rapidly and in

unison during application and release.

19. Drive vehicle at a low speed in a safe area and check for

brake effectiveness prior to putting back into service.

RELINE PROCEDURE

When removing rivets from the brake shoes, be careful to

avoid doing any damage to the holes in the shoe. Do not

use a chisel to shear them off as the force will elongate the

rivet holes. Neglecting any elongated holes may result in a

loose lining installation. If holes are burred, they should be

filed down flush with the shoe table.

Rust often develops on the surface of the shoe table under

the brake lining or blocks. In addition, scale may form from

salt on the highways, or tar and oil may find their way into

the brake assembly. During every reline job, shoe tables

should be thoroughly cleaned. The best procedure is to steam

clean the entire shoe or put it in a degreaser.

USE RIVETS OF CORRECT LENGTH AS SHOWN

TOO SHORT

FIGURE 10

CORRECT

TOO LONG

After cleaning the shoe, the shoe table should be scraped

clean of rust and scale. Any burrs or nicks should be filed

smooth. At the same time, the entire shoe should be

examined to see whether it is worn or bent.

The shoe should be either reconditioned or discarded. It is

also necessary to check for flat spots on the shoe that can

be caused by cleaning away the rust from the area that was

under the block previously. This can cause a mismatch of

shoe and lining arcs. After the shoe is cleaned and inspected,

it should be given a coating of rust preventative paint. Such

treatment of a new, unpainted shoe is also suggested to

7

Page 8

WHEN RIVETING BRAKE LINING

USE ROLL SET NOT STAR SET

ROLL SET EXPANDS RIVET INTO

HOLE BEFORE UPSETTING.

FIGURE 11

START SET SPLITS TUBE AND

RIVET DOES NOT FILL HOLE

prevent the initial rusting problem. Before riveting, clamp the

blocks tightly to the shoe, placing the clamps close to the

rivet holes. Be sure the holes in the blocks and the shoes

are exactly matched.

Never shim the brake linings as this will only cause problems.

Brake noise may result because of cracked and loose lining

since a tight installation is not possible. The inside surface

of the lining is the correct arc to match the shoe table, and

the rivet holes in the linings will only line up with holes in the

shoes when they are in direct contact.

The sequence of riveting should be such that the center of

the block is attached first and then the ends.

Some brake failures result from the use of rivets which are

too short, too long, or the wrong diameter. Incorrect setting

of the riveting machine may induce other types of failures.

The correct length rivet must be selected for each application.

A variation in shoe table thickness may require a different

length rivet.

The solid portion of the rivet should end just at the inner

surface of the shoe. The hollow portion of the rivet should

protrude past the inner surface of the shoe.

The proper size rivet must be used to completely fill the rivet

hole.

Brass plated steel rivets are recommended but cartridge

brass rivets can be used if so desired.

USE ONLY

#10-10 RIVETS

The riveting machine must be adjusted so that the roll of the

rivet is complete, but the rivet should not split. Always use a

roll set, never a star set, when riveting brake linings. A star

set does not compress the rivet and expand it to fill the

hole. Consequently , the lining may work loose in service.

8

Page 9

FOUNDA TION BRAKE TROUBLESHOOTING CHART

SYMPTOM CAUSE REMEDY

1. Degraded brake A. T oo much push rod free travel. A. Adjust brakes.

performance. B. Severely glazed or worn out linings. B. Deglaze linings or replace.

C. Grease or oil on linings. C. Replace linings.

D. Worn, heat checked, cracked drums. D. Replace part.

E. Push rod length too long. E. Adjust device, shorten push rod

length.

F . Air chamber in wrong position in F . Reposition.

G . Broken or bent parts. G. Replace part.

H. Cam flipover, drum I.D. too large. H . Replace drum.

I. Flat spots on cam or rollers. I. Replace flat-spotted parts.

2. Slow brake A. Cam shaft bushings binding. A. Clean and lubricate. Check for

application. seal leakage.

3. Slow brake release. A. Binding cam shaft and bushings. A. Clean and lubricate.

B. Weak or broken shoe return spring. B. Replace part.

C. Flat spotted cam or rollers. C. Replace flat-spotted parts.

4. Grabbing or pulling A. Grease, oil or dirt on lining. A. Replace lining.

B. Glazed linings. B. Deglaze lining or replace.

C. Brake linings not a balanced set, C. Replace linings.

different friction codes, or lining brand.

D. Loose or broken linings. D. Replace linings.

E. Brake drum out-of-round. E. Turn, per manufacturer’s

specifications.

F. Defective brake drum. F. Replace part.

G . Clevis pin or cam shaft binding at one G. Clean and lubricate.

or more wheels.

H. Defective slack adjuster. H. Replace part.

I. Uneven brake adjustment (side to side) I. Adjust brakes.

J. Broken or bent parts. J . Replace part.

K. Loose spider or drum mounting bolts. K. Retorque, per manufacturer’s

specifications.

L. Different air chamber size or slack L. Use same size and materials on

adjuster length (side to side). all brakes.

9

Page 10

BRAKE SHOE AND LINING TROUBLESHOOTING CHART

SYMPTOM CAUSE REMEDY

1. Poor lining to drum A. Bell-mouth drum. A. Replace part.

contact. B. Bent brake spider . B. Repl ace part.

C. Bent or stretched brake shoe. C. Replace p art.

D. Undersize linings. D. Replace linings.

E. Loose wheel bearing. E. Correct as required.

F. Improper lining grind. F. Regrind linings to drum radius

minus .015".

2. Linings tapered A. Bell-mouth drum. A. Replace parts.

across width. B. Bent brake shoe. B. Replace parts.

C. Bent brake spider. C. Replace part.

D. Loose wheel bearings. D. Correct as required.

3. Unequal wear on A. Mismatched lining friction codes. A. Replace linings.

in same brake. B. S tretched shoe. B. Replace part.

C. Flat spots on cam or roller. C. Replace flat-spotted parts.

D. Worn anchor pin. D. Repla ce part.

E. Worn cam shaft or bushings. E. Re place part .

4. Unequal wear side A. Mismatched lining friction codes. A. Replace linings.

to side brakes, B. Seized or binding cam shaft. B. Clean and lubricate.

same axle. C. Brake drum surface in poor condition. C. Replace or turn I.D.

D. Loose wheel bearing. D. Correct as required.

E. Dragging spring brake E. Correct as required

F. Reline F. Reline both drags together.

5. Wear on edge of A. Wrong width lining. A. Replace linings.

lining. B. Holes improperly drilled in lining. B. Clean and lubricate.

C. Wrong drum, or improperly machined. C. Replace or turn I.D.

D. Loose bearing adjustment; bearing D. Correct as required.

spacer missing or too thin.

E. Improper wheel bearing or cone. E. Correct as required.

F. Bent brake shoe. F. Replace part .

G . Bent brake spider. G . Replace part.

H. Worn axle spindle. H . Correct as required.

6. Glazed linings A. Overheating, due to unbalanced A. Correct as required.

(hard and shiny) braking system.

B. Wrong type linings for service involved. B. Replace linings.

C. Dragging spring brake chamber. C. Correct as required.

7. Scored or grooved A. Scored or worn drum, not machined A. Replace or remachine.

linings and drum. at reline.

B. Abrasive material between lining and B. Clean, remove dirt and debris.

drum.

C. Broken springs. C. Replace springs.

10

Page 11

8. Loose lining. A. Improper size rivets (too long, too A. Re-rivet.

short, improper diameter).

B. Improper crimping of rivet. B. Re-rivet.

C. Enlarged rivet holes in shoe. C. Replace part.

D. Incorrect lining hole size or counter D. Replace linings.

bore depth.

E. Rust build up on shoe table. E. Clean, remove rust and paint shoe

9. Cracked lining at A. Ove rtighte ning bolts. A. Correct as required.

rivet holes or

bolt holes. B. Wrong type rivets or bolts. B. Replace part.

C. Rivets not properly crimped. C. Replace lining.

D. Dirt or rust on shoe table. D. Clean, remove dirt and debris.

E. Wrong size lining counter bore. E. Replace linings.

10. Elongated rivet A. Loose rivets or bolts. A. Replace shoe and lining.

holes.

BRAKE DRUM TROUBLESHOOTING CHART

SYMPTOM CAUSE REMEDY

1. Brake drum heat A. Out of round brake drum. A. Turn, per manufacturer’s

checked. specifications.

B. Eccentric mounting of drum. B. Inspect wheel and drum and

replace defective part.

C. Loose wheel bearing. C. Correct as required.

D. Glazed linings. D. Replace linings.

E. Improper friction materials for duty E. Consult vehicle manufacturer.

cycle of vehicle.

F. Overworked brake. F. Check for proper brake balance.

(Ref; Bendix procedure to check

out system.)

G. Driver abuse. G. Correct as required.

H. Wrong drum, too light. H. Replace part.

2. Excessive scoring A. Defective brake lining. A. Replace linings.

of drum. B. Abrasive material between lining and B. Clean, remove dirt and debris.

drum.

C. Soft drum. C. Check hardness on flange. Should

be 187 Brinnel minimum.

D. Excessive lining wear, rivets D. Replace lining.

contacting drum.

E. Drum not turned at last reline. E. Turn per manufacturer’s

specifications.

F. Build up of abrasives in rivet holes. F. Blow out debris.

11

Page 12

12

BW1459 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 5/2004 Printed in U.S.A.

Loading...

Loading...