Page 1

®

Bendix® C-5™ Cut-Out Cock

SD-07-2601

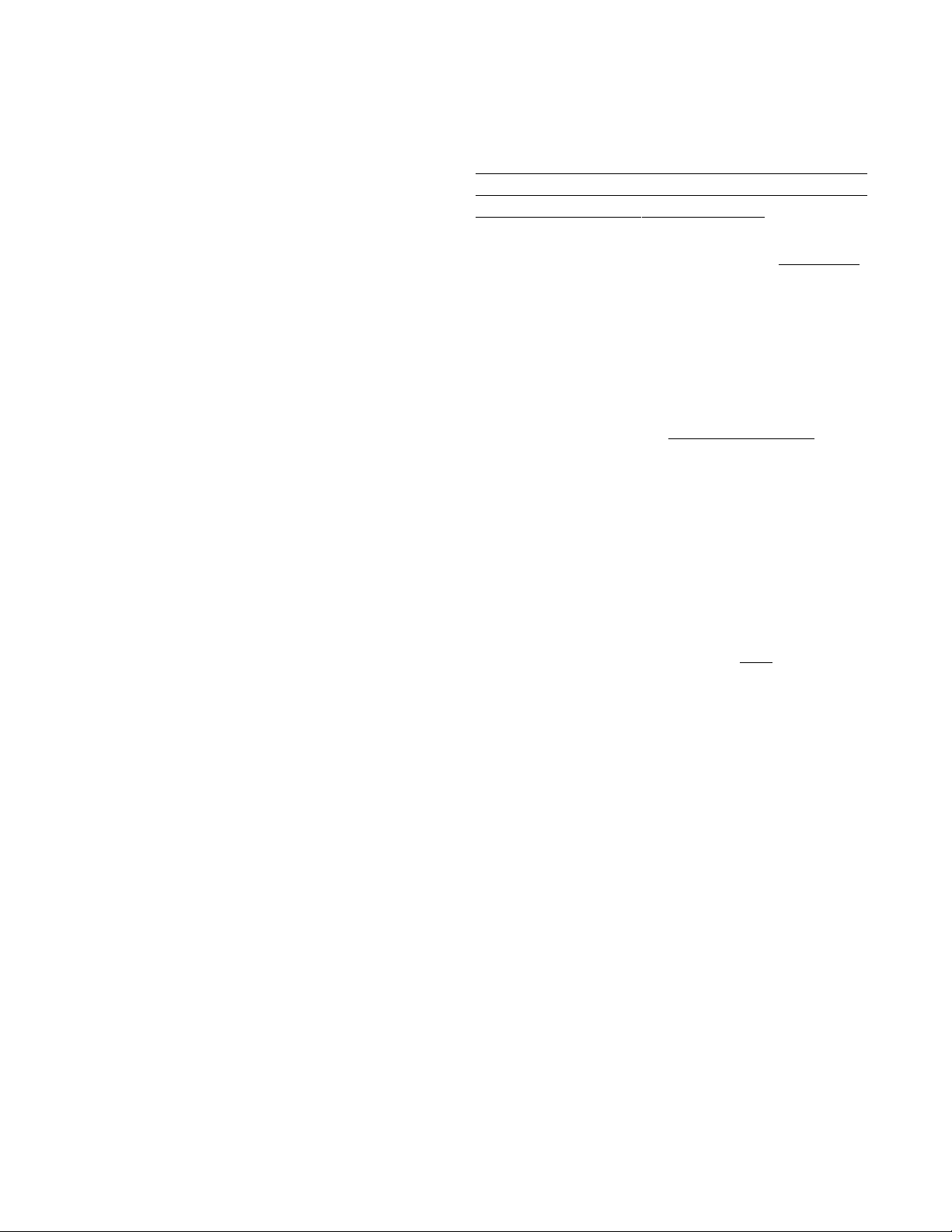

OPERATING HANDLE

CAP NUT

REDUCER

BUSHING

FIGURE 1

DESCRIPTION

The C-5™ cut-out cock is a manually operated on-off valve.

Cut-out cocks are used in an air brake system where a

manual shut off air lines is desirable such as in trailer and

trailer dolly systems.

OPERATION

Note that in Figure 1 the C-5™ cut-out cock uses a metal

ball valve between two valve seats. Rotating the ball valve

90° will either open or close the air passage through the

cut-out cock.

PREVENTIVE MAINTENANCE

LOCK NUT

STEM

STEM

O-RING

VALVEO-RING VALVE SEATS

BODY

WASHER

CLAMPING

STUD

LEAKAGE CHECK

With the valve in the closed position and air pressure present

on either side, a soap solution is applied to the side open to

atmosphere. A leakage of not more than a 1" bubble in 5

seconds is permitted.

NOTE: Leakage should be checked in each direction since

it is possible for the valve to seal in one direction

but not the other.

If the cut-out cock leaks excessively or if wear or deterioration

is noted during routine maintenance, it is recommended that

it be replaced with a new unit or repaired with genuine Bendix

parts.

Every six months, 1800 operating hours, or 50,000 miles

the cut-out cock should be checked for leakage around the

ball valve and past the stem o-ring. Once each year , 3600

hours, or 100,000 miles the C-5™ cut-out cock should be

disassembled, cleaned, and inspected for signs of wear or

deterioration.

REMOVING AND INSTALLING

REMOVING

Block and hold vehicle by means other than air brakes.

Completely drain all reservoirs. Disconnect air lines from

both sides of the cut-out cock.

1

Page 2

INSTALLING

Prior to installing, check, and if necessary , clean or replace

lines leading to the cut-out cock.

Place o-ring on cap nut and install cap nut in body and

tighten (T orque to 150-400 inch pounds).

TESTING

Install the valve taking care the operating handle is in a

convenient position for use.

DISASSEMBL Y

Unscrew cap nut from body and remove cap nut o-ring.

NOTE: Early models of the C-5™ cut-out cock had a cap

nut at both ends of the body . Parts from the earlier

model C-5™ cut-out cock are not interchangeable

with the new model and are not available. When

service is required on the older model it should be

replaced with the current style.

Rotate the operating handle of the cut-out cock until the

passage through the valve is closed. Note the position of

the handle for reassembly .

Lightly tap the open end of the valve body on the work

surface. The ball valve and both seats will drop out.

Remove the lock nut located in the center of the operating

handle and remove the handle from the stem.

Remove handle stem by pushing into valve body and shaking

out.

Remove stem washer and o-ring from stem.

CLEANING AND INSPECTION

Wash all metal parts in mineral spirits.

Ball valve seats and o-rings should be wiped clean.

Inspect seats and o-rings for nicks, wear or deterioration.

Inspect valve body , cap nut, handle and stem for cracks and

wear. Any part considered unserviceable will necessitate

that the entire valve be rebuilt or replaced.

ASSEMBL Y

All o-rings should be lightly lubricated with Bendix silicone

lubricate BW650M piece no. 291 126.

Position stem washer and o-ring on stem.

Push stem through body (threaded end first) from the inside

out.

Position operating handle on stem and replace and tighten

stem lock nut. Torque to 30-70 inch pounds.

Position one of the two valve seats in the body with the

contoured side up.

Place operating handle in position noted during disassembly .

(Drive tang on end of stem should be parallel with center line

of body .)

Place ball valve in body with slot coinciding with stem.

Place remaining valve seat in body with contoured side down

and against the ball valve.

2

BW1596 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 4/2004 Printed in U.S.A.

Perform leakage test on reassembled or rebuilt valve.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

™

Loading...

Loading...