Page 1

Bendix™ BlindSpotter® Collision Warning System

Troubleshooting Guide

Bendix™ BlindSpotter® Collision Warning System

BW2860 (Formerly VOTS0032)

September 2011

Page 2

General Information

General Warnings

Before starting a vehicle:

1. Sit in the driver’s seat.

2. Place the vehicle in neutral.

3. Set the parking brake.

4. Disengage the clutch.

Before working on the vehicle or leaving the cab with the engine

running:

1. Place the vehicle in neutral.

2. Set the parking brake.

3. Block the wheels.

Do not operate the vehicle if the alternator lamp is lit or if the

gauges indicate low voltage.

Suggested Tools

Part No. Description

5505027 Volt/Ohm Meter

(Standard commercially available VOM)

For Bendix Service Parts call 1-800-AIR-BRAKE (1-800-247-2725).

Related Publications

Related documents are available for download on the Document

Library or from the Literature Center on www.bendix.com.

Page 3

Table of Contents

Section 1: Introduction

Diagnostic Procedure ................................................................ 1-2

Section 2: Fault Isolation Procedures

Electrical Pretest ....................................................................... 2-1

Power-Up Sequence Test .......................................................... 2-4

Section 3: Symptom Isolation Procedures

Operator Display Unit Audible Indictor

(Buzzer) Not Functioning ..................................................... 3-1

Side Sensor Not Detecting Targets ........................................... 3-5

Side Sensor Continuously Detecting Targets ............................ 3-7

Appendix

Wiring Diagrams .......................................................................A-1

Table of Contents

Table of Contents

1-1

Page 4

Introduction

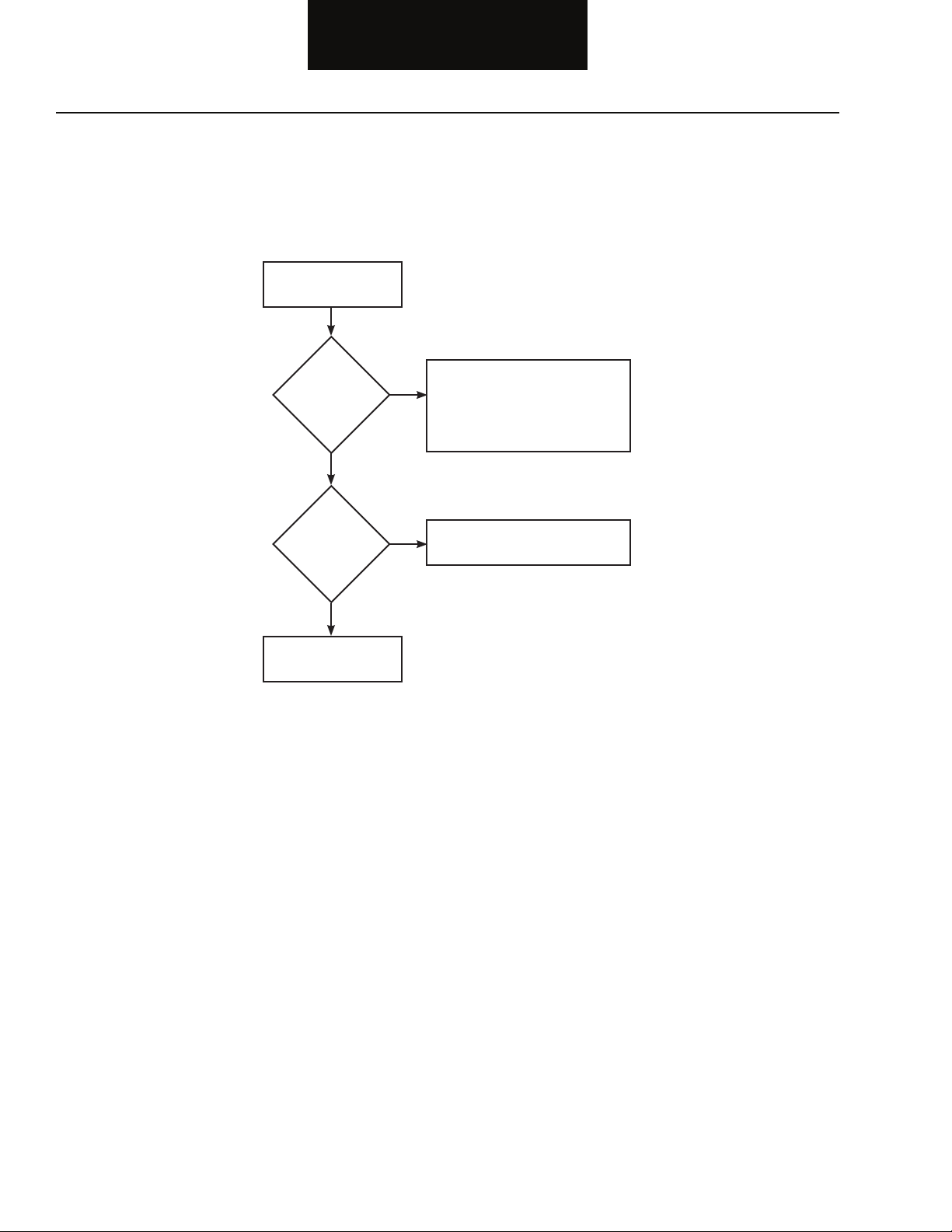

Diagnostic Procedure

Follow the fl owchart below for all Bendix™ VORAD® system failures. Perform the tests and procedures as directed by the fl owchart.

Key On

Is the

Operator Display

Unit lamp lit?

YES

Is Driver

Experiencing System

Problems?

NO

Test Complete.

NO

YES

Perform Electrical Pretest

•

(page 2-1)

Perform Power-up Sequence Test

•

(page 2-5)

See System Isolation Procedures

•

(page 3-1)

1-2

Page 5

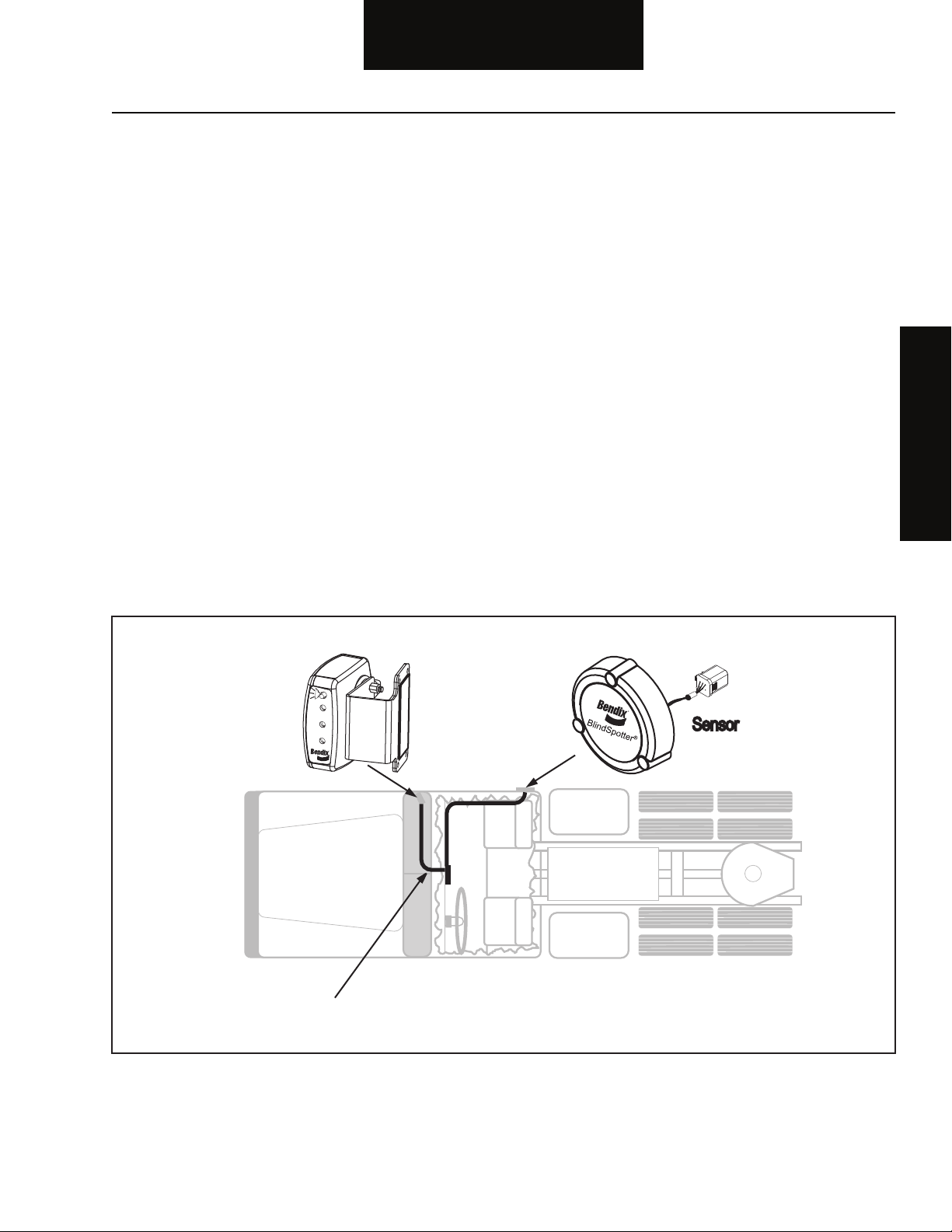

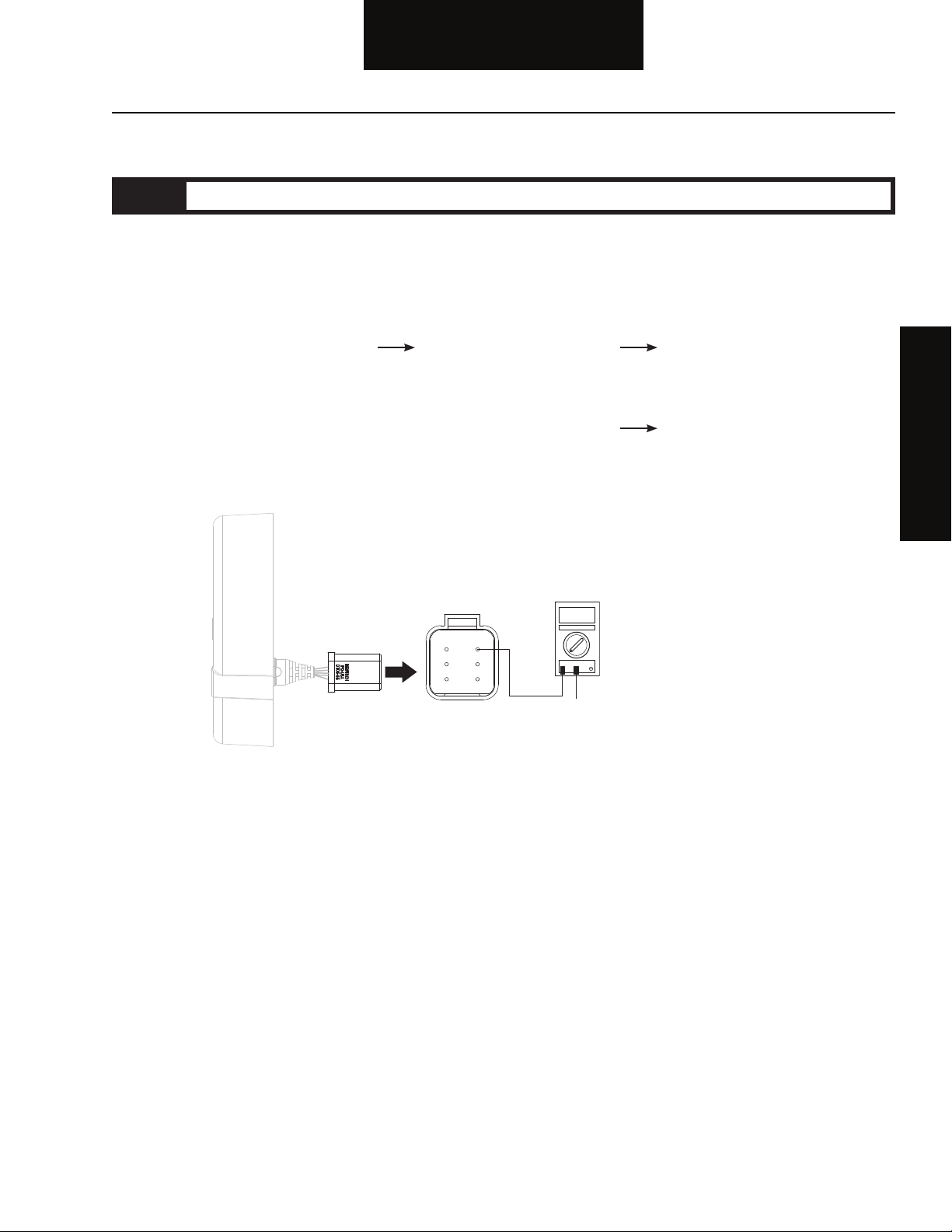

Electrical Pretest

Harness

P2 SOD

Operator

Display Unit

(ODU)

Sensor

Fault Isolation Procedures

Overview

The pretest verifi es the basic electrical inputs before testing

individual circuits.

Detection

There is no detection process specifi cally for the basic electrical

supply. However, failures of this type are generally detected by the

Bendix™ VORAD® system or the driver as some other type of fault

code or symptom.

Fallback

There is no fallback for the electrical pretest, however, it may affect

other systems.

Required Tools

• Basic Hand Tools

• Digital Volt/Ohm Meter

• Troubleshooting Guide

Possible Causes

This pretest can be used for any of the following:

• Corroded Power Contacts

• Blown Fuse

• Wiring Harness

• Low Batteries

Electrical Pretest

2-1

Page 6

Fault Isolation Procedures

OHMS

GROUND

V ACOM

1

2

3

4

5

6

VOLT

V ACOM

Electrical Pretest

Step A Procedure Condition Action

1. Key off.

2. Inspect starter/battery

connections for integrity.

3. Measure voltage across

battery.

If voltage is 11 to 13 volts

on a 12 volt system or 22 to

26 on a 24 volt system

If voltage is outside of

range

Go to Step B.

Repair or replace batteries and

charging system as required.

Repeat this step.

Step B Procedure Condition Action

1. Key off.

2. Disconnect negative (-) battery

cable.

3. Disconnect the sensor J2 harness.

4. Measure resistance

between sensor harness

J2 pin 2 and ground.

If resistance is 0 to .5 ohms

Go to Step C.

2-2

If resistance is outside of

range

Repair ground path to system.

Go to Step A.

Page 7

Fault Isolation Procedures

OHMS

GROUND

V ACOM

1

2

3

4

5

6

Electrical Pretest, continued

Step C Procedure Condition Action

1. Key off.

2. Connect negative (-) battery

cable.

3. Key on.

4. Measure voltage

between sensor harness

J2 pin 1 and ground.

If voltage is within .5 volts

of battery voltage

If voltage is outside of

range

Test complete.

Electrical Pretest

Repair power path to system.

Fuse may be blown. Reconnect all

connectors. Go to Step A.

2-3

Page 8

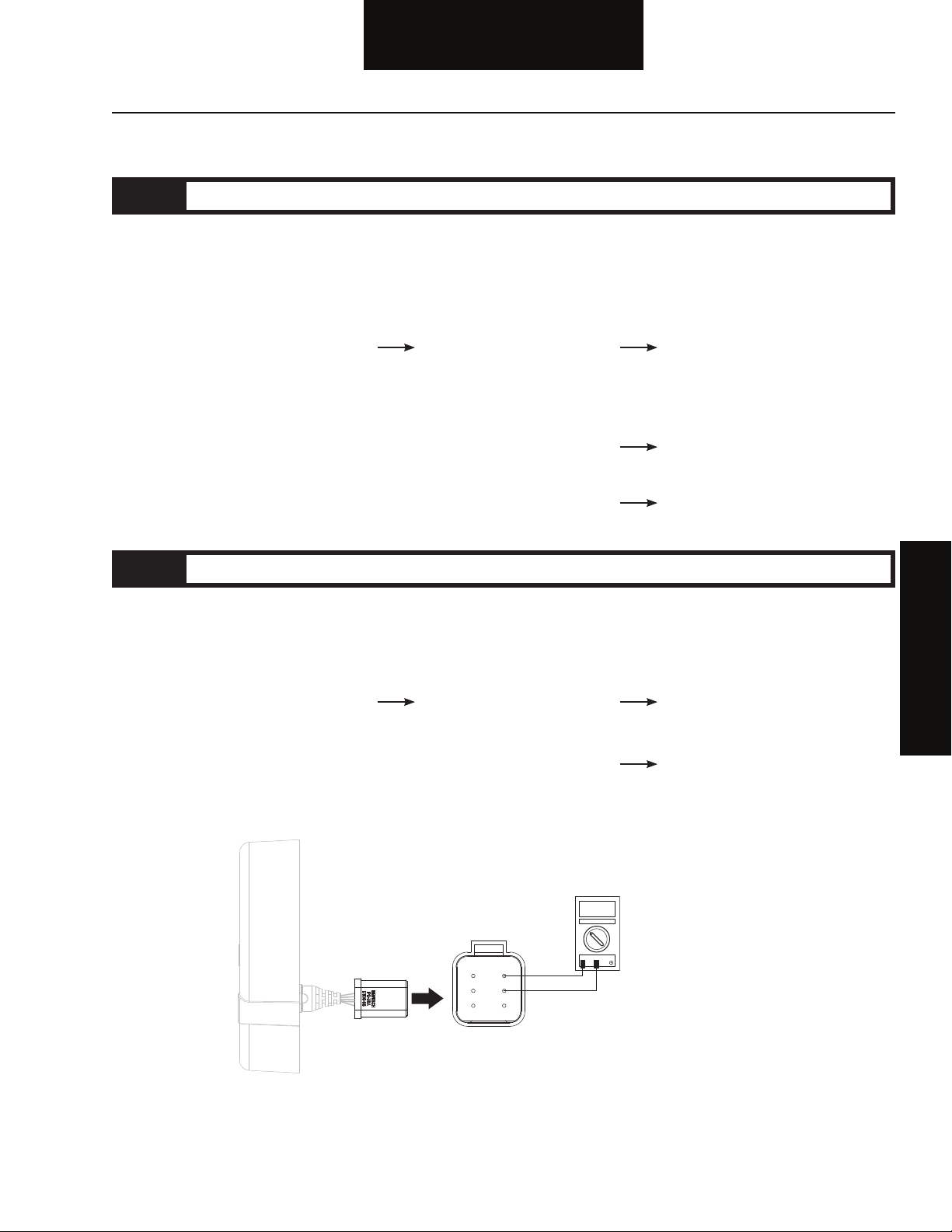

Power-Up Sequence Test

Harness

P2 SOD

Operator

Display Unit

(ODU)

Sensor

Fault Isolation Procedures

Overview

The failure during the power-up self-check indicates a system

failure.

Detection

The power-up self-check is performed automatically each time the

key is turned on. Turn the key on and watch the Operator Display

Unit (ODU). If lights on the ODU remain on after 15 seconds, or

never come on, the self-check has failed.

Fallback

If self-check fails, the product can not perform any operations.

Required Tools

• Digital Volt/Ohm Meter

Possible Causes

• Sensor

• Operator Display Unit

• Vehicle Harness

2-4

Page 9

Fault Isolation Procedures

VOLT

V ACOM

1

2

3

4

5

6

Power-Up Sequence Test

Step A Procedure Condition Action

1. Before performing this test, the

Electrical Pretest must pass.

2. Clear area around sensor of objects.

3. Key on.

4. Observe the Operator

Display Unit.

If both LED lights turn on

for .5 seconds – followed by

Test complete.

the red LED for 5 seconds –

followed by a continuous

yellow light

If lights fail to turn on

If lights turn on and stay on

Go to Step B.

Go to Step D.

Step B Procedure Condition Action

1. Key on.

2. Disconnect sensor harness J2.

3. Key on.

4. Measure voltage

between sensor harness

J2 pins 1 and 2.

If voltage is between 10

and 14 volts

If voltage is outside of

range

Go to Step C.

Repair harness. Go to Step V.

Power-Up Sequence Test

2-5

Page 10

Fault Isolation Procedures

VOLT

V ACOM

ODU P1

1

2

3

4

Power-Up Sequence Test, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Operator Display

Unit from harness J1.

3. Key on.

4. Measure voltage between

sensor harness J2

pins 1 and 2.

If voltage is between 10 and

14 volts

If voltage is outside of range

Replace ODU. Go to Step V.

Replace sensor. Go to Step V.

2-6

Page 11

Fault Isolation Procedures

OHMS

V ACOM

1

2

3

4

ODU P1

1

2

3

4

5

6

Power-Up Sequence Test, continued

Step D Procedure Condition Action

1. Key off.

2. Disconnect sensor harness J2.

3. Disconnect Operator Display Unit

from harness J1.

4. Measure resistance between

J1 pin 3 and J2 pin 3.

If resistance is between

0 and 0.3 ohms

If resistance is outside of range

Replace ODU. Go to Step E.

Replace sensor. Go to Step V.

Power-Up Sequence Test

2-7

Page 12

Fault Isolation Procedures

VOLT

V ACOM

ODU P1

1

2

3

4

Power-Up Sequence Test, continued

Step E Procedure Condition Action

1. Key off.

2. Disconnect Operator Display

Unit from harness J1.

3. Key on.

4. Measure voltage between

sensor harness J2

If voltage is between 10 and

14 volts

Replace ODU. Go to Step V.

pins 1 and 2.

If voltage is outside of range

Replace Sensor. Go to Step V.

Step V Procedure Condition Action

1. Key off.

2-8

2. Reconnect all connectors.

3. Key on.

4. Drive vehicle to determine

if problem has been

corrected.

If problem is corrected

If problem is not corrected

Test complete.

Return to Step A to fi nd error

in testing.

Page 13

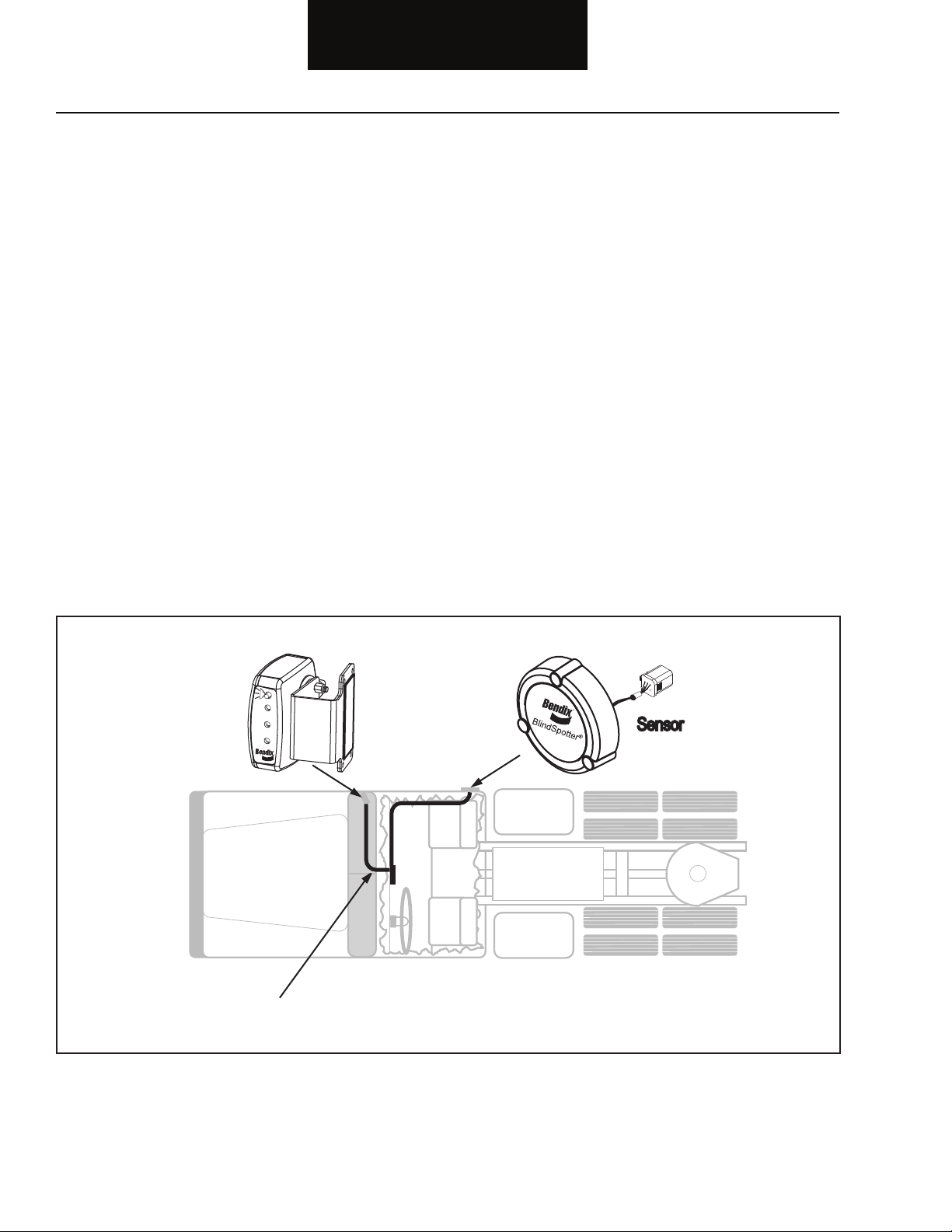

Symptom Isolation Procedures

Harness

P2 SOD

Operator

Display Unit

(ODU)

Sensor

Operator Display Unit Audible Indictor

(Buzzer) Not Functioning

Overview

This symptom-driven test is performed when the system fails to

detect objects properly.

Detection

The symptom is observed by the driver when:

1) objects closer than ten (10) feet are detected,

2) when the turn signal is activated, and

3) when no audible sound is heard.

Fallback

There is no fallback mode for this symptom. The system will not

operate properly.

Required Tools

• Digital Volt/Ohm Meter

Possible Causes

This fault can be caused by any of the following:

• Operator Display Unit

• Vehicle Harness

Operator Display

Audio Test

3-1

Page 14

Symptom Isolation Procedures

OHMS

V ACOM

ODU P1

To Turn Signal Source

1

2

3

4

Operator Display Unit Audible Indictor (Buzzer) Not Functioning

Step A Procedure Condition Action

1. Key off.

2. Active turn signal.

3. Place a target between 3

and 10 feet directly in

front of the sensor.

Note: If both LEDs are

illuminated, go to the

appropriate isolation

If the Operator Display Unit

has red LED on and buzzer

sounds

If the Operator Display Unit

has red LED on only

(no sound)

Test complete.

Go to Step B.

procedure.

Step B Procedure Condition Action

1. Key off.

2. Disconnect Operator Display Unit

from harness J1.

3. Measure resistance between

sensor harness J1 pin 4

and turn signal source.

If resistance is between

0 and 0.3 ohms

If resistance is outside

of range

Go to Step C.

Repair wiring harness.

Go to Step V.

3-2

Page 15

Symptom Isolation Procedures

VOLT

V ACOM

ODU P1

1

2

3

4

Operator Display Unit Audible Indictor (Buzzer) Not Functioning, continued

Step C Procedure Condition Action

1. Key off.

2. Disconnect Operator Display Unit

from harness J1.

3. Measure resistance between

display harness J1 pins

2 and 4.

If resistance is between

0 and .5 ohms

If resistance is outside of

range

Go to Step D.

Repair wiring harness.

Go to Step V.

Operator Display

Audio Test

3-3

Page 16

Symptom Isolation Procedures

VOLT

V ACOM

ODU P1

1

2

3

4

Operator Display Unit Audible Indictor (Buzzer) Not Functioning, continued

Step D Procedure Condition Action

1. Key off.

2. Disconnect Operator Display

Unit from harness J1.

3. Key on.

4. Activate turn signal.

5. Measure voltage between

display harness J1

If voltage is between 10 and

14 volts

Replace display. Go to Step V.

pins 2 and 4.

If voltage is outside of range

Repair wiring harness.

Go to Step V.

Step V Procedure Condition Action

1. Key off.

3-4

2. Reconnect all connectors.

3. Key on.

4. Drive vehicle to determine

if problem has been

corrected.

If problem is corrected

If problem is not corrected

Test complete.

Return to Step A to fi nd error

in testing.

Page 17

Symptom Isolation Procedures

Harness

P2 SOD

Operator

Display Unit

(ODU)

Sensor

Side Sensor Not Detecting Targets

Overview

This symptom driven test is performed when the system fails to

detect objects properly.

Required Tools

Detection

The symptom is observed by the driver when objects at three (3)

to ten (10) feet are not detected. The yellow light also continuously

illuminates when the sensor has failed.

Fallback

There is no fallback mode for this symptom. The Sensor will not

operate properly.

• None

Possible Causes

This fault code can be caused by any of the following:

• Sensor

• Operator Display Unit

3-5

Detection Test

Side Sensor

Page 18

Symptom Isolation Procedures

Side Sensor Not Detecting Targets

Step A Procedure Condition Action

1. Clear area around sensor of

objects.

2. Key on.

3. Allow Operator Display

Unit to go through selftest and shows no

targets (yellow LED

light should be on).

If both LED lights turn on

for .5 seconds – followed by

red LED for 5 seconds –

followed by a continuous

yellow light

If only the yellow LED light

turns on for .5 seconds,

followed by a continuous

yellow light

If both LED lights turn on

for .5 seconds, followed by

continuous yellow and red

lights

Go to Step B.

Replace Operator Display Unit.

Go to the “Power-Up Sequence

Test” on page 2-4.

Step B Procedure Condition Action

1. Key on.

2. Place a target 3 to 10

feet directly in front of

the Sensor.

If the Operator Display Unit

indicates that a target is

detected (red light on)

Go to Step V.

If the Operator Display Unit

does not indicate a target is

present (yellow light on)

Replace sensor.

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Drive vehicle to

determine if problem

has been corrected.

3-6

If complaint has been

repaired

If complaint has not

been repaired

Test complete.

Return to Step A to fi nd

error in testing.

Page 19

Symptom Isolation Procedures

Harness

P2 SOD

Operator

Display Unit

(ODU)

Sensor

Side Sensor Continuous

Side Sensor Continuously Detecting

Targets

Overview

This symptom driven test is performed when the system

continuously detects objects.

Detection

The symptom is observed by the driver when sensor continuously

detects targets.

Fallback

There is no fallback mode for this symptom. The Sensor will not

operate properly.

Detection Test

Required Tools

• None

Possible Causes

This fault code can be caused by any of the following:

• Sensor

• Operator Display Unit

3-7

Page 20

Symptom Isolation Procedures

Side Sensor Continuously Detecting Targets

Step A Procedure Condition Action

1. Clear area around sensor

of objects.

2. Key on.

3. Allow Operator Display

Unit to go through self-test

and shows no targets

(yellow LED light should

be on).

If both LED lights turn on

for .5 seconds – followed by

a red LED for fi ve (5) seconds –

followed by a continuous

yellow light

If both LED lights turn on

for .5 seconds, followed by

a continuous red light

If only red LED lights

Go to Step V.

Go to Step B.

Replace Operator Display Unit.

Step B Procedure Condition Action

1. Key on.

2. Remove Sensor from mounting

position.

3. Move Sensor out away from the

vehicle and place in an open area.

3-8

4. Key on.

5. Allow Operator Display

Unit to go through self-test

and shows no targets

(yellow LED light should

be on).

If both LED lights turn on

for .5 seconds – followed by

a red LED for fi ve (5) seconds –

followed by a continuous

yellow light

If both LED lights turn on

for .5 seconds, followed by

a continuous red light

Reposition sensor on vehicle

to allow clear detection zone.

Go to Step V.

Replace sensor. Go to Step V.

Page 21

Symptom Isolation Procedures

Side Sensor Continuous

Side Sensor Continuously Detecting Targets, continued

Step V Procedure Condition Action

1. Key off.

2. Reconnect all connectors.

3. Drive vehicle to

determine if problem

has been corrected.

If complaint has been

repaired

If complaint has not been

repaired

Test complete.

Return to Step A to fi nd error

in testing.

Detection Test

3-9

Page 22

Symptom Isolation Procedures

Side Sensor Continuously Detecting Targets, continued

3-10

This page left blank intentionally.

Page 23

Wiring Diagrams

J2 SOD

ODU PWR

ODU GND

COM M

PWR

GND

SIDE OBJECT

DETECTION SENSOR

P2 SOD

J1 ODU

ODU PWR

ODU GND

ODU COMM

TUR N SIGN AL

OPERATOR

DISPLAY

UNIT

ODU P1

INTERCONNECT

HARNESS

TURN SGNL

IGNI TION

GROU ND

1

2

3

4

5

6

1

2

3

4

CONNECTOR REAR

CONNECTOR REAR

BlindSpotter

®

Appendix

Appendix

A-1

Page 24

Appendix

J2

J1

3

2

1

4

5

6

2

1

3

4

J1 O D U

DISPLAY

SENSOR

J2 S O D

72 INCHES

240 INCHES

1

23456

342

1

PW R

GN D

CO MM

OD U PW R

OD U GN D

RE D

BL AC K

WH IT E

DK G RE EN

BR OW N

RE D

BL AC K

IG NI TI ON

GR OU ND

DK G RE EN

BR OW N

WH IT E

OR AN GE

TU RN S IGN AL

OD U PW R

OD U GN D

OD U CO MM

TU RN S IG

SI DE

SE NS OR

OP ER AT OR

DI SP LA Y

UN IT

WI RI NG DI AG RA M

IGN ITION

GRO UND

TURN SGNL

CONNECTOR FRONT

CONNECTOR FRONT

A-2

Page 25

Appendix

ODU P1

2.0

.70

2.3

2.1

1.0

2.0

2.8

BRACKET CAN

BE BENT± 15°

10°

FOUR #4

METAL SCREWS

4 X 0 .125 THRU

MTG. HOLES

ADHESIVE BACKING

1.6

1.2

39" ±3"

Appendix

A-3

Page 26

5.6

5.36

1.25 MTG. HOLE TO

CLEAR CONNECTOR

1.38

0.9

0.82

2.04 2.04

3.53

P2 SOD

P2 SOD

1) USE 3 #10-24 X 1 1/2" S.S.

BUTTON HEAD CAP SCREWS FOR

MOUNTING.

2) TORQUE TO 22 IN/LBS.

MADE IN USA

PART

NUMBER

*86989492*

NO.

SERIAL

000003

FCC ID: OXZSTDPREVIEW

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1) This device may not cause harmful interference and

2) This device must accept any interference received.

Including interference to cause undesired operation.

3.2

5.36

0.25

BlindSpotter

®

Appendix

A-4

Page 27

Appendix

Appendix

This page left blank intentionally.

Page 28

Page 29

Page 30

901 Cleveland Street • Elyria, OH 44035 • 1-800-AIR-BRAKE • www.bendix.com

BW2860 ©2011 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group • All Rights Reserved • 09/11

Loading...

Loading...