Page 1

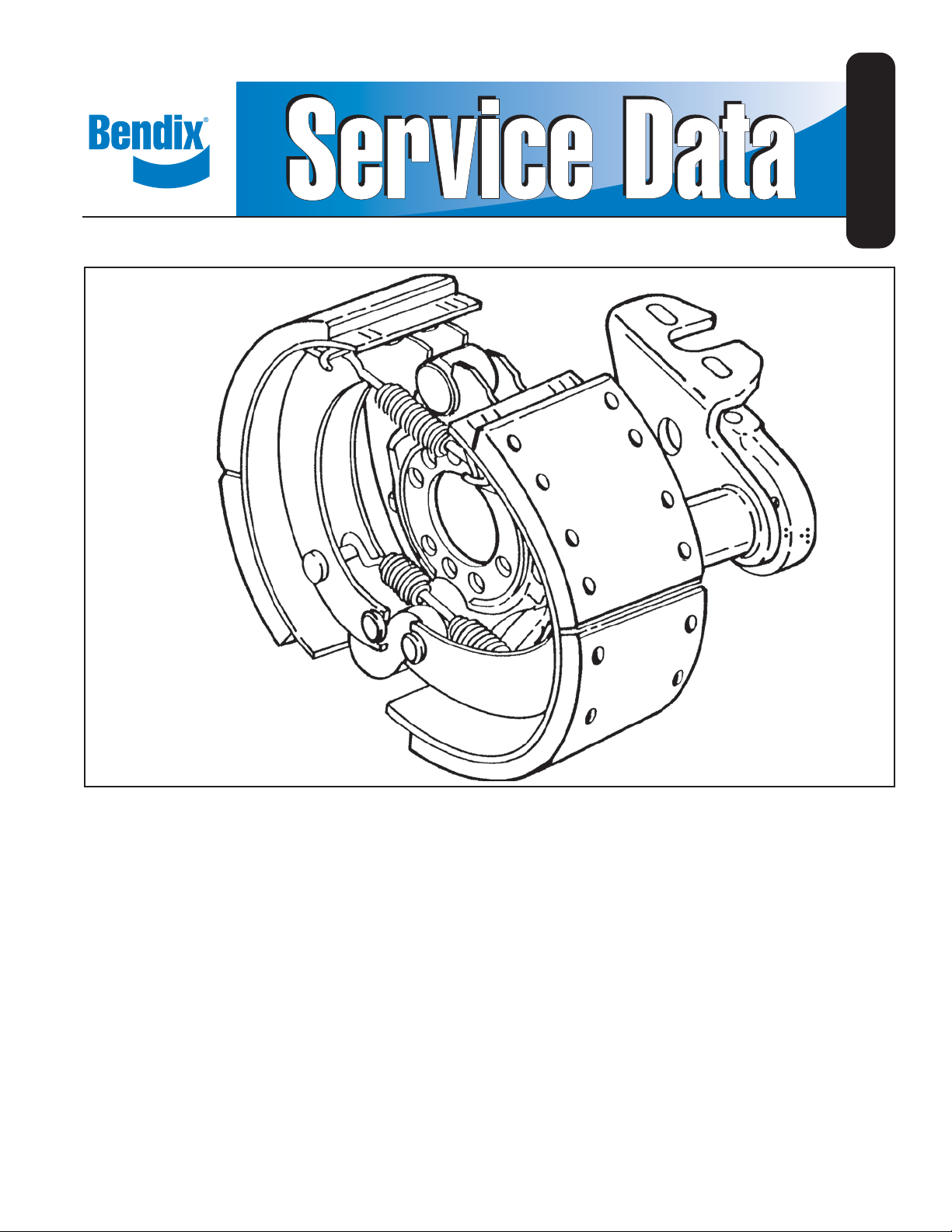

Bendix® BEPA (Ford) 15" x 4" Cam Brake

SD-22-3250

FIGURE 1

GENERAL DESCRIPTION

The Bendix® BEP A (Ford) 15" x 4" cam brake is designed

for use on heavy duty highway vehicles. It is a mechanically

actuated, leading/trailing shoe brake with a fi xed position

cam and anchor.

The brake consists of two fabricated steel shoe assemblies

anchored to a cast iron torque spider and actuated by a

single forged S-cam shaft. Two retaining springs secure

the shoe assemblies to the anchor pin. The twin webs of

each shoe assembly are keyed to the anchor pin on one

end and the cam roller on the other. A single shoe to shoe

return spring is used to maintain constant contact between

the shoe, cam roller and cam.

OPERATION

The Bendix® cam brake operates in the following manner

during a braking application. The force of the push rod of

the actuator is converted from a linear force to a rotary

torque. This is accomplished by use of the slack adjuster .

This torque is transferred to the cam shaft of the foundation

brake due to the spline of the cam shaft being connected to

the gear of the slack adjuster. On the opposite end of the

cam shaft is the S-cam which when rotated lifts the cam

rollers. This spreads the brake shoe ends apart equally and

pivots the shoes about the anchor pin so the brake lining

comes in contact with the rotating brake drum. The friction

created by the lining pressure against the drum generates

the torque necessary to provide a retarding force to slow

down the vehicle. The energy of the vehicle in motion is

converted to heat at the surface of the drum and lining.

This heat raises the temperature of the drum. The heat is

stored in the drum, and fi nally dissipated to the air.

1

Page 2

22

13

18

15

18

14

19

23

21

12

20

9

8

5

6

9

10

11

3

2

4

7

8

24

16

FIGURE 2 - BENDIX® BEPA (FORD) 15" X 4" CAM BRAKE

17

Key No. Description Qty.

1 Snap ring 1

2 Spacer washers # +reqd.

3 Yoke pin 1

4 Slack adjuster 1

5 Yoke 1

6 Cotter pin 1

7 Washer 1

8 Grease seal 2

9 Bushing 2

10 Cap screw 4

11 Lock washer 4

12 Chamber bracket and cam tube 1

13 Brake shoe assembly 2

13

26

25

Key No. Description Qty.

14 Cam roller assembly 2

15 Anchor pin 1

16 S-Cam shaft 1

17 Shoe return spring 1

18 Anchor spring 2

19 Spider 1

20 Dust shield 2

21 Rubber inspection plug 2

22 Cap Nut 6

23 Star Washer 6

24 Actuator 1

25 Mounting Nuts 2

26 Washers 2

2

Page 3

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing

any intrusive maintenance procedures. An extended

warranty may be voided if intrusive maintenance is

performed during this period.

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable

guide in determining the best maintenance interval for a

vehicle.

1. BRAKE LUBRICATION

Grease camshaft bracket with vehicle manufacturer’s

recommended chassis lube. Lube once every six

months or at each chassis lubrication.

2. BRAKE RELINE

The life of the brake lining is dependent on many factors

such as the material of the lining, type of operation

the vehicle is used for, and the driver of the vehicle.

If driving conditions require frequent braking, lining

replacement will be required more often. Reline when

lining thickness at center of shoe is 5/16". Refer to

section “Reline Procedure”.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO A VOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking

brakes, and always block the wheels. Always wear

safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When working

in the engine compartment, the engine should be

shut off and the ignition key should be removed.

Where circumstances require that the engine be

in operation, EXTREME CAUTION should be used

to prevent personal injury resulting from contact

with moving, rotating, leaking, heated or electrically

charged components.

3. Do not attempt to install, remove, disassemble

or assemble a component until you have read

and thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work

on the vehicle. If the vehicle is equipped with an

AD-IS® air dryer system or a dryer reservoir module,

be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power

from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fi ttings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifi cally for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifi cally stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

PREPARATION

1. Park vehicle on a level surface and prevent movement

by means other than the brakes.

2. If equipped with spring brakes, cage the spring on all

axles to be worked on.

3. Drain air from all reservoirs.

4. Raise the axle, to be worked on until the tires clear the

ground.

5. Turn the slack adjuster adjusting screw in the opposite

direction used to adjust the brakes until the cam rollers

return to the start position on the S-cam.

6. Remove wheels and drums using the procedures

specifi ed in the vehicle maintenance manual.

FIGURE 3 - REMOVING CAM ROLLERS

3

Page 4

FIGURE 4 - REMOVING SHOE RETURN SPRING

FIGURE 5 - REMOVING SHOES

FIGURE 6 - REMOVING SLACK ADJUSTER

FIGURE 7 - REMOVING ACTUA TOR BRACKET

DISASSEMBLY (See Figure 2)

1. Insert a sturdy lever between one of the shoes and

the cam shaft housing. Pry shoe away from cam roller

until pin and roller assembly can be removed. Repeat

on opposite shoe. (See Figure 3) (If cam rollers or pins

show signs of wear, galling, pitting, cracks; discard and

replace with new.)

2. Remove shoe return spring and discard. Force

shoes towards the S-cam to relieve spring tension.

(Figure 4)

4

3. Remove shoes. Lift one of the shoes off anchor pin and

lower both shoes to the fl oor. (See Figure 5)

4. Remove the two shoe retainer springs and discard.

NOTE: If only replacing the brake shoes, no further

disassembly is required. Reverse Steps 1 thru 4. NOTE:

Always install new springs.

5. Remove the anchor pin by sliding it out of the spider.

6. Remove the cotter pin from the yoke of the actuator.

Remove yoke pin so the slack arm is free of the yoke.

Remove the two nuts and washers that secure the

actuator to the bracket and remove the actuator.

Page 5

7. Remove snap ring and washer from splined end of

cam shaft. Remove slack adjuster from cam shaft. (A

puller may be required.) Remove spacers and the thick

washer from cam shaft. (See Figure 6)

8. Remove cam shaft from actuator bracket and cam

tube.

9. Mark and remove the dust shields from the spider

by removing the six cap screws using a 3/8" socket.

Do not remove unless there is apparent damage

(See Figure 7).

10. Remove the actuator bracket and cam tube from

the spider by removing the four cap screws and

lockwashers using a 3/4" socket.

11. Remove and discard the two cam shaft grease seals.

One at each end of the cam tube.

12. Remove and discard the two cam shaft bushings

located in the same area as the seals in Step 1 1. Use a

tool of proper diameter and length to drive the bushings

out from the backside. NOTE: Prior to removal see the

“Inspection of Parts” section, Step 1B.

13. To facilitate assembly, note or mark the relationship

of the spider to the axle (driver or curb side) and the

orientation on the axle fl ange. Remove the spider from

the axle fl ange by removing the fi ve bolts, nuts, and

lockwashers and the nuts and lockwashers from the

three studs. NOTE: If the spider is to be reused and

there is damage to any of the three studs, they may be

pressed out of the spider and replaced with grade 8,

5/8" bolts.

CLEANING OF PARTS

After disassembling the foundation brake, wash the metallic

components in mineral spirits and wipe dry . Be careful not

to get any foreign material, especially grease on the brake

shoes or interior of the brake drum. Use a wire brush to

remove heavy contamination from the spider and outside

of the brake drum.

INSPECTION OF PARTS

1. ACTUATOR BRACKET AND CAM TUBE

A. Check assembly for bent actuator bracket and

broken or cracked cam tube welds.

B. Inspect cam shaft bushing for signs of wear . Bearing

surfaces should be smooth and free of any pitting or

fractures. Insert cam shaft and measure looseness

at both ends with a dial indicator. If more than .020"

movement is noted, replace bushings and/or cam

shaft. NOTE: If it is determined that a bushing

requires replacement, both cam shaft bushings

should be replaced.

2. CAM SHAFT

A. Inspect cam shaft spline for cracks and excessive

deformation. Replace as necessary.

B. Inspect the cam shaft bearing journals for wear or

corrosion. If the shaft shows wear or roughness that

is visible or roughness that can be detected by feel,

it must be replaced.

C. Inspect cam head for cracks, and its roller surfaces

for fl at spots, brinneling, or ridges. Note unusual

wear patterns which may indicate an out-of-square

condition. Replace if any of these conditions

exist.

3. SPIDER

A. Inspect for cracked or broken surfaces on the

spider at the cam, anchor pin, and mounting bolt

holes. Replace any spider with visible damage. Do

not attempt to weld or repair. Check fi t of anchor

pin in torque spider. Radial clearance in excess of

.010" indicates excessive wear. Replace anchor pin

and/or torque spider.

4. ROLLERS AND PINS

A. Inspect rollers and pins for fl at spots, galling, broken

or cracked surfaces. Replace as necessary.

5. ANCHOR PIN

A. Inspect anchor pin for worn, broken or cracked

surfaces. Replace as necessary.

6. SHOES AND LINING

A. Check shoes for bent shoe webs, cracks in shoe

table welds or webs, and elongated rivet holes.

Replace shoes if any of these conditions exist.

B. Measure the shoe span by loosely installing the

anchor pin and cam roller in the appropriate ends of

the shoe web. If the distance from center of anchor

pin to center of cam roller exceeds 11.78" replace

shoe.

C. Check linings. Replace when any of the following

conditions exist:

1. Lining thickness at thinnest point is 1/4" or

less.

2. Linings are cracked or worn in an unusual or

odd pattern, i.e., lining wear tapered from side

to side across shoe table. Unusual wear patterns

can indicate damage to foundation brake parts.

3. Rivet holes are elongated in lining or shoes.

4. Lining is oil soaked.

5. Linings can be moved by hand, i.e.; loose

rivets.

5

Page 6

7. BRAKE DRUMS

A. Inspect drums for cracks, heat checking, glazing,

grooving, severe out-of-round condition or bell

mouthing (must not exceed .025 T.I.R.). Replace

any cracked drums. It is recommended that drums

be turned at reline to prevent hot spotting and

achieve quicker, more complete burnishing of the

new lining.

B. Measure the drum I.D. to be sure the maximum limit

allowed (stamped on drum) has not been exceeded,

due to wear or machining.

8. MANUAL SLACK ADJUSTER

A. Check for cracks in the body and arm of the slack

adjuster.

B. Check for spline wear. The amount of backlash in

the slack adjuster to camshaft should be no more

than .094" measured 6" from centerline of the cam

shaft (See Figure 8).

.094”

6”

CAUTION: If the vehicle is equipped with spring

brakes, refer to manufacturer’s instructions. High

spring load, if not handled properly, may result in

serious injury or death may result.

ASSEMBLY (SEE FIGURE 2)

1. Install the spider onto the axle fl ange using the fi ve

bolts, three 5/8" studs, lockwashers and nuts. Be sure

spider is properly oriented as noted during disassembly .

Tighten mounting bolts to vehicle manufacturer’s

specifi cations.

2. If cam shaft bushings were removed, replace with

new bushings. Drive into place using Owatonna 630-7

piloted driver or similar tool, taking care not to damage

or distort the I.D. of the bushings. NOTE: Bushings are

located at each end of cam shaft tube.

3. Install new cam shaft grease seals in the end of the

cam tube and chamber bracket. Use Owatonna 630-7

piloted driver or similar tool to install grease seals.

CAUTION: The lip of the grease seals must be installed

correctly to prevent possible damage. The lip of the seal

that is installed in the cam end must enter the opening

fi rst. The lip of the seal that is installed in the opposite

end of the cam tube must enter last (See Figure 9).

FIGURE 8 - CHECKING SLACK ADJUSTER BACKLASH

C. Check ability to rotate the adjusting nut at least

one complete revolution in each direction. Force

required to rotate the adjusting nut should not

exceed 15 ft. lbs. NOTE: If any of the above

conditions are found, replace the slack adjuster.

Do not attempt to repair.

9. AUTOMATIC SLACK ADJUSTERS

A. Consult manufacturer’s service information. (For

information on Bendix Automatic Slack Adjusters,

see Service Data sheet SD-05-1200, formerly

SD-05-1).

10. ACTUA TORS

A. Check for cracked housing, loose mounting

studs.

B. Check for damage to the push rod, and push rod

boot (if so equipped).

C. Check for broken push rod return spring.

D. Check for excessive wear on yoke, yoke pin, and

slack adjuster yoke pin hole or bushing. There

should be no more than .031 combined free play

in these components.

NOTE: BOTH LIP SEALS POINT THE SAME DIRECTION LIP

LIP SEAL

SLACK ADJUSTER END

FIGURE 9 - SEAL INSTALLATION

TOWARD SLACK ADJUSTER

CAM END

ACTUATOR BRACKET

AND CAM TUBE

LIP SEAL

4. Install the actuator bracket and cam tube onto the

spider using four cap screws and lockwashers. Torque

to 70-80 ft. lbs. Secure the actuator to the bracket

using the two nuts and washers. Torque to vehicle

manufacturer’s specifi cation.

5. If removed, reinstall the dust shields. Tighten the six cap

screws and lockwashers to 90-110 in. lbs. torque.

6. Coat cam shaft journals with light fi lm of chassis lube.

Do not coat “S”-cam head. Install the cam shaft into

the cam tube. Be careful not to damage the grease

seals.

6

Page 7

7. Install the thick cam shaft fl at washer, the slack adjuster ,

spacers, washer, and a new snap ring in that sequence

onto the splined end of the cam shaft. Adjust end play

of the cam shaft to between .005" and .045" by using

the appropriate number of spacer washers. Make sure

the snap ring is seated into the groove at the end of the

splined camshaft.

8. Install the anchor pin into the spider. Center the anchor

pin in the spider so it protrudes equally from each

side.

9. Install new brake shoe retaining springs. Engage hook

ends of the two springs into each of the tabs of the two

brake shoes.

10. Place the top shoe onto the spider by engaging the

open slots on the end with the retaining springs onto the

anchor pin. Place opposite end of the shoe against the

S-cam. Swing the opposite shoe, with springs attached,

back until slots in the shoe engage the anchor pin, then

swing shoe toward the S-cam. Spring tension will hold

the shoes in this position.

1 1. Place the hook of the brake shoe return spring onto the

return spring pins on one shoe. Hold shoes against the

S-cam and connect the other hook of the brake shoe

return spring over the return spring pin of the other

shoe.

12. Insert a sturdy bar between the end of one of the brake

shoes and the spider housing at the S-cam end of the

shoe. Pry down until the brake shoe roller and pin can

be installed between the S-cam and the slots in the end

of the brake shoe. Repeat the same procedure on the

other shoe.

13. Adjust the slack adjuster until the yoke pin can be

installed through the proper hole in the arm. Install a

new cotter pin to retain. Make sure the cam rollers are

in the lowest position on the cam.

14. Lubricate the cam shaft bushings by fi lling the cam shaft

tube with chassis lube through the zerk fi tting provided.

Fill until grease is forced out in the area of the slack

adjuster. Grease should not appear at the cam head

end. If it does, the new seal has not been properly

installed, or the old seals should be replaced.

15. Reinstall brake drums and wheels. Torque and adjust

to manufacturer’s specifi cations.

16. Spin the wheel slowly and adjust the slack adjuster

until wheel will no longer turn. Back off slack adjuster

just enough for wheel to spin freely. Be sure to adjust

brakes equally on each axle.

17. Apply and release brakes and observe slack adjusters.

Both slacks on each axle should respond rapidly and

in unison during application and release.

18. Drive vehicle at a low speed in a safe area and check

for brake effectiveness prior to putting back into service.

7

Page 8

8

BW1458 © 2000 Bendix Commercial Vehicle Systems LLC. All rights reserved. 5/2009 Printed in U.S.A.

Loading...

Loading...