Page 1

Checklist for the Bendix® Air System Inspection Cup (BASIC) Test

Note: Follow all standard safety precautions. Only for vehicles using an air dryer.

Service Writer - Please fill out

the information in this section.

Also, indicate any customer

complaint below.

è

Number of Days Since Air Tanks Were Last Drained: ________ Date: ___________Vehicle #: ____________

è

Engine SN __________________________ Vehicle Used for: _______________Typical Load:________ (lbs.)

No. of Axles: ____ (tractor) ____ (trailer) No. of Lift Axles: ____ Technician’s Name: ____________________

Checklist for Technician

Customer’s Complaint Have you confirmed complaint?

(Please check all that apply)

è

“Relay valve Gleaks oil / G malfunctions” . . . . . . . Gno Gyes*

“Dash valve Gleaks oil / Gmalfunctions” . . . . . . . Gno Gyes*

G“Air dryer leaks oil” . . . . . . . . . . . . . . . . . . . . . . . Gno Gyes*

G“Governor malfunction” . . . . . . . . . . . . . . . . . . . . Gno Gyes*

G“Oil in gladhands” . . . . . . . . . . . . . . . . . . . . . . . . Gno Gyes*

how much oil did you find? ________________________________

G“Oil on ground or vehicle exterior” . . . . . . . . . . . Gno Gyes*

amount described: ______________________________________

G“Short air dryer cartridge life”

replaces every: ______________ G miles, G kms, or G months

G “Oil in air tanks” amount described:_______________________

We will measure amount currently found when we get to step B of the test.

G“Excessive engine oil loss”amount described: ______________

Is the engine leaking oil? . . . . . . . . . . . . . . . . . . . . . Gno Gyes*

Is the compressor leaking oil? . . . . . . . . . . . . . . . . . G no Gyes*

G Other complaint: ______________________________________

GNo customer complaint.

Note: A confirmed complaint above does NOT mean that the compressor

*

must be replaced: the full BASIC test below will investigate the facts.

BASIC test starts here:

STEP A - Select one:

GThis is a low air use vehicle: Line haul (single trailer) with 5 or

less axles, or

GThis is a high air use vehicle: Garbage truck, transit bus, bulk

unloader, or line haul with 6 or more axles.

Then go to Step B.

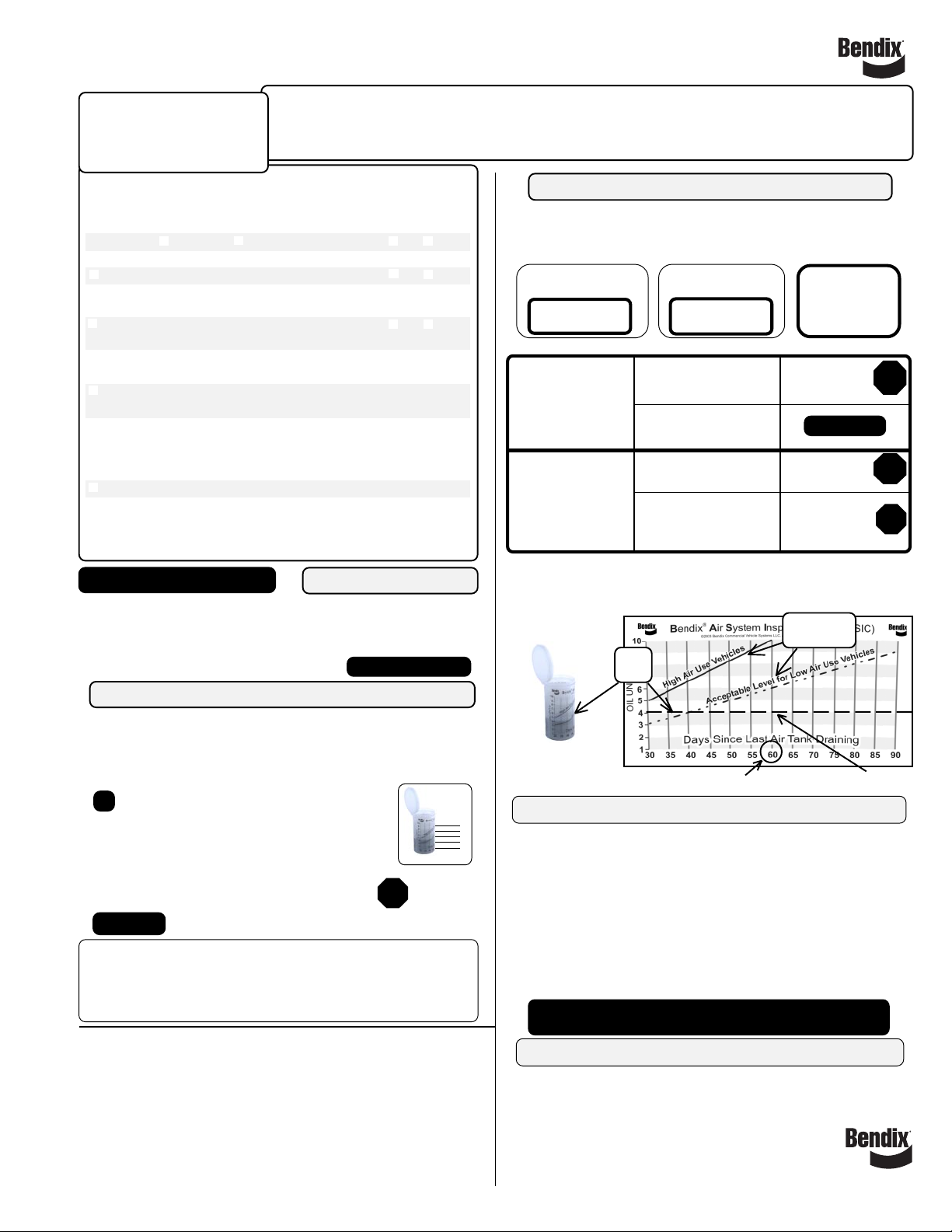

STEP C - How to Read the BASIC Test Chart

Use the chart (label) on the BASIC test cup to decide the action to take.

Use the lower acceptance line for low air use vehicles, and upper line for high

air use vehicles (from Step A).

1. Record days since air

tanks were last drained.

_________ days _________ units

è

If number of days is:

30-60 days (high air use)

or

30-90 days (low air use)

(if the number of days is

unknown, or outside the

è

Otherwise . . .

è

limits above)

An oil level of 4 units in a sixty-day period is within the acceptance area

(at or below the line) for both low and high air use vehicles. Return the

vehicle to service.

Oil

Level

2. Record amount

of oil found:

è

if oil level is at or below

acceptance line for number

of daysè

if oil level is above

acceptance line for number

of days è

if oil level is at or below

30-day acceptance line è

if oil level is above 30-day

acceptance line è

BASIC Test Example

3. Action to

take

è

System OK.

Return to service.

Go to Step D

System OK.

Return to service.

Stop inspection.

Test again

after 30 days.

See Footnote 2.

Acceptance

Lines

STOP

TEST

STOP

TEST

STOP

+ CK.

STEP B - Measure the Charging System Contents

1. Park and chock vehicle on level ground. Drain the air system by

pumping the service brakes.

2. Completely drain ALL the air tanks into a single BASIC cup.

3. If there is less than one unit of contents total, end the test now and

return the vehicle to service. Vehicle passes.

4. If more than one oil unit of water (or a cloudy

emulsion mixture) is found:

(a) Change the vehicle’s air dryer cartridge

- see Footnote 1,

(b) Conduct the 4 minute leakage test (Step D),

(c) STOP the inspection, and check the vehicle

again after 30 days - see Footnote 2.

STOP

+ CK.

Otherwise, go to Step C.

Note for returning vehicles that are being retested after a water/

cloudy emulsion mixture was found last time and the air dryer

cartridge replaced: If more than one oil unit of water or a cloudy

emulsion mixture is found again, stop the BASIC test and consult the

air dryer's Service Data sheet troubleshooting section.

Footnote 1: Note: Typical air dryer cartridge replacement schedule is every 3 yrs/

300K miles for low air use vehicles and every year/100K miles for high air use vehicles.

Footnote 2: Caution: To get an accurate reading for the amount of oil collected

during a 30 day period, ask the customer not to drain the air tanks before returning.

(Note that 30-90 days is the recommended air tank drain schedule for vehicles

equipped with a Bendix air dryer that are properly maintained.) If, in cold weather

conditions, the 30 day air tank drain schedule is longer than the customer's usual

draining interval, the customer must determine, based on its experience with the

vehicle, whether to participate now, or wait for warmer weather. See the cold weather

tips in Bendix Bulletins TCH-008-21 and TCH-008-22 (included in Appendix B of the

Advanced Troubleshooting Guide).

Oil

Units

X

Sixty days since last air tank draining

STEP D - Air Brake System Leakage Test

Park the vehicle on level ground and chock the wheels. Build system pressure

to governor cut-out and let the pressure stabilize for one minute.

1: Observe the dash gauges for two additional minutes without the service brakes

applied. 2: Release the parking brake and apply the service brakes (you may

use a block of wood to hold the pedal in position). Allow the air pressure to

stabilize, and then observe the dash gauges for 2 minutes. If you see a

noticeable decrease of the readings, repair leaks and repeat this test to confirm

that air leaks have been repaired. Return vehicle to service, but please repeat

BASIC test at next service interval. Note: Leaks can also be present in the

charging system, parking brakes, and/or other components.

If no air leakage was detected, and if you are conducting

this test after completing Step C, go to Step E.

STEP E - If no air leakage was detected in Step D

Replace the compressor. Note: If the compressor is within warranty period,

please follow standard warranty procedures. Attach the completed checklist to

warranty claim.

If, after a compressor was already replaced, the vehicle fails

the BASIC test again, do not replace the compressor again,

instead use the Advanced Troubleshooting Guide to

investigate the cause(s).

BW2377 ©2004 Bendix Commercial Vehicle Systems LLC. All Rights Reserved. 8/30/04. Printed in USA.

Decision point

Loading...

Loading...