Page 1

®

Bendix® AH-1B™ Air Hydraulic Intensifier

ELECTRICAL FLUID

LEVEL INDICATOR

CONNECTION

RESERVOIR

CAP

BRAKE FLUID

DELIVERY PORT

MASTER

CYLINDER

SD-11-1326

BRAKE FLUID

RESERVOIR

AIR

INLET

PORT

ACTUATOR

MOUNTING

BRACKET

NON-PRESS

PLATE

CLAMP RING

AIR INLET

PRESSURE

PLATE

DIAPHRAGM

PUSH ROD

FIGURE 1

RETURN

SPRING

BOOT

O-RING

DRAIN HOLE

DESCRIPTION

The AH-1B™ air hydraulic intensifier is a hydraulic brake,

power booster which utilizes compressed air for its power

assist. Its function is to convert air pressure to hydraulic

pressure for use in the brake system.

The AH-1B™ intensifier consists of three major component

groups; a specially designed type 30 air actuator is bolted

to a single piston master cylinder which incorporates an

ELECTRICAL

CONNECTOR

SEAL

PISTON

MOUNTING

BRACKET

INDICATOR

SWITCH

FILLER CAP

ASSY.

RESERVOIR

FLOAT

COMPENSATING

VALVE

HYD.

DELIVERY

PORT

RETURN

SPRING

PISTON

ACTUATOR

LIP

integral brake fluid reservoir. A bracket installed between the

actuator and master cylinder provides a means for mounting.

A float actuated, low fluid level, on/off electrical switch is

incorporated in the reservoir filler cap assembly. A two

“prong” connector is provided to permit the installation of a

vehicle electrical cable assembly . Switch actuation occurs

when the reservoir fluid level drops below the “minimum”

level marking on the reservoir.

1

Page 2

HYDRAULIC

PUSH-PULL VALVE

DISC BRAKE

™

AIR OVER

AH-1B

HYDRAULIC

INTENSIFIER

BRAKE

VALVE

AIR DRYER

RESERVOIR

COMPRESSOR

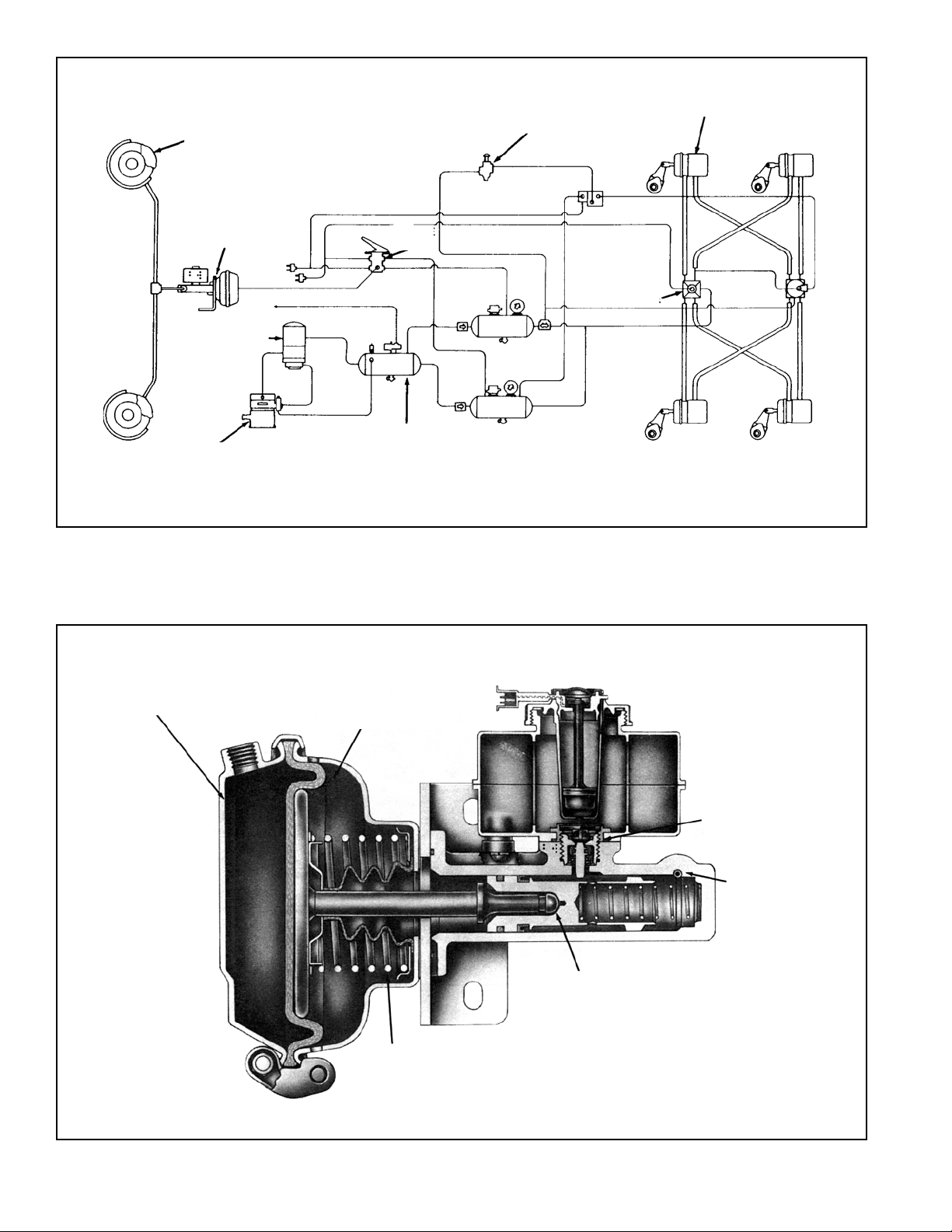

FIGURE 2 - TYPICAL AH-1B™ AIR HYDRAULIC INTENSIFIER SYSTEM

SPRING BRAKE

ACTUATOR

RELAY

VALVE

AIR APPLIED

POSITION

DIAPHRAGM

APPLIED

POSITION

COMPENSATING

TILT VALVE SEALED

HYDRAULIC FLUID

BEING DELIVERED

PISTON APPLIED

POSITION

RETURN

SPRING

COMPRESSED

FIGURE 3 - CUTA WA Y VIEW OF APPLIED POSITION

2

Page 3

AIR INLET

NON-APPLIED POSITION

DIAPHRAGM

NON-APPLIED POSITION

COMPENSATING TILT

VALVE UNSEALED

POSITION

HYDRAULIC

FLUID PORT

PISTON

NON-APPLIED

POSITION

RETURN SPRING

NON-APPLIED POSITION

FIGURE 4 - CUT AW A Y VIEW OF RELEASED POSITION

OPERATION

Brakes Applied

During a brake application, modulated air pressure from the

foot operated air brake valve enters the actuator inlet port.

Air pressure acting upon the area of the actuator diaphragm

causes the diaphragm and push rod assembly to move

toward the master cylinder. The actuator push rod forces

the master cylinder piston to move within its bore. Initial

forward travel of the piston moves the actuating lip of the

piston away from the stem of the compensating (tilt) valve

allowing it to close due to spring force. (Refer to Figure 2 &

3.) Closure of the compensating valve shuts off the fluid

passage between the cylinder bore and fluid reservoir which

allows hydraulic pressure to build and the brakes to apply .

The amount of hydraulic pressure generated is dependent

upon the air pressure applied to the air actuator.

Brakes Released

When air pressure is exhausted from the actuator the push

rod returns to the released position due to spring force.

With the push rod load removed, fluid pressure combined

with return spring force causes the piston to return to the

brakes released position. The actuator lip of the piston

contacts the stem of the compensating valve and unseats

the valve as the piston returns. When the compensating

valve opens, the passage between the fluid reservoir and

master cylinder bore is also open. Any excess fluid

remaining at the end of the stroke due to “pumping” and/or

volume change due to temperature fluctuation is transmitted

back to the fluid reservoir as the compensating valve opens.

The push rod is used as the piston stop in the fully released

position. (Refer to Figure 4).

Fluid Level Indicator

The reservoir fluid level is reduced as the brake linings wear

due to an increase of fluid volume required in the hydraulic

brake system. The float contained in the reservoir filter cap

assembly is suspended in the reservoir fluid and responds

to changes in the fluid level. As long as the reservoir fluid

level is adequate, a metal contact plate on top of the float

stem is held away from two electrical contacts. When the

reservoir fluid level drops below the “MINIMUM” fluid level

mark on the reservoir, the contact plate on the float stem

will move and complete the electrical circuit through the

switch.

3

Page 4

TECHNICAL SPECIFICATIONS

AH-1B™ Air Hydraulic Intensifier Assembly

Power ratio - 20.2 to 1

Weight - approximately 2-1/2 pounds

Air Actuator

Effective area of diaphragm at 2-1/8 inches of push rod stroke

- approximately 28 sq.in.

Volume at 2-1/8 inches of push rod stroke - approximately

75 cubic inches.

Master Cylinder

Bore diameter - 1.38 inches

Maximum piston stroke - 2-1/8 inches

Maximum fluid displacement - 3.17 cubic inches

Fluid Reservoir

Volume - 33.5 cubic inch to “MAXIMUM” level mark with

cap removed.

PREVENTIVE MAINTENANCE

Every month, after 8,000 miles, or 300 operating hours;

1. Remove accumulated dirt and grime from the area

around the reservoir cover. With the ignition switch in

the on position, remove the cover and hold in an upright

position and allow brake fluid in the tube of the cap to

drain back into the reservoir. Check to see if the low

fluid indicator bulb is operating (in cab of vehicle).

2. If the fluid level is low, fill to proper level indicated on the

side of the reservoir. CAUTION: Fill the reservoir with

type and grade of fluid recommended by the vehicle

manufacturer.

3. Check tightness of the mounting nuts, air and hydraulic

fittings.

4. Make a visual inspection of air and hydraulic lines for

kinking, bending or fraying. Replace as necessary.

Every 12 months; 100,000 miles; or 3,600 operating hours;

1. Perform the operating and leakage tests. Replace or

repair components or assemblies as indicated using

only genuine Bendix parts.

OPERATING AND LEAKAGE TESTS

1. With vehicle air system pressure built to governor cut-out,

make and hold a full brake application. Hold for at least

5 minutes. Using a soap solution, check for air leaks at

fittings and air lines. Tighten and/or replace as necessary .

Apply a soap solution around the actuator clamp ring.

No leakage is permitted. Tighten or replace as necessary .

Apply a soap solution to the actuator non-pressure plate

drain holes. Replace the actuator diaphragm if leakage

is detected.

2. While holding the brake valve in the fully applied position,

check for hydraulic fluid leaks at all fitting connections

and at the hydraulic cylinders in the foundation brake.

Check for fluid leakage at the drain holes of the actuator

non-pressure plate. Repair or replace components as

necessary .

3. With the reservoir filter cap removed apply and fully

release the brakes several times while observing the fluid

in the reservoir. CAUTION: WEAR SAFETY GLASSES

AS FLUID MA Y EXIT THE RESERVOIR.

A slight fluid turbulence should be noted at the beginning

of the application and should immediately cease. If

prolonged turbulence is noted, the master cylinder must

be repaired or replaced.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around brake systems and

components, the following precautions should be

observed at all times:

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

When working around or under the vehicle, stop

the engine and remove the key from the ignition.

Always keep hands away from chambers as they

may apply as system pressure drops. Always wear

safety glasses.

2. When working in the engine compartment, the

engine should be shut off and the ignition key

should be removed. Where circumstances require

that the engine be in operation, extreme caution

should be used to prevent personal injury resulting

from contact with moving, rotating, leaking, heated

or electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to the use of those tools.

4. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

5. If the vehicle is equipped with an air over hydraulic

brake system or any auxiliary pressurized air

system, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

6. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or pipe plug unless you are certain all

system pressure has been depleted.

7. Never exceed manufacturer’s recommended

pressure.

™

4

Page 5

NON-PRESS

PLATE

SPRING

SEAT

RETURN

SPRING

BOOT

BUSHING

ASSEMBLY

DIAPHRAGM

NUT (2)

PRESSURE

PLATE

1-1/4” RES.

RETAINING

NUT

RESERVOIR

RESERVOIR CAP

ASSEMBLY

MASTER

CYLINDER BODY

FIGURE 5 - EXPLODED VIEW

SEAL

LOCKWASHER

(2)

COMPENSATING

(TILT) VALVE

ASSEMBLY

RESERVOIR

MTG. PAD

PHILLIPS

SCREW (2)

8. Never attempt to disassemble a component until

you have read and understand all recommended

procedures. Some components contain powerful

springs and injury can result if not properly

disassembled. Use only proper tools and observe

all precautions pertaining to use of those tools.

9. Use only genuine Bendix® replacement parts,

components and kits.

A. Use only components, devices and mounting

and attaching hardware specifically designed

for use in hydraulic brake systems.

B. All replacement hardware, tubing, hose,

fittings, etc. must be of equivalent size, type

and strength as the original equipment.

10. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

11. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

SPRING

FIGURE 6

ACTUATOR

NUT (2)

O-RING

PISTON ASSY.

(W/ SEAL)

CLAMP RING

WASHER (2)

O-RING

GASKET

MOUNTING

BRACKET

5

Page 6

REMOVAL FROM VEHICLE

1. Disconnect the hydraulic line from the delivery port of

the master cylinder and plug the line. Allow the hydraulic

fluid from the master cylinder to drain into a suitable

container . Remove reservoir cover to facilitate drainage.

2. Disconnect the air line from the air actuator and cover

the end of the air line.

3. Remove the electrical connection from the low level

indicator on the reservoir cover.

4. Remove the hardware that secures the mounting bracket

of the AH-1B™ intensifier to the vehicle and remove the

complete unit.

INSTALLING ON VEHICLE

1. Install the hardware which secures the AH-1B™ intensifier

mounting bracket to the vehicle. T orque all hardware per

the vehicle manufacturer’s recommendations.

2. Reconnect the air line to the actuator. Use a small amount

of thread sealant.

3. Reconnect the hydraulic line to the master cylinder.

4. Connect the electrical terminal from the low fluid indicator

onto the terminal on the cap of the reservoir.

5. Fill the master cylinder fluid reservoir using the type and

grade fluid specified by the vehicle manufacturer.

6. Bleed the hydraulic brakes following the vehicle

manufacturer’s recommended procedure.

7. Refill the master cylinder fluid reservoir to replace fluid

lost during the bleeding procedure.

DISASSEMBLY

General

The following procedure is presented for reference only.

Disassembly of the AH-1B™ intensifier should not be

attempted without having the appropriate maintenance kits

or replacement parts on hand as some parts may be

damaged during disassembly.

FIGURE 8

1. Drain the hydraulic fluid from the reservoir.

2. Remove the two Phillips screws and lockwashers from

the bottom of the reservoir located at the reservoir

mounting pad on the master cylinder next to the flange.

3. Remove the reservoir cap and retain. DO NOT

DISASSEMBLE CAP . Using a 1-1/4" socket remove the

retaining nut on the inside of the reservoir. Reservoir is

now free of the master cylinder. Remove the seal on the

bottom of the reservoir and discard. (Refer to Figure 6.)

4. Remove the compensating valve assembly from the

master cylinder by placing a crescent wrench across

the flats and turning counterclockwise. If only changing

the reservoir, do not remove the compensating valve

assembly as it cannot be replaced unless the master

cylinder is disassembled. The compensating valve must

be replaced as an assembly (Figure 7).

FIGURE 7

6

FIGURE 9

Page 7

5. Note and mark the orientation of the actuator and master

cylinder to the mounting bracket. Remove the two nuts

and washers from the mounting studs of the actuator

(use a 15/16" socket wrench). Separate the master

cylinder and actuator from the mounting bracket and

retain the actuator for later disassembly. CAUTION:

Piston under spring load and retained by the push rod

only when compensating tilt valve assembly has been

removed. (Refer to Figure 8.)

6. Remove the o-ring from the flange of the master cylinder

and the gasket between the bracket and actuator.

7. Remove the piston assembly and spring from the body

of the master cylinder. (Refer to Figure 9.)

Actuator Disassembly

8. Mark the relationship of the clamp ring, pressure and

non-pressure plates. Remove the two nuts and bolts from

the clamp ring of the actuator (use a 1/2" socket wrench).

Grasp the ears of the clamping ring and spread slightly

until ring will come off and pressure plate and

non-pressure plates separate. CAUTION: Parts are

spring loaded. Use a press or clamp to retain the push

rod and return spring during disassembly .

9. Remove the spring seat, spring, and boot from the push

rod and separate the diaphragm from the push rod.

(NOTE: Do not separate the diaphragm from the push

rod.) If the diaphragm is to be replaced, a new push rod

and diaphragm assembly will be required.

CLEANING & INSPECTION

1. Wash all master cylinder parts retained during

disassembly in clean DOT 3 or 4 brake fluid. CAUTION:

DO NOT use any solvent other than clean brake fluid

for cleaning or flushing master cylinder parts. The use

of unapproved solvents with a trace of mineral oil will

damage rubber parts.

2. Remove all sediment or foreign material from the bottom

of the fluid reservoir. If the reservoir is equipped with

filters, make certain they are thoroughly cleaned. If the

filters are thoroughly plugged and/or cannot be cleaned,

the entire brake system should be flushed. If the filter

cannot be cleaned, it may be removed after the system

is flushed.

3. Inspect the condition of the piston. Measure the major

diameter (around the top edge of the o-ring groove and

piston actuator lip) of each piston in several places around

its circumference. The difference between the largest

and smallest measurement on each of the diameters

measured should not exceed .005 inches (.13mm). If

the diameter of the piston varies more than the maximum,

the master cylinder should be replaced or repaired using

a maintenance kit.

FIGURE 10

4. Examine the master cylinder bore after cleaning. If pitting,

scratching or visible wear patterns are noted, the master

cylinder should be replaced. Dirt, gum and stained areas

not removed during cleaning can be polished with crocus

cloth. DO NOT USE EMERY CLOTH OR SAND P APER.

Master cylinder bores may be honed provided that the

diameter is not increased substantially . Honing to remove

scratches and pitting will most likely increase the bore

diameter beyond the sealing ability of piston seals. To

make certain the bore diameter has not been excessively

increased, measure the piston clearance in the master

cylinder bore. Using a feeler gauge make certain the

clearance does not exceed .010 inches (.25 mm). Make

certain that no burrs or sharp edges remain in the cylinder

bore. Thoroughly clean and rinse the master cylinder in

brake fluid after polishing or honing.

5. Inspect the actuation push rod return spring for corrosion

and pitting and replace if necessary .

6. Inspect the actuator diaphragm for wear and abrading.

(It is recommended that the diaphragm be replaced

whenever a complete disassembly of the AH-1B

intensifier takes place.)

7. The push rod boot should be replaced each time a

complete disassembly is undertaken.

ASSEMBLY

Actuator Assembly

1. Install the boot onto the push rod assembly . The small

I.D. of the boot must be forced over the larger O.D. on

the shaft of the push rod. Place the spring over the

push rod and boot and place the spring seat onto the

spring. Force large flange end of the boot through the

center hole of the spring seat.

™

7

Page 8

2. Place the push rod and diaphragm assembly into the

pressure plate and place non-pressure plate onto the

push rod. Check to assure that the spring is in proper

position (each end contained and centered in the spring

guides).

3. Orient the pressure and non-pressure plates as marked

and compress the spring by pushing down on the

non-pressure plate. Retain with a clamp or light pressure

from a press. Be sure the ferrule on the pressure plate

is properly oriented and the edges of the non-pressure

plate, diaphragm, and pressure plate are equally

distributed around the entire circumference.

4. Install clamping ring and retain with the two bolts and

nuts. T orque to 130-150 inch pounds. IMPOR T ANT : Be

sure the beads of the pressure plate and the non-pressure

plate are contained by the clamping ring a full 360°. T a p

around the circumference of the clamp ring to assure it

is seated evenly all around.

5. Install a new gasket on the mounting studs of the

nonpressure plate of the assembled actuator and put

the assembly aside.

Master Cylinder Assembly

6. Install new o-rings on the master cylinder mounting flange

and the master cylinder piston.

7. Carefully insert the spring and piston into the master

cylinder body. Making certain not to damage the seal

and o-ring. The lip seal and o-ring must enter the body

last. Depress and hold the piston by inserting a dull

object into the recess in the end of the piston. Piston

actuator lip should be completely past the compensating

TRT valve assembly port to allow for proper installation

of the compensating valve assembly. Install the

compensating valve assembly into the threaded port of

the top of the master cylinder. Be sure compensating

valve is installed between the two larger diameters on

the piston. Torque to 30-40 foot pounds. NOTE: The

compensating valve assembly should retain the piston

assembly in the master cylinder if installed correctly.

(See Figure 10.)

8. Install a new seal on the bottom of the reservoir and

place both on the master cylinder. Be sure reservoir is

oriented so that holes for the Phillips screws line up

with the holes on the master cylinder. Install the two

Phillips screws and lockwashers and tighten snugly .

9. Install the reservoir retaining nut onto the compensating

valve through the reservoir cover opening. Use a 1-1/4"

socket and torque to 13-16 foot pounds.

10.Install the reservoir filler cap assembly on the reservoir.

1 1. Clamp the mounting bracket securely in a vise, making

sure it is oriented so that the unit may be assembled,

and lining up the marks made prior to disassembly .

FIGURE 11

12.Install the new gasket(6) over the mounting studs of the

brake chamber. Make sure the gasket is flat against the

top of the brake chamber.

13. Place the brake chamber onto the mounting bracket with

the push rod extending through the center hole and the

mounting bolts extending through the outer holes.

14.Install the master cylinder/reservoir assembly onto the

brake chamber mounting studs and retain with nuts(4)

and washers(5). T orque to 100-1 15 foot pounds. NOTE:

The end of the push rod must enter the recess of the

master cylinder piston.

Bench Bleeding

Before installing the AH-1B™ intensifier assembly on the

vehicle the master cylinder should be bench bled. Follow

the vehicle manufacturer’s recommendations in lieu of the

following.

1. Plug outlet port and secure cylinder in a vise with front

end tilted slightly downward. NOTE: Bleeder tubes or

Bendix bleeding kit #74013 may also be used following

the kit instructions enclosed. (Refer to Figure 1 1.)

2. Fill reservoir with brake fluid. Refer to vehicle

manufacturer’s manual for fluid requirements.

3. Apply and release air pressure to the actuator several

times.

4. Re-position the master cylinder in the vise with the front

end tilted slightly up. Again, apply and release air

pressure several times. NOTE: When using this method

of bench bleeding, the master cylinder will not be capable

of being stroked once all the air is removed.

5. Install the AH-1B™ intensifier on the vehicle and perform

the “Operating and Leakage Test s” prior to placing the

vehicle in service.

8

BW1599 © 2004 Bendix Commercial Vehicle Systems LLC All rights reserved. 4/2004 Printed in U.S.A.

Loading...

Loading...