Page 1

®

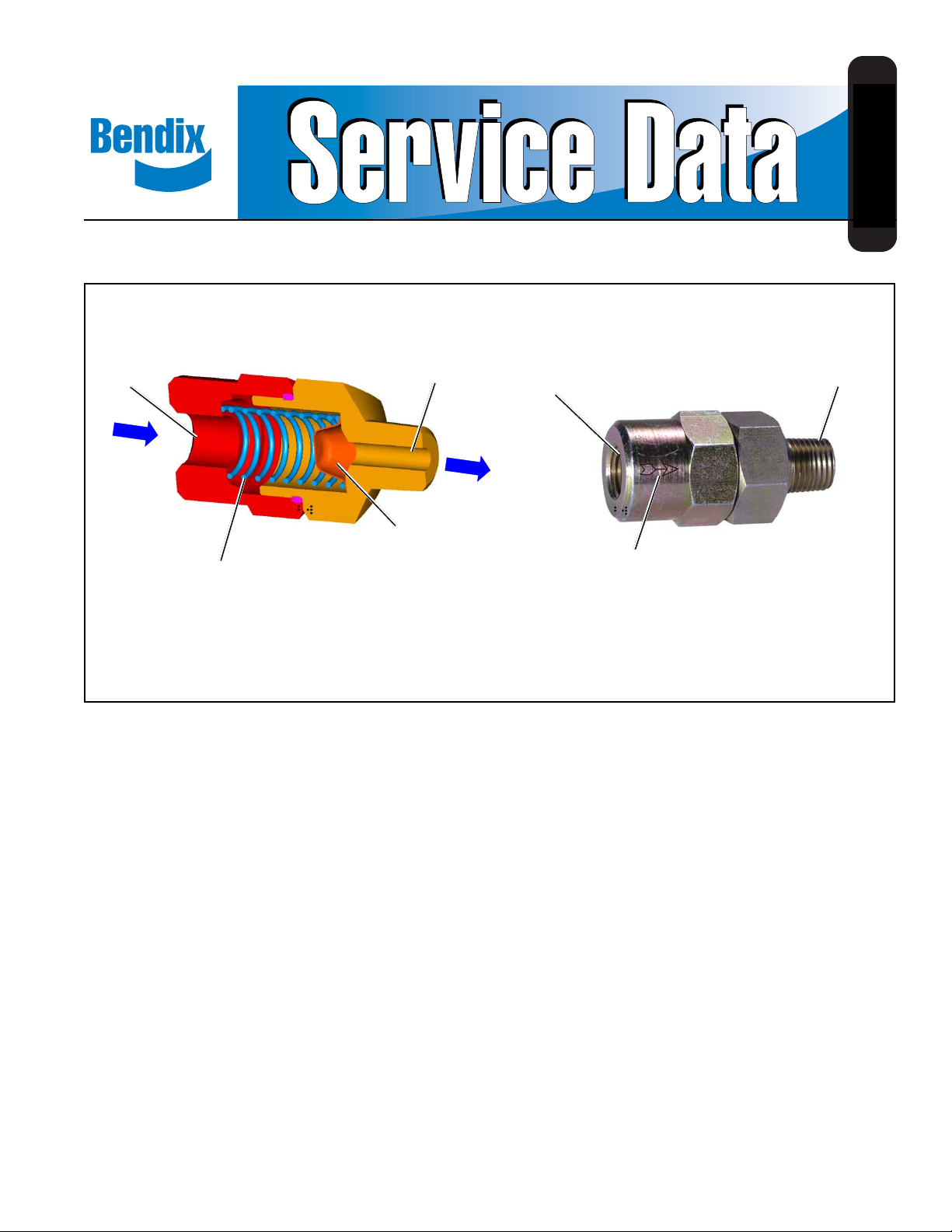

Bendix® AF-3™ In-Line Filter

SUPPLY

SPRING

DELIVERY

SCREEN

1/4" NPT

SUPPLY

DIRECTIONAL ARROW -

INDICATES AIR FLOW

SD-08-2401

1/4" NPT

DELIVERY

FIGURE 1 - AF-3

™

IN-LINE FILTER SECTIONAL AND EXTERIOR VIEW

DESCRIPTION

GENERAL

The AF-3™ in-line filter assembly is designed to prevent

foreign material from entering the control port of the Trailer

ABS modulator or spring brake relay. The filter body is made

of steel with an internal screen element of stainless steel held

in place by a spring. The filter is capable of removing particles

0.012 inches in size or larger. The filter has a ¼ NPT female

supply port and a ¼ NPT male delivery port. Note: If the

filter is installed in the reversed direction, its filtering

capability will be reduced.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking brakes, and always block the wheels. Always

wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When working in the engine compartment, the engine should

be shut off and the ignition key should be removed.

Where circumstances require that the engine be

in operation, EXTREME CAUTION should be used

to prevent personal injury resulting from contact

with moving, rotating, leaking, heated or electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended procedures. Use only the proper tools and observe all

precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

™

1

Page 2

5. Following the vehicle manufacturer’s recommended procedures, deactivate the electrical system in a manner that safely removes all electrical

power from the vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing pressure; it may whip. Never remove a component or plug unless you are certain all system

pressure has been depleted.

8. Use only genuine Bendix

®

replacement parts, components and kits. Replacement hardware, tubing,

hose, fittings, etc. must be of equivalent size, type

and strength as original equipment and be designed specifically for such applications and systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

PREVENTIVE MAINTENANCE

Because no two vehicles operate under identical conditions,

maintenance intervals will vary. Experience is a valuable

guide in determining the best maintenance interval for a

vehicle. As a recommended minimum, every 12 months,

100,000 miles or 3,600 operating hours, perform the

Operational and Leakage Tests noted below. Inspect the

filter for unrestricted airflow and blockage from debris

collection. Remove the filter assembly and clean as

needed. If the unit cannot be cleaned of debris, replace the

filter. There are no serviceable parts within the assembly.

SERVICING AND CLEANING

1. Identify the control line to the trailer ABS modulator or

spring brake relay valve. Disconnect the control line and

remove the filter from the control port.

2. With the AF-3™ in-line filter removed, apply shop air to the

delivery port of the filter to clean the debris from the filter

screen.

NOTE: Disassembly/reassembly of the AF-3™ in-line

filter is not recommended. If an assembly does not

meet the Operational and Leakage Tests, it should

be replaced with a new AF-3™ in-line filter.

ECU

CONTROL

PORT

Figure 2 - Trailer Antilock Modulator

4. Apply thread sealant (do not use Teflon tape) to the

male threads of the control line and the AF-3™ in-line

filter.

5. Install the filter in the control port of the ABS modulator

or spring brake relay valve. Torque the filter body in place

to approximately 10 pound-feet.

6. Connect the control line to the supply port of the AF-3

in-line filter.

OPERATIONAL AND LEAKAGE TESTS

Apply the brakes and hold 20 psi pressure to the line. Apply

a soap solution to the threads to check for leakage. A oneinch bubble in 5 seconds is permitted. Repair any excessive

leaks. Perform the Service Check before placing the vehicle

in service.

SERVICE CHECK

Apply and release air pressure to the control line containing

the filter. The AF-3™ in-line filter should allow delivery and

exhausting of the pressure without any noticeable delay in

service brake response. A delay can be identified by making

a service brake application and viewing the actuator push

rods. A delay may indicate foreign material is present in the

control line, preventing the proper flow of air. If a delay is

found, clean or replace the AF-3™ in-line filter.

™

3. Clean the contaminants from the control line by applying

shop air to the control line at the gladhand. If the trailer

is connected to the tractor, build system pressure and

make a light brake application. Caution: Pressurized

debris can cause bodily injury, be sure the area

around the trailer is vacated before performing this

operation.

BW2263 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 5/2004 Printed in U.S.A.

2

Loading...

Loading...