Page 1

Technical Bulletin

Bulletin No.: PRO-13-01 Effective Date: 8/15/78 Cancels: N/A Page: 1 of 4

Subject: ANTI-LOCK SYSTEM – ROADWAY EXPRESS

Roadway Express is placing a fleet of tractors and trailers in service with Bendix

Anti-Lock components.

The tractors are White Model RB-2 tandem axle with a trailing dead axle. The tractor

Anti-Lock system is somewhat unique as follows:

Both axles of the tandem are controlled by a single MC-1 Anti-Lock assembly. The tag

axle only is equipped with WS-1 hub mounted speed sensors.

The power supply is arranged so that there is a redundant source of power for the anti-

lock through an air-operated switch. The air-operated switch is connected to the air

source for the spring parking brake release. Consequently, if the parking brakes are

released (by applying air pressure) the anti-lock system is powered up. It also receives

power from the ignition switch. In either case, the anti-lock will self-check as it first

receives power. To hear the air bursts of the self-check sequence, the service brakes

should be applied first and then the ignition switch turned on or the parking brakes

released. The anti-lock indicator lamp will light for two seconds and then go out and two

short bursts of air will be heard from the anti-lock modulator.

The White tractors also are equipped with a relay in the cab which will sense a loss of

ground for the MC-1 or a severing of all three conductors running from cab to controller

and light the indicator lamp. A simplified diagram of this circuit is shown in Fig. 1

The Roadway trailers are Budd and Monon and are equipped with MC-3 controller

modulators with WS-1 speed sensors identical to those used on the tractor. The trailers

do not have the optional indicator lamp; consequently, the only way the trailer anti-lock

system can be checked for functional integrity is by a dynamic check and/or by checking

the fuse in the MC-3.

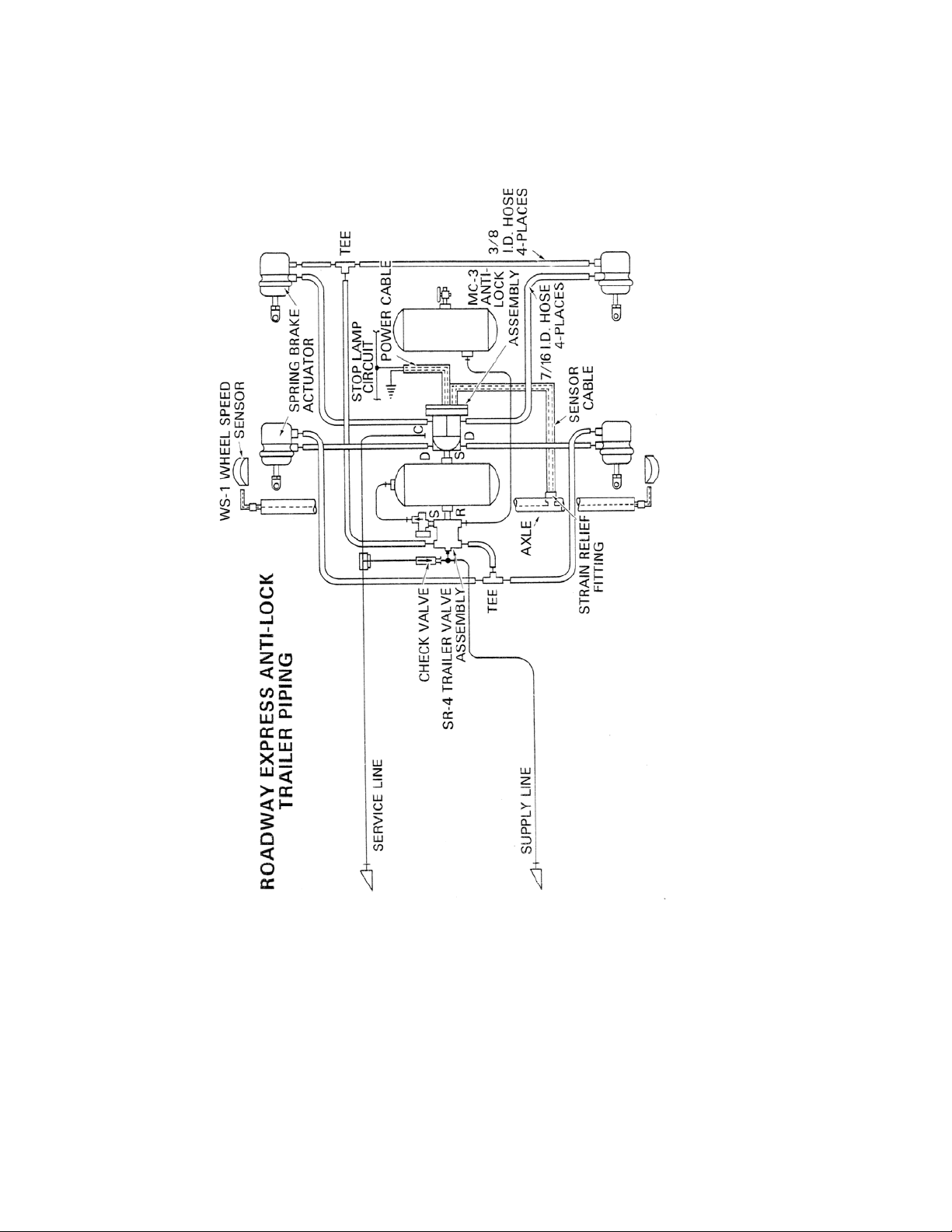

The Roadway trailers are also equipped with a Bendix two reservoir reduced volume

pneumatic system using an SR-4 trailer supply valve. If any problems occur with the

SR-4, care should be taken not to install the SR-2 by mistake. Only the SR-4 is

designed for the reduced volume system. The primary difference between the SR-2

system and the SR-4 system is that the SR-2 requires separate reservoirs for service

application and for spring brake hold-off, whereas the SR-4 uses both reservoirs for

service application but either will retain air to hold the spring brakes in the release

position in case of the loss of the other. This reduces the total reservoir volume required

to meet “121” requirements. A schematic of the trailer piping is shown in Fig. 2.

A chart showing service piece numbers for servicing the various components is shown in

Fig. 3.

Page 2

Page 3

Page 4

SERVICE PIECE NUMBERS

ROADWAY FLEET

Tractor Trailer

Complete Controller-Modulator MC-1 - 289252 MC-3 – 288473

Controller EC-1 - 289359 EC-3 – 288475

Modulator M-6 - 289614 M-7 – 288673

Repair Kit 289277 289277

Solenoid Kit 289278 289278

Cable, Speed Sensor 101315 289977

WS-1 Speed Sensor 101123 288600

*

Hub Cap Assembly 288601 288601

*

Flange 291963 291963

*

Fill Cap 291964 291964

*

Stator Spring 291974 291974

*

Spring Retainer 291975 291975

*

Bearing Cap 291978 291978

*

Retaining Ring 293147 293147

Cable, Power 101150

Strain Relief Fitting 289980

Check Valve 229603

Fig. 3

*These are contained in the WS-1

Loading...

Loading...