Page 1

Technical Bulletin

Bulletin No: Effective Date: Cancels: Page: 1 of

Subject:

There are many myths and much misinformation when it comes to minimizing the impact of contamination

in the air braking system. Bendix Commercial Vehicle Systems LLC (Bendix) has found that the majority of

the procedures available today do not reect current recommended practices for air treatment and storage

systems. Chief among our concerns are the concepts that air system antifreeze or alcohol is often considered

acceptable, along with the practice of draining air system reservoirs daily.

Refer to Bendix Technical Bulletin TCH-008-042 which strongly discourages the use of alcohol in the air

braking system.

Recommended Reservoir Draining & Dryer Service Intervals

Bendix discourages draining air system reservoirs daily when powered vehicles are equipped with a properly

functioning desiccant type air dryer. Why? Because daily draining tends to saturate an air system (with a

properly functioning air treatment system) on initial charge, and because it also causes the system’s air

compressor to work unnecessarily, thus reducing its durability.

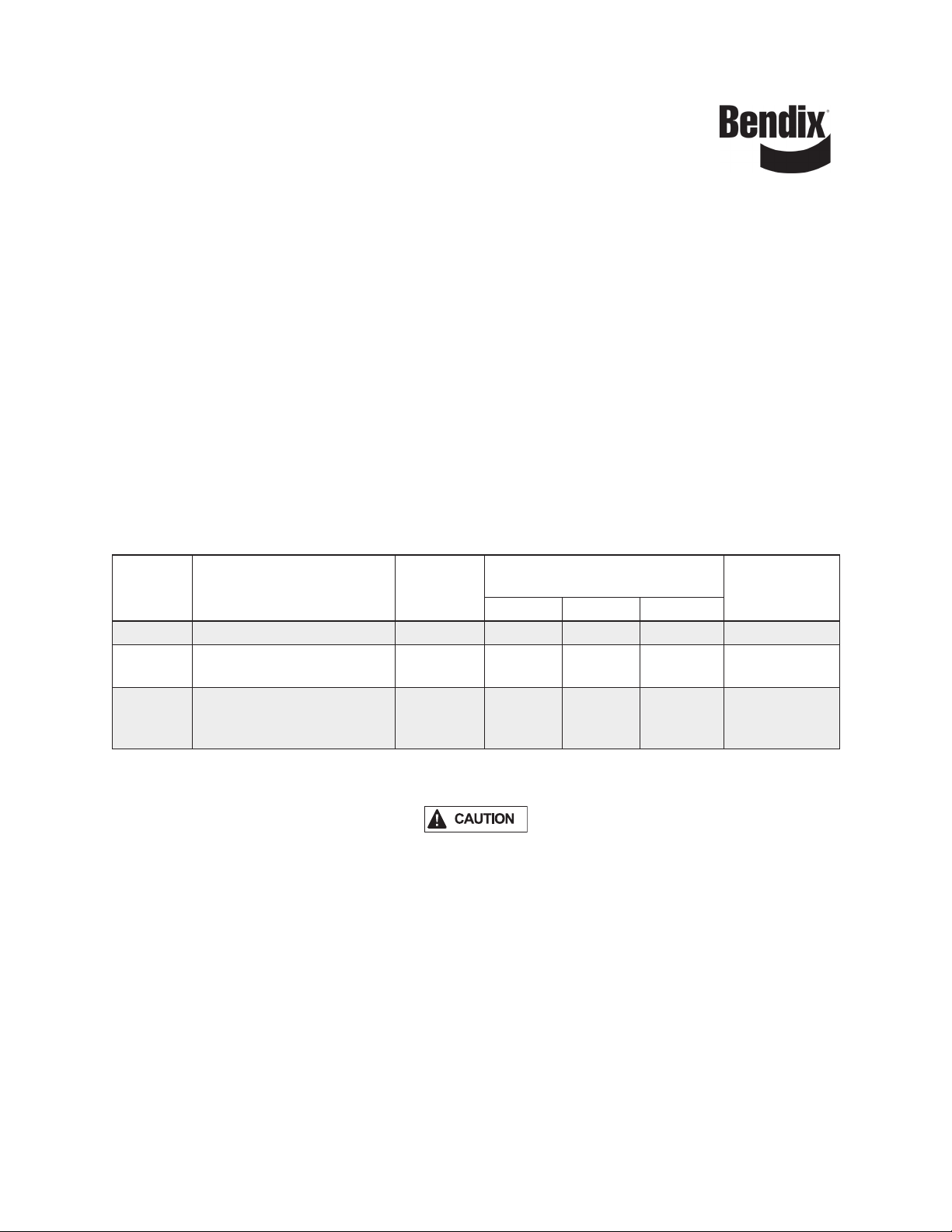

Refer to the chart below for recommended reservoir draining and air dryer service intervals for powered

vehicles:

Usage

Standard Line haul, city delivery 5 or less 900 25,000 3 months Every 3 years

Medium Double trailer trains, light

TCH-008-044

1-9-2015

Steps to Prevent Air Brake System Contamination – Best Practices

Air

High Multiple trailer trains, city

Typical Vehicle

Vocation

transit, light off-highway

transit, school bus, heavy

duty off-road

Axles *Reservoir Drain Interval

Hours Mileage Time

8 or less 450 12,000 2 months Every 2 years

11 or less 300 6,000 1 month Every year

N/A

(Whichever comes rst)

*Desiccant

Cartridge

Replacement

2

* If more than just a trace of moisture is found in any of the reservoirs if may be necessary to replace the desiccant cartridge.

Completely draining reservoirs can reduce the life expectancy of all of the components in the air braking

system by ushing internal lubrication. Air dryers operate most efciently when the reservoir pressures are

between governor cut-in and cut-out.

System Design Limitations

Total air system demand must be considered for proper sizing of the charging, treatment, and storage system

on a powered vehicle. It is very important to take into account the number of axles — and all auxiliary features

for the entire vehicle combination — as this will minimize the possibility of system freeze-up on combination

including any trailers. Air system leakage can cause contamination in the system by challenging the charging

and air treatment system capacity. Please refer to Bendix Application Guidelines BW2600 for air dryers

and BW2625 for air compressors. For acceptable air leakage recommendations refer to video BW2327.

Page 2

Bulletin No: Page: 2 of

TCH-008-044

2

Shutting Vehicle Down in Cold Temperatures

When powered vehicles must be shut down for a period of time and ambient temperatures are expected to

be below freezing, it is benecial to fan the air brake system down to just below the system cut-in pressure.

Doing this with the engine OFF, while it is still at operating temperature, allows the compressor and dryer

to be in the “charge mode” on engine start-up. This minimizes the potential for these components to be

frozen in the “unloaded mode” until the air dryer heater and power train heat allows these units to reach

normal operating temperature.

Protecting Towing Connections on all Towing Vehicles

For all tractors, towing trucks, trailers and converter dollies, Bendix recommends that vehice

operators take precautions to ensure that all glad-hand connections are protected from the

environment when not coupled. This involves using glad-hand hangers and glad-hand dummy couplings

for both front (input on trailers & dollies) and rear (output on tractors, trailers, & dollies) couplings to protect

against the entry of foreign airborne contaminants. This includes protection from road debris, contaminants

and weather elements in the form of precipitation. These items can be sucked into the open glad-hands

due to the vortex created at the back of the trailer as it travels down the highway.

Please note that all front (input) glad-hands still need to be vented to atmosphere. This can be through a

small hole — or breather valve — to prevent mishaps such as “false parking” via trapped pressure in the

trailer service line, or to prevent the unintentional release of the trailer parking brakes by pressurizing the

trailer supply line as a result of system leakage. To further reduce any potential issues related to liquid water

entering via open glad-hand connections, Bendix offers the Cyclone DuraDrain® trailer water separator

which helps remove all liquid water and other contaminants from the trailer control and supply lines. See

SD-08-2402 for information on the Cyclone DuraDrain trailer water separator.

Also, note that Bendix recommends vented shut-off valves on the back of trailers and the use of the Bendix®

SV-4™ synchro valve in the supply line on converter dollies to prevent false charging on trailers and dollies.

Refer to technical bulletin TCH-003-027 for details concerning this recommendation.

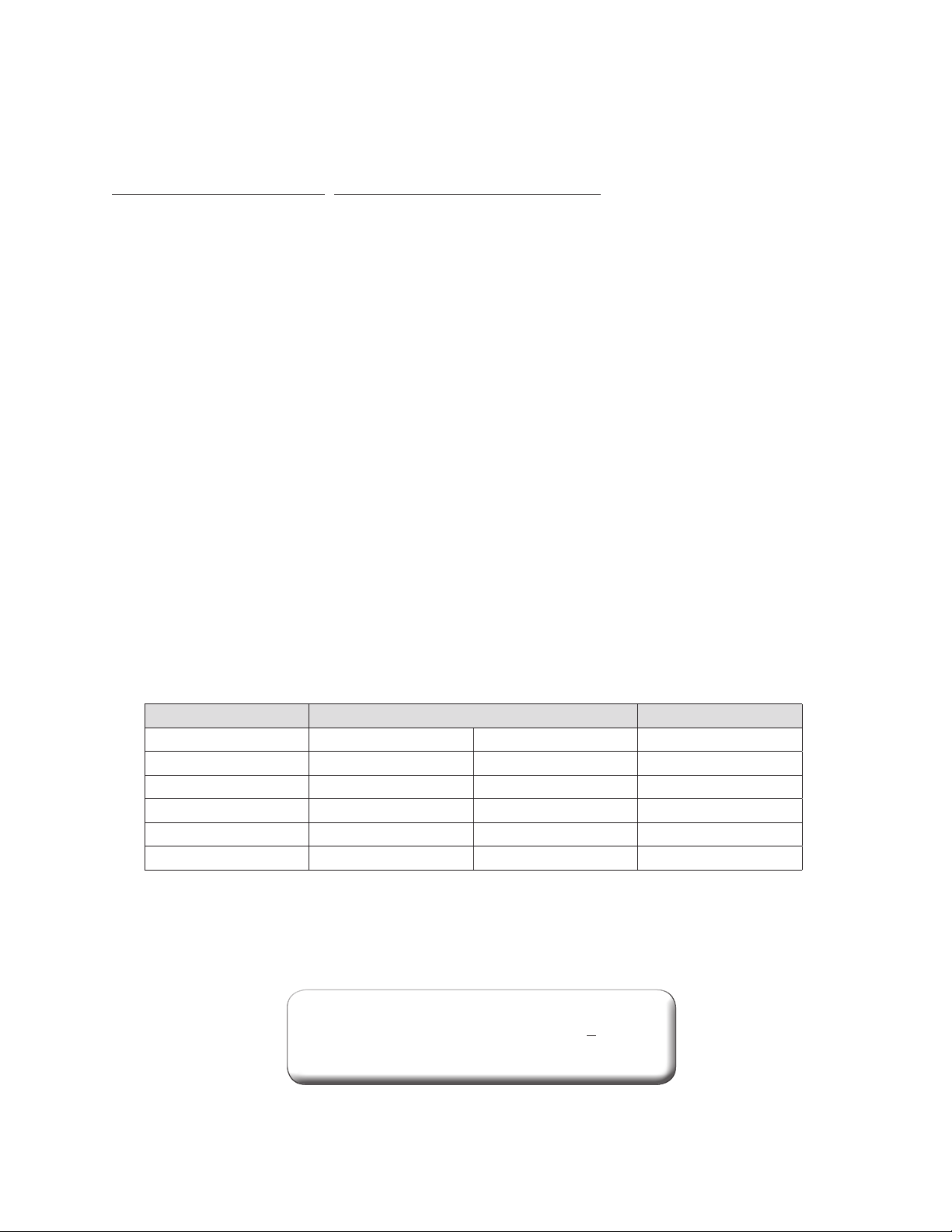

Shown below are the documents referenced in this bulletin, as well as additional pieces that may be of

interest. To download or order these items and more, visit the document library online at www.bendix.com.

Technical Bulletins Service Data Miscellaneous

TCH-003-027 SD-08-187 SD-08-2412 BW2600

TCH-008-021 SD-08-187B SD-08-2416 BW2625

TCH-008-022 SD-08-2401 SD-08-2417 BW2327

TCH-008-042 SD-08-2402 SD-08-2418

SD-08-2403 SD-08-2433

SD-08-2407 SD-98-9808

Log-on and Learn from the Best

On-line training that's available when you are 24/7/365.

Visit www.brake-school.com.

© 2015 Bendix Commercial Vehicle Systems LLC, a member or the Knorr-Bremse Group. All Rights Reserved.

Loading...

Loading...