Page 1

Technical Bulletin

Bulletin No: Effective Date: Cancels: Page: 1 of

Subject:

The Bendix® AD-9™ air dryers are available with various purge valve confi gurations; hard seat, soft seat

and DLU discharge line unloader types. The difference between these types relates to the type of sealing

surface for the turbo cut-off valve. All AD-9™ air dryers contain two valve sections and have a rubber (soft)

seat for the actual purge valve, but the turbo cut-off valve section can be one of three types:

TCH-008-041

6-20-2006

Bendix® AD-9™ Air Dryer Purge Valve Identifi cation & Kits

N/A

3

Metal

Black

Hard Seat

Figure 1 - Identifi cation of Hard and Soft Seat Purge Valves

1. Hard seat purge valve has a metal to metal turbo cut-off valve sealing surface. Most AD-9

come standard with the hard seat purge valve.

2. Soft seat purge valve has a bonded rubber ring on the piston that contacts a metal seat on the housing

to make the turbo cut-off valve seal. This seal is extremely air tight for applications that require zero

leakage, such as the Bendix® EverFlow™ system and drop-in style air dryers which use older Holset

type E compressors.

3. Discharge line unloading (DLU) purge valve has the turbo cut-off valve bypassed by removing the

middle o-ring sealing surface from the body. This valve is used to positively vent the compressor

discharge line, such as when the vehicle has a non-unloading compressor.

NOTE: Although a soft seat purge valve can be substituted for a hard seat purge valve, a hard seat purge

valve should not be substituted for a soft seat purge valve. DLU purge valves cannot be substituted for any

other type.

© 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 6/2006 Printed in U.S.A.

Rubber

Soft Seat

™

air dryers

Page 2

Bulletin No: Page: 2 of

TCH-008-041

3

3 o-rings

2 o-rings

Letter “U” stamped into

the body

Standard Style Purge

Valve

Figure 2 - Standard and DLU Purge Valves

DLU Style Purge Valve

Selecting the Purge Valve Replacement Kit for a Bendix® AD-9™ Air Dryer

When servicing your AD-9™ dryer with a purge valve replacement kit, you will need to identify the type of

purge valve being replaced. Removal of the purge valve from the dryer body is necessary to identify the

correct maintenance kit.

First, identify whether the purge valve is a DLU style. The DLU type can easily be distinguished from the

others, because the DLU type have only two o-rings on the outside of the purge valve body, rather than

the standard three o-rings. For DLU purge valves, the middle o-ring seat has been removed. Additionally,

AD-9™ air dryers with a DLU purge valve have the letter “U” stamped on the side of the purge valve housing.

Because the letter “U” is not always visible, it is best to use the number of o-ring grooves for identifi cation.

See fi gure 2.

If the purge valve is a standard style (not a DLU), look through the upper oval hole in the purge valve

housing to view the piston. If a black band encircling the piston is visible, then the purge valve is a soft

seat type. If the piston is all metal, then the purge valve is a hard seat. See fi gure 1 for hard and soft seat

purge valves.

After the purge valve type has been identifi ed, the next step is to identify the heater size; voltage and wattage.

The electrical connector on the purge valve is color coded as shown in the Purge Valve Replacement Kits

table on the following page.

Once the correct maintenance kit is identifi ed, service the purge valve following the instructions provided in

the kit for proper replacement.

Electrical Connector

Figure 3 - Voltage and Wattage

© 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 6/2006 Printed in U.S.A.

Page 3

Purge Valve Replacement Kits

Kit Part Purge Valve Heater Connector Comments

Number Type Color

5004479 Hard Seat 12V / 75W White 5004480 Hard Seat 24V / 75W Gray 5004381 Hard Seat 24V / 100W Yellow -

800405 Soft Seat 12V / 75W White 5004338 Soft Seat 24V / 75W Gray 5004341 Soft Seat 12V / 75W White Reman.

5004342 Soft Seat 24V / 75W Gray Reman.

5004339 DLU 12V / 75W White 5004340 DLU 24V / 75W Gray 5006580 DLU 24V / 100W Yellow -

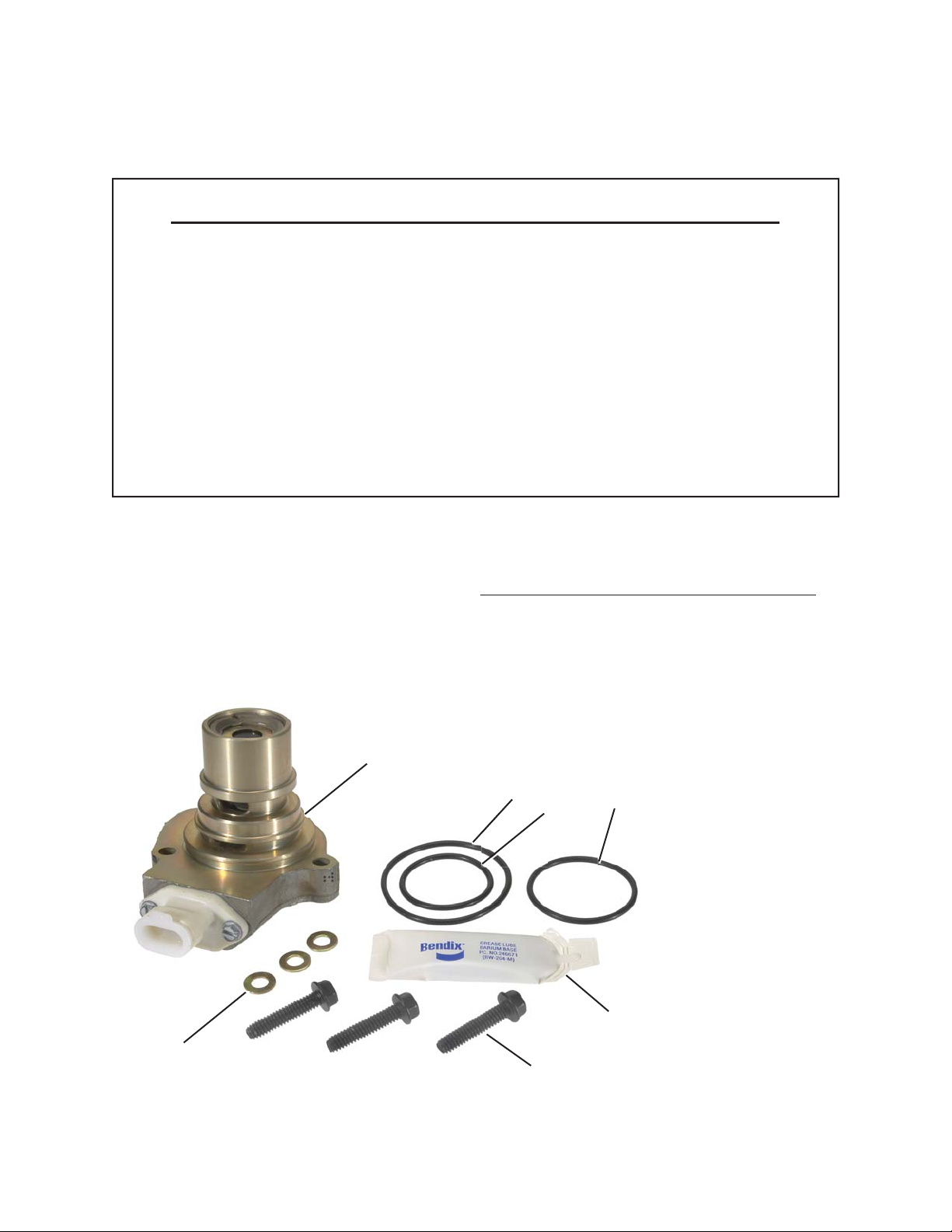

Purge Valve Replacement Kits consist of

the following components:

3Bulletin No: Page: 3 of TCH-008-041

Item Description Qty

1 Purge Valve Assembly 1

2 1/4” Cap Screw 3

3 Washer 3

4 O-ring 1

5 O-ring 1

6 O-ring (not included in DLU kits) 1

7 Lubricant 1

1

5

6

4

7

3

2

© 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 6/2006 Printed in U.S.A.

Loading...

Loading...