Page 1

Technical Bulletin

Bulletin No: Effective Date: Cancels: Page: 1 of

Subject:

In addition to the service information presented in the Cyclone DuraDrain™ trailer water separator Service Data

Sheet SD-08-2402 dated 8/2004, it is recommended that the following service intervals be followed to ensure

proper maintenance. Also included are additional guidelines for troubleshooting air leakage in the Cyclone

DuraDrain™ trailer water separator.

CYCLONE DURADRAIN™SERVICE INTERVALS

Service intervals are dependent on specific environmental and operational factors that control the amount of

contamination removed by the Cyclone DuraDrain™ unit. Experience should be used to determine how frequently

the unit must be serviced. As a recommended minimum, every 12 months, 100,000 miles or 3,600 operating

hours, perform the Operational and Leakage Tests. As indicated in the Service Data Sheet, inspect the

Cyclone DuraDrain™ unit for unrestricted airflow and blockage from debris collection. Remove the purge nut

and service according to the “Disassembly and Cleaning” instructions.

CYCLONE DURADRAIN™ TRAILER WA TER SEPARATOR AIR LEAKAGE TROUBLESHOOTING

This is the recommended troubleshooting procedure should an audible air leak be detected from the Cyclone

DuraDrain™ trailer water separator. Be sure to review and follow all safety guidelines in the Service Data Sheet

before servicing the DuraDrain™ trailer water separator.

DO NOT DISCONNECT OR REMOVE THE CYCLONE DURADRAIN™ BODY .

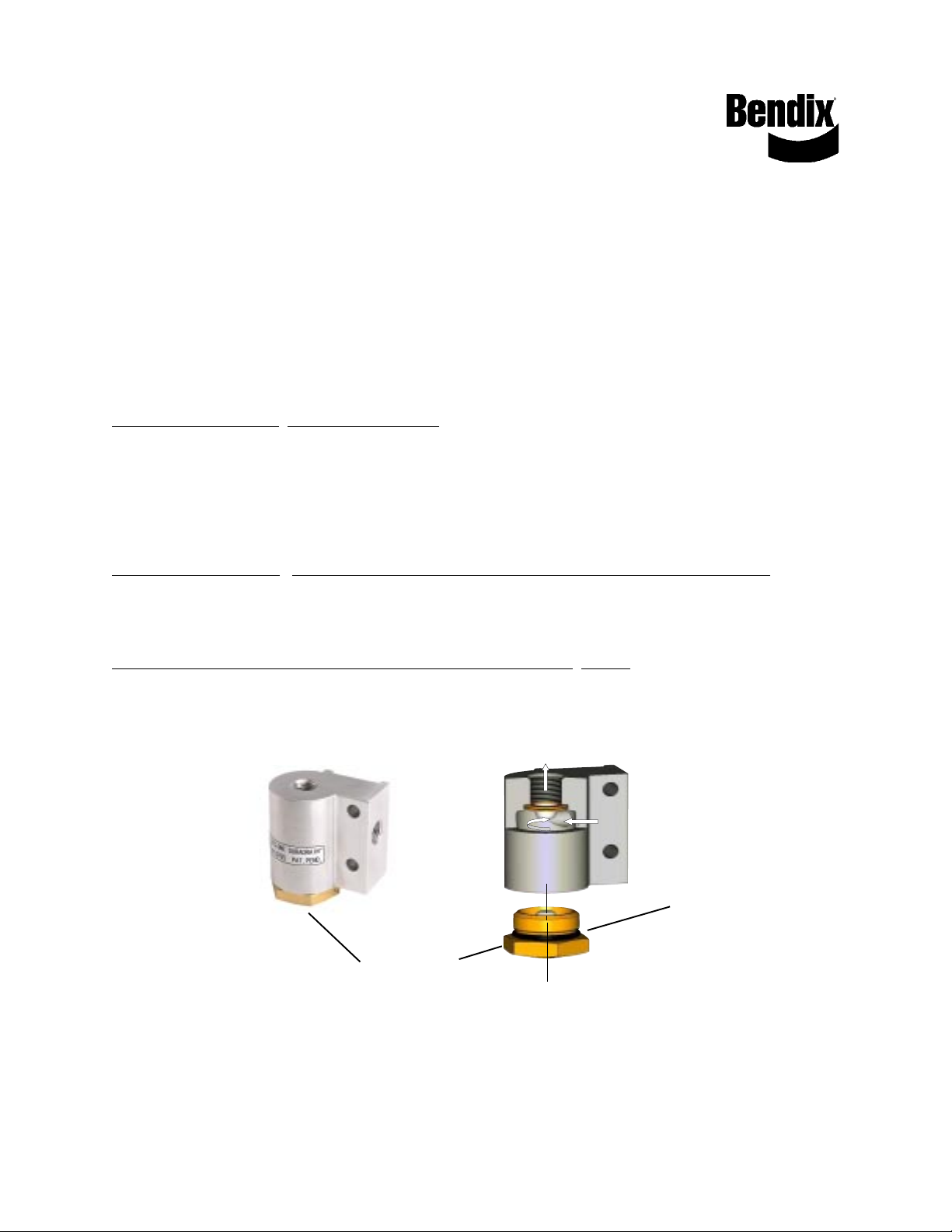

All servicing can be done without disconnecting the air lines and without removing the Cyclone DuraDrain

trailer water separator body . All servicing is done to the removable hex purge nut located on the bottom. See

the illustration below.

TCH-008-038

03-28-2006

Cyclone DuraDrain™ Trailer Water Separator

Same dated 04-08-2005

2

™

Cyclone DuraDrain

trailer water separator

™

O-ring

Hex Purge Nut

© 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 3/2006 Printed in U.S.A.

Page 2

Bulletin No: Page: 2 of

TCH-008-038

2

NUT REMOVAL

Disconnect both upstream gladhands from the trailer or dolly before beginning work on the Cyclone DuraDrain

trailer water separator.

1. Remove the 1-3/8" hex purge nut assembly with o-ring from the bottom of the leaking Cyclone DuraDrain

trailer water separator.

AIR CLEANING

A rubber pressure-activated valve is located under the screen in the purge nut. The screen is permanently

installed and cannot be removed. Attempts to remove the screen and access the pressure-activated valve will

damage the purge nut necessitating its replacement.

WARNING NOTE: an air gun blowing backward through the drain hole in the bottom of the nut can dislodge the

pressure-activated valve necessitating replacement of the purge nut.

The most common cause of air leakage is sandy debris on the valve seat inside the purge nut. Dislodging and

ejecting the debris can restore leak-free operation.

2. Gently tap the purge nut upside down and sideways to dislodge possible debris taking care not to

damage the screen.

3. Blow air in the normal downward direction through the screen to remove debris out the drain hole. See

the warning note above.

4. Inspect the o-ring for damage and reinstall the purge nut into the Cyclone DuraDrain™ body using hand

tools with low to moderate torque (150 in-lbs).

™

™

5. Reapply air pressure and determine if the leak has been eliminated.

SOLVENT CLEANING

If air leakage was not eliminated by air cleaning, the purge nut may be cleaned in a mineral spirits parts washer .

6. Remove the hex purge nut and wash in mineral spirits parts washer . Flow solvent downward through

the screen and out the drain hole.

7. For stubborn debris, the purge nut may be soaked in the parts washer overnight to dissolve persistent

deposits.

8. Reinstall the purge nut into the Cyclone DuraDrain™ body using hand tools with low to moderate torque

(150 in-lbs).

9. Reapply air pressure and determine if the leak has been eliminated.

10. If the air leak persists, replace the entire purge nut with Bendix service kit piece number 5013824.

© 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 3/2006 Printed in U.S.A.

Loading...

Loading...