Page 1

Technical Bulletin

Bulletin No: TCH-008-032-A Effective Date: 11/29/99 Cancels: NA Page: 1 OF 2

Subject:

It has been brought to our attention that there was a manufacturing defect in a small number of AD-SP and AD-IS

air dryer cartridges. The defective air dryer cartridges may allow desiccant beads to pass from the cartridge into

the purge valve assembly of the air dryer. If the desiccant becomes trapped in the purge valve assembly, the

purge valve may be prevented from closing completely, causing the system to leak charge air to atmosphere. This

leakage of air will then result in the inability to build system air pressure.

The table on page two identifies suspect piece numbers and their corresponding date codes. The defect has been

corrected, therefore all components manufactured on or after November 13, 1999 (L1399H) are not suspect.

1. If the system is unable to build air pressure, inspect the air dryer for leakage around the purge valve during

2. Refer to instruction sheets provided in the maintenance kits where applicable.

3. Using shop air, remove all desiccant material from the air dryer body assembly. Caution: Wear proper eye

4. Wipe all of the body bores clean with a clean rag.

5. Install the air dryer cartridge.

6. Install the purge valve assembly and test per the installation instruction sheet.

AIR DRYER CARTRIDGE DEFECT

the charge cycle. Wear appropriate eye protection and review all caution notes printed in the service manual

for the appropriate air dryer (SD-08-2415 for the AD-SP or SD-98-9808 for the DRM with AD-IS).

a. Use a strap wrench to remove the cartridge. Position the strap wrench next to the lower lip of the

cartridge to prevent cartridge damage. Turn the cartridge counterclockwise to remove.

b. If desiccant beads are present in the purge valve area, the air dryer cartridge and purge valve assembly

must be replaced. See page two for service replacement piece numbers.

c. Re move the purge valve snap ring and purge valve assembly.

protection when using compressed air to blow the desiccant out of the air dryer body assembly.

a. Lubricate the cartridge sealing ring with lubricant provided.

b. Screw the desiccant cartridge on to the body, by hand, clockwise until the seal makes contact with the

body. Turn one full turn. If necessary, place a strap wrench on the desiccant cartridge next to the lower

lip of the cartridge.

Page 2

The piece numbers that are suspect are shown below with their respective date codes. Also shown are the

appropriate cartridge and purge valve assembly piece numbers to be used for servicing the air dryer. Ensure the

date code of the component you are using for service does not fall within the defective range.

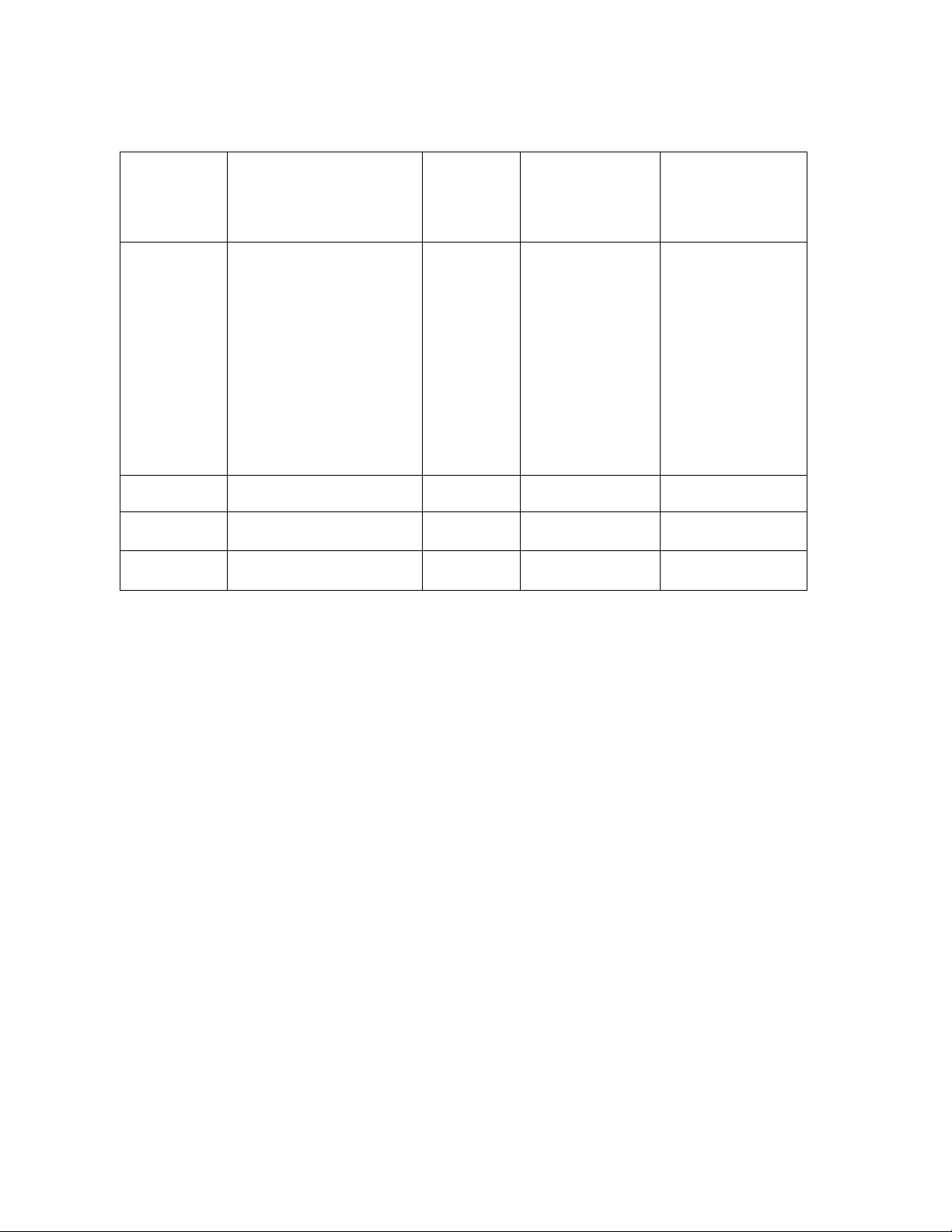

Suspect Piece Numbers and Service Replacements

Description Defective Component

Date Code

AD-SP H2399H – L1299H

(8/23/99 – 11/12/99)

AD-IS All dates through L1299H

(11/12/99)

Cartridge Kit

(Truck Prod.)

Cartridge Kit H2399H – L1299H

J2599H – L1299H

(9/25/99 – 11/12/99)

(8/23/99 – 11/12/99)

Suspect

Piece

Numbers

065691

065694

109872

131031

131032

800042

800043

5000104

5000445

5000587

5002747

5002748

5006639

800383

5003424

BR950011 BR950011 N/A

109994 109994 N/A

Cartridge

Service

Replacement

Piece Numbers

109994 109995

109994 800404

Purge Valve

Assembly Service

Replacement

Piece Numbers

Return all defective or suspect piece numbers to:

Truck Brake Systems Co.

1850 Riverfork Dr. West

Huntington, IN 46750

Phone 1-800-247-2725

Loading...

Loading...