Page 1

Technical Bulletin

Bulletin No: TCH-008-028 Effective Date: 11/17/97 Cancels: TCH-008-027 Page: 1 of 5

Subject:

GENERAL

This is to announce the availability of new upgraded purge valve assemblies for the AD-9DI Drop-In and AD-IP

air dryers.

Bendix Commercial Vehicle Systems LLC began using the new purge valve assemblies in production on

November 1, 1997.

Because of the improvements made to the new purge valve assemblies we recommend that all affected AD-9DI

and AD-IP air dryers be upgraded with the new purge valve subassemblies. Upgrades for in-service air dryers, as

well as shelf stock of purge valve kits and service new and remanufactured exchange air dryers are available free

of charge when the return procedure described in this bulletin is followed. Bendix strongly encourages all

customers to take advantage of this valuable upgrade offer.

THE FOLLOWING TOPICS ARE COVERED IN THIS BULLETIN.

• SUMMARY OF PURGE VALVE ASSEMBLY IMPROVEMENTS

• PART NUMBER CHANGES

• WHAT IS ELIGIBLE FOR REPLACEMENT

• IDENTIFYING IN-SERVICE AIR DRYERS WITH LATEST PURGE VALVE ASSEMBLY

• OBTAINING A REPLACEMENT

AD-9DI & AD-IP Purge Valve Upgrade

Note: The AD-9DI is a specialized version of the AD-9 which is specifically designed for air systems where

the Holset (Cummins) type E or QE compressor was in use. See figure 3.

SUMMARY OF PURGE VALVE ASSEMBLY IMPROVEMENTS

AD-IP Air Dryer Purge Valve Assemblies

The AD-IP purge valve assembly has been upgraded for improved temperature resistance. The changes which will

eliminate recently reported incidents of intermittent sticking are:

1. A heavier purge piston return spring to assure positive closing.

2. A modified piston and seal combination for improved sealing at higher temperatures.

AD-9DI Drop-In Air Dryer Purge Valve Assemblies

The AD-9DI purge valve assembly has been upgraded for improved temperature resistance required for Holset

(Cummins) compressors which produce higher discharge temperatures. The changes which will eliminate recently

reported incidents of intermittent sticking are:

1. A heavier purge piston return spring to assure positive closing.

2. A modified piston and seal combination for improved sealing at higher temperatures.

Page 2

Page: 2 of 5

PART NUMBER CHANGES

The part numbers of AD-9DI and AD-IP air dryer assemblies have not been changed. The part numbers of the

replacement purge valves have been changed to assist in identifying old and new inventory.

WHAT IS ELIGIBLE FOR REPLACEMENT

Replace purge valve assemblies as follows;

1. In-Service AD-9DI air dryers (i.e. installed on vehicles) that have a build date between October 1, 1996

(K0196T or F) and October 31, 1997 (K3197T or F). See note below for build date information.

2. In-Service AD-IP air dryers (i.e. installed on vehicles) that have a build date prior to L0197F (November 1,

1997). See note below for build date information.

Note: The first letter of the date code is the month, J = September, K = October L = November etc. The first

pair of digits is the day while the second pair is the year. The last letter indicates the location of the

plant that manufactured the unit as indicated by an “F” or a “T”. Plant origin is not pertinent to this

upgrade.

3. Shelf stock of purge valve assemblies and specified kits at the fleet, dealer and independent parts distributor

should be replaced. The new purge valve assemblies have new part numbers assigned to them to distinguish

them from the old assemblies. The part numbers involved are as follows;

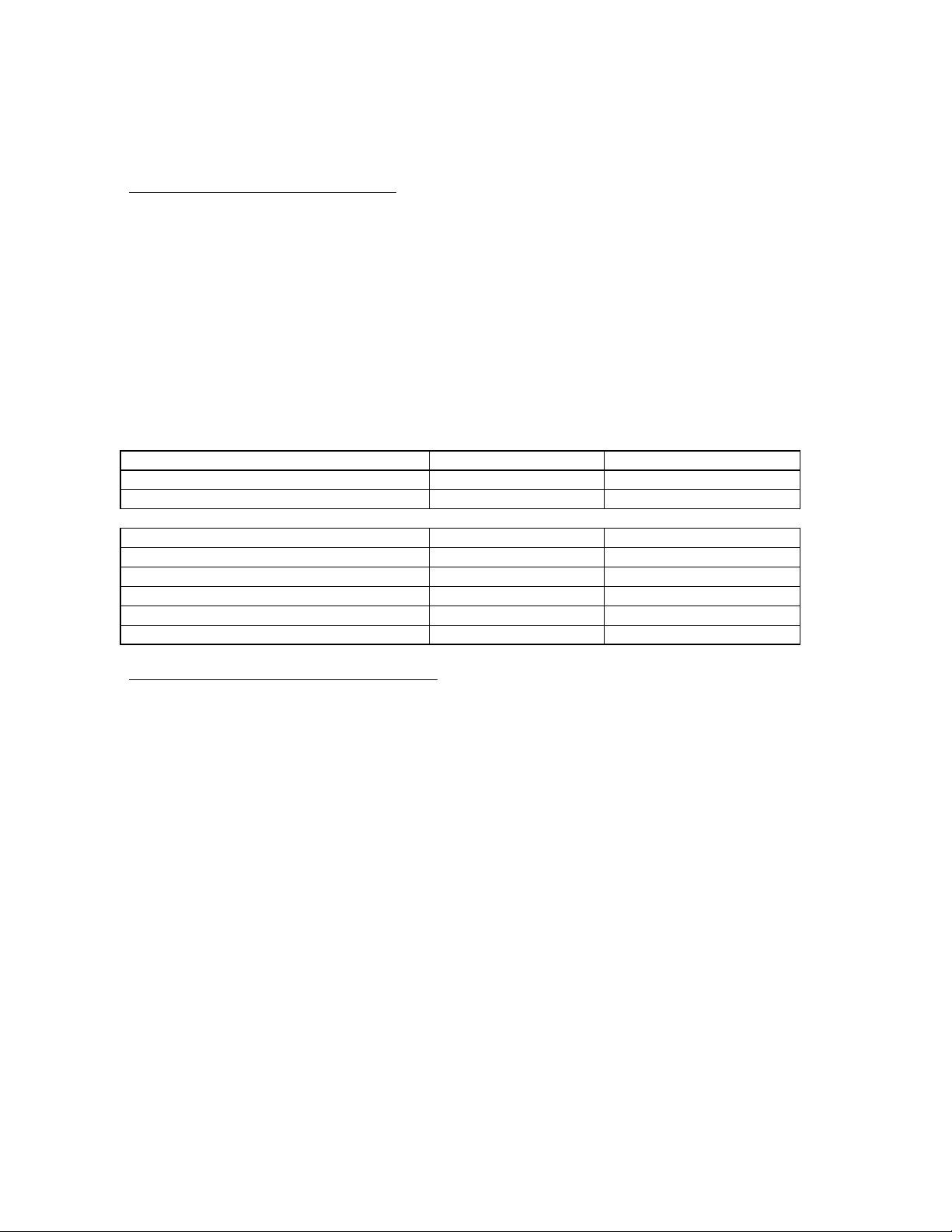

AD-IP Air Dryer Kit Name Original Part Number New Part Number

Service New Purge Valve Assembly 065626 800404

Service New Purge Valve Assembly 800340 800404

AD-9DI Air Dryer Kit Name Original Part Number New Part Number

Service New Purge Valve Assembly 109569 – 12 volt 800405 – 12 volt

Service New Purge Valve Assembly 109570 – 24 volt 5004338 – 24 volt

Remanufactured Purge Valve Assembly 109686 – 12 volt 5004341 – 12 volt

Remanufactured Purge Valve Assembly 109695 – 12 volt 5004342 – 24 volt

Purge Valve Modification Kit 265088 5004380

Replace complete air dryer assemblies as follows;

Shelf stock of air dryer assemblies at the fleet, dealer and independent parts distributor should be replaced as

follows;

1. AD-9DI air dryers that have a build date between October 1, 1996 (K0196T or F) and October 31, 1997

(K3197T or F). See note below for build date information.

2. AD-IP air dryers that have a build date prior to L0197F (November 1, 1997). See note below for build date

information.

Note: The first letter of the date code is the month, J = September, K = October L = November etc. The first

pair of digits is the day while the second pair is the year. The last letter indicates the location of the

plant that manufactured the unit as indicated by an “F” or a “T”. Plant origin is not pertinent to this

upgrade.

Page 3

The part numbers involved are as follows;

AD-IP Air Dryer Assemblies AD-9DI Air Dryer Assemblies

065612 Service New 065647 Service New

065613 Service New 065678 Service New

800089 Service New 800069 Service New

065693 Service New 800107 Service New

800067 DI Service New 800166 Service New

800168 DI Service New 800247 Service New

800250 Service New

IDENTIFYING IN-SERVICE AIR DRYERS WITH NEW PURGE VALVE ASSEMBLY

Identifying In-Service AD-9DI Air Dryers with New Purge Valve Assembly

All AD-9DI air dryers manufactured or remanufactured since November 1, 1997 incorporate the new purge valve

assembly. Air dryers with the latest purge valve assembly installed can be positively identified in one of two

ways.

1. Check the date code on the air dryer (see figure 1). All AD-9DI (Drop-In) air dryers installed with Holset

(Cummins) compressors manufactured between October 1, 1996 (K0196T or F) and October 31, 1997

(K3197T or F) should be upgraded using this program.

Note: The first letter of the date code is the month, J = September, K = October L = November etc. The first

pair of digits is the day while the second pair is the year. The last letter indicates the location of the

plant that manufactured the unit as indicated by an “F” or a “T”. Plant origin is not pertinent to this

upgrade.

2. Visually inspect for the presence of a white paint marking or green disk on the purge valve assembly (see

figure 2).

Identifying In-Service AD-IP Air Dryers with New Purge Valve Assembly

All AD-IP air dryers manufactured or remanufactured since November 1, 1997 incorporate the new purge valve

assembly. Air dryers with the latest purge valve assembly installed can be positively identified in one of two

ways.

1. Check the date code on the air dryer (see figure 1). Air dryers with a date code older than L0197F

(November 1, 1997) will have the old style purge valve and should be upgraded using this program.

Note: The first letter of the date code is the month, J = September, K = October L = November etc. The first

pair of digits is the day while the second pair is the year. The last letter indicates the location of the

plant that manufactured the unit as indicated by an “F” or a “T”. Plant origin is not pertinent to this

upgrade.

2. Visually inspect for the presence of a white paint marking or green disk on the purge valve assembly (see

figure 2).

Figure 1 - Date Code Location

Page 4

Figure 2 - Identifying New Purge Valve Assy.

Page: 4 of 5

Figure 3 - Identifying The AD-9DI Dr op-In Air Dryer

OBTAINING A REPLACEMENT (Effective 11/1/97 – 4/30/98)

The method for obtaining a replacement purge valve assembly (or inventory replacement of a purge valve kit) will

depend on the type of customer. Select the appropriate procedure below.

Fleet

1. Contact Bendix Commercial Vehicle Systems LLC by calling Bill Gantz (1-440-329-9579) and order the

number of no charge replacement assemblies required and obtain return shipping instructions.

2. Install the new purge valve assemblies and retain the old assemblies for return.

3. Return the old purge valve assemblies using the instructions obtained in number 1 and receive a $25 labor

reimbursement for each assembly returned.

Dealership

1. Contact customers that have the AD-IP or AD-9DI Drop-In (AD-9DI air dryers used with Holset or Cummins

compressors) dryers in use and advise them of the upgrade program.

2. Contact your OEM PDC for details regarding t he procedur e for obtaining no charge purge valve assembly

replacements and labor reimbursement.

Page 5

Page: 5 of 5

y

g

Authorized Independent Aftermarket Distributors

Replacement Stock

1. Using the attached order form, fax a request for replacement to Bendix Commercial Vehicle Systems LLC at

440-329-9557.

2. Within 30 days of receiving replacement stock, current stock should be shipped with core shipments to the

normal service plant for avoidance of part charges.

3. Include a copy of the return form in the box with an orange sticker affixed to the outside to indicate that the

material being returned is shelf stock.

Fleet Upgrades

1. All AD-IP purge valve upgrades, regardless of build date, can be processed as an over-the-counter warranty.

2. All AD-9DI purge valve upgrades within the period specified should be handled under the over-the-counter

warranty.

Methods for Fleet Customer to Obtain Upgrade

Bendix

Commercial

stems

OEM PDC

Fleet

Customer

Vehicle S

Local Dealer

Authorized

Independent

Distributor

Bendix Commercial

Vehicle Systems

Account Mana

er

Loading...

Loading...