Page 1

Technical Bulletin

Bulletin No: TCH-001-052 Effective Date: 5/4/04 Cancels: TCH-001-052 of 11/11/03 Page: 1 of 2

Subject: Troubleshooting Bendix

DDC Series 60 low-emission engines

the compressor does not build air.

If a DDC Series 60 low emission engine does not build

air, as part of the investigation to find the cause, you

may use the following test to check that the Inlet Check

Valve (ICV) is operating correctly. We recommend

that other less labor-intensive inspections, for example,

to check for a leaking or broken discharge line, be

carried out before conducting this test.

Before beginning this test, read the complete

instructions, and follow all standard safety practices

including, but not limited to, the General Precautions

listed below. With the vehicle parked and the wheels

blocked, shut off the engine. Clean the area around

the ICV of road grime, etc.

Disassembly

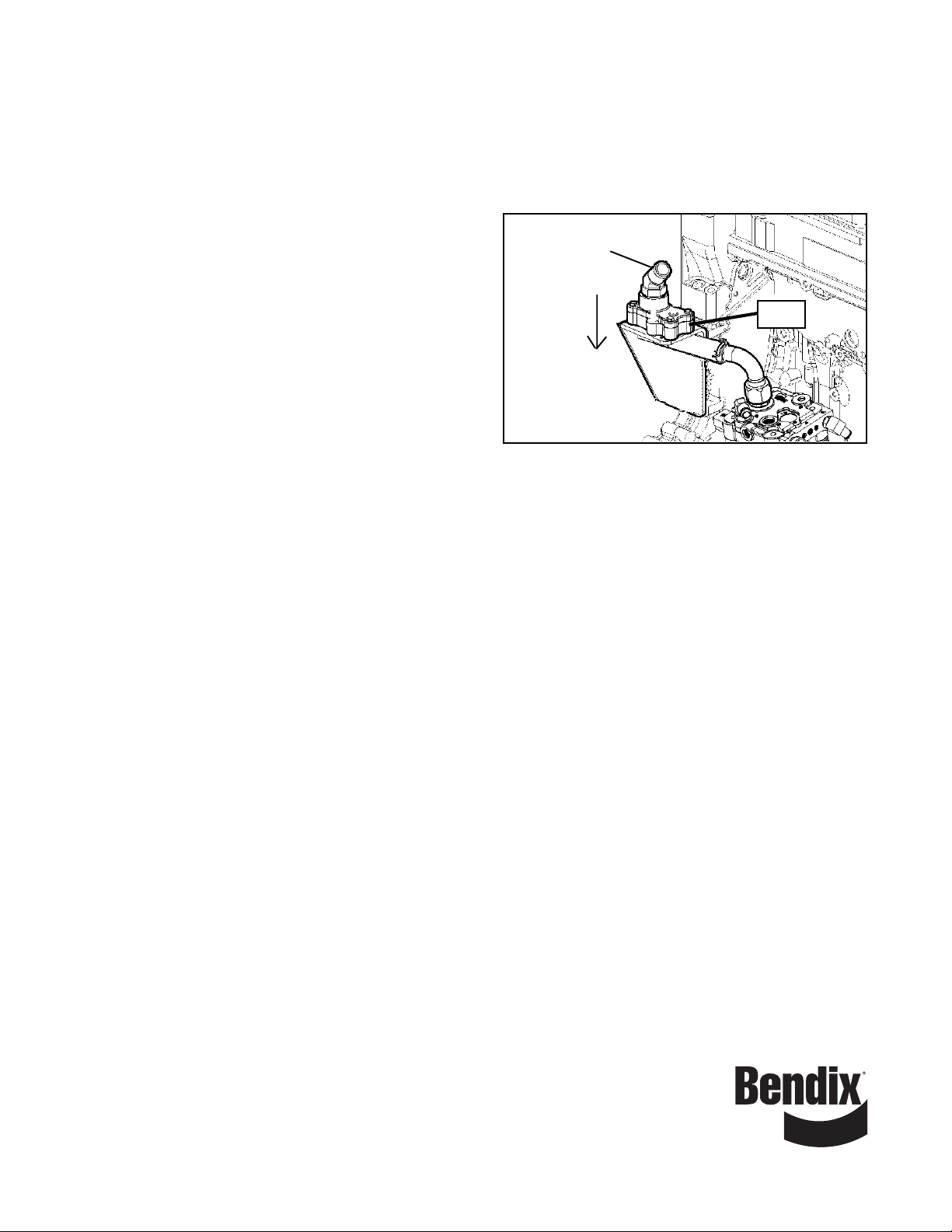

To test the ICV, disconnect the hose that supplies air

from the inlet air supply system of the engine to the

ICV. Carefully remove the clamp holding the inlet

hose from the ICV - see Figure 1 for a typical inlet

hose location. Retain the clamp for re-installation.

Note that the ICV has a raised flange on the side

through which the air enters. This test will necessitate

the removal of the ICV from the vehicle, therefore

remove the mounting hardware attaching it to the

vehicle - in some instances it will be easier to remove

the mounting bracket from the engine to assist with

the disassembly.

Test the ICV

Caution: Eye protection equipment must be worn

during this procedure to prevent eye injury in the event

loose material is expelled from the ICV port. On a

test bench securely mount the ICV. Attach a nonpressurized shop air supply line to the delivery side of

the ICV using any necessary fittings. Apply shop air

to the ICV and, with caution, observe the inlet port of

the ICV for air being expelled. A correctly operating

ICV will produce only a small amount of air coming

(backwards) through the valve. A malfunctioning ICV

will release a full burst of air (similar to a blow nozzle).

End the test by shutting off the shop air.

®

inlet check valves on

in cases where

© 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 4/2004. Printed in U.S.A.

Inlet hose attaches here

Air flows

in this

direction

through valve

Figure 1: Inlet Check Valve (location varies by vehicle)

If the ICV is operating normally, reinstall the ICV

by reversing the steps taken to remove it from the

vehicle. Re-attach the inlet hose using the clamp

retained during disassembly, ensuring a good seal

between the hose and the fitting. Consult other

troubleshooting materials and vehicle manuals to help

you investigate why the compressor is not building

air.

In the case of a malfunctioning ICV, where the

compressor does not built air, replace the ICV valve

and the compressor because of possibility of debris in

the system.

ENERAL PRECAUTIONS

G

IMPORTANT! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the following

General Precautions should be observed at all times:

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

2. Stop the engine when working around the vehicle.

3. Except as directed in these instructions, make

certain to drain the air pressure from all reservoirs

before beginning

any work on the vehicle.

ICV

(continued over.)

Page 2

Bulletin No: TCH-001-052 Effective Date: 5/4/04 Cancels: TCH-001-052 of 11/11/03 Page: 2 of 2

Subject: Bendix

®

Inlet Check Valves

4. As needed, following the vehicle manufacturer’s

recommended procedures, deactivate the

electrical system in a manner that removes all

electrical power from the vehicle.

5. Typically, when working in the engine

compartment the engine should be shut off.

Where circumstances require that the engine be

in operation,

extreme caution should be used to

prevent personal injury resulting from contact

with moving, rotating, leaking, heated, or

electrically charged components.

6. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a component or plug unless you are certain all

system pressure has been depleted.

7. Never exceed recommended pressures and always

wear safety glasses.

8. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

9. Use only genuine Bendix replacement parts,

components, and kits. Replacement hardware,

tubing, hose, fittings, etc. should be of equivalent

size, type, and strength as original equipment and

be designed specifically for such applications and

systems.

10. Components with stripped threads or damaged

parts should be replaced rather than repaired.

Repairs requiring machining or welding should

not be attempted unless specifically approved and

stated by the vehicle or component manufacturer.

11. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

See vehicle manual, Bendix troubleshooting materials, or visit www.bendix.com for more information.

© 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 5/2004. Printed in U.S.A.

Loading...

Loading...