Page 1

®

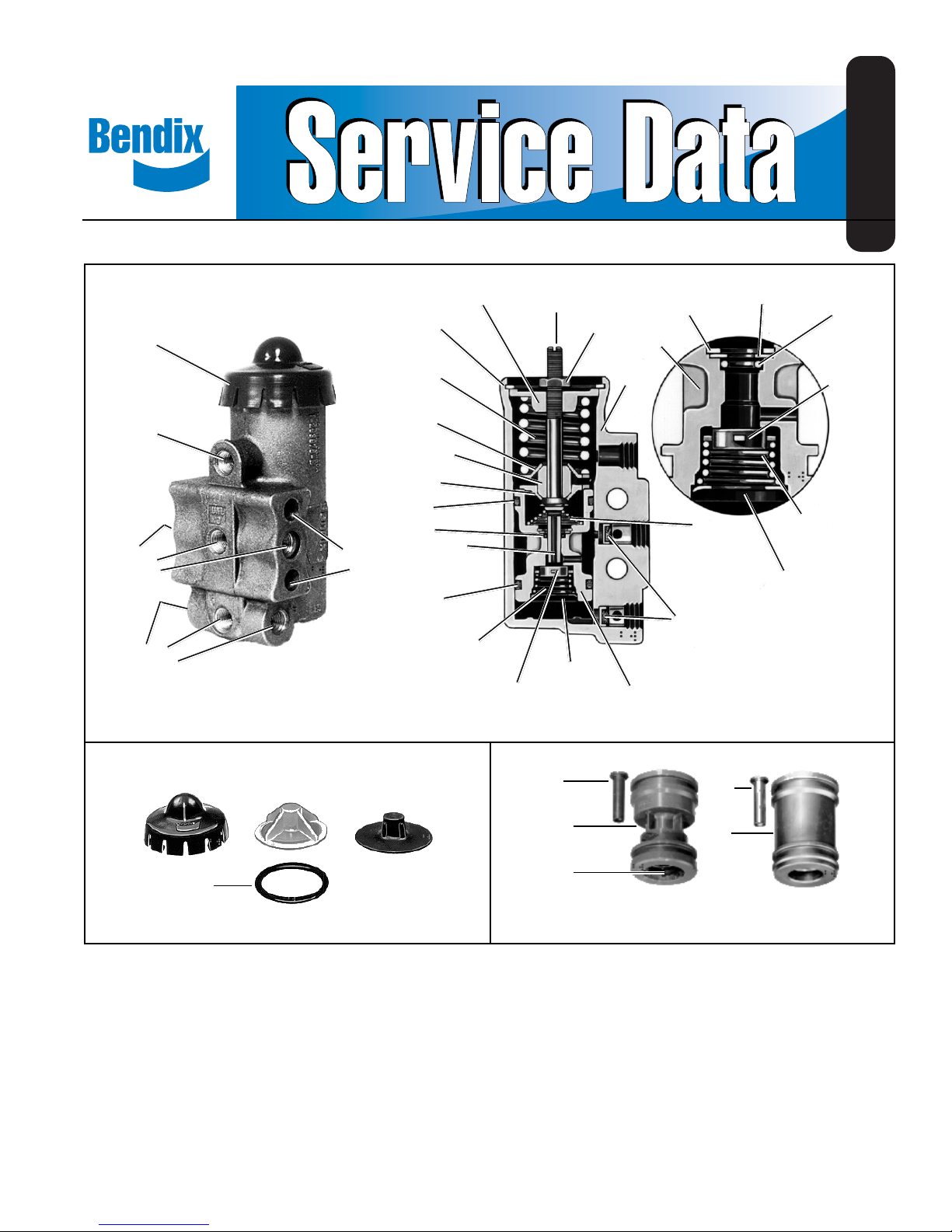

Bendix® D-2™ Governor

SD-01-503

COVER

EXHAUST

PORT

UNLOADER

PORTS (3)

RESERVOIR

PORTS (3)

UPPER SPRING

1

RETAINING

RING

PRESSURE SETTING

MOUNTING

HOLES

17

SPRING

19 LOWER

SPRING SEAT

18

SPRING GUIDE

19 LOWER

SPRING SEA T

8 O-RING

12 O-RING

EXHAUST

(2)

INLET/EXHAUST

8

O-RING

9

VALVE SPRING

16

SEA T

5

STEM

INLET/EXHAUST

VAL VE

ADJUSTING

10

4

SCREW

15

RETAINING

RING

3

LOCKNUT

2

BODY

PISTON

RETAINING

RING

11

PISTON

EXHAUST

FILTERS

11

14

STEM

7

6

13

WASHER

RETAINING

O-RING

INLET/

EXHAUST

VAL VE

9

INLET/EXHAUST

COVER VALVE

SPRING

15

RING

12

10

FIGURE 1 - D-2™ GOVERNOR

BLUE

NONMETALLIC

20

O-RING

CLEAR/BLACK

NONMETALLIC

WITH O-RING

BLACK

RUBBER

FIGURE 2 - TYPES OF COVERS

DESCRIPTION

The D-2™ governor, operating in conjunction with the unloading

mechanism, automatically controls the air pressure in the

air brake or air supply system between a maximum (cutout) pressure and a minimum (cut-in) pressure. The

compressor runs continually while the engine runs, but the

actual compression of air is controlled by the governor

actuating the compressor unloading mechanism which stops

or starts the compression of air when the maximum or

minimum reservoir pressures are reached.

5

11

15

NONMETALLIC METALLIC

5

11

FIGURE 3 - TYPES OF PISTONS

D-2™ governors are provided with mounting holes which allow

direct mounting to the compressor or remote mounting.

Porting consists of three reservoir ports (1/8 inch P.T.),

three unloader ports (1/8 inch P.T.) and one exhaust port

(1/8 inch P.T.).

1

Page 2

OPERATION

Reservoir air pressure enters the D-2™ governor at one of its

reservoir ports and acts on the piston and inlet/exhaust valve.

As the air pressure builds up, the piston and valve move

together against the resistance of the pressure setting spring.

When the reservoir air pressure reaches the cut-out setting

of the governor, the exhaust stem seat s on the inlet/exhaust

valve, closing the exhaust passage, and then opens the

inlet passage. Reservoir air pressure then flows around the

inlet valve, through the passage in the piston and out the

unloader port to the compressor unloading mechanism. Air

also flows around the piston which is slightly larger at the

upper end. The added force resulting from this larger area

assures a positive action and fully opens the inlet valve.

As the system reservoir air pressure drops to the cut-in

setting of the governor, the force exerted by the air pressure

on the piston will be reduced so that the pressure setting

spring will move the piston down. The inlet valve will close

and the exhaust will open. With the exhaust open, the air in

the unloader line will escape back through the piston, through

the exhaust stem and out the exhaust port.

Never condemn or adjust the governor pressure settings

unless they are checked with an accurate test gauge or a

dash gauge that is registering accurately. If the pressure

settings of the D-2™ governor are inaccurate or it is necessary

that they be changed, the adjustment procedure follows.

Note: If the governor cover is marked nonadjustable and the

adjusting stem has been sheared off, this is a nonserviceable

governor and must be replaced with a new or remanufactured

unit.

A. Remove the top cover from the governor.

B. Loosen the adjusting screw locknut.

C. T o raise the pressure settings, turn the adjusting screw

counter-clockwise. To lower the pressure settings,

turn the adjusting screw clockwise. Note: Be careful

not to overadjust. Each 1/4 turn of the adjusting screw

raises or lowers the pressure setting approximately 4

psi.

D. When proper adjustment is obtained, tighten the

adjusting screw locknut and replace the cover.

(Note: The pressure range between cut-in and cut-out is not

adjustable.)

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the D-2

governor should be inspected every 6 months or 1500

operating hours, whichever comes first, for proper operation.

Should the D-2™ governor not meet the elements of the

operational tests noted in this document, further investigation

and service of the governor may be required.

SERVICE TESTS

OPERATING TESTS

St art the vehicle engine and build up air pressure in the air

brake system and check the pressure registered by a dash

or test gauge at the time the governor cuts-out, stopping the

compression of air by the compressor. The cut-out pressure

should be in accordance with the pressure setting of the

piece number being used. (Common cut-out pressures are

between 105-125 psi.) With the engine still running, make a

series of brake applications to reduce the air pressure and

observe at what pressure the governor cuts-in the

compressor. As in the case of the cut-out pressure, the cutin pressure should be in accordance with the pressure setting

of the piece number being used. (Common cutting pressures

are between 90-105 psi.)

LEAKAGE TEST

Leakage tests on the D-2™ governor should be made in both

cut-in and cut-out positions.

CUT-IN POSITION

Apply soap solution around the cover and to the exhaust

port. Slight bubble leakage permitted. Excessive leakage

indicates a faulty inlet valve or lower piston o-ring.

™

CUT-OUT POSITION

Apply soap solution around the cover and to the exhaust

port. Slight bubble leakage permitted. Excessive leakage

indicates a faulty exhaust valve seat, exhaust stem o-ring,

or o-ring at the top of the piston.

If the governor does not function as described or leakage is

excessive, it is recommended that it be replaced with a new

or remanufactured unit, or repaired with genuine Bendix parts

available at authorized Bendix parts outlets.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

2

Page 3

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning

ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

REMOVING AND INSTALLING

REMOVING

1. Block and hold vehicle by means other than air brakes.

2. Drain air brake system.

3. If the governor is compressor-mounted type, disconnect

reservoir air line. If the governor is remote-mounted,

disconnect both the unloader and reservoir air lines.

4. Remove governor mounting bolts, then governor.

Caution: Prior to disassembly, it is required to have the

proper maintenance kit available to replace parts to be

discarded during disassembly .

DISASSEMBLY

1. Clean the governor exterior of dirt and grease.

2. If the governor cover is marked nonadjustable and the

adjusting screw has been sheared off, this is a

nonserviceable governor and must be replaced with a

new or remanufactured unit.

3. If the governor has a blue nonmetallic cover, (refer to

Figure 2) hold governor with one hand, with the other

hand grip cover from the top and pull up with thumb until

cover disengages from the governor body . If top cover on

governor is made of rubber or clear nonmetallic material

unscrew cover until it releases from the adjusting screw

(4) of governor. Remove o-ring (20, Figure 2) if present.

™

Note: O-ring (20) is used on Hi-Temp and waterproof

governors only .

4. With a pair of retaining ring pliers, remove the spring

assembly retaining ring (1) and save.

5. Pull the adjusting screw (4) and spring assembly out of

the governor body (2).

Note: Disassembly of the spring assembly normally is

not required. (Reuse and do not wash the assembly

because lubrication may be removed.) If Disassembly

of the spring assembly is necessary, the following instructions apply; otherwise, proceed to Step 6.

Remove the lock nut (3), then the hex-shaped upper

spring seat (16) from the adjusting screw (4). Remove

the pressure setting spring (17), lower spring seat (19),

spring guide (18) and the other lower spring seat (19)

from the adjusting screw (4).

6. Gently tap the open end of the valve body on a flat surface to remove the exhaust stem (5), the exhaust stem

spring (6), and piston assembly (11). Items 5 and 11

may be made of metal or nonmetallic material.

7. Remove and discard the two o-rings (8) on the piston

O.D. and with a hooked wire remove and discard the

o-ring (12) from the piston l.D. On nonmetallic piston,

washer (13) and retaining ring (14) may be removed to

facilitate removal of o-ring (12).

8. If piston assembly is nonmetallic (Figure 3), use a small

screwdriver and carefully insert blade of screwdriver between two of the ears of the retainer ring in the bottom of

the piston (1 1) and pry retainer ring (15) out of the piston

and discard. Remove inlet/exhaust valve spring (9) and

the inlet/exhaust valve (10) and discard. If piston assembly is metallic, disengage inlet/exhaust valve spring

(9) from recess in bottom of piston (11), remove inlet/

exhaust valve spring (9), and the inlet exhaust valve (10)

and discard.

9. Remove and discard filters (7) from unloader and

reservoir ports in governor body .

3

Page 4

CLEANING AND INSPECTION

1. Clean all remaining parts in mineral spirits.

2. Inspect body for cracks or other damage. Be particularly careful that all air passages in the body, exhaust

stem, and piston are not obstructed.

3. Check springs for cracks, distortion, or corrosion.

4. Replace all parts which are worn or damaged.

ASSEMBLY

Prior to assembly, lubricate the two lower body bores, all

o-rings and o-ring grooves with lubricant provided. Note: Also

spring guide and adjusting screw (if disassembled).

1. Install o-ring (12) in piston (11). Replace washer (13)

and retaining ring (14) on nonmetallic piston if removed

during disassembly .

2. Drop the inlet/exhaust valve (10) into place at the

bottom of the piston (1 1).

3. Nonmetallic Piston: Install the inlet/exhaust valve spring

(9) with the small end against the valve, place the retaining ring (15) on top of the large end of the valve spring (9)

[concave side of retaining ring (15) facing away from piston (1 1)], press into piston with thumb, making sure ears

of retaining ring (15) are seated into piston (1 1) as far as

possible.

Note: Do not use a press or hammer to install retaining

ring. Excessive force may damage the piston.

Metallic Piston: Install the inlet/exhaust valve spring

(9) with the small end against the valve. Press the spring

down until the larger coiled end snaps into the recess

inside the piston (1 1).

4. Install the piston o-rings (8) on the piston (1 1).

5. Install the exhaust stem spring (6) in the piston (1 1) with

the large coil end next to the piston.

6. Install the exhaust stem (5) through spring (6) and into

piston (1 1).

7. Install assembled piston (11) into the governor body (2).

8. If the spring assembly was not disassembled, proceed

to Step 9. If the spring assembly was disassembled,

the following instructions apply: install on the adjusting

screw (4) in this order; lower spring seat (19), spring

guide (18), spring seat (19), pressure setting spring (17),

hex-shaped upper spring seat (16). Screw the upper

spring seat onto the adjusting screw until the distance

from the top of the seat to the bottom of the adjusting

screw head is approximately 1-7/8 inches. Install the

lock nut (3).

9. Install the adjusting screw (4) and spring assembly into

the governor body (2).

10.Install retaining ring (1) making certain that it seats completely into the groove in the governor body (2).

If cover provided in kit is black rubber, (refer to Figure 2)

install by pushing it onto the adjusting screw .

If cover provided in kit is clear nonmetallic, install o-ring

(20) and screw cover onto the adjusting screw. Tighten

until cover bottoms on governor body . Note: O-ring (20)

is used only on Hi-Temp and waterproof governors. If

cover provided in kit is blue nonmetallic place cover over

one edge of top of governor; with index finger catch knob

on top of cover and pull until cover snaps into place.

Note: Nonmetallic cover should be at room temperature

for ease of assembly . Do not attempt to force cover on

square to the governor body.

1 1. Install filters (7) in governor body. The head of a pencil

makes a satisfactory installation tool.

INSTALLATION

1. If the governor is compressor-mounted, clean the mounting pad on both the compressor and governor. Clean

connecting line, or lines. Be certain the unloading port

is clear and clean. If the governor is mounted remotely ,

it should be positioned so that its exhaust port points

down. It should be mounted higher than the compressor

so that its connecting lines will drain away from the

governor.

2. Install governor.

3. If compressor-mounted type, use the governor mounting

gasket provided.

4. Connect air lines to governor.

5. Perform operating and leakage tests as outlined under

Service T ests section.

4

BW1425 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.

Loading...

Loading...