Page 1

RSD and Aftermarket Friction

Frequently Asked Questions

One of your top priorities as a fleet or owner-operator is maintaining the safe operation of your vehicles. Bendix, as

always, remains committed to helping you do just that. With the recent implementation of the final phase of the

Reduced Stopping Distance (RSD) mandate, selecting the proper replacement friction is more critical than ever.

Choosing replacement friction for RSD trucks can be confusing, especially in light of conflicting information in the

marketplace. Think of Bendix as your resource on these important issues. To help you better understand what’s at

stake in vehicle maintenance decisions, we share these commonly asked questions.

Why was the RSD mandate implemented?

The National Highway Traffic Safety Administration (NHTSA) implemented the RSD mandate with the goal of

improving highway safety, and reducing injuries, fatalities, and property damages resulting from accidents. The

regulation requires vehicles to stop in 250 feet from 60 mph.

Estimated annual benefits of RSD*

o 227 lives saved

o 300 serious injuries avoided

o $169 million in property damages avoided

*Source: Federal Motor Carrier Safety Administration (FMCSA)

How do I know if RSD affects the truck(s) I am maintaining?

The regulations affect tractors built after August 2011 (for Phase One) and August 2013 (for Phase Two). There is

no requirement to retrofit older vehicles.

RSD Phase One: Aug. 1, 2011, affects 6 x 4 tractors below 59,600 lbs. GVWR

RSD Phase Two: Aug. 1, 2013, affects all other tractor applications, including 4 x 2s

Is there any legal obligation to maintain RSD after service? If not, why would I choose to?

Although there is currently no legal requirement to maintain RSD compliance, your choice of aftermarket

friction can have a significant impact on your vehicle’s stopping distance performance and safety. If you

reline with noncompliant friction (friction material that is not RSD certified), you may not maintain the stopping

distance performance your vehicle is capable of. In the event of a crash, you may expose yourself to potential

fatalities and property damages, as well as higher insurance rates and a negative impact to your CSA scores.

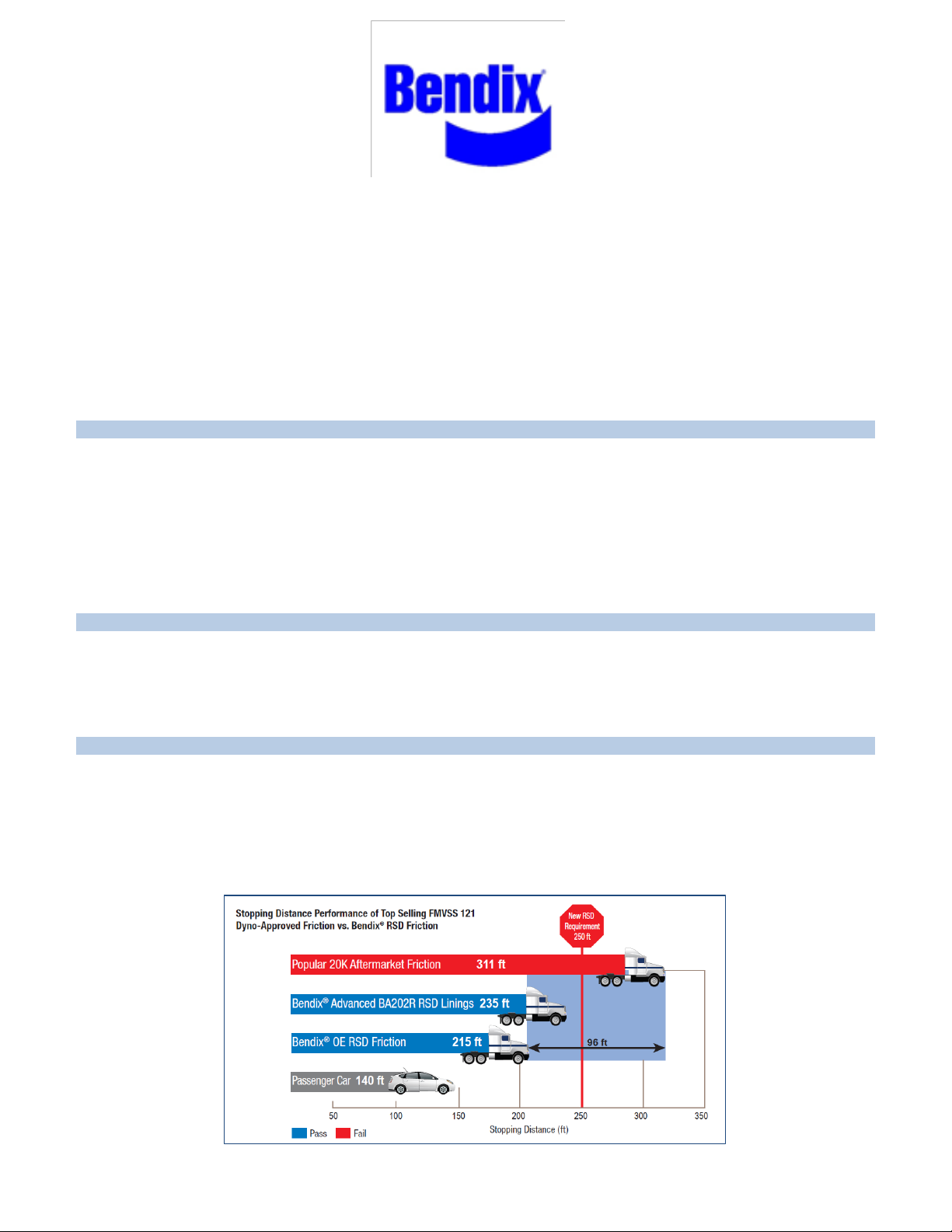

Review this chart to see how friction selection impacts stopping distance.

Source: Bendix testing

Page 2

Will RSD-certified friction increase my operating costs?

No. While it’s true that RSD-certified friction carries a higher initial price tag, it’s important to factor in what you may

save by avoiding the potential pitfalls of relining with noncompliant friction (friction material that is not RSDcertified). This protection and peace of mind far outweigh the cost of RSD friction.

In addition, to address concerns regarding additional costs, we developed Bendix® Advanced BA202R, a costeffective solution to maintain RSD compliance. The BA202R material is an RSD-certified replacement friction that is

comparable in cost to previous generation OE materials. Like all Bendix RSD-certified linings, BA202R comes with

a letter of certification from Bendix, so you can be confident it will give you the performance you expect.

Since RSD trucks already have larger brakes, does it matter which replacement lining I select?

Yes. Bigger brakes are only half the battle. During an emergency stop, heat is generated faster than it can be

dissipated through the drum. RSD-certified friction has a superior ability to handle high temperatures while

maintaining torque. Prior generation OE and most aftermarket friction are simply not engineered to handle these

conditions.

How do I know if a shoe is RSD compliant? Does it have a different edge code?

Unfortunately, RSD-certified friction does not have a special edge code. Because of this, it’s critical that you

always do two things to ensure you’re getting what you need for your vehicle:

First, look for labeling on the

shoe that indicates whether

the shoe is RSD compliant.

Bendix has added a label on our

RSD shoes to make technicians

aware they are servicing an RSD

brake, but this is not currently

done throughout the industry.

Next, ask your supplier for an

RSD-certified friction that’s

appropriate for your vehicle.

Take caution in simply taking a

supplier’s word on this issue.

Ensure you are getting the

performance you expect – ask for

evidence of RSD certification.

For a list of Bendix RSD-certified friction,

see our RSD Friction Certification letter

(BW7537) in the online Literature Center

at foundationbrakes.com.

Does the FMSI indicate that the friction is RSD-certified?

No. The FMSIs used on RSD-compliant trucks are available in the marketplace with a wide variety of frictions;

some are compliant, some are not. To maintain RSD compliance, you must get the proper friction on the proper

FMSI. For a friction material to be certified as RSD compliant, it must not only be dynamometer certified to

FMVSS 121, it must also pass the newly mandated vehicle test. Both elements must be in place for RSD

compliance – there is not a choice of one or the other.

Page 3

If it says 20K on the friction, it must be OK to put it on any 20K axle, including an RSD truck, correct?

Again, FMVSS 121 is not sufficient to certify a friction as RSD compliant. There are two different methods to

officially certify friction as RSD compliant:

1. Certification as part of an OE truck build, or

2. Approval by a certified vehicle test provider

To eliminate any doubts about appropriate friction selection, we encourage you to ask your supplier for evidence of

this compliance.

Can I reline with Bendix RSD friction and maintain compliance if my RSD truck is not equipped with Bendix

brakes?

That’s a question we are asked quite often. With the wide variety of vehicle platforms available in the marketplace,

it would be impossible to test every one. Bendix has tested a number of representative vehicles, and we believe

that when identical vehicle parameters and brake sizes are in place, using Bendix® brand RSD friction materials on

non-Bendix brakes may enable you to maintain RSD compliance.

If it’s torque that is needed for RSD compliance, can’t I just run higher torque rated materials?

We do not recommend this practice. Just because a material has a high torque does not mean it is designed to

handle the high heat generated during emergency braking conditions. Plus, you may experience undesirable side

effects such as brake noise, rapid wear, and poor system balance.

In addition to selecting RSD-certified linings, what else do I need to be concerned about when selecting

replacement friction?

RSD friction cannot perform as engineered unless it is paired with a quality brake shoe. When selecting aftermarket

friction for your RSD-equipped truck, make sure you also get a brake shoe that’s built to deliver the performance

you need. Keep these factors in mind when selecting a

brake shoe supplier. :

Structural integrity: RSD shoes must be able to

handle the required torque. Shoes that have

been relined too many times may be fatigued or

corroded.

Coining: If the shoe is not coined, it may have

poor geometry. This may result in a weak or

small contact patch of friction to the drum. This

can create excessive heat and fade, resulting in

longer stopping distance.

Your brake shoe supplier should be able to provide you

with information on the brake shoe production process.

Still have questions? Want more information?

It can be difficult to separate fact from fiction when selecting replacement friction for your RSD truck. For assistance

in understanding RSD and selecting the appropriate friction to maintain RSD compliance, count on the experts at

Bendix. Talk to your Bendix account manager or call the Bendix Tech Team at 1-800-AIR-BRAKE.

Visit www.foundationbrakes.com for additional information and resources regarding wheel-end solutions

from Bendix Spicer Foundation Brake.

Log in and learn from the best 24/7/365. Visit www.brake-school.com.

Bendix Spicer Foundation Brake LLC • 901 Cleveland Street • Elyria, OH 44035 • www.foundationbrakes.com • 1- (866) 610-9709

BW7551 ©2014 Bendix Spicer Foundation Brake • All Rights Reserved

Loading...

Loading...