Page 1

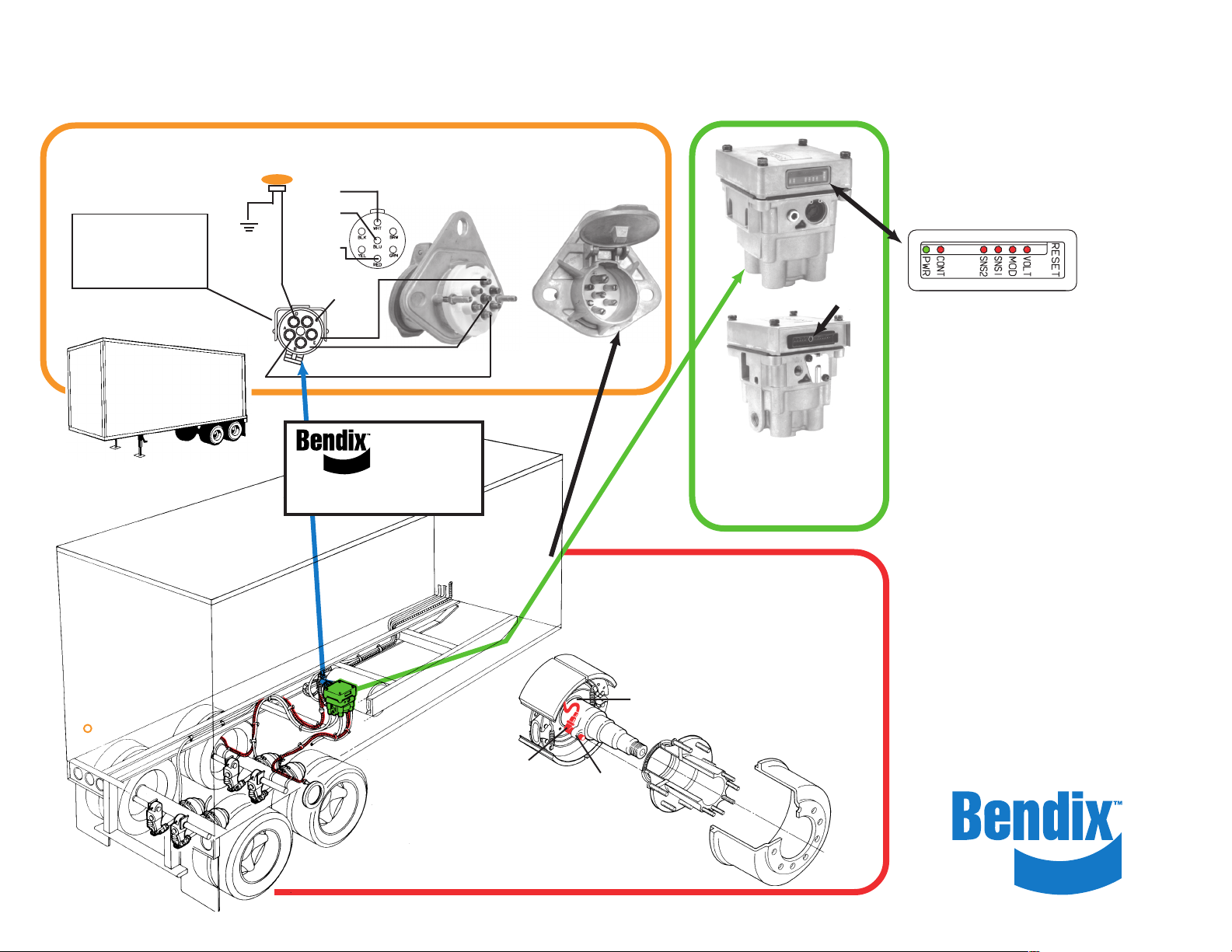

Troubleshooting The Bendix® MC-12 Trailer AntiLock System (Post 2/98)

A Stop Lamp Power

B Constant Power

C In Cab Status Light

D Trailer Status Light

E Ground

STATUS INDICATOR

Ground

Constant

Power

Stop Light

Power

In Cab Status

Light

IF INDICATOR REMAINS ILLUMINATED

SYSTEM REQUIRES SERVICE

ANTILOCK

INDICATOR

7 PIN CONNECTOR

Back

Front

Connector

MC-12 Modulator

Controller

(Ref. SD-13-4762)

WHEEL SPEED SENSOR

CONNECTOR

Resistance Across Pins

1500 - 2500 ohms

(Ref. SD-13-4754)

OPERATIONAL INFORMATION

The EC-12 controller houses the

electronics that regulate the antilock

system. The EC-12 contains a diagnostic

window and a 14 pin connector.

Diagnostic

Window

The EC-12 mounts on the M-12 modulator

with four bolts and it is internally connected

to the solenoids by a four pin connector.

Sensors mounted at the wheel end send

wheel speed information to the EC-12

through the 14 pin connector. If wheel lock

up is impending, the EC-12 commands the

solenoids to modulate brake chamber

pressure on the axle(s) in which the system

is installed. The MC-12 modulator controller

receives power and ground from the vehicles

electrical system. During start up, trailer

antilock immediately runs a self check. The

trailer status light flashes once and then goes

off. Should a problem occur, the status light

comes on and remains on.

TROUBLESHOOTING

If the status light remains on, inspect the

EC-12 for illuminated LEDs. If no status light

was installed, the diagnostic LEDs should

be checked periodically.

Wheel Speed

Sensor

Mounting

Block

TYPICAL

TRAILER AXLE

Tie Wrap

Reset controller with magnet after repair.

Page 2

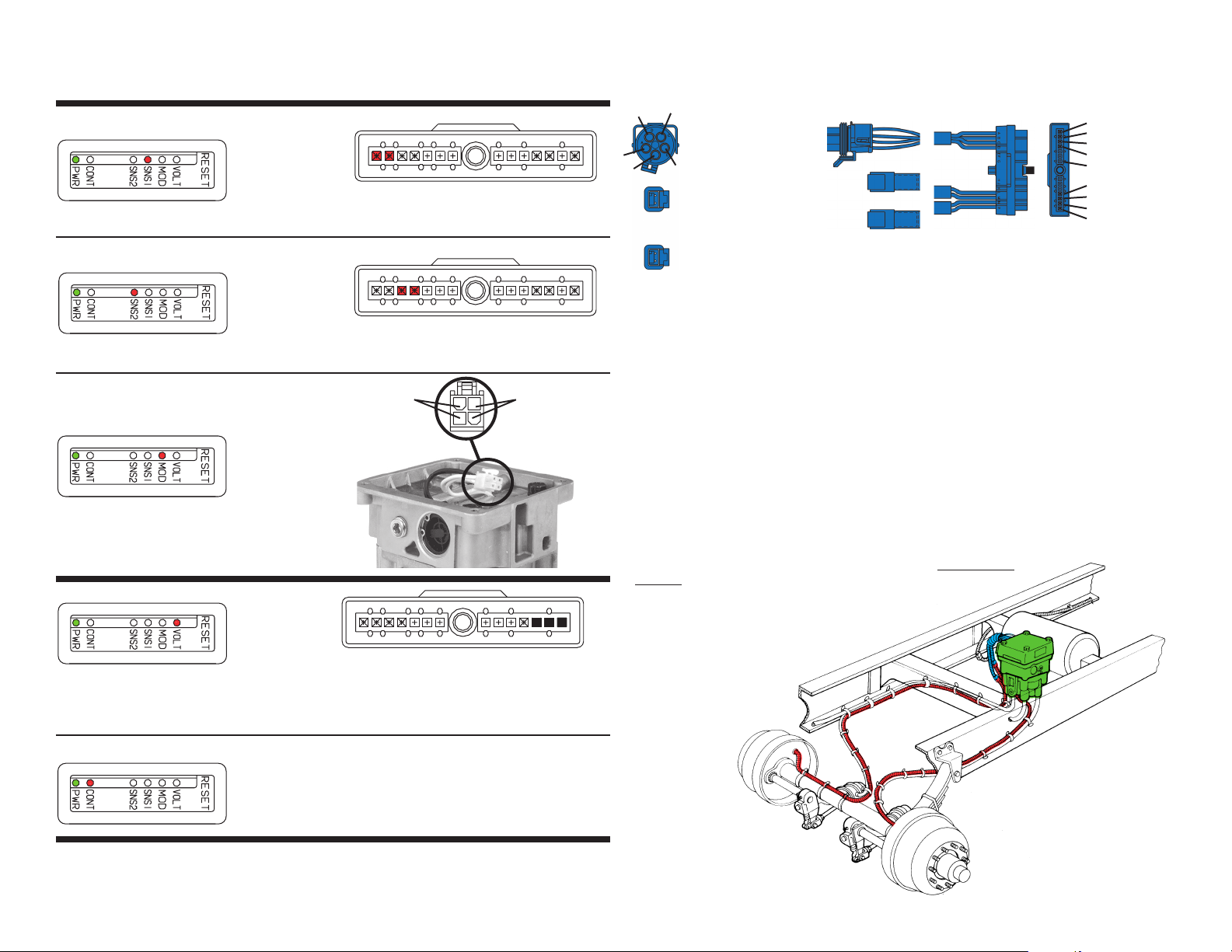

IF THESE LED'S

ARE ILLUMINATED

CHECK THE VEHICLE WIRING HARNESS CONNECTOR

FOR THE PROPER RESISTANCE WITH

STOP LAMP POWER OFF

SENSOR 1

P N M L K J H G F E D C B A

N - P 15 -2500 Ohms

MC-12 Controller Cable Assembly

D

C

A Stop Lamp Power

B Constant Power

C In Cab Status Lamp

A

B

D Trailer Status Lamp

E Ground

E

Sensor 2 (yellow)

Sensor 2 (yellow)

To Controller

Stop Lamp Power

Constant Power

Ground

Trailer Status Lamp

Cab Status Lamp (optional)

Sensor 2

Sensor 2

Sensor 1

Sensor 1

SENSOR 2

MODULATOR

VOLTAGE

w/STOP

LAMP

POWER

P N M L K J H G F E D C B A

L - M 15 -2500 Ohms

9.5 - 11.5

Ohms

White to White

P N M L K J H G F E D C B A

A - C 9 to 18 Volts DC

B - C 9 to 18 Volts DC

9.5 - 11.5

Ohms

Black to Black

Sensor 1 (blue)

Sensor 1 (blue)

Vehicle wire harness

Most Commonly Encountered Problems That Result In LEDs Being Illuminated.

Repair or Replacement Components As Necessary

• Damaged connectors or wires, caused by dangling or loose wires not properly restrained.

• Power connection not capable of supplying 12 volts at 3 amps because of a poor connection,

bad crimp

• Corroded connectors and connections not properly sealed or seated.

• Terminals not completely latched or sealed into connectors; harness connector bolt not tight.

• Improperly spliced connection repair or repair not sealed properly.

• Excessive sensor air gap, sensor bushing tension or excessive bearing end play.

(Gently push sensor against exciter ring, or readjust bearings)

• Non functioning antilock components, sensor, controller, modulator.

Additional Servicing Tips

• Do not pierce wires with probes when troubleshooting harnesses.

• Gently probe terminals when checking for resistances,

contacts

• Apply nonconductive dielectric grease to any and all

connectors if inspecting or disconnecting connectors.

• If excessive cable length is present, bundle and

tie wrap neatly to adjacent air lines or

framing members.

do not deform

ECU

CONTROLLER

All CONTACT OF THE 14 PIN CONNECTOR ABOVE SHOULD NOT HAVE ANY CONTINUITY

TO THE GROUND CONTACT "C". CONTACTS "A" & "B" ARE POWER TO THE MC-12

BW1959 © Bendix Commercial Vehicl Systems LLC 2/2000

Replace Controller

• Printed in USA • All Rights Reserved

ADDITIONAL INFORMATION:

1-800-247-2725

-2-1

Visit: www.bendix.com

Loading...

Loading...