Page 1

Quality

remanufactured

valves

Page 2

Inside Front Cover

Page 3

Table of Contents

INTRODUCTION

Table of Contents ..................................................................................................... 1 3

Part Number to Page Index...................................................................................... 4 5

General Information ................................................................................................. 6

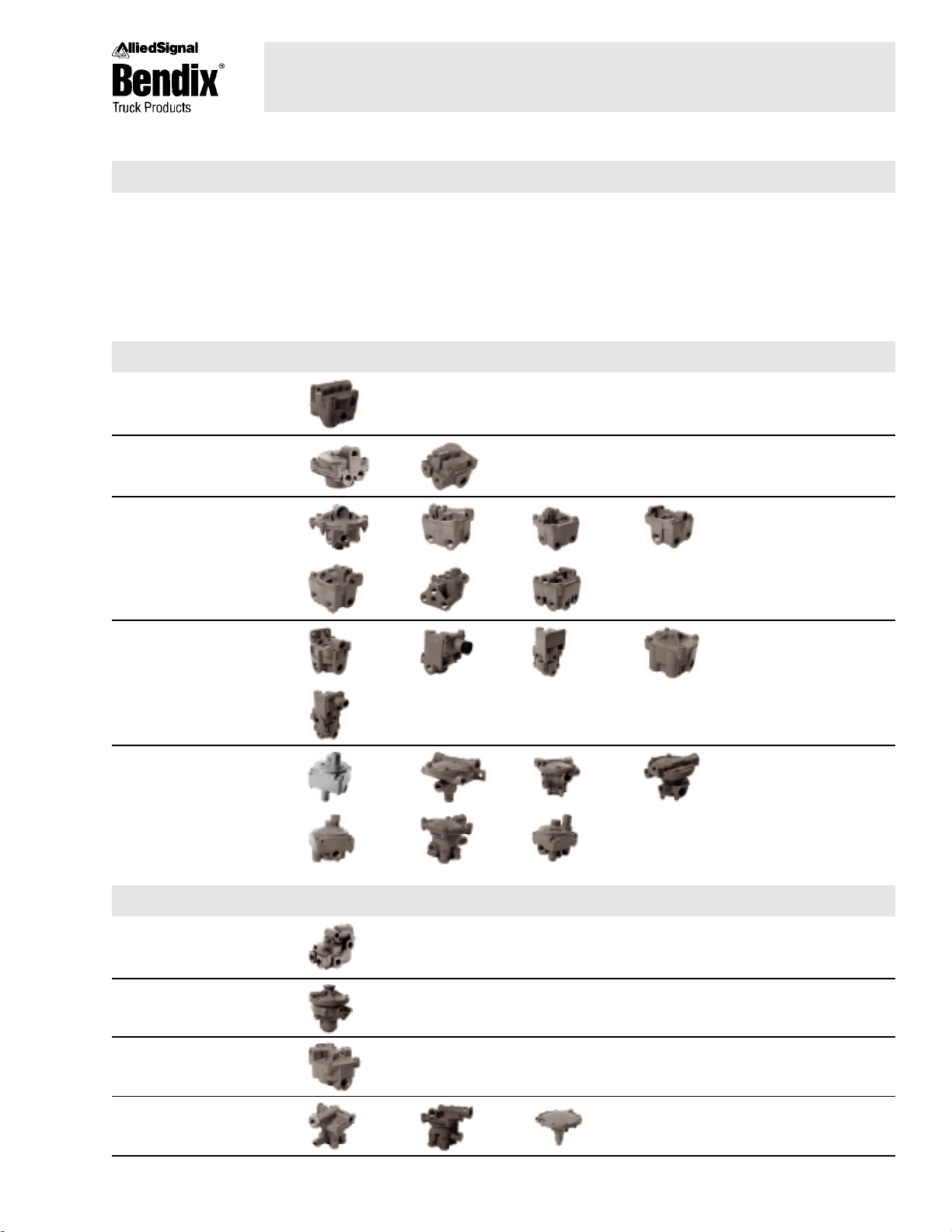

RELAY VALVES

Kelsey Hayes 7

Midland/Berg 7 8

Midland

8 12

Midland/Wagner

12 14

Sealco

15 18

RELAY EMERGENCY VALVES

Midland/Berg 19

Midland 20

Midland/Wagner 20

Sealco 21 22

BW1746 © AlliedSignal January 1995 Printed in U.S.A.

3

Page 4

Table of Contents

TRAILER SPRING BRAKE VALVES

Midland/Berg 23

Midland/Wagner 23 25

Sealco 25 - 26

TRACTOR SPRING BRAKE VALVES

Midland 26

TRACTOR PROTECTION VALVES

Midland 27 28

FOOT OPERATED VALVES

Midland 29

Sealco 30

TRANSMISSION VALVES

Fuller 31 32

MISCELLANEOUS VALVES

Neway 33

Sloan 33

Cummins 34

4

Page 5

Table of Contents

ADDITIONAL INFORMATION

Minor Maintenance Kit Cross Reference .................................................................35 36

Product Warranty ..................................................................................................... 37

Sample Core Return Memo ..................................................................................... 38

5

Page 6

Part Number to Page Index

Part

Number

3100X Sealco Mini-Relay Valve VM-10348 W3 3 VK1006S 15

5457X Kelsey Relay Valve VR-10368 W8 2 VK1000K 7

5461X Kelsey Relay Valve VS-10372 W9 2 VK1000K 7

5462X Kelsey Relay Valve VS-10372 W9 2 VK1000K 7

5470X Kelsey Relay Valve VR-10370 W8 2 VK1000K 7

9125X Sealco Relay Valve VN-10350 W4 4 VK1007S 16

12343X Mid/Berg Relay Valve VL-10342 W2 2 VK1020B 7

12345X Mid/Berg Relay Valve VL-10344 W2 2 VK1019B 8

12346X Mid/Berg Relay Valve VL-10346 W2 2 VK1019B 8

12350X Mid/Berg Relay Valve VX-10384 X5 3 N/A 19

12360X Mid/Berg TASK Valve VZ-10388 X7 3 VK1021B 23

12361X Mid/Berg TASK Valve VZ-10388 X7 3 VK1021B 23

10005AX Sealco Cartridge WJ-10414 Y8 1 VK1001S 22

110139X Sealco Relay Valve VO-10354 W5 5 VK1008S 17

110147X Sealco Ratio Relay Emergency Valve VT-10374 X1 5 VK1008S 25

110170X Sealco Ratio Relay Emergency Valve VU-10376 X2 4 VK1009S 25

110171X Sealco Ratio Relay Emergency Valve VU-10376 X2 4 VK1009S 25

110191X Sealco Ratio Relay Emergency Valve VU-10376 X2 4 VK1009S 25

110197X Sealco Trailer Relay Valve VN-10352 W4 4 VK1007S 16

110200X Sealco Ratio Relay Emergency Valve VO-10356 W5 7 VK1010S 21

110205X Sealco Ratio Relay Emergency Valve VO-10356 W5 7 VK1010S 21

110267X Sealco Relay Emergency Valve VO-10358 W5 6 VK1010S 21

110310X Sealco Ratio Relay Emergency Valve VU-10376 X2 4 VK1009S 25

110315X Sealco Ratio Relay Emergency Valve VU-10376 X2 4 VK1009S 25

110338X Sealco Relay Emergency Valve VO-10358 W5 6 VK1010S 21

110360X Sealco LOV (Low Opening Valve) VP-10360 W6 3 VK1011S 17

110375X Sealco LOV-CF Control Line Valve VP-10362 W6 3 VK1011S 15

110380X Sealco LOV (Low Opening Valve) VQ-10366 W7 3 VK1011S 18

110400X Sealco Dual Circuit Foot Valve VC-10306 V3 4 N/A 30

110410X Sealco LOV (Low Opening Valve) VP-10360 W6 3 VK1011S 17

110415X Sealco LOV (Low Opening Valve) VQ-10364 W7 3 VK1011S 18

401033X Sloan Push Pull Dash Valve WK-10416 Y9 2 N/A 33

401037X Sloan Push Pull Dash Valve WK-10416 Y9 2 N/A 33

6997312X Cummins Fuel Solenoid Valve WQ-10428 Z6 1 N/A 34

6997324X Cummins Fuel Solenoid Valve WQ-10428 Z6 1 N/A 34

90054007X Neway Leveling Valve WL-10418 Z1 2 VK1003N 33

A1000X Sealco Relay Emergency Valve WI-10412 Y7 6 VK1012S 22

A3546X Fuller Shift Valve WM-10420 Z2 1 VK1004F 31

A3547X Fuller Range Selector Valve WN-10422 Z3 4 VK1005F 31

A3991X Fuller Range Selector Valve WO-10424 Z4 4 VK1005F 32

A4668X Fuller Range Selector Valve WP-10426 Z5 4 VK1005F 32

A80070X Mid/Wagner RS Relay Valve VK-10336 W1 3 VK1026W 13

A85490X Mid/Wagner RG-4 Tandem Relay Valve VK-10338 W1 4 VK1024W 13

A85493X Mid/Wagner RG-4 Tandem Relay Valve VK-10338 W1 4 VK1024W 13

A86473X Mid/Wagner RF Relay Valve VJ-10332 V9 3 VK1022W 14

A86477X Mid/Wagner RF Relay Valve VJ-10332 V9 3 VK1022W 14

A88802X Mid/Wagner RT Valve WA-10390 X8 3 VK1027W 24

A88812X Mid/Wagner RT Valve WA-10390 X8 3 VK1027W 24

A97600X Mid/Wagner RS-2 Tandem Relay Valve VK-10340 W1 4 VK1024W 14

A98730X Mid/Wagner RT-2 Valve WB-10392 X9 3 VK1027W 24

A99370X Mid/Wagner RT-2 Valve WB-10392 X9 3 VK1027W 24

A103600X Mid/Wagner RF Relay Valve VJ-10334 V9 3 VK1022W 14

Core

Class/DeviceDescriptionModel

Core

Group

Weight

(lbs.)

Minor

Maint. Kit

Catalog

Page No.

6

Page 7

Part Number to Page Index

Part

Number

KN22100X Midland Single Circuit Foot Valve VA-10300 V1 2 VK1014M 29

KN22140X Midland Dual Circuit Foot Valve VB-10302 V2 2 VK1017M 29

KN22150X Midland Dual Circuit Foot Valve VB-10304 V2 3 VK1017M 29

KN26000X Mid/Wagner RT-4 Spring Brake Valve VY-10386 X6 5 VK1025W 23

KN26010X Mid/Wagner RT-4 Spring Brake Valve VY-10387 X6 5 VK1025W 23

KN28010X Midland Relay Valve VE-10308 V4 3 VK1013M 8

KN28011X Midland Relay Valve VE-10310 V4 3 VK1013M 8

KN28030X Midland Inversion Valve WE-10398 Y3 2 N/A 26

KN28060X Midland Relay Valve VF-10312 V5 3 VK1016M 10

KN28061X Midland Relay Valve VF-10314 V5 3 VK1016M 10

KN28065X Midland Relay Valve VF-10316 V5 3 VK1016M 9

KN28071X Midland Relay Valve VH-10322 V7 3 VK1016M 9

KN28080X Midland Relay Valve VF-10318 V5 3 VK1016M 12

KN28085X Midland Relay Valve VF-10318 V5 3 VK1016M 12

KN28130X Midland Relay Valve VG-10320 V6 3 VK1016M 11

KN28131X Midland Relay Valve VH-10324 V7 3 VK1016M 10

KN28132X Midland Relay Valve VF-10314 V5 3 VK1016M 10

KN28140X Midland Relay Valve VH-10324 V7 3 VK1016M 9

KN28300X Midland FAB (Fast Air & Balancing) Valve VF-10314 V5 3 VK1016M 11

KN28500X Mid/Wagner RG-2 Relay Valve VI-10326 V8 2 VK1023W 12

KN28510X Mid/Wagner RG-2 Relay Valve VI-10328 V8 2 VK1023W 12

KN28520X Mid/Wagner RG-2 Relay Valve VI-10330 V8 2 VK1023W 12

KN28600X Mid/Wagner FF2 Full Function Valve UA-10429 U1 3 N/A 25

KN30010X Midland Relay Emergency Valve VW-10378 X4 5 VK1015M 20

KN30100X Mid/Wagner Relay Emergency Valve VV-10380 X3 3 VK1022W 20

KN30200X Mid/Wagner Relay Emergency Valve VV-10382 X3 3 VK1022W 20

KN30300X Mid/Wagner Relay Emergency Valve VV-10380 X3 3 VK1022W 20

KN30400X Mid/Wagner Relay Emergency Valve VV-10382 X3 3 VK1022W 20

KN32040X Midland Quick Release Valve WD-10396 Y2 1 VK1018M 26

KN34030X Midland Tractor Protection Valve WG-10402 Y5 2 VK1002M 27

KN34050X Midland Tractor Protection Valve WG-10404 Y5 2 VK1002M 27

KN34060X Midland Tractor Protection Valve WF-10400 Y4 2 N/A 28

KN34070X Midland Tractor Protection Valve WG-10406 Y5 2 VK1002M 27

KN34080X Midland Tractor Protection Valve WH-10408 Y6 2 N/A 28

KN34090X Midland Tractor Protection Valve WH-10410 Y6 3 N/A 28

Core

Class/DeviceDescriptionModel

Core

Group

Weight

(lbs.)

Minor

Maint. Kit

Catalog

Page No.

Minor Maintenance Kits

(Reference Minor Maintenance Repair Kit Cross Reference) ......................................................... 3536

VK1000K VK1007S VK1014M VK1021B

VK1001S VK1008S VK1015M VK1022W

VK1002M VK1009S VK1016M VK1023W

VK1003N VK1010S VK1017M VK1024W

VK1004F VK1011S VK1018M VK1025W

VK1005F VK1012S VK1019B VK1026W

VK1006S VK1013M VK1020B VK1027W

7

Page 8

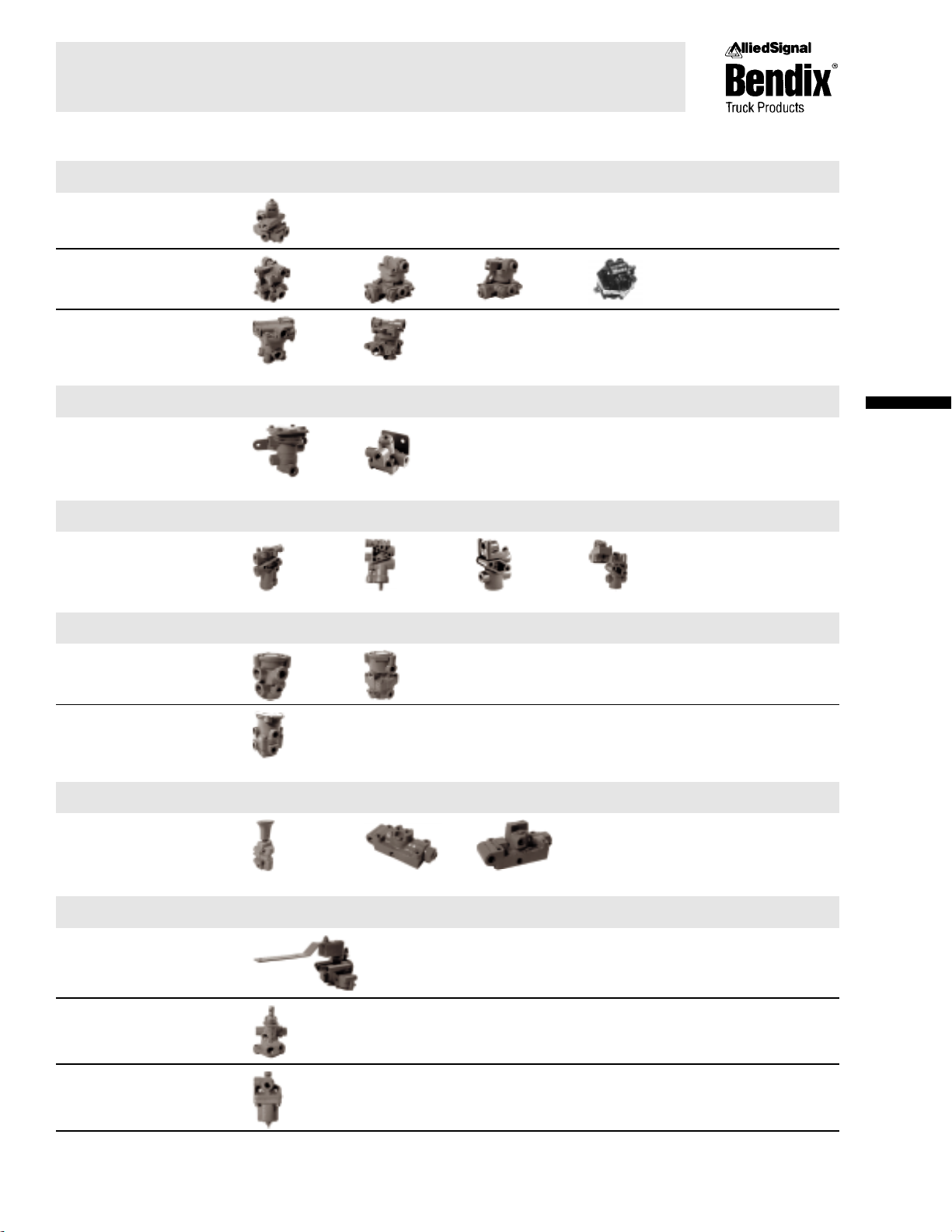

General Valve Information

Valve Identification Tag

A metal identification tag is attached to each valve. The tag is

secured to the valve using one of the assembly cap screws or

bolts. The part number and serial number of the device is

Device Part Number

Valve Crack

Pressure

stamped into the metal tag in the area indicated. In most cases

a crack pressure will also appear.

REMFRD

Device Serial Number

The part number displayed on the tag is the manufacturers

part number with the letter X added to the end to designate

that the unit is remanufactured. The alpha numeric alpha serial number indicates the date and place of manufacture. The

first letter indicates the month, A (January) through M (December) with the letter I not used. The first pair of digits indicate

the day and the second pair the year. The last character represents the remanufacturing facility. For example, a tag bearing

serial number, H1894X, was built August 18,1994.

Disclaimer

The purpose of this AlliedSignal Bendix Truck Products Catalog is to provide a means for identification and replacement of the devices presented. AlliedSignal has made every effort to provide

the most accurate data available for the products offered in this catalog, however in no case

should the information presented be used for other than simple identification and replacement of

like for like.

Photographs of representative device groupings are presented along with pertinent data to assist in visual identification. The original manufactures published data, where available to

AlliedSignal, was used to obtain device application, port sizing and location as well as pressure

specifications. It should be noted that the devices original manufacturer may have model variations and updates that are not presented or explained in this catalog.

8

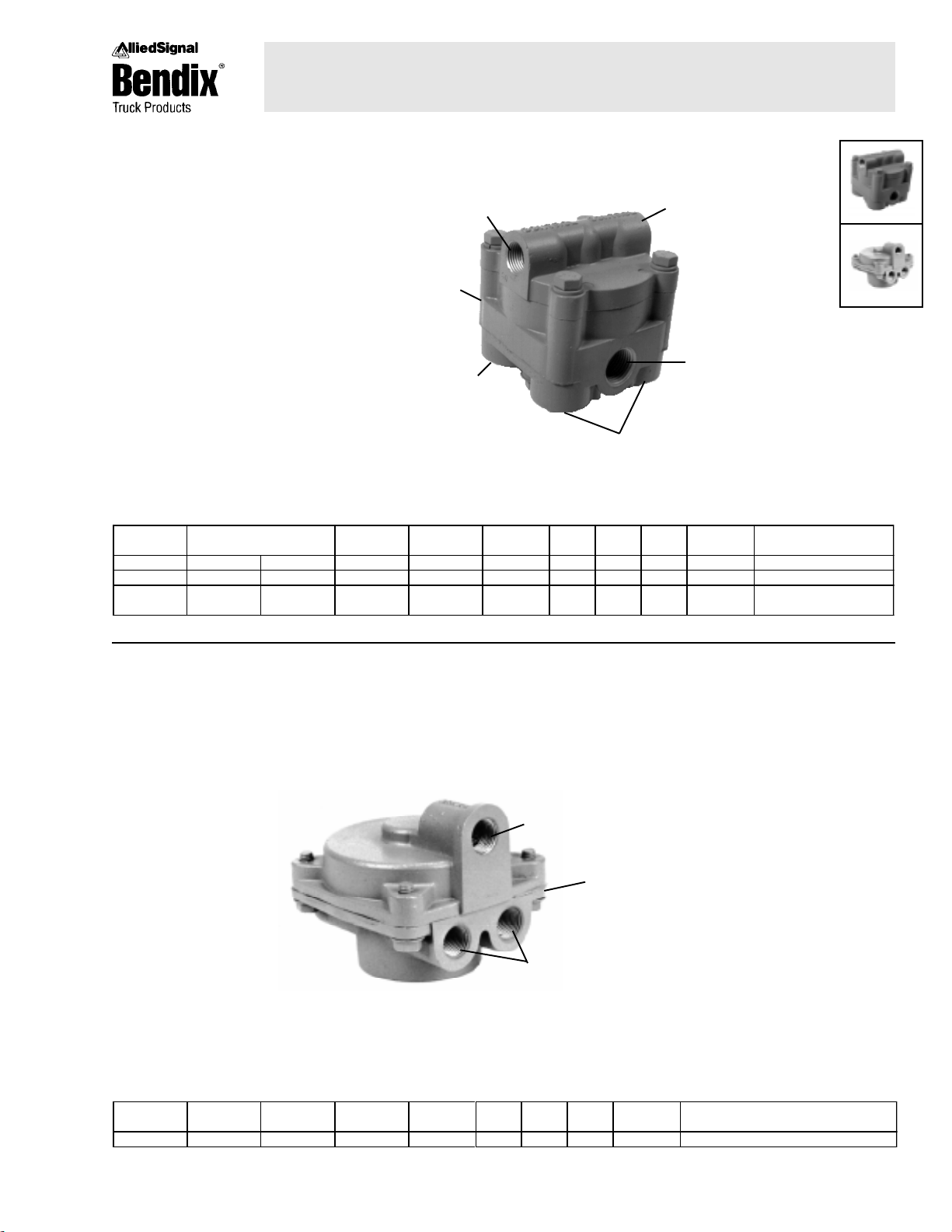

Page 9

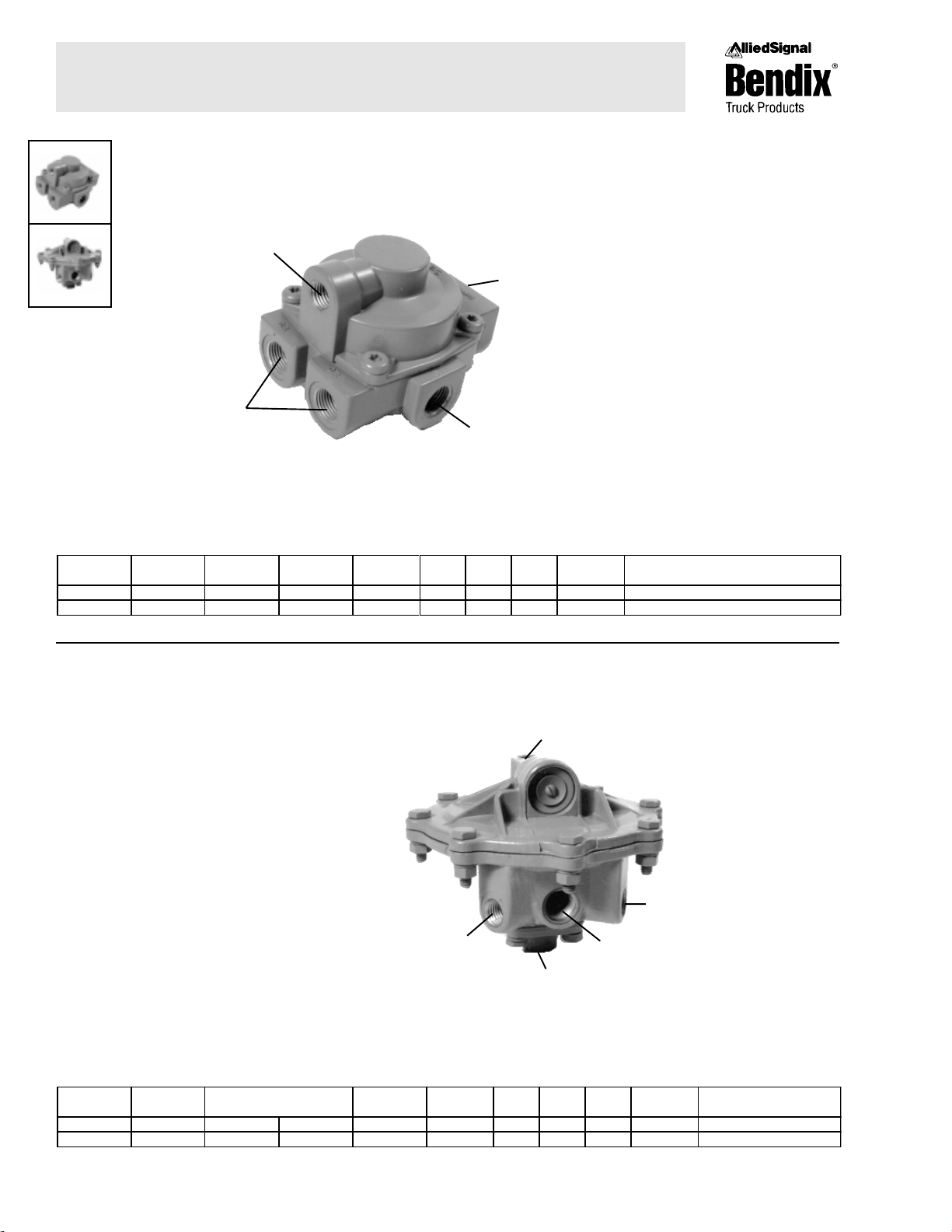

Kelsey Hayes

5457X, 5461X,

5462X, 5470X

2 & 4 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

5461X

Shown

Control

Supply

Delivery

Relay Valves

Control

Supply

Delivery

Part No. Supply Ports

5461X 1 - 1/2" PT 1 - 3/4" PT 2 - 3/8" PT 2 - 3/8" PT N/A 2 lbs. VS W9 VK1000K Casting No. 998901

5462X 1 - 1/2" PT -- 2 - 3/8" PT 1 - 1/4" PT N/ A 2 lbs. VS W9 VK1000K Casting No. 9995701

5457X 1 - 1/2" PT 1 - 3/4" PT 4 - 1/2" PT 2 - 3/8" PT N/A 2 lbs. VR W8 VK1000K

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

Casting No.

9403501,2

Midland/Berg

12343X

4 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

Control

Supply

Delivery

Part No.

12343X 1 - 3/4" PT 4 - 3/8" PT 1 - 3/8" PT N/A 2 lbs. VL W2 VK1020B

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

9

Comments

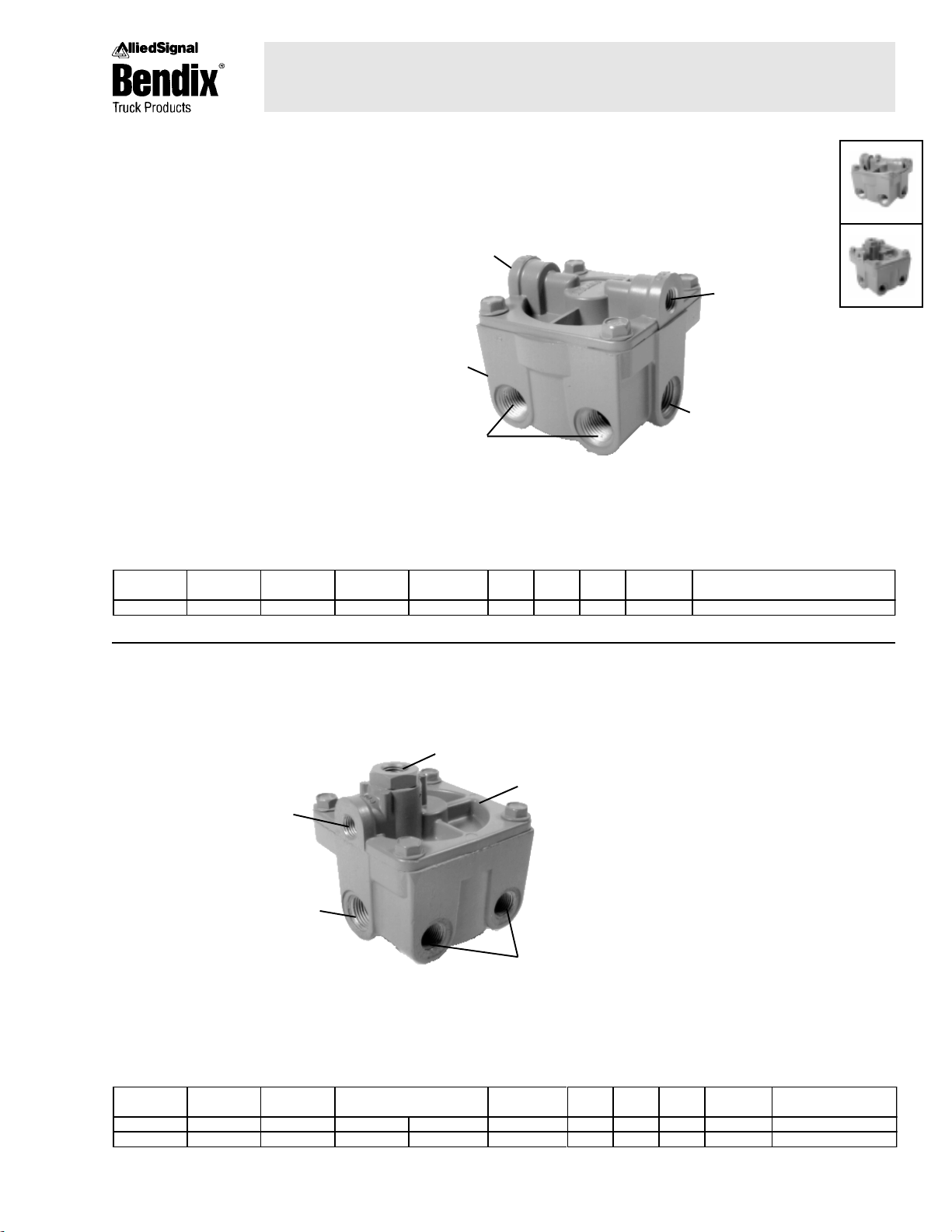

Page 10

Relay Valves

Control

Delivery

Midland/Berg

12345X, 12346X

2 & 4 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

Supply

12345X

Shown

Delivery

Part No.

12345X 1 - 3/4" PT 4 - 3/4" PT 1 - 1/4" PT N/A 2 lbs. VL W2 VK1019B

12346X 1 - 1/2" PT 2 - 3/8" PT 1 - 1/4" PT N/A 2 lbs. VL W2 VK1019B

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Maint. Kit

Midland

KN28010X, KN28011X

Control

3 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

KN28010X

Shown

Delivery

Supply

Minor

Comments

Delivery

Delivery

Part No.

KN28010X 1 - 3/8" PT 2 - 1/4" PT 1 - 3/8" PT 1 - 1/4" PT N/A 3 lbs. VE V4 VK1013M

KN28011X 1 - 3/8" PT 3 - 3/8" PT -- 1 - 1/4" PT N/A 3 lbs. VE V4 VK1013M

Supply

Ports

Delivery Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

10

Comments

Page 11

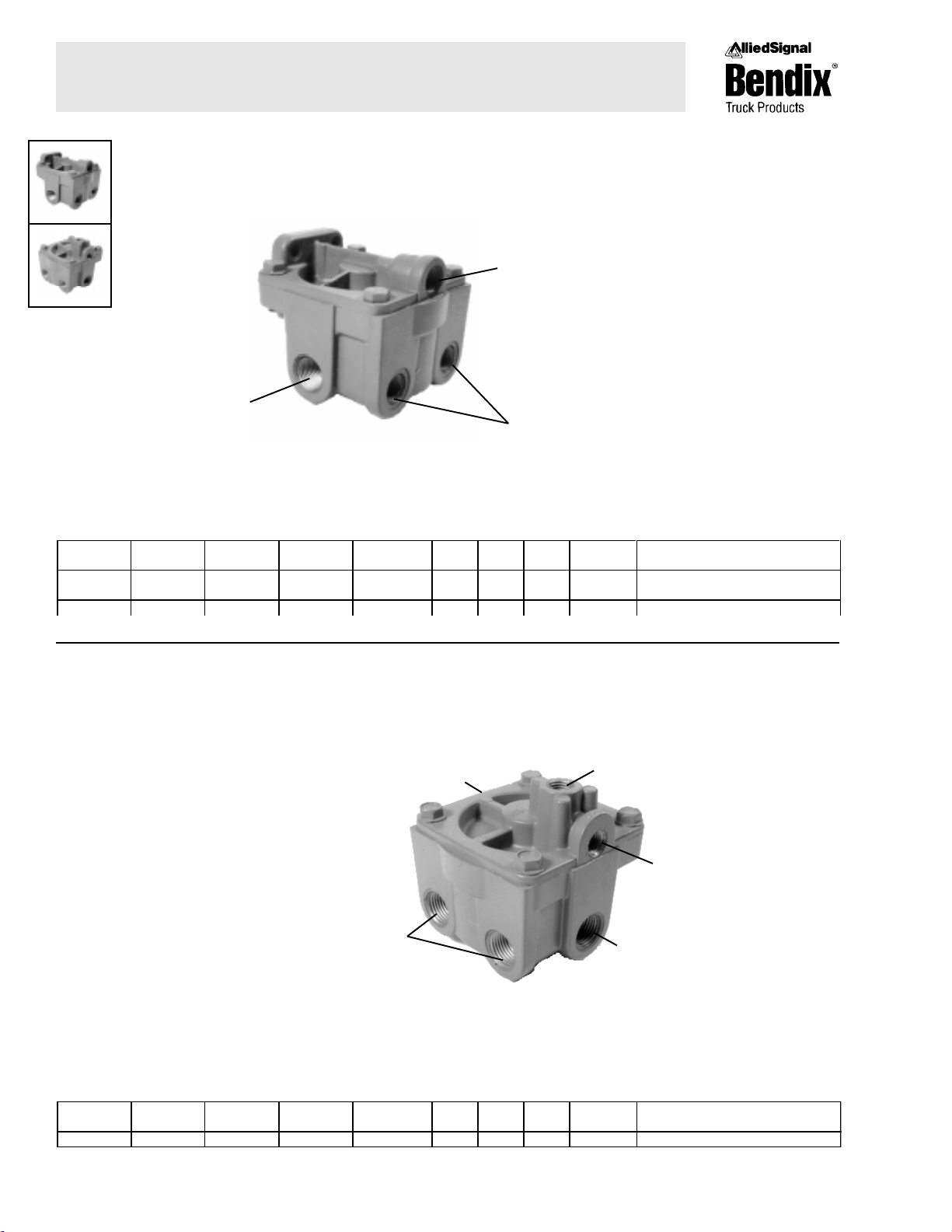

Midland

KN28065X

2 Port Delivery

Used to apply and release service brakes

on tractor or trailer. Can be used to control application and release of spring

brakes on tractor. Incorporates anti-compounding feature to prevent simultaneous

service and spring brake application.

Relay Valves

Control

Control

Supply

Supply

Delivery

Part No.

KN28065X 2 - 1/2" PT 2 - 1/2" PT 2 - 1/4" PT 4.0 ±1 PSI 3 lbs. VF V5 VK1016M

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

KN28071X, KN28140X

Control

Cover

Control

Supply

Delivery

Used to apply and release service brakes

on tractor or trailer. Can be used to control application and release of spring

brakes on tractor. Incorporates anti-compounding feature to prevent simultaneous

service and spring brake application.

Comments

Midland

2 Port Delivery

KN28140X

Shown

Part No.

KN28071X 1 - 1/2" PT 2 - 1/2" PT 1 - 1/4" PT 1 - 1/8" PT 4.0 ±1 PSI 3 lbs. VH V7 VK1016M Cover, as shown

KN28140X 1 - 1/2" PT 2 - 1/2" PT 1 - 1/4" PT -- 4.0 ±1 PSI 3 lbs. VH V7 VK1016M Cover, rotated 90°

Supply

Ports

Delivery

Ports

Control Po rts

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

11

Page 12

Relay Valves

Midland

KN28060X,

KN28061X, KN28132X

Supply

Part No.

KN28060X 2 - 1/2" PT 2 - 3/8" PT 1 - 3/8" PT

Supply

Ports

Delivery

Ports

"

"

Control

Ports

"

Midland

KN28131X

Crack

Pressure

4.6 ±1.5

PSI

4.6 ±1.5

Control

Used to apply and release service brakes

on tractor or trailer.

Delivery

Core

Wght.

Class

3 lbs. VF V5 VK1016M

Core

Grp.

Minor

Maint. Kit

2 Port Delivery

KN28060X

Shown

Comments

2 Port Delivery

Used to apply and release service brakes

on tractor or trailer. Can be used to control application and release of spring

brakes on tractor. Incorporates anti-compounding feature to prevent simultaneous

service and spring brake application.

Supply

Control

Delivery

Part No.

KN28131X 2 - 1/2" PT 2 - 1/2" PT 2 - 1/4" PT 4.0 ±1 PSI 3 lbs. VH V7 VK1016M

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

12

Control

Supply

Comments

Page 13

Midland

KN28130X

Relay Valves

2 Port Delivery

Used to apply and release service brakes

on tractor or trailer. Can be used to control application and release of spring

brakes on tractor. Incorporates anti-compounding feature to prevent simultaneous

service and spring brake application.

Control

Control

Supply

Delivery

Part No. Supply Ports

KN28130X 1 - 1/2" PT 1 - 3/8" PT 2 - 1/2" PT 2 - 1/4" PT 4.0 ±1 PSI 3 lbs. VG V6 VK1016M

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

FAB (Fast Air & Balancing)

Control

Supply

Supply

Delivery

Part No.

KN28300X 2 - 1/2" PT 2 - 1/2" PT 1 - 3/8" PT 0 PSI 3 lbs. VF V5 VK1016M

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Used on converter dollies and long wheel base

towing trailers to speed the tractor control signal to the rear trailer(s) service brakes. Original manufacturer claims a 0 psi crack pressure

and 0 psi differential.

Minor

Maint. Kit

Midland

KN28300X

Relay Valve

2 Port Delivery

Comments

13

Page 14

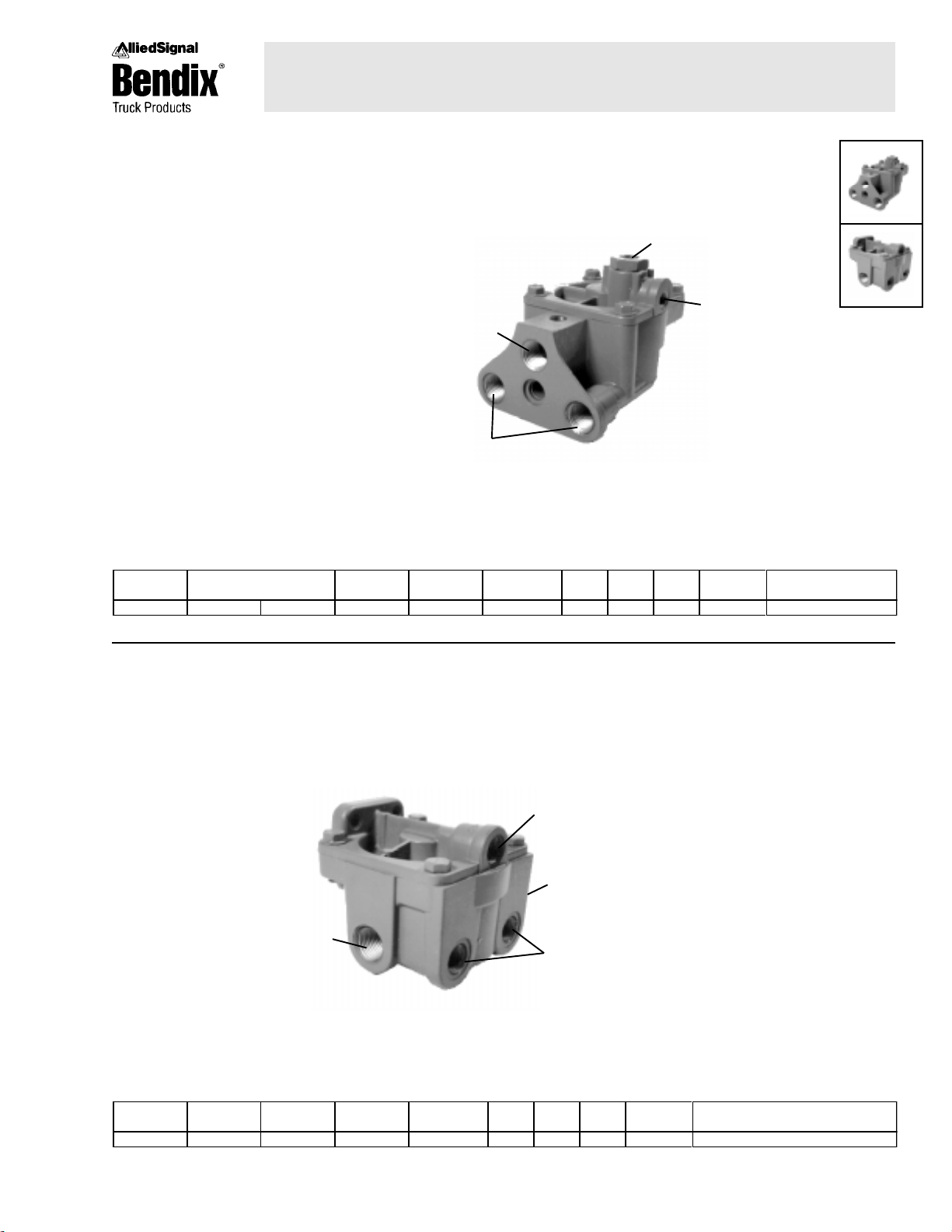

Relay Valves

Control

Midland

KN28080X, KN28085X

4 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

Supply

Delivery

Supply

Delivery

Delivery

Part No.

KN28080X 2 - 1/2" PT 4 - 3/8" PT 1 - 3/8" PT 7.0 ±1 PSI 3 lbs. VF V5 VK1016M

Supply

Ports

Delivery

Ports

"

"

Control

Ports

"

Crack

Pressure

4.6 ±1.5

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Midland/Wagner

KN28500X,

KN28510X, KN28520X

KN28080X

Shown

Comments

RG-2 Relay Valve

Supply

Core

Grp.

Control

Delivery

Minor

Maint. Kit

2 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

Supply

KN28500X

Shown

Part No. Supply Ports

KN28500X 2 - 3/8" PT -- 2 - 3/8" PT 1 - 1/4" PT 5.5 PSI 2 lbs. VI V8 VK1023

KN28510X 1 - 3/8" PT 1 - 1/2" PT 2 - 3/8" PT 1 - 1/4" PT 5.5 PSI 2 lbs. VI V8 VK1023

KN28520X 2 - 1/2" PT -- 2 - 1/2" PT 1 - 1/4" PT 5.5 PSI 2 lbs. VI V8 VK1023

Delivery

Ports

Delivery

Control

Ports

Crack

Pressure

Wght.

Core

Class

14

Comments

Page 15

Midland/Wagner

A80070X

Relay Valves

RS Relay Valve

Service

2 Port Delivery

Used apply and release service brakes on

trailer.

Supply

Delivery

Part No.

A80070X 1 - 1/2" PT 2 - 3/8" PT 1 - 1/4" PT N/A 3 lbs. VK W1 VK1026

Supply

Ports

Delivery

Ports

Service

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

Midland/Wagner

A85490X, A85493X

Control

RG-4 Tandem Valve

4 Port Delivery

Used to apply and release service brakes

on trailer. Is two relay valves in one housing with a single control port. Has dependent supplies (2) and treats the service

brakes on two axles dependently.

Supply

Delivery

Supply

Delivery

Part No.

A85490X 2 - 1/2" PT 4 - 3/8" PT 1 - 1/4" PT N/A 4 lbs. VK W1 VK1024 Tank Mtg.

A85493X 2 - 1/2" PT 4 - 3/8" PT 1 - 1/4" PT N/A 4 lbs. VK W1 VK1024 Frame Mtg.

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

A85490X

Shown

Comments

15

Page 16

Relay Valves

Control

Delivery

Supply

Midland/Wagner

A86473X, A86477X,

A103600X

RF Relay Valve

4 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

A86473X

Shown

Part No.

A86473X 1 - 1/2" PT 4 - 1/2" PT 1 - 1/4" PT 4.5 ±1 PSI 3 lbs. VJ V9 VK1022

A86477X 1 - 3/4" PT 4 - 1/2" PT 1 - 1/4" PT 4.5 ±1 PSI 3 lbs. VJ V9 VK1022

A103600X 2 - 3/4" PT 4 - 3/8" PT 1 - 1/4" PT 4.5 ±1 PSI 3 lbs. VJ V9 VK1022

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Midland/Wagner

A97600X

RS-2 Tandem Valve

4 Port Delivery

Used to apply and release service brakes

on trailer. Is two relay valves in one housing with a single control port. Has dependent supplies (2) and treats the service

brakes on two axles dependently.

Supply

Control

Delivery

Comments

Supply

Delivery

Part No.

A97600X 2 - 1/2" PT 4 - 3/8" PT 1 - 1/4" PT N/A 4 lbs. VK W1 VK1024

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

16

Comments

Page 17

Sealco

110375X

Relay Valves

LOV-CF Control Line Valve

Control

1 Port Delivery

Used on converter dollies to speed the tractor

control signal to the rear trailer(s) service

brakes. Original manufacturer claims a 1.5 psi

crack pressure.

Delivery

Part No.

110375X 1 - 1/2" PT 1 - 3/8" PT 1 - 3/8" PT 1.5 PSI 3 lbs. VP W6 VK1011S

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Supply

Comments

Control

Control

Delivery

Supply

Part No.

3100X 1 - 3/8" PT 2 - 1/4" PT 2 - 1/4" PT N/A 3 lbs. VM W3 VK1006S

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Delivery

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Sealco

3100X

Mini-Relay Valve

2 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

Comments

17

Page 18

Relay Valves

Control

Delivery

Control

Delivery

Sealco

9125X

2 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

Wght.

Supply

Core

Class

Core

Grp.

Maint. Kit

Supply

Part No.

9125X 2 - 1/2" PT 2 - 3/8" PT 2 - 1/4" PT N/A 4 lbs. VN W4 VK1007S

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Sealco

110197X

Trailer Relay Valve

2 Port Delivery

Used to apply and release service brakes

on tractor or trailer.

Control

Minor

Comments

Control

Delivery

Part No.

110197X 1 - 1/2" PT 2 - 3/8" PT 2 - 3/8" PT 4.0 PSI 4 lbs. VN W4 VK1007S

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

18

Supply

Comments

Page 19

Sealco

110410X, 110360X

LOV-2

(Low Opening Valve)

2 Port Delivery

Used to apply and release service brakes

on trailer. Original manufacturer claims a

1.5 psi crack pressure.

110360X

Shown

Delivery

Relay Valves

Control

Delivery

Supply

Part No.

110410X 1 - 1/2" PT 2 - 3/8" PT 1 - 3/8" PT 4.0 PSI 3 lbs. VP W6 VK1011S

110360X 1 - 1/2" PT 2 - 3/8" PT 1 - 3/8" PT 1.5 PSI 3 lbs. VP W6 VK1011S

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Control

Used on trailers only to apply and release

service brakes. Delivers slightly higher

pressure to trailer service brakes than the

control signal received from the tractor.

Supply

Reservoir

Delivery

Comments

Sealco

110139X

Ratio Relay Valve

4 Port Delivery

Delivery

Part No.

110139X 1 - 3/8" PT 1 - 3/4" PT 4 - 3/8" PT 1 - 3/8" PT N/A 3 lbs. VO W5 VK1008S

Supply

Ports

Reservoir

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

19

Comments

Page 20

Relay Valves

Sealco

110415X, 110380X

Control

Used to apply and release service brakes

on trailer. Original manufacturer claims a

1.5 psi crack pressure.

Supply

Delivery

Part No.

110415X 1 - 1/2" PT 4 - 3/8" PT 1 - 3/8" PT 4.0 PSI 3 lbs. VQ W7 VK1011S

110380X 1 - 3/4" PT 4 - 3/8" PT 1 - 3/8" PT 1.5 PSI 3 lbs. VQ W7 VK1011S

Supply

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

LOV-4

(Low Opening Valve)

4 Port Delivery

110415X

Shown

Comments

20

Page 21

Midland/Berg

12350X

Relay Emergency Valves

4 Port Delivery

Used on converter dollies and pre-1975

trailers. Relay function applies & releases

service brakes during normal operation.

Automatically applies all service brakes

when trailer supply (emergency) line loses

pressure (disconnected or break away).

Emergency

Control

Delivery

Emergency

Supply

Delivery

Delivery

Part No.

12350X 1 - 3/4" PT 4 - 3/8" PT 1 - 1/4" PT 2 - 3/8" PT N/A 3 lbs. VX X5 N/A

Supply

Ports

Delivery

Ports

Control

Ports

Emerg.

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

21

Page 22

Relay Emergency Valves

Service

Reservoir

ReservoirEmergency

Delivery

Midland

KN30010X

4 Port Delivery

Used on converter dollies and pre-1975

trailers. Relay function applies & releases

service brakes during normal operation.

Automatically applies all service brakes

when trailer supply (emergency) line loses

pressure (disconnected or break away).

Aux.

Part No.

KN30010X 1 - 3/4" PT 1 - 1/4" PT 4 - 1/4" PT 1 - 1/4" PT 1 - 1/4" PT N/A 5 lbs. VW X4 VK1015M

Reservoir

Ports

Aux.

Reservoir

Delivery

Ports

Service

Ports

Emerg.

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Midland/Wagner

KN30100X, KN30200X,

KN30300X, KN30400X

Emergency

4 Port Delivery

Used on converter dollies and pre-1975 trailers. Relay function applies & releases service brakes during normal operation. Automatically applies all service brakes when

trailer supply (emergency) line loses pressure (disconnected or break away).

KN30100X

Shown

Delivery

Service

Reservoir

Aux.

Reservoir

Minor

Maint. Kit

Part No. Reservoir Ports

KN30100X -- -- 4 - 1/4" PT 1 - 1/4" PT 1 - 1/4" PT 4.5 ±1PSI 3 lbs. VV X3 VK1022W

KN30200X 1 - 3/4" Nipple 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 1 - 3/8" PT 4.5 ±1PSI 3 lbs. VV X3 VK1022W

KN30300X 1 - 3/4" Nipple -- 4 - 1/4" PT 1 - 1/4" PT 1 - 1/4" PT 4.5 ±1PSI 3 lbs. VV X3 VK1022W

1 - 3/4" Female

Aux.

Reservoir

Delivery

Ports

"

Service

Ports

"

Emerg.

Ports

"

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

22

Page 23

Sealco

110267X, 110338X

Relay Emergency Valves

4 Port Delivery

Used on converter dollies and pre-1975

trailers. Relay function applies & releases

service brakes during normal operation.

Automatically applies all service brakes

when trailer supply (emergency) line loses

pressure (disconnected or break away).

110267X

Shown

Emergency

Service

Service

Delivery

Supply

Delivery

Part No.

110267X 1 - 3/8" PT 1 - 3/4" PT 4 - 3/8" PT 2 - 3/8" PT 1 - 3/8" PT 5.5 PSI 6 lbs. VO W5 VK1010S

110338X 1 - 3/8" PT 1 - 3/4" PT 4 - 3/8" PT 2 - 3/8" PT 1 - 3/8" PT 4.5 PSI 6 lbs. VO W5 VK1010S

Supply

Ports

Reservoir

Ports

Delivery

Ports

Service

Ports

Emerg.

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

110200X, 110205X

Service

Service

Emergency

Reservoir

Emerg.

Ports

Delivery

Crack

Pressure

Wght.

Core

Class

Delivery

Part No.

110200X 1 - 3/4" PT 4 - 3/8" PT 2 - 1/4" PT 1 - 1/4" PT 4.5 PSI 7 lbs. VO W5 VK1010S

110205X 1 - 3/4" PT 4 - 3/8" PT 2 - 3/8" PT 1 - 3/8" PT 4.5 PSI 7 lbs. VO W5 VK1010S

Reservoir

Ports

Delivery

Ports

Service

Ports

Ratio Relay Emergency

4 Port Delivery

Used on pre-1975 trailers. Relay function

applies & releases service brakes during

normal operation. Automatically applies all

service brakes when trailer supply (emergency) line loses pressure (disconnected

or break away). Special feature: During

normal braking, was designed to provide

a higher application pressure to trailer

brakes than the signal received from tractor.

110200X

Core

Grp.

Minor

Maint. Kit

Sealco

Shown

Comments

23

Page 24

Relay Emergency Valves

Control

Control

Delivery

Reservoir

Sealco

A1000X

4 Port Delivery

Used on converter dollies and pre-1975

trailers. Relay function applies & releases

service brakes during normal operation.

Automatically applies all service brakes

when trailer supply (emergency) line loses

pressure (disconnected or break away).

Sealco

10005AX

Cartridge for A1000X

Supply

10005AX

Cartridge

Part No.

A1000X 1 - 1/4" PT 1 - 1/2" PT 4 - 1/4" PT 2 - 1/4" PT 1.5 PSI 6 lbs. WI Y7 VK1012S

10005AX -- -- -- -- -- 1 lbs. WJ Y8 VK1001S

Supply

Ports

Reservoir

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

24

Page 25

Midland/Berg

12360X, 12361X

Trailer Spring Brake Valves

TASK Valve

Reservoir

4 Port Delivery

Used on 121 trailers to control both parking and emergency brake functions. Also

controls reservoir charging and air pressure retention upon loss of trailer supply

(emergency) line pressure. Automatically

applies emergency (parking) brakes when

trailer supply (emergency) line pressure

is lost (disconnected or break away).

12360X

Service

Supply

Delivery

Emergency

Delivery

Shown

Part

No.

12360X 1 - 3/4" PT 2 - 3/8" PT 4 - 3/8" PT 1 - 1/4" PT 1 - 1/4" PT 3 lbs. VZ X7 VK1021B With Anti-Componding

Supply

Ports

-

"

Reservoir

Ports

-

"

Delivery

Ports

-

"

Service

Ports

-

"

Emerg.

Ports

-

"

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

Without

Midland/Wagner

KN26000X, KN26010X

Supply

Cover

Used on 121 trailers to control both parking and emergency brake functions. Also

controls reservoir charging and air pressure retention upon loss of trailer supply

(emergency) line pressure. Automatically

applies emergency (parking) brakes when

trailer supply (emergency) line pressure

is lost (disconnected or break away).

Supply

Control

Reservoir

Delivery

Part No.

KN26000X 2 - 3/8" PT 1 - 1/2" PT 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 3 lbs. VY X6 VK1025 Cover as shown

KN26010X 2 - 3/8" PT 1 - 1/2" PT 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 3 lbs. VY X6 VK1025 Cover rotated 180°

Supply

Ports

Reservoir Ports

Delivery

Ports

Control

Ports

Wght.

Core

Class

Core

Grp.

RT-4 Valve

4 Port Delivery

KN26000X

Shown

Minor

Maint. Kit

Comments

25

Page 26

Trailer Spring Brake Valves

Supply

Control

Reservoir

Supply

Delivery

Reservoir

Midland/Wagner

A88802X, A88812X

RT Valve

4 Port Delivery

Used on 121 trailers to control both parking and emergency brake functions. Also

controls reservoir charging and air pressure retention upon loss of trailer supply

(emergency) line pressure. Automatically

applies emergency (parking) brakes when

trailer supply (emergency) line pressure

is lost (disconnected or break away).

A88802X

Shown

Part No.

A88802 2 - 3/8" PT 1 - 1/2" PT 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 3 lbs. WA X8 VK1027 With Anti-Compounding

Supply

Ports

"

Reservoir Ports

"

Delivery

Ports

"

Control

Ports

"

Wght.

"

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

Without

Midland/Wagner

A98730X, A99370X

RT-2 Valve

4 Port Delivery

Used on 121 trailers to control both parking and emergency brake functions. Also

controls reservoir charging and air pressure retention upon loss of trailer supply

(emergency) line pressure. Automatically

applies emergency (parking) brakes when

trailer supply (emergency) line pressure

is lost (disconnected or break away).

A98730X

Shown

Supply

Reservoir

Supply

Control

Reservoir

Delivery

Part No.

A98730X 2 - 3/8" PT 1 - 1/2" PT 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 3 lbs. WA X8 VK1027

A99370X 1 - 3/8" PT 1 - 1/2" PT 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 3 lbs. WA X8 VK1027

Supply

Ports

Reservoir Ports

Delivery

Ports

Control

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

26

Comments

With

Anti-Compounding

Without

Anti-Compounding

Page 27

Sealco

110147X

Ratio Relay Valve

4 Port Delivery

Used on 121 trailers to control both parking and emergency brake functions. Also

controls reservoir charging and air pressure retention upon loss of trailer supply

(emergency) line pressure. Automatically

applies emergency (parking) brakes when

trailer supply (emergency) line pressure

is lost (disconnected or break away). Generally used in a three reservoir system on

tandem axle trailers. Has anti-compound

feature to prevent simultaneous service

and parking applications.

Trailer Spring Brake Valves

Supply

Supply

Service

Service

Reservoir

Delivery

Delivery

Part No.

110147X 2 - 3/8" PT 1 - 3/4" PT 4 - 3/8" PT 2 - 3/8" PT N/A 5 lbs. VT X1 VK1008S

Supply

Ports

Reservoir

Ports

Delivery

Ports

Service

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

110170X, 110171X,

Supply

110170X

Shown

Reservoir

Cover

Control

Reservoir

Delivery

110191X, 110310X,

110315X

Ratio Relay Valve

4 Port Delivery

Used on 121 trailers to control both parking and emergency brake functions. Also

controls reservoir charging and air pressure retention upon loss of trailer supply

(emergency) line pressure. Automatically

applies emergency (parking) brakes when

trailer supply (emergency) line pressure

is lost (disconnected or break away). Generally used in a two reservoir system on

tandem axle trailers. Has anti-compound

feature to prevent simultaneous service

and parking applications.

Comments

Sealco

Part No.

110170X 1 - 3/8" PT 2 - 1/2" PT -- 4 - 3/8" PT 1 - 3/8" PT 4 lbs. VU X2 VK1009S Cover as shown

110171X 1 - 3/8" PT 1 - 1/2" PT 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 4 lbs. VU X2 VK1009S Cover rotated 90°

110191X 1 - 3/8" PT 1 - 3/8" PT 1 - 1/2" PT 4 - 3/8" PT 1 - 3/8" PT 4 lbs. VU X2 VK1009S Cover rotated 90°

110310X 1 - 3/8" PT 1 - 3/8" PT 1 - 1/2" PT 4 - 3/8" PT 1 - 3/8" PT 4 lbs. VU X2 VK1009S Cover as shown

110315X 1 - 3/8" PT 1 - 1/2" PT 1 - 3/8" PT 4 - 3/8" PT 1 - 3/8" PT 4 lbs. VU X2 VK1009S Cover as shown

Supply

Ports

Reservoir Ports

Delivery

Ports

Control

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

27

Page 28

Tractor Spring Brake Valves

Control

Delivery

Supply

Reservoir

Midland

KN28030X

Inversion Valve

Provides modulated control of spring

brakes (emergency) in the event of loss

of service pressure in the rear axle service system (primary).

Part No.

KN28030X 1 - 1/4" PT 1 - 1/4" PT 1 - 1/4" PT 1 - 1/4" PT N/A 2 lbs. WE Y3 N/A

Supply

Ports

Reservoir

Ports

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Midland

KN32040X

Quick Release Valve

With Two Way Check

Primarily used to deliver hold-off air pressure to the emergency (parking) side of

spring brakes. Prevents compounding of

service (air) and parking (spring) brake

applications through the two way check

valve.

Delivery

Control

Delivery

Comments

Part No.

KN32040X 2 - 1/4" PT 2 - 1/4" PT N/A 1 lbs. WD Y2 VK1018M

Delivery

Ports

Control

Ports

Crack

Pressure

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

28

Comments

Page 29

Midland

KN34030X

2 Line Automatic Style

In everyday use, valve shuts off the trailer

service (control) and emergency (supply)

lines before disconnecting the tractor from

the trailer. In emergency, protects tractor

air system by closing both lines to trailer

during break away condition.

Tractor Protection Valves

Tractor

Control

Trailer

Service

Dash

Valve

Trailer

Emergency

Part No.

KN34030X 1 - 3/8" PT 1 - 1/2" PT 1 - 1/2" PT 1 - 3/8" PT 2 lbs. WG Y5 VK1002M

Tractor

Control

Trailer

Service

Tractor

Control

Trailer

Emerg.

Dash

Valve

Wght.

Class

Stoplight

Switch

Core

Core

Grp.

Minor

Maint. Kit

Trailer

Reservoir

Service

Trailer

Emergency

Dash

Valve

Comments

Midland

KN34050X, KN34070X

3 Line Automatic Style

In everyday use, valve shuts off the trailer

service (control) and emergency (supply)

lines before disconnecting the tractor from

the trailer. In emergency, protects tractor

air system by closing both lines to trailer

during break away condition.

KN34050X

Shown

Part No.

KN34050X 1 - 3/8" PT 1 - 3/8" PT 1 - 1/2" PT 1 - 1/2" PT 1 - 1/4" PT -- 2 lbs. WG Y5 VK1002M

KN34070X 1 - 3/8" PT 1 - 3/8" PT 1 - 1/2" PT 1 - 1/2" PT 1 - 1/4" PT 1 - 1/8" PT 2 lbs. WG Y5 VK1002M

Reservoir

Ports

Tractor

Control

Trailer

Service

Trailer

Emerg.

Dash

Valve

Stoplight

Switch

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

29

Page 30

Tractor Protection Valves

Tractor

Service

Tractor

Emergency

Trailer

Service

Trailer

Emergency

Midland

KN34060X

2 Line Non-Automatic Style

In everyday use, valve shuts off the trailer service (control) and emergency (supply) lines

before disconnecting the tractor from the trailer.

In emergency, protects tractor air system by

closing both lines to trailer during break away

condition.

Part No.

KN34060X 1 - 3/8" PT 1 - 1/2" PT 1 - 1/4" PT 1 - 1/2" PT 2 lbs. WF Y4 N/A

Tractor

Service

Trailer

Service

Tractor

Emerg.

Trailer

Emerg.

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Midland

KN34080X, KN34090X

2 Line Manifold Style

In everyday use, valve shuts off the trailer

service (control) and emergency (supply)

lines before disconnecting the tractor from

the trailer. In emergency, protects tractor

air system by closing both lines to trailer

during break away condition.

KN34080X

Shown

Hand

Control

Foot

Control

Tractor

Emergency

Comments

Stoplight

Switch

Trailer

Service

Trailer

Emergency

Part No.

KN34080X 1 - 3/8" PT 1 - 3/8" PT 1 - 3/8" PT 1 - 1/4" PT 1 - 3/8" PT 1 - 3/8" PT 2 - 3/8" PT 2 lbs. WH Y6 N/A

KN34090X 1 - 1/2" PT 1 - 3/8" PT 1 - 1/2" PT 1 - 1/4" PT 1 - 3/8" PT 1 - 3/8" PT 2 - 3/8" PT 3 lbs. WH Y6 N/A

Trailer

Service

Tractor

Emerg.

Trailer

Emerg.

Stoplight Switch

Hand

Control

Foot

Control

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

30

Page 31

Midland

KN22100X

Single Circuit

Foot operated service brake control. Used

primarily on pre-1975 vehicles to control

service brakes. All supply and delivery

ports are common.

Foot Operated Valves

Delivery

Supply

Part No. Supply Ports

KN22100X 2 - 1/2" PT 2 - 1/4" PT 4 - 1/2" PT 2 lbs. VA V1 VK1014M

Delivery

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Supply

Delivery

Delivery

Supply

Comments

Midland

KN22140X, KN22150X

Dual Circuit

Two separated, individual service brake

circuits in a single housing. Each circuit

used to control different service brakes

(front vs. rear). Supply and delivery ports

common in each individual circuit. Used

on 1975 to present vehicles.

KN22150X

Shown

Part No.

KN22140X 4 - 3/8" PT 4 - 3/8" PT 2 lbs. VB V2 VK1017M

KN22150X 4 - 3/8" PT 4 - 3/8" PT 3 lbs. VB V2 VK1017M Plastic Cover

Supply

Ports

Delivery

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

31

Page 32

Foot Operated Valves

Sealco

110400X

Dual Circuit

Two separated, individual service brake

circuits in a single housing. Each circuit

used to control different service brakes

(front vs. rear). Supply and delivery ports

common in each individual circuit. Used

on 1975 to present vehicles.

Delivery

Delivery

Part No.

110400X 4 - 3/8" PT 4 - 3/8" PT 4 lbs. VC V3 N/A

Supply

Ports

Delivery

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Supply

Supply

Comments

32

Page 33

Fuller

A3546X

Transmission Shift Valve

Transmission Valves

Inlet

Outlet

Core

Part No. Inlet Outlet Wght.

A3546X 1 - 1/8" PT 1 - 1/8" PT 1 lbs. WM Z2 VK1004F

Class

Supply

Core

Grp.

Delivery

Minor

Maint. Kit

Supply

Comments

Fuller

A3547X

Range Selector Valve

Control

Part No.

A3547X 2 - 1/8" PT 1 - 1/8" PT 1 - 1/8" PT 4 lbs. WO Z4 VK1005F

Supply

Ports

Delivery

Ports

Control

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

33

Comments

Page 34

Transmission Valves

Fuller

A3991X, A4668X

Cover

Range Selector Valve

Delivery

Control

Supply

Supply

Part No.

A3991X 2 - 1/8" PT 1 - 1/8" PT 1 - 1/8" PT 4 lbs. WO Z4 VK1005F Cover as shown

A4668X 2 - 1/8" PT 1 - 1/8" PT 1 - 1/8" PT 4 lbs. WO Z4 VK1005F Cover rotated 180°

Supply

Ports

Delivery

Ports

Control

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

34

Page 35

Neway

90054007X

Leveling Valve

Used to maintain a set distance between

axle and frame on vehicles equipped with

air suspension. Valve increases or decreases air pressure to suspension based

vehicle load.

Miscellaneous Valves

Supply

Delivery

Supply

Part No.

90054007 2 - 1/8" PT 1 - 1/8" PT 2 lbs. WL Z1 VK1003N

Supply

Ports

Delivery

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Double

Check

Supply

Supply

Delivery

Exhaust

Supply

Comments

Sloan

401033X, 401037X

Push-Pull Dash Valve

401033X

Shown

Part No.

401033X 3 - 1/4" PT 2 - 1/4" PT Threaded 2 lbs. WK Y9 N/A With double check valve (as Illustrated)

401037X 1 - 1/4" PT 2 - 1/4" PT Non-Thread 2 lbs. WK Y9 N/A Without double check valve (not illustrated)

Supply

Ports

Delivery

Ports

Exhaust

Ports

Wght.

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

35

Page 36

Miscellaneous Valves

Cummins

6997312X, 6997324X

Outlet

Inlet

Fuel Solenoid Valve

6997312X

Shown

Part No. Inlet Outlet Voltage Wght.

6997312X 1 - 1/4" PT 1 - 1/4" 12 volts 1 lbs. WQ Z6 N/A Outlet is Non-Threaded

6997324X 1 - 1/4" PT 1 - 1/4" 24 volts 1 lbs. WQ Z6 N/A Outlet is Non-Threaded

Core

Class

Core

Grp.

Minor

Maint. Kit

Comments

36

Page 37

Maintenance Repair Kits

Minor Maintenance Repair Kit Cross Reference

The Minor Maintenance Repair Kits include the seals and valves required to repair typical leakage problems. In most cases, hard parts like springs and pistons are not included.

Below is a cross reference listing the Minor Maintenance Kit part number and the valve part

number(s) it services. In the Part Number to Page Index located on pages 4 and 5 of this catalog,

you will find a listing by valve part number and the Minor Maintenance Kit that services each

valve.

Maint. Kit

Part Number

VK1000K 5457X Kelsey Relay Valve 7

VK1001S 10005AX Sealco Cartridge 22

VK1002M KN34030X Midland Tractor Protection Valve 27

VK1003N 90054007X Neway Leveling Valve 33

VK1004F A3546X Fuller Shift Valve 31

VK1005F A3547X Fuller Range Selector Valve 31

VK1006S 3100X Sealco Mini-Relay Valve 15

VK1007S 110197X Sealco Trailer Relay Valve 16

VK1008S 110139X Sealco Relay Valve 17

VK1009S 110170X Sealco Ratio Relay Emergency Valve 25

VK1010S 110200X Sealco Ratio Relay Emergency Valve 21

VK1011S 110360X Sealco LOV (Low Opening Valve) 17

VK1012S A1000X Sealco Relay Emergency Valve 22

VK1013M KN28010X Midland Relay Valve 8

Valve

Part Number Model Description

5461X Kelsey Relay Valve 7

5462X Kelsey Relay Valve 7

5470X Kelsey Relay Valve 7

KN34050X Midland Tractor Protection Valve 27

KN34070X Midland Tractor Protection Valve 27

A3991X Fuller Range Selector Valve 32

A4668X Fuller Range Selector Valve 32

9125X Sealco Relay Valve 16

110147X Sealco Ratio Relay Emergency Valve 25

110171X Sealco Ratio Relay Emergency Valve 25

110191X Sealco Ratio Relay Emergency Valve 25

110310X Sealco Ratio Relay Emergency Valve 25

110315X Sealco Ratio Relay Emergency Valve 25

110205X Sealco Ratio Relay Emergency Valve 21

110267X Sealco Relay Emergency Valve 21

110338X Sealco Relay Emergency Valve 21

110375X Sealco LOV-CF Control Line Valve 15

110380X Sealco LOV (Low Opening Valve) 18

110410X Sealco LOV (Low Opening Valve) 17

110415X Sealco LOV (Low Opening Valve) 18

KN28011X Midland Relay Valve 8

Catalog

Page No.

37

Page 38

Maintenance Repair Kits

Maint. Kit

Part Number

VK1014M KN22100X Midland Single Circuit Foot Valve 29

VK1015M KN30010X Midland Relay Emergency Valve 20

VK1016M KN28060X Midland Relay Valve 10

VK1017M KN22140X Midland Dual Circuit Foot Valve 9

VK1018M KN32040X Midland Quick Release Valve 26

VK1019B 12345X Mid/Berg Relay Valve 8

VK1020B 12343X Mid/Berg Relay Valve 7

VK1021B 12360X Mid/Berg TASK Valve 23

VK1022W A103600X Mid/Wagner RF Relay Valve 14

VK1023W KN28500X Mid/Wagner RG-2 Relay Valve 12

VK1024W A97600X Mid/Wagner RS-2 Tandem Relay Valve 14

VK1025W KN26000X Mid/Wagner RT-4 Spring Brake Valve 23

VK1026W A80070X Mid/Wagner RS Relay Valve 13

VK1027W A88802X Mid/Wagner RT Valve 24

Valve

Part Number Model Description

KN28061X Midland Relay Valve 10

KN28065X Midland Relay Valve 9

KN28071X Midland Relay Valve 9

KN28080X Midland Relay Valve 12

KN28085X Midland Relay Valve 12

KN28130X Midland Relay Valve 11

KN28131X Midland Relay Valve 10

KN28132X Midland Relay Valve 10

KN28140X Midland Relay Valve 9

KN28300X Midland FAB (Fast Air & Balancing) Valve 11

KN22150X Midland Dual Circuit Foot Valve 29

12346X Mid/Berg Relay Valve 8

12361X Mid/Berg TASK Valve 23

A86473X Mid/Wagner RF Relay Valve 14

A86477X Mid/Wagner RF Relay Valve 14

KN30100X Mid/Wagner Relay Emergency Valve 20

KN30200X Mid/Wagner Relay Emergency Valve 20

KN30300X Mid/Wagner Relay Emergency Valve 20

KN30400X Mid/Wagner Relay Emergency Valve 20

KN28510X Mid/Wagner RG-2 Relay Valve 12

KN28520X Mid/Wagner RG-2 Relay Valve 12

A85490X Mid/Wagner RG-4 Tandem Relay Valve 13

A85493X Mid/Wagner RG-4 Tandem Relay Valve 13

KN26010X Mid/Wagner RT-4 Spring Brake Valve 23

A88812X Mid/Wagner RT Valve 24

A98730X Mid/Wagner RT-2 Valve 24

A99370X Mid/Wagner RT-2 Valve 24

Catalog

Page No.

38

Page 39

Product Warranty

WARRANTY

AIR BRAKE PRODUCTS

The AlliedSignal Truck Brake Systems Company warrants to the original retail purchaser of air brake products* that all products sold by AlliedSignal Truck Brake Systems Company will be free of defective materials

and workmanship, including Bendix Truck Product, for 12 months; 100,000 miles (160,000 kilometers) or

3,600 hours, EXCEPT for the following devices:

WARRANTY PERIOD

DEVICE

Mos.

FD-3 TorqueMaster Fan Clutch 36 300,000 (480,000) 10,800

Miles

(kilometers)

Hours

Tu-Flo 501 & Tu-Flo 550

Compressors

Tu-Flo 700 & Tu-Flo 750

Compressors EL1300 & EL1600

Midland Style Compressors

The above does not include defects caused by improper installation, maintenance or service.

Products claimed to be defective should be returned freight prepaid to AlliedSignal Truck Brake Systems

Company within 30 days after the date any defect is first discovered. AlliedSignal Truck Brake Systems

Company will inspect the product and make the final determination as to whether the product is covered

under the terms of this warranty.

When a warranty claim is allowed, AlliedSignal Truck Brake Systems Companys responsibility is limited, at

AlliedSignal Truck Brake Systems Companys option, to repair or replace the defective product. For the first

12 months, 100,00 miles (160,000 kilometers), or 3,600 hours, whichever occurs first, AlliedSignal Truck

Brake Systems Company will also allow its current labor allowance for removal and replacement when the

defective product has been installed.

THIS WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, ARISING BY OPERATION OF LAW OR OTHERWISE, INCLUDING ANY IMPLIED WARRANTY

OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, AND IN NO EVENT WILL ALLIED TRUCK BRAKE SYSTEMS COMPANY BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES INCLUDING BUT NOT LIMITED TO COSTS INCURRED FOR SERVICE CALLS, TOWING, OR

DOWNTIME.

24 200,000 (320,000) 7200

*Friction materials, Foundation Brakes, ASA-5 Automatic Slack Adjusters, and Hydraulic Brake products are covered under a separate

warranty.

39

Page 40

Sample Core Return Memo

PLEASE PACK WARRANTY MATERIAL

SEPARATE FROM CORES AND ATTACH

LISTING TO CORE RETURN FORM

40

Page 41

Inside Rear Cover

Page 42

Outside Rear

Cover

BW1746 © AlliedSignal Inc. January 1995 Printed in U.S.A.

Loading...

Loading...