Page 1

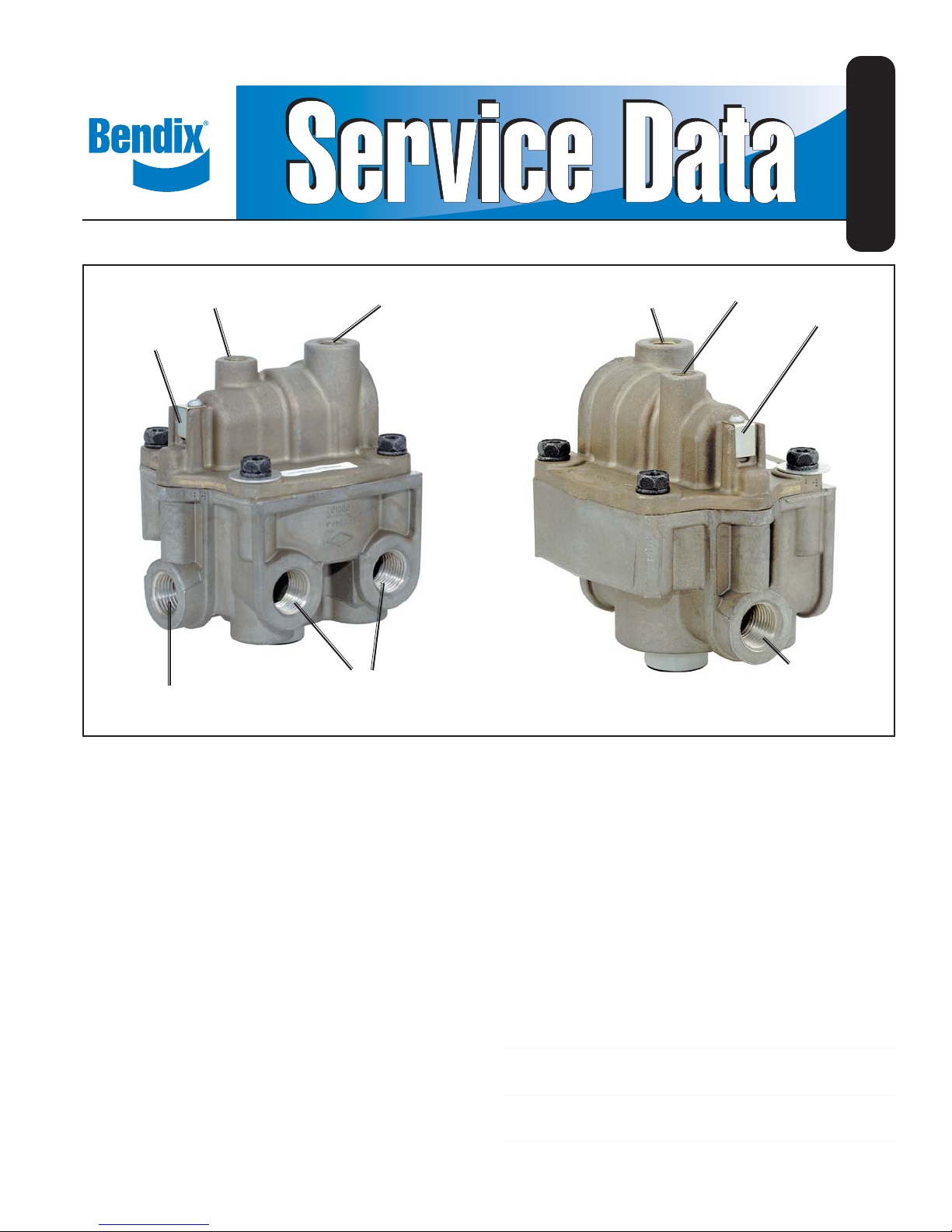

Bendix® BP-R1™ Bobtail Proportioning Relay Valve

SD-03-1067

EXHAUST

SUPPLY

CONTROL

SERVICE

DELIVERY

CONTROL

SERVICE

EXHAUST

SUPPLY

DESCRIPTION

The BP-R1™ bobtail proportioning relay valve is a combination of two individual valves in a single housing. The lower

portion, or body , of the BP-R1

service brake relay valve, which functions as a relay station

to speed up brake application and release. The upper portion, or cover, houses a brake proportioning valve, which

reduces normal service brake application pressure when

the tractor is not towing a trailer.

Used in tractor air brake systems only, the BP-R1

is installed in place of a standard relay valve. It functions

as a standard service relay during operation of a tractortrailer combination. During bobtail tractor operation, the

BP-R1™ valve improves controllability and reduces stopping

distances by reducing air pressure to the rear actuators/

chambers, whose axle load has been greatly reduced.

While the BP-R1™ valve can incorporate various crack

pressures to accommodate specific applications, the

standard is 4 psi.

™

valve contains a “standard”

™

valve

FIGURE 1 - BP-R1™ BOBTAIL PROPORTIONING RELAY VALVE

Designed for frame or cross member mounting, the BP-R1™

valve is furnished with a mounting bracket which is attached

to two of the four cover cap screws. Replacement valves

are furnished with a universal mounting bracket, which

allows the BP-R1™ valve to replace most standard

relays.

All air connections on the BP-R1™ valve are identifi ed with

cast, embossed letters for ease of installation. The letter

identifi cation and air line connections are shown below

for reference.

BP-R1™ Valve Air Connection Embossed Identifi cation

Supply (to reservoir) SUP

Delivery (to brake actuator) DEL

Service (brake valve rear axle service delivery) SER

Control (to delivery of trailer supply valve) CON

1

Page 2

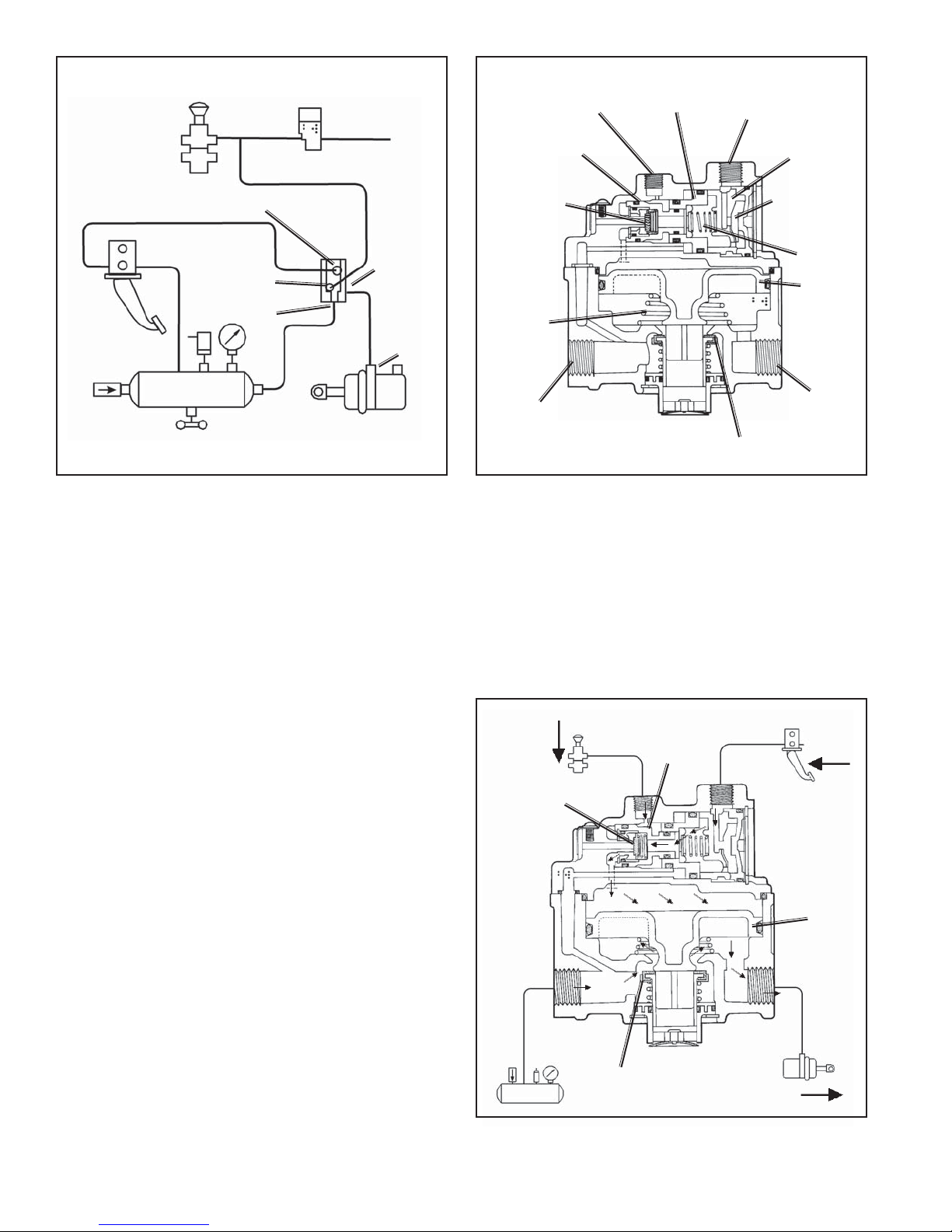

TRAILER

SUPPLY

TRACTOR

PROTECTION

CONTROL

PORT

“BLEND BACK”

PISTON

SERVICE

PORT

SERVICE PORT

BP-R1™

VALVE

CONTROL

PORT

DUAL

BRAKE

VALVE

REAR AXLE

SERVICE RESERVOIR

FIGURE 2 - BP-R1™ TRACTOR AIR SYSTEM

SUPPLY

DELIVERY

PORT(4)

SERVICE

SPRING

BRAKE

OPERATION

INITIAL CHARGING

During the initial build up of tractor system air pressure,

supply air fl ows through internal body and cover passages

in the BP-R1™ valve to the blend back piston.

PROPORTIONING

PISTON

INLET-EXHAUST

VALVE

SPRING

(NOT USED

IN ALL

MODELS)

SUPPLY

PORT

INLET-EXHAUST

VALVE

FIGURE 3 - BP-R1™ BOBTAIL PROPORTIONING RELAY

VALVE

SERVICE

PISTON

EARLIER

MODELS HAVE

A DIAPHRAGM

HERE

SPRING

RELAY

PISTON

DELIVERY

PORT

of the inlet and exhaust valve. With the exhaust passage

sealed, continued movement of the piston unseats the inlet

portion of the inlet and exhaust valve, allowing supply air

from the reservoir to fl ow out the BP-R1™ valve delivery

ports to the brake actuators. (See Figure 4.)

Activating the trailer supply valve (dash control with red

octagonal button), simultaneously charges the trailer and

the BP-R1™ valve control port. Air entering the BP-R1™

valve control port causes the proportioning piston to move

toward its stop in the cover. The integral inlet and exhaust

valve is carried along with the piston until it seats and

seals the exhaust passage. Continued movement of the

proportioning piston opens the inlet valve. With the tractor

and trailer air system fully charged, the vehicle may be

operated.

SERVICE BRAKES APPLYING — TRACTOR/

TRAILER COMBINATION

Brake application air enters the BP-R1™ valve service port

and is conducted through the service piston to the exhaust

diaphragm which fl exes in response to the incoming air and

seals the exhaust passage in the exhaust piston. Air fl ows

around the exhaust diaphragm then through the center of

both the blend back and proportioning pistons to the inlet

and exhaust valve. Flowing around the inlet valve, application air moves through a passage in the cover to the top of

the service relay piston. In response to air pressure, the

relay piston moves into contact with the exhaust portion

INLET-EXHAUST

VALVE

FIGURE 4 - BP-R1

COMBINATION

PROP

PISTON

INLET-EXHAUST

PISTON

™

APPLYING - TRACTOR/TRAILER

RELAY

PISTON

2

Page 3

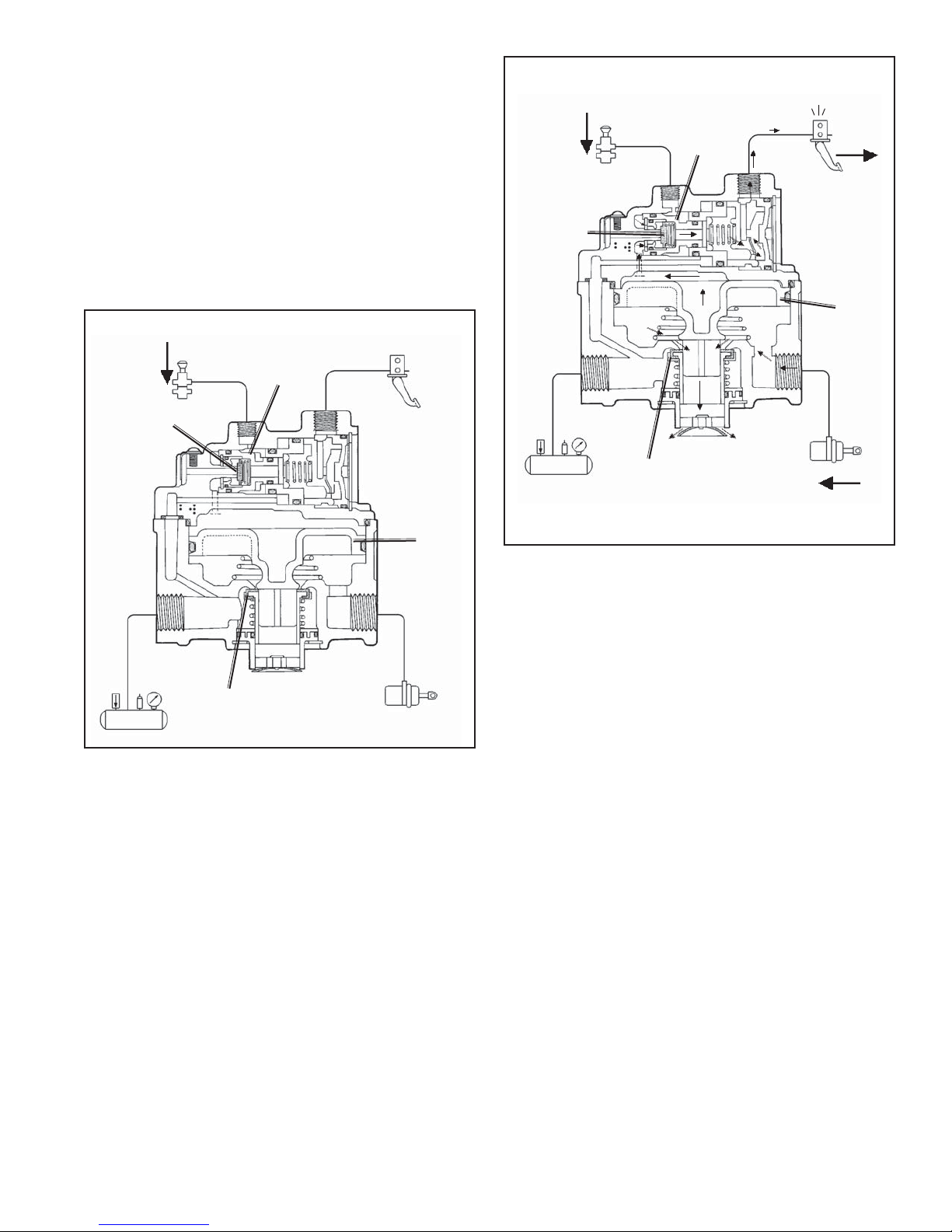

SERVICE BRAKES HOLDING — TRACTOR/

TRAILER COMBINATION

The air pressure being delivered to the brake actuators is

also present beneath the relay piston.

When the air pressure above and below relay piston is

equal, the piston moves slightly allowing the inlet valve to

return to its seat. The exhaust valve remains closed. With

both the inlet and exhaust valves closed, air pressure in

the brake actuators is held stable and neither increases

nor decreases. (See Figure 5.)

PROP

PISTON

INLET-EXHAUST

VALVE

PROP

PISTON

INLET-EXHAUST

VALVE

RELAY

PISTON

INLET-EXHAUST

PISTON

RELAY

PISTON

INLET-EXHAUST

PISTON

FIGURE 5 - BP-R1

COMBINATION

™

HOLDING - TRACTOR/TRAILER

SERVICE BRAKES RELEASING — TRACTOR/

TRAILER COMBINATION

When the brake application is released, air pressure in the

service port of the BP-R1™ valve returns to the foot brake

valve and is exhausted. Air from above the relay piston fl ows

back through the proportioning, blend back and service

pistons to the exhaust diaphragm. If the service brakes are

rapidly released, the diaphragm fl exes in response to the

returning air and opens the exhaust.

If the brakes are slowly released, service air pressure will

fl ow through the slot behind the diaphragm and back to

the brake valve. As air pressure is reduced above the relay

piston, pressure beneath it lifts the piston away from the

exhaust valve and opens the exhaust passage. Air from

the service brake actuators returns to the BP-R1

and fl ows out the open exhaust. (See Figure 6.)

™

valve

FIGURE 6 - BP-R1™ RELEASING - TRACTOR/TRAILER

COMBINATION

SERVICE APPLICATION BOBTAIL TRACTOR

When the trailer supply valve (dash control with red octagonal button) is activated to disconnect the trailer, air in the

BP-R1™ valve control port and trailer supply line is exhausted to atmosphere. During bobtail tractor operation, service

application air enters the BP-R1™ valve service port

causing the exhaust diaphragm to seal the exhaust port.

Service application air passing through the blend back

piston exerts a force on the full effective diameter of

the piston. The blend back piston remains stationary at

application pressures below approximately 80 psi because

of opposing reservoir air acting on the large diameter.

Application air fl owing through the blend back piston also

exerts a force on the small diameter of the proportioning

piston while simultaneously fl owing through the center of

it on its way to the inlet and exhaust valve. Once past the

inlet and exhaust valve, service air pressure exerts a force

on the larger diameter end of the proportioning piston,

which opposes the air pressure and spring force exerted

on the other end. The proportioning piston inlet valve

remains open until a preset, initial application pressure

has reached the relay piston assuring that the foundation brake shoes are brought into contact with the drum.

As service pressure begins to exceed the preset initial

application, the proportioning piston will move suffi ciently

to close its inlet valve without opening the exhaust.

3

Page 4

INLET-EXHAUST

VALVE

PROP

PISTON

Service applications of more than 80 psi cause the blend

back piston to begin to move. Service air pressure acting

on the full diameter of the blend back piston overcomes the

resistance of reservoir pressure acting on the large diameter of the other side. Above 80 psi the dif ference between

control and delivered air pressure is reduced and “blends

back” from a proportioned delivery to a full 1:1 delivery.

Complete “blend back” to a 1:1 delivery is achieved when

a full brake application is made, and it will occur regardless

of reservoir pressure level.

RELAY

PISTON

INLET-EXHAUST

PISTON

FIGURE 7 - BP-R1™ HOLDING - BOBTAIL TRACTOR

As service air pressure continues to increase, the inlet valve

opens as necessary to deliver additional but reduced air

pressure to the relay piston, thus to the rear axle brakes.

Proportioning occurs due to the difference in effective area

on each end of the proportioning piston.

TRACTOR/

TRAILER

COMBINATION

SERVICE BRAKES RELEASING — BOBTAIL

TRACTOR

When the brake application is released, air pressure in the

service port of the BP-R1™ valve returns to the foot brake

valve and is exhausted. Air between the closed proportioning piston inlet valve and the service piston returns to the

exhaust diaphragm. If the release is rapid, the diaphragm

fl exes in response to the returning air and opens the

exhaust.

Air from above the relay piston, fl ows back to the pro-

portioning piston causing it to move. As it moves, the

proportioning piston unseats the exhaust valve allowing

air from above the relay piston to escape to atmosphere.

Reducing the air pressure above the relay piston causes

pressure beneath it to lift the piston away from the exhaust

valve. Air from the service brake actuators returns to the

BP-R1™ valve and fl ows out the open exhaust.

PROP

PISTON

INLET-EXHAUST

VALVE

VALVE DELIVERY PORT)

™

(BP-R1

SERVICE BRAKE CHAMBER PRESSURE

0 PSI

0 PSI

FIGURE 8 - BP-R1™ CONTROL VS. DELIVERY PRESSURE

4

BRAKE VALVE DELIVERY PRESSURE

™

VALVE CONTROL PORT)

(BP-R1

RELAY

PISTON

BOBTAIL

TRACTOR

INLET-EXHAUST

PISTON

FIGURE 9 - BP-R1™ RELEASING - BOBTAIL TRACTOR

Page 5

PREVENTIVE MAINTENANCE

GENERAL

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty may be voided if intrusive maintenance is performed

during the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the valve

should be inspected every 6 months or 1500 operating

hours, whichever comes fi rst, for proper operation. Should

the valve not meet the elements of the operational tests

noted in this document, further investigation and service

of the valve may be required.

Perform the tests and inspections presented at the prescribed intervals. If the BP-R1

described or leakage is excessive, it should be repaired

or replaced with a new or genuine Bendix remanufactured

unit, available at any authorized parts outlet.

Every 3 months, or 25,000 miles or 900 operating

hours:

1. Remove any accumulated contaminates and visually

inspect the exterior for excessive corrosion and physical

damage.

2. Inspect all air lines connected to the BP-R1™ valve

for signs of wear or physical damage. Replace as

necessary.

3. Test air line fi ttings for excessive leakage and tighten

or replace as necessary.

4. Perform the Leakage Test described in this manual.

Every year, 100,000 miles, or 3,600 operating hours:

1. Perform the Operation and Leakage Tests described

in this manual.

™

valve fails to function as

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO A VOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble

or assemble a component until you have read

and thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work

on the vehicle. If the vehicle is equipped with an

AD-IS® air dryer system or a dryer reservoir module,

be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power

from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fi ttings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifi cally for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifi cally stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Antilock T raction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

OPERATION & LEAKAGE TESTS

OPERATING TEST

To properly test the function of the BP-R1™ valve, a pair of

test gauges or gauges of known accuracy must be used.

1. Park the vehicle on a level surface and block the wheels

and/or hold the vehicle by means other than the air

brakes.

2. Drain air pressure from all vehicle reservoirs.

3. Install a “tee” at the BP-R1™ valve service port and

at one of the delivery ports, then install a gauge in

each.

5

Page 6

37

36

10

30

32

34

28

21

19

17

1820

16

Note:

Early models used

a Diaphragm(19),

Dust Shield(16)

Service Piston(17),

and

o-ring(21)

15

35

12

2

31

11

33

26

24

22

20A

18

29

15

27

13

14

25

23

17A

1

9

8

7

6

5

4

BODY ...........................................1

VALVE COVER .................................2

RETAINING RING .............................. 3

EXHAUST COVER .............................4

O-RING ..........................................5

O-RING ..........................................6

VALVE SPRING ................................7

VALVE RETAINER .............................8

VALVE ASSEMBLY ............................9

CAP SCREWS ...............................10

O-RING ........................................11

RELAY PISTON .............................. 12

O-RING .......................................13

RETURN SPRING ...........................14

RETAINING RING ............................ 15

DUST SHIELD (IF FITTED) .................16

EXHAUST PISTON (ORIGINAL STYLE) ...17

EXHAUST PISTON (NEW STYLE) ......17A

EXHAUST PISTON O-RING ................18

EXHAUST DIAPHRAGM (IF FITTED) ......19

3

SERVICE PISTON (ORIGINAL STYLE- RE-

QUIRED O-RING 21) .......................20

SERVICE PISTON (NEW STYLE - DOES NOT

REQUIRE O-RING) ........................20A

SERVICE PISTON O-RING (IF FITTED) .21

SPRING ....................................... 22

SPRING CAGE ...............................23

BLEND BACK PISTON ...................... 24

O-RING ........................................25

O-RING ........................................26

O-RING ........................................27

PROPORTIONING PISTON .................28

O-RINGS .....................................29

RETAINING RING ............................ 30

O-RING .......................................31

INLET VALVE SEAT .........................32

INLET VALVE ................................. 33

VALVE SPRING ..............................34

SEALING RING ..............................35

EXHAUST COVER SCREW ................36

EXHAUST COVER ...........................37

FIGURE 10 - BP-R1™ BOBTAIL BRAKE PROPORTIONING RELAY VALVE

4. Connect the tractor service and emergency “glad

hands” (hose couplings) to hose couplings that have

been plugged, or alternatively , to a trailer. Build the tractor system air pressure to governor cut-out and make 4

to 5 full brake applications. Check the air fi ttings at the

BP-R1™ valve for leakage. Tighten as needed.

6

5. With the trailer supply valve (dash control w/red octagonal button) and system park control (dash control

with yellow diamond button) activated for tractor/trailer

operation, apply , hold, then release the brakes several

times varying the application pressures while watching the reaction of the gauges installed on the BP-R1™

valve. Check that a prompt application occurs and that

it can be held then promptly released.

Page 7

6. Check the BP-R1™ valve differential pressure by applying 10 psi to the service port and noting the pressure

registered at the delivery port. Subtract delivery port

pressure from the 10 psi service pressure to obtain the

differential. Compare the measured differential with the

™

pressure specifi ed for the BP-R1

valve part number.

Note: For BP-R1™ valves not incorporating a relay

piston return spring (14), the measured differential

should be approximately 4 psi. When a spring is in use,

the differential will be higher (see the I.D. washer also

for the differential).

7. Make and hold a full (100 psi or greater) brake

application and note that full pressure is delivered to

the chambers.

8. Activate the dash mounted trailer supply valve for

bobtail tractor operation. Then make a slow brake

application, increasing the pressure at the BP-R1™

valve service port to 20 psi while watching the reaction

at the delivery port gauge. Note that delivery pressure

rises to approximately 5 to 10 psi and remains constant

while service pressure continues to rise to 20 psi.

Release the application.

9. Make another brake application and slowly increase the

pressure at the BP-R1™ valve service port to between

60 and 70 psi while observing the gauge installed at

the delivery port. Note that when service port pressure

rises to between 20 and 30 psi, delivery pressure begins

to rise above the initial pressure noted in step 6. The

rise of delivery pressure should be at a proportioned

rate of approximately 3:1. At 70 psi service pressure,

delivered pressure should be 15 to 25 psi.

10. Make a full brake application and note that both test

gauges register the same pressure.

11. Drain air pressure from all vehicle reservoirs and

remove the test gauges from the BP-R1™ valve.

LEAKAGE TESTS

1. Build the air system pressure to governor cut-out. With

the dash mounted trailer supply valve activated for

tractor/trailer operation, apply a soap solution to both

exhaust ports (one in the cover and one in the body).

The leakage noted should not exceed a 1" bubble in

less than 3 seconds at any exhaust port.

2. Make and hold a full brake application and apply a

soap solution to both exhaust ports and around the

cover where it joins the body . The leakage noted should

not exceed a 1" bubble in less than 3 seconds at any

exhaust port.

VALVE REMOVAL

1. Park the vehicle on a level surface and block the wheels

and/or hold the vehicle by means other than the air

brakes.

2. Drain the air pressure from all vehicle reservoirs.

3. Identify and mark or label all air lines and their

respective connections on the valve to facilitate ease

of installation.

4. Disconnect all air lines.

5. Remove the valve from the vehicle.

VALVE INSTALLATION

1. Install all air line fi ttings and plugs making certain thread

sealing material does not enter the valve.

2. Install the assembled valve on the vehicle.

3. Reconnect all air lines to the valve using the identifi ca-

tion made during VALVE REMOVAL (step 3).

4. After installing the valve, test all air fi ttings for excessive

leakage and tighten as needed.

DISASSEMBLY

GENERAL

The following disassembly and assembly procedure is

presented for reference purposes only and presupposes

that the appropriate maintenance kit is on hand at the time

of disassembly . The instructions provided with the maintenance kit should always be used in lieu of those presented

here. Refer to Figure 10 throughout the disassembly and

assembly procedure.

Caution: The BP-R1™ valve may be lightly clamped in a

bench vise during disassembly, however, overclamping will cause damage to the valve and result in leakage

and/or malfunction. If a vise is to be used, position the

valve so that the jaws bear on the supply ports on opposing

sides of the valve’s body.

1. Remove all air fi ttings and plugs from the valve.

2. Mark the relationship of the valve cover to the body and

if the valve is equipped with a mounting bracket, mark

the relationship of the bracket to the cover.

3. While holding the exhaust cover (4), remove and

discard the retaining ring (3) that secures it to the body

(1).

4. Remove and discard the exhaust cover (4) along with

both o-rings (5 & 6).

5. Remove and discard the valve spring (7), valve retainer

(8), and the valve assembly (9) from the body (1).

6. Remove and retain the four cap screws (10) that secure

the cover (2) to the body (1).

7. Separate the cover (2) from the body (1), then remove

and discard the sealing ring (35) and o-ring (11).

8. Remove and retain the relay piston (13) and relay piston

spring (14) from the body (1).

Note: The relay piston spring, item 14 is not used in

all valves.

7

Page 8

9. Remove and discard the o-ring (12) from the relay

piston (13).

10. Remove and discard dust shield (16), if fi tted, and the

retaining ring (15) from the valve cover (2), then remove

and discard the exhaust piston (17 or 17A).

1 1. Remove and discard the exhaust piston o-ring (18) and

the exhaust diaphragm (19), if fi tted.

12. Remove and discard the service piston (20) and its

o-ring (21) from the valve cover (2).

13. Remove the spring (22) and spring cage (23) from the

valve cover (2). Discard the spring and retain the spring

cage.

14. Use shop air at the control port to extract the blend back

piston from the valve cover (2). Retain the blend back

piston (24), then remove and discard both o-rings (25

& 26).

15. Remove and retain the proportioning piston (28) from

the valve cover (2), then remove and discard both

o-rings (27 & 29).

16. While holding the inlet valve seat (32) in place, remove

and discard the retaining ring (30) from the proportioning piston (28).

17. Remove the inlet valve seat (32), the inlet valve (33),

and the valve spring (34) from the proportioning piston

(28), then remove and discard the o-ring (31) from the

valve seat (32). Discard the valve and spring (33 & 34)

also.

18. Remove and discard the exhaust cover screw (36) and

exhaust cover (37).

6. Make certain the air channel running between the top

surface of the body (1) and its supply port is clear and

free of obstruction.

7. Make certain all air channels and exhaust passages in

the valve cover (2) are clear and free of obstruction.

8. Inspect the pipe threads in the body (1) and valve cover

(2). Make certain they are clean and free of thread

sealant.

9. If the valve was equipped with a relay piston spring

(14), inspect it for signs of corrosion, pitting and cracks.

Replace as necessary.

10. Inspect all air line fi ttings for corrosion and replace

as necessary. Make certain to remove all old thread

sealant before reuse.

ASSEMBLY

1. Prior to assembly , lubricate all o-rings (identify by using

Figure 1 1), seals, and pistons as well as body and cover

bores, using the lubricant provided with the Bendix

maintenance kit. Use all of the lubricant and spread it

evenly on the rubbing surfaces.

2. Install the o-ring (31) on the inlet valve seat (32).

I.D."

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all metal parts. Do not damage bores

with metal tools.

2. Wash all non-metallic components (key nos. 4, 12, 17,

20, 23, 24, 28, 32) in a soap and water solution making

certain to rinse and dry thoroughly.

3. Inspect the interior and exterior of all metal parts that

will be reused for severe corrosion, pitting and cracks.

Superfi cial corrosion and/or pitting on the exterior por-

tion of the body (1) and cover (2) is acceptable. Replace

the entire valve if the interior of the body or cover exhibit

signs of corrosion or pitting.

4. Inspect each non-metallic component for cracks, wear

or distortion. Replace the entire valve if these conditions

are found.

5. Inspect the bores of both the body (1) and cover (2)

for deep scuffi ng or gouges. Replace the entire valve if

either are found.

W"

O.D."

O-RING IDENTIFICATION

KEY NO. I.D. O.D. W

5 .8620 1.068 .103

6 1.424 1.630 .103

11 3.487 3.693 .103

13 3.234 3.512 .139

18 1.356 1.496 .070

21 1.176 1.316 .070

25 1.112 1.318 .103

26 .7370 .9430 .103

27 .4120 .5520 .070

29 .7390 .8790 .070

31 .4890 .6290 .070

FIGURE 11 - O-RING IDENTIFICATION

8

Page 9

3. Install the small end of the inlet/exhaust valve spring

(34) over the rubber of the valve (33), making sure the

spring coils rest on the valve’s four tabs. Note: Both

ends of spring (34) are the same diameter on valves

manufactured after June 1990.

4. Insert the spring and valve into the valve seat (32),

making sure the four tabs are within the seat’s bore.

5. Insert the valve, seat and spring assembly into the

proportioning piston (28).

6. While holding the seat (32) in place, install the retaining

ring (30) to secure it in the piston (28). Make certain the

retaining ring is fully seated in its groove. Make sure

the valve is straight against the exhaust seat and free

to move.

7. Install both the large and small diameter o-rings (27 &

29) on the proportioning piston (28).

8. Install both the large and small diameter o-rings (25 &

26) on the blend back piston (24), then insert the small

diameter of the proportioning piston (28) into the small

diameter end of the blend back piston (24).

9. Carefully insert the assembled proportioning and blend

back pistons (24 & 28) to the edge of the bore in the

cover (2). Do not cut or pinch the o-rings.

10. With the bore of the cover facing up, install the spring

cage (23) in the blend back piston (24) so that its fl at

side rests against the blend back piston (its depressed

side out towards spring (22)).

11. Install the service piston (20) over the spring (22) in

the cage (23) so that its coils are within the l.D. of the

cage.

12. Install o-ring (18) on exhaust piston (17A).

13. Place exhaust piston on service piston with its six ribbed

side facing the service piston. Then install both pistons

while pushing the proportioning and blend back pistons

(28 & 24) all the way into the cover.

14. Install the retaining ring (15), making certain it is fully

seated in its groove.

15. Install the exhaust cover (37) using screw (36) to retain

it. Torque the screw to 8 to 15 lb. in.

16. Install the valve retainer (8) on the inlet and exhaust

valve (9) so that the fl ange of the retainer (8) surrounds

the rubber portion of the valve. Install the inlet and

exhaust valve in the body (1).

17. Install the inlet and exhaust valve return spring (7) in

the body (1).

18. Install the large and small diameter o-rings (5 & 6) in

the exhaust cover (4), then install the exhaust cover

in the body (1), taking care not to damage the o-rings.

Hold the exhaust cover in place.

19. While depressing the exhaust cover (4), install the

retaining ring (3) in the body (1). Make certain the

retainer (3) is fully seated in its groove in the body.

™

20. If the BP-R1

valve was equipped with a relay piston

return spring (15), install the spring in the body, large

diameter fi rst.

21. Using lubricant to hold them in place, install the large

and small sealing rings (11 & 35) on the cover (2).

22. Install the o-ring (12) on the relay piston (13), then install

the piston in the body (1).

23. After noting the relationship marks made prior to disassembly , install the mounting bracket (not illustrated) on

the cover (2) then secure the cover (2) and mounting

bracket on the body (1) using the four cap screws (10).

Torque the cap screws to 120 to 150 lb. in.

24. Install all air line fi ttings and plugs making certain thread

sealing material does not enter the valve.

25. Install the BP-R1™ valve on the vehicle and perform

the Operation and Leakage Tests before returning the

vehicle to service.

9

Page 10

10

BW1624 © 2007 Bendix Commercial Vehicle Systems LLC. All rights reserved. 7/2007 Printed in U.S.A.

Loading...

Loading...