Operation Manual

BSH5000

myBlock Dry Bath Incubator

Contents

CHAPTER 1 INTRODUCTION ------------------------------- ERROR! BOOKMARK NOT DEFINED.

CHAPTER 2 SPECIFICATIONS ----------------------------- ERROR! BOOKMARK NOT DEFINED.

1. AMBIENT OPERATING ENVIRONMENT: --------- ERROR! BOOKMARK NOT DEFINED.

2. TECHNICAL DATA ----------------------------- ----------- ERROR! BOOKMARK NOT DEFINED.

CHAPTER 3 OVERVIEW ----------------------------- ---------------------------- ------------------------------- 3

1. STRUCTURE OVERVIEW -------------------------------------------------------------------------------- 3

2. KEYPADS ------------------------------------------------------------------------------------------------------ 4

3. DISPLAY -------------------------------------------------------------------------------------------------------- 4

CHAPTER 4 OPERATION --------------------------------------------------------------------------------------5

1. TEMPERA TURE AND TIME SETTING ------------- ERROR! BOOKMARK NOT DEFINED.

2. ADVANCED TIME SETTING ------ ------- ------- ------- ERROR! BOOKMARK NOT DEFINED.

3. TEMPERATURE CALIBRATION --------------------- ERROR! BOOKMARK NOT DEFINED.

4.TEMPERATURE CONTROL BY EXTERNAL SENSOR ------------------------------------------ 10

CHAPTER 5 FAILURE ANALYSIS AND TROUBLESHOOTING ----------------------------------- 11

ANNEX:WIRING DIAGRAM --------------------------------------------------------------------------------- 12

BSH5000 Operation manual Chapter 1 Introduction

Chapter 1 Introduction

The dry bath incubator is controlled by sophisticated software, which

can be widely used for the preservation and reaction of samples, the

amplification of DNA, the pre-denaturation of the electrophoresis, blood

serum coagulation and a variety of laboratory procedures.

Features:

Large digital display of time and temperature

Extremely accurate temperature control up to 105°C

Built-in over-temperature protection

In-Lab calibration

Plastic lid for enhanced precision and eliminating waste of energy

Quick-Flip blocks available for a variety of tube sizes

─ 1 ─

BSH5000 Operation manual Chapter 3 Basic Instructions

Chapter 2 Specifications

1. Ambient operating environment:

Ambient temperature:5C 35C

Relative humidity:≤70%

Power supply:AC115V or 230V, 50-60Hz

2. Technical Data:

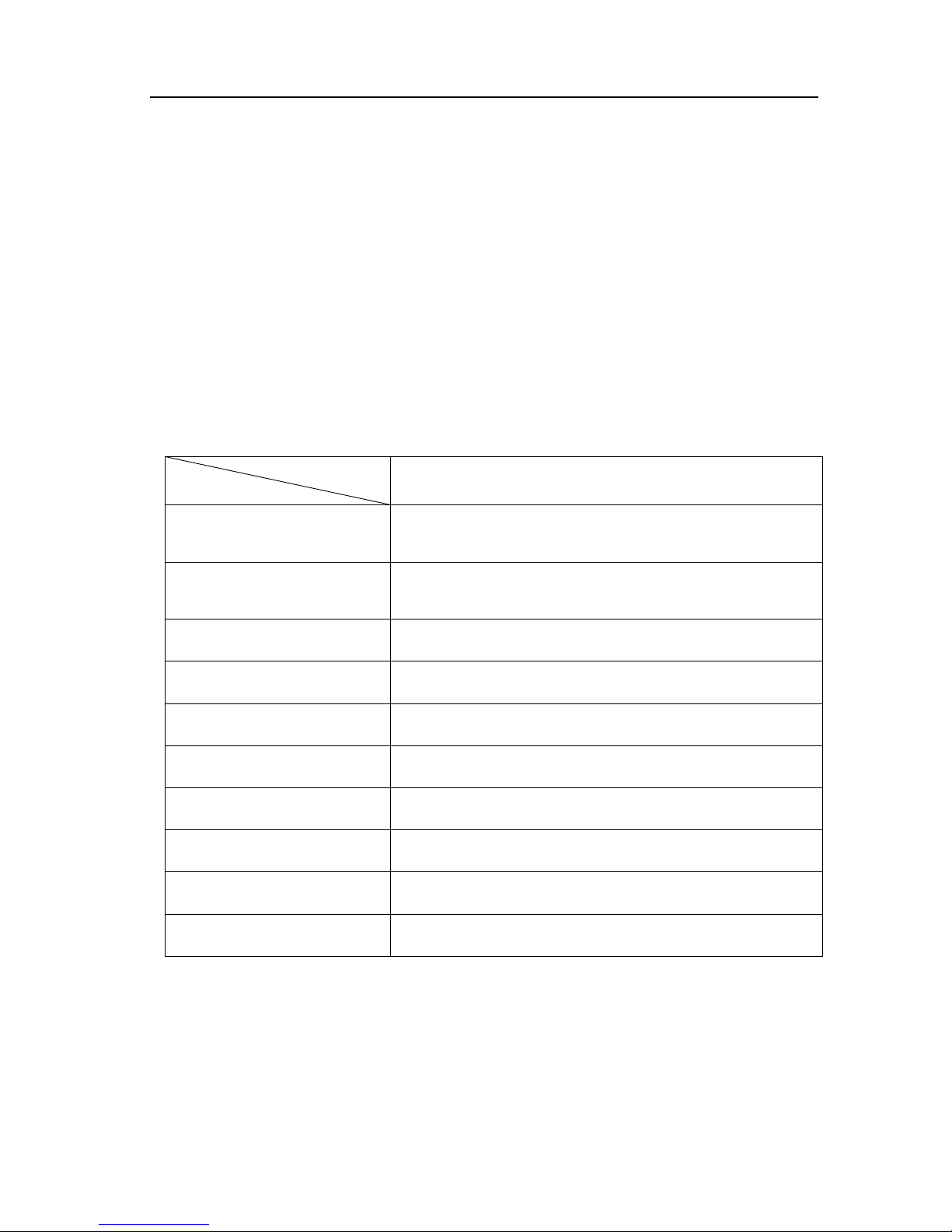

Item No.

BSH5000 (-E)

Temperature range

Timer Max. 99h59min.

Temperature accuracy

Temperature uniformity

Heating time(20-105C) ≤20min

Block Material: Aluminum

Power 240W

Fuse 250V 4A Ф5×20

Meas.(mm)(L×W×H) 360x180x130

Weight(kg) 2

Ambient (Room Temp) +5C 105C

≤ 0.5 C

≤ 0.5 C

— 2 —

BSH5000 Operation manual Chapter 3 Basic Instructions

Chapter 3 Overview

This chapter focuses on the introductions of the structure, keypads and key-functions of

the instrument, as well as preparatory work prior to initial operation.

1. Structure overview

Transparent cover

Dual Block chamber

Housing

Control Panel

On/Off button

Power inlet

— 3 —

g

BSH5000 Operation manual Chapter 3 Basic Instructions

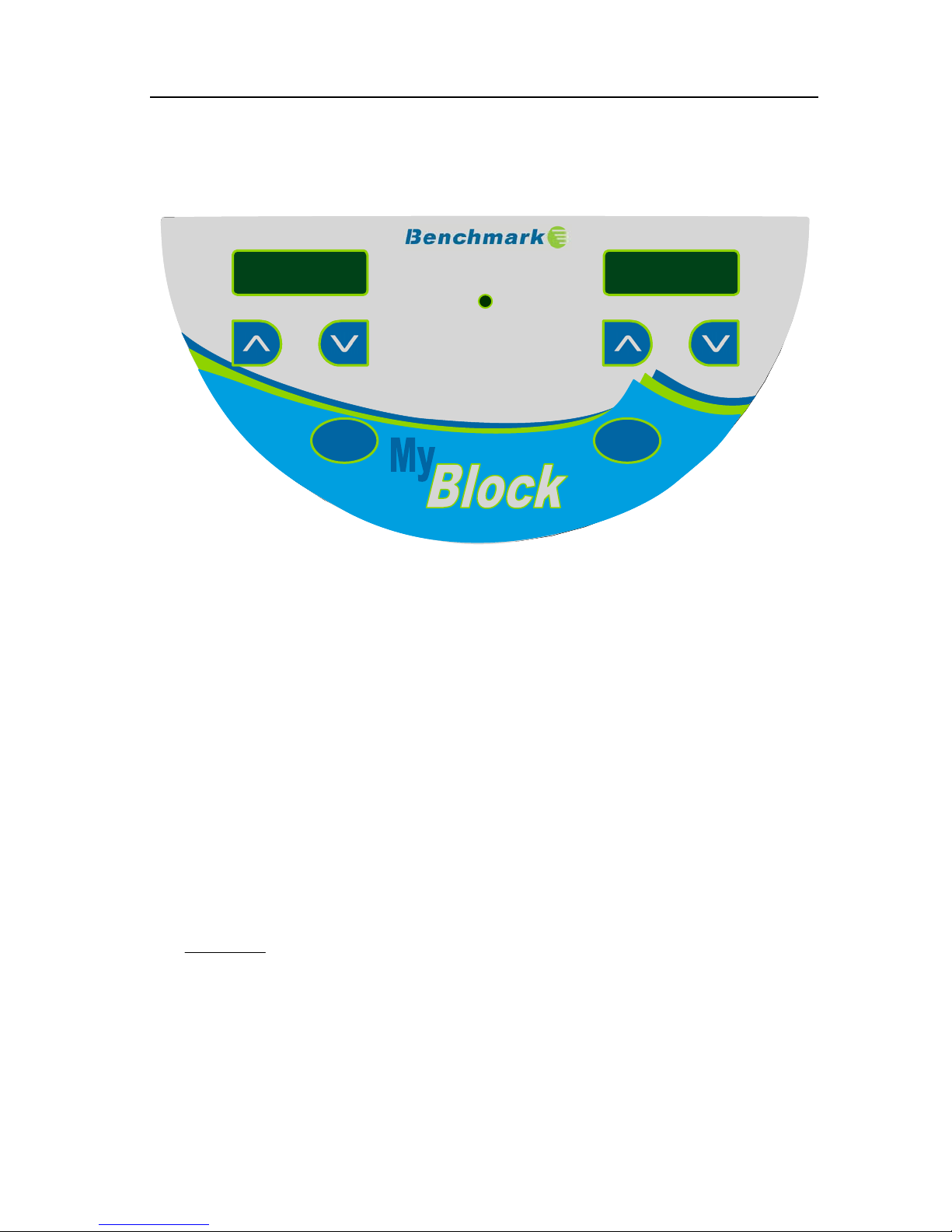

2. Keypads

Temp.

Temp.

℃

℃

External

External

TM

TM

Time

Time

StopStart

StopStart

3. Display

Mode

Start

Stop

The “Mode” button is used to toggle between the time

and temperature setting.

Down key: Used in both time and temperature mode to

decrease the settin

Up key: Used in both the time and temperature mode to

increase the setting.

Start/Stop key. After the temperature and time setting is selected,

press this key to start the timer. This key can also be pressed to

stop the timer.

.

— 4 —

BSH5000 Operation manual Chapter 4 Operation Guide

Chapter 4 Operation

1. Temperature and time setting

a) Press the On/Off switch to power on the

instrument. The instrument performs a self

test followed by an alarm to signal that the

product is ready for use.

b) After about 3 sec. the temperature will

automatically increase to the most recent

setting. The values shown on the display

are actual settings (real time temperature &

time remaining.) The example shows an

actual temp. of 28.5°C and 35 min. remaining.

c) To adjust the set temperature,use the and

keys to selectl the desired temperature (Ex.

55.5). After 5 seconds, the temperature is

stored and the instrumnent will begin heating.

d) To set the time, Press the “Mode” key, the

displayed time begins flashing, press or

keys to set the desired time (ex. 1 hr 20 min.).

After 5 seconds the desired time is stored.

NOTE: The timer will not begin unless the

“Start/Stop” button has been pressed

— 5 —

BSH5000 Operation manual Chapter 4 Operation Guide

2.

Timer Operation (Advanced)

The default setting of the instrument is designed so that the heater will continue to hold

the set temperature even once time has expired and “oVEr” is showing on the time display.

This setting can be adjusted so that the heater will shut down once time has expired. To

adjust the advanced timer setting pres the “Mode” key and hold it for 10 seconds. After

10 seconds, the display will show “OP:1” use the or key to select “OP:2”. The

setting has now been changed and can be stored by pressing the “Start/Stop” key.

3. Temperature Calibration

The temperature of the instrument has been calibrated prior to shipment from the

factory. However, in the event that an adjustemnt to the calibration is required, the

user can adjust the calibration with either a thermometer/thermocouple or with the

optional external temperature probe. (sold separately).

Caution: the instrument uses double temperatures adjustment to ensure accuracy over

a wide range of temperature. It is linearly adjusted at both 40° and 100°C.

a) Calibration with a thermometer:

— 6 —

BSH5000 Operation manual Chapter 4 Operation Guide

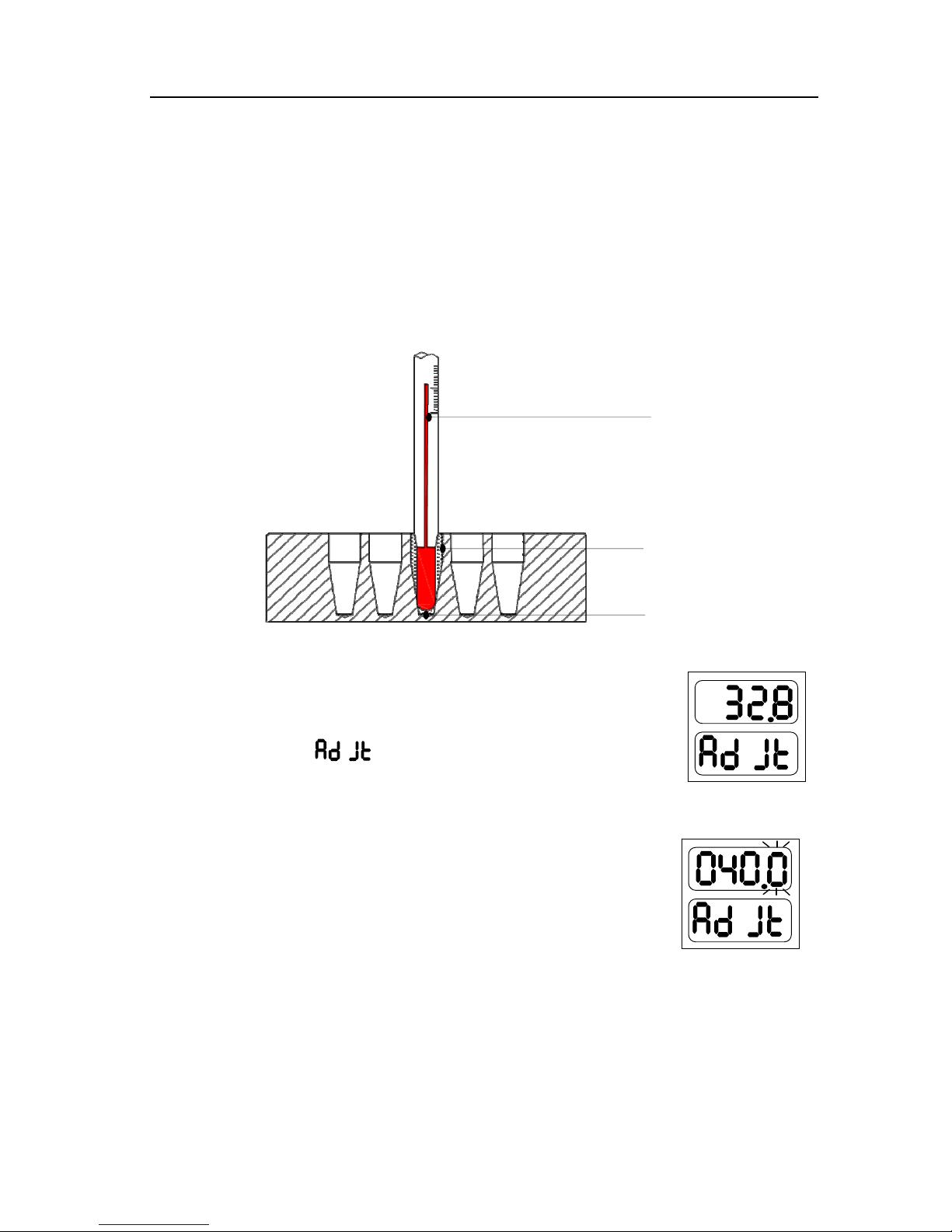

a) Power on the machine and ensure that the temperature on the display is less than

35°C.

b) Inject olefin oil into one of the cone-shaped wells, and then put a

thermometer/thermocouple into this well (make sure that the precision of the

thermometer should be within 0.1℃ and the temperature ball should be absolutely

immerged into the cone-shaped well). See Fig a.

Thermom

Fig a

c) Press “Mode” key without releasing, then press key

at the same time and hold for 3 seconds, it will enter into

the temperature calibration interface, see the right.

At this point, “ ” displayed, which indicates entering

into temperature calibration program. The temperature

displayed is current temperature and begins to rise to

40.0° automatically.

When the temperature reaches to 40° and is able to hold

a constant temperature, the decimal digit begins to flicker.

After 20 minutes, the user can read the value on the

Thermometer and use the up and down keys to enter the

value of the thermometer.

Notes: Please read the actual value after 20 minutes’ constant

Olefin

cone-shape

— 7 —

BSH5000 Operation manual Chapter 4 Operation Guide

temperature to ensure the calibration accuracy.

If the actual read out of thermometer is 39.6, modify the

temperature to 39.6 by pressing or . Then press “Start/Stop”

to confirm the input value.

d) Then the instruments will the automatically begin to heat to 100℃. Once 100C is

reched and held as constact, the decimal begins to flicker. After 20 minutes, the

user can read the actual value from thermometer.

Notes: Please read the actual value after 20 minutes’ constant temperature to ensure

the calibration accuracy.

If the actual readout is 101.5, modify the temperature display

to 101.5 by pressing or . Then press “Start/Stop” to confirm

the input value.

Note: Pressing “Set” and “” simultaneously during the temperature calibration

indicates exiting the temperature calibration program. The adjustments will be

cancelled and the changed value will be of no effect.

3.2. Calibration with the External sensor:

a) Power on the machine and ensure that the temperature on the display is less than

35°C.

b) Put External sensor into a block well.

c) Press “Mode” key without releasing, press “Start/Stop” key

and hold for 3 seconds, it will enter into temperature

calibration interface, see the right. At this point, “ ”

displayed, which indicates entering into external temperature

calibration program. The temperature displayed is External

sensor’s current temperature and it begins to rise to 40.0°

automatically.

It will automatically display “ ” six seconds later.

— 8 —

BSH5000 Operation manual Chapter 4 Operation Guide

The upper displayed temperature (Ex. 32.0) is the

current temperature measured by the External sensor.

When the temperature reaches to 40° and is held as constant

the decimal digit begins to flash.

Notes: Please allow 20 minutes before reading the

displayed actual value to ensure the calibration accuracy.

Press “Mode” key to view the temperature value of External

Sensor. If the displayed value is 39.6°C.

Press “Mode” again, or wait for 6 seconds, then display

“

” , modify the displayed temperature to 39.6 by

pressing or . Then press to confirm the input value.

d) Then the instrument will heat to 100℃ automatically. Once 100 ℃ has been

reached and held constant, the decimal point will begin to flash.

Notes: Once flashing, the user must allow 20 minutes before proceeding to the next

step. This will ensure calibration accuracy.

Press the “Mode” key to show the actual readout of

The external sensor (for ex. 101.5℃).

Press “Mode” again, or wait for 6 seconds, then display

“

” , modify the displayed temperature to 101.5 by

pressing or . Then press to confirm the input value.

Note: Pressing “Mode” and “Start/Stop” simultaneously during the temperature

calibration indicates exiting the temperature calibration program. The

— 9 —

BSH5000 Operation manual Chapter 4 Operation Guide

procedure will be cancelled and the changed value will have of no effect.

4.Temperature control by external sensor

a) Insert the external temperature probe into a well of the drybath or directly into a

sample tube.

b) Press and hold “Stop”, then simultaneously press and hold “” for 3 seconds, the

external indicator light goes on to indicate that it has entered into the temperature

control mode of external sensor.

Note: After entering into the external temperature control mode, the user can

simultaneously press “Stop” and "" for 3 seconds to exit this mode. Upon

exiting the external indicator light will go off.

— 10 —

BSH5000 Operation manual Chapter 5 Failure Analysis and Troubleshooting

Chapter 5 Failure Analysis and Troubleshooting

Problems and actions

No. Common problem Possible cause Action(s)

No display on the

1

screen

The actual and

2

displayed temperatures

are quite different

“OPEn” displayed,

alarming “beep”

“SHOr” displayed,

3

alarming “beep”

No power on the main

power plug

Faulty fuse Change fuse

On/Off button broken Change button

Others Contact the supplier

Broken sensor or

loose contact of the

block

Sensor disconnect

Sensor short-circuit

Check power supply and

plugged properly

Contact the supplier

Contact the supplier

“HHHH” displayed,

alarming “beep”

4 No heating

5 Keys don’t work Faulty key Contact the supplier

Sensor broken, or

block temperature is

too high

Sensor broken

Contact the supplier

Heating tube broken

— 11 —

BSH5000 Operation manual Annex

Annex:Wiring Diagram

(

for reference only)

L

PE

N

Switch

POWER

J1 AC 220 V

BOARD

J4 Heat

J2 AC9V

J3 HeatCtl

HEAT

Block

PT100

J1 AC9V

MAIN

BOARD

X1 He atCtl

J2 PT100 J4 PT1000USB1 USB

J3 J2

CONN BOARD

USB PT1000

— 12 —

Memo

Loading...

Loading...