Page 1

Page 2

KC-4112 Service´s Manual

P/N: 6705 . Rev.1.0

December 2005

(First edition)

Copyright by Bematech S.A. Curitiba, Brazil.

All rights reserved.

No part of this publication may be copied, reproduced, adapted or translated without the prior written

permission of Bematech S.A., except when allowed by patent rights.

Information in this publication is purely informative, subjected to change without notice and no liability is assumed

with respect to the use of this. However, as product improvements become available, Bematech S.A. will make

every effort to provide updated information for the products described in this publication. The latest version of this

manual can be obtained through Bematech website:

www.bematech.com

Notwithstanding the other exceptions contained in this Manual, the consequences and responsibility are

assumed by the Purchaser of this product or third parties as a result of: (a) intentional use for any improper,

unintended or unauthorized applications of this product, including any particular purpose; (b) unauthorized

modifications, repairs, or alterations to this product; (c) use of the product without complying with Bematech

S.A. Corporation’s operating and maintenance instructions; (d) use of the product as component in systems or

other applications in which the failure of this could create a situation where personal injury or material

damages may occur. In the events described above, Bematech S.A. and its officers, administrators, employees,

subsidiaries, affiliates and dealers shall not be held responsible or respond by any claim, costs, damages,

losses, expenses and any other direct or indirect injury, as well as claims which alleges that Bematech S.A.

was negligent regarding the design or manufacture of the product.

Bematech S.A. shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as original Bematech products or approved products by

Bematech S.A.

Any product names or its logotypes mentioned in this publication may be trademarks of its respective owners

and shall be here recognized.

Product warranties are only the ones expressly mentioned in the User’s Manual. Bematech S.A. disclaims any

and all implied warranties for the product, including but not limited to implied warranties of merchantability or

fitness for a particular purpose. In addition, Bematech S.A. shall not be responsible or liable for any special,

incidental or consequential damages or lost profits or savings arising from the use of the product by the

Purchaser, the User or third parties.

2

Page 3

EMC and Safety Standards Applied

Product Name: KC-4112

Model Name: 6200 and 6300 (all)

*EMC is tested using an EPSON PS180 power supply

Europe:

CE marking

Safety: EN60950

North America:

EMI: FCC Class A

Safety: UL recognized

WARNING

The use of non-shielded communication cables as well as unauthorized changes or modifications on the

equipment could void the certifications described in this page. Please contact your dealer for further information.

CE Marking

The printer conforms to the following Directives and Norms:

Directive 89/336/EEC

EN 55022 Class B (Conducted and Radiated emission)

EN 55024

IEC 61000-4-2 ESD

IEC 61000-4-3 Radiated immunity

IEC 61000-4-4 EFTB

IEC 61000-4-5 Surge

IEC 61000-4-6 Conducted immunity

IEC 61000-4-11 Voltage Dips

FCC CLASS A

DECLARATION OF CONFORMITY

This equipment has been tested and found to comply with the limits for a Class A digital service, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, use and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to the radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

3

Page 4

Safety Precautions

This section presents important information intended to ensure safe and effective use of this product. Please

read this section carefully and store it in an accessible location.

Immediately unplug the equipment if it produces smoke, a strange odor, unusual noise or if foreign matter

including water or other liquid falls into the equipment. Continued use may damage it or lead to fire *. Please

contact your dealer or a BEMATECH service center for advice.

Never attempt to repair this product yourself. Improper repair work can be dangerous.

Never disassemble or modify this product. Tampering with this product may result in injury or fire *.

Be sure to use the specified power source. Connection to an improper power source may cause malfunction or

fire *.

CAUTION:

WARNING:

Do not connect cables in ways other than those mentioned in this manual. Different connections may cause

equipment damage and burning *.

Be sure to set this equipment on a firm, stable surface. The product may break or cause injury if it falls.

Do not install this equipment in locations that do not comply with the environmental requirements specified in

this manual.

Do not place heavy objects on top of this product. Never stand or lean on this product. Equipment may fall or

collapse, causing breakage and possible injury.

To ensure safety, unplug this product before leaving it unused for an extended period. In this case, please be sure

to place a piece of paper between the platen and the paper roll, in the thermal mechanism, to avoid damage

when restarting the printer.

* Note that this equipment was developed complying with international safety standards and therefore contains

only limited flammability components.

NOTICE:

If static electricity or electromagnetism causes data transfer to discontinue midway (fail), restart the application

or disconnect and connect the communication cable (USB, etc…) again.

4

Page 5

SummarSummar

Summar

SummarSummar

Chapter 1 - Introduction ................................................................................ 6

Chapter 2 - Getting Started ............................................................................. 7

Chapter 3 - Product Information .................................................................... 9

Chapter 4 - Communication Interfaces ............................................................. 13

Chapter 5 - Technical Specifications ................................................................. 16

Chapter 6 - Dip Switch .................................................................................. 17

Chapter 7 - General Flowchart ........................................................................ 18

Chapter 8 - Blocks Diagram ........................................................................... 20

Chapter 9 - Testing ........................................................................................ 21

Chapter 10 - Troubleshooting ......................................................................... 23

Chapter 11 - Replacing Deffective Parts or Modules ........................................... 27

Chapter 12 - Preventive Maintenance ............................................................... 36

yy

y

yy

Appendix A - Family Codes ............................................................................. 38

Appendix B - Field Replacement Unit (FRU´s) ................................................... 40

Appendix C - Firmware Update ........................................................................ 42

Appendix D - Assemblies ................................................................................ 45

5

Page 6

Chapter 1

IntroductionIntroduction

Introduction

IntroductionIntroduction

How this manual is organized:

• Chapter 2 and 3 refers to product presentation (unpacking, packing, product components, operations and

handling).

• Chapters 4 refers to interfaces and communications.

• Chapters 5 to 8 refers to the technical information of the product. It contains a flowchart, a block diagram

that compose the kiosk printer and its accessories besides the technical specifications.

• Chapters 9 to 12 refers to tests that may be run in order to help diagnosing a faulty product. It shows how

to indentify and replace a deffective part or module and how to avoid future problems.

• Appendix A lists the available product configurations and corresponding part numbers.

• Appendix B lists the Fild Replacement Unit (FRU´s) that may be used to repare the product.

• Appendix C explains the firmware update procedure.

• Appendix D shows all optional assemblies configuration

6

Page 7

Chapter 2

Getting StartedGetting Started

Getting Started

Getting StartedGetting Started

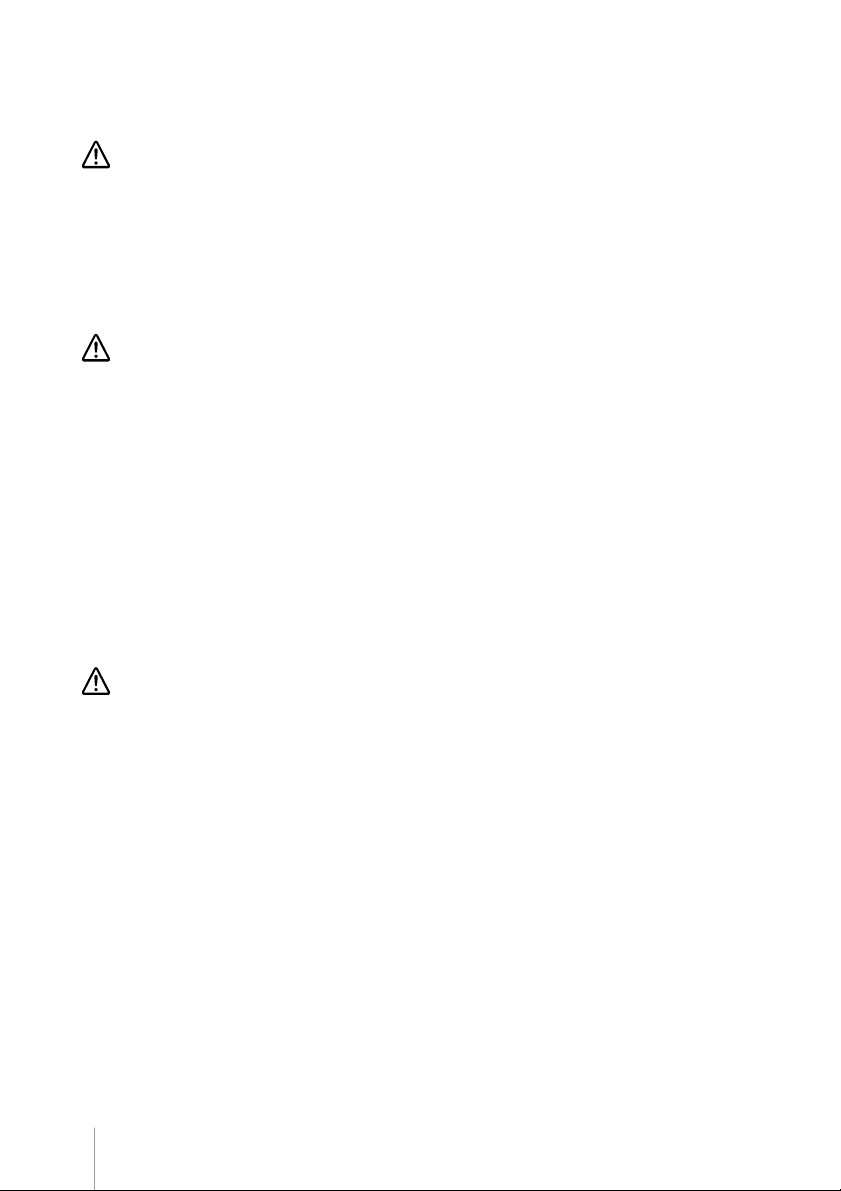

The printer

The communication connectors, DC connector, On/Off switch and key panel can be found in different locations of

the printer, according to the selected assembly.

Cutter

Presenter

Key panel

On/Off switch

Figure 1

DC connector

Parallel

connector

Figure 2

Paper

entrance

Serial

connector

7

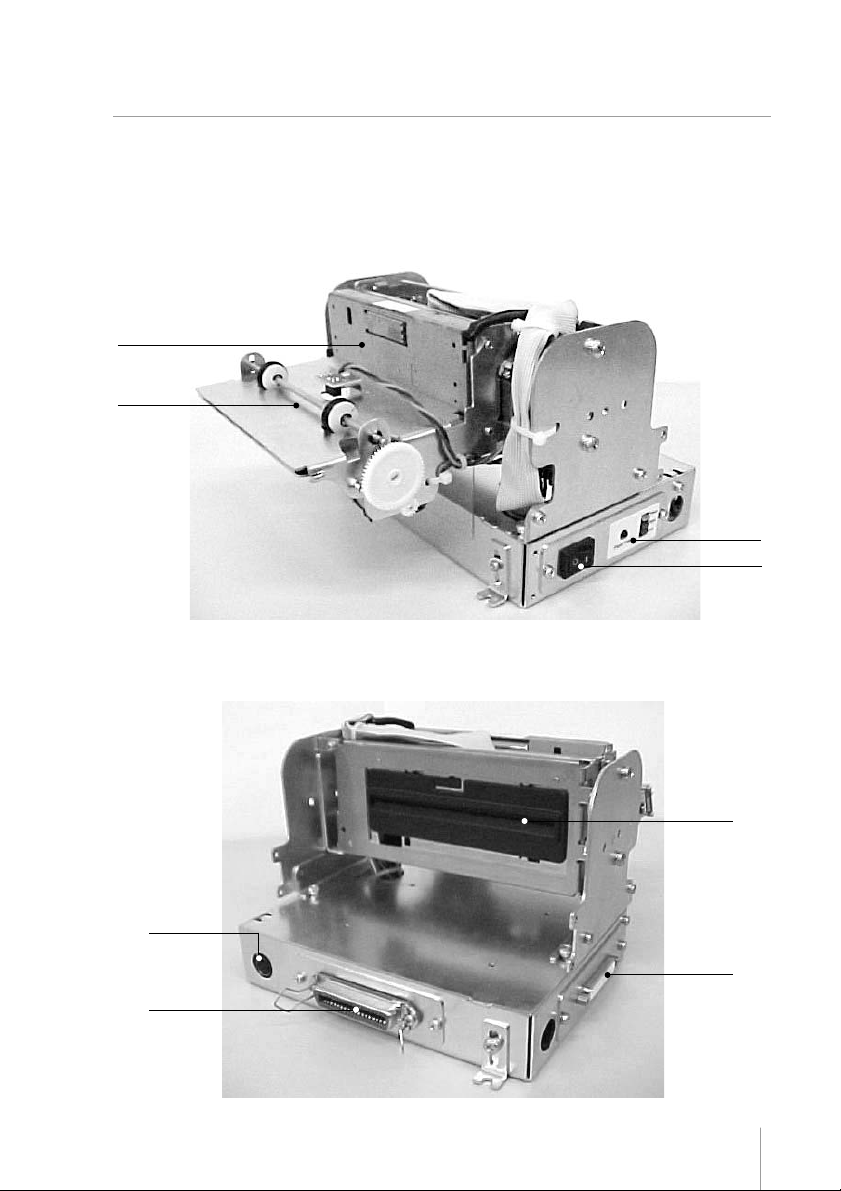

Page 8

Paper holder

Paper near end sensor

Damping device

Figure 3

Paper roll is not included – the appropriate thermal paper should be used. Refer to the Technical

Specifications section in this manual for paper details.

Spindle

Unpacking

Take the printer out of its box and verify that the following items are included:

• Printer

• User´s Manual

Keep the box and packing materials for future use if necessary.

Paper roll is not included – the appropriate thermal paper should be used. Refer to the Technical

Specifications section in this manual for paper details.

Be sure to follow current laws or regulations before disposing parts or packing materials

8

Page 9

Chapter 3

Product InformationProduct Information

Product Information

Product InformationProduct Information

Powering

Make sure that the printer is turned off.

Connect the power cord to the power supply‘s

AC connector and to an electrical outlet. This

outlet must have its ground pin connected as

shown on the right:

Figure 4

Connect the DC cable of the power supply in the printer as shown below – note that the arrow in the connector must

be facing up:

DC

connector

Figure 5

GROUND

Turn on the printer using the on / off switch located on the printer. Check, also in the panel, if the Power LED is lit.

If no paper is present, the Paper LED will also be lit.

DC Cable Specification:

Connector

A

C

B

Figure 6

Specification

24VDC

A

B

C

GND

N.C.

C

A

B

Figure 7

9

Page 10

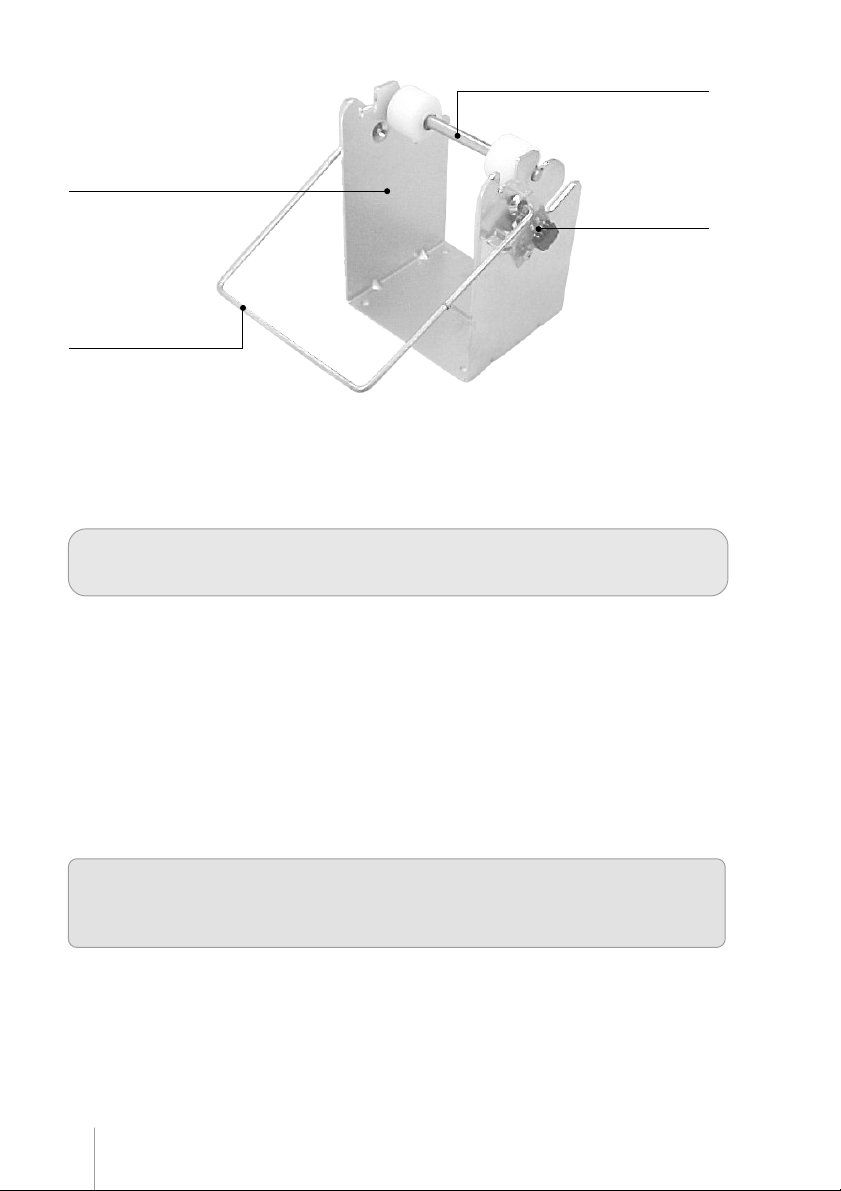

Paper handling

Loading Paper

To insert a new paper roll, please do as follows:

The end of the paper roll must

be cut evenly, as shown on the

right.

Be sure that the presenter is in

the locked position.

Place the spindle in the paper

roll’s core and then place the roll

and spindle in the paper holder

as shown.

Note that the paper must go

under the damping device.

Gently push the paper into the

paper entrance. The printer will

automatically pull the paper, and

turn off the Paper LED.

Figure 8

Figure 9

10

Figure 10

Page 11

Removing Jammed Paper

Note: If the cutter remains blocked due to a paper jam, unplug the printer and use the manual lever to

move the cutter blade prior to perform the steps below.

If a paper jam occurs, follow the steps below:

• Cut the paper at the paper entrance.

• Unlock the presenter mechanism using the presenter lock.

• Unlock the head up switch raising the print head.

• Gently pull the paper out of the mechanism.

• Lock the head up switch back to initial position.

• Lock the presenter.

Key Panel

The key panel gives visual printer status and manual control to the operator.

These functions are accomplished using one switch and LEDs, described below:

• POWER LED: This green LED will be on whenever power is applied to the printer and the power switch is on.

• PAPER LED: This red LED will be on when the printer is without paper. If the print head is up, this red LED

will blink.

• ERROR LED: This red LED will blink in error conditions. See ERROR TABLE on page 25.

• PAPER FEED BUTTON: Use to feed paper line by line with fast button touches or feed paper continuously, by

pressing and holding down the button.

11

Page 12

Presenter operation

The presenter mechanism is responsible for the ejection of the receipts printed by the kiosk printer. It is designed

so that paper jam is minimized, especially while in operation. However, due to paper feed conditions (wrong paper

feeding, paper wrinkles etc.) paper jam may occur, especially when replacing paper. We may, then, consider the

following:

• When a paper jam occurs in the presenter entrance, the paper will not reach the presenter sensor (located in

the presenter cover) – in this case, the kiosk printer goes into error condition, thus requiring manual intervention.

After removing the jammed paper, the printer must be turned off and on again, in order for the printer to come back

on line.

• When the paper jam occurs in the presenter paper exit, the kiosk printer will try to force the paper out for 8

seconds. If that does not happen, the printer will wait for 10 seconds, after which it will try a new paper presenting

sequence. If the second try is not effective, the printer will go permanently in error condition, thus requiring a

manual intervention to remove the paper. This paper jam may occur while replacing paper or if there is vandalizing

of the paper exit. However, to prevent that, the presenter has a clutch device that prevents paper jamming if

paper exit is blocked.

Retractable Function

It is possible to set by command the retractable function in the presenter. If this feature is enabled, after a full

cut command the presenter will push the paper and return it to its sensor. As a default, if the paper remains above

the sensor during 10 seconds, the presenter will pull the paper automatically. The retractable time can also be

programmed by command. To enable the retractable function or change the retractable time, please refer section

COMMAND TABLE (Operation). The printer is prepared mechanically to pull the paper without any receipt jam.

Reliability of presenter operation without the recommended paper is not guaranteed.

Operation Modes

The printer can be operated in the following modes:

Normal (Remote mode)

In this state, the printer is being controlled by the host through the serial or parallel communication interfaces.

Dump mode

In this mode advanced users and programmers can identify communication problems between the host and the

printer or check if a certain programmed data is correctly being sent to the printer, thus being a debugging tool. To

start the hexadecimal dumping, turn on the printer while pressing the paper feed switch. A message will be printed

on the paper asking you to press once more the paper feed switch if Dump mode is desired, as shown:

- Press PAPER switch once for DUMP MODE

Self-testing

To run a self-test, turn the printer off. Press and hold the Paper Feed switch and turn it on. When the printer starts

printing, the paper feed button can be released. A message will be printed asking you to wait the self-test. In the

self-test you will find the printer firmware version, among other information.

12

Page 13

Chapter 4

Communication InterfacesCommunication Interfaces

Communication Interfaces

Communication InterfacesCommunication Interfaces

Communication between a host and the printer can be performed in two communication protocols: Parallel or Serial

RS-232, according to the printer model.

Communication cables are not supplied with the printer

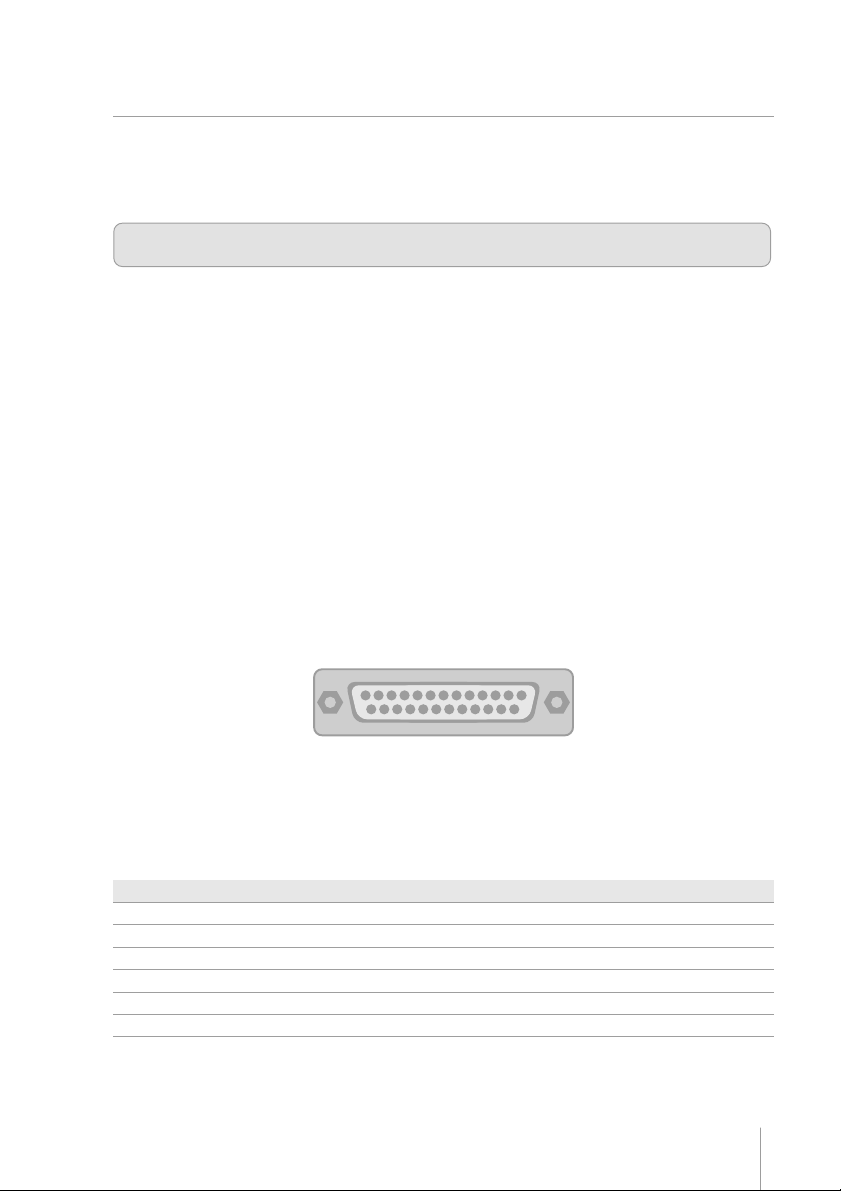

Serial Interface

The RS232 serial interface uses a female DB-25 connector. The serial port can operate using the DTR/DSR

mode, with 7 or 8 data bits, with or without parity, even or odd parity, one start bit and one or more stop bits. In

the RS232 standard, the logic low level corresponds to a +12V voltage level and a logic high level corresponds

to a –12V voltage level.

DTR / DSR mode

In this mode, the printer’s DTR line controls the flow of data sent from the host’s TX line and received by the

printer’s RX pin. In this case, when the printer’s DTR signal is low (+12V) the printer requests the host to send

data. When the DTR signal is high (-12V) the printer tells the host to stop sending data.

DB-25 Serial connector

01

.................13.................12.................11.................10.................09.................08.................07.................06.................05.................04.................03.................02.................

.............24.............23.............22.............21.............20.............19.............18.............17.............16.............15.............14.............

25

Figure 14

The serial cable needed for the DTR / DSR mode is shown below:

Printer Side (DB-25) Host Side (DB-9)

2 (TD) 2 (RD)

3 (RD) 3 (TD)

6 (DSR) 4 (DTR)

7 (GND) 5 (GND)

20 (DTR) 6 (DSR)

1-7-8 (jumper)

13

Page 14

Printer Side (DB-25) Host Side (DB-25)

2 (TD) 3 (RD)

3 (RD) 2 (TD)

6 (DSR) 20 (DTR)

7 (GND) 7 (GND)

20 (DTR) 6 (DSR)

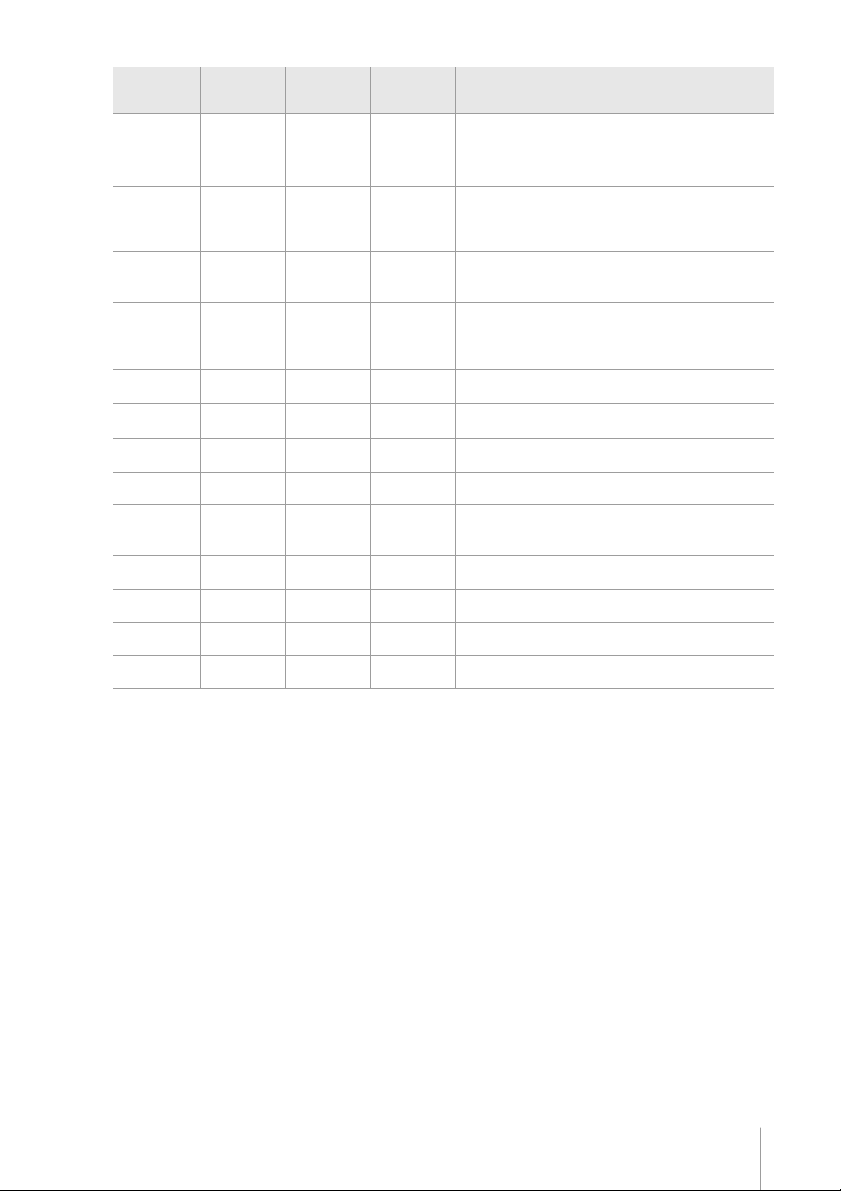

Parallel Interface

The unidirectional parallel interface has the following specifications:

• Synchronization: Externally supplied Strobe signal

• Handshaking: Ack and Busy signal

• Signal levels: TTL compatible

• Data transmission: 8-bit parallel

Parallel Interface Pin Assignments

.................17.................16.................13.................12.................11.................10.................09.................08.................07.................06.................05.................04.................03.................02.................

4-5-8 (jumper)

01

Signal pin

14

.............35.............33.............32.............31.............30.............29.............28.............27.............26.............25.............24.............23.............22.............21.............20.............19.............

36

Figura 15

Associated

return pin

Signal

Direction

Description

1

19

2

3

4

5

6

7

8

9

20

21

22

23

24

25

26

27

/STROBE

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

Data 8

IN

Strobe pulse for data reading. The pulse’s width

must be larger than 0.5 us.

Data in signals (LSB is Data 1). The signal high

IN

level corresponds to bit 1 and the low level

corresponds to 0.

Page 15

Signal pin

10

11

12

13

14,15,18,36

16

17

19-30

31

32

33

34

35

Associated

return pin

28

29

30

Signal

/ACK

BUSY

PE

OL OUT

NC

GND

Frame

GND

/INIT

/ERROR

GND

NC

PULLUP

Direction

OUT

OUT

OUT

OUT

IN

OUT

OUT

Description

This pulse is active low and indicates that data

sent to the printer has been received. The pulse

width must be larger that 10us.

When high, indicates that the printer cannot

receive data.

Becomes high in case of:

1 – Paper end.

0 – Near paper end.

On line Out. When high, indicates operation in

remote mode. When low, indicates operation in

local mode.

Not connected.

Circuit ground.

Frame ground.

Circuit ground.

When low initializes the printer. It may be larger

than 50us.

Paper absence.

Circuit ground.

Not connected.

“Pulled Up” to +5V

15

Page 16

Chapter 5

Technical Specifications KC-4112

Characteristics Specifications

Printing

Method: Thermal Line Printing

Dot Density: 8 dots/mm (203 dpi x 203 dpi)

Print Width: 104 mm (4.1”) (832 dot-positions)

Print Speed: 80 mm/s (3.15”/s) (text mode)

Characters per line: 34, 46, 69 and 92

Character Set: Alphanumeric CP850 and CP437

Features

Modular design.

Automatic cutter (full and partial cut).

Presenter with retractable function: 450 mm/s (17.7”/s).

High reliability.

Low paper sensor (paper near end).

Automatic paper loading.

Bar code type: UPC-A, UPC -E, EAN13, EAN8, CODE 39, ITF, CODABAR,

CODE 93, CODE 128, ISBN, MSI, PLESSEY, PDF-417.

Communication Buffer Capacity: 31 Kbytes

Interface: Parallel (Unidirectional) and Serial(RS-232)

Serial interface specification:

• Baud rate: configurable 9600 or 19200

• Start bit: 1 bit

• Data bits: configurable 7 or 8 bits

• Parity bit: odd / even or no parity

• Stop bit: one bit or two bits

Power requirements

Environment

Reliability

Voltage: 24 Vdc ± 10%

Current: 2 A nominal (4A load, 1s max.)

Operating temperature: 5 to +40ºC (+41 to +104°F)

Storage temperature:

Operating humidity: 35 to 80% RH, non condensing

Storage humidity:

Print head service life: 100 Km, hundred million pulses

Cutter lifetime: 500,000 cuts

-20 to +60ºC (-4 to +140°F) (except for paper)

10 to 90% RH, non condensing (except for paper)

Media Type: Single-ply thermal paper roll

Thickness: 67 ± 5 um

Width: 111.0~112.0 mm (4.37~ 4.41”)

Roll diameter: External 8” (maximum) with internal

1” core.

Please contact your dealer for more

details.

* thermal side is on the outside of the roll.

Recommended paper brand:

•

TF50KS-E made by NIPPON SEISHI or equivalent

• AF50KS-E made by JUJOTHERMAL

• KF50 made by KANZAN

• P350 made by KSP

16

Page 17

Chapter 6

Dip SwitchDip Switch

Dip Switch

Dip SwitchDip Switch

One set of dip switches is mounted in the control board of the KC-4112. To access these dip switches, please do

as follows:

• Turn off the printer

• Remove the paper from the mechanism

• Remove the screws that hold the cover of the control board

• Using the tables below, change the configuration of the dip switches

• Mount the cover of the control board and fasten the screws back

Dip Switch Function

1 Reserved Must be in off position

2 PNE ** On: activated

Off: not activated

3 Baud Rate On: 115200 bps

4 Stop Bits On: 1 stop bit *

5 Character leght On: 7 bits

6 Parity Select On: Odd

7 Parity On: not used *

8 Presenter On: activated ***

* Default

*** Default for printers with presenter

**** Default for printers without presenter

** ON - Default or :

After Esc m: PNE sensor is returned in status bit (serial) or PE line (Parallel)

After Esc l: Presenter sensor is returned in status bit (serial) or PE line (Parallel)

OFF - Default or after Esc m: always return paper ok

After Esc l: always return paper ok

Off: 9600 bps *

Off: 2 stop bits

Off: 8 bits *

Off: Even *

Off: used

Off: not activated ****

17

Page 18

Chapter 7

General FlowchartGeneral Flowchart

General Flowchart

General FlowchartGeneral Flowchart

Blink Led Error 8

Times

Blink Led Error 11

Times

Blink Led Error 15

Times

Print head

YES

cools?

NO

Blink Led Error 12

Times

Blink Led Error 16

Times

YES

YES

YES

YES

YES

YES

YES

RESET

INIT PRINTER

Error

Mechanism?

NO

Error Cuter?

NO

Verify Panel Key

Paper Feed

Pressed?

NO

Error

Mechanism?

NO

Error Power ?

NO

Error Head

Temperature?

NO

Error Cutter ?

NO

Error Presenter

Jam?

NO

Verify Panel Key

YES

Print Message

Verify Panel Key

Paper Feed

Pressed?

NO

Print Self Test

Blink Led Error

and Led Paper 2

Times

Paper Feed

pressed once?

NO

Paper Feed

pressed twice?

NO

YES

DUMP MODE

Print RUN IN

YES

TEST

YES

18

Paper Feed

Pressed?

YES

Advance Paper

NO

Running Schedule

Page 19

General Flowchart Description

Initialization

After a hardware reset, the following steps are performed:

- The system verifies if there is a mechanism error or an auto-cutter error

- The panel key is verified

- Final error verification

Self Test, Dump Mode & Run-In

If the paper feed key is kept pressed during the printer startup, a message is printed asking the user to

wait for self-test or choose dump mode.

If the paper feed key is pressed once the printer enters Dump-Mode. If the paper feed key is pressed

twice the printer will begin a run-in test. If the paper-feed key isn’t pressed after startup state the printer

will print a self-test. After a Run-In or Self-Test the error and paper LEDs will blink two times. If the key isn’t

pressed after startup the system will run idle mode and is ready for printing.

Error Detection

- In case of mechanism error, the error led will blink 8 times

- In case of cutter error, the error led will blink 12 times

- In case of power error, the error led will blink 11 times

- In case of head temperature error, the error led will blink 15 times*

- In case of Presenter Jam error, the error led will blink 16 times

*The system will recover from this error condition, if the temperature falls into the specified operating

range

19

Page 20

Chapter 8

Block DiagramBlock Diagram

Block Diagram

Block DiagramBlock Diagram

(Accessory)

Paper Holder

Paper Near

End Sensor

Oscillator

25.00 MHz

+24V

DC - DC

Sensor

+5V

Converter

Autocutter

(Paper &

DC motor

- µcontroller

- memories

Centronics

Sensors

- logic

RS232

Thermal

Temperature)

Sensors

Thermal

Mechanism

Head

Motor

Stepper

Thermal

Mechanism

Driver

&

Keyboard

DC motor

Motors

LEDs

(optional)

Presenter

KC-4112

Sensor

Drivers

Control Board

Interfaces

20

Service

(External)

24VDC / 2A

Power Supply

Application

drivers)

(DLL or

Spooler

Field

person

Page 21

Chapter 9

TT

estingesting

T

esting

TT

estingesting

This section describes tests that are implemented in the kiosk printer microcode (firmware) as well as SWs that

may be run in order to help diagnosing issues.

Hexadecimal Dump Mode: This feature allows experienced users and programmers to see exactly what data is

being sent to the printer. It can be useful in finding software problems. When you turn on the hex dump mode,

the system prints all commands and other data in hexadecimal format along with a guide section to help you

find specific commands.

To use the hex dump mode, follow these steps:

1. Make sure that the printer is off.

2. Hold down the PAPER FEED button while you turn on the kiosk printer

3. Release the PAPER FEED button while the system prints a menu asking you to selecting the mode.

4. Press once more the PAPER FEED button.

5. Run any software program that sends data to the kiosk printer. The system prints the message “Data

Dump Mode” and then all the codes it receives in a three-column format. The first column contains the

bytes number, the second column contains the hexadecimal codes and the third column gives the ASCII

characters that correspond to the codes.

#

0000

0008

0016

6. Turn off the printer or reset it to turn of the hex dump mode.

• In the ASCII column a dot (.) is printed for each code that has no ASCII equivalent.

Self-Test: The self-test lets you know if your printer is operating properly, in stand-alone mode, with no communication.

This test may be run to help diagnosing problems that are not related to communication. (Ex.: mechanism, cutter,

etc).

To run a self-test, follow these steps:

1. Make sure that the printer is turned off.

2. While holding down the PAPER FEED button, turn on the printer.

3. When the printer starts printing, the PAPER FEED button can be released.

4. A message will be printed asking you waiting for the self-test. In the self-test you will find the

printer firmware version.

5. After printed the LEDS (led error and led paper) will blinking two times. To start a new self-test

press PAPER FEED button once.

Run-In: Run this test after a service procedure that includes parts replacement, specially in the presenter

module.

To run Run-In, follow these steps:

1. Make sure that the printer is off.

2. Hold down the PAPER FEED button while you turn on the kiosk printer

3. Set free the PAPER FEED button while the kiosk printer prints on the paper asking you to selecting

the mode.

4. Press twice more the PAPER FEED button.

Hex Codes

1D 6B 49 0A 31 32 33 34

35 36 37 38 39 30 1D 6B

49 0A 31 32 33 34 35 36

ASCII

KI.1234

567890.k

I.123456

21

Page 22

Keyboard and LED´s: The control panel LED provide information on printer conditions:

- POWER (green)

- PAPER (red)

- ERROR (red)

The POWER LED is on when the printer power is on.

The ERROR LED is on blinking under the following conditions:

The PAPER LED is on blinking under the following conditions:

Condition Number Of Blinks

Head-Up Unlocked Continuously

Without Paper Is On

With Paper and Head-Up Locked Is Off

Note: For more information on error conditions, see Chapter 10 “Troubleshooting”.

Test Application: This SW is included in the driver package available at www.bematech.com/support. Once

installed, it is located at “DISK:\Program Files\Bematech Printer Installer\TestApp.exe”. Please refer to the

included documentation (PDF) for further details.

22

Page 23

Chapter 10

TT

rr

oubleshootingoubleshooting

T

r

oubleshooting

TT

rr

oubleshootingoubleshooting

This Chapter shows possible solutions to some of the more usual printer problems.

Diagnostic failure methods

Use one of the following methods to diagnose the areas where failures occurred.

• Refer to General problems for diagnosing failures that are not reported by the ERROR LED

• Refer to ERROR LED coded problems for diagnosing failures reported by the ERROR LED

In case of defective parts, refer to chapter 9 and select the right FRU to order.

General problems

Table 1

The printer does not turn on; the LEDs on the control panel do not come on

Possible Cause

There is no power in the electric outlet

Power cord disconnected or open

A problem with DC board

Power supply is not working

The PAPER LED is blinking, and nothing is printed

Possible Cause

Head up is unlocked

Possible Solution

Check if there is a central switch for the room / outlets.

Turn off the printer, check the power cord’s continuity

and the connection between the printer and the electric

outlet

Replace DC board (refer to Chapter 12)

Replace power supply

Possible Solution

Lock the head up lever

The printer makes a noise, but nothing is printed

Possible Cause

The control board may be damaged

The thermal mechanism may be damaged

The printout is faint

Possible Cause

The control board may be damaged

A column of dots is missing in printout

Possible Cause

The thermal mechanism may be dirty

The control board may be damaged

The Thermal mechanism may be damaged

Possible Solution

Replace the control board

Replace the mechanism

Possible Solution

Replace the control board

Possible Solution

Clean the thermal head

Replace the control board

Replace the thermal mechanism

23

Page 24

Parallel communication is faulty

Possible Cause

The parallel cable has one or more lines with faulty

connections / broken wires

The pin layout does not follow the Centronics standard

The parallel interface is not set to normal

(unidirectional) at the host side (PC)

Command or parameters incorrect(s)

Paper near end cable is not correctly connected to the

paper

Serial communication is faulty

Possible Cause

The serial cable has one or more lines with faulty

connections / broken wires

The pin layout does not meet the specification

The baud rate is incorrectly set

Command or parameters incorrect(s)

Possible Solution

Check for a good connection between the printer and

the host or change the parallel cable

Check the correct pin layout in this manual

Check in your computer bios if parallel port is set to

NORMAL (SPP and EPP are not supported)

Turn on the printer in Dump mode to see exactly what

data is being sent to the printer

Connect the paper near end cable correctly

Possible Solution

Check for a good connection between the printer and

the host or change the serial cable

Check if the pin layout used complies with the protocol

being used for data transmisson. Remenber that the

printer uses the DTR/DSR protocol. For more information

on serial pin layout, see Chapter - 4

If the baud rate set on the printer is different from the

baud rate of the host, the printer will print random

characters or not print at all. Check carefully the host’s

serial baud rate configuration as well as the printer’s

Dipswitch settings

Turn on the printer in Dump mode to see exactly what

data is being sent to the printer

24

Page 25

self-test

Wait for 1st

to be printed

YES

Continue

self-test ?

NO

YES

RESET

switch held

Turn printer on

with Paper F eed

NO

Self test

started ?

NO

mode ?

Start dump

YES

15 blinks 16 blinks

Run in test

switch twice for

Press Paper Feed

switch once

Press Paper Feed

printer

key panel led

Count blinks on the

ERRO LED coded problems

Diagnosing general failures by cheking the Error LED on the printer key panel

12 blinks11 blinks8 blinks

See Error table for

error possible cause

25

Page 26

Table 2

The ERROR LED is blinking 8 times

Possible Cause

Thermal Head flat cable is disconnected or damaged

Thermal Head flat flexible cable is disconnected or

damage

Thermal Head is damaged

The ERROR LED is blinking 11 times

Possible Cause

Power supply voltage below 20V

Control board is damaged

The ERROR LED is blinking 12 times

Possible Cause

Cutter can not cut the paper or initialize

Cutter is obstructing paper path

The ERROR LED is blinking 15 times

Possible Cause

Print Head overheated

Error Table

Possible Solution

Check for a good connection between the control board

and the extension board

Check for a good connection between the control board

and flat flexible cable from mechanism

Change mechanism

Possible Solution

Check if the power supply voltage is between 21.6

and 26.4 V

Change control board

Possible Solution

Check if the cutter cable is disconnected or damaged

Replace the cutter if necessary

Check if the cutter cable is disconnected or damaged

Replace the cutter if necessary

Possible Solution

The system blocks printing until the head cools and

then resumes printing

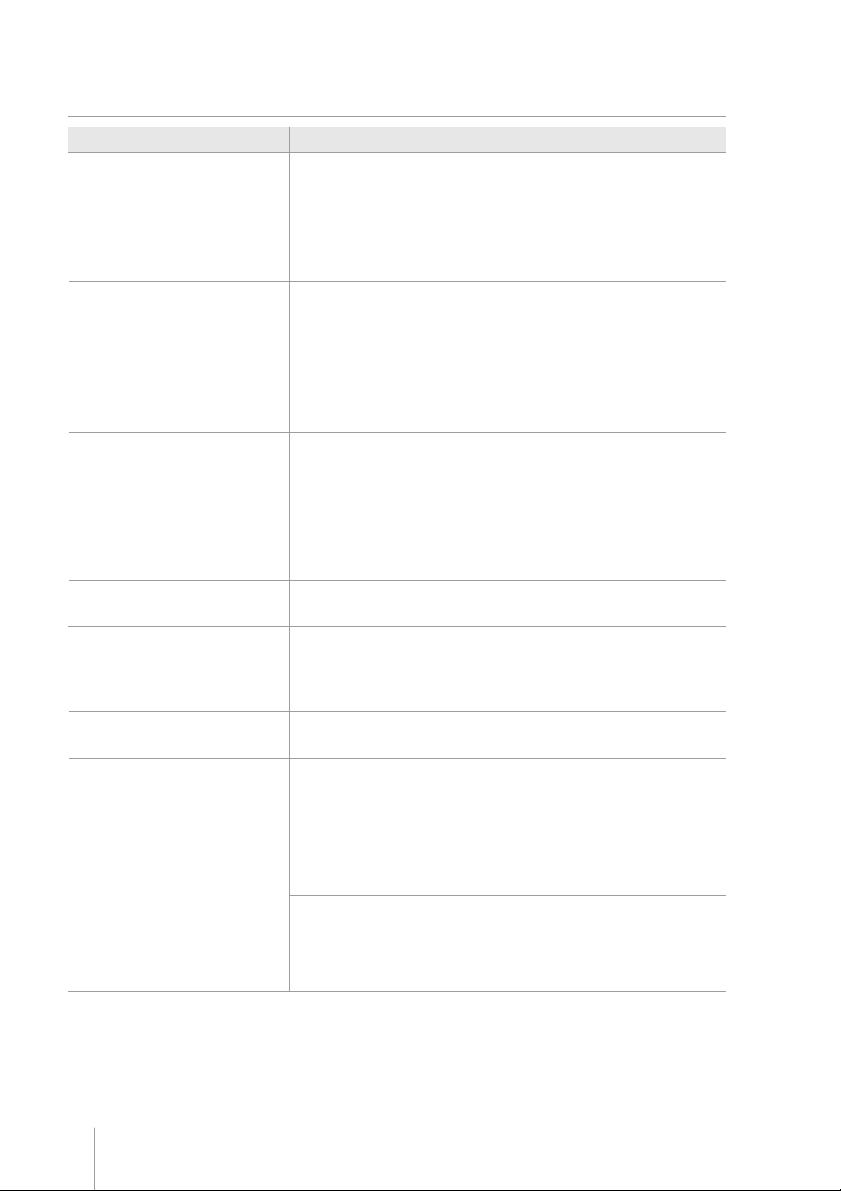

Error

Mechanism

Power Supply

Cutter

Printe Head

Temperature

Entrance Presenter jam

Exit Presenter jam

* It is possible to clear the error “Exit Presenter Jam” by removing the paper inside the presenter

26

Number

of Blinks

8

11

12

15

16

16

Type

Non-recoverable

Non-recoverable

Non-recoverable

Recoverable

Non-recoverable

Recoverable (*)

Possible cause

Thermal Head is damaged or Thermal Head

cable is disconnected

Power supply is voltage below 20V

Can´t perform a paper cut

Depending on environmental temperature,

length and density of graphics the printer

might pause until the print head cools down.

Printing will resume after this.

Paper did not enter in the presenter

Presenter is unable to eject the paper

Page 27

Chapter 11

RR

eplacing Defective Peplacing Defective P

R

eplacing Defective P

RR

eplacing Defective Peplacing Defective P

1. FRU90022 - FRU KC4112 PRESENTER FULL

1.1 Open the mechanism module (3 screws).

1.2 Disconnect the cables.

arts or Modulesarts or Modules

arts or Modules

arts or Modulesarts or Modules

1.3 Release the mechanism module by loosening the screws (4x).

27

Page 28

1.4 Take off the cables from the opening in the control board box.

1.5 Cut to liberate the cables and remove the side screws.

28

Page 29

1.6 Cut the fastener and remove the side screws.

FRU90022 - FRU KC4112 PRESENTER FULL

29

Page 30

2. FRU90023 - FRU KC4112 PRES KIT

2.1 Remove the screws. (2x).

2.2 Pull in the sense of the arrows to remove. 2.3 Remove the screws. (2x).

30

FRU90023 - FRU KC4112 PRES KIT

Page 31

3. FRU90024 - FRU KC4112 TH MECH KIT

3.1 Cut to liberate the cables.

3.2 Remove the screws. (7x).

3.3 Remove the e-ring (1x).

FRU90024 - FRU KC4112 TH MECH KIT

31

Page 32

4. FRU90025 - FRU KC4112 CUTTER KIT

4.1 The process to loosen the cutter is the same of the presenter. (1.0 up to 1.6)

32

FRU90025 - FRU KC4112 CUTTER KIT

Page 33

5. FRU90026 - FRU KC4112 CTR BOARD DUAL

5.1 disconnect the cables

5.2 Remove the screws. (x4).

FRU90026 - FRU KC4112 CTR BOARD DUAL

33

Page 34

6. FRU90027 - FRU KC4112 CABLE KIT

6.1 Remove the screws to liberate the panel

of the parallel interface.

6.2 To set up the screws in the following

order

6.3 Remove the screws to liberate the panel

of the keyboard and key on/off.

34

Page 35

6.2 To set up the screws in the following order

6.2 To set up the screws in the following order

FRU90027 - FRU KC4112 CABLE KIT

35

Page 36

Chapter 12

Preventive MaintenancePreventive Maintenance

Preventive Maintenance

Preventive MaintenancePreventive Maintenance

Cleaning the Presenter:

Remove debris and paper dust from the presenter by using a vacuum cleaner, or by blowing or by using a dry soft

brush. Perform this operation when replacing paper roll.

Printer head cleaning procedure

Adhesion of dusts of paper and foreign materials may deteriorate the print quality and the lifetime of the head and

platen. When they adhere, clean the head according to the following procedures:

1. Take measures against static electricity such as a disposable wrist strap for the work.

2. Cleaning should be done with the presenter or the cutter (depends on your configuration) lifted up and

the platen part separated from the head (use the head-up lever).

Note: do not hit the thermal head surface with anything hard!

3. Wipe off the heating element part of the head surface lightly with cotton swabs to which Ethyl-alcohol

is applied. Be sure to clean the platen roll as well.

4. After Ethyl-alcohol has completely been dried, set the platen and perform the action check (print a self

test ticket and check the printing quality).

Note: do not use anything that may destroy the heating element, such as sandpaper. Do not apply

any unnecessary force to the thermal head.

Tests revealed that this procedure becomes necessary more often as the printer head gets used.

Lubrication:

Lubricate the presenter axle and bearings once a year, at least.

Clean axle and bearings, removing deposits of paper dust, aply the lubricant and remove any excess of oil.

Attention:

- Do not lubricate gears

- Use a high viscosity lubrificant. Low viscosity lubrificants are very likelly to be removed by force of axle

rotation

36

Page 37

See details on the lubrication points in figures below.

Parts to be cleaned and lubricated:

37

Page 38

Appendix A

FF

amily Codesamily Codes

F

amily Codes

FF

amily Codesamily Codes

KC-4112 is available with two options:

- With presenter and cut . (6200 - PB20 DRL1PR33 STACKED)

- Without presenter, with cut . (6300 - PB20 DRL1FC33 STACKED)

Custumers are not allowed to change the original configuration. This operation voids warranty terms, may

void the EMC and SAFETY certifications and may cause malfunction or injury. For further information, please

contact your dealer.

Identifying the kiosk printer model:

Check the four digits at the beggining of the serial number. They correspond to the printer model.

Ex.: SN 6200050612345 corresponds to:

• model 6200 (KC-4112, with presenter)

• Year (of manufacturing): 05 (2005)

• Month (of manufacturing): 06 (June)

• Sequencial: 12345

38

Page 39

Physical

Configuration *

Printer with presenter

(stacked version)

Dual

Height: 128.9 mm (5.03"")

Width: 184.4 mm (7.24"")

Depth: 230.8 mm (9.50"")

Weigth: 2.41 Kg (4.40 lbs)

Printer without

presenter (Stacked

Version)

Printer with presenter

(Low Profile)

Printer without

presenter

(Low Profile)

Printer with presenter

(Side Mount)

Printer without

presenter

(Side Mount)

Printer without

presenter

(Cut & Drop)

Paper Holder 6”/8”

Height: 128.9 mm (5.03"")

Width: 184.4 mm (7.24"")

Depth: 157.3 mm (6.18"")

Weigth: 2.13 Kg (4.40 lbs)

Height: 93 mm (3.66"")

Width: 184.4 mm (7.24"")

Depth: 315.8 mm (12.4"")

Weigth: 2.41 Kg (4.40 lbs)

Height: 93 mm (3.66"")

Width: 184.4 mm (7.24"")

Depth: 232.3 mm (9.13"")

Weigth: 2.13 Kg (4.40 lbs)

Height: 186 mm (7.32"")

Width: 244.3 mm (9.6"")

Depth: 223.7 mm (8.77"")

Weigth: 2.41 Kg (4.40 lbs)

Height: 186.0 mm (7.32"")

Width: 232.3 mm (9.13"")

Depth: 145.0 mm (5.7"")

Weigth: 2.13 Kg (4.40 lbs)

Height: 93 mm (3.66"")

Width: 184.4 mm (7.24"")

Depth: 216.7 mm (8.5"")

Weigth: 2.13 Kg (4.40 lbs)

Height: 123 mm (4.8”)

Width: 114,7 mm (4.5”)

Depth: 78 mm (3.1”)

Weight: 0.30 Kg (0.6 lbs)

* You are not authorized to change the printer configuration. This may void the EMC and Safety

certifications and may cause malfunction or injury. For further information, please contact your dealer.

39

Page 40

Appendix B

Field Replacement UnitField Replacement Unit

Field Replacement Unit

Field Replacement UnitField Replacement Unit

1. FRU90022 - FRU KC4112 PRESENTER FULL

2. FRU90023 - FRU KC4112 PRES KIT

3. FRU90024 - FRU KC4112 TH MECH KIT

40

Page 41

4. FRU90025 - FRU KC4112 CUTTER KIT

6. FRU90027 - FRU KC4112 CABLE KIT

5. FRU90026 - FRU KC4112 CTR BOARD DUAL

41

Page 42

Appendix C

Firmware UpdateFirmware Update

Firmware Update

Firmware UpdateFirmware Update

The kiosk printer has the capability to receive firmware updates from PC using ther RS-232 (COM1 or COM2) port.

This section explains the SW used to download FW to the kiosk printer.

Get the latest version of this SW at www.bematech.com/support

- Make sure that the printer is on and the cable (RS232) is correctly connected.

- Launch WinTest.exe

Printer Test

Boot Loader

Interfaces

File Name

C:\WinTesteMP\partial.bin

Output Window

Start Cancel

Clear Output Window

- Select the binary file (microcode) to download.

Open

Figure 59

42

Page 43

- The default interface is COM1 and baud-rate 115.200 bps.

Output Window

Clear Output Window

Boot Loader

Interfaces

Interfaces

USB

COM1

COM2

115200

Printer Test

- To choose other interface, select the interfaces TAB and changes interface.

Figure 60

- Select the boot loader TAB and click start button.

Printer Test

Boot Loader

Interfaces

File Name

C:\WinTesteMP\partial.bin

Output Window

Open

Start Cancel

Clear Output Window

Figure 61

43

Page 44

- The ERROR and PAPER LEDs on the kiosk printer start blinking.

- Use the Output Window to follow the update progress.

Printer Test

Boot Loader

Interfaces

File Name

C:\WinTesteMP\partial.bin

Start Cancel

57%

Open

Output Window

Clear Output Window

Figure 62

- The flash update will take a few seconds. Do not power off the printer or computer after the update has

started.

WinTestMP

Upgrade OK!

OK

Figure 63

- After the firmware update is complete the printer will be reset automatically.

44

Page 45

Appendix D

Assemblies

Control Board Box

45

Page 46

Printer Mechanism Module

46

Page 47

Presenter

47

Page 48

Stacked without Presenter

48

Page 49

Stacked with Presenter

49

Page 50

Low Profile with Presenter

50

Page 51

Low Profile without Presenter

51

Page 52

Side Mount with Presenter

Side Mount without Presenter

52

Page 53

Cut and drop

53

Page 54

Page 55

Page 56

Loading...

Loading...