Page 1

Thermoglaze

Model TG 50

Operator’s Manual

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

Toll Free: 1-800-578-2547

Email: service@belshaw.com • http://www.belshaw.com

Page 2

Page 3

Congratulations on buying a new

Thermoglaze from Belshaw Adamatic Bakery

Group. Please inspect the unit carefully for

damage or missing pieces immediately after

receiving your system. Belshaw cannot pay for

shipping damage, because the freight company

has accepted the machine from Belshaw in good

condition, and is responsible for its safe delivery.

For your protection, each crate should be

inspected before signing the Bill of Lading to

report any visible damage caused by the

trucker in transit, and account for the number

of crates.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

010810

MN-1720WM

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: (206) 322-5474 • Fax: (206) 322-5425

Toll Free: 1-800-578-2547

Email: service@belshaw.com • http://www.belshaw.com

Page 4

Page 5

Contents

1 Unloading and Uncrating 1

2 Installation 2

3 Assembly 3

4 Operation 6

SB-0345 R1 8

5 Cleaning 14

Disassembly 14

Cleaning 18

Assembly 19

6 Maintenance 23

7 Troubleshooting 24

8 Appendix 27

SB-0361 30

Parts List Drawing Insert Page Insert

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720 iii

Page 6

Preface

The operator of the Thermoglaze is expected to

behave safely, read this manual before operation,

and follow its instructions and warnings.

Study the instructions and warnings in this

manual carefully before operating the equipment.

A thorough understanding of how to install,

maintain, and safely operate the Thermoglaze

will prevent production delays and injuries. Prior

operation of the equipment before reading and

understanding the instructions in the manual will

void the warranties of the equipment.

To use the Thermoglaze safely, heed the

following warnings and all other warnings that

appear in this manual:

• To avoid damaging the Thermoglaze,

never use force to assemble,

disassemble, operate, clean, or maintain

it.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv MN-1720 Thermoglaze 50

Page 7

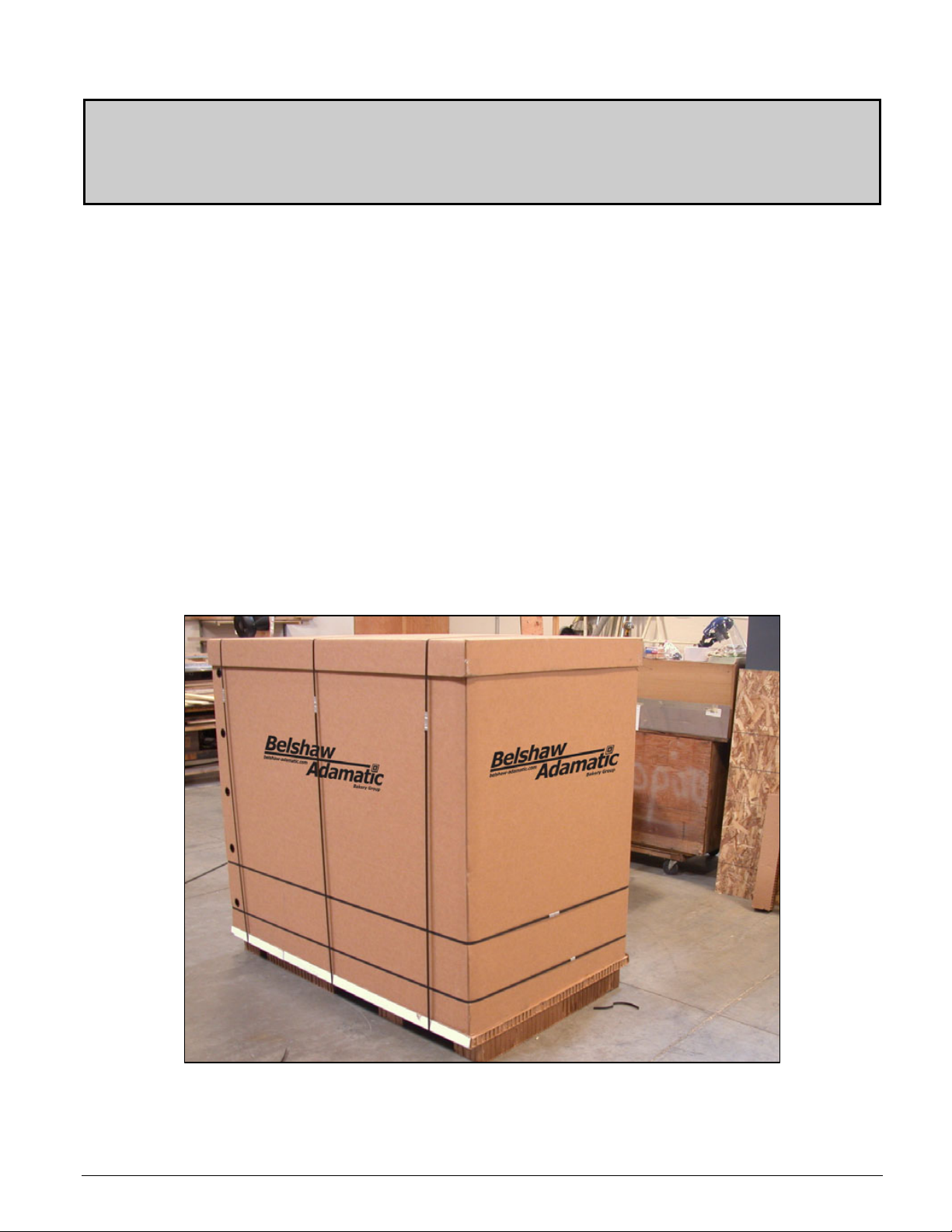

1 Unloading and Uncrating

DO NOT LIFT EXCESSIVE

WEIGHT

Once the crate has been delivered,

immediately take the covers off the crate and

inspect for hidden damage. If damage is

found, make a damage claim to the shipping

company. After inspection, cut the banding

and remove any other restrains from the

Thermoglaze unit. Remove the banding and

other packing material from the Thermolizer

unit. Roll the Thermolizer, carefully, off the

skid first and move it near the area where it

will be assembled. Roll the Thermoglaze

unit, carefully, off the skid and move it near

the area where it will be assembled.

Do not connect the Thermoglaze or the

Thermolizer to electrical power before

completing the assembly and placement of

the products.

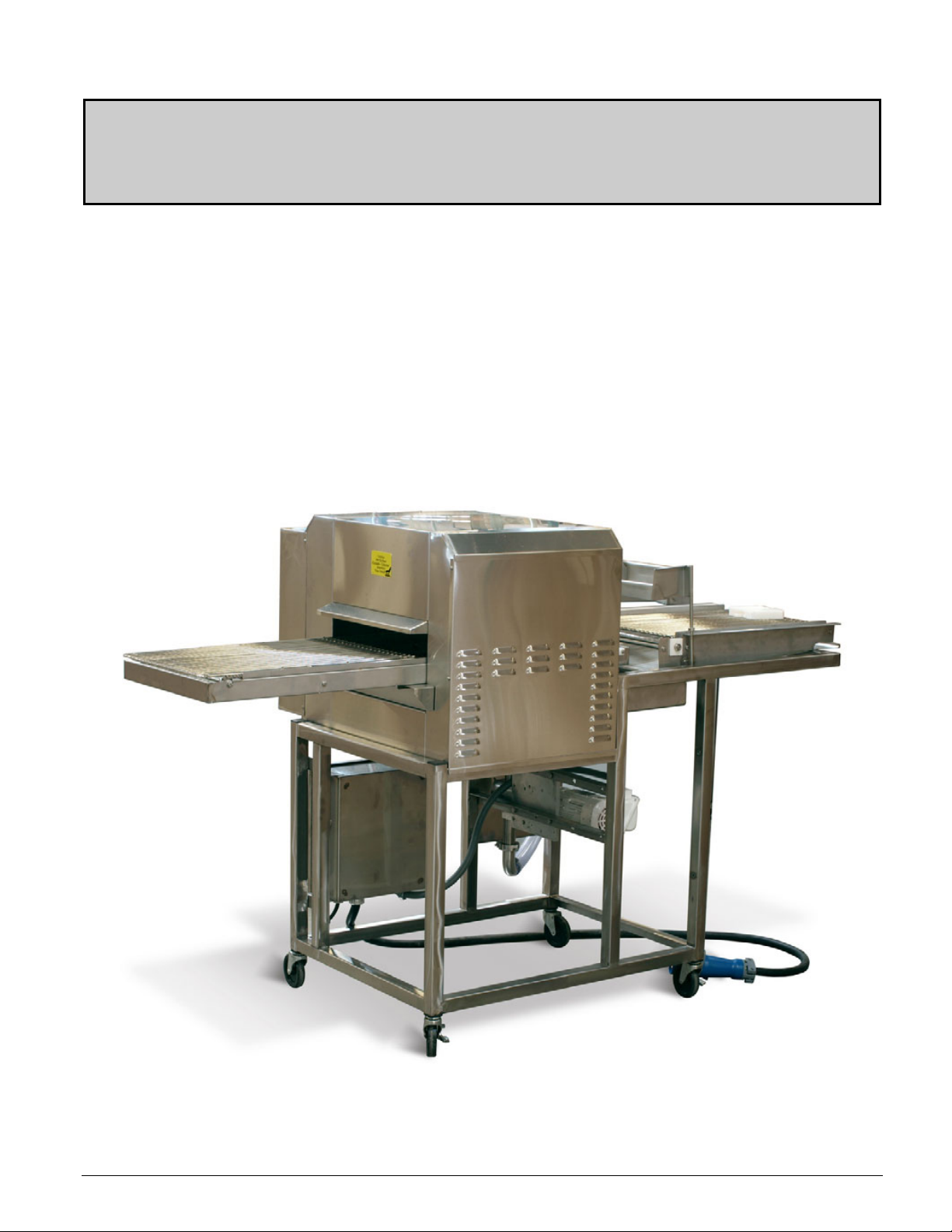

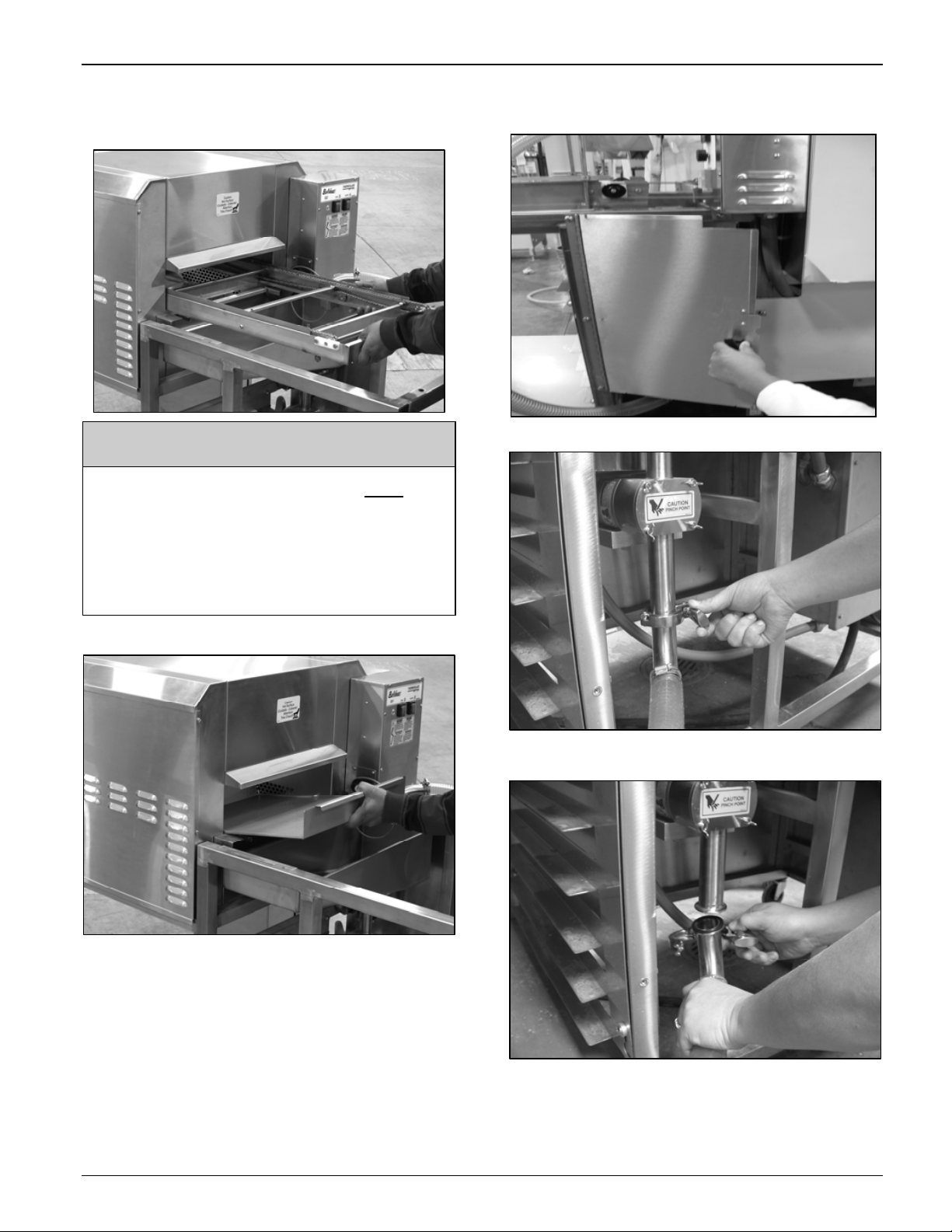

Figure 1-1 shows the system in the crate ready to

be unpacked. The cartons under the Thermoglaze

contain the glaze trough. See Section 4 to

assemble the unit. The carton in the Thermolizer

contains the doors and other interior parts. See

Thermolizer manual for assembly instructions.

The Thermoglaze system has been designed for

quick assembly and installation. Within a short

time of receiving the system, the installer can

have the Thermoglaze ready to make donuts if

the electrical connections are properly installed

and inspected by the prevailing local authorities.

Figure 1-1 Packed Thermoglaze System

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1720WM 1

Page 8

Installation 2

Venting:

WARNING

To avoid electrocuting yourself or damaging

the Thermoglaze, never allow water, steam,

cleaning solution, or other liquid to enter the

electrical panels or connections

Local codes prevail. The authorities having

jurisdiction are stated in NFPA 96-1994

regarding requirements for the Thermoglaze.

Building Layouts:

Electrical:

Model Dimensions Power Requirements

88"L x 40W x

TG50

Make sure that the power requirements of the

Thermoglaze, shown on the data plate, match

your power source.

Only plug in to power source that matches the

required voltage and current for the

Thermoglaze. (The Thermoglaze unit TG50

comes standard with a Hubbel 360P6W plug that

needs a 360C6W socket or equivalent for

electrical current.

Thermoglaze must be electrically grounded and

connected in compliance with the National

Electrical Code, ANSI-NFPA 70, and applicable

municipal building codes.

63"H See data tag

Specification sheets and AutoCAD drawings for

use in developing architectural drawings can be

provided by request. Please call your Belshaw

Bros., Inc. representative for help in defining

your requirements.

Do not apply electrical power to the system until

the assembly has been completed. See Section 4

for the assembly of the Thermoglaze.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 MN-1720 Thermoglaze 50

Page 9

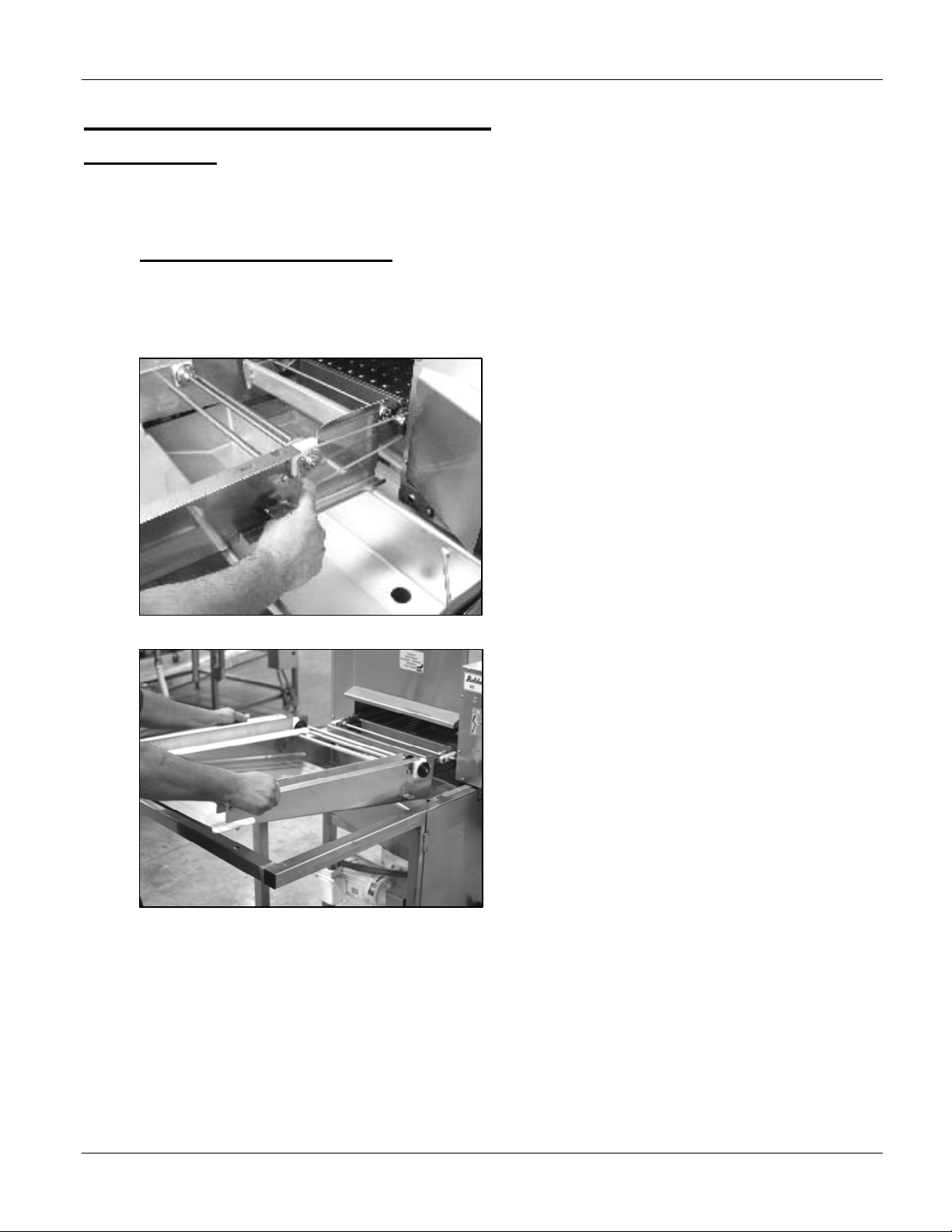

Assembly 3

Clean all parts with mild soap and water and

let dry before assembly and applying

electrical power to the equipment.

The Thermoglaze unit is design for ease of

assembly and use. The system is crated in a

manner so there are few pieces to put together

once the Thermoglaze is in place for production.

After unpacking the system per the uncrating

instructions, 1 item needs to be placed on the

Thermoglaze to finish assembly: the glaze

trough. The Glaze trough slips into the 2 holes on

either side of the drain tray with the waterfall

headed toward the oven. See figure 3-1 and 3-4

for help setting the trough in place. After the

trough is in place attach the glaze hose to the

trough by pushing it in the hose mount in the

center of the trough.

To help familiarize you with your Thermoglaze,

please study the following photographs:

Figure 3-1 Thermoglaze front view

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1720WM 3

Page 10

Figure 3-2 Right Hand View:

Figure 3-3 Control Panel View:

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 MN-1720 Thermoglaze 50

Page 11

WARNING

TURN OFF POWER SOURCE TO THE

MACHINE BEFORE REMOVING ANY

ACCESS COVER OR GUARDS

The Thermoglaze system consists of a Thermoglaze

unit and the Thermolizer. They are placed in unison

in the area located for the production of donuts. See

Figure 4-6 for Thermoglaze system.

Figure 3-5 Thermoglaze System.

WARNING

DO NOT CONNECT THE

THERMOGLAZE TO ELECTRICAL

POWER BEFORE COMPLETING THE

ASSEMBLY PLACEMENT OF

PRODUCTS

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1720WM 5

Page 12

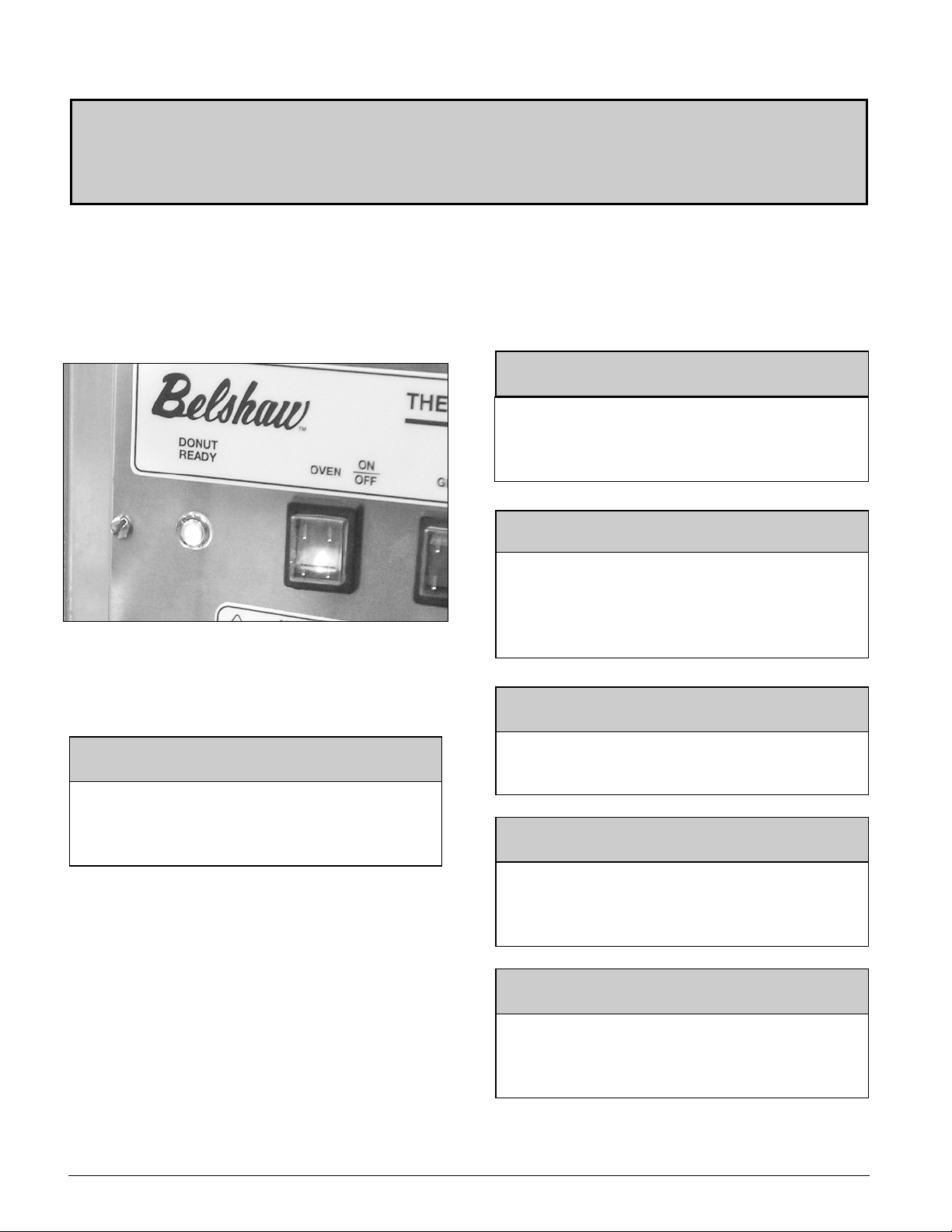

Operation 4

• Turn on oven power switch and allow to heat

to operating temperature. (Note: conveyor

will not move until the oven is up to

operating temperature and the donut

ready light is on. See Figure 4-1.)

Figure 4-1. Oven Ready Light.

• Load glaze reservoir with 40 pounds (one

large bucket) of glaze and turn on the glaze

pump.

• When the screen of donuts is through the

glazer and stopped forward travel, place the

glazed product on a rack for cooling using

the 2 delrin tray grips provided with the unit.

WARNING

To avoid burning yourself, never touch the

Thermoglaze unit, conveyor, or interior of the

oven while the machine is in use.

WARNING

Thoroughly clean and dry the floor if water or

other materials are spilled. Materials spilled

on the floor may cause serious injury and loss

of life.

WARNING

WARNING

Do not operate glazer without glaze or water

in the pump. Doing so can cause permanent

damage to the pump.

• After the donuts have been in the

Thermolizer for at least 20 minutes (60

minutes for filled product), turn on glazer

using the on switch located on the main

control panel.

Conveyor will automatically start when

Thermoglaze reaches operating temperature.

CAUTION!

Donut screens are hot after coming out of the

glazer and will burn you if you grab them

without the handles.

CAUTION!

• After the donuts are thawed, place a screen of

donuts from Thermolizer box to the infeed

end of the Thermoglaze conveyor and allow

the screen to travel through the oven and

glazer. This takes approximately 1-1/2 to 3

minutes.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

6 MN-1720 Thermoglaze 50

To avoid burning yourself, never touch the

hot infeed oven end panel when the machine

is in operation.

Page 13

CAUTION!

To avoid burning yourself, never touch hot

screens when the machine is in operation.

WARNING

Lifting the glaze bucket may cause sprains or

back injury.

WARNING

Serious personal injury may result from

contact with pinch points between chain,

sprockets and pulley. Cuts or loss of limb

may occur when contacting these pinch

points. Never operate the machine with

guards and covers removed.

CAUTION!

To avoid burning yourself, never touch the

hot outfeed oven end panel when the machine

is in operation.

CAUTION!

Serious personal injuries, such as scratches or

cuts, may result from contact with sharp

edges.

CAUTION!

Reaching across or leaning over the machine

may result in burns when the machine is in

operation.

CAUTION!

To avoid burning yourself, never touch the

hot conveyor chain when the machine is in

operation.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze 50 MN-1720WM 7

Page 14

SB-0345 Rev 1

AFFECTS: TG-50

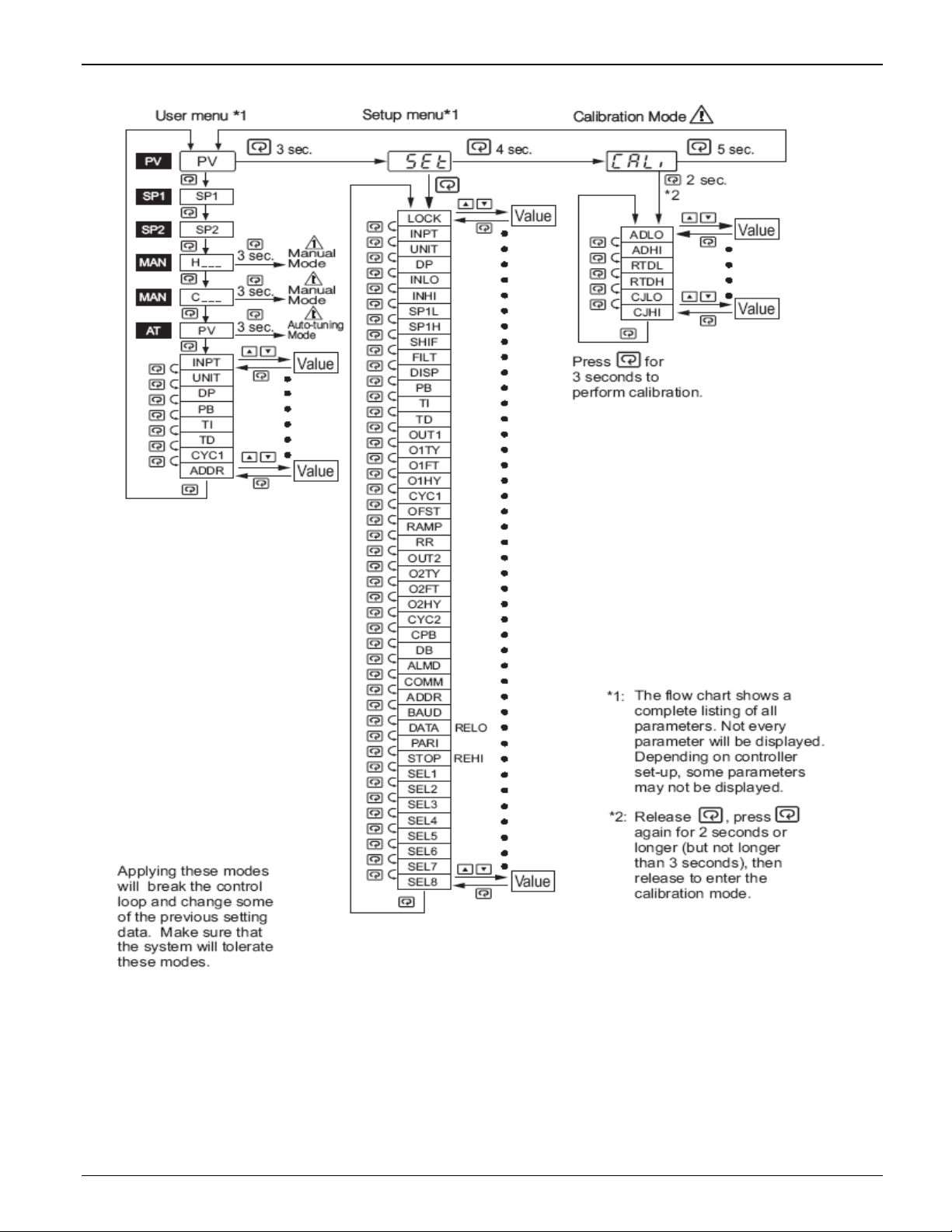

PURPOSE: PROGRAMMING THE OGDEN ETR-9000 TEMPERATURE CONTROLLER

Operator Interface:

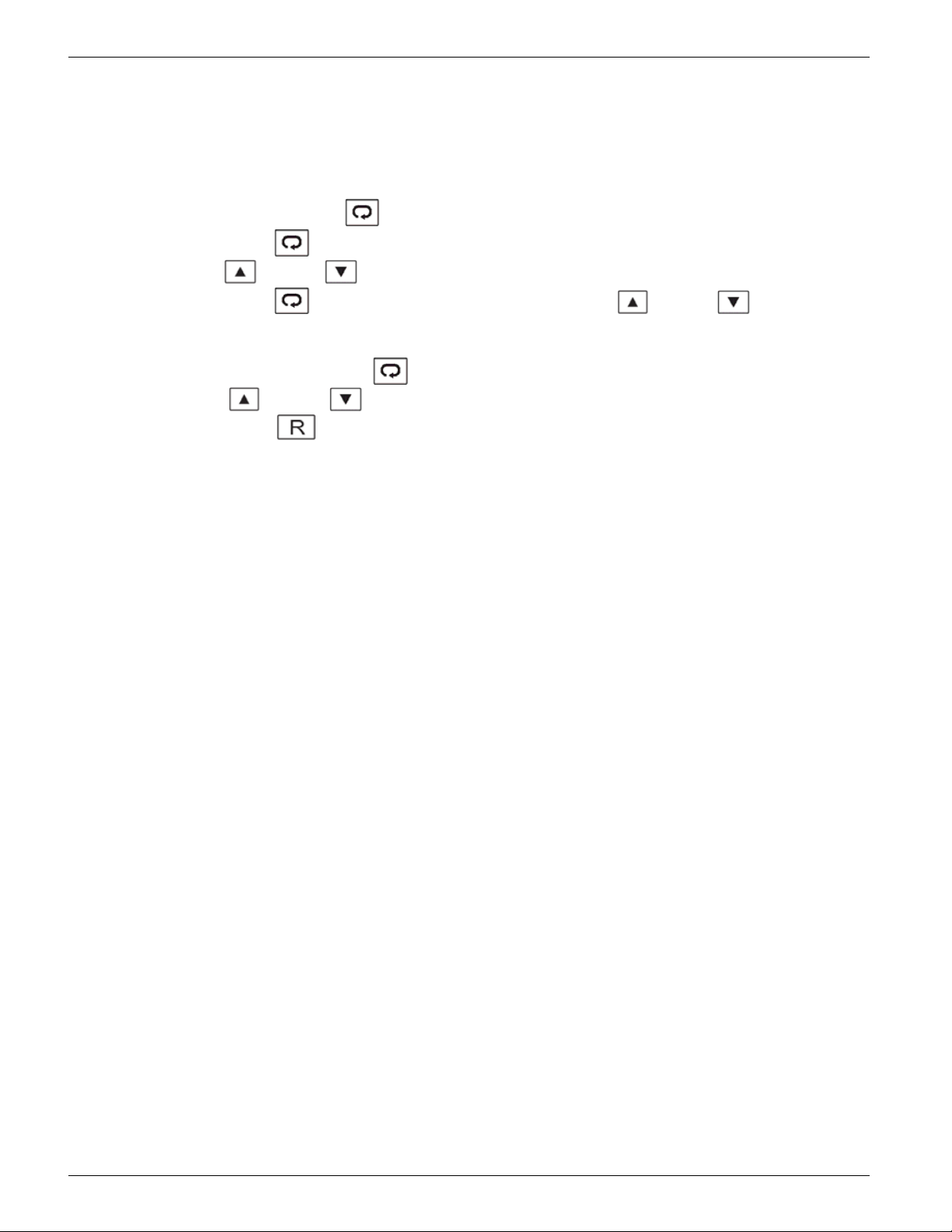

The operator interface on the Ogden ETR-9000, Temperature Controller, consists of the following:

• A scroll key

• Up

• A reset key

and down arrow keys are used to increase or decrease the selected parameter.

used to select a parameter to be viewed or adjusted.

used to return to normal operation mode.

Figure 1 – Operator Interface Description

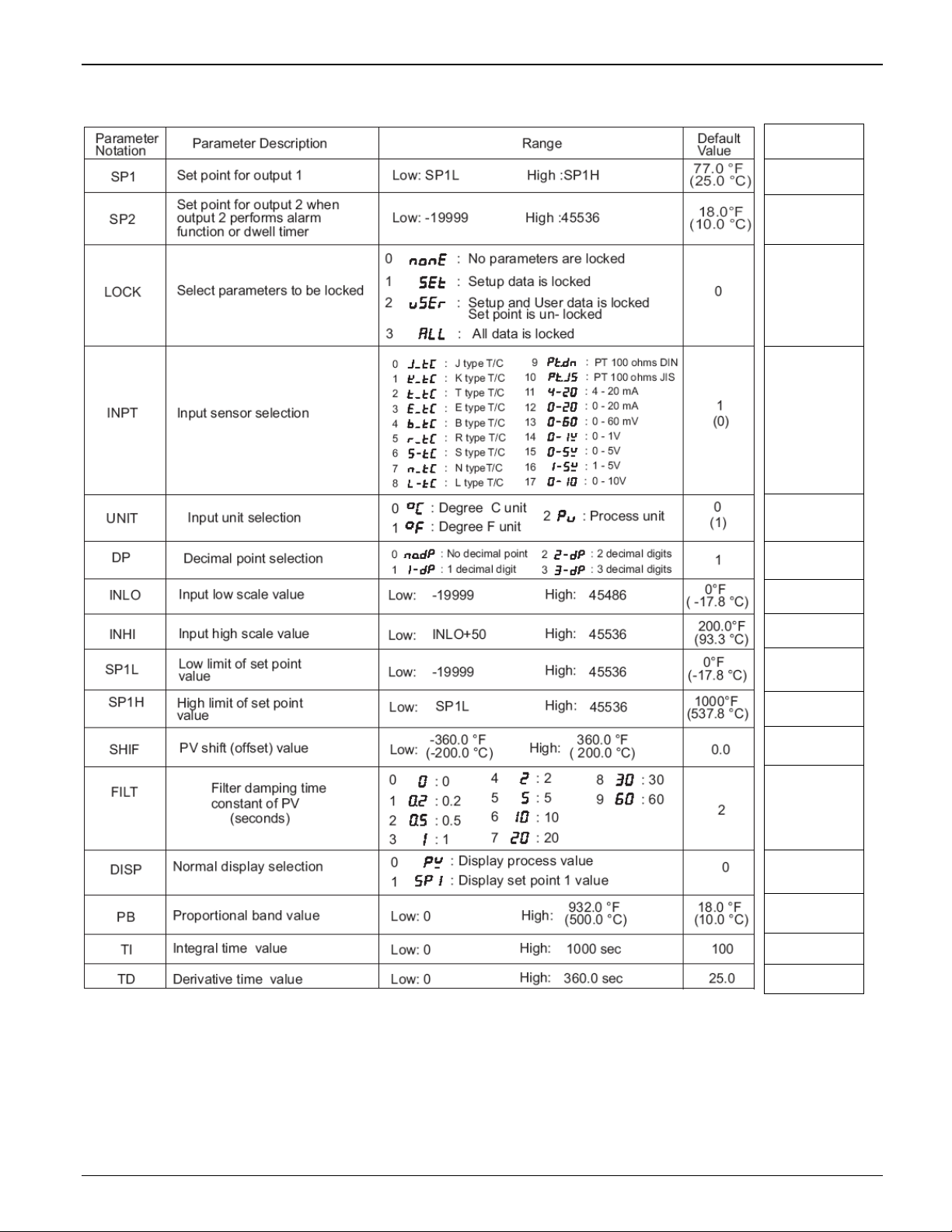

Menu Overview:

There are three main menus that contain parameters that require programming; they are User Menu,

Setup Menu, and Calibration Mode. The figure below (Figure 2) shows the sequence of operations

necessary to access the programming parameters in each menu.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

8 MN-1720 Thermoglaze 50

Page 15

Figure 2 - Menu Flow Chart

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 9

Page 16

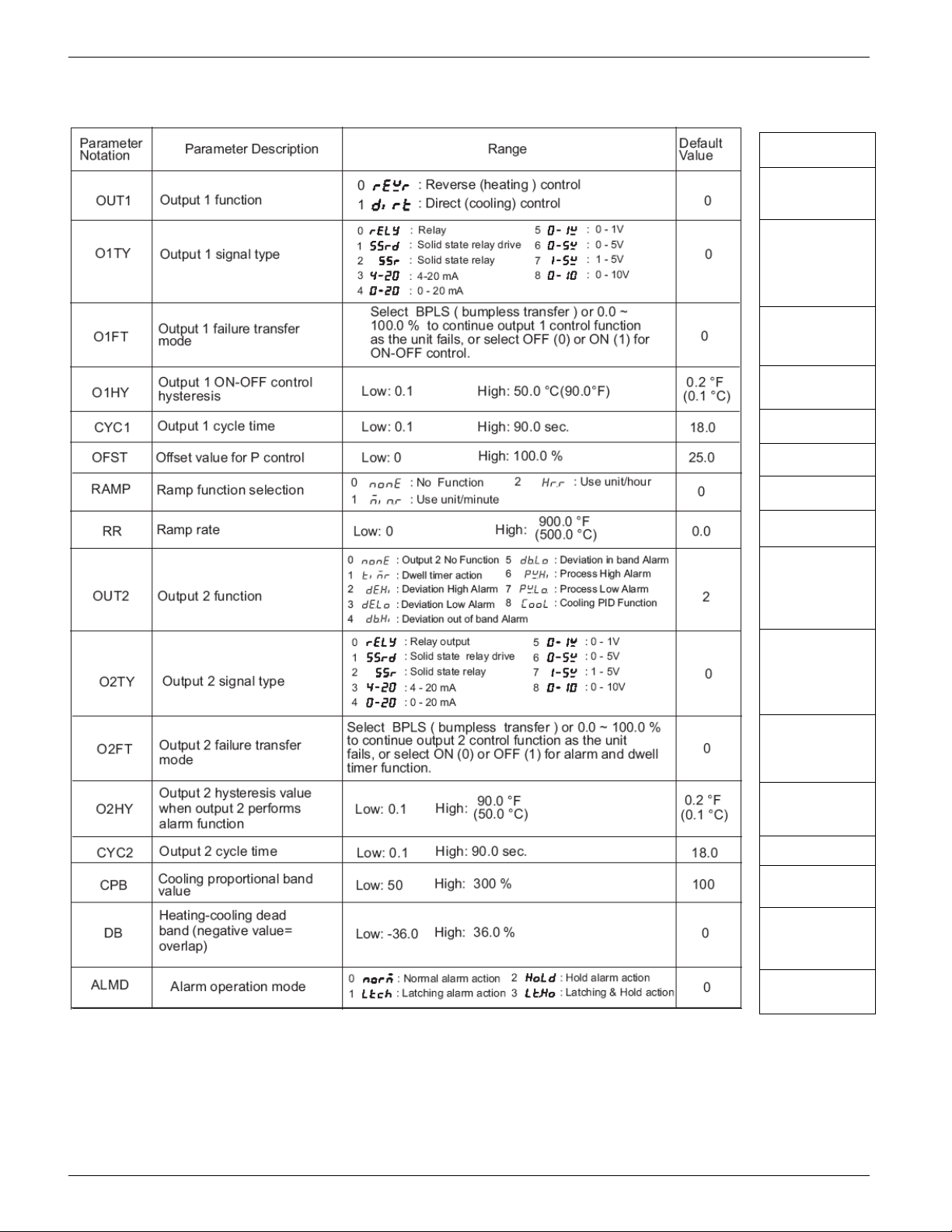

TG-50 Parameter Settings

Tables 1, 2 and 3 below list of the temperature controller default settings and the Belshaw Factory

settings. When installing a new controller 3 of the default setting must be changed to the Belshaw

Factory settings.

• Push and hold the scroll key

• Push the scroll key

• Push the Up

• Push the scroll key

change the settings listed in the Belshaw “Factory” column. (see tables 1, 2 and 3)

When finished setting parameters.

• Continue pushing the scroll key

• Push the Up

• Push the reset key

or down arrow keys to change “LocK” to “nonE”.

or down arrow keys to set “LocK” to “uSEr”.

once to access the “LocK” parameter.

to page through the settings and the Up or down arrow keys to

to return normal operation.

for 3 seconds, this will take you to the “SEt” menu.

until you are back to “LocK”.

Default Settings:

In the event that parameters have been modified without recording the modifications, change each

parameter to match those listed in Tables 1, 2 and 3 listed below (controller parameter default settings).

Then adjust SP1H, PB, OUT2 and the LocK parameters as listed in Belshaw “Factory” below. Then set

SP1 to 420ºF.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

10 MN-1720 Thermoglaze 50

Page 17

Table 1 - Parameter Descriptions

Factory

420ºF

set to

“uSEr”

after

setup

450ºF

-40ºF

0ºF

0ºF

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 11

Page 18

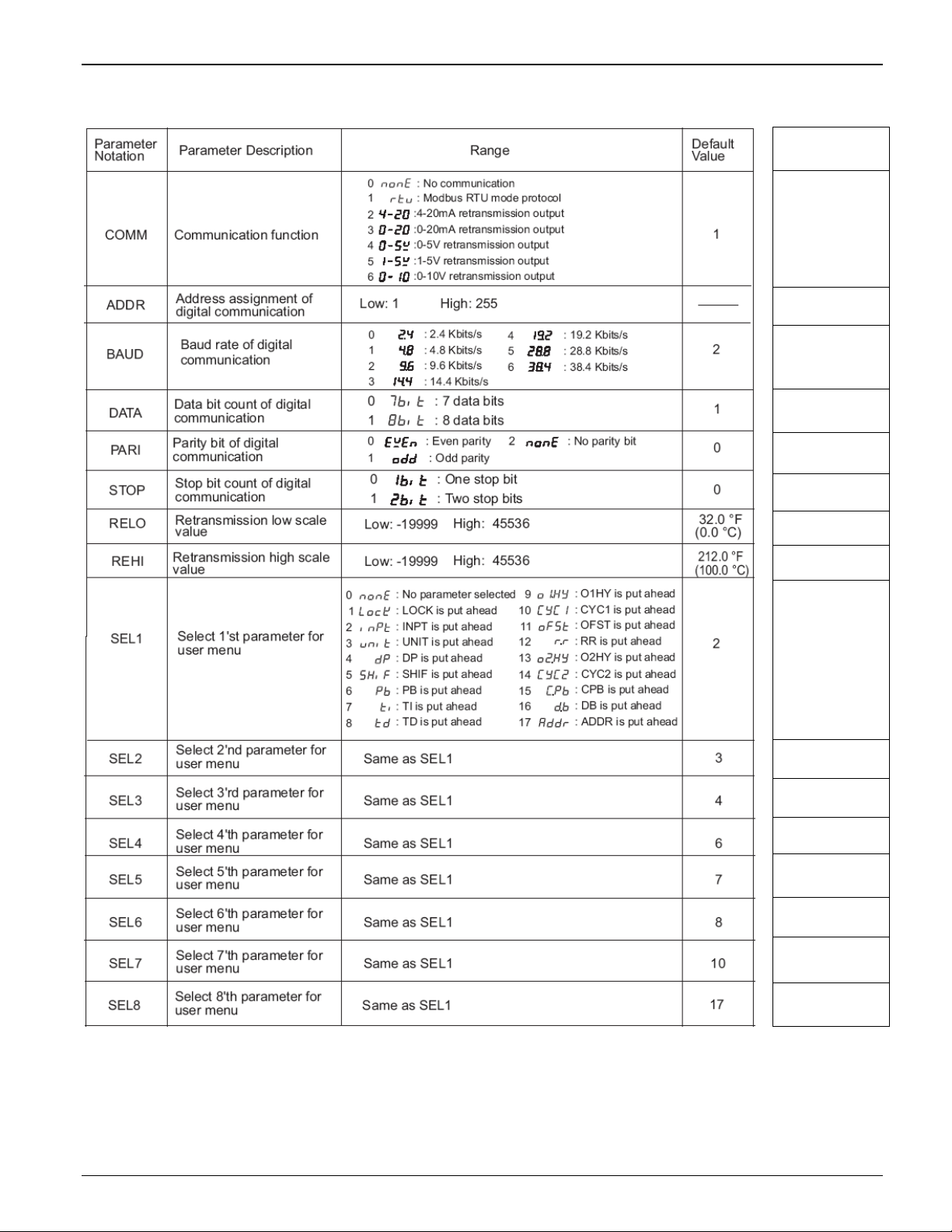

Table 2 - Parameter Descriptions

Set to

“nonE”

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

12 MN-1720 Thermoglaze 50

Page 19

Table 3 - Parameter Descriptions

Set to

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 13

Page 20

Cleaning 5

Daily TG Cleaning

Instructions

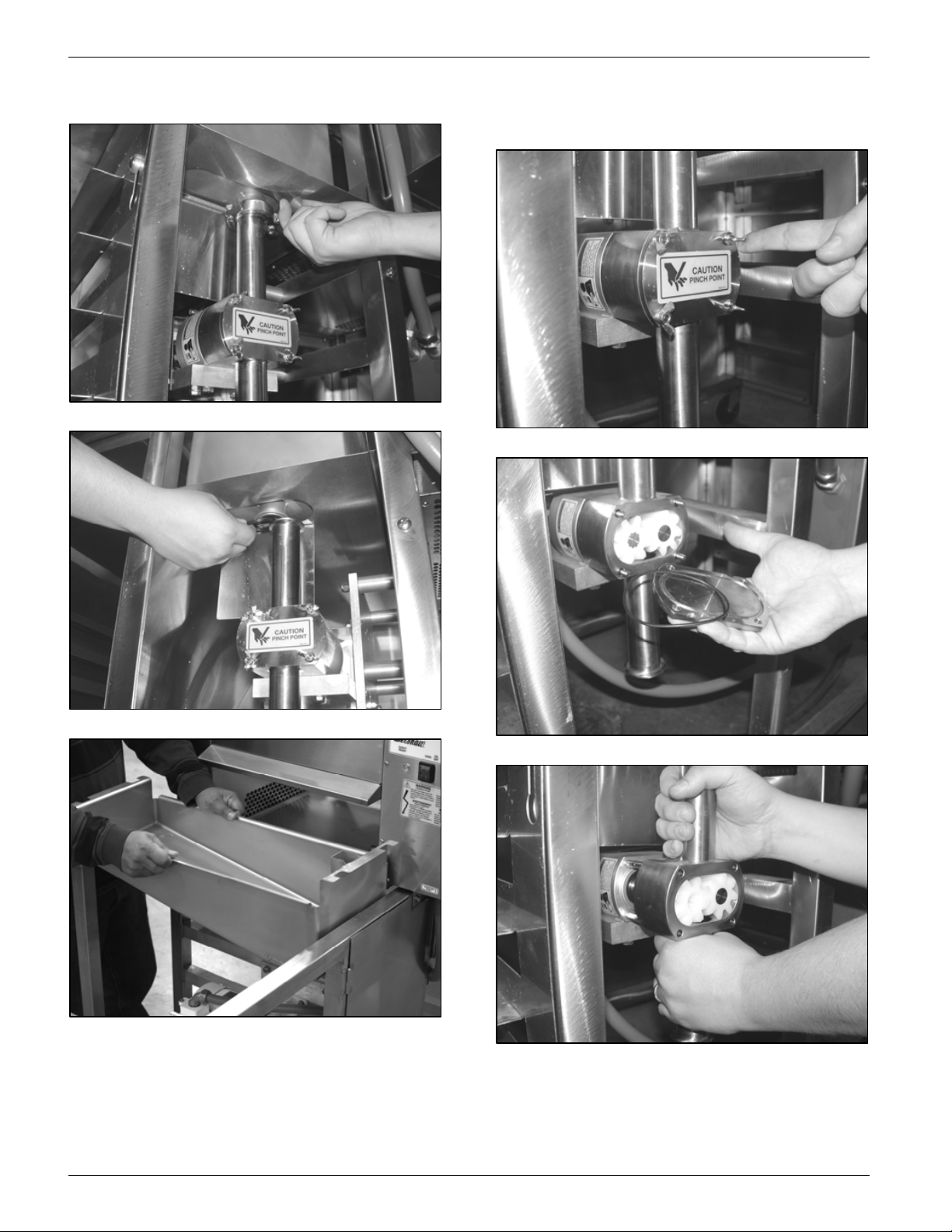

Disassembly

1. Allow the Thermoglaze to completely cool.

(All material must under 130º)

2. Pump the unused glaze back into a bucket.

3. Disconnect the TG from power!

4. Remove the glaze trough.

6. Remove the glazer drain tray.

7. Disconnect the conveyor drive coupling.

5. Remove the drive belt.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

14 MN-1720 Thermoglaze 50

Page 21

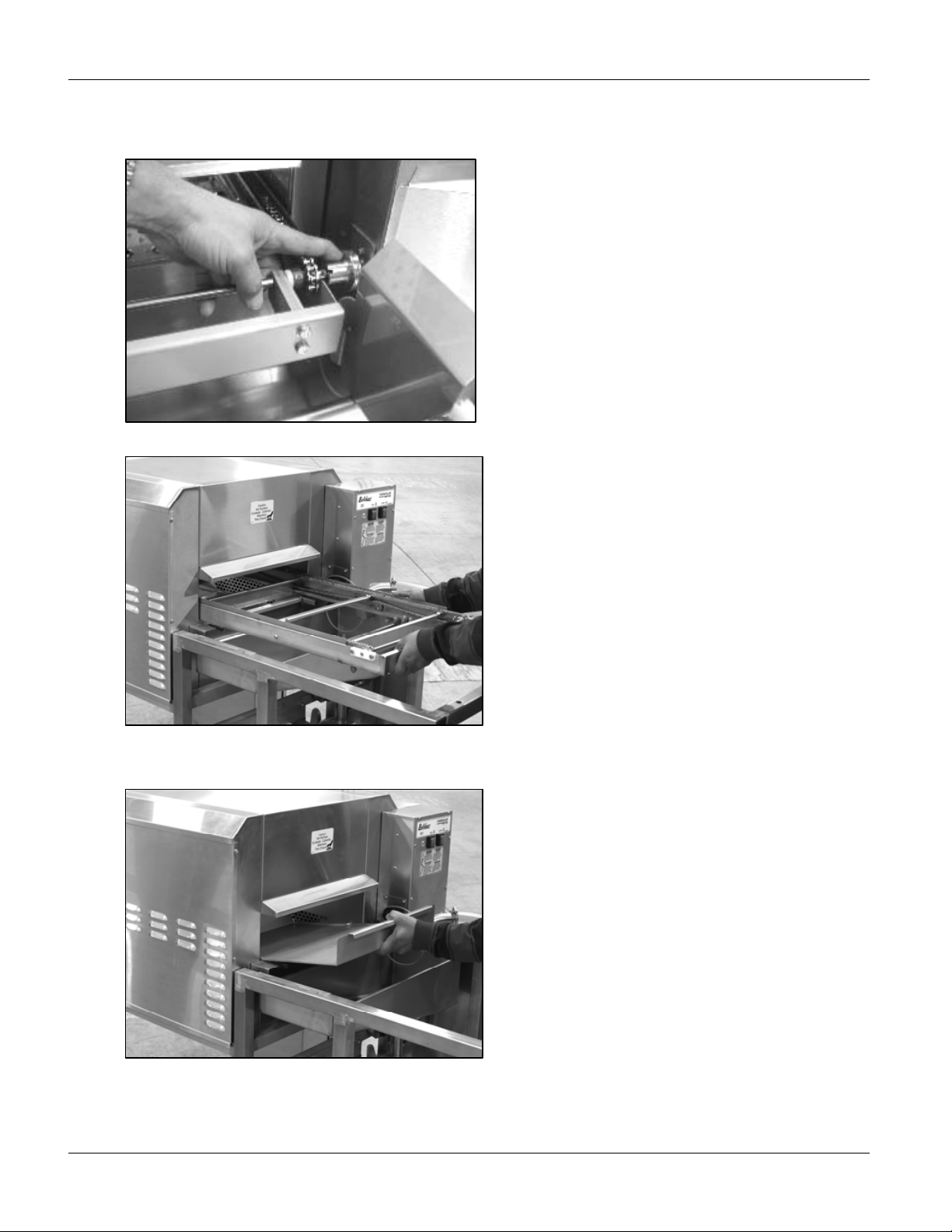

8. Remove the conveyor assembly through the

outfeed end of the oven.

WARNING

Failure to wash the conveyor chain daily may

cause damage to the conveyor drive motor.

The Thermoglaze will shut down if the chain

becomes stiff from glaze buildup. After

cleaning, the motor reset button may need to

be pressed, located under the control panel.

10. Open the safety cover.

11. Loosen the lower glaze hose clamp.

9. Remove the oven crumb tray.

12. Remove the lower glaze hose clamp and

gasket.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 15

Page 22

13. Remove the upper pump clamp.

14. Lift the glaze reservoir and remove the gasket

17. Unscrew and remove the 4 glaze pump cover

wing nuts.

18. Remove the glaze pump cover and “O” ring.

15. Remove the glaze reservoir and hose.

19. Remove the glaze pump body.

16. Remove the drip pan.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

16 MN-1720 Thermoglaze 50

Page 23

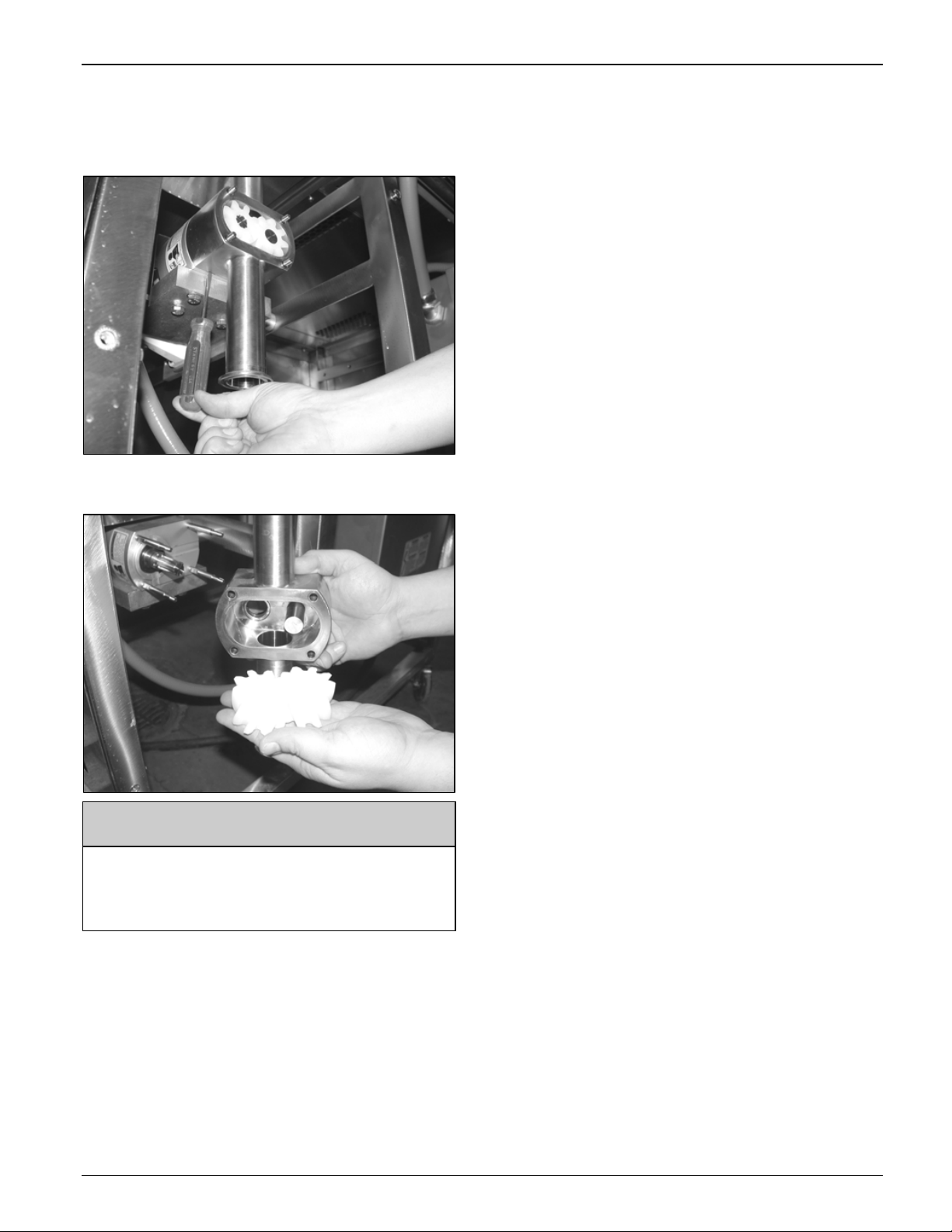

20. Insert a flat tip screw driver into the slot to

loosen the pump body if it can not be

removed by hand.

21. Remove the pump body and impellers.

22. Remove the impellers from the pump body.

WARNING

Spilled glaze on the floor may cause slipping

and falling, resulting in sprains, burns, broken

bones or back injury.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 17

Page 24

Cleaning

1. Hand wash all parts of the oven and glazer

with warm soapy water.

2. Do not use caustic cleaners on oven parts.

3. You may use an approved oven cleaner on

the stainless steel finger cover only.

4. Do not use oven cleaner on any other part of

the oven or glazer!

5. Do not hose/spray down any part of this

machine.

6. Glaze pump body and parts.

CAUTION

Failure to properly clean or lubricate glaze

pump may cause damage to the pump gear

impellers.

7. Wash the conveyor and chain daily with

warm soapy water to remove all glaze buildup on the chain.

NOTE

Lubricate the Pump Body, Shaft “O” Ring, and

gear impellers with “Kay” Food Grade

Lubricant. See following picture.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

18 MN-1720 Thermoglaze 50

Page 25

WARNING

Growth of organisms in gaps, crevices, glaze

pump, lines, or frame can result from

improper cleaning and can cause mild to

serious ill health.

WARNING

Donuts or filling may catch fire due to

improper cleaning and can cause serious

injury, burns, or death.

Assembly

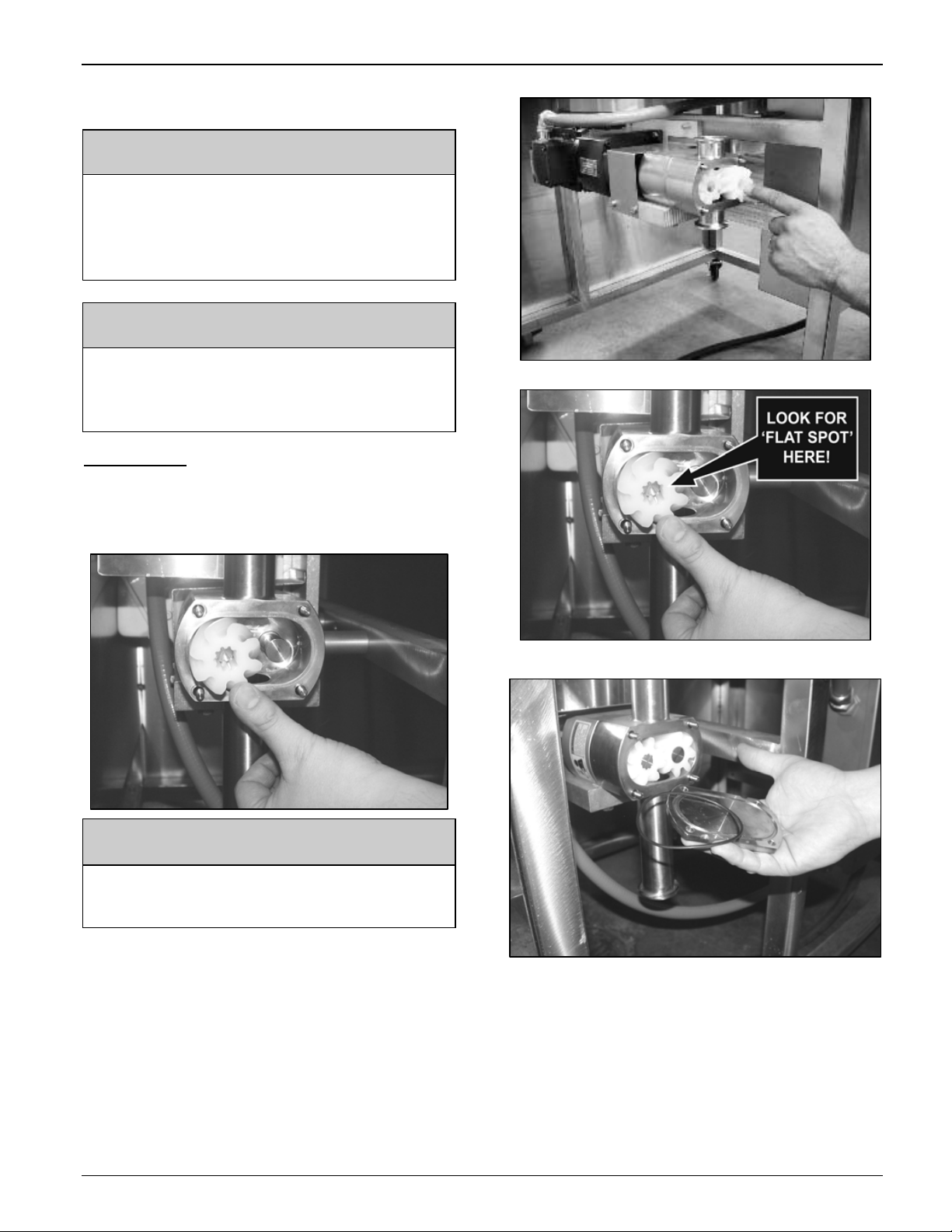

1. Install the glaze pump body.

2. Install the drive gear impeller. Line up the

flat on the shaft with the flat in the impeller.

3. Install the lay gear impeller.

NOTE

Lubricate the pump body, shaft “o” ring and

gear impellers with food grade mineral oil.

4. Install the “O” ring into the glaze pump

cover. Make sure it stays in place and you do

not pinch it between the pump and cover. The

“O” ring may need to be stretched before

installing.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 19

Page 26

5. Install the 4 wing nuts finger tight.

6. Set the upper gasket on top of the glaze

pump.

8. Install the upper clamp.

9. Install the lower gasket, hose and clamp.

7. Install the glaze reservoir.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

20 MN-1720 Thermoglaze 50

Page 27

10. Close the safety cover. Make sure the key is

in the safety switch.

NOTE

The glaze pump will not run with the safety

cover open.

12. Insert the conveyor through the outfeed end

of the oven.

13. Make sure the locating pin is in the matching

hole.

11. Install the oven crumb tray.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 21

Page 28

14. Pull the drive coupling back and line it up

with the conveyor drive shaft.

15. Install the glaze drain tray.

16. Connect the drive belt.

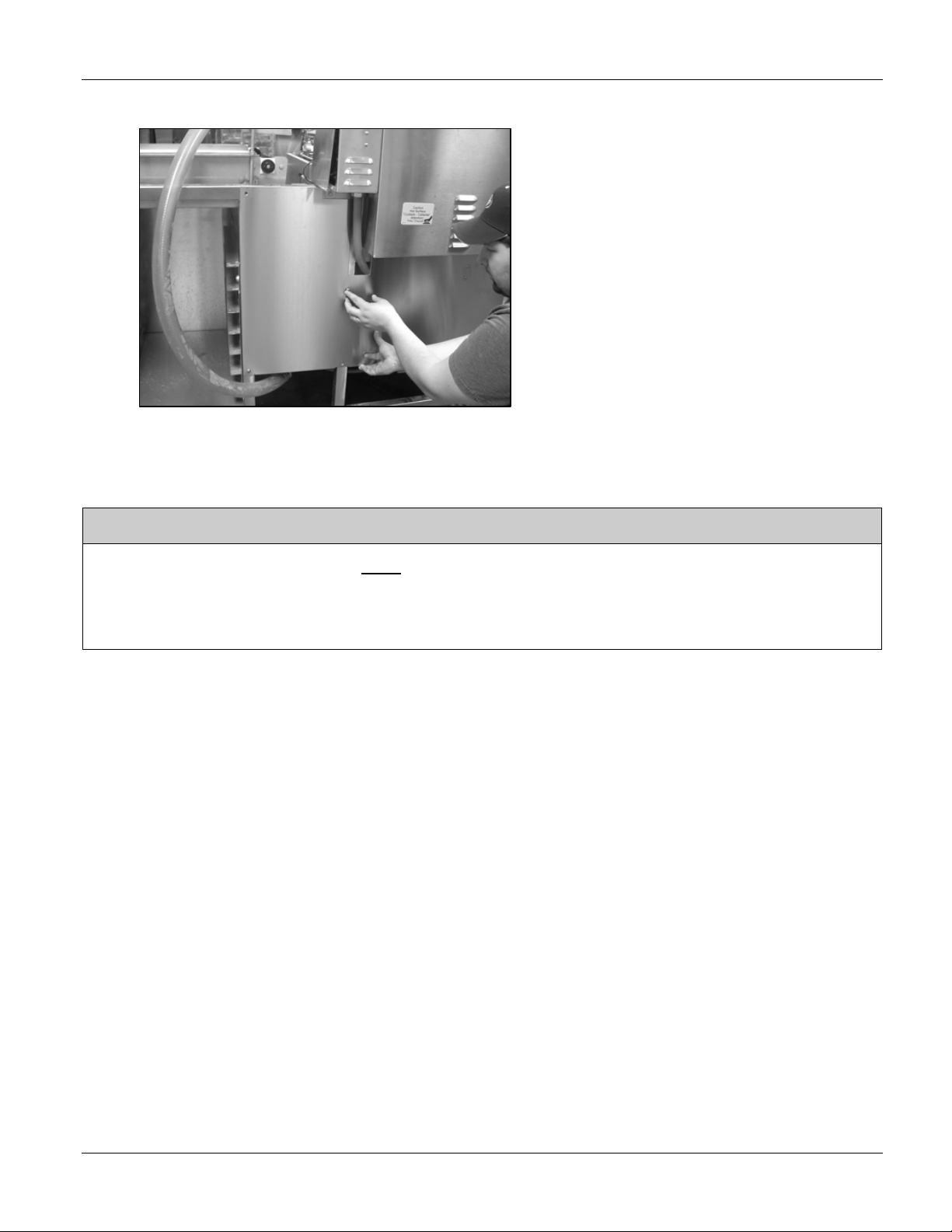

17. Install the rear panel by making sure the key

attached to the rear panel is inserted into the

safety interlock switch, then screwing in the

thumb screw.

NOTE

The glaze pump will not run with the rear

panel removed.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

22 MN-1720 Thermoglaze 50

Page 29

Maintenance 6

The ThermoGlaze is engineered to need little

maintenance. By keeping the system clean, the

equipment will last for years. The only

maintenance that is required is the following:

When cleaning the donut system, check all

rubber gaskets for wear and replace when

necessary. Check for wear on impellers of the

glaze pump, replace when necessary. .

DO NOT spray machine with water or cleaning

agents to clean. Only wipe main unit off with

damp cloth.

WARNING

HAZARDOUS VOLTAGE

Contact with electricity in the control box can

cause shocks, burns or death. Always

disconnect the control box from power source

before maintenance.

WARNING

Contact with electricity in the main cable can

cause shocks, burns or death. Always

disconnect the main electrical cable from the

power source before maintenance.

WARNING

Electrical fires can cause serious shock,

injury, burns or death. Always disconnect the

machine from power source before

maintenance.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 23

Page 30

Troubleshooting 7

Call Belshaw Bros. at (206)322-5474, or (800)

578-2547. One of our customer support

representatives will be happy to help you. When

you call, please specify the following:

• The model name of the machine.

• The serial number of the machine.

• The voltage, phase, and hertz (cycle) of

the machine. This information can be

found on the small, rectangular data

tag/plate.

CAUTION

If you perform repairs yourself or have them

performed by anyone other than Belshaw

Bros. or a service technician authorized by

Belshaw Bros., you do so at your own risk.

Following is a troubleshooting chart to help you

identify and solve some basic problems.

WARNING

Disconnect the machine from the power

source before disassembling, repairing, or

wiring.

WARNING

To avoid serious injury, always disconnect the

Thermoglaze from the power source before

troubleshooting.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

24 MN-1720 Thermoglaze 50

Page 31

CONVEYOR WILL NOT MOVE

Possible Causes What To Do

Oven not to correct temperature yet. Wait until the oven comes to temp.and the ready

light comes on.

Conveyor is jammed. Check for obstruction in conveyor and remove.

Motor circuit breaker is tripped. Push the black circuit breaker reset at bottom of

oven control panel.

GLAZER WILL NOT PUMP GLAZE

Glazer motor is not running. Check to make sure the motor is running.

(See Pump Motor Will Not Run)

Glazer pump impellers are worn. 1. Disconnect power.

2. Replace impellers.

The rear panel safety key is not inserted in the

safety switch.

Make sure the rear panel safety key is inserted into

the safety switch.

GLAZE IS MISSING THE DONUTS ON ONE SIDE OF THE GLAZE SCREEN

Glazer or glaze trough is not level. Adjust level of glaze trough by moving set collar.

Glaze pump is running too slow. 1. Disconnect from power.

2. Open Electrical Enclosure.

3. Turn glazer speed control clockwise.

4. Close Electrical Enclosure.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 25

Page 32

THE PUMP MOTOR WILL NOT RUN

Possible Causes What To Do

The connection of the power cord to the power

source is faulty.

The circuit breaker has been tripped. 1. Disconnect from power.

The rear panel is not installed properly 1. Reinstall the rear panel.

The glaze pump will not run with the rear panel

Make sure the power cord is fully plugged in to a

proper power source.

2. Open electrical enclosure.

3. Reset circuit breaker.

4. Close electrical enclosure.

2. Make sure that the key attached to the rear

panel is inserted into the safety interlock switch.

NOTE

removed.

THE FILL HOSE IS LEAKING

Possible Causes What To Do

Fill hose is leaking at the connection. Hose bracket needs adjusting or tightening.

Fill hose is leaking near the pump. Check for missing or damaged o-ring.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

26 MN-1720WM Thermoglaze

Page 33

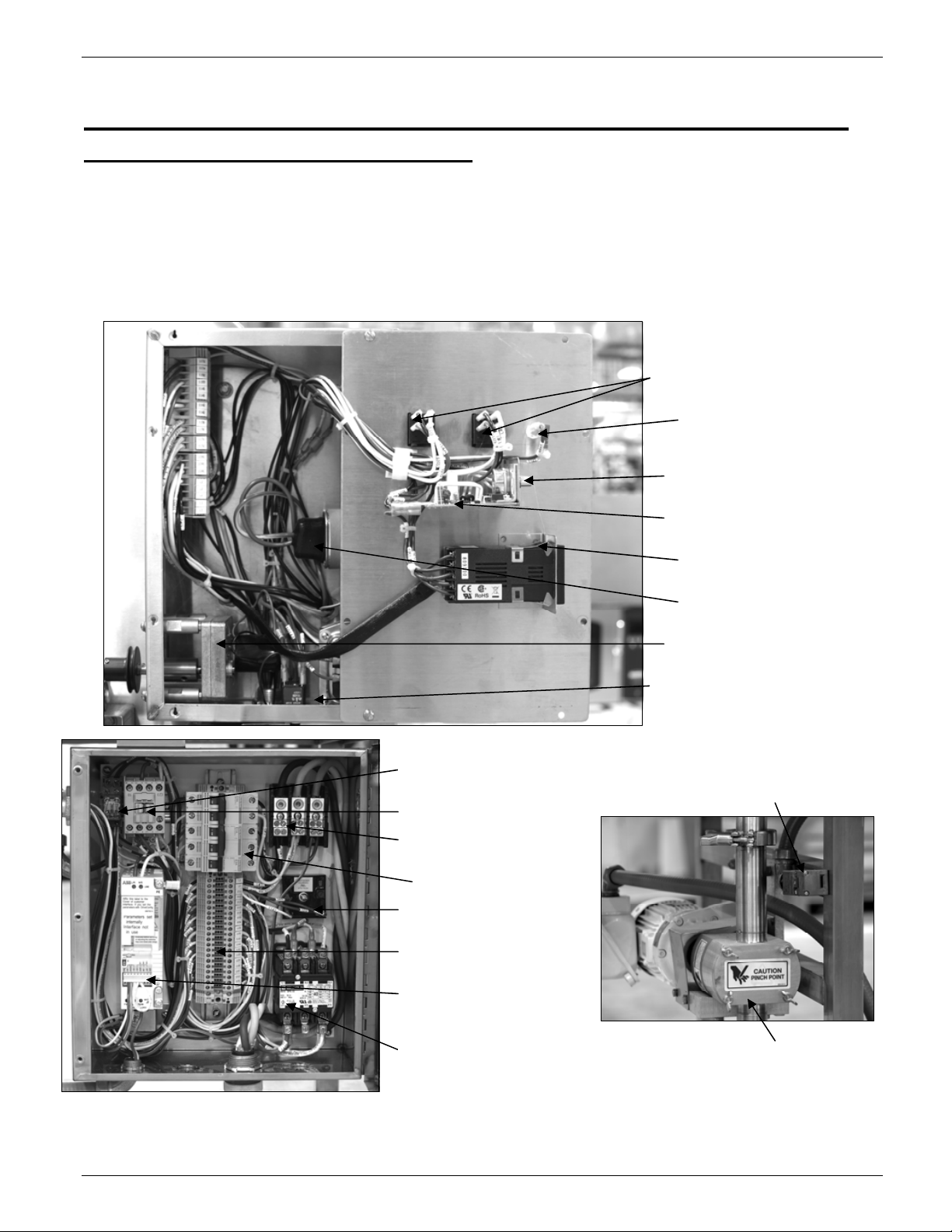

Calibration Procedure for Temperature and Cook Time on

the Thermoglaze Model TG50

Turn off power to the TG50 before removing any

access covers. This procedure should be

performed only by qualified service technicians.

Remove the electrical box cover on the oven to

access the temperature and speed control

adjustment potentiometers. The following is a

photo of the location of the adjustment

potentiometers for the temperature and cooking

time for the Belshaw TG50 Thermoglaze.

Rocker Switches

Donut Ready Light

Speed Controller

Conveyor Drive Board

Temperature Controller

Transformer

Conveyor drive motor

Reset Breakers for Pump and

Conveyor Relay

Heater Contactor

Power Distribution Block

Circuit Breakers

Time Delay Relay

Terminal Block

VFD

MCR

Conveyor

Safety Switch

Glaze Pump

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 27

Page 34

Speed control/cook time

adjustment:

Turn on the oven and allow it to heat for 30

minutes.

Put a glaze screen on the conveyor chains that

run through the oven. With the oven in operation,

time the leading edge of the screen as it enters

the oven until the leading edge just leaves the

exit end of the oven. Adjust the potentiometer

until the desired time/speed is found. To increase

the cook time, turn the potentiometer clockwise.

To decrease the cook time, turn the

potentiometer counterclockwise. The factory

setting for cook time for the TG50 is 1 ½

minutes.

Temperature Adjustment:

Measure the temperature from the lower baffle

on the exit end of the oven. Place a thermocouple

in the hole located on the baffle, 3rd row from the

outside, 3rd hole from the back side of the oven.

Note: The back side of the oven has a fan

motor extended from it. Adjust the

temperature by rotating the potentiometer

located to the right of the speed control,

clockwise increases the temperature, and

counterclockwise decreases the temperature.

The factory setting is 400º F.

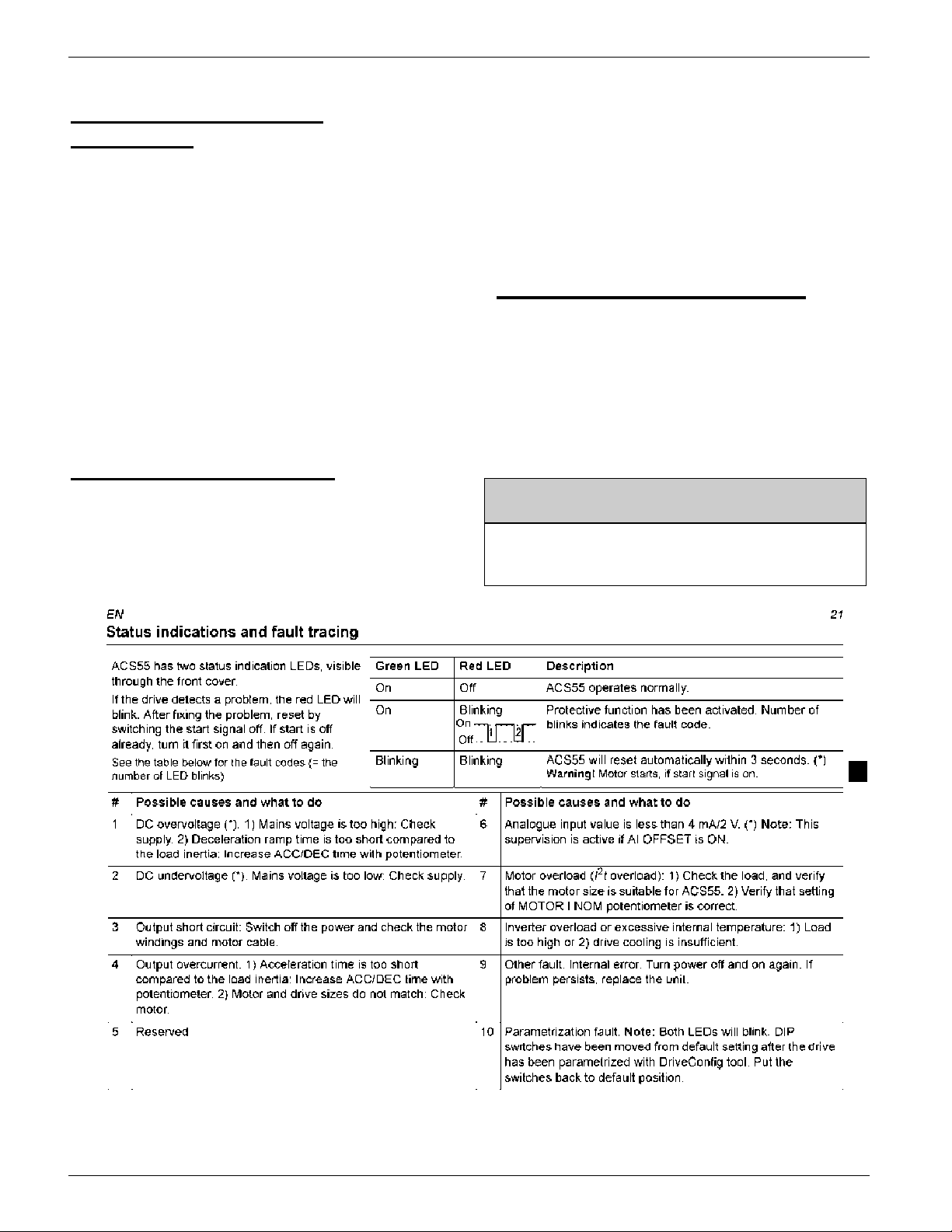

Glaze Pump VFD Setup

The glaze pump VFD (ABB model ACS55) does

not require any programming. All parameters are

factory set via dipswitches and potentiometers as

shown on sheet 2 of the electrical schematic.

For older TG-50’s with the Telemecanique VFD

see SB-0315R3 for programming and trouble

shooting

NOTE

PUMP COVER CAN BE REMOVED

WITHOUT TOOLS.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

28 MN-1720WM Thermoglaze

Page 35

Appendix 8

Service Bulletin SB-0361

WARNING: Special Cleaning Instructions

Parts List Drawing Insert Page.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 29

Page 36

SERVICE BULLETIN SB-0361

This is a maintenance advisory for all owners of Thermoglaze TG-25 and TG-50 machines.

Belshaw has recently been informed of conveyor chain binding and/or failures on these machines. We

have addressed the problem by inspecting machines during assembly, and by testing and inspecting chains

returned to us from the field.

We have concluded that almost all of these problems can be avoided if the recommended maintenance

procedures from the manual be strictly adhered to.

A label (TG-9031) is included with this service bulletin and it should be placed on your machine in a

prominent area that will easily remind all employees of the necessity to maintain and clean this

equipment. Please note – equipment failure caused as a result of not following

these maintenance and cleaning instructions will not be covered under

warranty.

Specifically – The conveyor

MUST be removed from the

unit and thoroughly cleaned

with water and a mild

detergent to remove all glaze,

and any other contaminants,

DAILY. See manual for more

information.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

30 MN-1720WM Thermoglaze

Page 37

Daily TG Cleaning Instructions

Disassembly

1. Allow the Thermoglaze to completely cool. (All material must under 130º)

2. Pump the unused glaze back into a bucket.

3. Disconnect the TG from power!

4. Remove the REAR panel by unscrewing the thumb screws

5. Remove the glaze trough.

6. Remove the drive belt.

7. Remove the glazer drain tray.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 31

Page 38

8. Disconnect the conveyor drive coupling.

9. Remove the conveyor assembly through the outfeed end of the oven.

10. Remove the oven crumb tray.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

32 MN-1720WM Thermoglaze

Page 39

11. Remove the safety cover.

WARNING

Failure to wash the conveyor chain daily may cause damage to the conveyor drive motor. The

Thermoglaze will shut down if the chain becomes stiff from glaze buildup. After cleaning, the motor

reset button may need to be pressed, located under the control panel. NOTE – THE SERVICE CALL

TO FIX THIS PROBLEM WILL NOT BE COVERED UNDER WARRANTY.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Thermoglaze MN-1720WM 33

Loading...

Loading...