Belshaw Adamatic Donut Robot Mark 1, Mark I GP User Manual

Donut Robot®

Mark I

Operator’s Manual

and

Technical Supplement

Belshaw Bros., Inc.

814 44th Street NW, Suite 103 Auburn, WA 98001 USA

Tel: (206) 322-5474

Fax: (206) 322-5425

Toll Free (US): 1-800-578-2547 E-mail: service@belshaw.com www.belshaw.com

Donut Robot®

Mark I & Mark I GP

Operator’s Manual

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: + -1-206-322-5474 • Fax: + -1-206-322-5425

E-mail: service@belshaw.com • http://www.belshaw.com

If you accept the machine from the shipping company, you are, in effect, saying that the machine is in good condition, and you must pay for the machine. Belshaw cannot pay for shipping damage, because the freight company has accepted the machine from Belshaw in good condition, and is responsible for its safe delivery. For your protection, inspect the machine to see that no parts are bent, scratched, or otherwise damaged. If any damage has occurred in shipping, file a freight claim with the shipping company immediately.

To unpack the Donut Robot® Mark I and transport it to the work station:

1.Remove the foam and other packing materials from the two boxes.

2.Carry the hopper, plunger, and column to the work station.

3.Coil the cutter head power cord and carry the cutter head to the work station.

4.Carry the conveyor assembly to the work station.

5.Tilt the heater head back. Remove the kettle from the fryer case and carry it to the work station.

6.Tilt the heater head down.

7.Coil the main power cord and place it in the fryer case.

8.Move the heater head and fryer case to the work station.

EQUIPMENT RECORD

Please provide the information below when you correspond with us about your machine.

Purchased by _____________________________________________________________________

Installed by ______________________________________________________________________

Date of Installation ________________________________________________________________

Model number ___________________________________________________________________

Serial number

010808

MN-1002EN

Belshaw Bros., Inc.

814 44th Street NW, Suite 103

Auburn, WA 98001 USA

Phone: + -1-206-322-5474 • Fax: + -1-206-322-5425 E-mail: service@belshaw.com • http://www.belshaw.com

Contents

1 |

Operation |

1 |

||

2 |

Cleaning |

3 |

|

|

Cleaning the Hopper and the Plunger |

3 |

|

|

|

Cleaning the Conveyor and the Kettle |

4 |

|

|

|

3 |

Maintenance |

9 |

|

|

Taking Care of the Plunger, Hopper, and Cylinder |

9 |

|

|

|

Lubricating |

9 |

|

||

4 |

Related Products |

11 |

|

|

Roto Cooler |

11 |

|

|

|

Icing Finishing Tree and Roto Cooler |

13 |

|

|

|

Sugaring Tray and Roto Cooler |

14 |

|

||

Filter Flo Siphon |

15 |

|

||

Shortening Reserve Tank |

18 |

|

|

|

5 |

Donut Making Helps |

19 |

|

|

Tips on Making Quality Cake Donuts |

19 |

|

||

Temperature Conversion |

20 |

|

|

|

Calculating Correct Water Temperature |

20 |

|

||

Ratios of Plunger Sizes to Donut Weights |

20 |

|||

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Donut Robot Mark I OM MN-1002EN iii

Preface

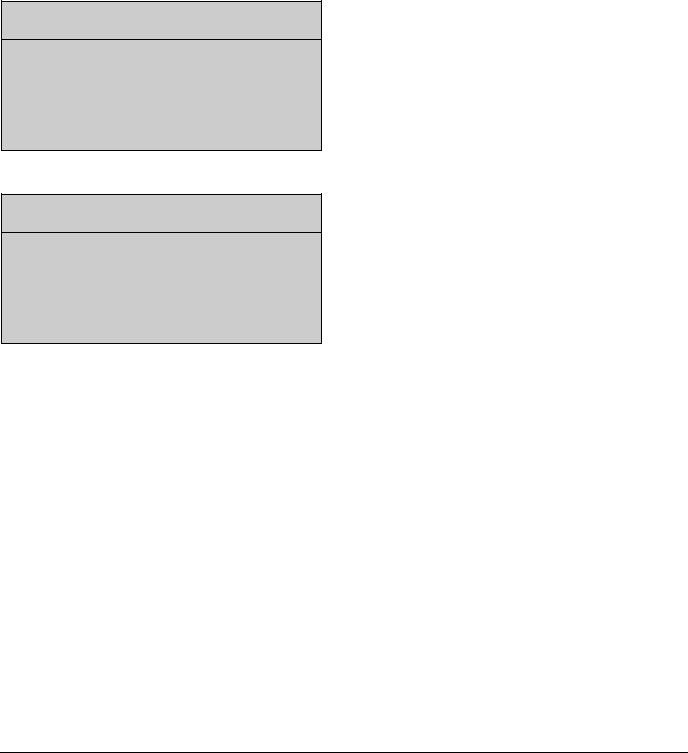

The Donut Robot® Mark I is designed to automatically cut and fry cake donut products. It can also be used to fry yeast-raised donuts.

It is meant to be used on a flat, stationary table or countertop, with the operator standing opposite the heater head of the machine. The operator must work safely at all times and read this manual and follow its instructions and warnings.

The Mark I uses electrical elements to heat shortening in its kettle. In the European Community, the machine is available with the following electrical configurations:

•220 volts, 1 phase, 50 hertz

•240 volts, 1 phase, 50 hertz

The Donut Robot Mark I produces less than 70 dB(A) of equivalent continuous A-weighted sound pressure at work stations. This has been determined during a run of the machine with shortening in the kettle, using a Bruel & Kjaer sound level meter, type 2236.

To use the Mark I safely, heed the following warnings and all other warnings that appear in this manual:

•Make sure the machine is secured to the work surface. Doing so will prevent the machine from moving or falling, which could cause serious injury.

•Never let water and hot shortening come in contact with each other. Moisture causes hot shortening to spatter, which may cause serious burns.

•Do not overfill the kettle with shortening. If shortening overflows the kettle, it could cause serious burns or could cause someone to slip on the floor and be seriously injured.

•Hot shortening can cause serious burns. Make sure that the system and the shortening are cool before attempting any adjustment, repair, disassembly, or cleaning.

•To avoid electrocution or other injury, unplug the machine before attempting any adjustment, repair, disassembly, or cleaning.

•To avoid damaging the machine, never use force to assemble, disassemble, operate, clean, or maintain it.

•Be careful never to get shortening, water, or other materials on the floor. If anything does get spilled on the floor, mop it up immediately. Materials on the floor can cause people to slip or fall, resulting in serious injury or loss of life.

•To prevent unintentional startup and possible fire, unplug the machine if there is a local power outage. When the power is restored, it is safe to plug the machine in again.

•To avoid electrocution, make sure that all electrical cords are not frayed or cracked and that they do not pass through any water or shortening.

•Make sure that all electrical cords are routed so that no one will trip over them.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

iv |

MN-1002EN |

Donut Robot Mark I OM |

1 |

Operation |

|

|

Read each step completely before following its directions.

1.When the shortening reaches the correct frying temperature, it should reach the middle of the flight bars.

Shortening expands as it increases in temperature. This means that unless the shortening is at frying temperature when it is put in the kettle, it should be added gradually. Let the shortening in the kettle heat up before adding more.

Put shortening in the kettle using one of these methods:

•Pre-melt shortening in a pan on the stove and carefully pour it into the kettle.

•Use the optional EZ Melt to melt shortening and transfer it to the kettle. See the EZ Melt manual.

WARNING

Do not touch hot shortening. It can cause severe burns.

•Put solid shortening into the kettle, packing it tightly around the elements and bulbs.

WARNING

Air spaces can cause the shortening to overheat and catch on fire.

2.Turn the heating element on by turning the thermostat knob to the desired temperature. Two pilot lights will come on. The one on top of the heater head indicates that the heating element has been turned on (that the thermostat is set above 200°F/93°C). The one on the front of the heater head indicates that the shortening has not yet reached the desired temperature. This light will go out if the high temperature limit control breaks the circuit.

Note: If the high temperature limit control does break the circuit, push the red reset button on the back of the heater head.

3.Wait for the shortening to reach the desired temperature. When it does, the pilot light on the front of the heater head will go out. DO NOT run the conveyor until all the shortening has melted.

4.If using the optional Shortening Reserve Tank, fill it with shortening. Then position it on the conveyor side panels either ahead of or behind the turner, but not above it. The heat of the fryer will melt the shortening in the tank.

5.Adjust the size selector dial on the cutter head’s crankshaft assembly. This dial regulates the donut weight. The higher the setting, the larger the donuts will be. Adjust the dial setting as follows:

a.Unscrew the dial lock nut 1/2 turn.

b.Turn the dial to the desired position, as indicated by the marks on the crank plate.

c.Tighten the dial in place with the lock nut. Tighten it using your fingers only.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Donut Robot Mark I OM MN-1002EN 1

6.Adjust the machine to provide the appropriate fry time for your product, as follows:

a.Decide on the fry time you desired— either 63, 70, 95, or 120 seconds. Choose 63 seconds only if using the GP model.

b.Locate the gear cover on the back of the heater head.

c.Use the label on the gear cover to determine which set of gears the gear belt should be on to provide the correct fry time.

d.Slide the gear cover up.

e.Move the belt to the appropriate set of gears.

f.Slide the gear cover down, ensuring that the belt tightener rests on the belt.

7.Put dough into the hopper.

8.Turn on the cutter using the power switch on the cutter head.

9.Turn on the conveyor drive using the power switch on the heater head.

Note: If the conveyor becomes jammed, a warning buzzer will sound about a minute later and stop when the conveyor is turned off. The conveyor drive is impedanceprotected so it will not burn out due to jamming.

WARNING

If the conveyor becomes jammed: 1. Turn off the conveyor drive and the heating element. 2. Allow the system to cool down. HOT SHORTENING IS DANGEROUS.

3.Determine the cause of the jamming.

4.Clear it. 5. Restart the system.

10.Continue adding shortening to the kettle to maintain the proper shortening level (see step 1). There are three ways to do this:

•Melt some shortening in a pan on the stove and carefully pour it into the kettle.

•If you are using the optional EZ Melt, transfer more shortening from it. See your EZ Melt manual.

•If you are using the optional Shortening Reserve Tank, push open the supply valve.

11.Continue adding dough to the hopper as needed.

12.When filling the hopper for the last time, use all of the dough in the hopper. To do so, push the dough to the bottom of the hopper using a rubber scraper or spatula. Be careful not to jam the scraper in the donut cutter.

WARNING

To avoid injury, never put your hand in or under the hopper while the machine is on.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

2 |

MN-1002EN |

Donut Robot Mark I OM |

2 |

Cleaning |

|

|

Read each step completely before following its directions.

WARNING

Thoroughly clean and dry the floor if shortening, water, or other materials are spilled. Materials on the floor can cause people to slip or fall, resulting in serious injury or loss of life.

WARNING

To avoid electrocuting yourself or damaging the machine, never allow water, steam, shortening, cleaning solution, or any other liquid to enter the heater head or cutter head assemblies.

Cleaning the Hopper and the Plunger

Follow these general guidelines:

•Use household dishwashing detergent. Do not use strong alkali cleaners such as lye, soda ash, or trisodium phosphate, as these discolor and corrode aluminum.

•Wash, dry, and lubricate parts thoroughly to prevent rusting.

•When washing parts by hand, wash each part separately; do not put any other utensil or dish in the sink with the part being washed.

To clean the hopper and the plunger:

1.Unplug the cutter head power cord.

2.Remove the hopper. On Standard Model

a.Push up on the hopper so the plunger spring compresses.

b.Pull the hopper away from the hopper resting pins.

On GP Model

a.Release the plunger by swinging up the connecting rod.

b.Loosen the thumb nuts that hold the hopper in place.

c.Pull the hopper away from the bearing strut.

3.Remove the plunger from the hopper. On Standard Model

a.Press down on the plunger head and lift the release tab.

b.Rotate the release tab 1/2 turn so the square key slides into the slot in the bail.

c.Pull the plunger up and out of the hopper, passing the center rod through the slot.

On GP Model

Pull the plunger out of the hopper, passing the center rod through the slot in the bail.

4.Pre-soak the hopper and the plunger, if necessary, to loosen stubborn or dried-on deposits.

5.Wash the hopper and the plunger separately in hot water and a detergent recommended for aluminum. Use a non-scratching plastic

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Donut Robot Mark I OM MN-1002EN 3

scouring cloth to remove soil and restore luster.

6.Rinse the hopper and the plunger separately in clear, hot water (170°-190°F/77°-88°C).

7.Dry each part completely.

8.Dip the plunger and the hopper cylinder in mineral oil or liquid shortening to prevent rust and sticking.

9.Wipe the cutter head assembly with a soft cloth dampened with hot water and an appropriate cleaner. Wipe it with another damp cloth to remove the cleaner. Wipe it dry.

CAUTION

To avoid electrocuting yourself or damaging the machine, never immerse the cutter head.

4.Lift the cutter head and column out of the column mounting bracket.

5.Remove the conveyor assembly as follows:

a.Obtain two pieces of wood, each at least 1” x 1” x 11” (2.5 x 2.5 x 28 cm).

b.Lift the conveyor assembly from the conveyor locating pin and pull it away from the heater head to disengage the main drive shaft coupling from the conveyor drive coupling.

c.Lift the outfeed end of the conveyor. Slide one piece of wood under the conveyor and lay it across the top of the kettle. Lift the other end of the conveyor and do the same with the other piece of wood. The conveyor will now be resting on the two pieces of wood. Let the shortening drain off of the conveyor and into the kettle. See Figure 3-1.

Cleaning the Conveyor and the Kettle

There are four basic steps to cleaning the conveyor and the fryer kettle: removing the shortening, washing, rinsing, and drying. You must perform all four steps and perform them in the order listed.

Removing the Shortening

WARNING

To avoid burning or electrocuting yourself, unplug the machine before cleaning the fryer.

1.Disconnect the machine from the power source.

2.Let the shortening cool to 100°F/38°C.

3.Unplug the cutter head power cord.

Figure 3-1. Draining the Shortening off of the Conveyor.

6.After the shortening has drained off of the conveyor assembly, turn the conveyor assembly around and place it on the work surface. Set aside the pieces of wood.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

4 |

MN-1002EN |

Donut Robot Mark I OM |

7.If you want to clean the turner assembly, remove and clean it as follows:

a.Move the flight bars of the conveyor until the turner is in the middle of a flight pocket.

b.Swing the turner cam weight up out of position.

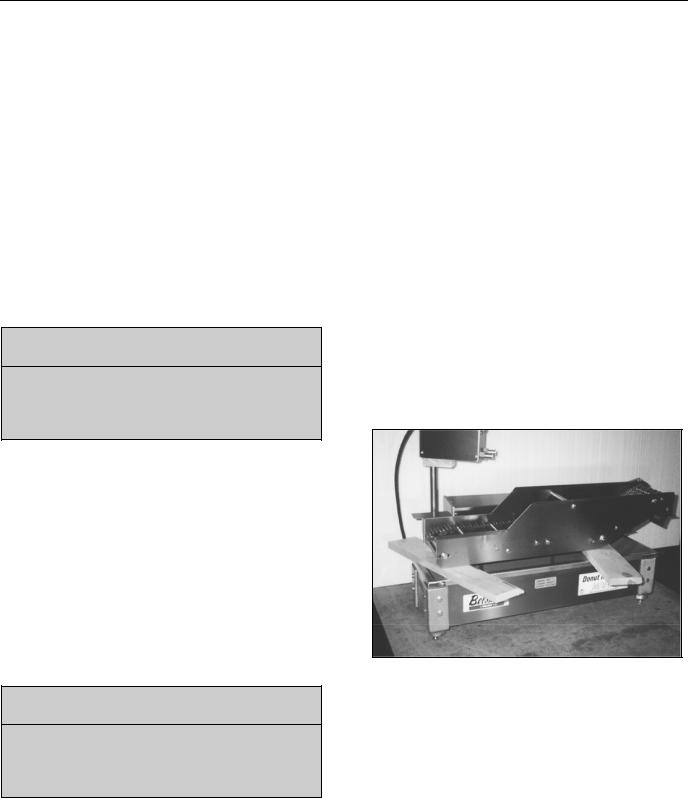

c.Lift up and pull out on the turner cam assembly. See Figure 3-2.

Figure 3-2. Removing the Turner Cam

Assembly.

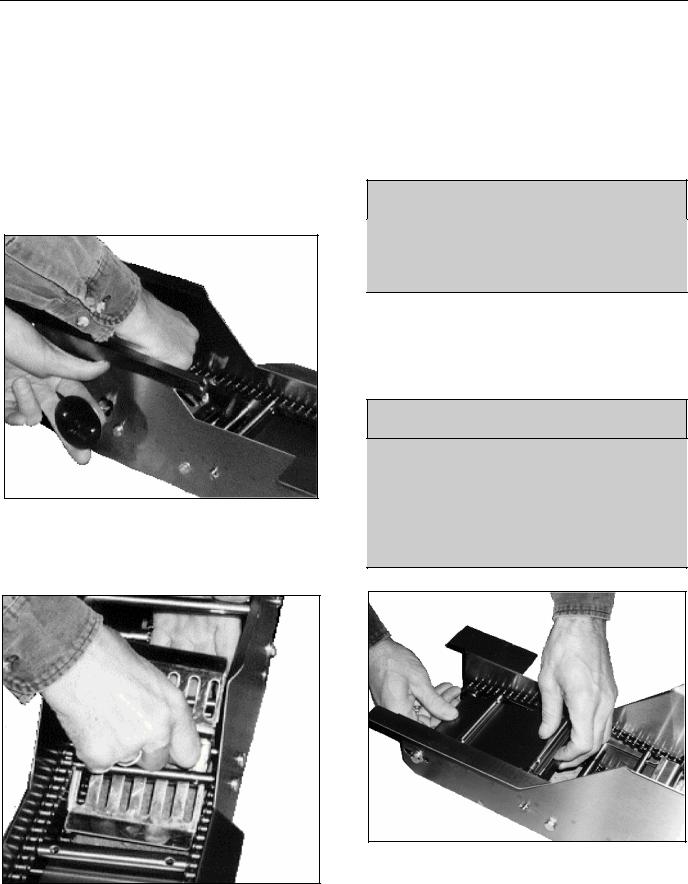

d.Lift out the turner assembly. See Figure 3-3.

e.Wash the turner cam assembly and turner assembly using mild detergent and warm water.

f.Rinse the turner cam assembly and turner assembly in clear water.

g.Dry these parts thoroughly.

WARNING

All parts must be dried thoroughly. Moisture causes hot shortening to spatter, which may cause serious injury.

8.If you want to clean the drop plate, remove it by lifting its forward end and sliding it toward the rear of the conveyor. (See Figure 3-4.) Wipe the drop plate with a damp cloth.

CAUTION

If thedrop plate is scratched, donuts will stick to it. To prevent this from happening, always wipe the drop plate in the direction of the grain in the metal, which runs parallel to the length of the conveyor, and never use abrasive cleaners.

Figure 3-4. Removing the Drop Plate.

Figure 3-3. Removing the Turner Assembly. |

9. Check again to see that the shortening in the |

|

kettle has cooled to 100°F/38°C. |

|

|

|

|

|

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425 |

|

|

Donut Robot Mark I OM |

MN-1002EN |

5 |

10.Remove the shortening from the kettle using one of these methods:

•Use an optional Filter Flo Siphon to siphon the shortening into one or more large metal buckets. (See the instructions in Appendix A.) Be careful not to disturb the sediment that has accumulated in the bottom of the kettle.

•Tilt the heater head assembly back, raising the heating element out of the kettle. Lift the kettle out of the fryer case and carefully pour the shortening into one or more large metal buckets. Be careful not to disturb the sediment that has accumulated in the bottom of the kettle.

•Using a small saucepan or a metal pitcher, scoop as much of the shortening as you can into one or more large metal buckets. Then lift the kettle out of the fryer case and carefully pour the rest of the shortening into a metal bucket. Be careful not to disturb the sediment that has accumulated in the bottom of the kettle.

WARNING

Do not use plastic buckets. If the shortening is not cool enough, the buckets will melt; possibly causing you to be burned, and causing shortening to get on the floor.

WARNING

Do not allow the shortening to overflow the buckets. Shortening will get on the floor, and if the shortening is not cool enough, you may be burned.

WARNING

Thoroughly clean and dry the floor if shortening is spilled. Shortening on the floor can cause serious injury or loss of life.

11.Return the kettle to the fryer case, if you have removed it, and tilt the heater head assembly down.

12.Brush off any carbon that has accumulated on the heating element. Accumulated carbon can cause corrosion and ineffective heating.

13.Tilt the heater head assembly back, raising the heating element out of the kettle.

14.Lift the kettle out of the fryer case. Remove and dispose of the remaining shortening and the accumulated sediment. Dry the outside of the kettle.

15.Put the kettle back in the fryer case.

16.Tilt the heater head assembly down.

17.Put the drop plate, turner cam assembly, and turner assembly back on the conveyor assembly.

18.Install the conveyor assembly.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

6 |

MN-1002EN |

Donut Robot Mark I OM |

Washing

1.Pour hot water into the kettle, up to the normal level of the shortening. Add about 2 oz/59 ml of trisodium phosphate or other appropriate cleaner.

2.Connect the machine to the power source. Heat the solution to 200°F/93°C. Turn on the conveyor. Keep the solution at this temperature for 15-20 minutes.

WARNING

Do not use plastic buckets. If the cleaning solution is not cool enough, the buckets will melt; possibly causing you to be burned, and causing cleaning solution to get on the floor.

3.Turn off the conveyor and scrub the soiled parts while the solution is under heat. Do not use any abrasive cleaners or scrapers.

4.Turn off the heater and disconnect the machine from the power source. Allow the cleaning solution to cool to 100°F/38°C.

5.Remove the conveyor and tilt the heater head back as you did before.

6.Remove the cleaning solution from the kettle using one of these methods:

•If you have an optional Filter Flo Siphon, remove its filter assembly. Then use the Filter Flo to siphon the cleaning solution into one or more large metal buckets. (See the instructions in Appendix A.) When the cleaning solution has stopped draining, carefully carry the buckets to the sink and slowly pour the solution into the sink.

•Lift the kettle out of the fryer case, carefully carry it to the sink, and slowly pour the cleaning solution into the sink.

•Using a small saucepan or a metal pitcher, scoop as much of the cleaning solution as you can into one or more large metal buckets. Then lift the kettle out of the fryer case and carefully pour the rest of the cleaning solution into a metal bucket. Carefully carry the buckets to the sink and slowly pour the solution into the sink.

WARNING

Do not allow the cleaning solution to overflow the buckets. Cleaning solution will get on the floor, and if the solution is not cool enough, you may be burned.

WARNING

Thoroughly clean and dry the floor if cleaning solution is spilled. Liquid on the floor can cause serious injury or loss of life.

7.Lift the kettle out of the fryer case, if you have not done so already.

8.Rinse the kettle thoroughly and dry it on the outside.

9.Install the kettle, tilt the heater head assembly down, and install the conveyor assembly as before.

Rinsing

1.Pour clean water into the kettle, up to the normal level of the shortening.

2.Connect the machine to the power source. Heat the water to 200°F/93°C.

3.Run the conveyor for 5-10 minutes.

4.Turn off the heater and disconnect the machine from the power source. Allow the water to cool to 100°F/38°C.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Donut Robot Mark I OM MN-1002EN 7

5.Lift the conveyor assembly out of the fryer case. Tilt the heater head assembly back.

6.Remove the water from the kettle using one of these methods:

•If you have an optional Filter Flo Siphon, remove its filter assembly. Then use the Filter Flo to siphon the water into one or more large metal buckets. (See the instructions in Appendix A.) When the water has stopped draining, carefully carry the buckets to the sink and slowly pour the water into the sink.

•Lift the kettle out of the fryer case, carefully carry it to the sink, and slowly pour the cleaning solution into the sink.

•Using a small saucepan or a metal pitcher, scoop as much of the water as you can into one or more large metal buckets. Then lift the kettle out of the fryer case and carefully pour the rest of the water into a metal bucket. Carefully carry the buckets to the sink and slowly pour the water into the sink.

WARNING

Do not use plastic buckets. If the water is not cool enough, the buckets will melt; possibly causing you to be burned, and causing water to get on the floor.

WARNING

Do not allow the water to overflow the buckets. Water will get on the floor, and if the water is not cool enough, you may be burned.

WARNING

Thoroughly clean and dry the floor if water is spilled. Water on the floor can cause serious injury or loss of life.

Drying

1.Thoroughly dry all parts, including the conveyor, the heating element, and the inside of the kettle.

WARNING

All parts must be dried thoroughly. Moisture causes hot shortening to spatter, which may cause serious injury.

2.Assemble the Donut Robot as before.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

8 |

MN-1002EN |

Donut Robot Mark I OM |

3 |

Maintenance |

|

|

WARNING

To avoid being burned, electrocuted, or otherwise injured, always unplug the machine and allow it to cool down before making adjustments, clearing obstructions, lubricating, cleaning, or disassembling.

Taking Care of the Plunger, Hopper, and Cylinder

The plunger, hopper, and cylinder of your Donut Robot are precision instruments. If you take good care of them, they will perform well for years. Follow these guidelines:

•Clean these parts only in the manner explained in this manual.

•Handle these parts with care. Avoid dropping them on hard surfaces.

•Do not force the machine if it becomes jammed. To avoid damaging the plunger, disassemble the machine and remove any obstructions.

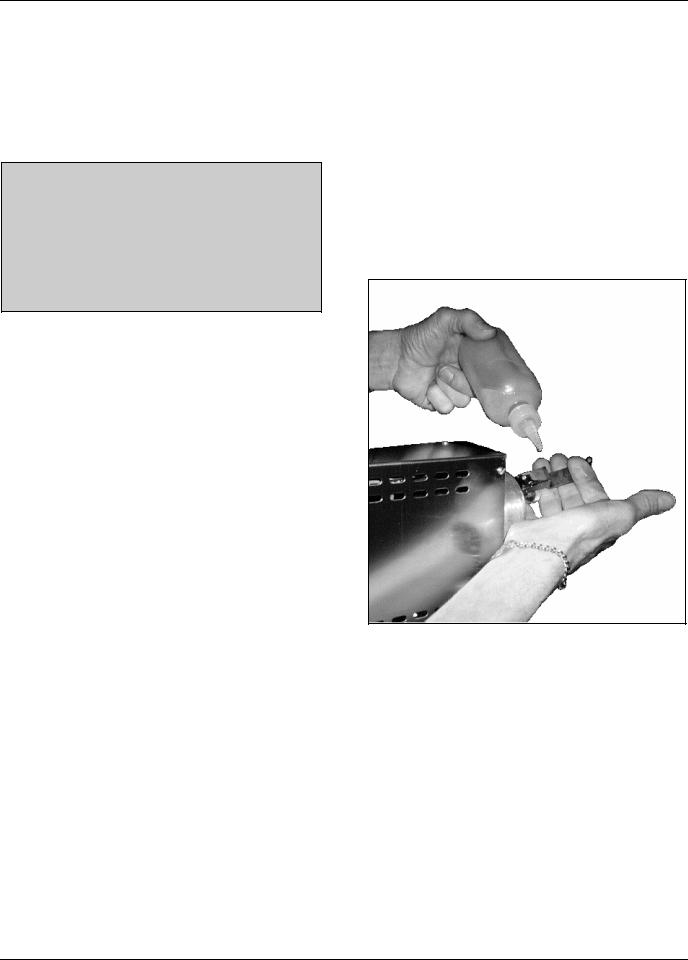

Lubricating

Before using the machine each day, apply ediblegrade mineral oil to the plunger connecting rod. The oil should penetrate the ball lock and the spring socket. See Figure 4-1.

Figure 4-1. Lubricating the Connecting

Rod–GP Model.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Donut Robot Mark I OM MN-1002EN 9

4 |

Related Products |

|

|

This appendix contains information about the following products which you might use with your Donut Robot®:

•Roto Cooler

•Icing Finishing Tree and Roto Cooler

•Sugaring Tray and Roto Cooler

•Filter Flo Siphon

•Shortening Reserve Tank

Roto Cooler

SPECIFICATIONS

Dimensions |

Shipping |

Electrical Data |

Construction |

Standard |

|

Weight |

|

|

Equipment |

|

|

|

|

|

Dia.=24”/61 cm |

16 lb/7.3 kg |

120 V |

Basket: High-density |

Basket and turntable |

H=6-5/8”/17 cm |

|

1 Phase |

polyethylene. Base: |

base with power cord |

|

Spun, polished, |

and motor. |

||

|

|

50 Hz |

heavy-gauge |

|

|

|

aluminum. |

|

|

|

|

|

|

|

|

|

|

|

|

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Donut Robot Mark I OM MN-1002EN 11

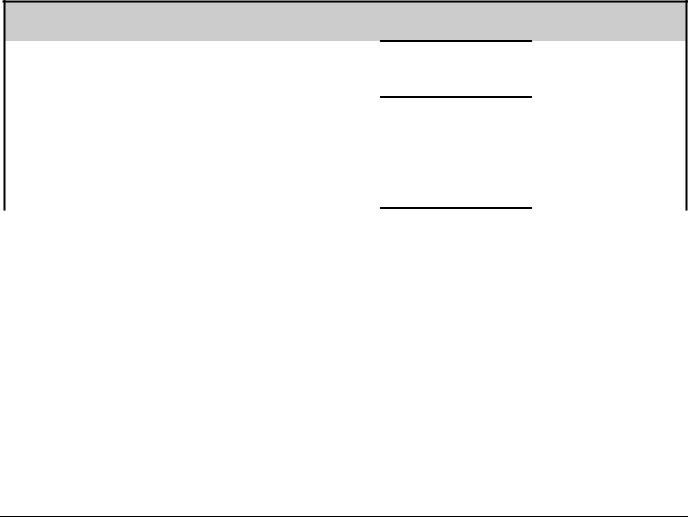

Figure A-1. Roto Cooler.

The Roto Cooler is designed to catch and cool donuts as they drop from the outfeed end of the Donut Robot.

The Roto Cooler produces less than 70 dB(A) of equivalent continuous A-weighted sound pressure at work stations. This has been determined while running the machine, using a Bruel & Kjaer sound level meter, type 2236.

The Roto Cooler is meant to be used on a flat, stationary table or countertop. The operator is expected to read and follow these instructions.

To use the Roto Cooler:

1.Place the Roto Cooler near the outfeed end of the Donut Robot so donuts will fall into it.

2.Connect the Roto Cooler power cord to the 120 V outlet on back of the Donut Robot’s heater head.

3.Turn on the Roto Cooler. It will rotate and receive donuts. Remove cooled donuts from the Roto Cooler as needed.

4.When you are finished using the Roto Cooler, turn it off and unplug it.

WARNING

To avoid electrocuting yourself or damaging the machine, never submerge the base of the Roto Cooler.

5.Clean the Roto Cooler using soap and water and a non-abrasive cloth or scrubber.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

12 |

MN-1002EN |

Donut Robot Mark I OM |

Icing Finishing Tree and Roto Cooler

SPECIFICATIONS

Dimensions |

Shipping |

Electrical |

Construction |

Standard Equipment |

|

Weight |

Data |

|

|

|

|

|

|

|

Dia.=24”/61 cm |

28 lb/ |

120 V |

Trays: Heavy-gauge |

Power turntable and four |

H=32”/81 cm |

12.7 kg |

1 Phase |

aluminum. Basket: High- |

trays, three of which have |

|

density polyethylene. |

dividers. |

||

|

|

50 Hz |

Base: Spun, polished, |

|

|

|

heavy-gauge aluminum. |

|

|

|

|

|

|

|

|

|

|

|

|

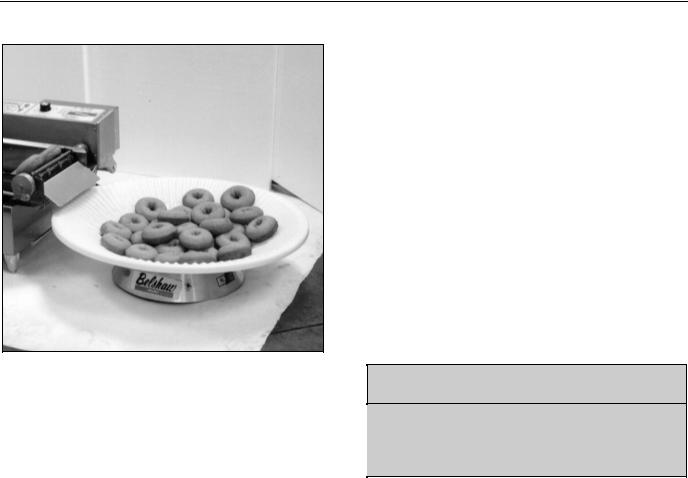

Figure A-2. Icing Finishing Tree and Roto

Cooler.

The Roto Cooler is designed to catch and cool donuts as they drop from the outfeed end of the Donut Robot. It produces less than 70 dB(A) of equivalent continuous A-weighted sound pressure at work stations. This has been determined while running the machine, using a Bruel & Kjaer sound level meter, type 2236.

The Roto Cooler is meant to be used on a flat, stationary table or countertop.

The Icing Finishing Tree, which mounts on the Roto Cooler, is designed to hold toppings in which donuts can be dipped. The operator is expected to read and follow these instructions.

To use the Roto Cooler and the Icing Finishing Tree:

1.Attach the Icing Finishing Tree to the Roto Cooler. Fill the trays with toppings.

2.Install and operate the Roto Cooler as explained in the previous section.

3.Decorate the donuts with the toppings in the trays.

4.When you are finished using the Roto Cooler and the Icing Finishing Tree, turn off the Roto Cooler and unplug it.

WARNING

To avoid electrocuting yourself or damaging the machine, never submerge the base of the Roto Cooler.

5.Clean the trays of the Roto Cooler and the Icing Finishing Tree using soap and water and a non-abrasive cloth or scrubber.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

Donut Robot Mark I OM MN-1002EN 13

Sugaring Tray and Roto Cooler

SPECIFICATIONS

Dimensions |

Shipping |

Electrical Data |

Construction |

Standard |

|

Weight |

|

|

Equipment |

|

|

|

|

|

Dia.=17-1/4”/ |

16 lb/7.3 kg |

120 V |

Spun, polished, |

Power turntable with |

44 cm |

|

1 Phase |

heavy-gauge |

sugar tray. |

H=6-5/8”/17 cm |

|

aluminum. |

|

|

|

50 Hz |

|

||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

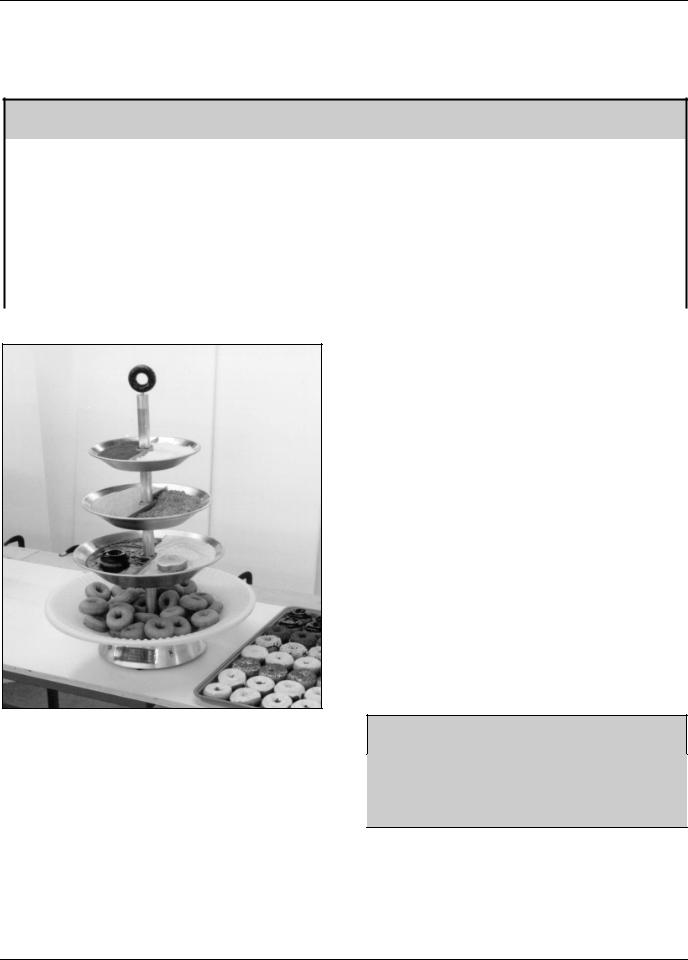

Figure A-3. Sugaring Tray and Roto Cooler.

The Roto Cooler base makes the Sugaring Tray rotate. It produces less than 70 dB(A) of equivalent continuous A-weighted sound pressure at work stations. This has been determined while running the machine, using a Bruel & Kjaer sound level meter, type 2236. The Roto Cooler base is meant to be used on a flat, stationary table or countertop.

The Sugaring Tray, which mounts on the Roto Cooler base, is designed to catch donuts as they drop from the outfeed end of the Donut Robot, and to hold toppings in which donuts can be dipped. The operator is expected to read and follow these instructions.

To use the Sugaring Tray and Roto Cooler:

1.Put sugar, powdered sugar, or cinnamonsugar in the tray.

2.Place the Sugaring Tray and Roto Cooler near the outfeed end of the Donut Robot so donuts will fall into the tray.

3.Connect the Roto Cooler power cord to the 120 V outlet on back of the Donut Robot’s heater head.

4.Turn on the Roto Cooler base. The Sugaring Tray will rotate and receive donuts.

5.Coat the donuts with the topping in the tray.

6.When you are finished using the Sugaring Tray, turn off and unplug the Roto Cooler base.

WARNING

To avoid electrocuting yourself or damaging the machine, never submerge the base of the Roto Cooler.

7.Clean the Sugaring Tray using soap and water and a non-abrasive cloth or scrubber.

Belshaw Bros., Inc. • www.belshaw.com • Phone 206-322-5474 • Fax 206-322-5425

14 |

MN-1002EN |

Donut Robot Mark I OM |

Loading...

Loading...